Patents

Literature

517 results about "Laser patterning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

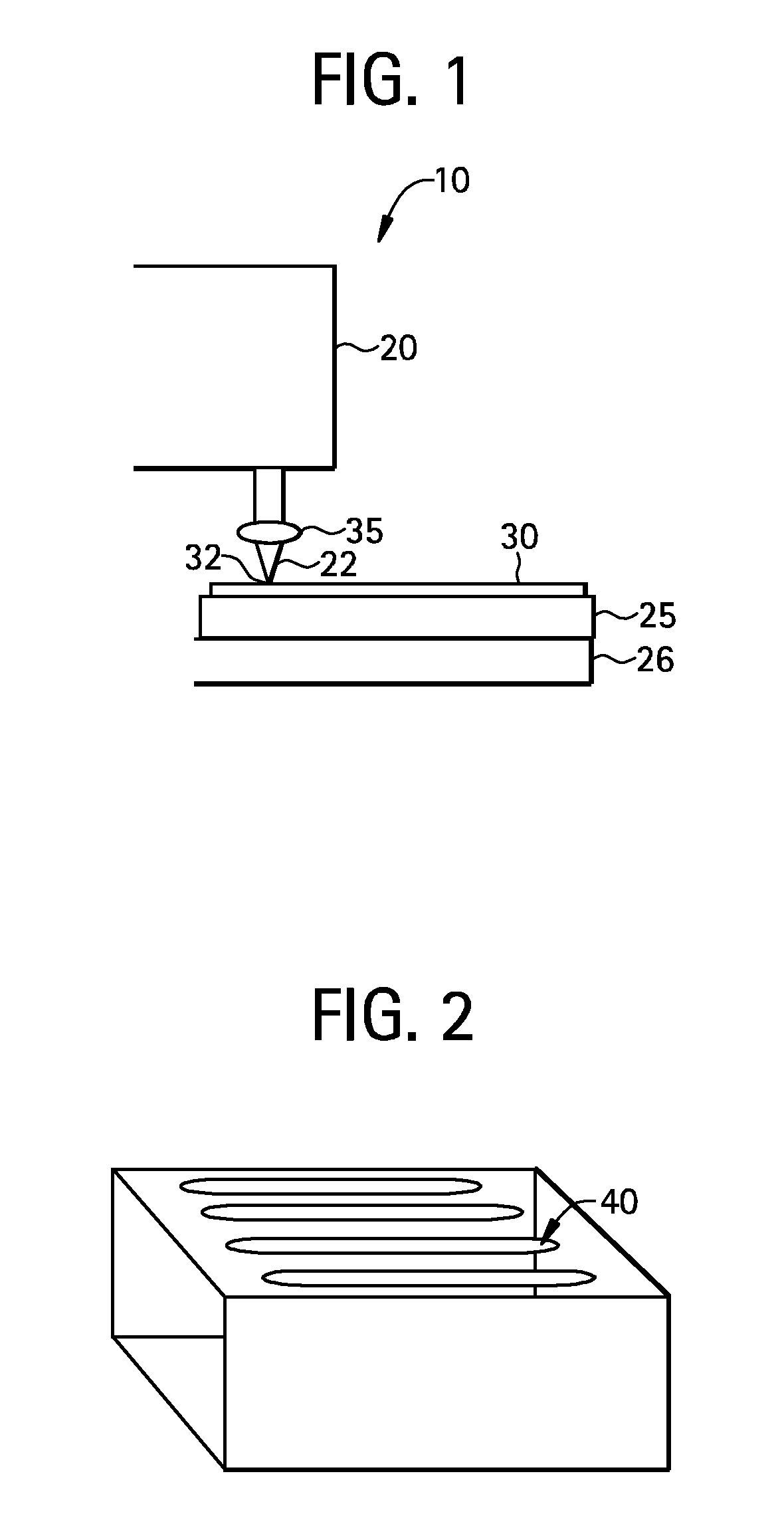

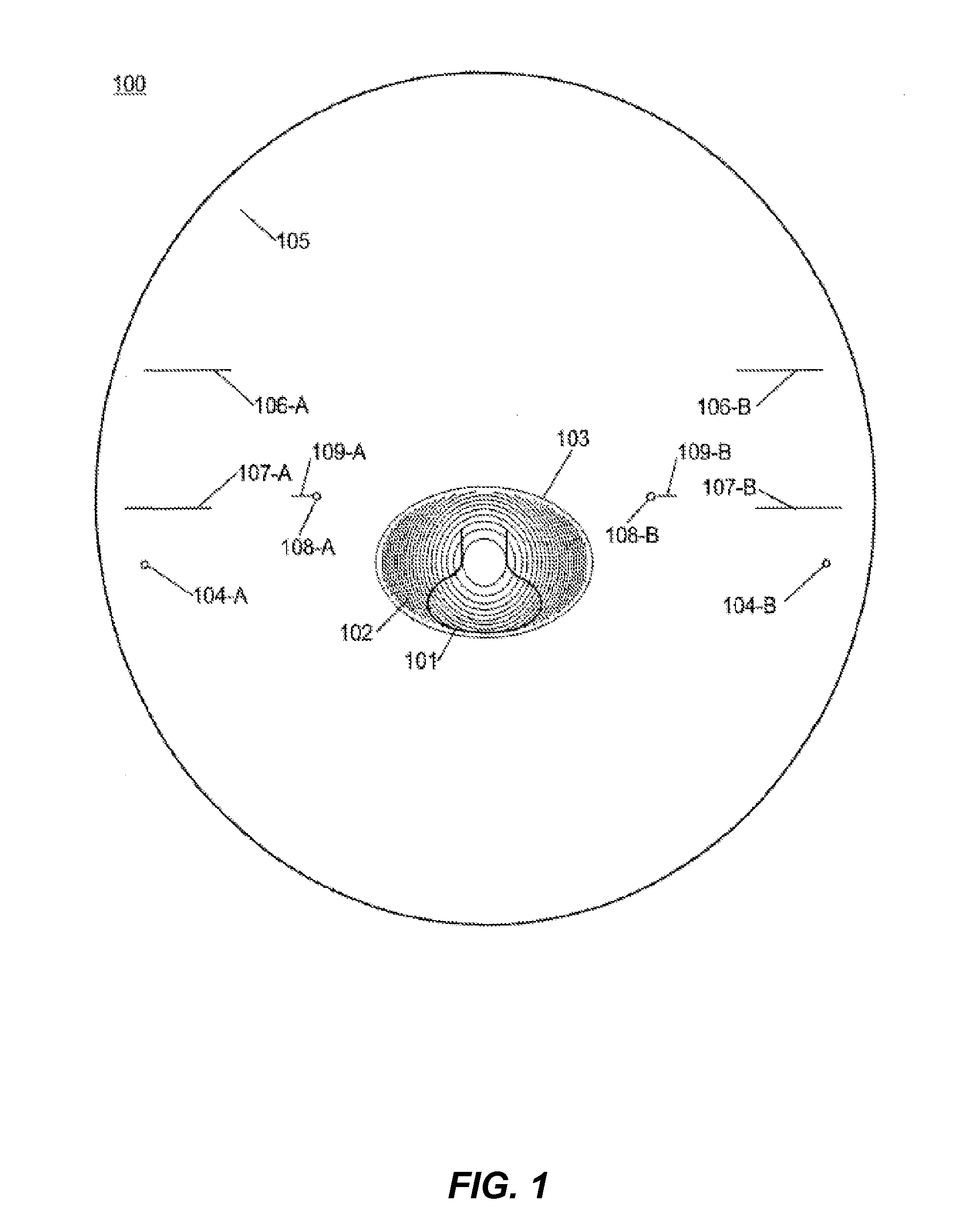

Auto-referenced system and apparatus for three-dimensional scanning

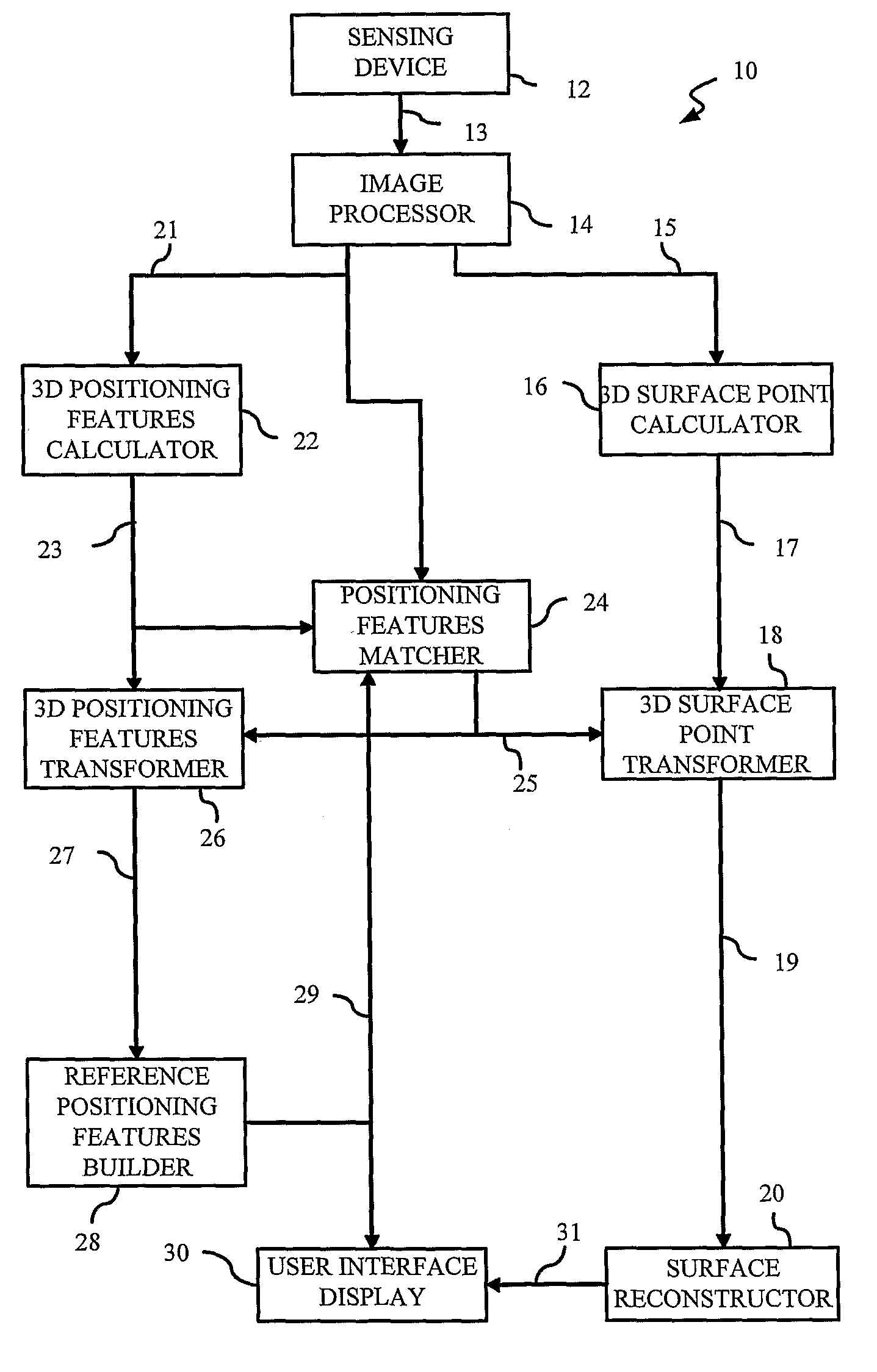

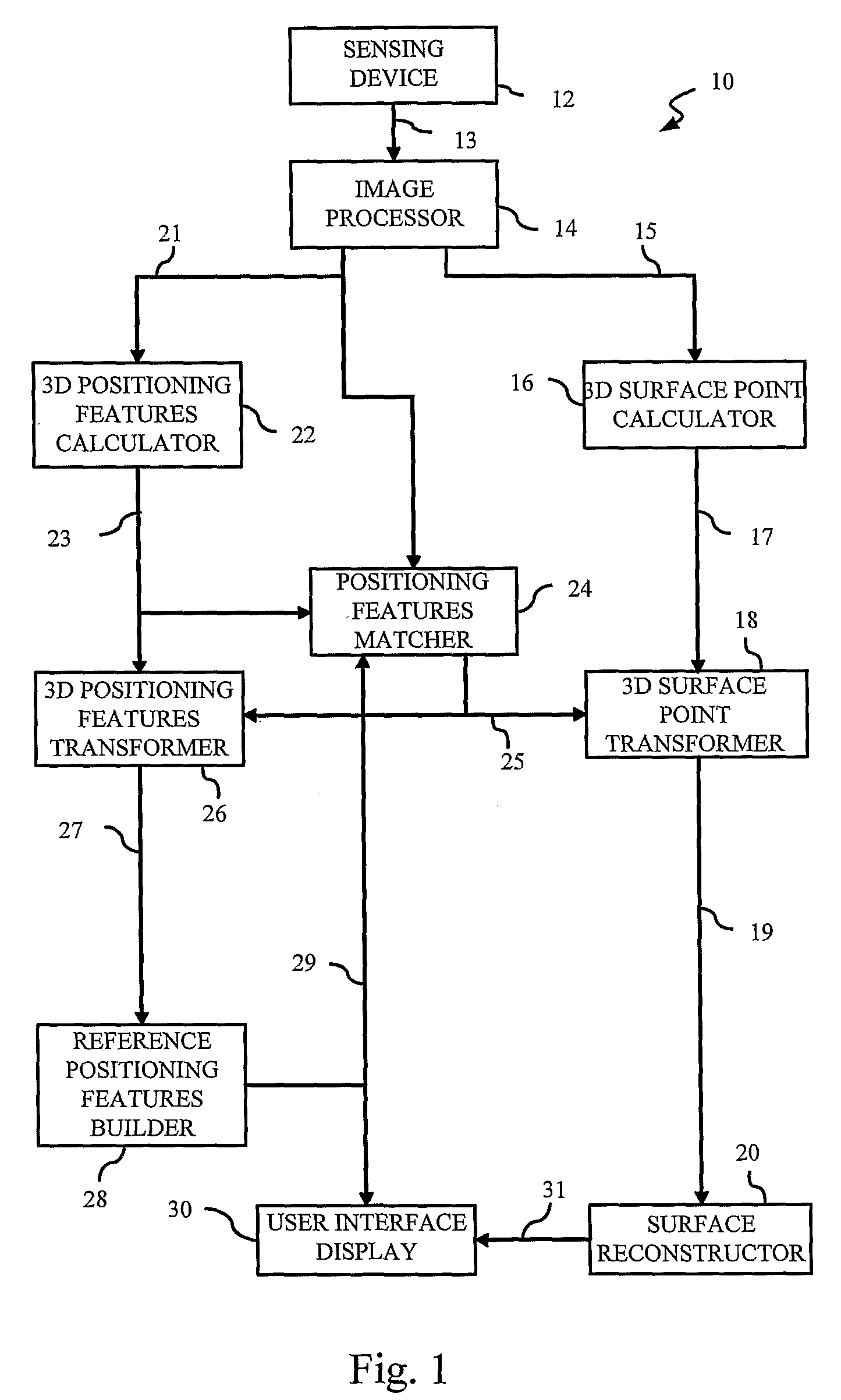

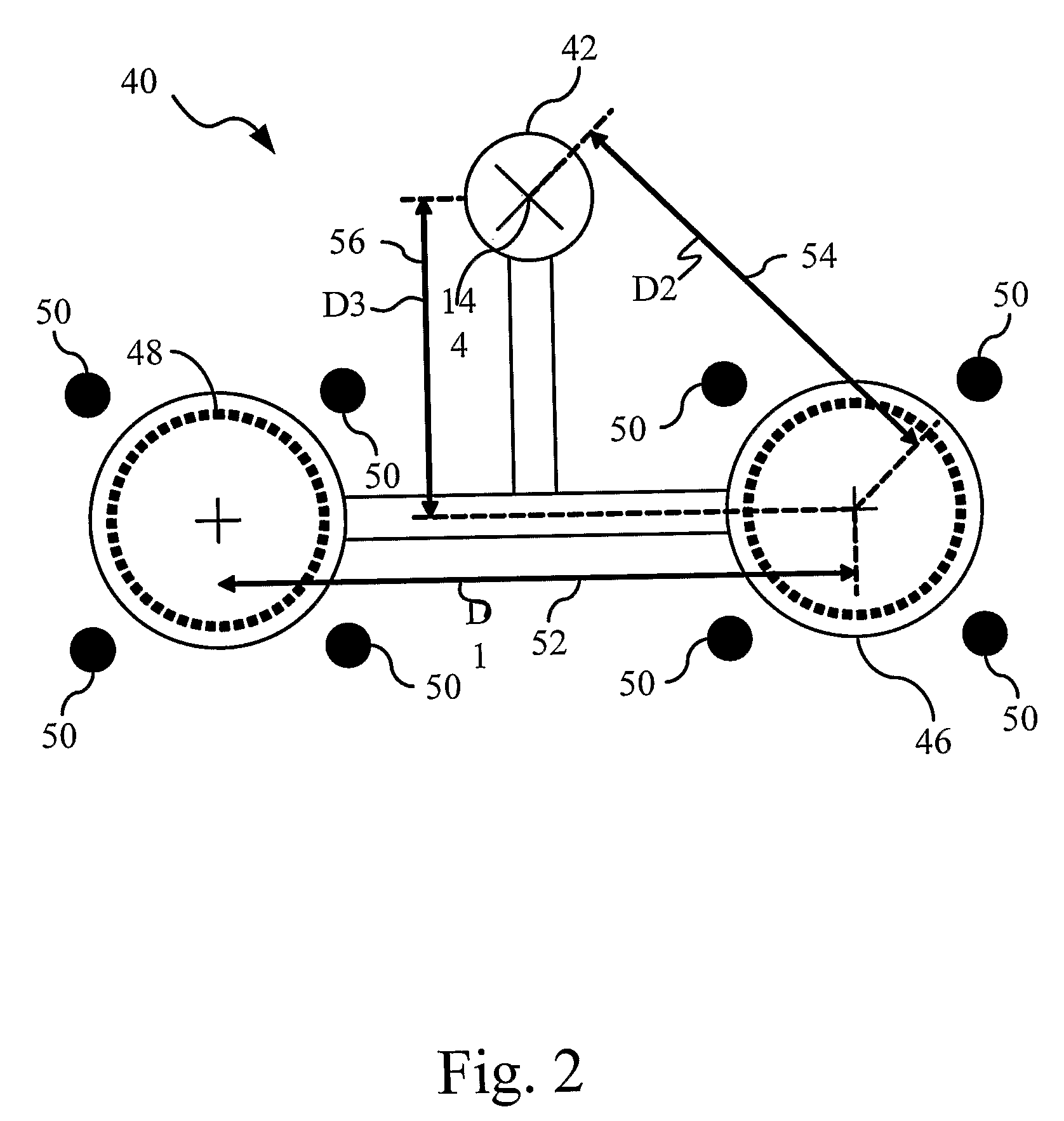

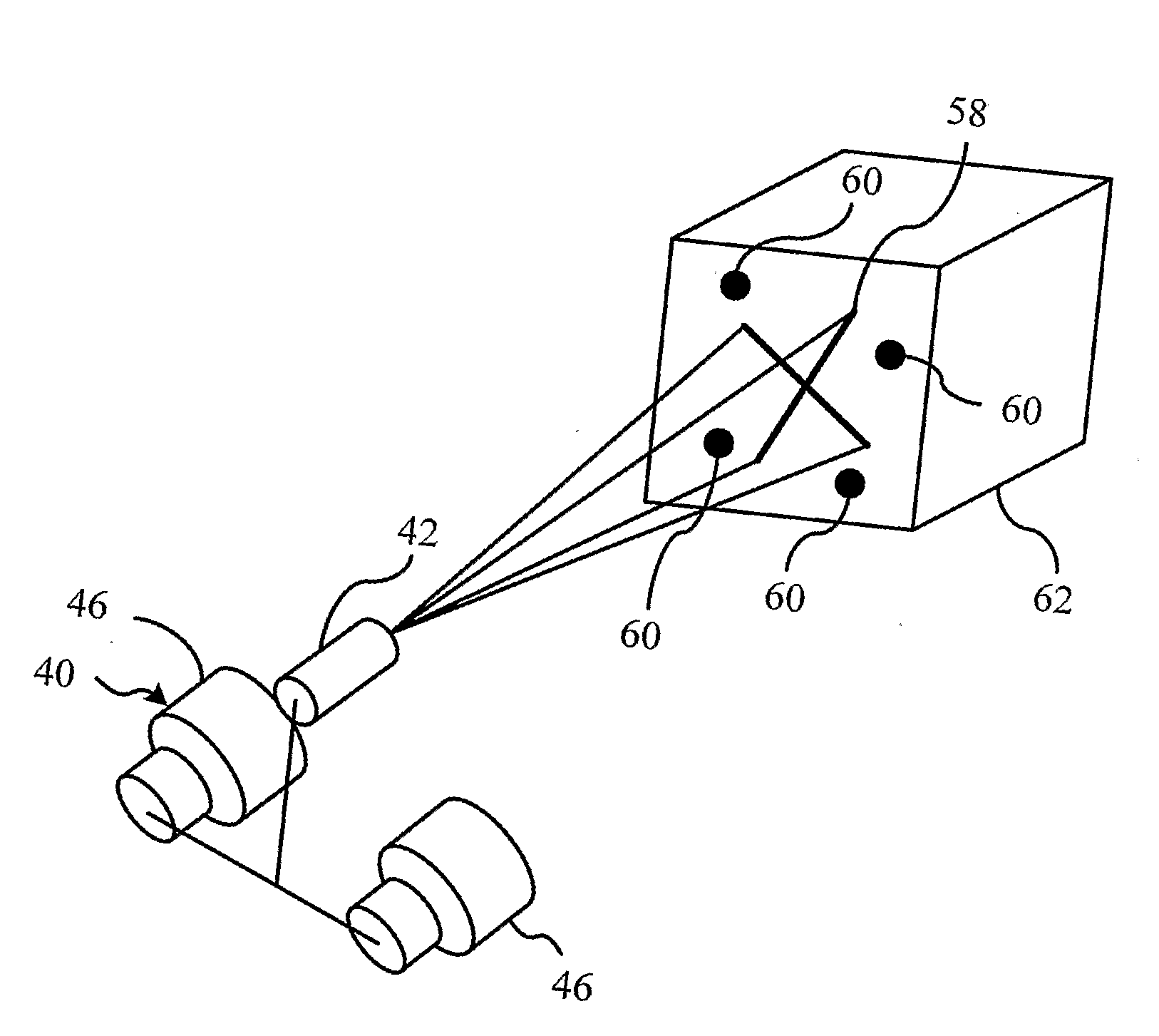

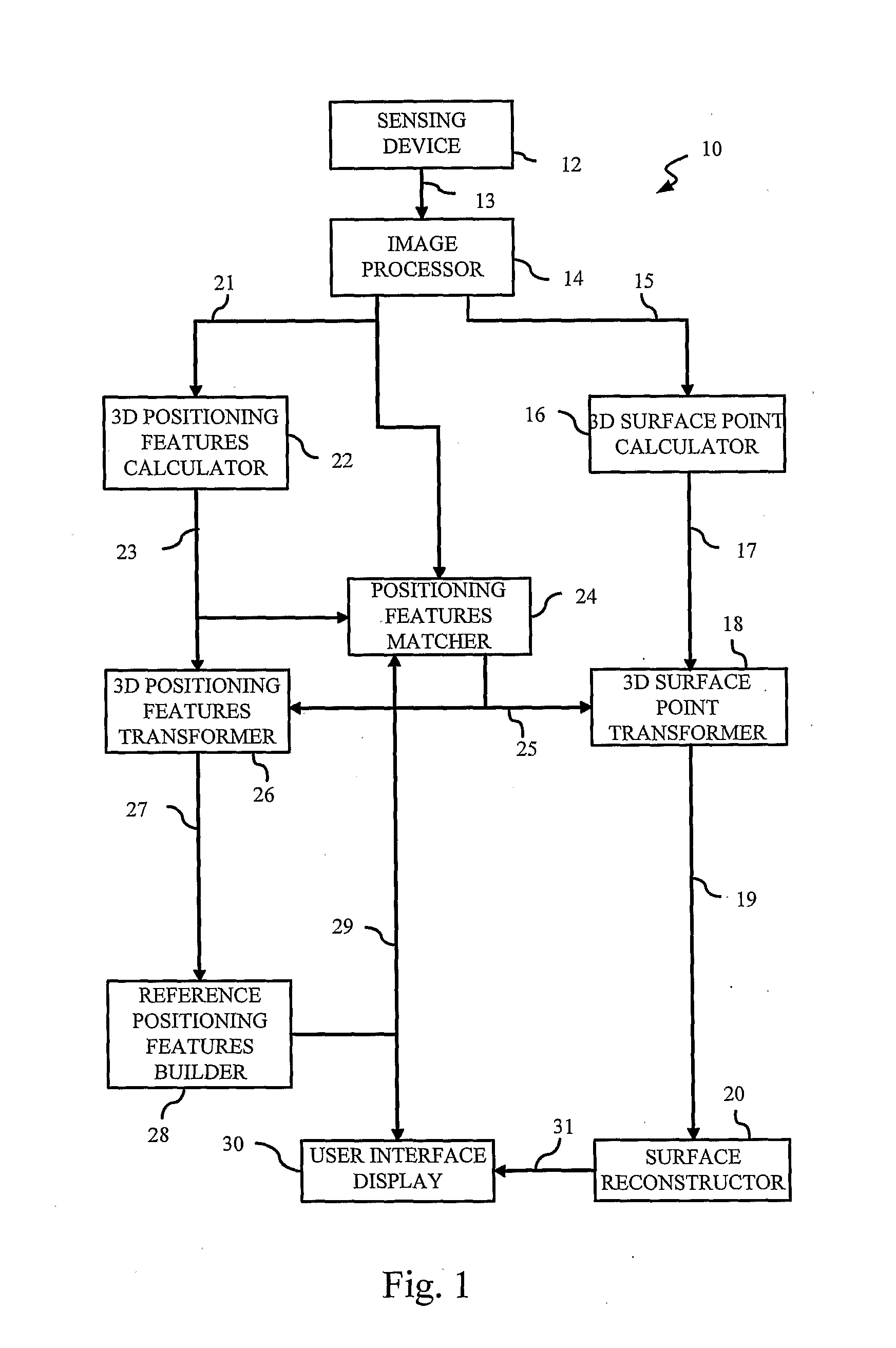

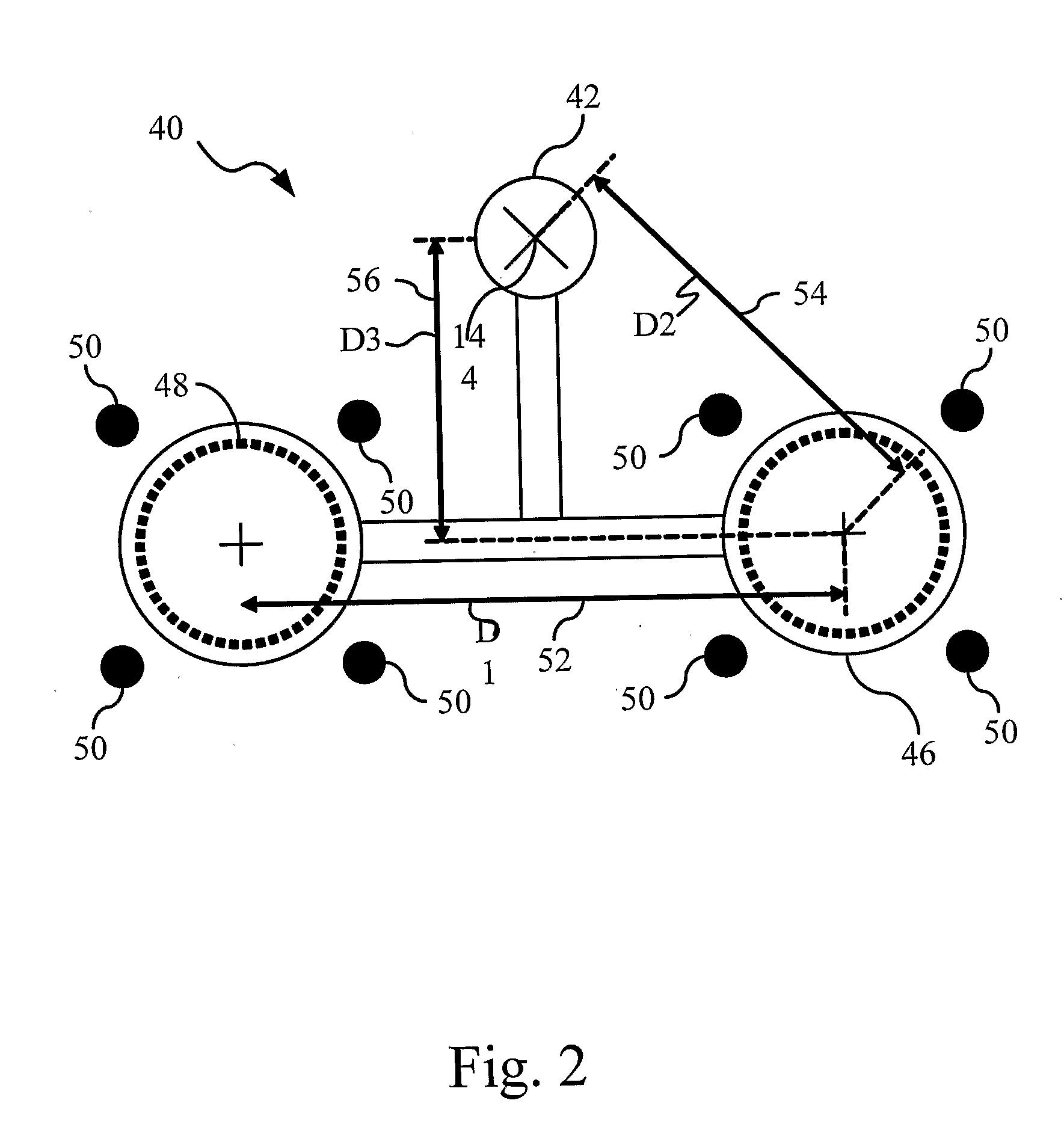

A system, apparatus and method for three-dimensional scanning and digitization of the surface geometry of objects are claimed. The system includes a hand-held apparatus that is auto-referenced. The system is auto-referenced since it does not need any positioning device to provide the 6 degree of freedom transformations that are necessary to integrate 3D measurements in a global coordinate system while the apparatus is manipulated to scan the surface. The system continuously calculates its own position and orientation from observation while scanning the surface geometry of an object. To do so, the system exploits a triangulation principle and integrates an apparatus that captures both surface points originating from the reflection of a projected laser pattern on an object's surface and 2D positioning features originating from the observation of target positioning features.

Owner:CREAFORM INC

Auto-Referenced System and Apparatus for Three-Dimensional Scanning

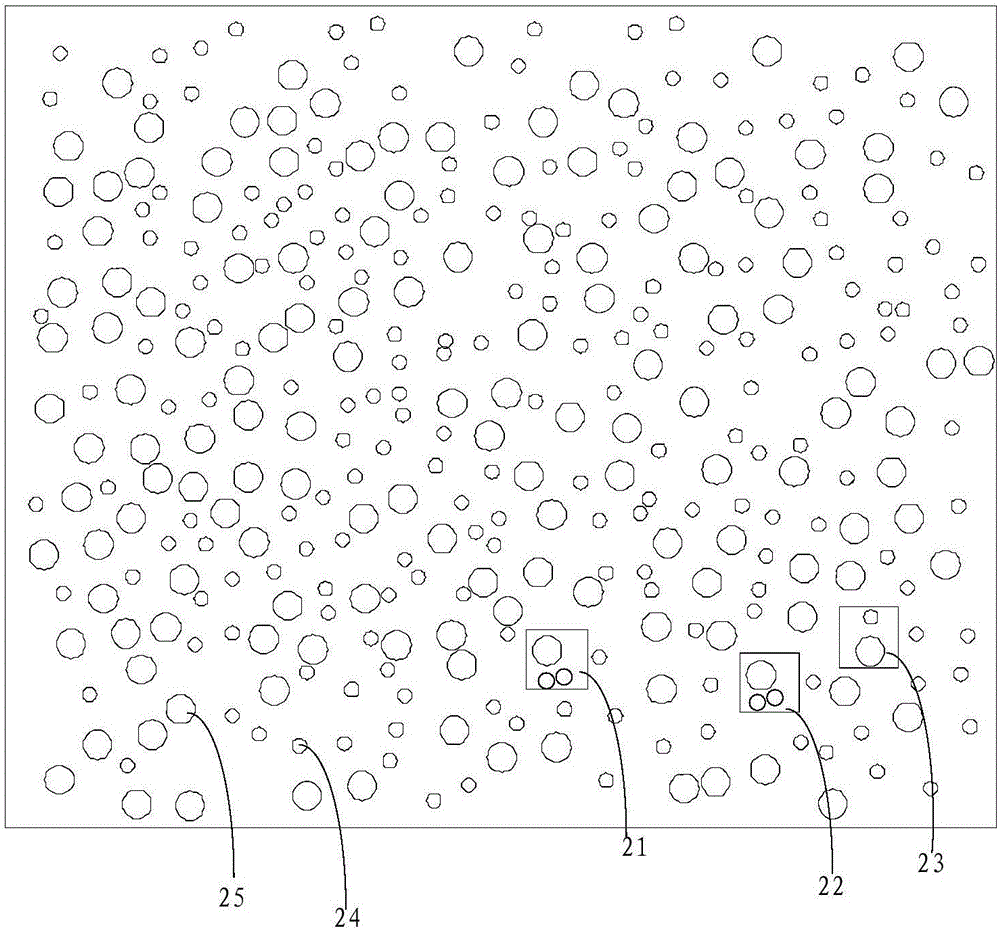

A system, apparatus and method for three-dimensional scanning and digitization of the surface geometry of objects are claimed. The system comprises a hand-held apparatus that is auto-referenced. The system is auto-referenced since it does not need any positioning device to provide the 6 degree of freedom transformations that are necessary to integrate 3D measurements in a global coordinate system while the apparatus is manipulated to scan the surface. The system continuously calculates its own position and orientation from the reflection of a projected laser pattern on an object's surface and 2D positioning features originating from the observation of target positioning features. Using the described system, it is possible to simultaneously build and match a 3D representation of the positioning features while accumulating the 3D surface points describing the surface geometry.

Owner:CREAFORM INC

High temperature insulation with enhanced abradability

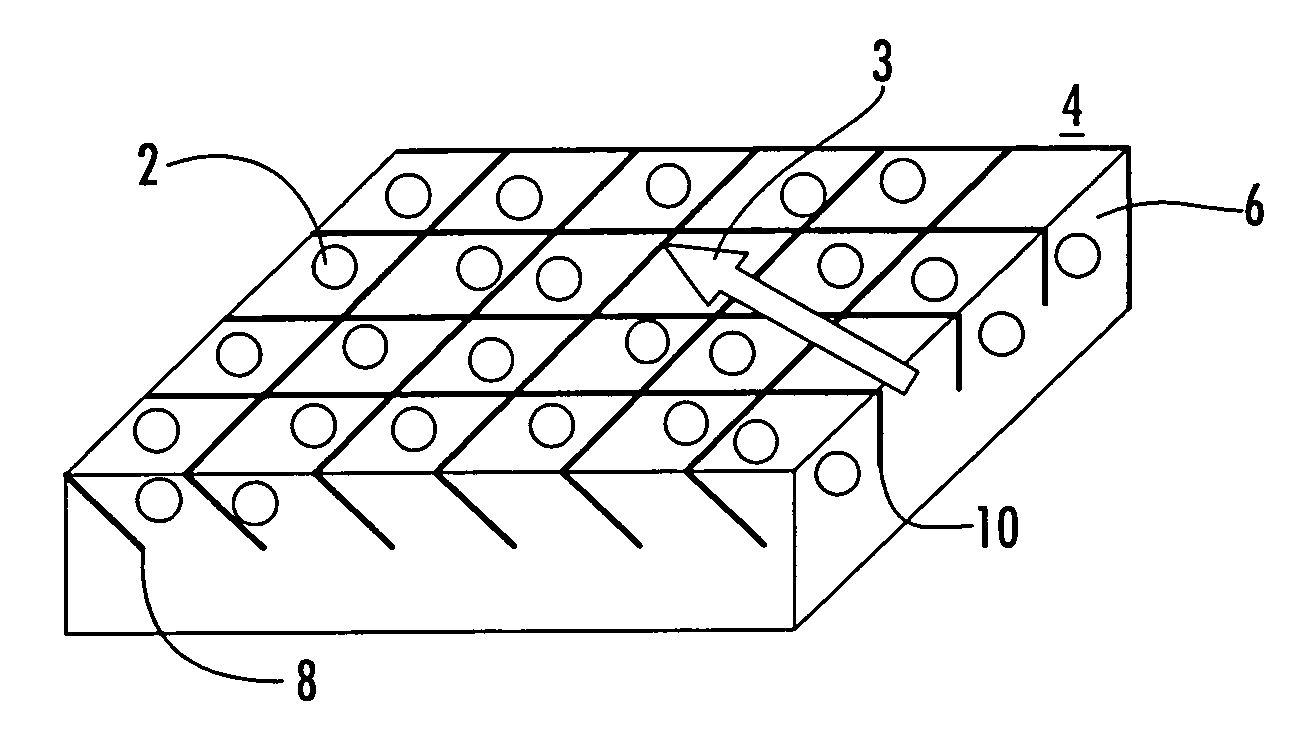

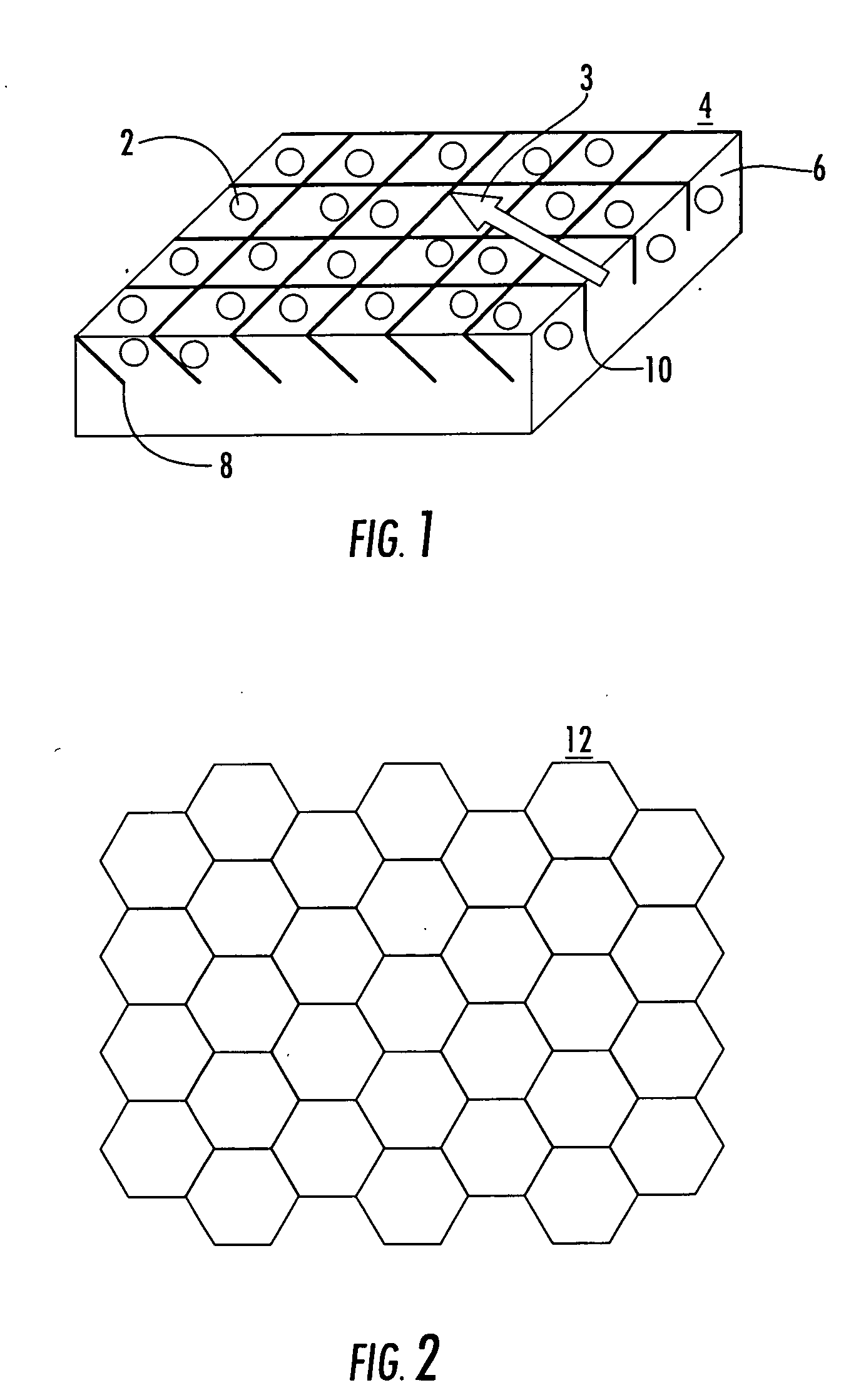

InactiveUS20080274336A1Improve abradabilityMolten spray coatingElectric discharge heatingAcute angleLaser patterning

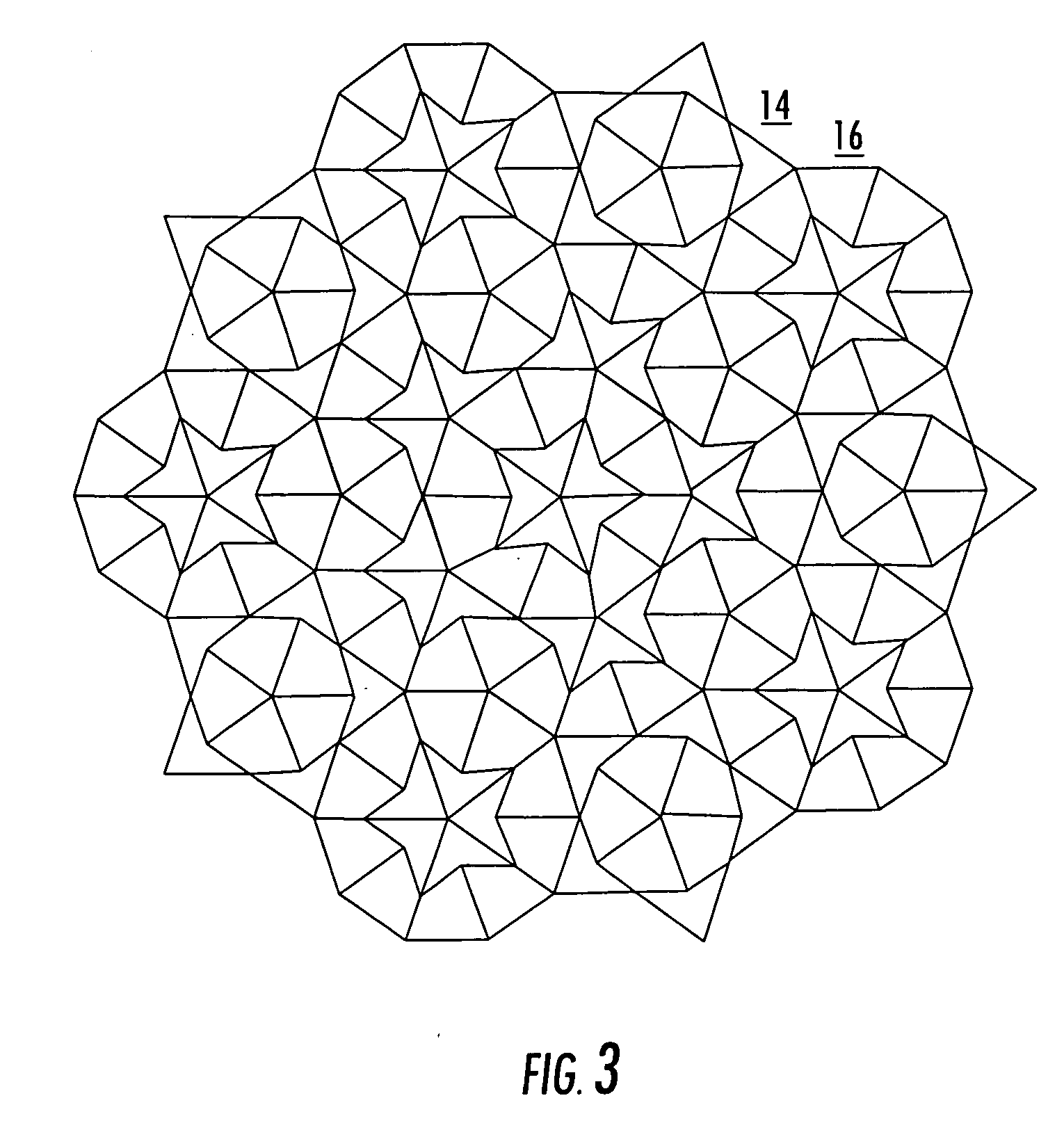

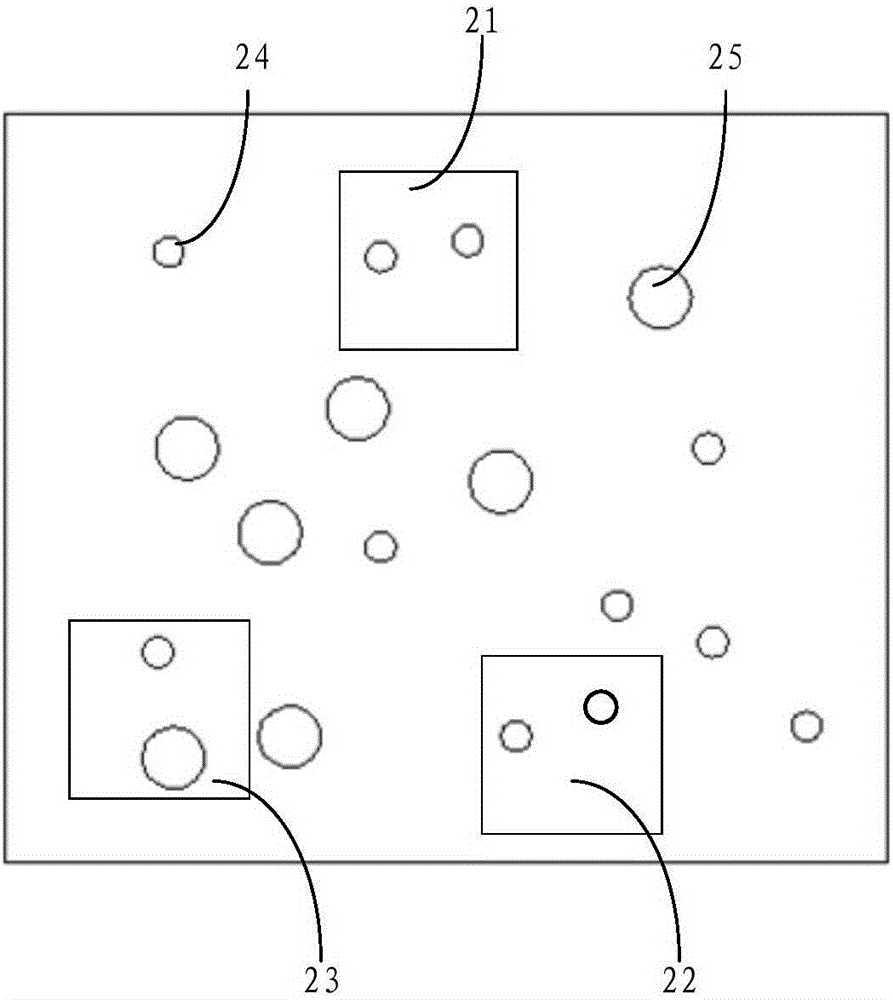

A enhanced abradable friable graded insulator FGI results from the laser patterning of a coating where a series of top surfaces reside on a series of columns such that the walls of the columns are not significantly densified relative to the interior of the columns. Patterns can be generated where the columns are oriented independently normal to or at an acute angle to the top surfaces. The cross sections of the top surfaces are formed to conform to the average dimensions of the spheres of the FGI coating. The cross sections of the top surfaces can be more than 1.5 times the diameter of the spheres. Various patterns of top surfaces can be used including regular, random, quasiperiodic patterns. A gradient of abradability can be imposed on the coating.

Owner:SIEMENS ENERGY INC

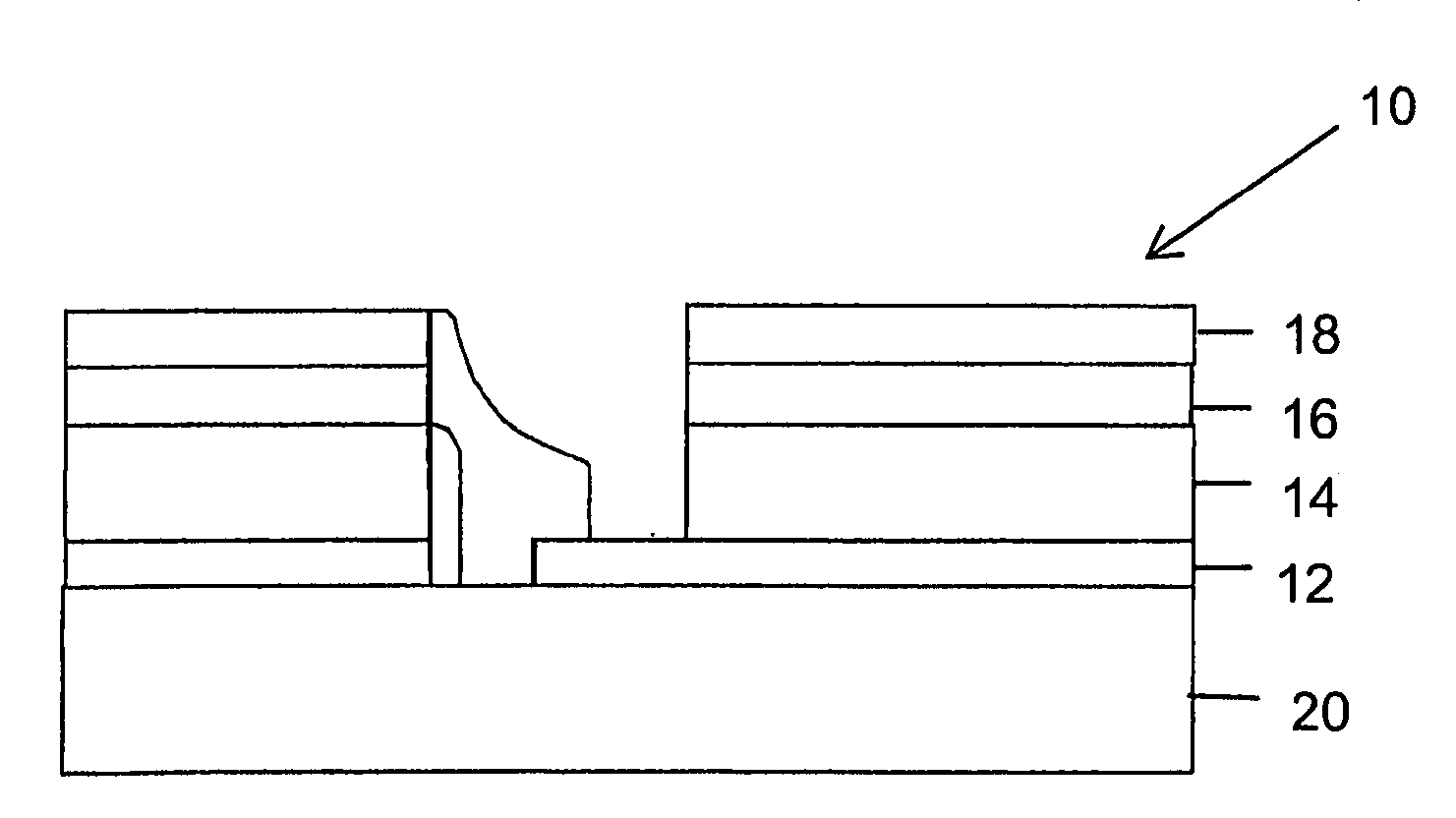

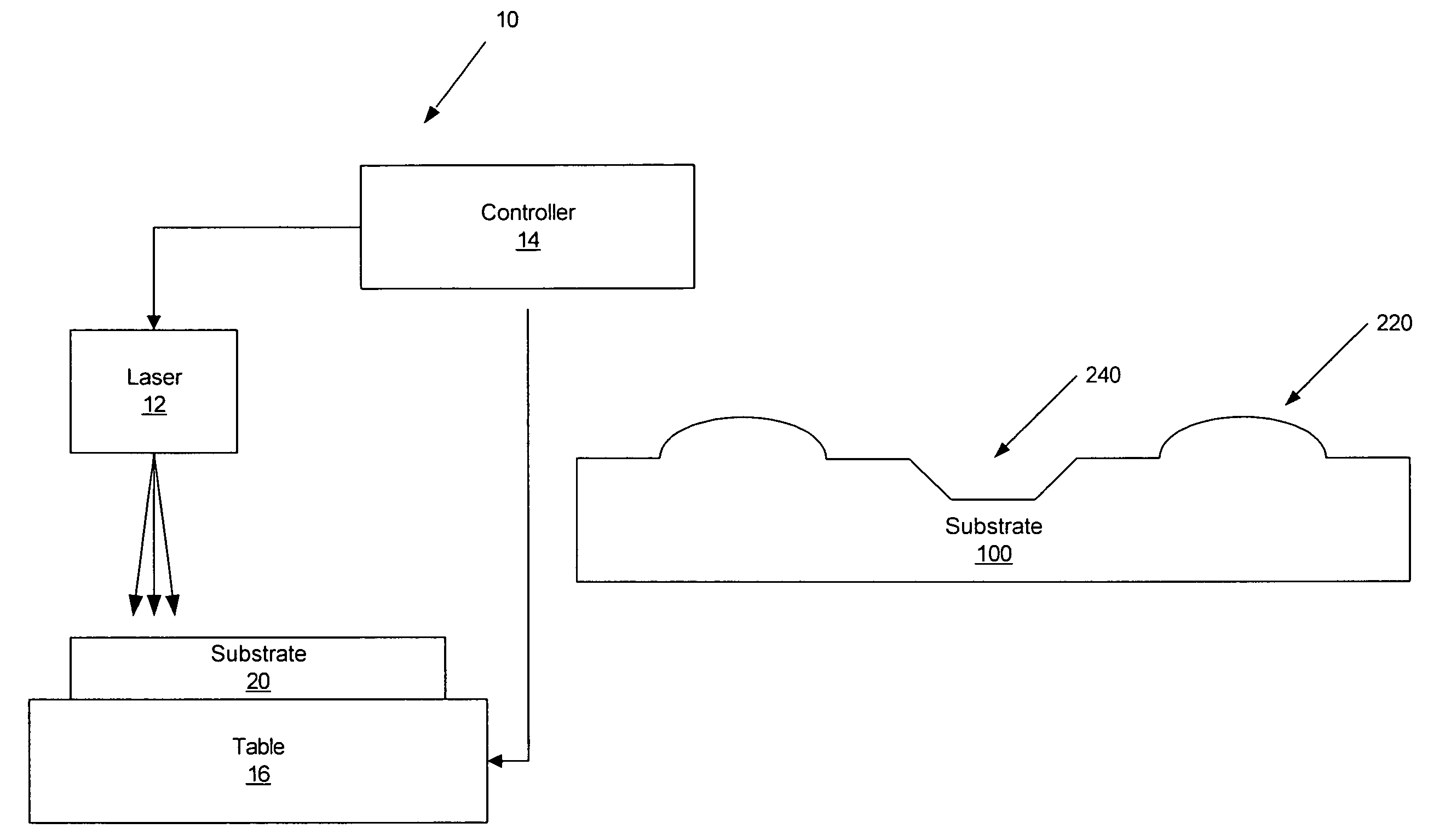

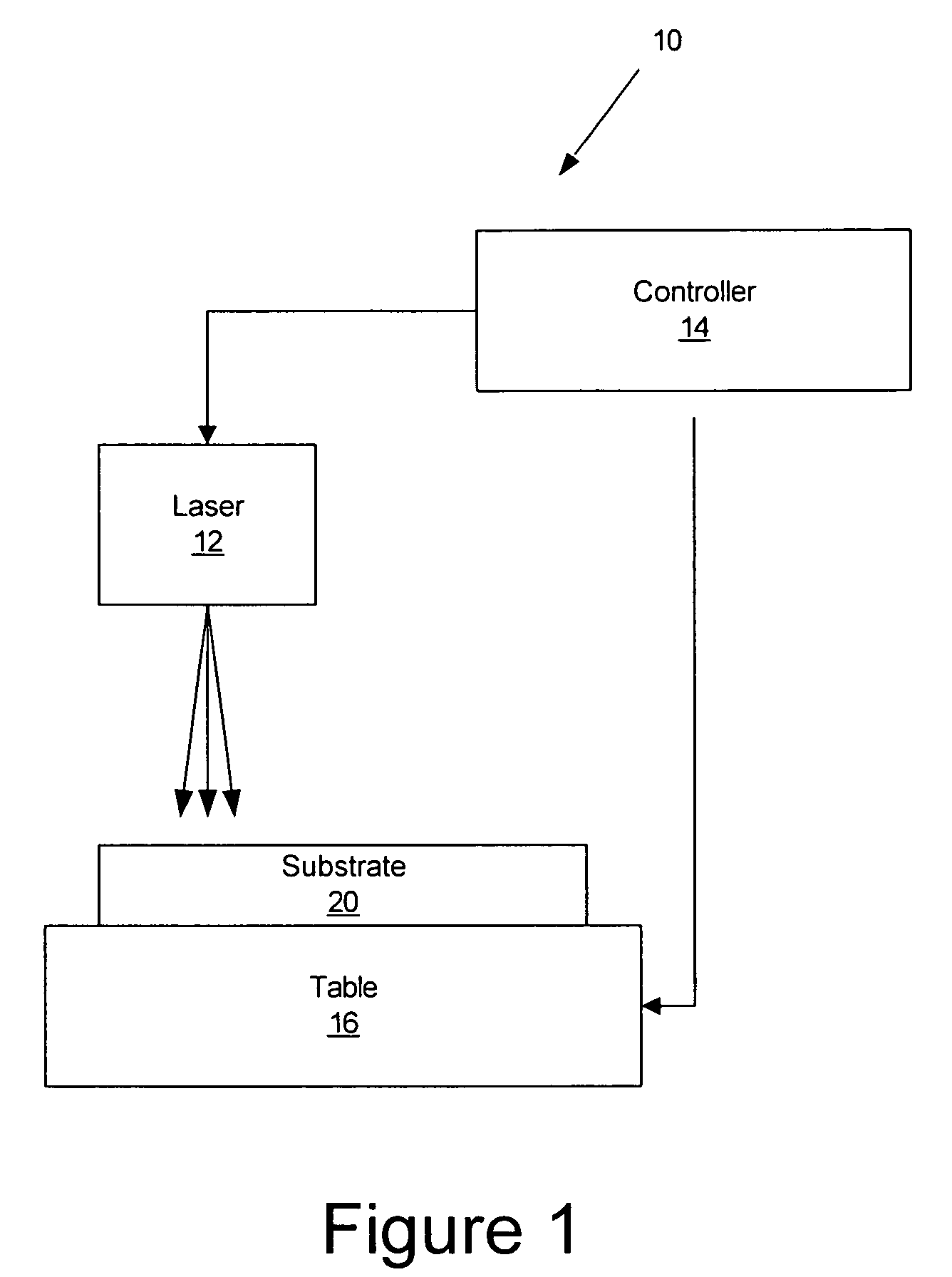

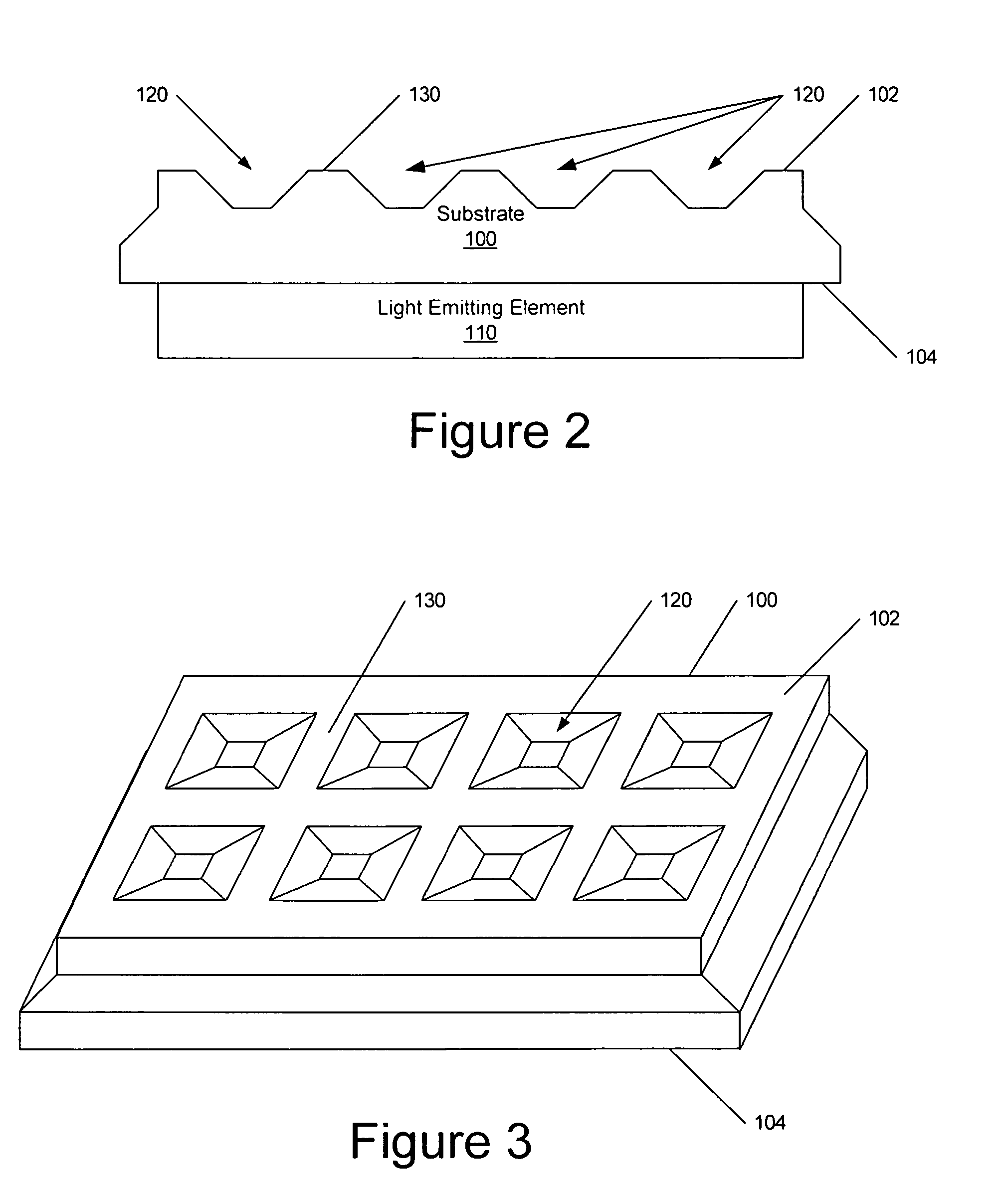

Laser patterning of light emitting devices and patterned light emitting devices

ActiveUS20050227379A1Fully removedDecorative surface effectsSemiconductor/solid-state device manufacturingSemiconductor materialsLaser patterning

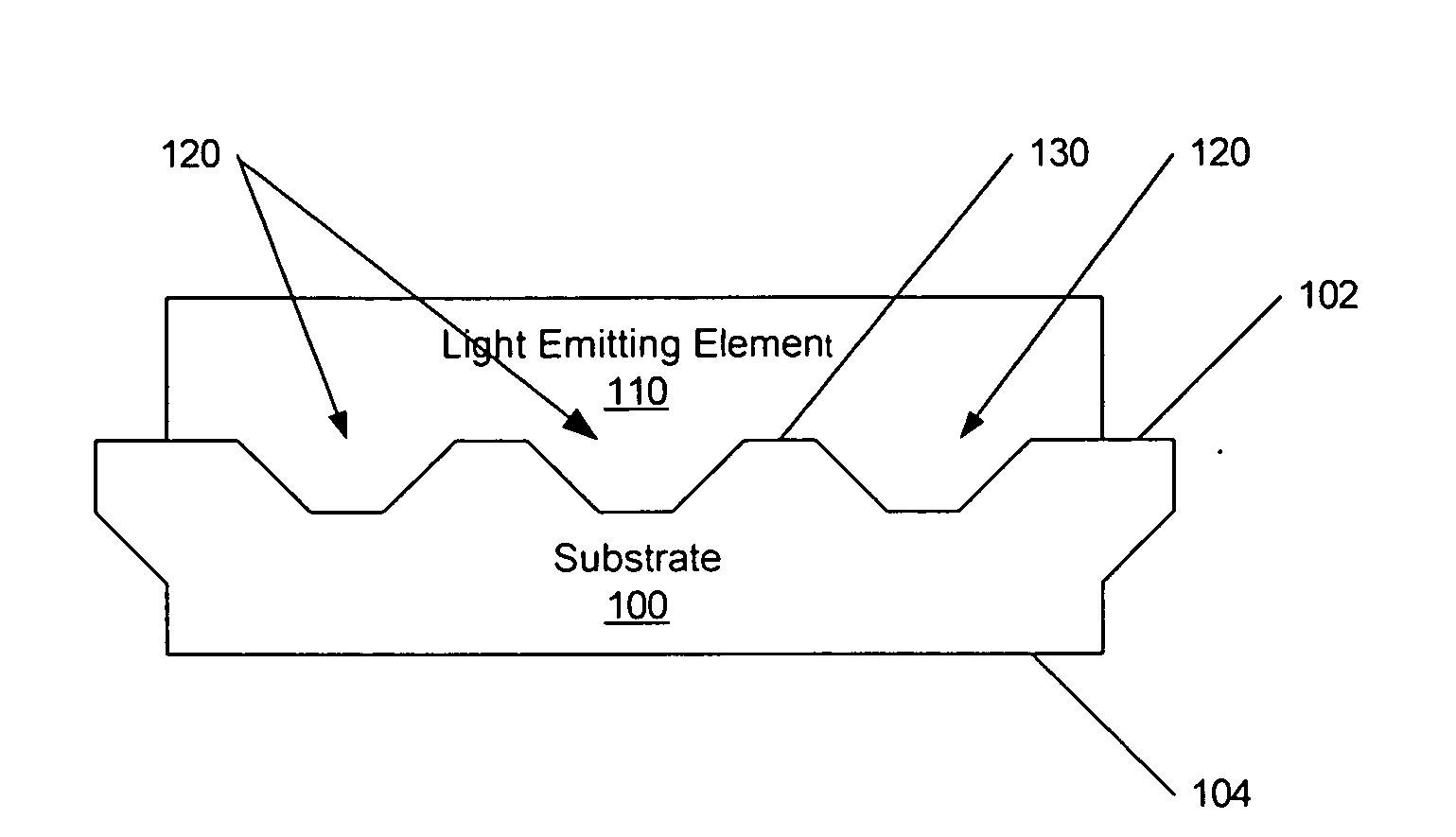

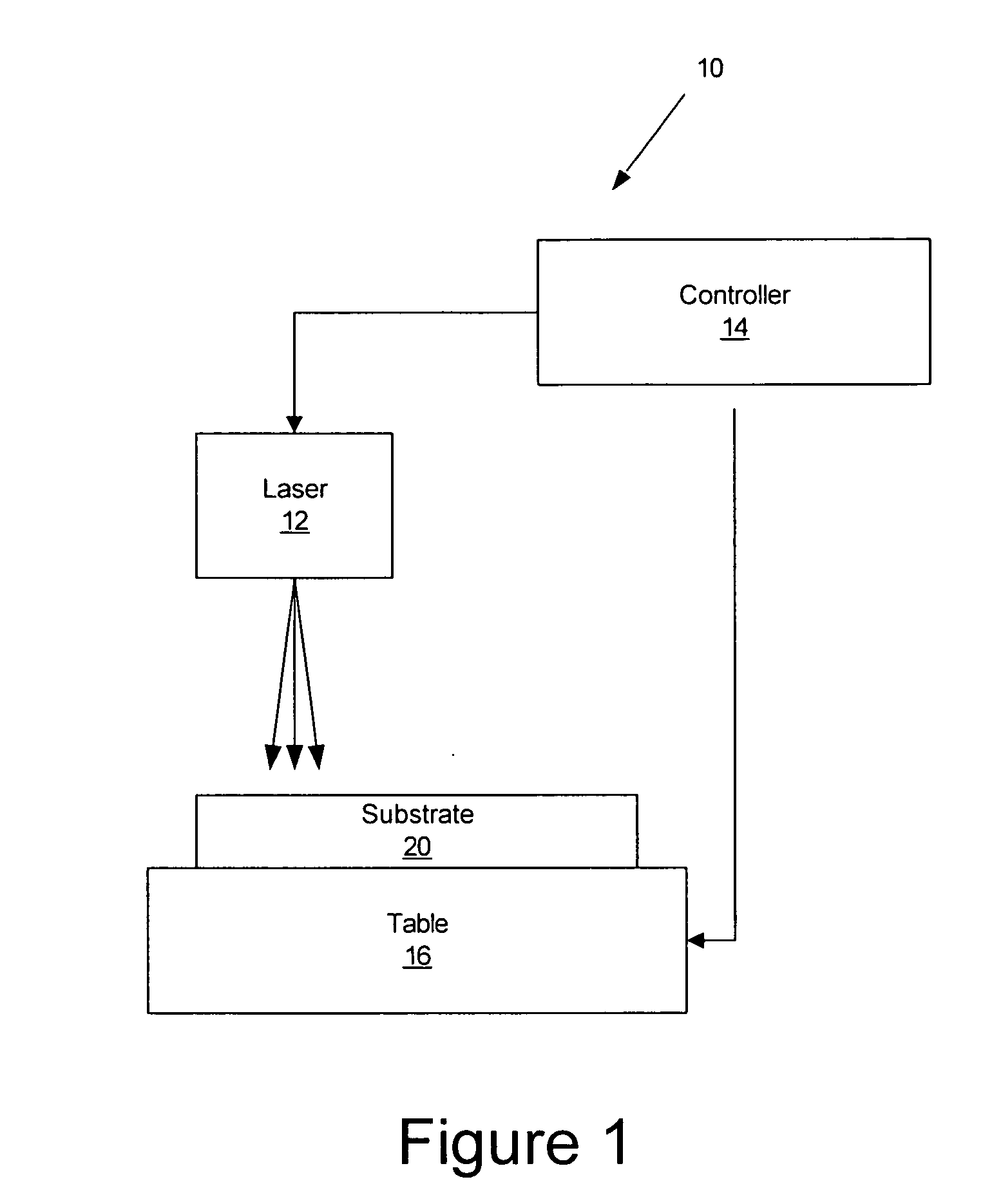

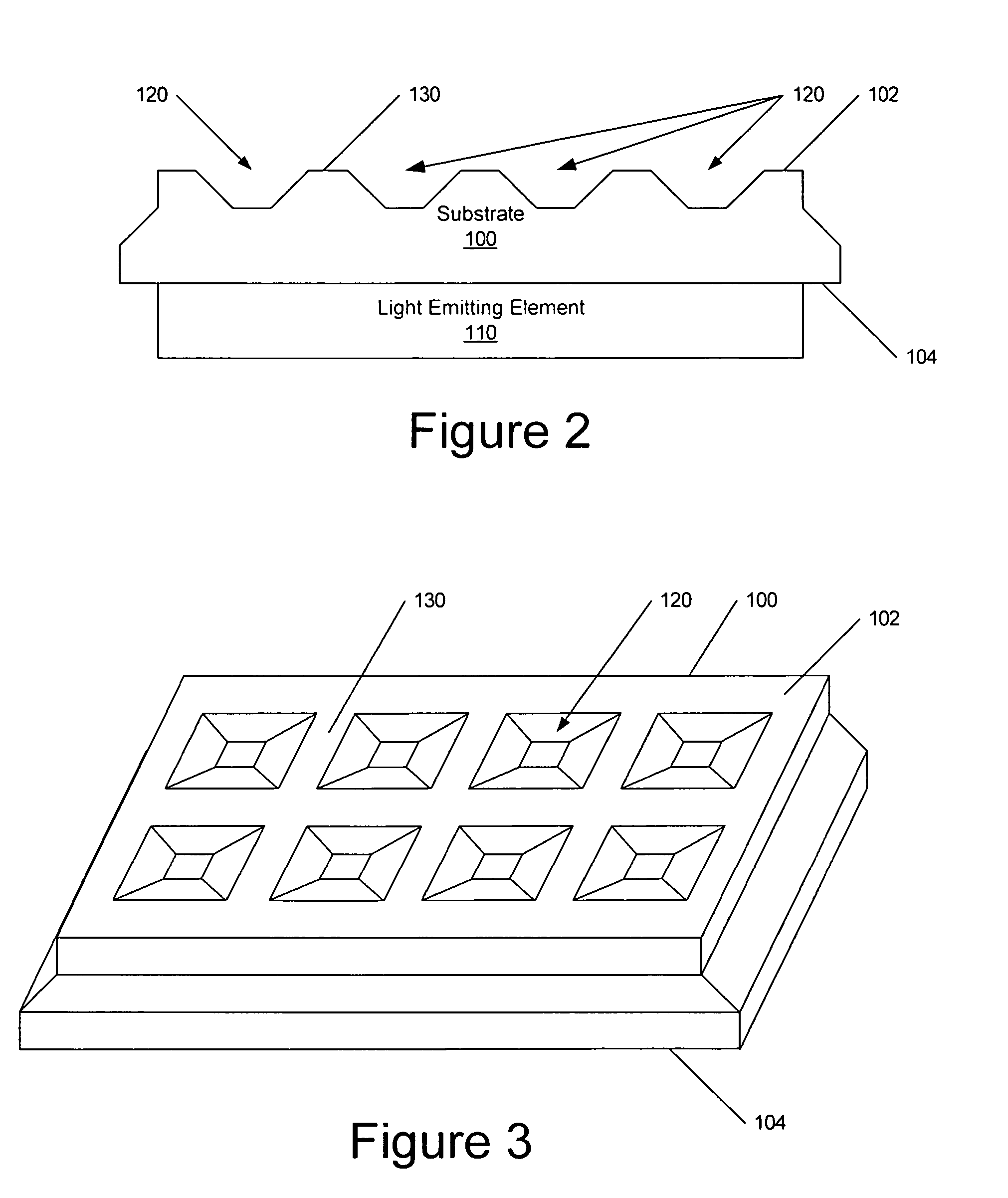

Light extraction features are provided for a light emitting device having a substrate and a semiconductor light emitting element on the substrate by shaping a surface of a layer of semiconductor material utilizing a laser to define three dimensional patterns in the layer of semiconductor material. The layer of semiconductor material may be the substrate. In particular embodiments of the present invention, the surface of the layer of semiconductor material is shaped by applying laser light to the layer of semiconductor material at an energy sufficient to remove material from the layer of semiconductor material. The laser light may also by applied in a blanket manner at a level below the ablation threshold. The application of laser light to the layer of semiconductor material may be followed by etching the substrate. The layer of semiconductor material may be anisotropically etched. A mask could also be patterned utilizing laser light and the layer of semiconductor material etched using the mask. Light emitting devices have three dimensional patterns in a layer of semiconductor material of the device are also provided.

Owner:CREE INC

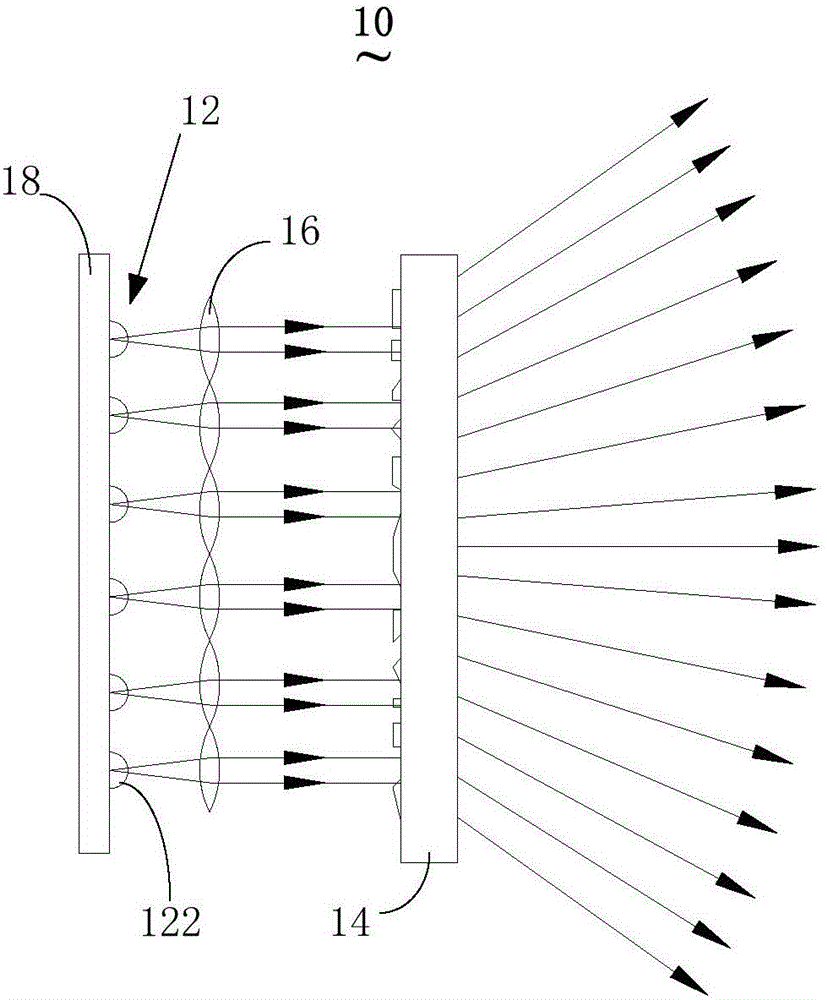

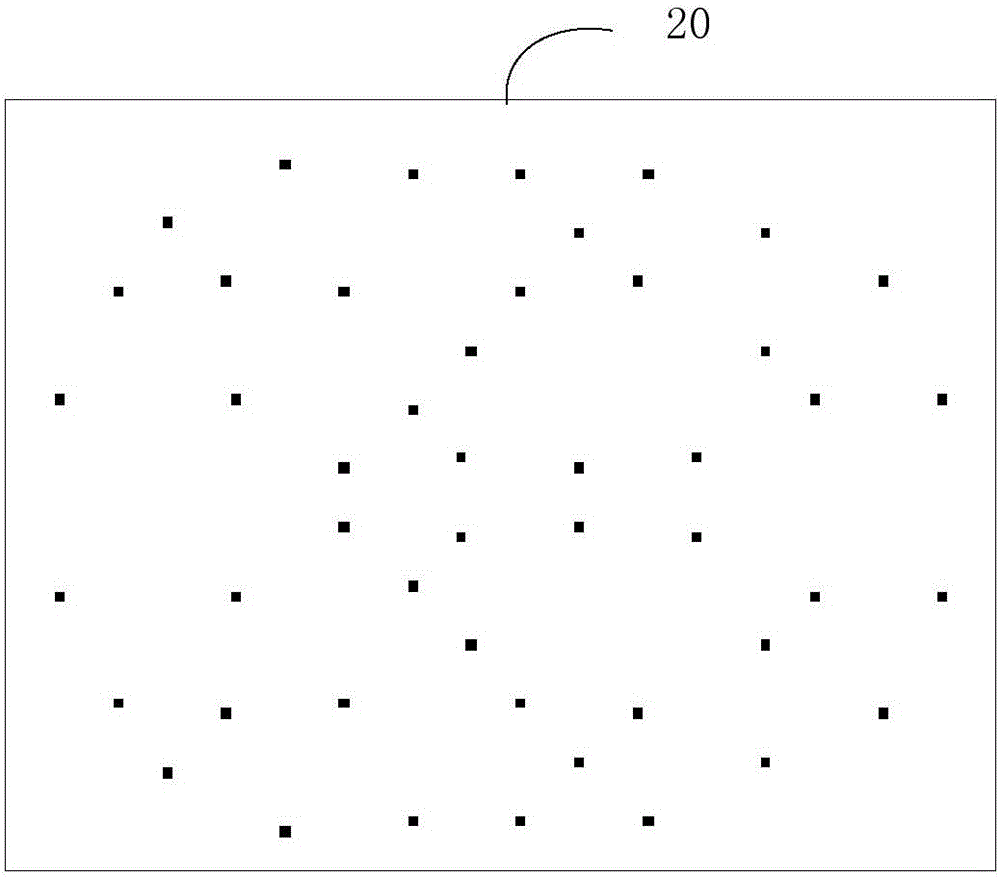

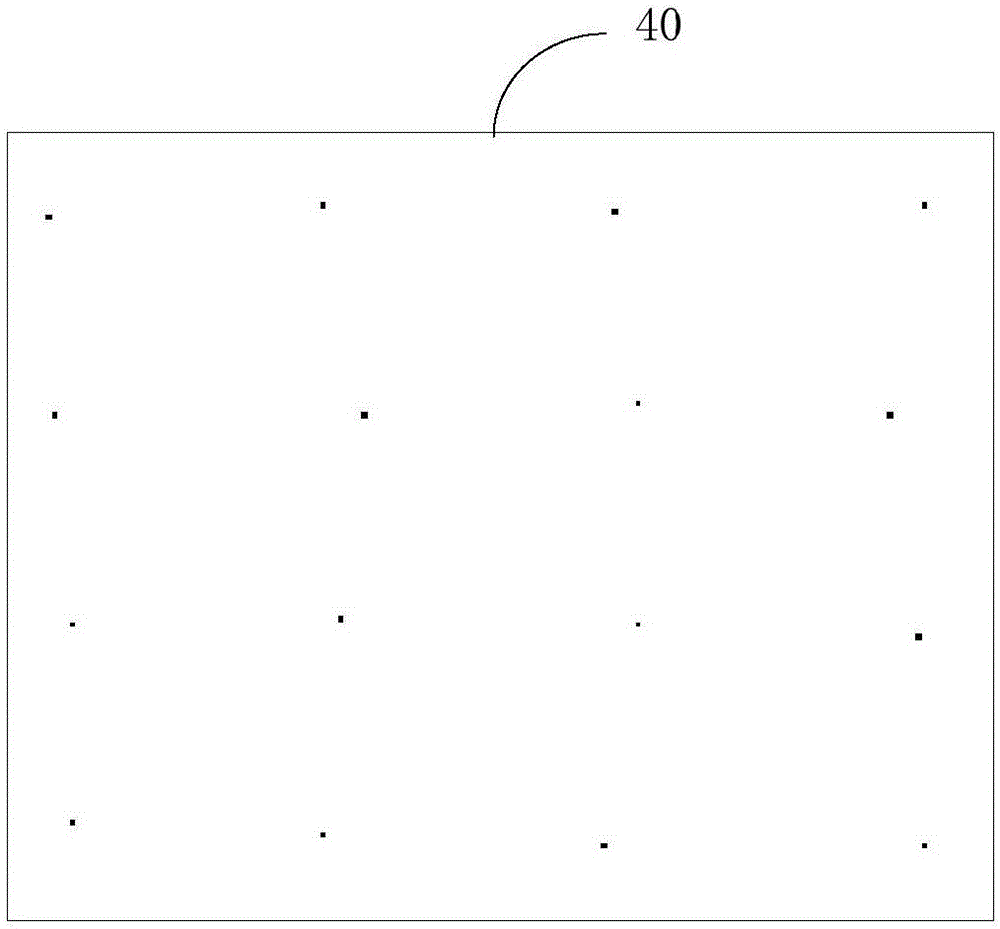

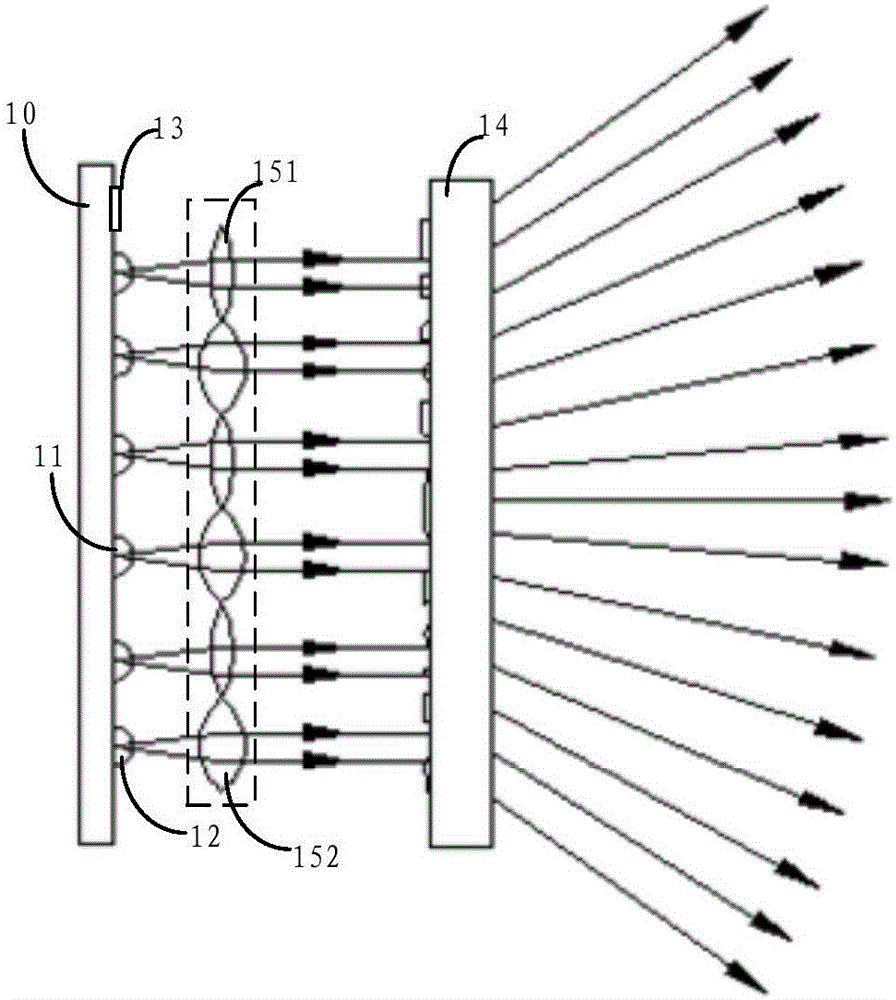

Planar array projection device and depth camera

ActiveCN106406002AGood optical projectionFacilitate thinningProjectorsCamera body detailsLight beamLaser patterning

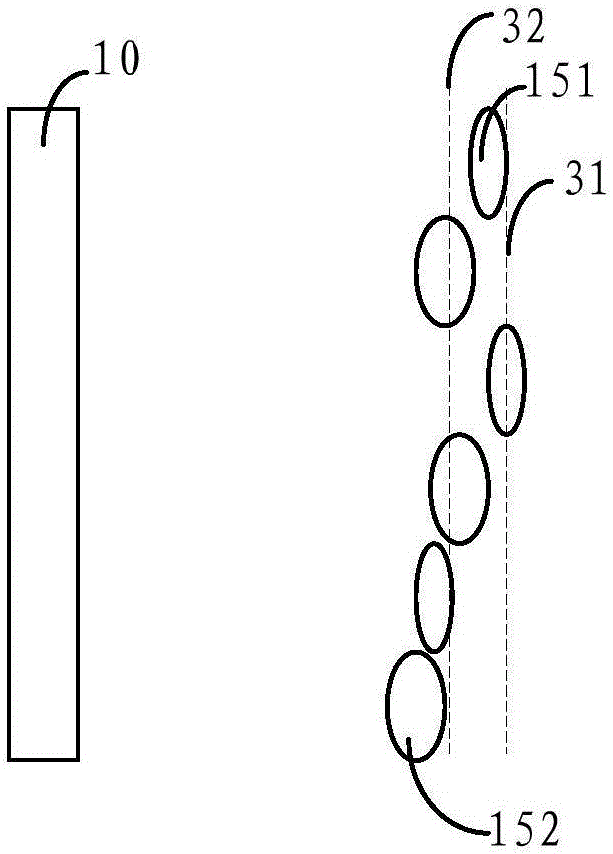

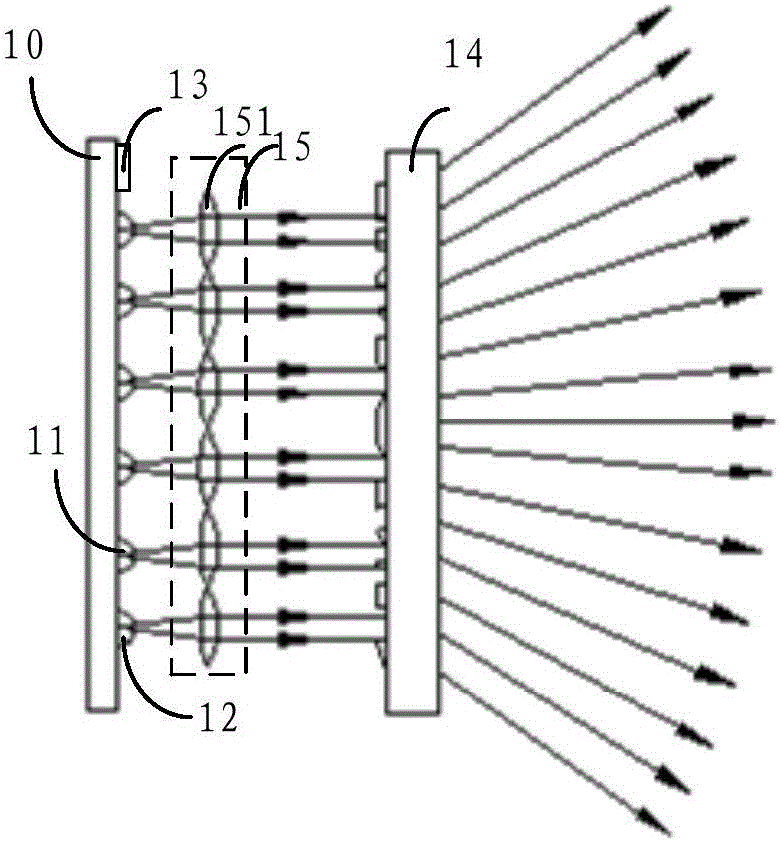

The invention discloses a planer array projection device and a depth camera. The planer array projection device comprises a planer array light source and a diffractive optical element, wherein the planer array light source comprises multiple light emitting elements for emitting laser; the diffractive optical element is used for carrying out beam expanding on the laser emitted by the planer array light source and converting the laser to patterned laser; the multiple light emitting elements are arranged into a first optical pattern; a pattern formed after a single beam of light is expanded through the diffractive optical element is a second optical pattern; the first optical pattern and the second optical pattern are composite to form a composite optical pattern, and the composite optical pattern is the patterned laser pattern; the first optical pattern, the second optical pattern and the composite optical pattern comprise multiple light beams; and the light beam layout in the composite optical pattern has local irrelevance, and the uniformity index is smaller than a preset threshold. Through the above mode, better optical projection effects can be achieved with a smaller light source, integration in a small device is realized, and the light weight and the thinness of the device are improved.

Owner:SHENZHEN ORBBEC CO LTD

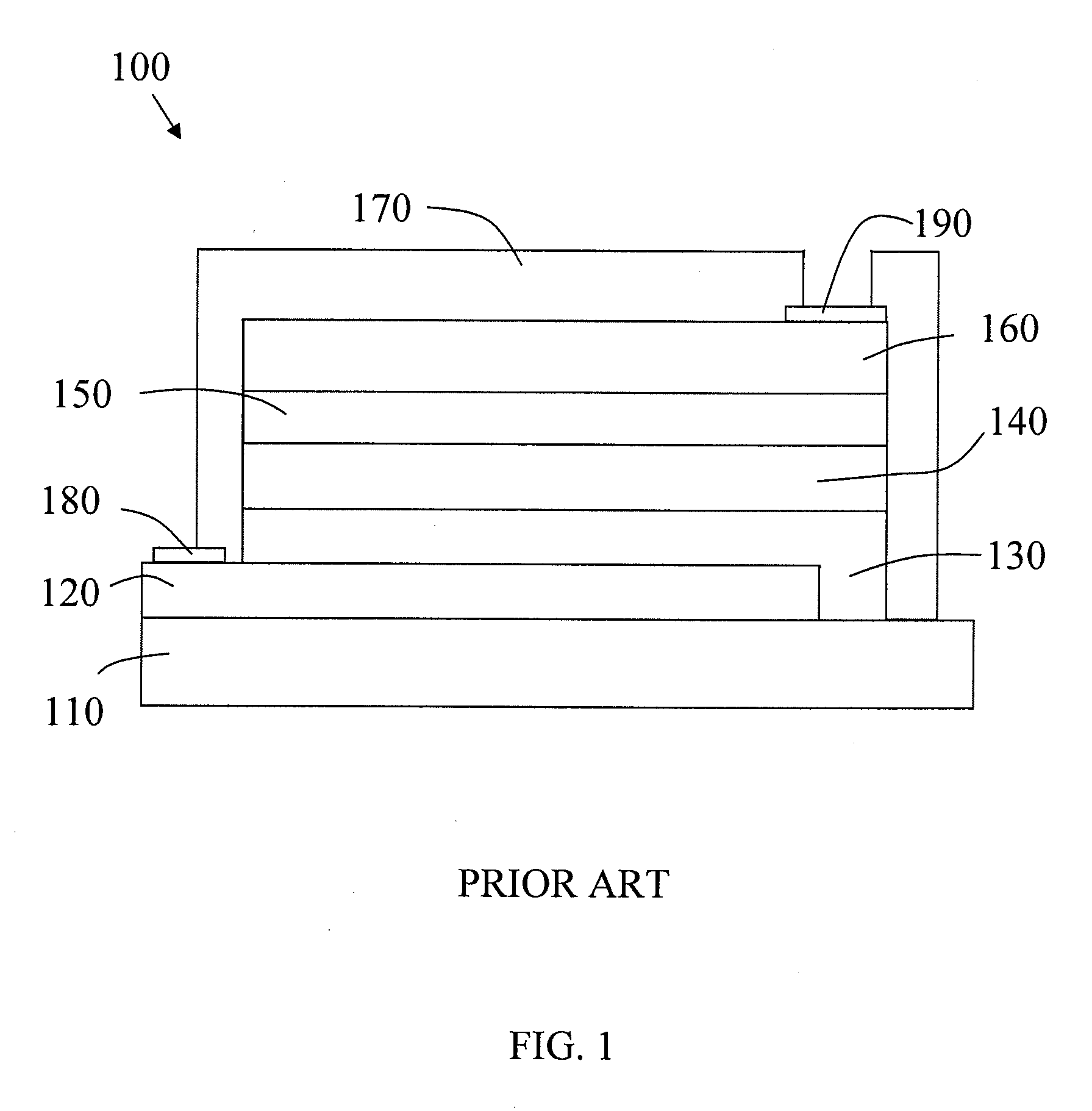

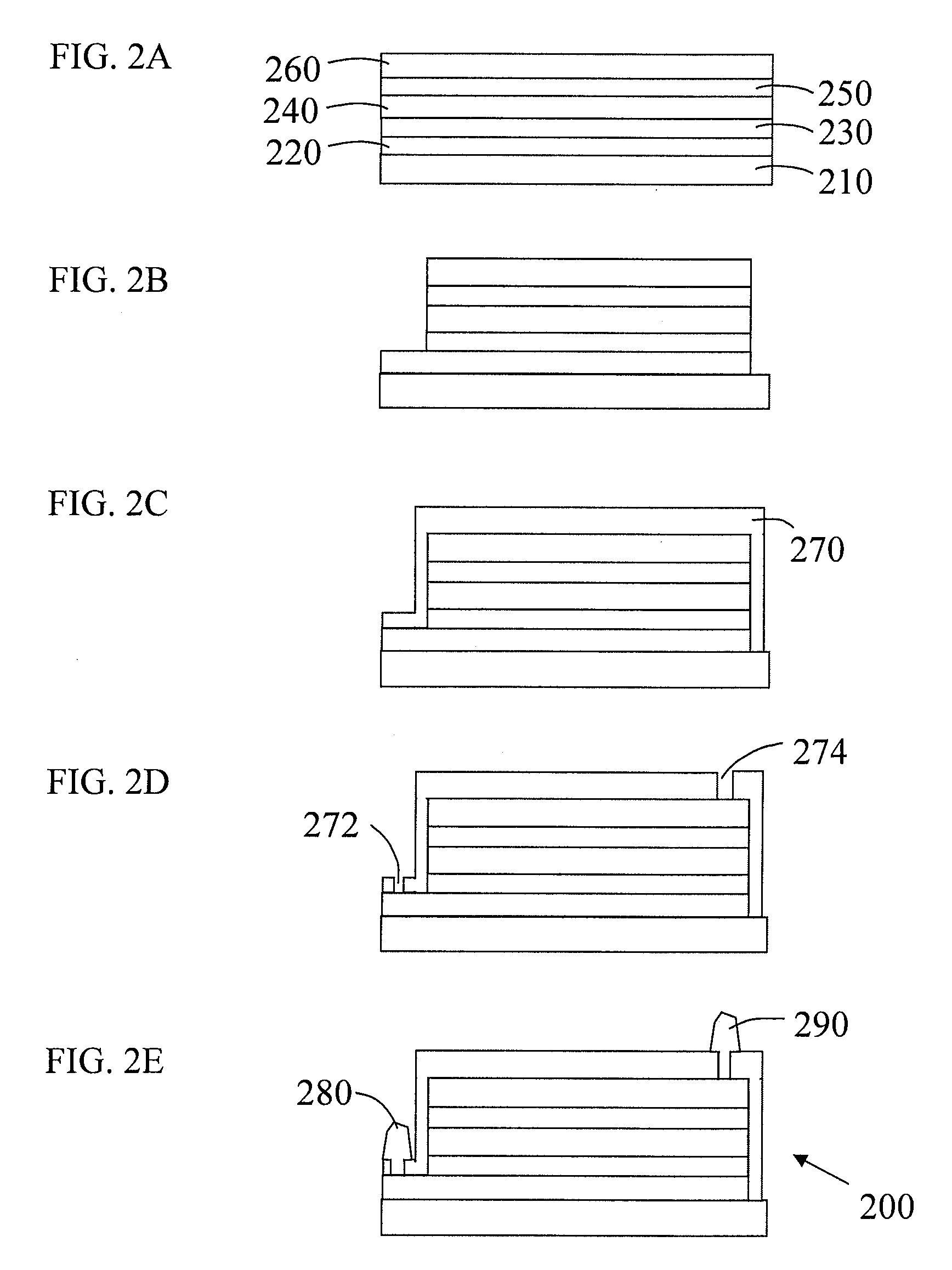

Method for manufacturing electrochromic devices

ActiveUS20090304912A1Improve manufacturabilityReduce complexityRadiation applicationsPretreated surfacesDevice materialLaser patterning

This invention contemplates the use of laser patterning / scribing in electrochromic device manufacture, anywhere during the manufacturing process as deemed appropriate and necessary for electrochromic device manufacturability, yield and functionality, while integrating the laser scribing so as to ensure the active layers of the device are protected to ensure long term reliability. It is envisaged that the laser is used to pattern the component layers of electrochromic devices by directly removing (ablating) the material of the component layers. The invention includes a manufacturing method for an electrochromic device comprising one or more focused laser patterning steps. To minimize redeposition of laser ablated material and particulate formation on device surfaces a number of approaches may be used: (1) ablated material generated by the focused laser patterning may be removed by vacuum suction and / or application of an inert gas jet in the vicinity of the laser ablation of device material; (2) spatial separation of the edges of layers and patterning of lower layers prior to deposition of upper layers; and (3) the laser patterning step may be performed by a laser beam focused directly on the deposited layers from above, by a laser beam directed through the transparent substrate, or by a combination of both.

Owner:APPLIED MATERIALS INC

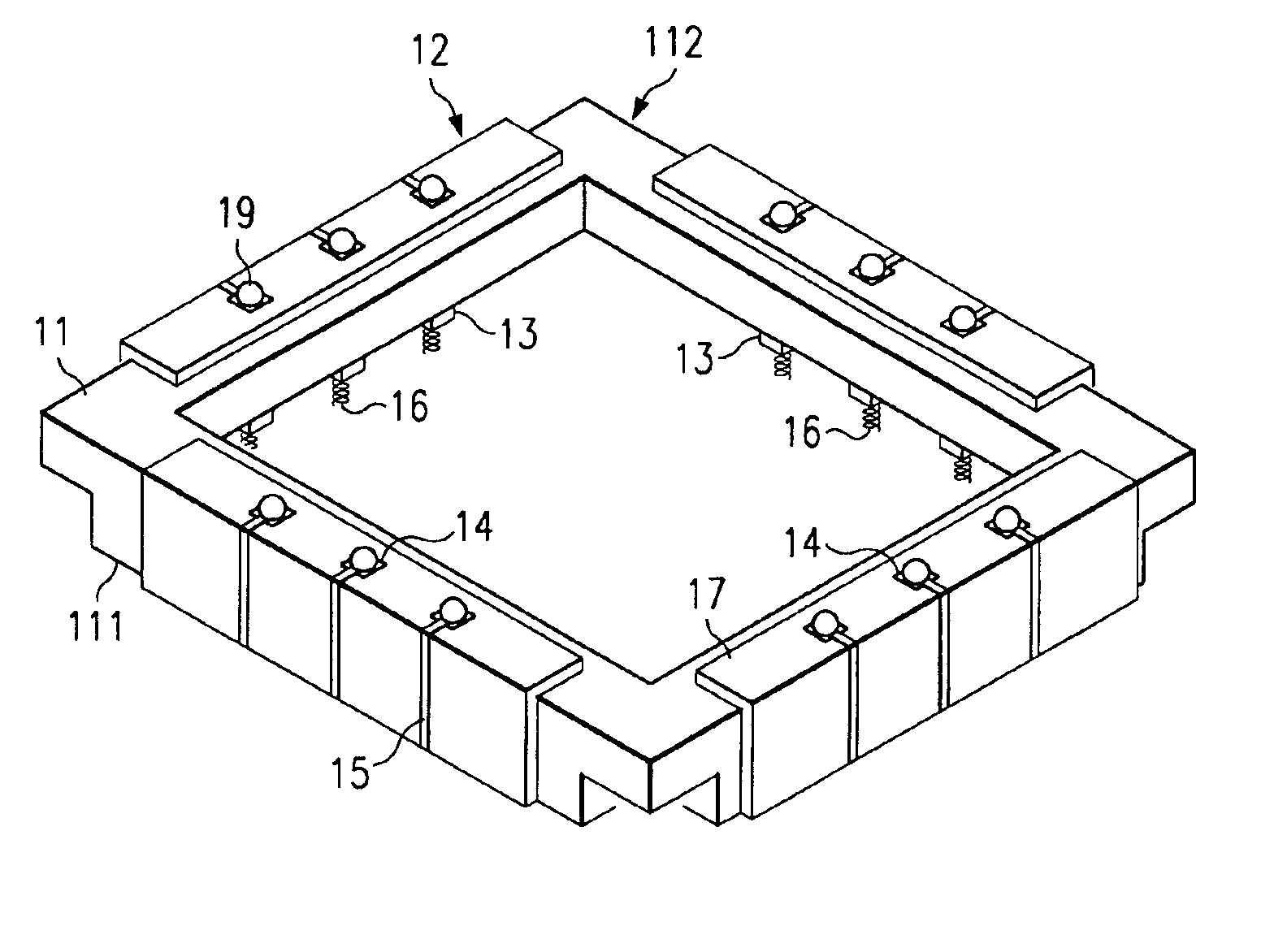

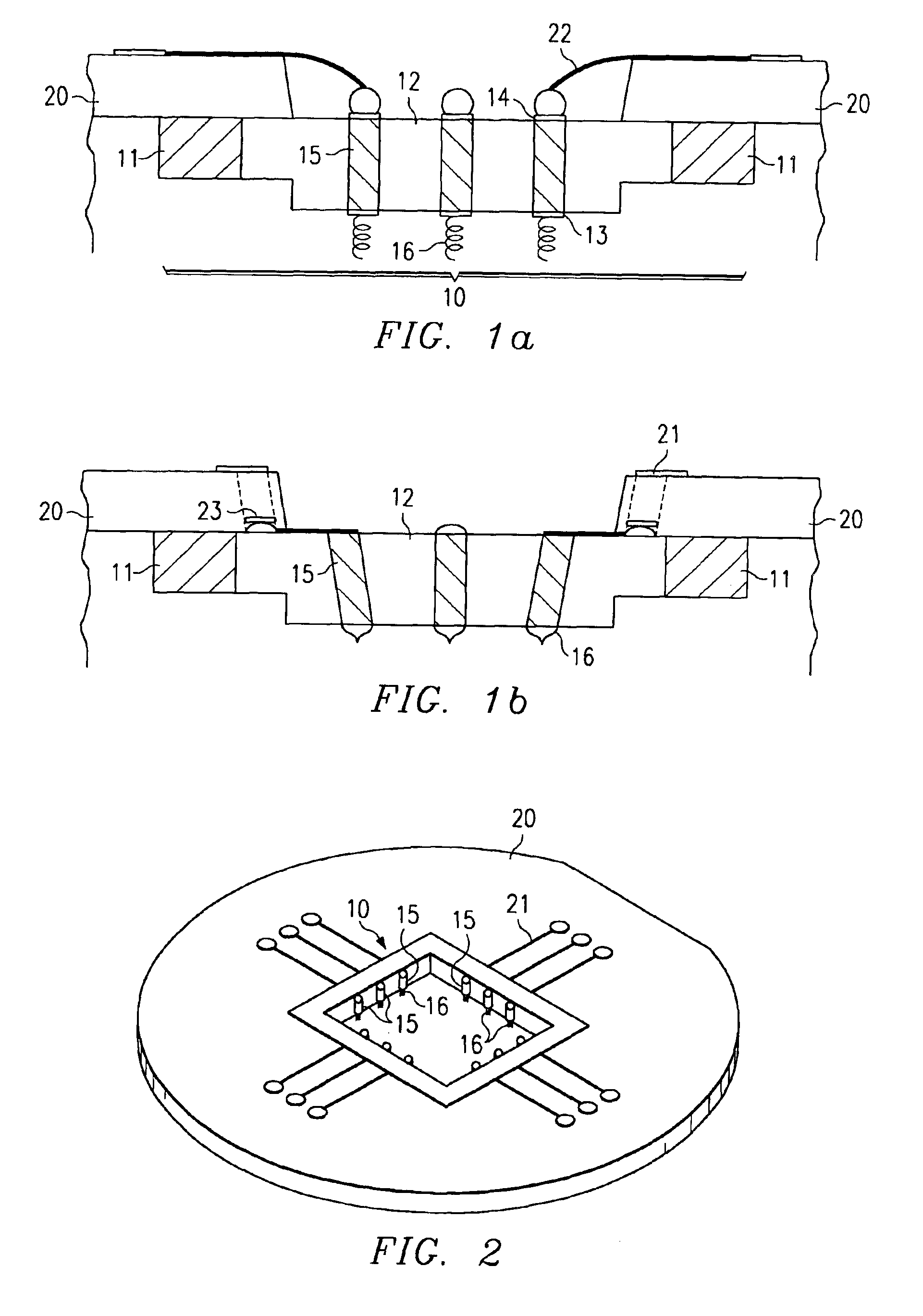

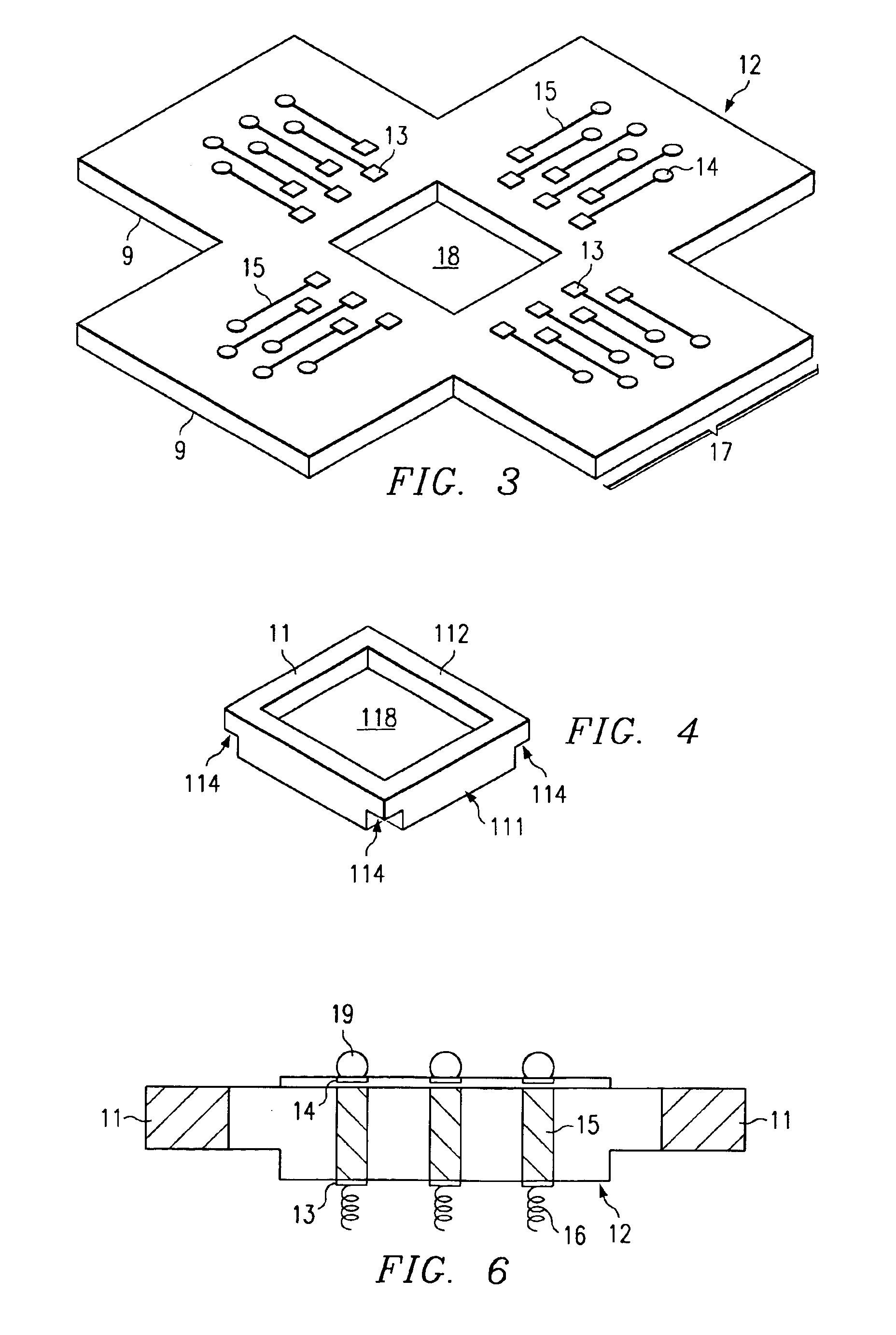

High density, area array probe card apparatus

InactiveUS6906539B2Change positionRapid response cycle timeSemiconductor/solid-state device testing/measurementElectrical measurement instrument detailsProbe cardHigh density

A probe card apparatus comprising a rigid substrate having thermal expansion characteristics near that of silicon, laminated with a flex film having laser patterned leads and contact pads, and contact elements comprising noble metals protruding from two major surfaces, the first mirroring the closely spaced chip pads, and the second aligned to the more generously spaced probe card pads, providing an accurate and reproducible, low cost, rapidly fabricated probe contact device, capable of contacting very high density bond pads in either area array or perimeter locations, of being electrically optimized, and readily maintained.

Owner:TEXAS INSTR INC

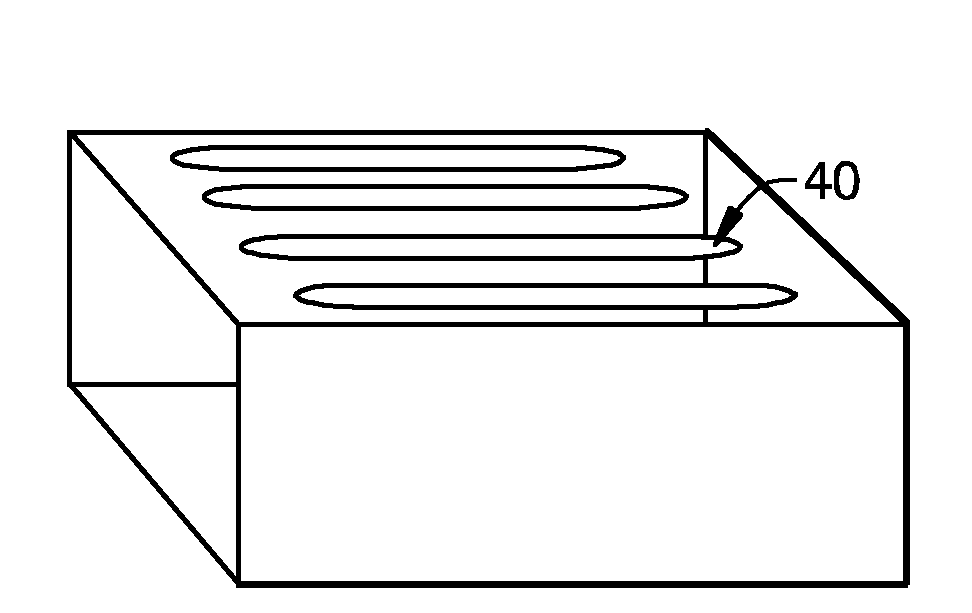

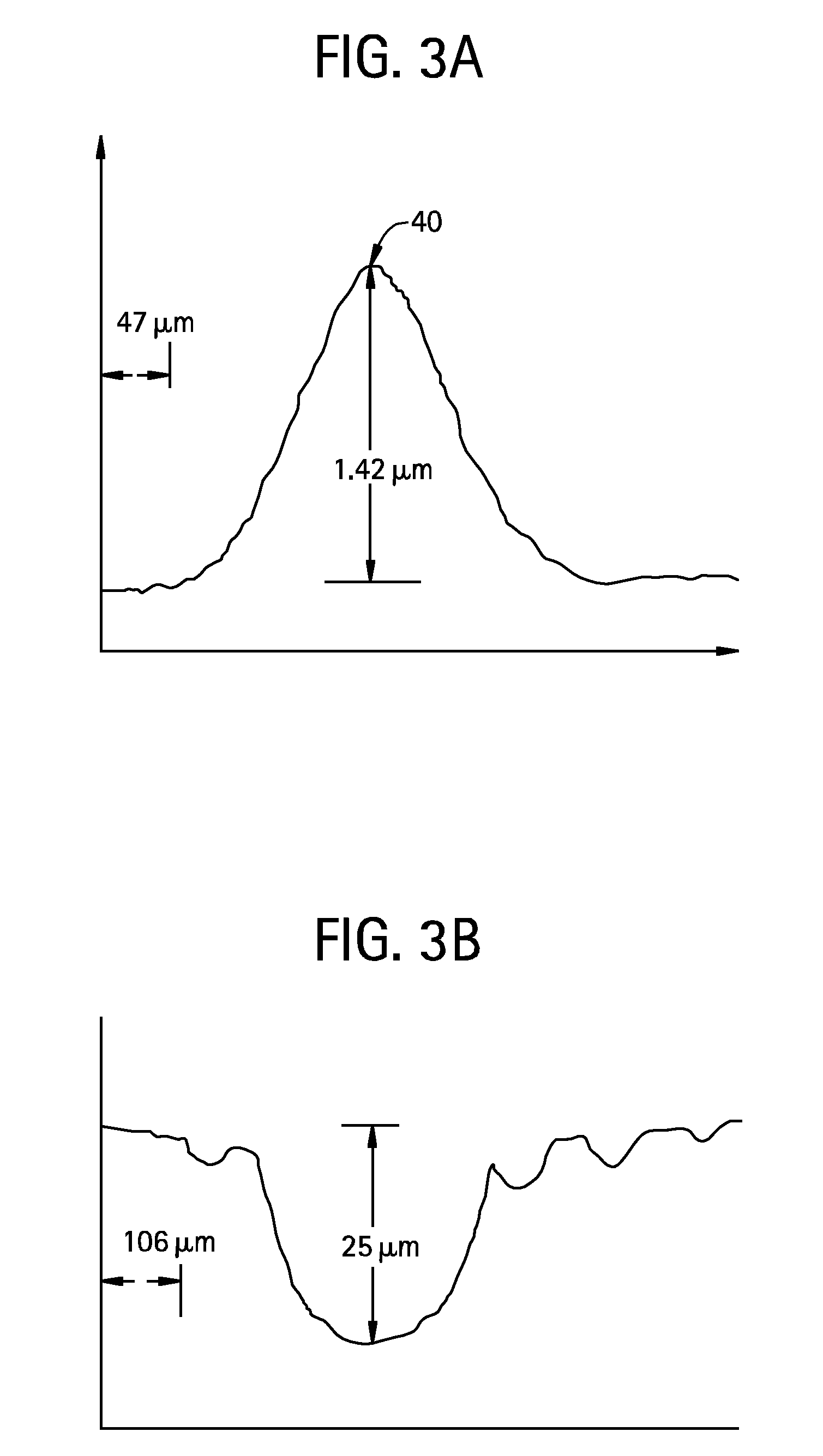

Laser Patterning of Glass Bodies

ActiveUS20100050692A1Decorative surface effectsLaser beam welding apparatusLaser patterningVitreous Bodies

A method for laser patterning of a glass body, the method comprising the steps of:(i) providing a laser, said laser having an output beam at a laser wavelength λ;(ii) providing a glass body having optical density at of at least 1.5 / cm at said wavelength;(iii) directing said laser output beam to (a) impinge on the glass body without ablating said glass, and (b) heat the glass body at a location proximate to said laser output beam so as to form a swell at this location; and(iv) etching this location.

Owner:CORNING INC

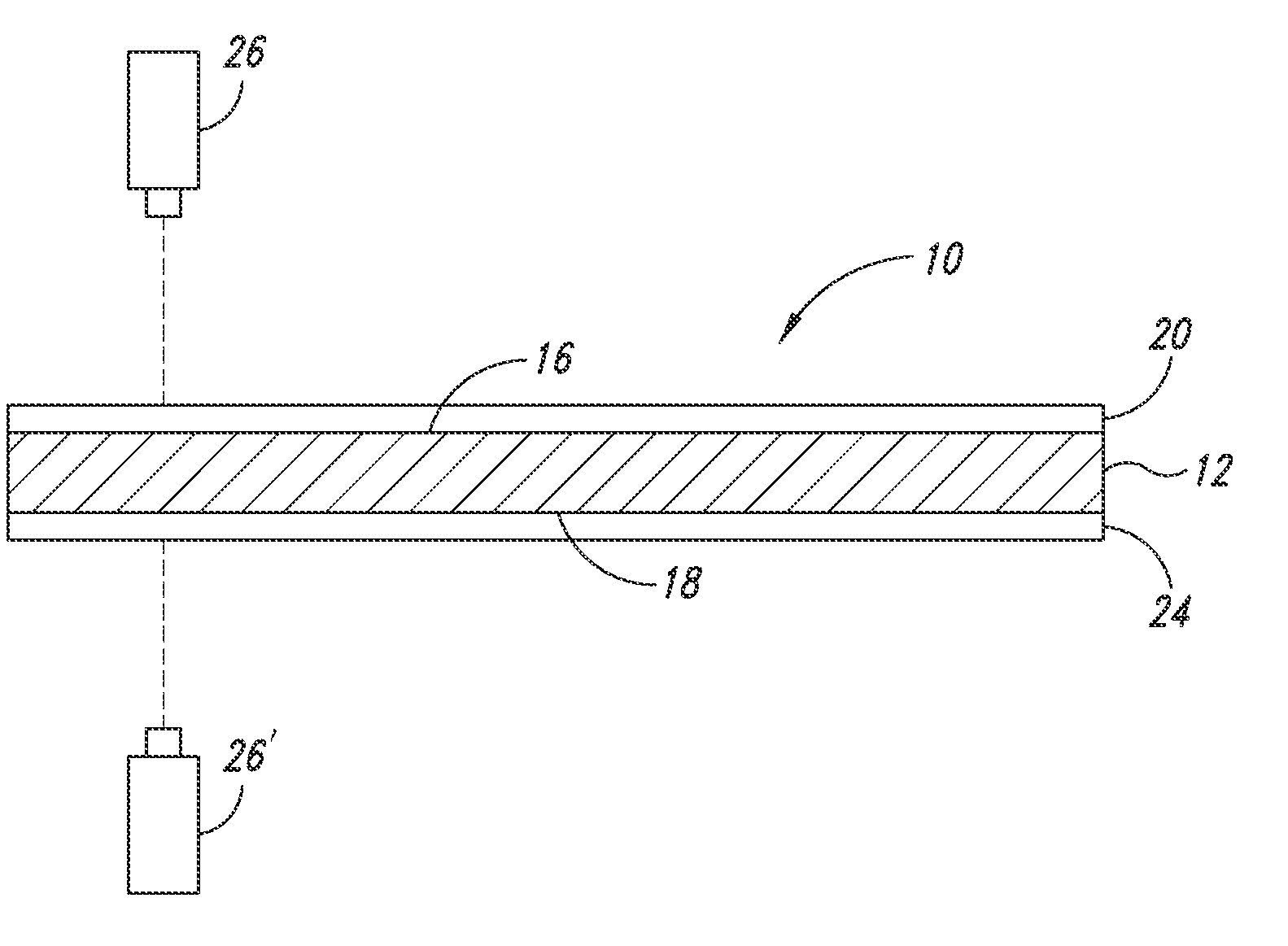

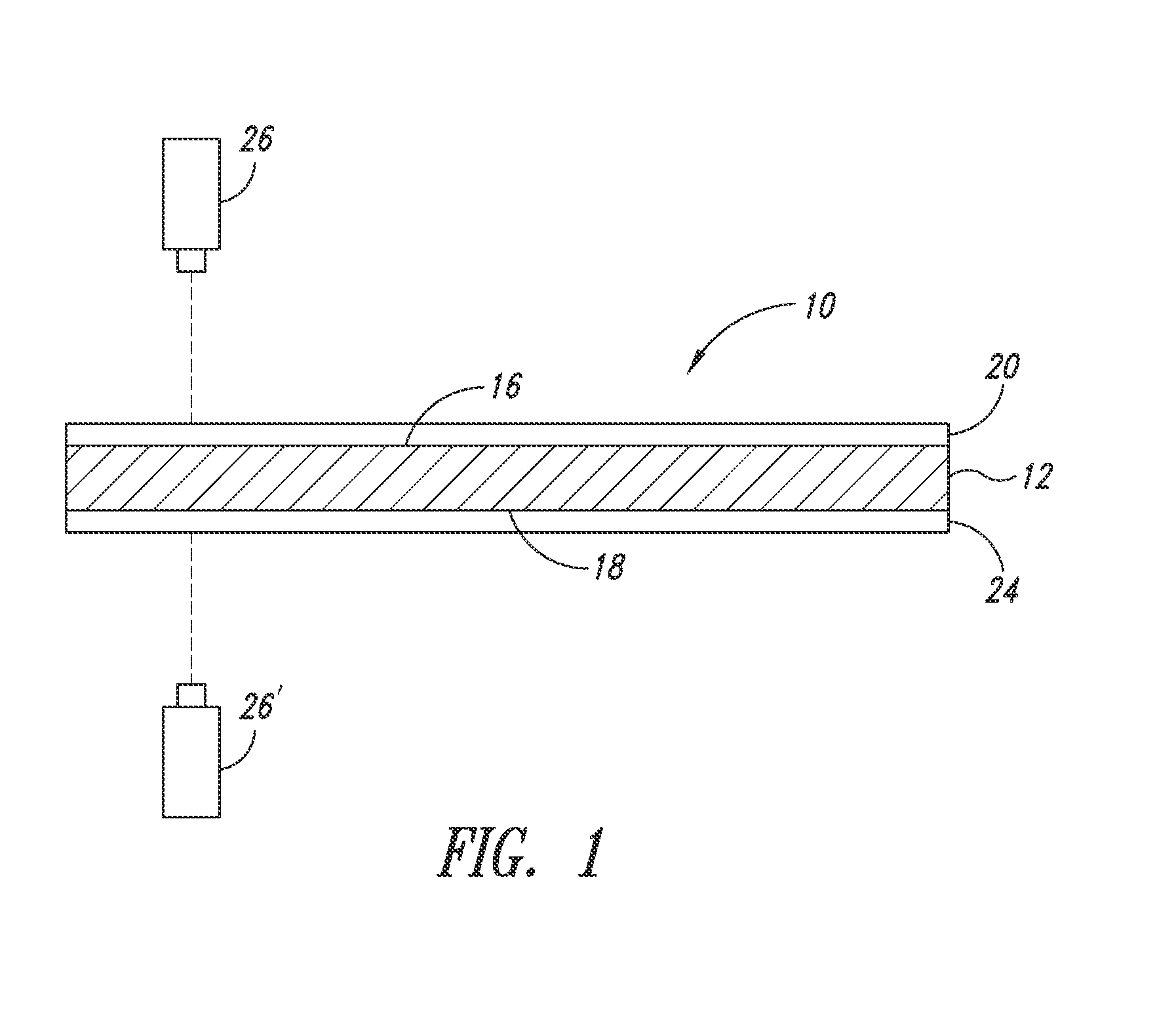

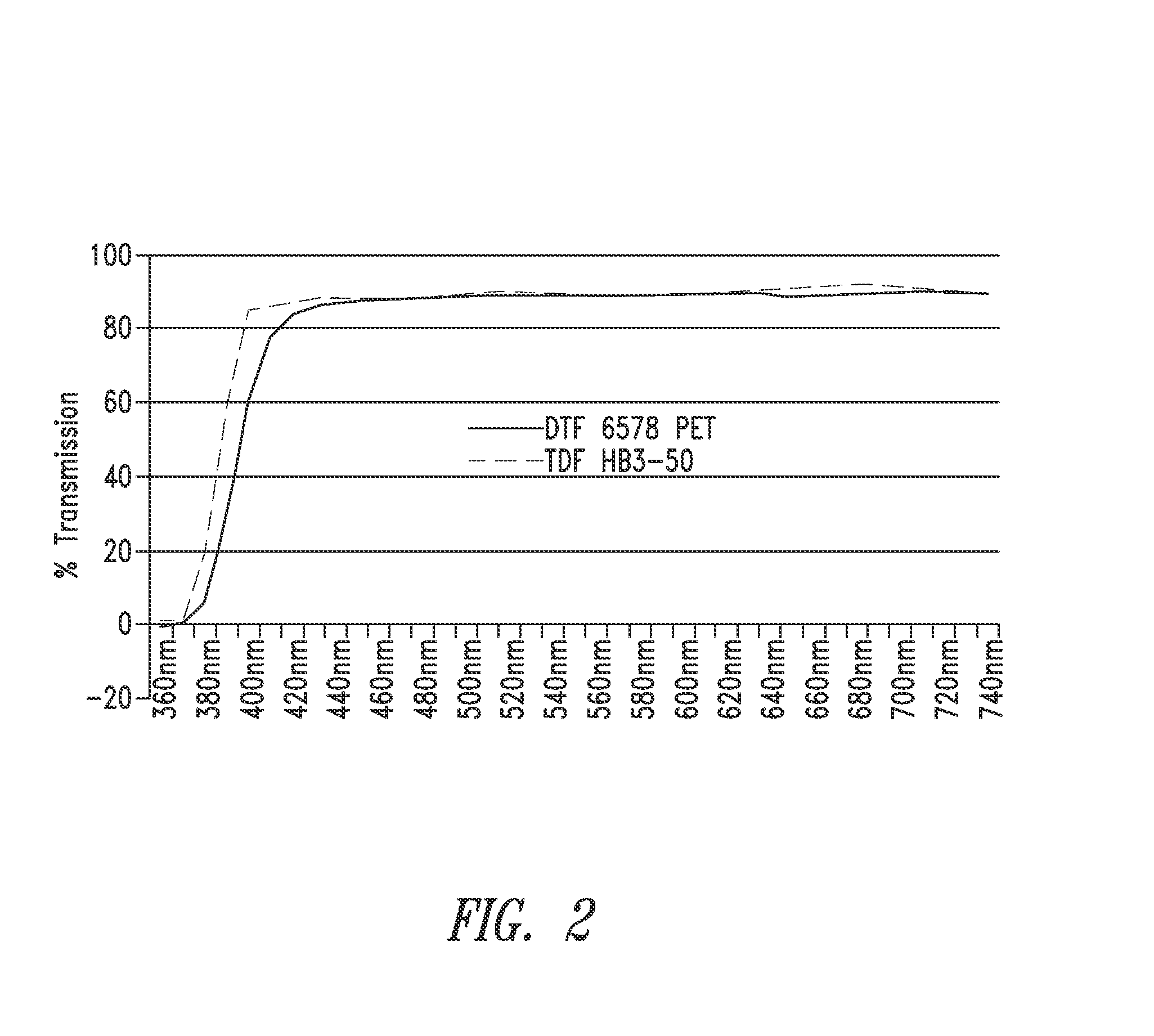

Two-sided laser patterning on thin film substrates

InactiveUS20140202742A1Improve throughputLight absorption dielectricsCircuit optical detailsLaser patterningTransparent conducting film

Owner:CHAMP GREAT INTL

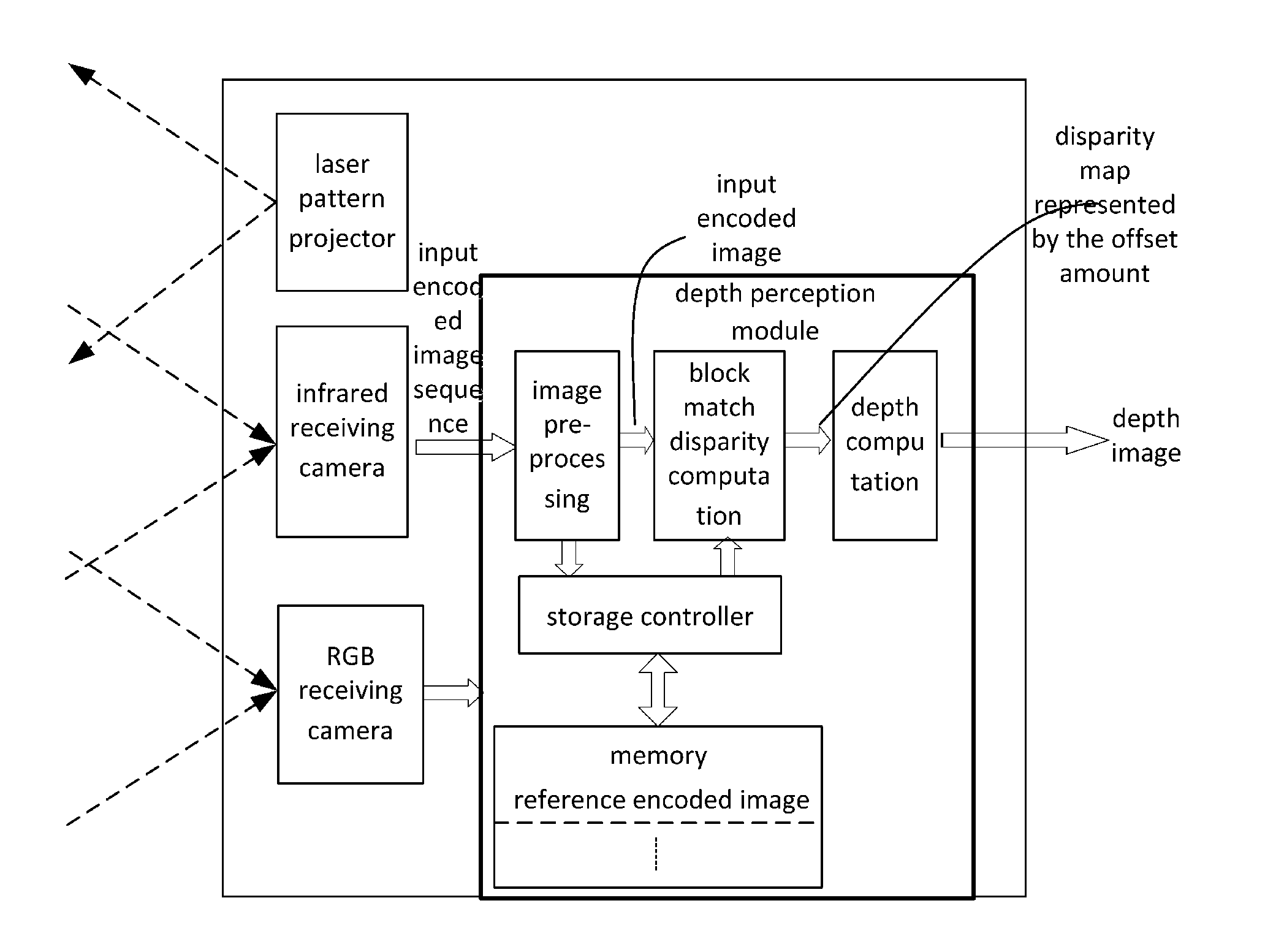

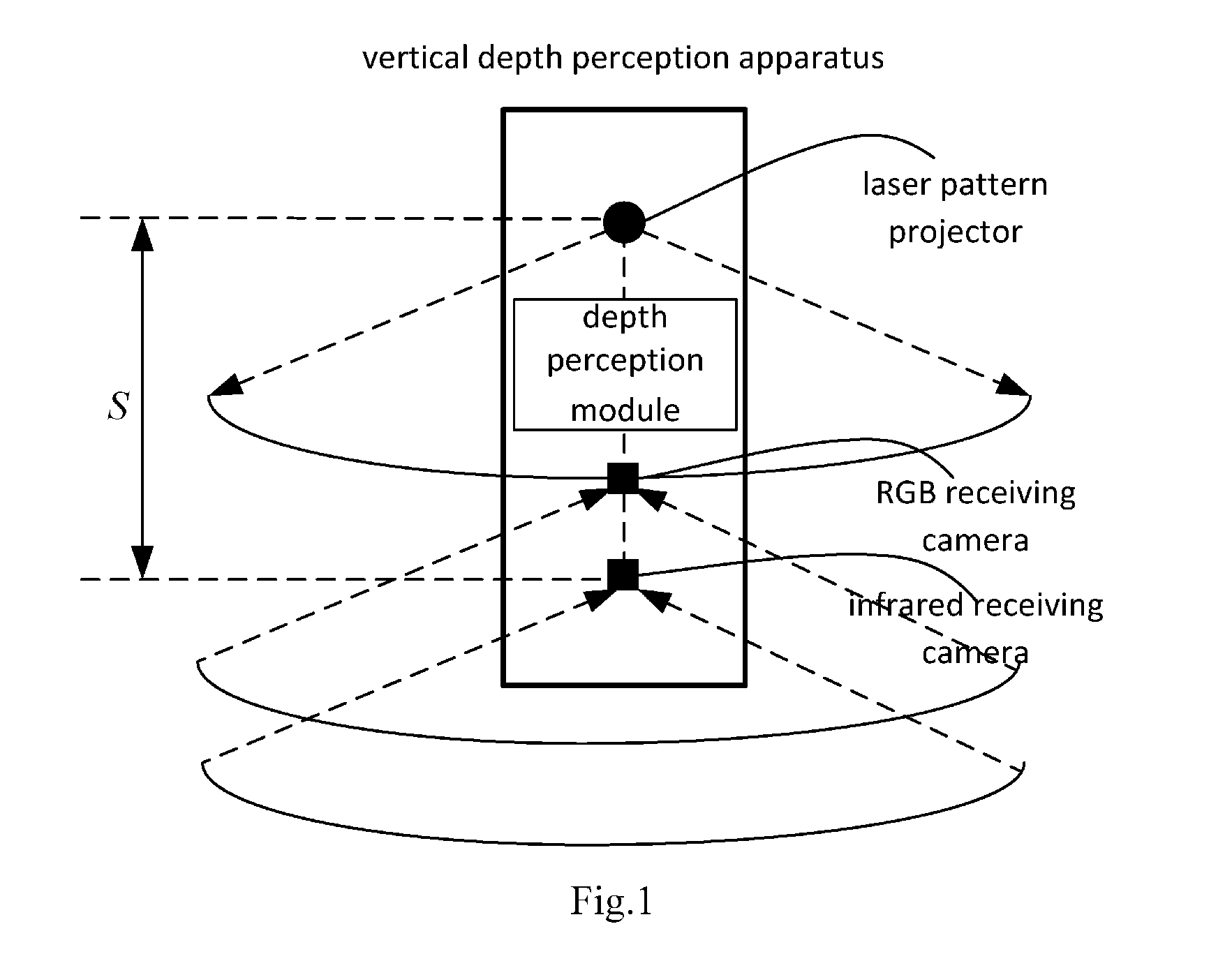

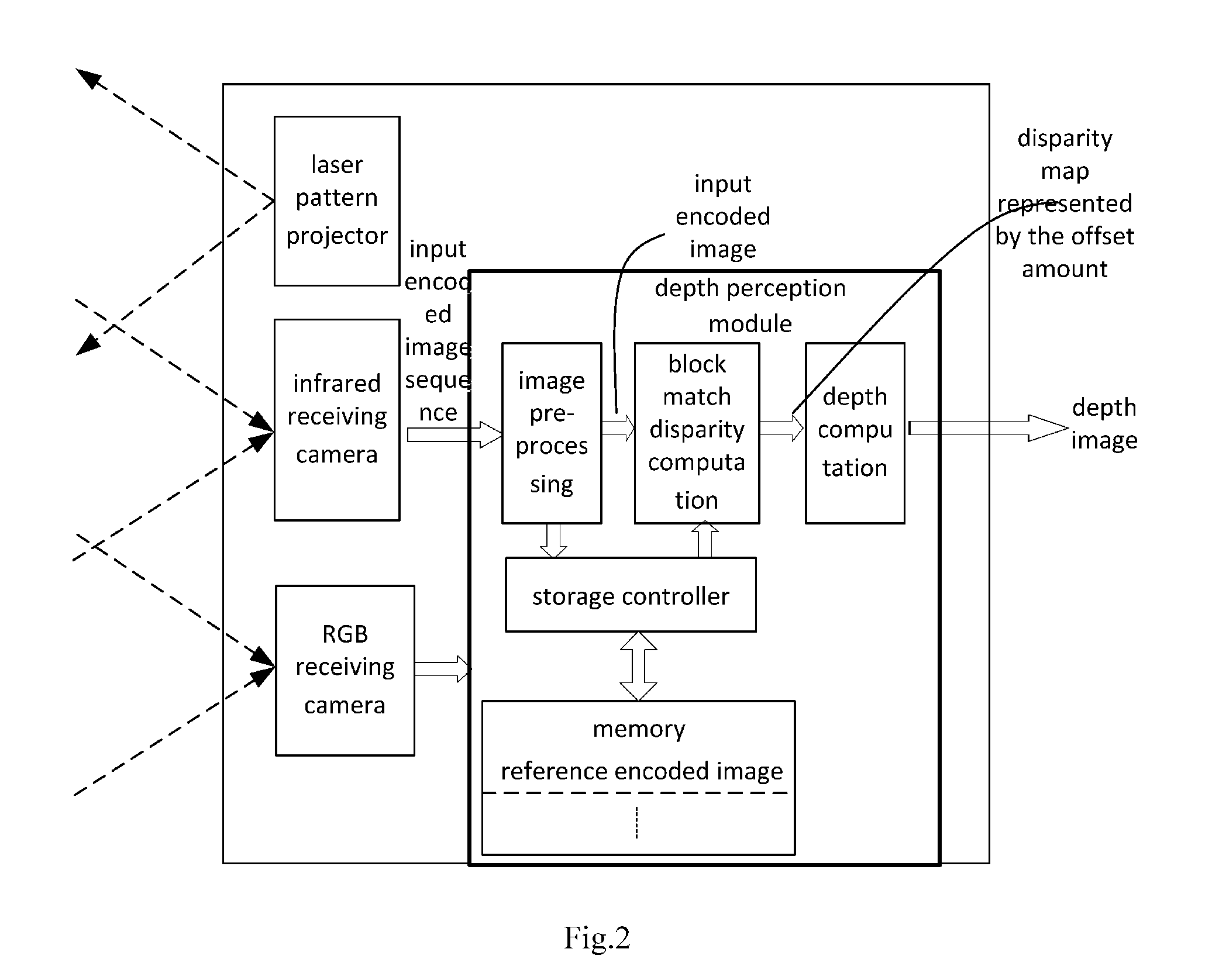

Structured light encoding-based vertical depth perception apparatus

ActiveUS20170054966A1Television system detailsCharacter and pattern recognitionInfraredLaser patterning

The present invention discloses a structured light encoding-based vertical depth perception apparatus, the apparatus comprising: a laser pattern projector, an infrared receiving camera, a RGB receiving camera, and a depth perception module; the laser pattern projector, the RGB receiving camera, and the infrared receiving camera are disposed along a straight line vertical to a horizontal plane; the laser pattern projector is for projecting a laser encoded pattern; the infrared receiving camera is for consecutively acquiring the encoded patterns and generating an input encoded image sequence; the RGB receiving camera is for acquiring RGB video stream; and the depth perception module is for generating a depth map sequence. The apparatus according to the present invention may not only generate high-resolution and high-precision depth information in real-time, and but also solve the cavity issue existing at the horizontal direction edge of the to-be-measured object when a horizontal depth perception device performs a depth measurement; besides, it facilitates uniform extraction of the depth map sequence and the to-be-measured object in the RGB video stream.

Owner:NINGBO YINGXIN INFORMATION TECH

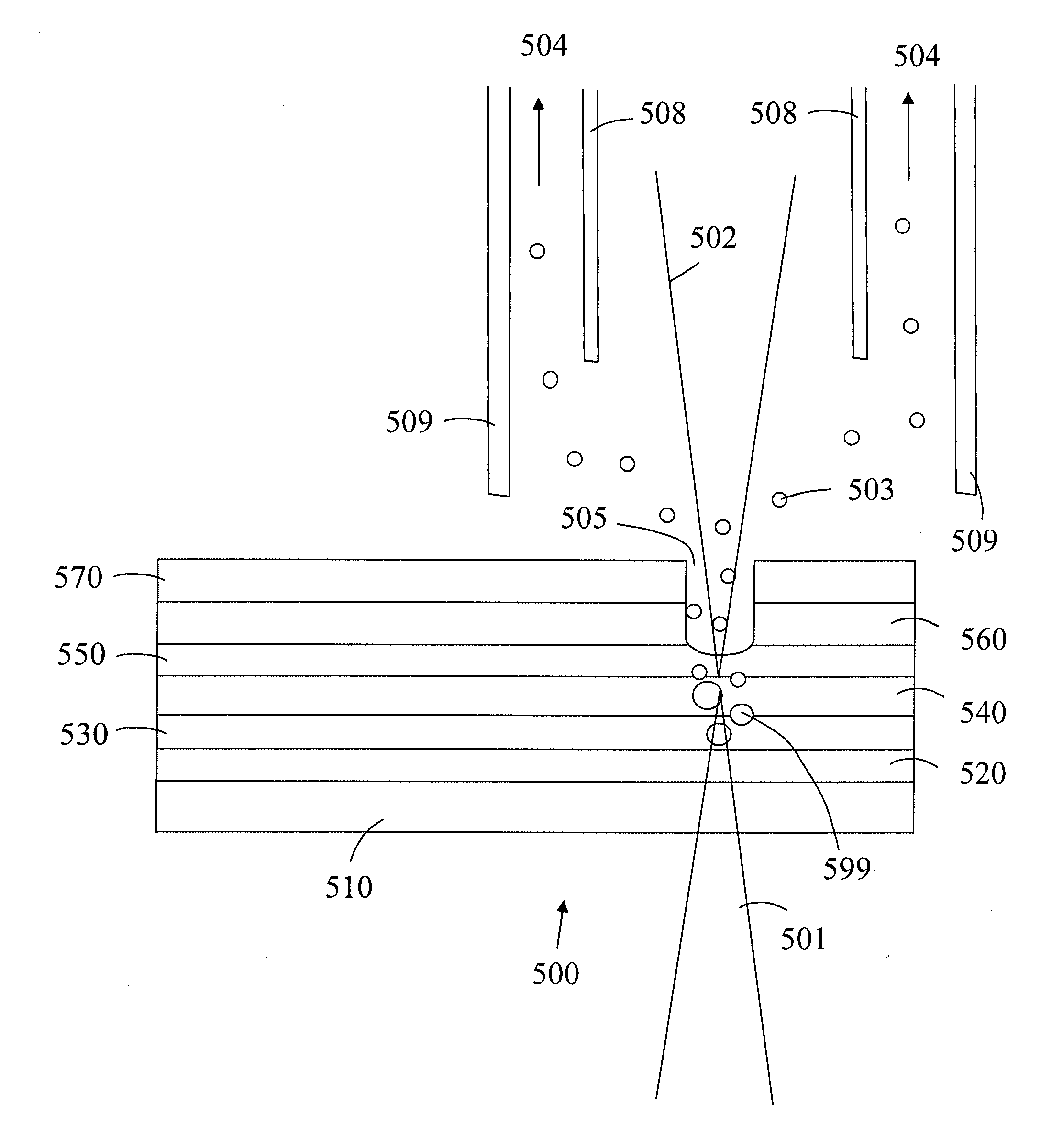

Precision separation of pv thin film stacks

InactiveUS20100233386A1Improve throughputQuality improvementElectric discharge heatingRadiation applicationsLaser arrayLaser patterning

A method for manufacturing thin film panels comprises providing a laser patterning system, depositing a base layer on a glass substrate, separating the base layer by scribing a plurality of separation lines corresponding with a predefined scribe pattern, depositing a functional layer on the base layer, determining a first base layer separation edge, moving the translation stage by a first distance, activating the laser array and moving the translation stage by a second distance, deactivating the laser array, determining subsequent separation edges of the base layer and scribing lines therein, depositing a top layer on the functional layer, determining a first functional layer separation edge, operating the stepper motor to move the translation stage by a third distance, activating the laser array and moving the translation stage by a fourth distance, deactivating the laser array, and determining subsequent separation edges of the functional layer and scribing lines therein.

Owner:IBM CORP

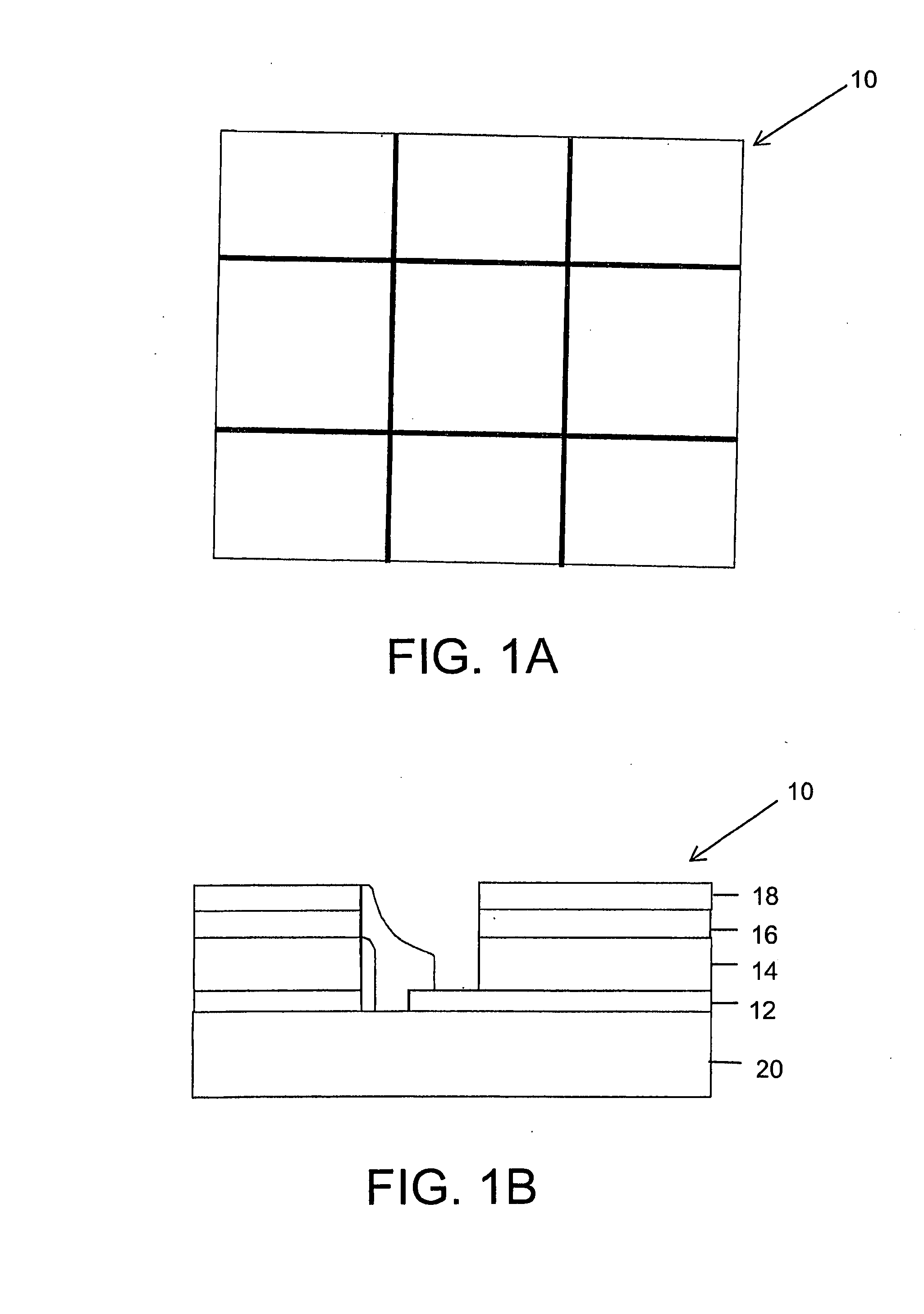

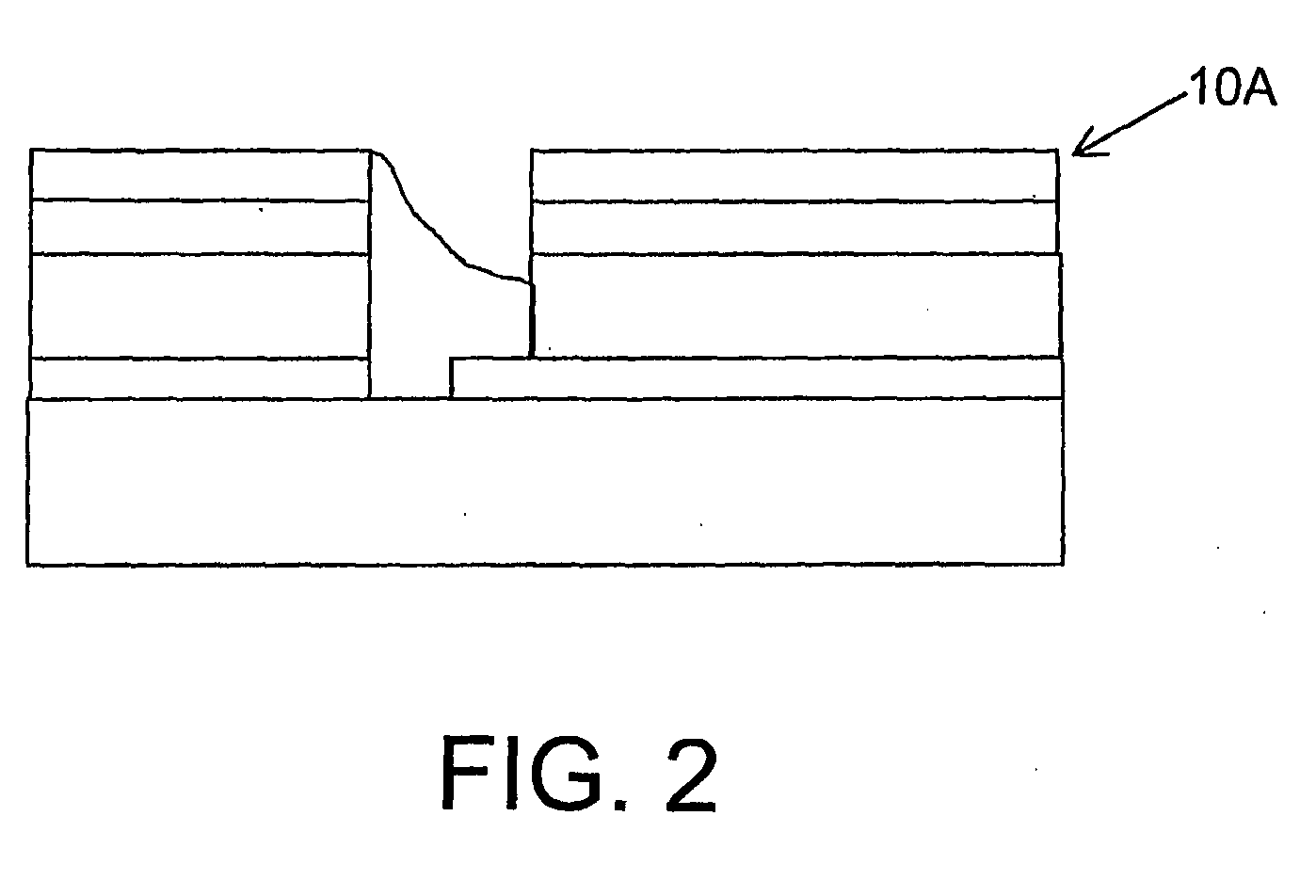

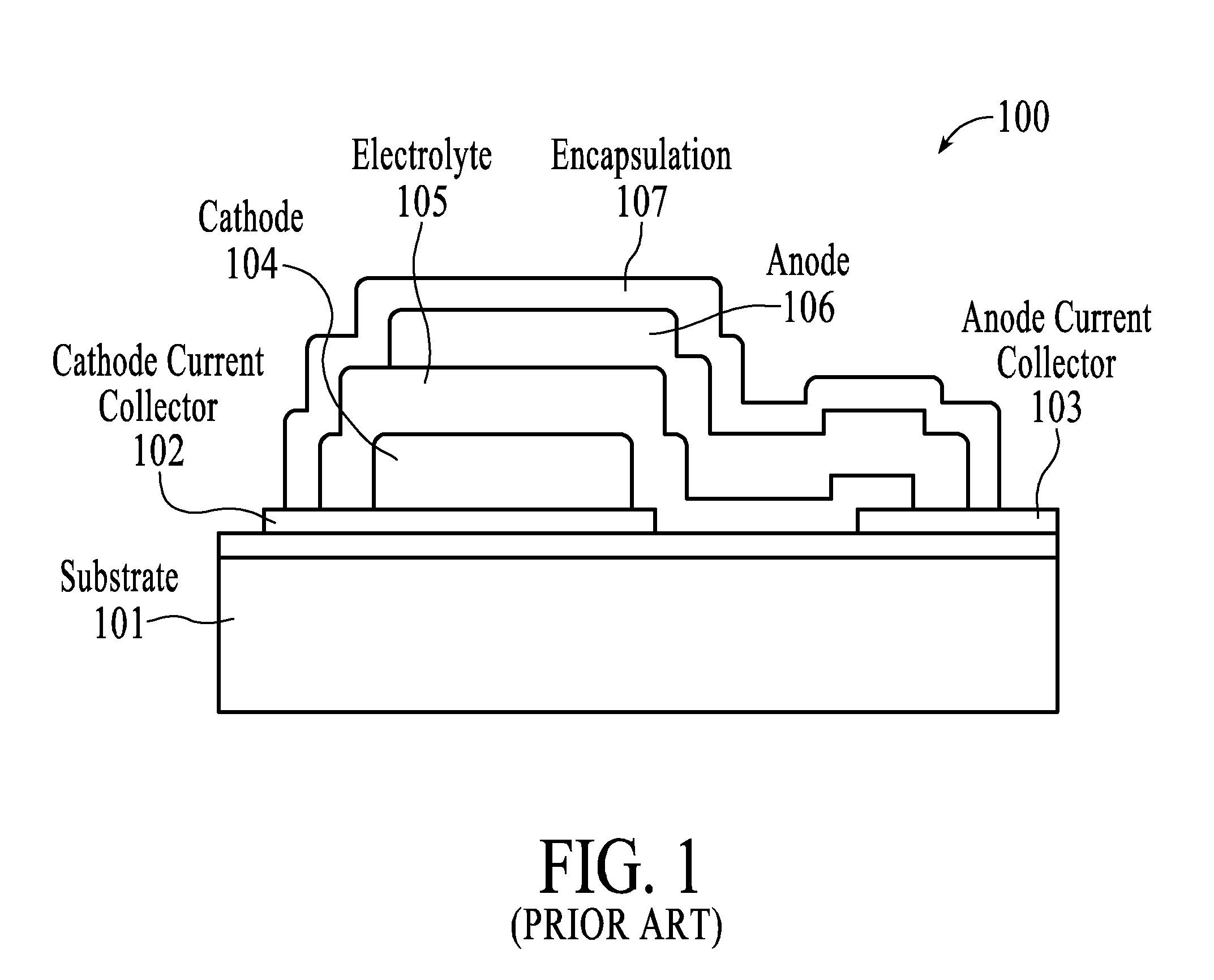

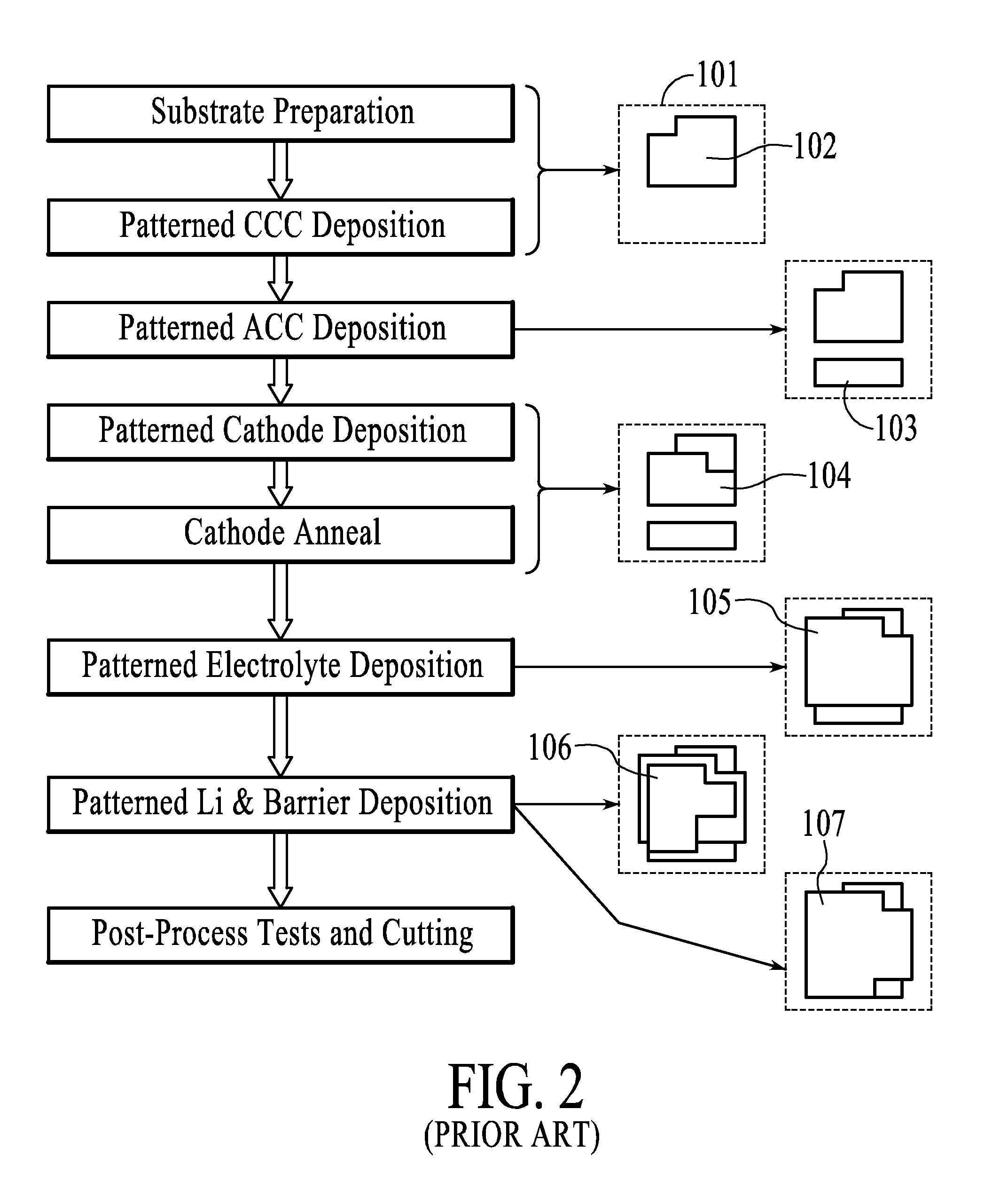

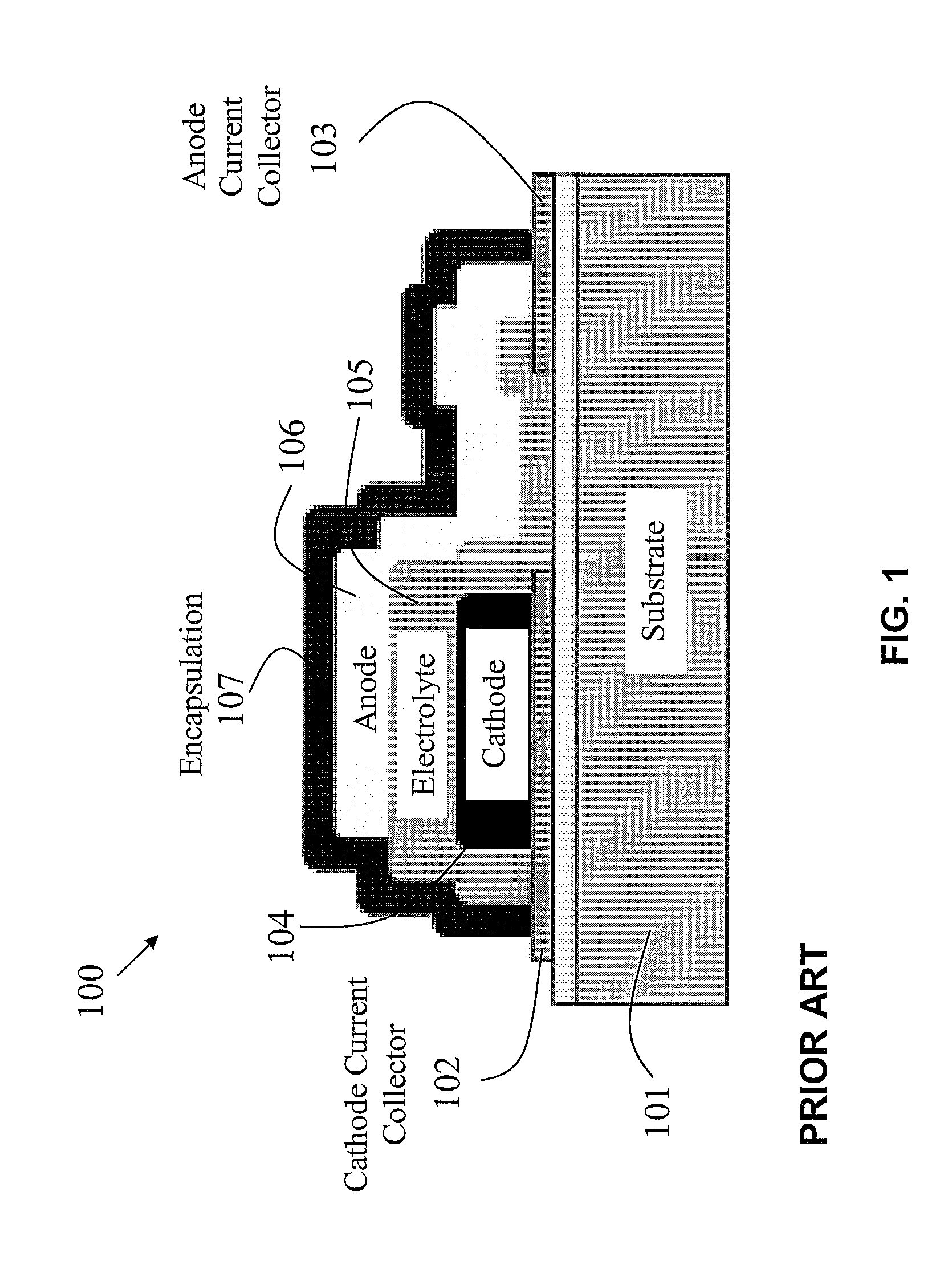

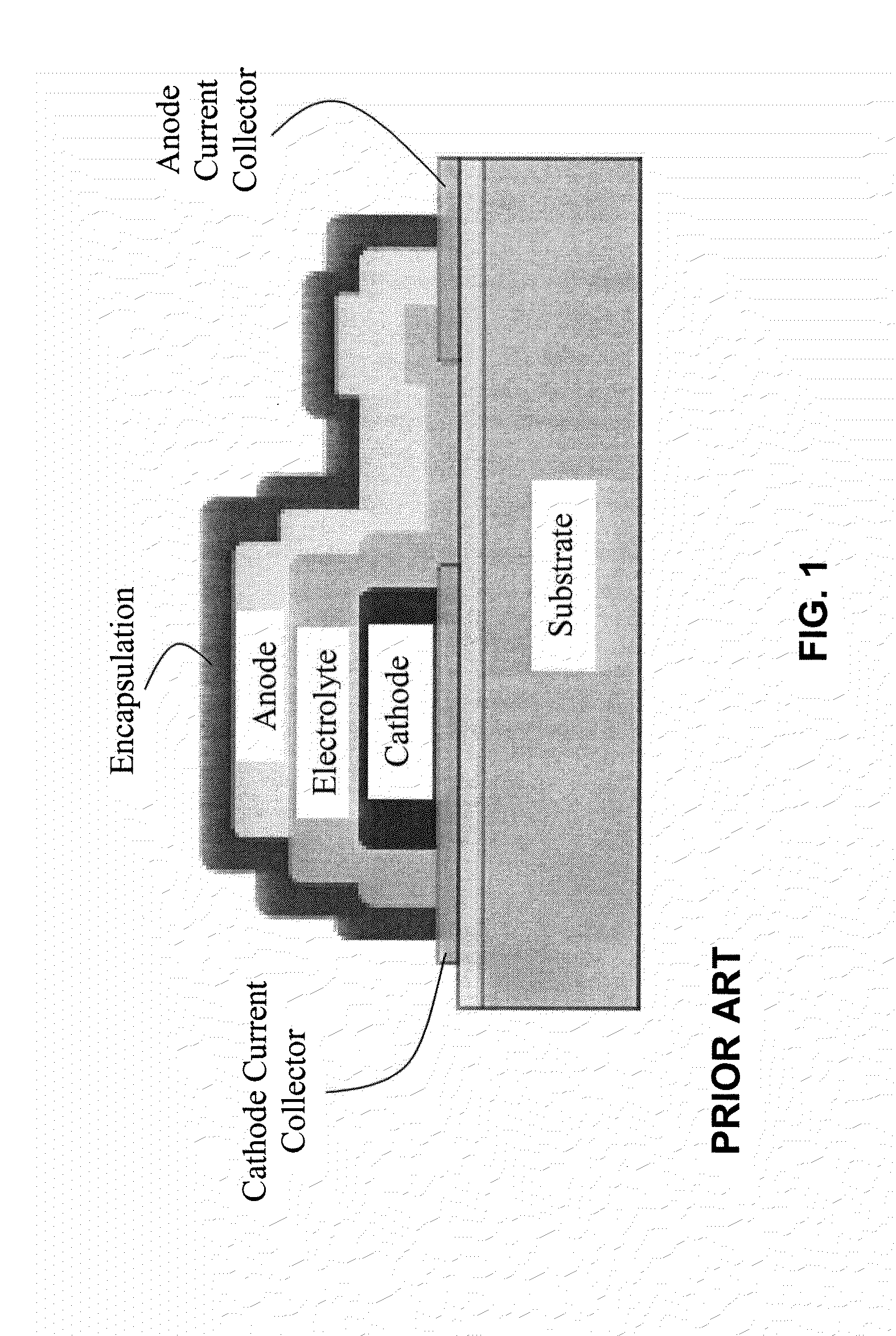

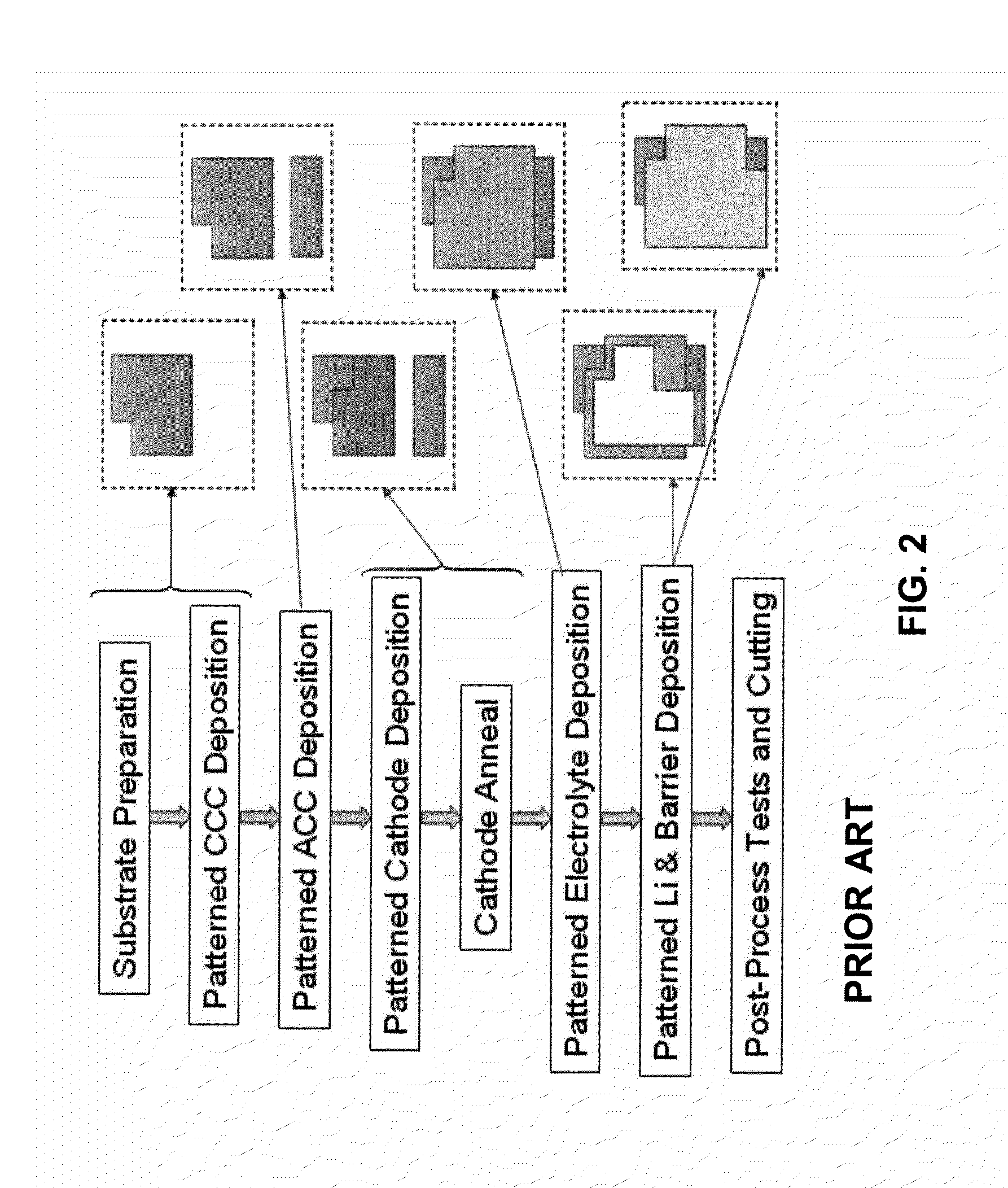

Mask-Less Fabrication of Thin Film Batteries

InactiveUS20140007418A1Reduce complexityLow costNitrogen compoundsFinal product manufactureLaser patterningOptoelectronics

Thin film batteries (TFB) are fabricated by a process which eliminates and / or minimizes the use of shadow masks. A selective laser ablation process, where the laser patterning process removes a layer or stack of layers while leaving layer(s) below intact, is used to meet certain or all of the patterning requirements. For die patterning from the substrate side, where the laser beam passes through the substrate before reaching the deposited layers, a die patterning assistance layer, such as an amorphous silicon layer or a microcrystalline silicon layer, may be used to achieve thermal stress mismatch induced laser ablation, which greatly reduces the laser energy required to remove material.

Owner:APPLIED MATERIALS INC

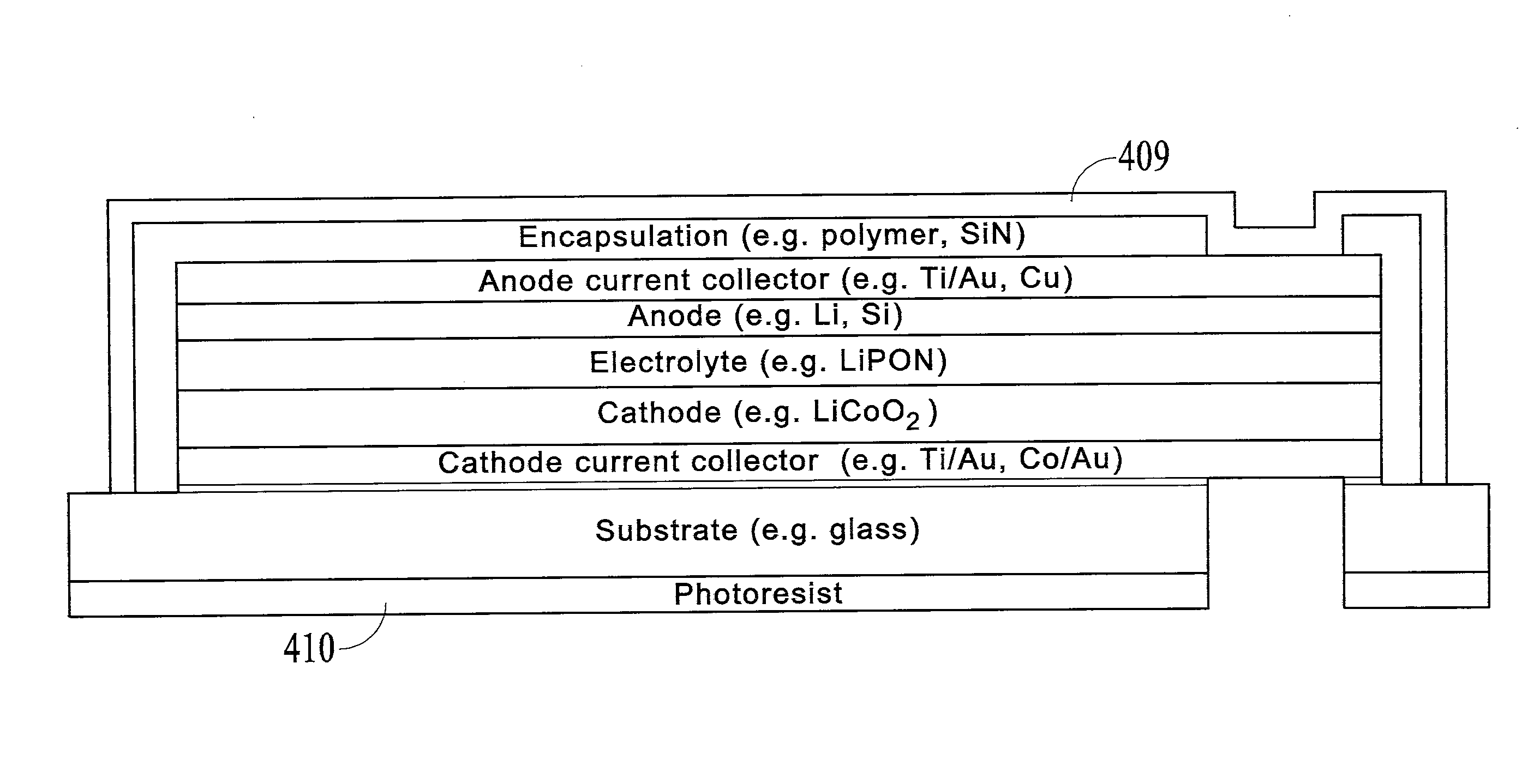

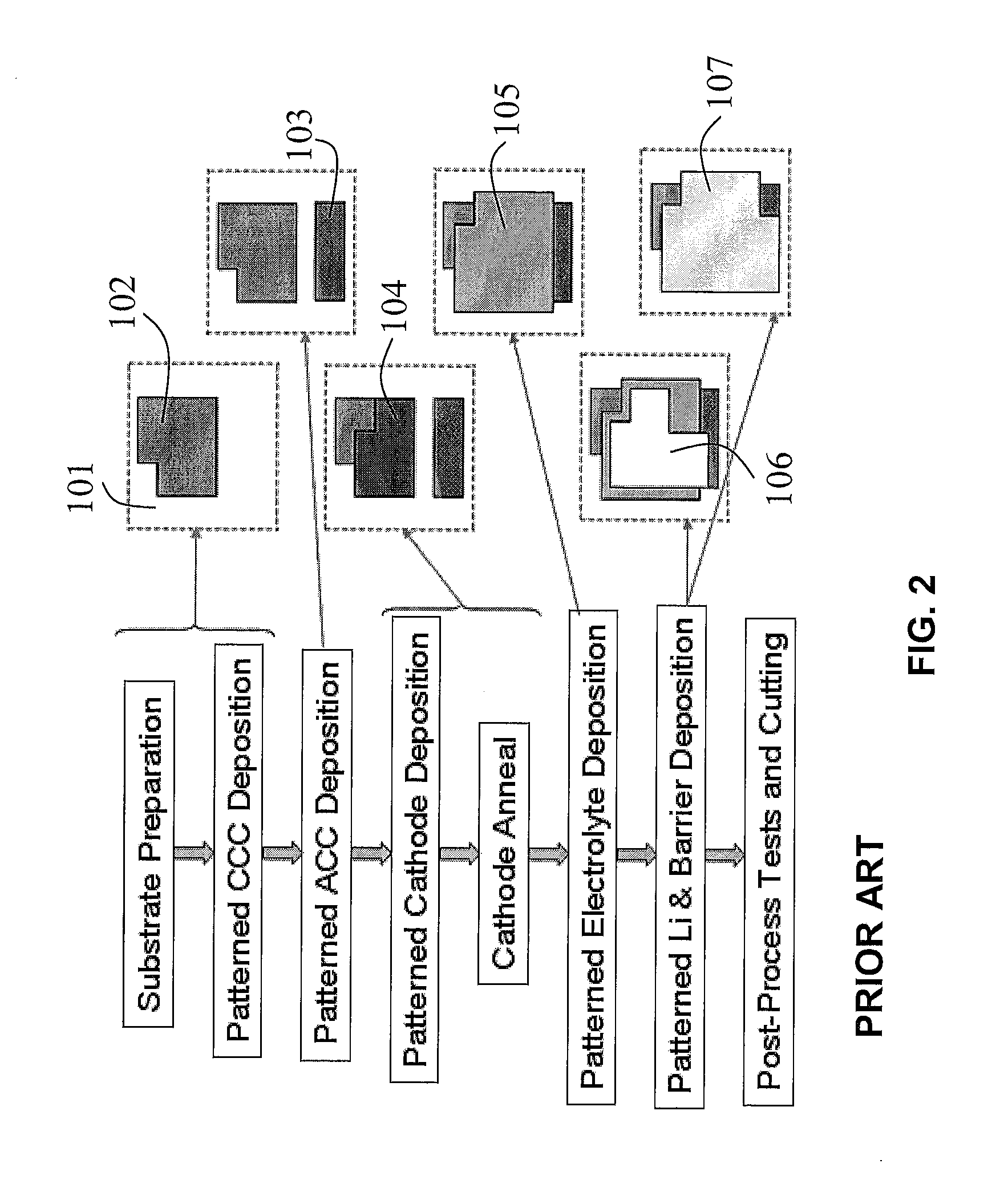

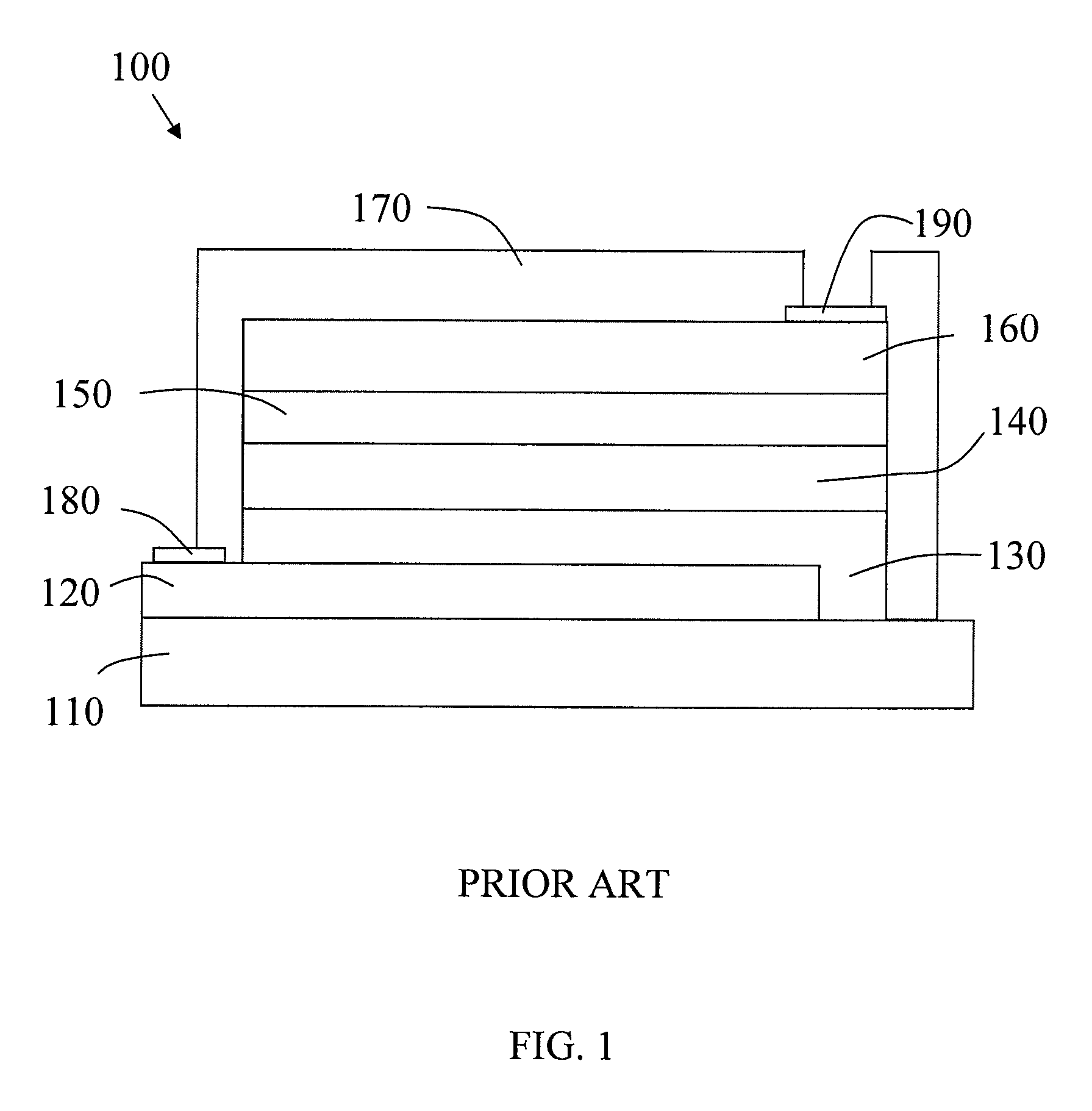

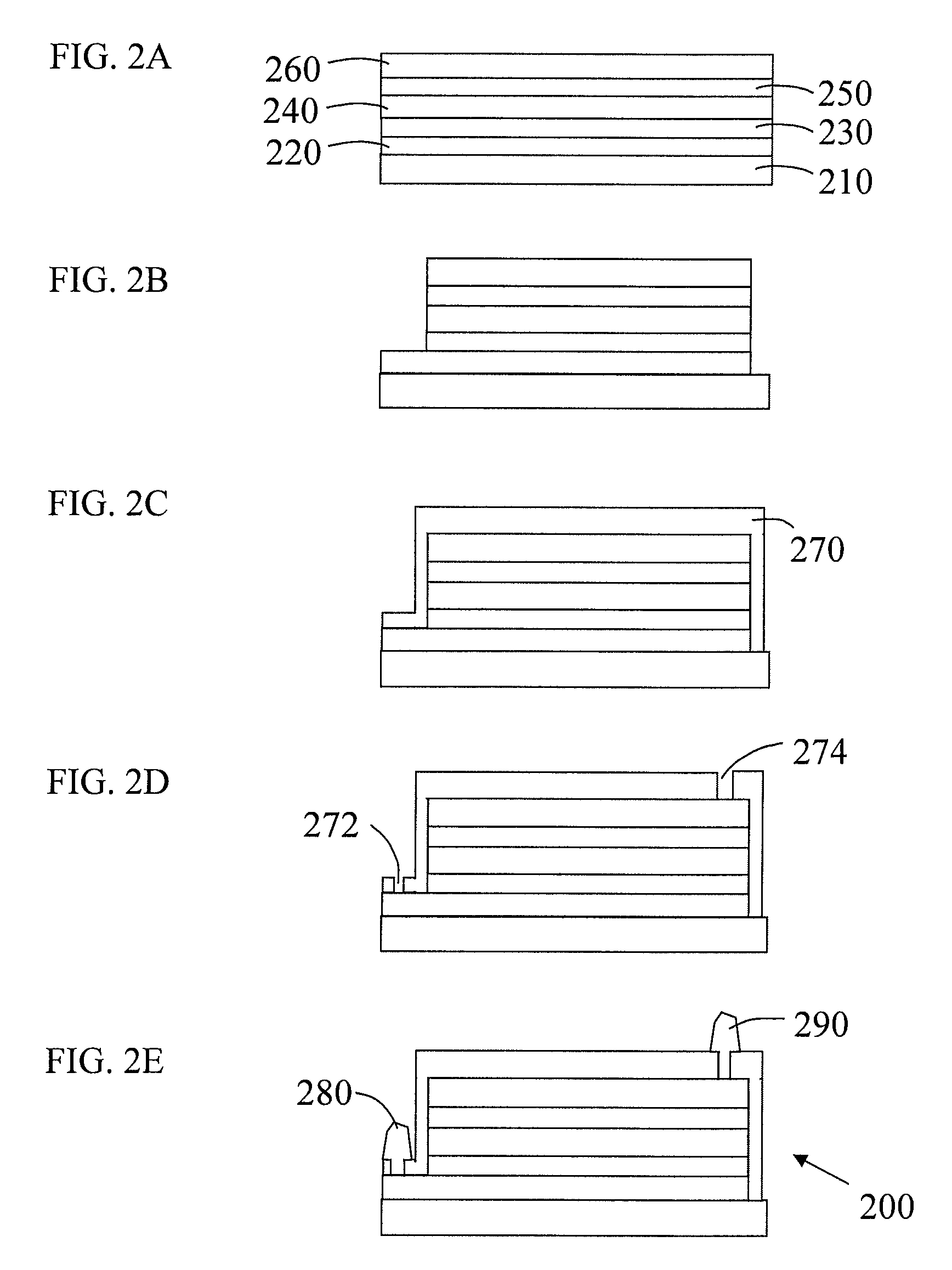

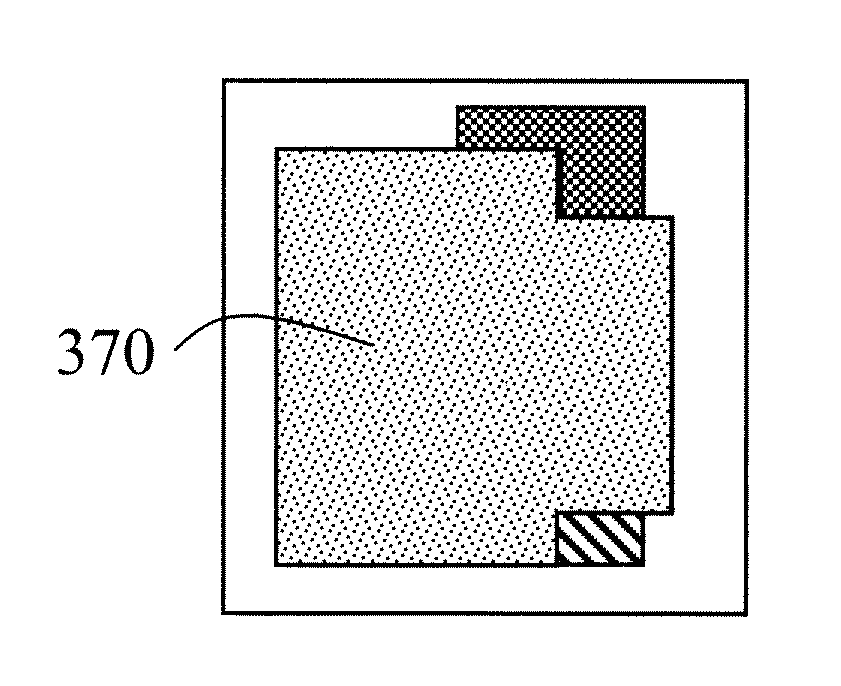

Mask-less fabrication of vertical thin film batteries

InactiveUS20150325862A1Improve substrate utilizationHigh yieldRadiation applicationsFinal product manufactureLaser patterningEngineering

A method of fabricating a thin film battery may comprise: depositing a first stack of blanket layers on a substrate, the first stack comprising a cathode current collector, a cathode, an electrolyte, an anode and an anode current collector; laser die patterning the first stack to form one or more second stacks, each second stack forming the core of a separate thin film battery; blanket depositing an encapsulation layer over the one or more second stacks; laser patterning the encapsulation layer to open up contact areas to the anode current collectors on each of the one or more second stacks; blanket depositing a metal pad layer over the encapsulation layer and the contact areas; and laser patterning the metal pad layer to electrically isolate the anode current collectors of each of the one or more thin film batteries. For electrically non-conductive substrates, cathode contact areas are opened-up through the substrate.

Owner:APPLIED MATERIALS INC

Method for manufacturing electrochromic devices

ActiveUS8168265B2Improve manufacturabilityLow costRadiation applicationsPretreated surfacesDevice materialPhysical chemistry

Owner:APPLIED MATERIALS INC

Thin Film Battery Fabrication With Mask-Less Electrolyte Deposition

InactiveUS20120321815A1Improve manufacturabilityLow costElectrode thermal treatmentRadiation applicationsLaser patterningOptoelectronics

A method of fabricating a thin film battery may include a blanket deposition of an electrolyte layer followed by selective laser patterning of the electrolyte layer. Some or all of the other device layers may be in situ patterned layers—formed using shadow masks.

Owner:APPLIED MATERIALS INC

Laser patterning of light emitting devices

Owner:CREE INC

Laser projector and depth camera thereof

ActiveCN106569382AHigh speedHigh precisionProjectorsUsing optical meansLaser patterningOptoelectronics

The invention discloses a laser projector and a depth camera thereof. The laser projector comprises a foundation, at least two light emitting elements, a controller, at least two lenses and a diffraction optical element, wherein the at least two light emitting elements are fixed at one side of the foundation facing towards the diffraction optical element and emit laser under the control of the controller, the diffraction optical element is arranged at a position spaced from the foundation a first distance and is used for emitting laser patterns after laser beam expansion, and the at least two lenses are arranged between the foundation and the diffraction optical element and / or at one side of the diffraction optical element opposite to the foundation, are used for carrying out focusing and / or collimation of the laser and are set to have at least two types of different focal lengths and / or at least two different second distances spaced from the at least two light emitting elements. The laser projector is advantaged in that laser pattern irrelevance is improved on the condition that output power and volume requirements can be satisfied, and thereby a depth image acquisition speed and acquisition precision of the depth camera are improved.

Owner:SHENZHEN ORBBEC CO LTD

Laser projector and depth camera thereof

InactiveCN106568396AMeet power requirementsMeet volume requirementsUsing optical meansOptical elementsLaser patterningLaser projector

The invention discloses a laser projector and a depth camera thereof. The laser projector includes a substrate, at least two light emitting elements, a controller and a diffractive optical element. The diffractive optical element is arranged at a position at a first distance from the substrate. The at least two light emitting elements are fixed at one side, facing the diffractive optical element, of the substrate. The at least two light emitting elements emit laser under the control of the controller, and have at least two different light emitting areas. The diffractive optical element is used for expanding laser beams sent by the at least two light emitting elements and then emitting laser patterns to the air. The laser projector meets the output power requirements by arranging the at least two light emitting elements, improves the irrelevance of the laser patterns by arranging at least two light emitting areas, and further improves the speed and the precision of obtaining the depth image of the laser pattern of the depth camera thereof.

Owner:SHENZHEN ORBBEC CO LTD

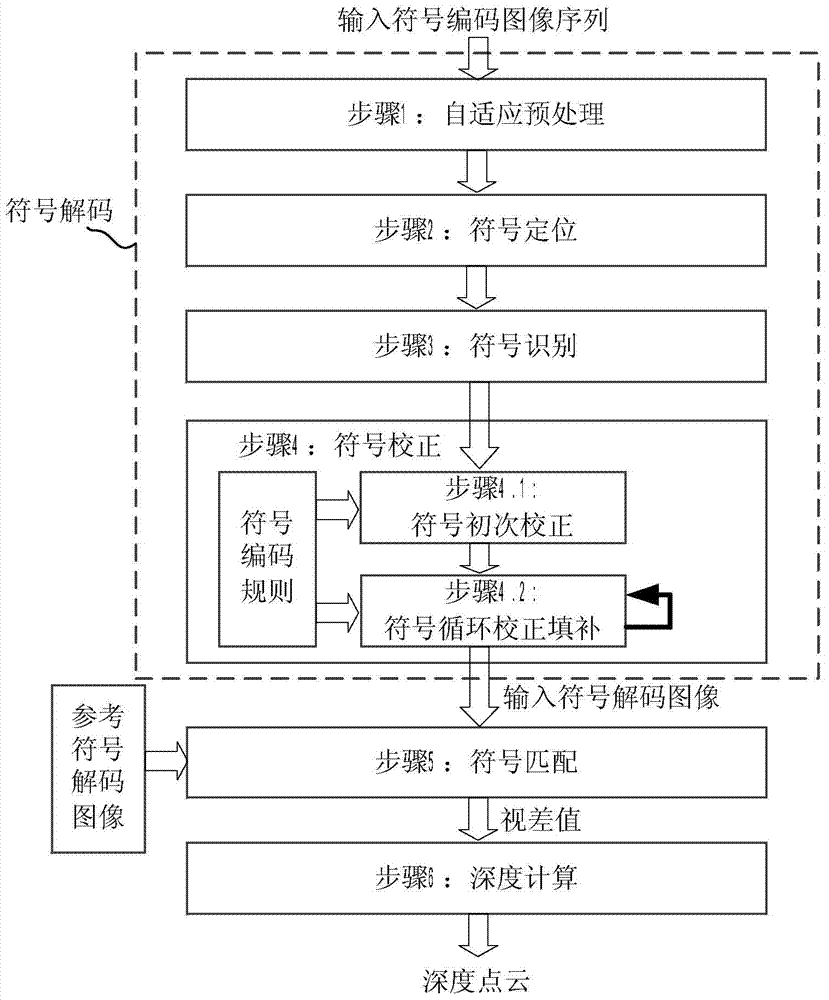

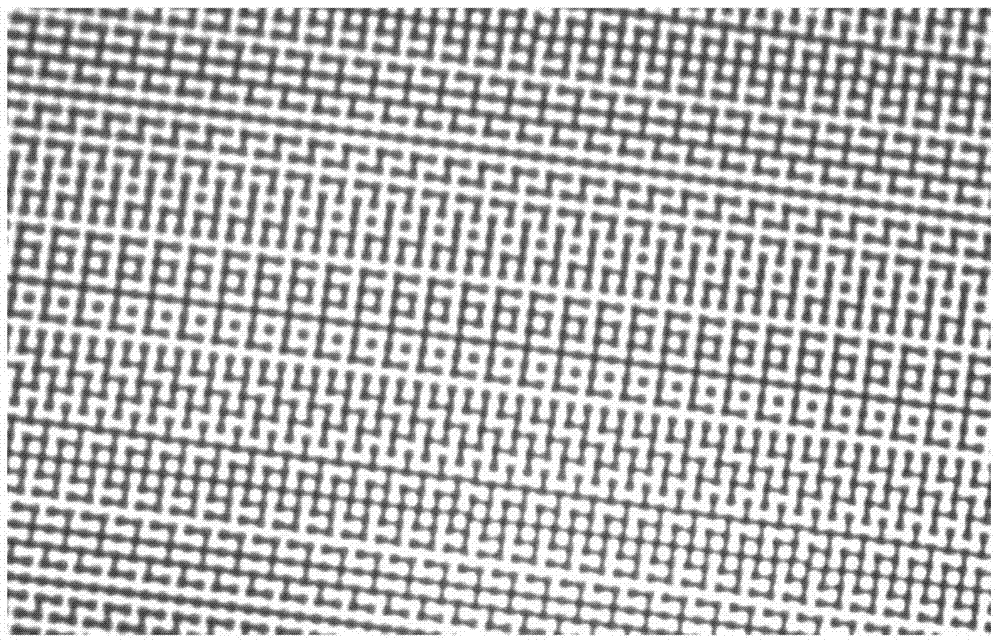

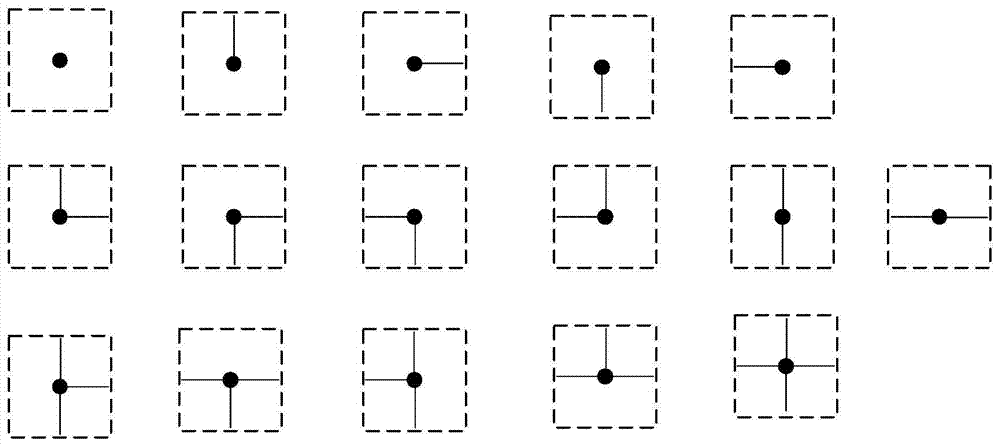

Method, device and system for sensing depth of symbol array surface structured light

ActiveCN104506838AHigh resolutionHigh precisionImage enhancementImage analysisIntelligent equipmentImage sequence

The invention discloses a method, a device and a system for sensing depth of symbol array surface structured light. The method comprises the following steps: using a laser pattern projector for projecting a coding pattern composed of symbol arrays to a target object or a projection space; using an image sensor for acquiring and obtaining a continuous input symbol coding pattern sequence, firstly decoding an input symbol coding pattern and then performing symbol matching calculation on a symbol-identified input symbol decoding pattern and a distance-known reference symbol decoding pattern to obtain an optical parallax value, wherein a decoding process comprises pretreatment, symbol location, symbol identification and symbol correction; generating depth point cloud information of the target object or the projection space presented in grid forms in combination with a depth calculation formula. The method, the device and the system disclosed by the invention can be used for rapidly acquiring high-resolution and high-precision depth information of the target object or the projection space in a dynamic scene and providing convenience for implanting or embedding a module mode into intelligent equipment so as to realize three-dimensional modeling, three-dimensional map generation and the like.

Owner:NINGBO YINGXIN INFORMATION TECH

Vehicle tread measurement method based on stereo vision and laser

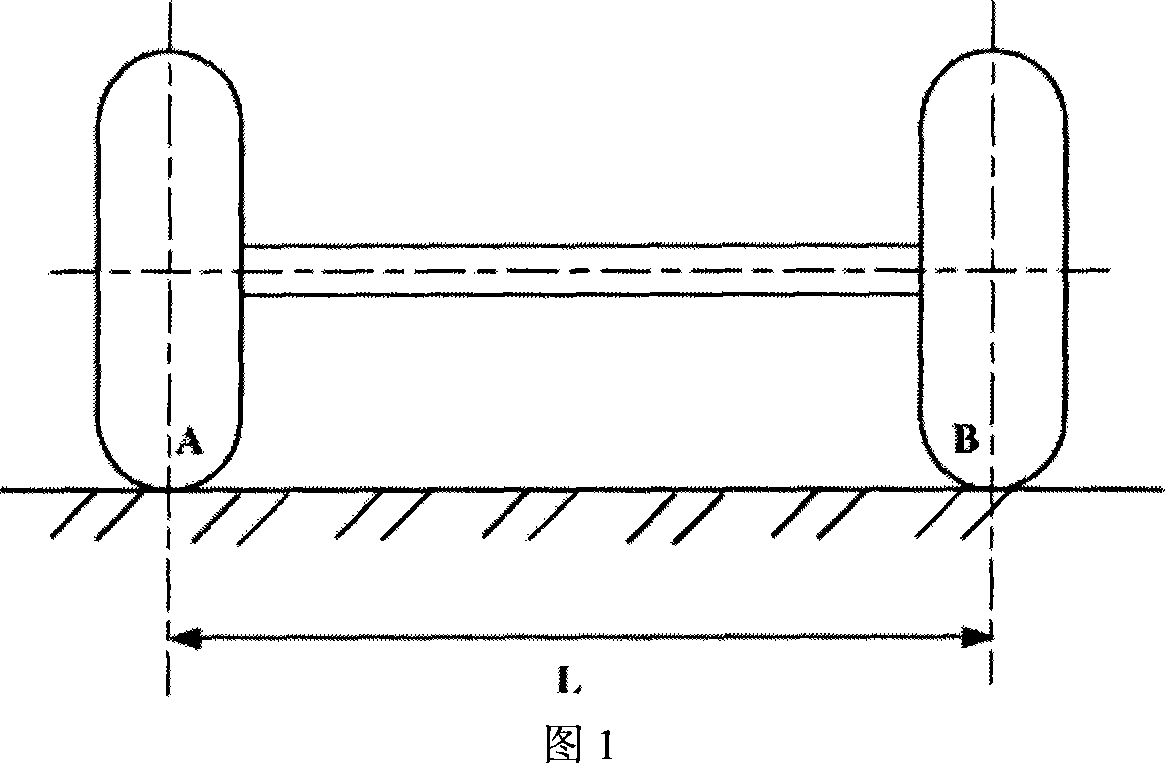

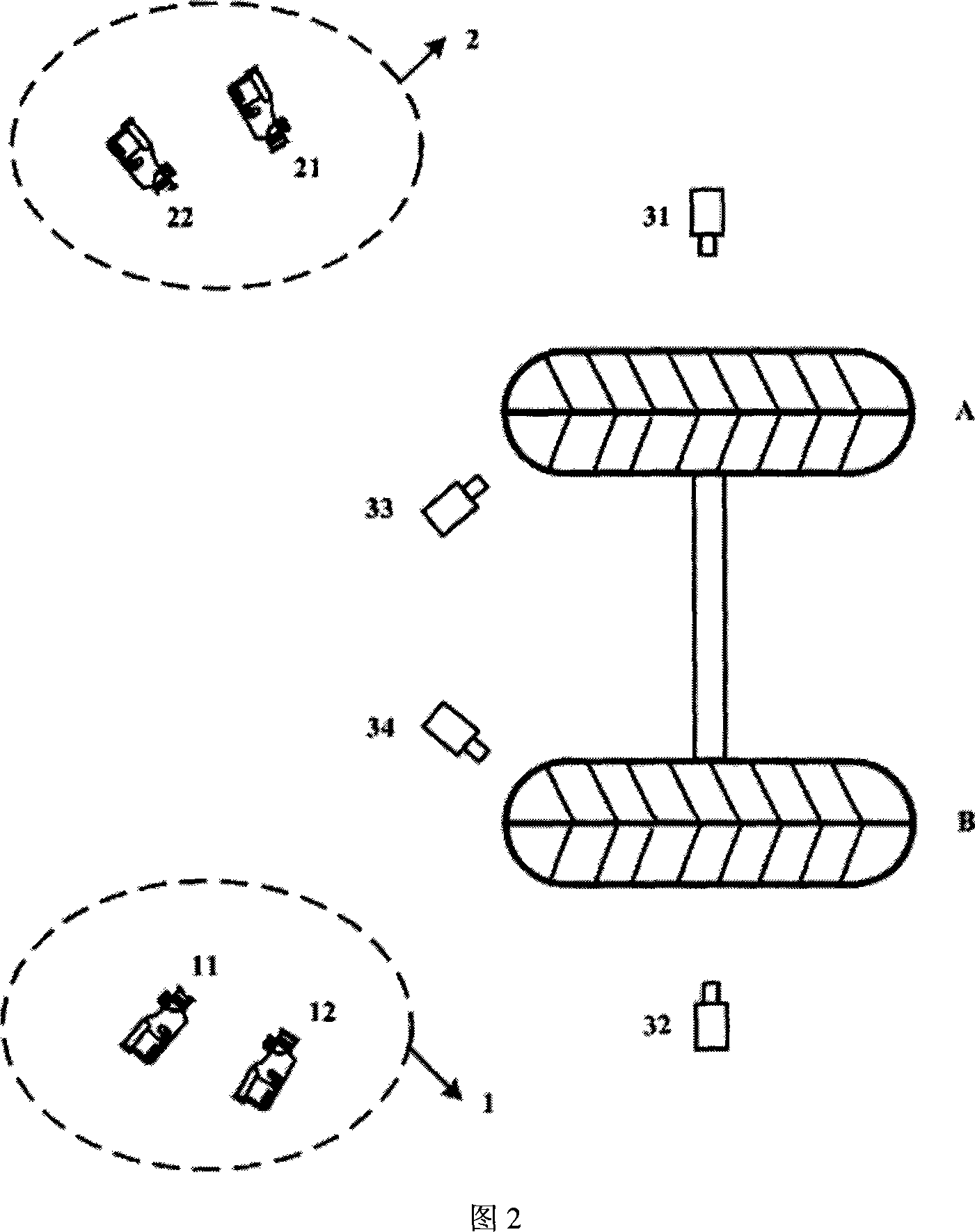

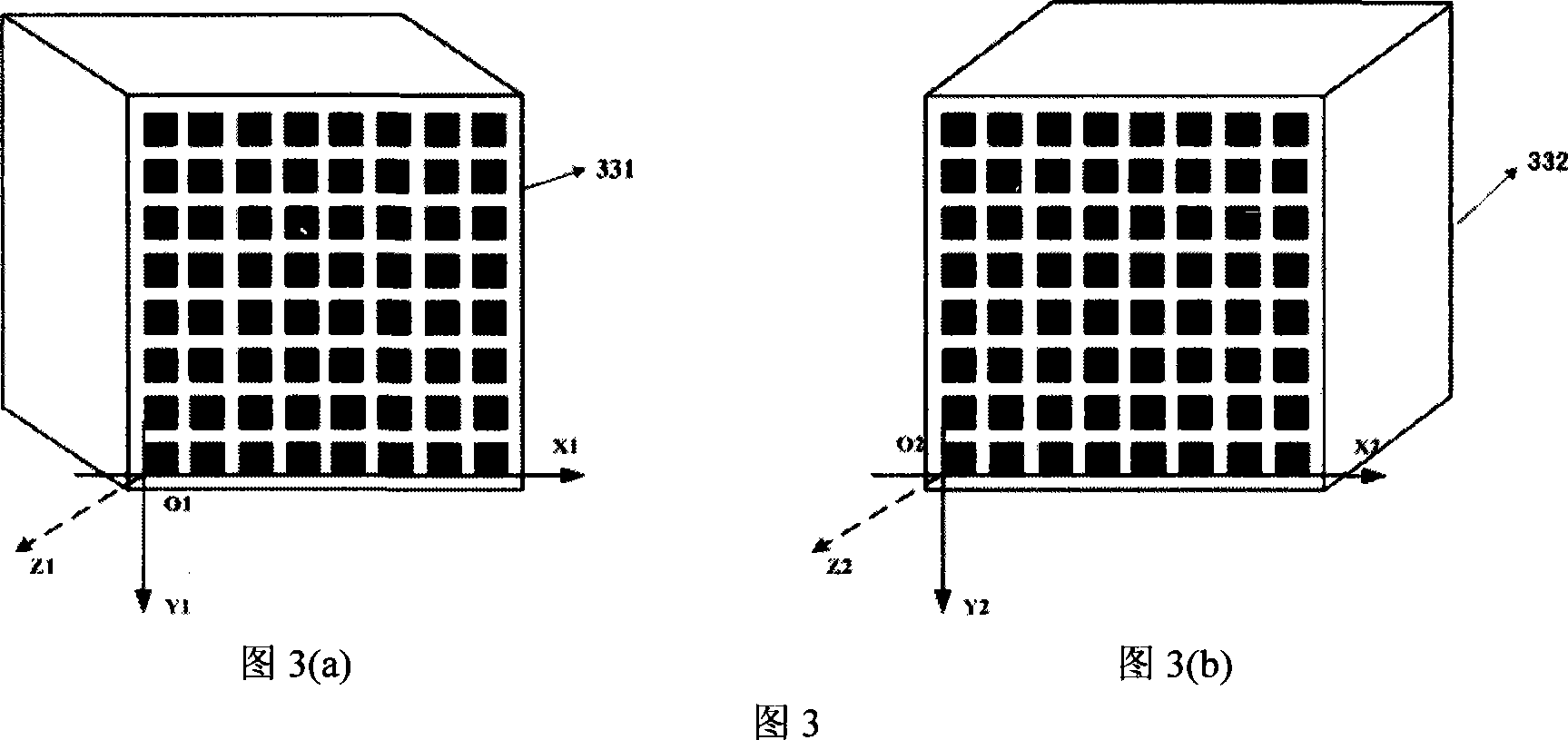

InactiveCN101059340AHigh precisionExpand field of viewUsing optical meansPicture interpretationVisual perceptionTangential point

The invention provides a wheel distance measuring method based on stereo vision and laser, which uses a stereo vision laser measuring system to obtain relative measuring parameters. The method uses a digit camera to shoot laser pattern projected on the tyre crown, uses image processing method to extract laser pattern target, uses stereo match algorism and three-dimension rebuild algorism to obtain laser pattern stereo point. And the invention projects the laser pattern stereo point on a simulated plane of the laser pattern, uses the projected point to generate a two-dimension curvature, to calculate out an extreme point of the two-dimension curvature, while the extreme point is relative to the tangential point of the tyre crown. And the invention uses one tangential point at inner tyre crown and at least three tangential points at outer tyre crown to simulate a tangential plane to calculate out the central plane of tyre. And the invention calculates out the distance between the cross lines of the central planes of left and right tyres on one shaft and the wheel support plane to obtain the vehicle wheel distance.

Owner:SOUTHEAST UNIV

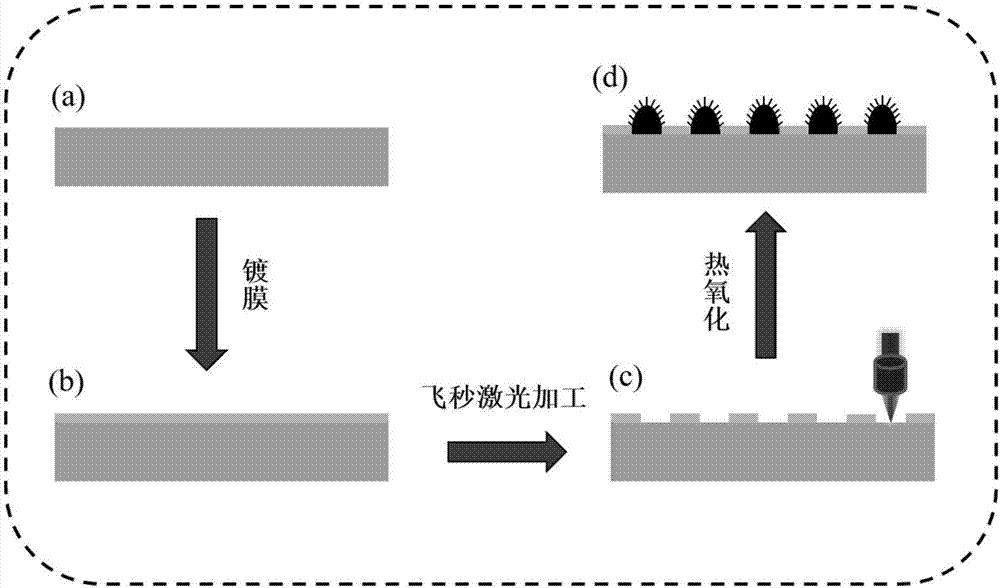

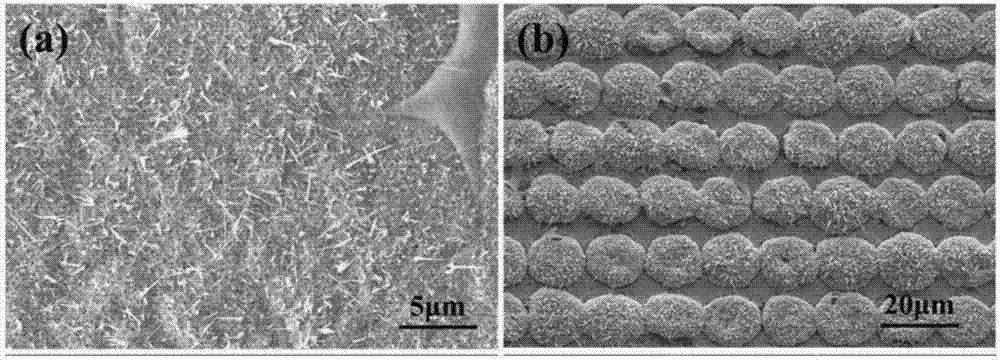

Maskless femtosecond laser manufacturing method for super-hydrophobic and anti-reflective surface

ActiveCN107243697ALow costExcellent superhydrophobicityVacuum evaporation coatingSputtering coatingFemto second laserEvaporation

The invention relates to a maskless femtosecond laser manufacturing method for a super-hydrophobic and anti-reflective surface and belongs to the field of preparation of super-hydrophobic and anti-reflective materials. The maskless femtosecond laser manufacturing method for the super-hydrophobic and anti-reflective surface comprises the following steps that (1) a copper substrate is plated with a film of a nanometer thickness through electron beam evaporation or a magnetron sputtering coating method; (2) through a femtosecond laser direct writing method, patterning is conducted on the copper substrate plated with the film of the nanometer thickness, and the shape of patterning can be controlled through a program; (3) a heating device is used for conducting thermal oxidation treatment on the substrate obtained after femtosecond laser patterning, and then a micro-nanometer composite structure is prepared. Compared with the prior art, the maskless femtosecond laser manufacturing method for the super-hydrophobic and anti-reflective surface has the advantages that the manufacturing process does not need a vacuum device or an optical mask, and the manufactured substrate is controllable in shape and has the super-hydrophobic performance, the self-cleaning performance, the anti-reflective performance and other performances.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

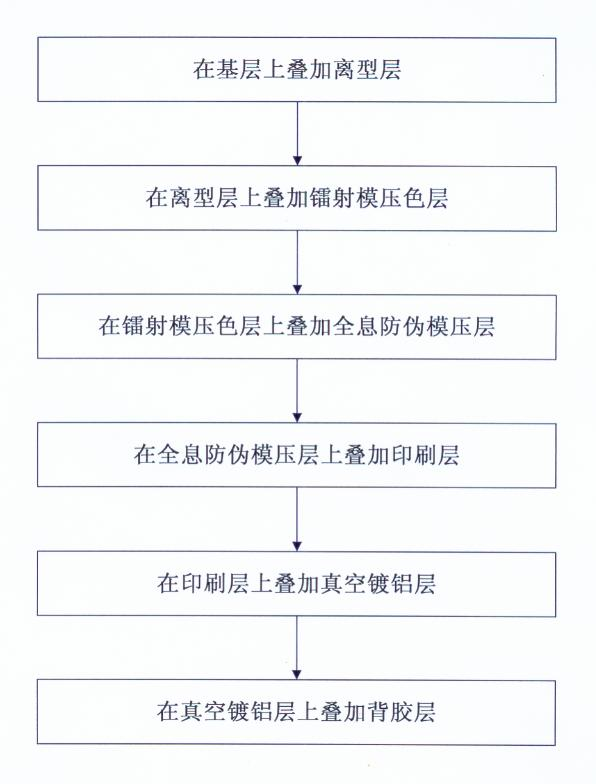

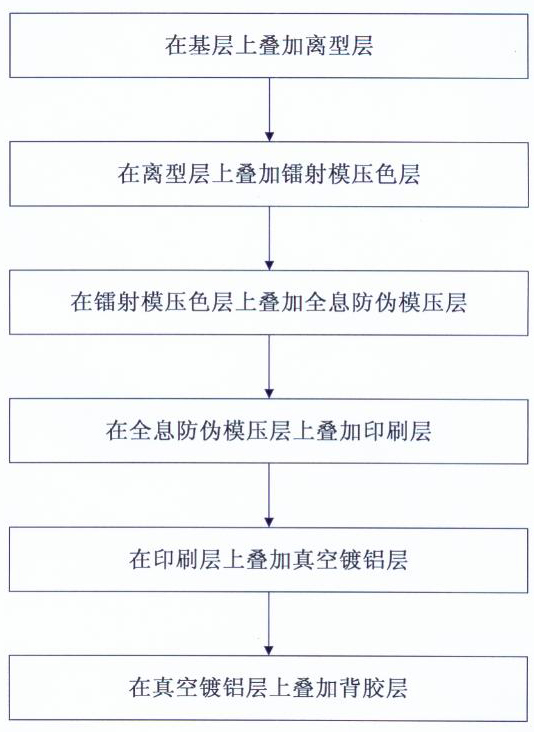

Method for manufacturing scratchable laser holography anti-fake foil

InactiveCN102092165AAdvantages of production methodHot stamping production efficiency is highSynthetic resin layered productsSpecial ornamental structuresInformation layerPolyester

The invention relates to a method for manufacturing scratchable laser holography anti-fake foil, taking a plastic polyester film as a substrate layer, comprising the following steps of: superposing a release layer on the substrate layer; superposing a laser molding color layer on the release layer, comprising evenly coating the dissolved resin on the surface of the release layer, and baking and drying via a five-section oven; superposing a holography anti-fake molding layer on the laser molding color layer, comprising forming visual laser patterns and information by a laser information layer via a roller coated with laser engraved laser plates; superposing a printing layer on the holography anti-fake molding layer; superposing a vacuum aluminized coating layer on the printing layer, comprising heating an evaporator to 1400-1500 DEG C, cooling the high-purity aluminum wires continuously sent to the evaporator into aluminum steam, evenly spraying aluminum molecules on the surface, and forming an aluminum film; and superposing a gum layer on the vacuum aluminized coating layer. The product manufactured by the method provided by the invention is high in printing production efficiency and is scratched once; the product has certain anti-fake effects and can replace a traditional method for scratching ink by a squeegee.

Owner:SHANGHAI SHENYONG STAMPING FOIL

Preparing technological process of laser aluminum plating paper

ActiveCN101324040AHigh glossGood film formingSpecial visual effect coatingsDecorative surface effectsSurface tension gradientAdhesive

The invention relates to a process method for preparing laser aluminium-plated paper, comprising the steps as follows: OPP film or PET film is coated with a disjuncting layer which is coated with an imaging layer that is mould pressed with laser patterns; the mould pressing layer is coated with adhesive; the OPP film or the PET film is stripped and enwound by a stripping machine, thus obtaining a paper substrate containing the disjuncting layer, the imaging layer and the mould pressing layer; the paper substrate is directly plated with aluminium in vacuum and the aluminium is plated on the disjuncting coating layer; the aluminium-plated layer is coated with a waterborne environmental-protective profile coating protection layer; the laser aluminium-plated paper is obtained by moisture reobtaining and resolved shearing; the process of the invention reasonably chooses resin solvent and adhesive on the basis of a plurality of tests, simultaneously, the process of the invention utilizes suitable tenacity endowed by the molecular structure when the resin and the adhesive are in a coating state, and the performance of the adhesion to optimize the proportion according to the principle of combined surface tension gradient distribution between layers, thus forming the coating layer with high blare, good film-forming performance, environmental-protection and excellent printing performance and good alkali solution permeability simultaneously.

Owner:青州金青云新材料有限公司

Cigarette aluminum-foil paper with anti-counterfeiting label

InactiveCN105178107AImprove temperature resistanceImprove aging resistanceFlexible coversWrappersHazardous substanceLaser patterning

The invention provides cigarette aluminum-foil paper with an anti-counterfeiting label. The cigarette aluminum-foil paper comprises liner paper and an aluminum foil layer. An anti-counterfeiting laser film is arranged on the surface of the aluminum foil layer. The manufacturing process comprises the steps that the laser film is manufactured, an aluminum foil body coated with glue is heated and baked, the laser film and the aluminum foil are composited, a BOPP film is stripped from a cured semi-finished product, a BOPP base film on a cooled composited film is removed, a complexing agent for connecting the liner paper and the aluminum foil layer is prepared, and finally the liner paper and the aluminum foil layer are composited. The BOPP base film has the good temperature resistance and ageing resistance, materials are soft, no transparent de-bonding layer needs to coat the materials, and the technological process is simple; the anti-counterfeiting film is transferred onto aluminum foil, laser patterns will not disappear and are not likely to be damaged, and the while film is good in high temperature resistance and will not crack. The complexing agent between the liner paper and the aluminum foil layer is not likely to volatilize to generate hazardous substances, the temperature is high, and adhesive force can be provided for the liner paper and the aluminum foil layer for a long time.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

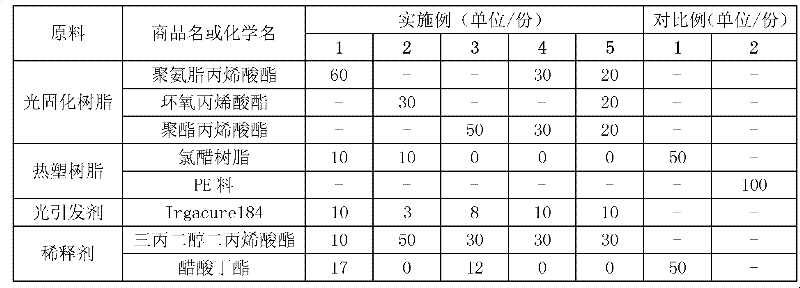

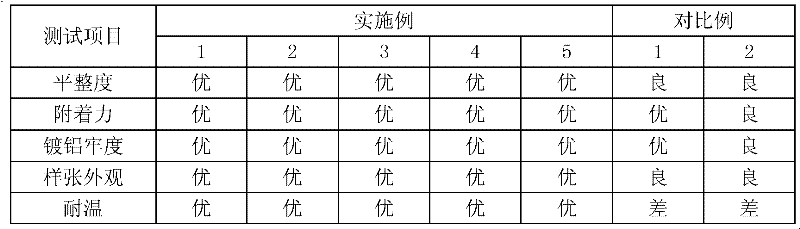

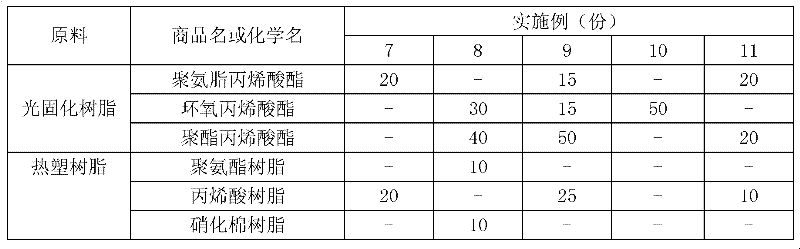

UV (Ultraviolet)-thermoplastic resin composite laser aluminum-plated coating composition

InactiveCN102643599AReduce volatilityReduce pollutionPolyurea/polyurethane coatingsEpoxy resin coatingsCross-linkHeat resistance

The invention discloses a UV (Ultraviolet)-thermoplastic resin composite laser aluminum-plated coating composition. The coating composition comprises the following components in parts by weight: 20-80 parts of light-cured resin, 0-50 parts of thermoplastic resin, 1-30 parts of light initiator, 20-200 parts of diluting agent and 0-10 parts of auxiliary agent. Compared with the prior art, the UV-thermoplastic resin composite laser aluminum-plated coating composition can realize a groove with a mould pressing depth so that the formed laser pattern stereoscopic impression is strong; furthermore, the UV-thermoplastic resin composite laser aluminum-plated coating composition adopts light-cured cross-linking to form a film and the heat resistance of the coating is good; and a laser pattern is not easy to deform by heating in a use process so that the timeliness of a laser aluminum-plated film is long.

Owner:SHANGHAI WEIKAI CHEM +1

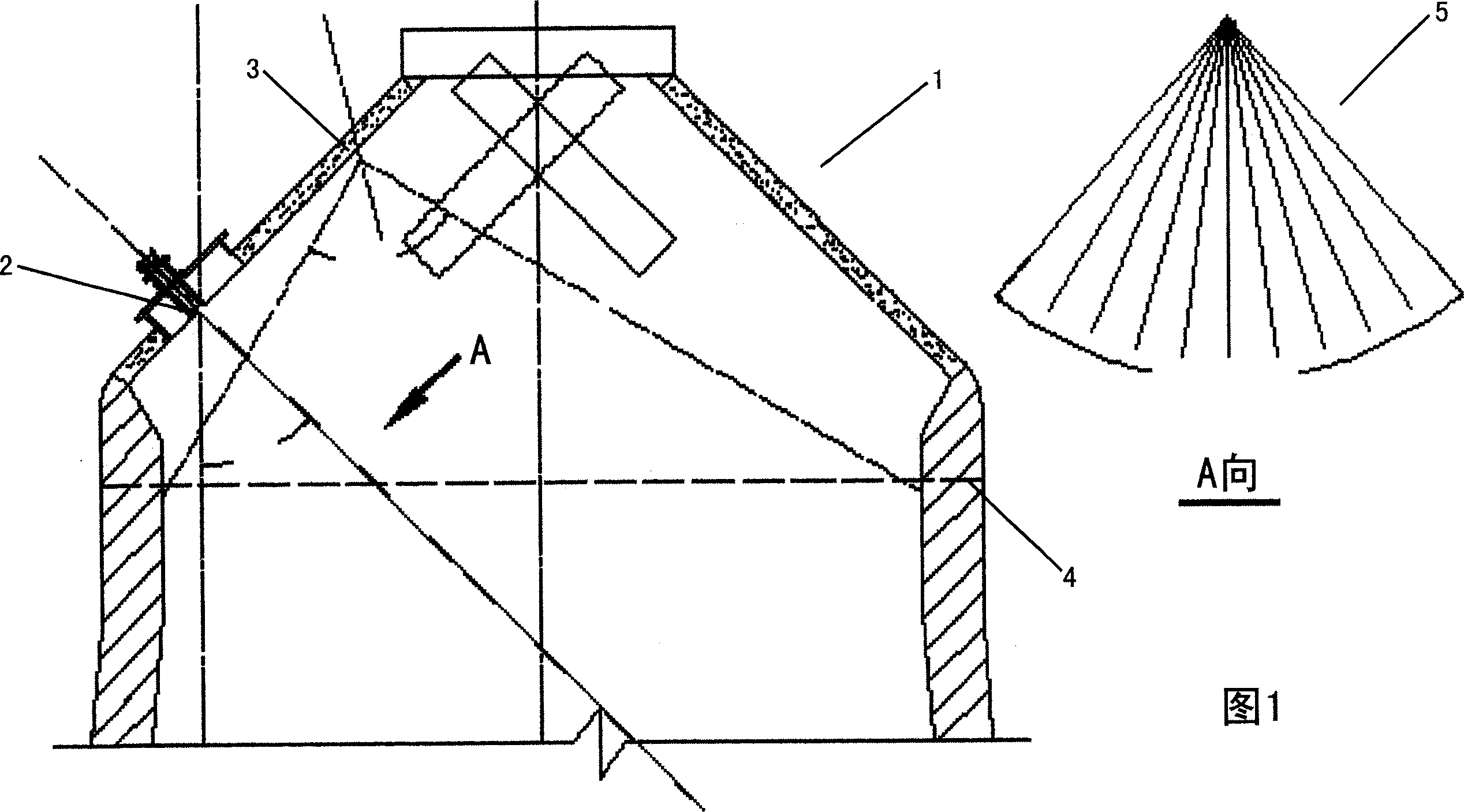

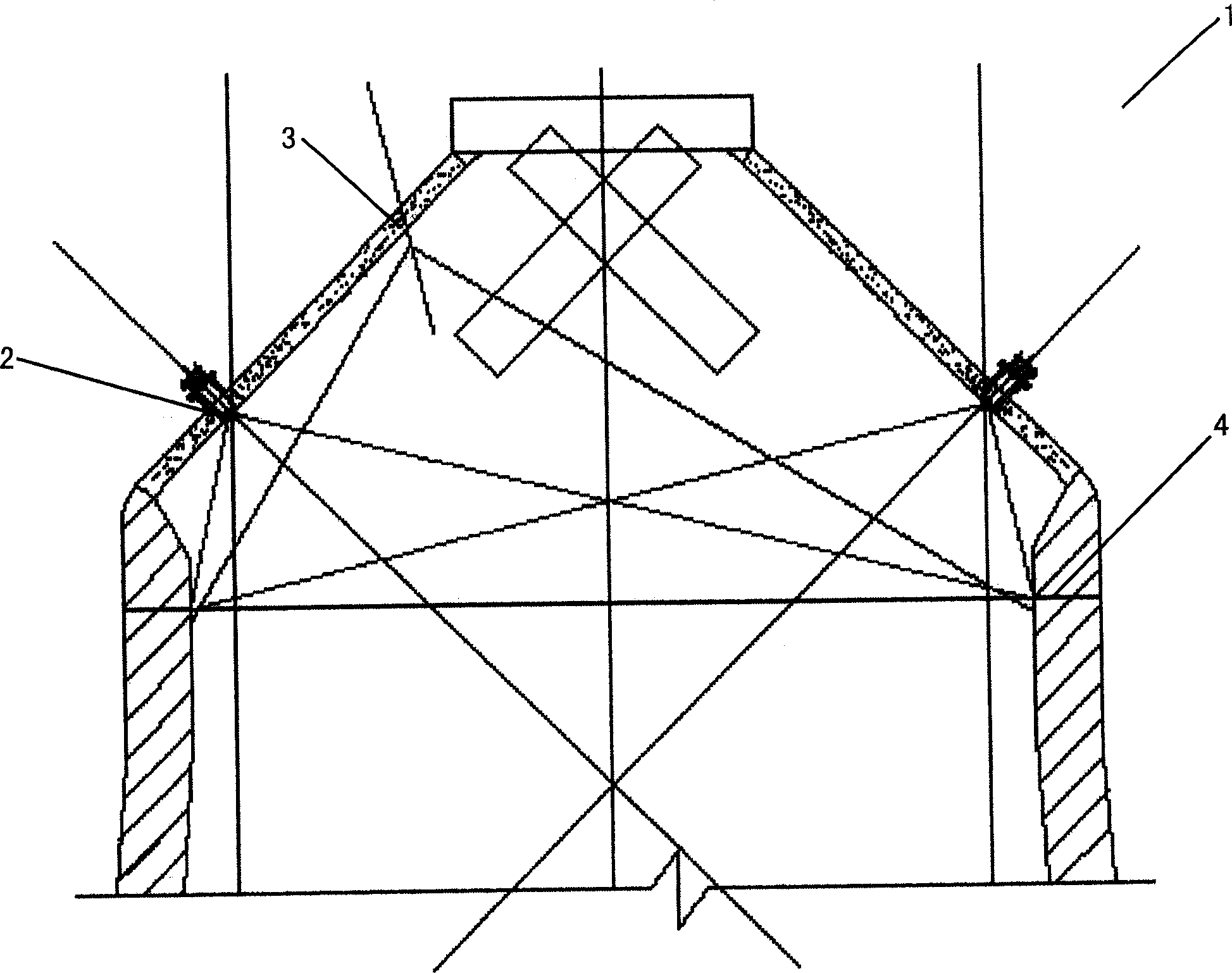

Laser detection apparatus and method for in-furnace information

InactiveCN1877249AReal-time online detectionFurnace componentsPhotogrammetry/videogrammetryLaser patterningOptoelectronics

The invention provides a laser detection device for monitoring information inside of the industrial kiln with heavy dust and / or heavy smoke in it. The inventive device comprises a laser device for generating laser light to get into the kiln; a vidicon which is installed on the kiln body for capturing image produced from laser light generated by the laser inside of the kiln, wherein the image includes laser pattern produced during laser light passing through dust and / or smoke. The invention is characterized in that the inventive device can detect information inside of the kiln online, such as operation situation of device, material feeding process and material situation, by means of laser tracing and camera shooting. The invention also provides a laser monitoring method for getting information inside of the kiln.

Owner:SHENVANG PAJONIIR TEK CORP BEJDZHING +1

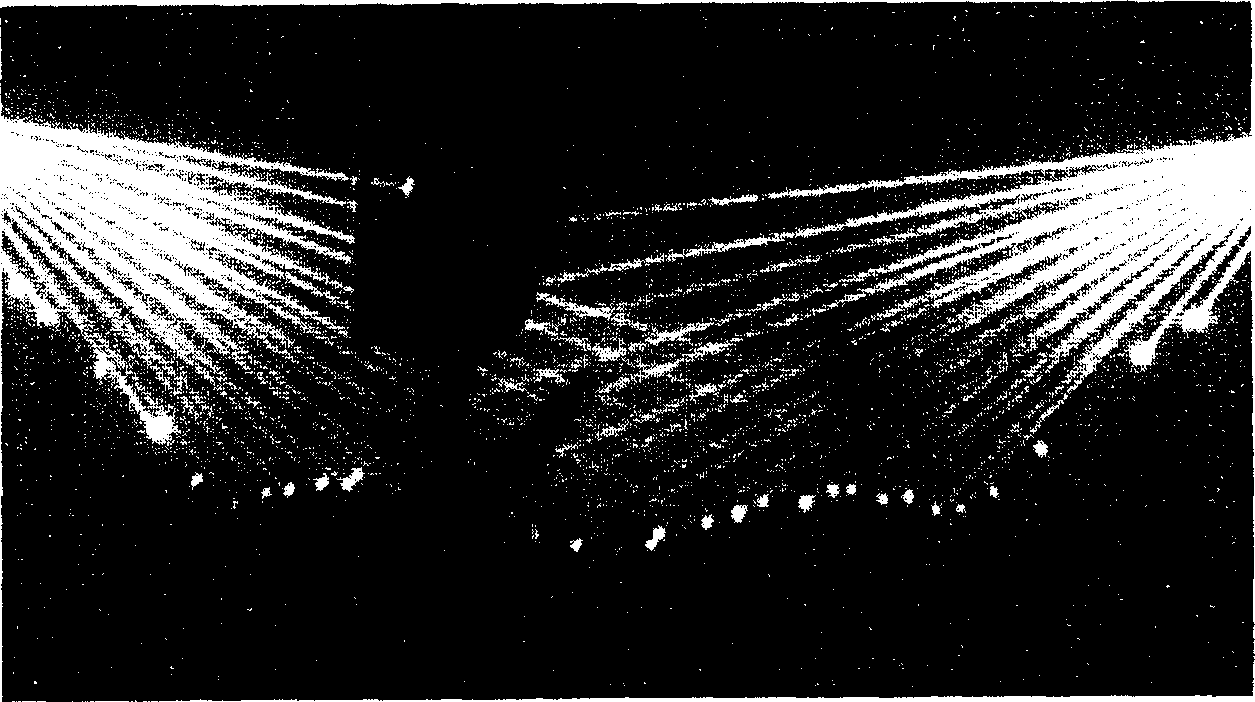

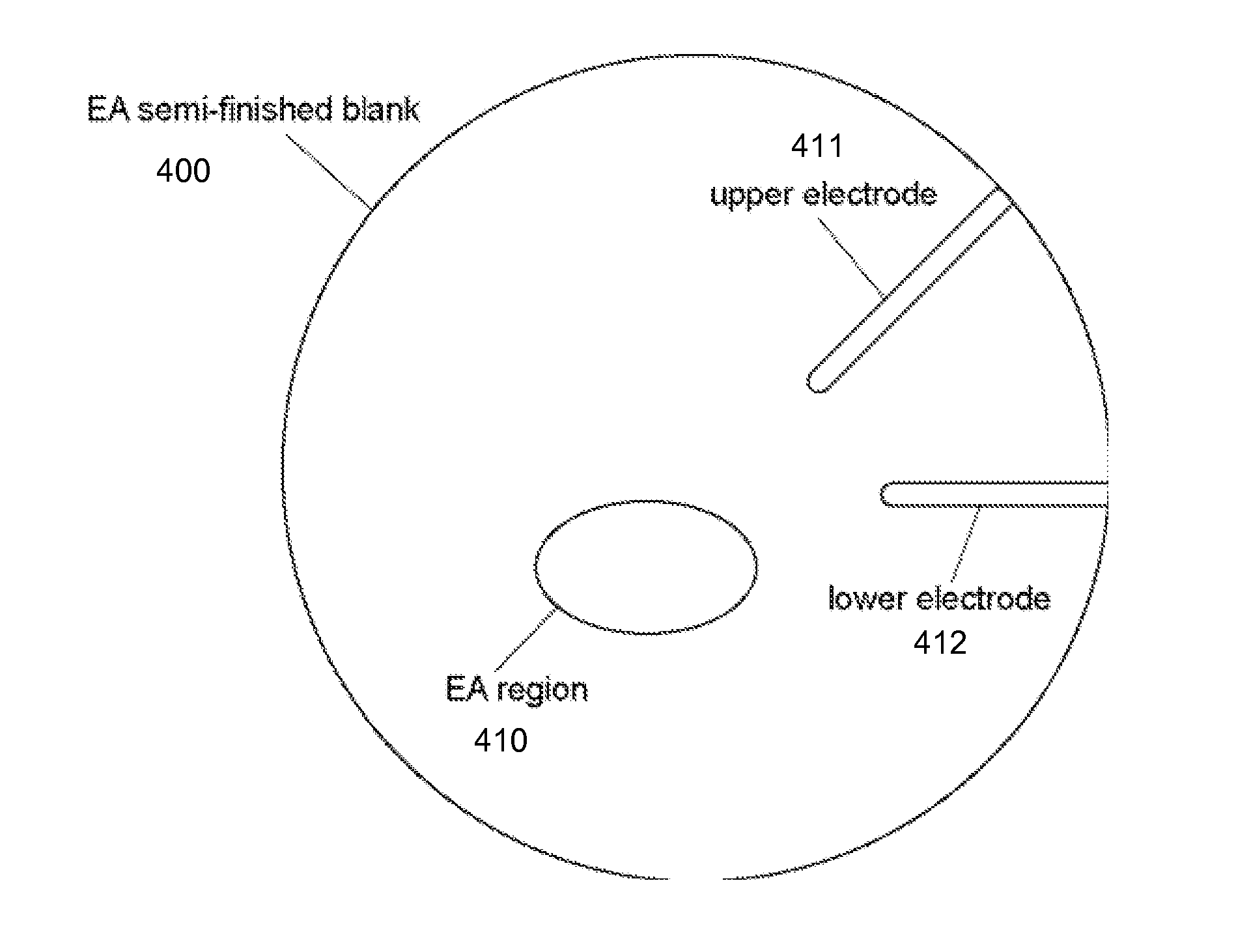

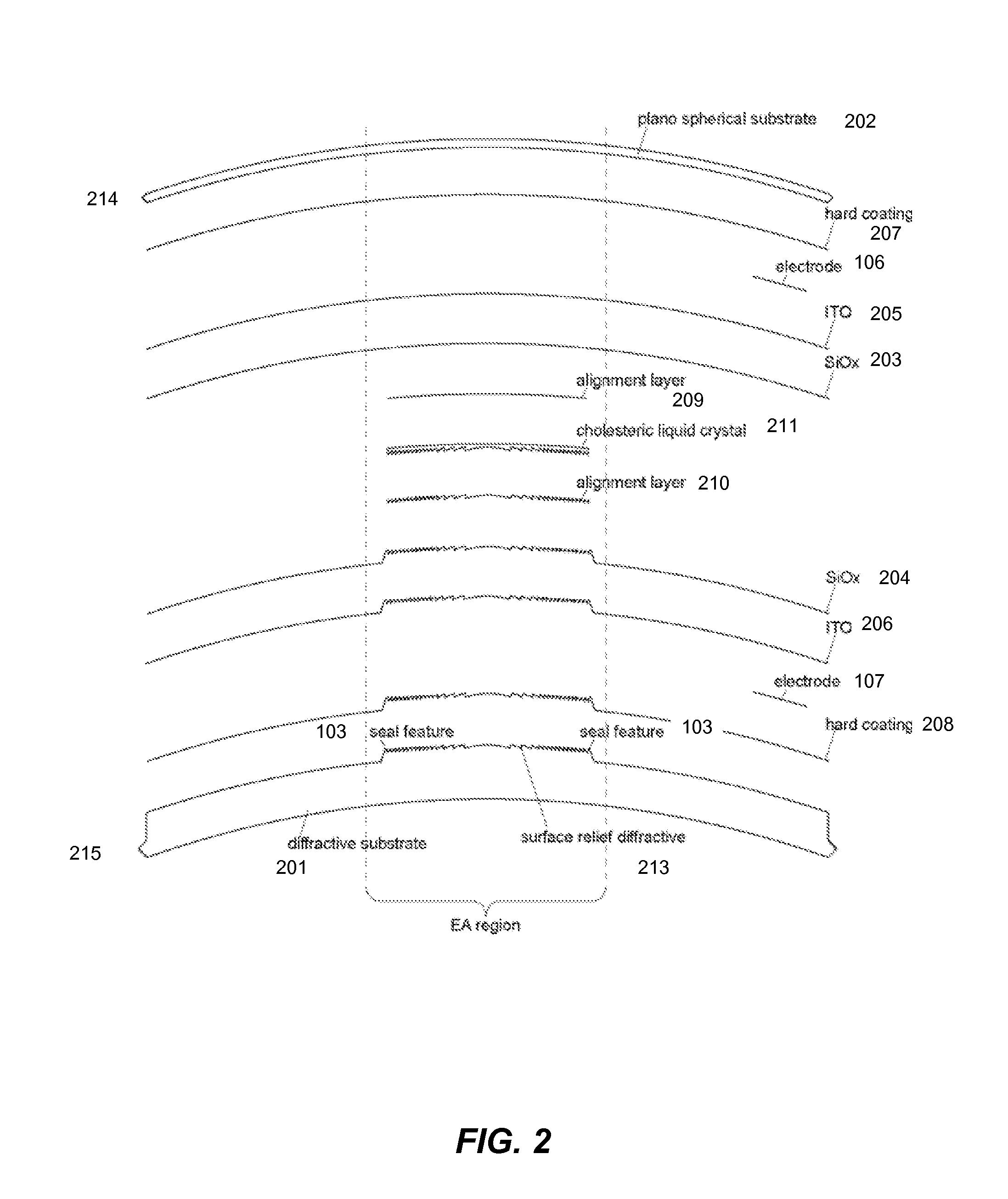

Laser patterning of conductive films for electro-active lenses

Systems and methods for manufacturing electro-active lenses including a peripheral edge, a discrete electro-active region, and at least two substrates. The at least two substrates include a layer of a transparent conductive material, that is laser cut to isolate regions required for establishing an electrical connection between the peripheral edge of the lens, from regions not required for establishing an electrical connection. Isolating the regions of the transparent conductive material required for establishing an electrical connection may include cutting patterns around an electrode of each of the substrates. The regions not required for establishing an electrical connection may be further cut into sections, which may be substantially band-shaped.

Owner:MITSUI CHEM INC

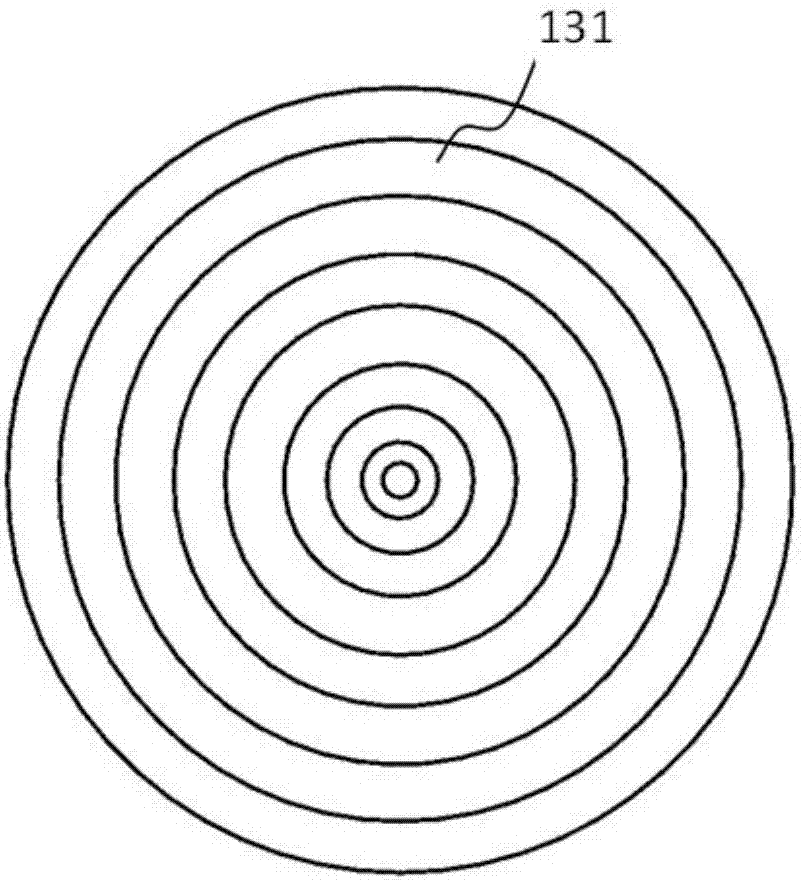

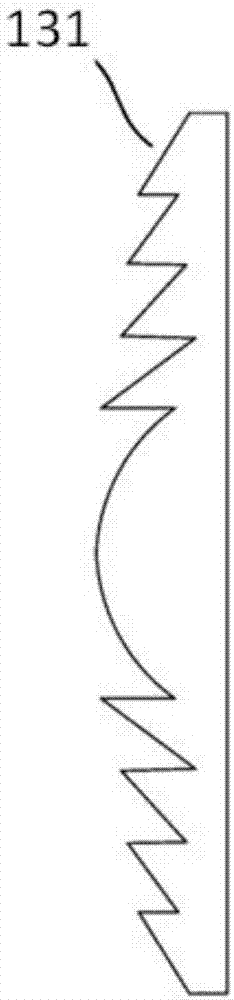

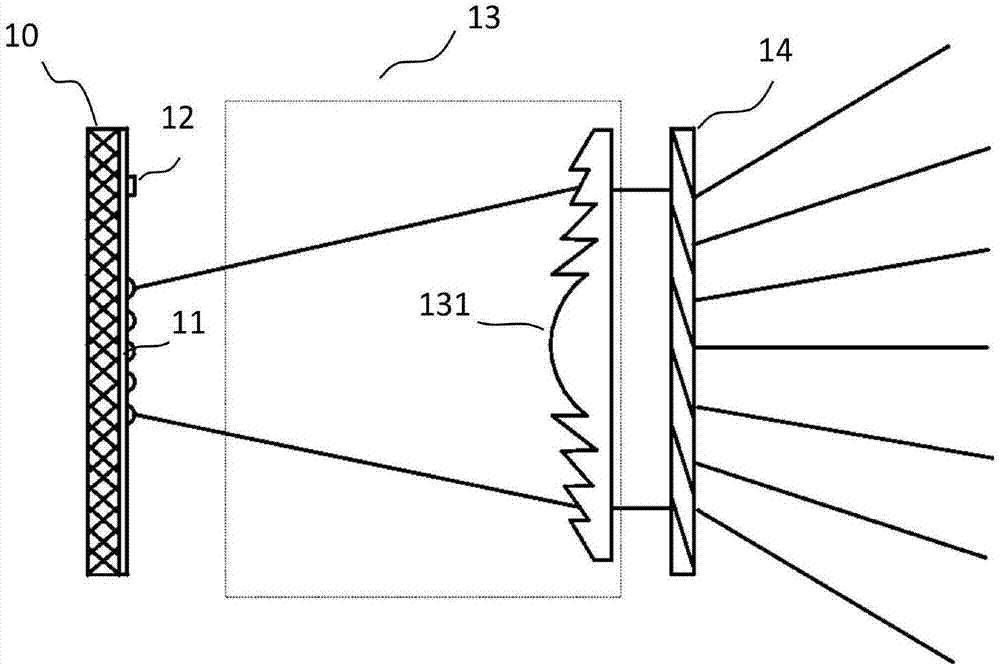

Laser projection apparatus comprising Fresnel lens

The invention discloses a laser projection apparatus. The laser projection apparatus comprises a light source, a collimation unit and a diffraction optical element, wherein the light source is used for emitting laser; the collimation unit is used for focusing the laser emitted by the light source so as to project parallel light beams to the diffraction optical element; the diffraction optical element is used for performing beam expansion on the parallel light beams to form laser patterns; and the collimation unit comprises a combination of multiple Fresnel lenses or a combination of a common lens and at least one Fresnel lens. By virtue of the laser projection apparatus, spherical aberration is eliminated and light beam quality is improved, and the laser projection apparatus is mainly applied to a depth camera.

Owner:SHENZHEN ORBBEC CO LTD

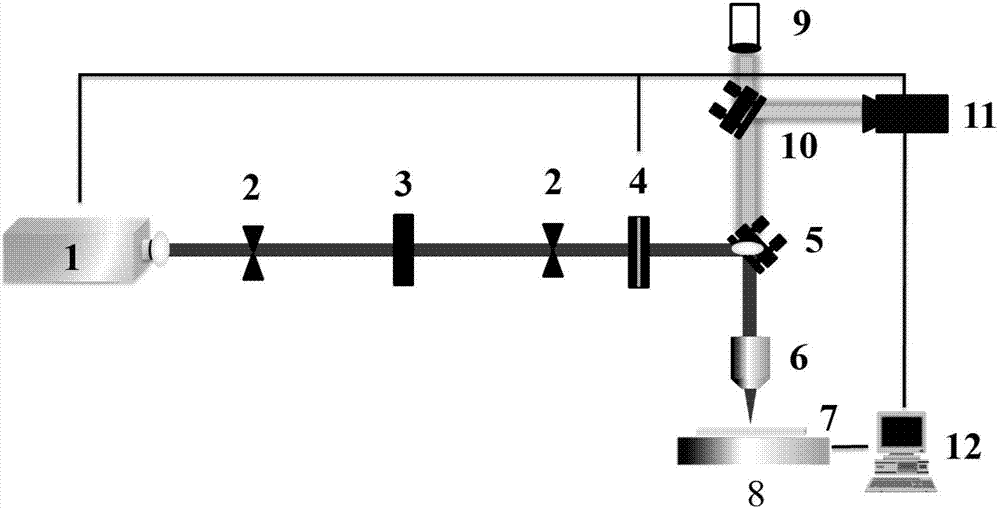

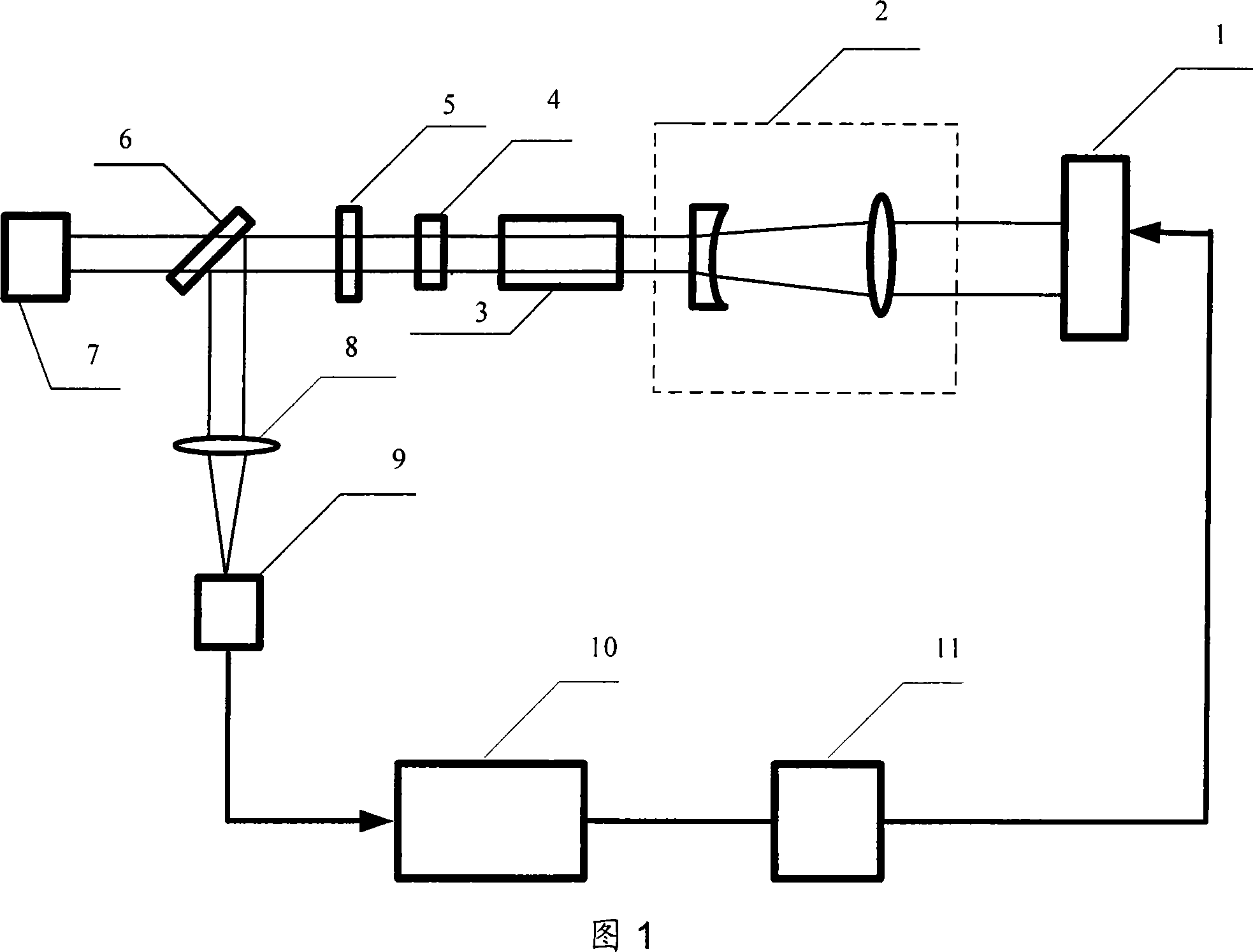

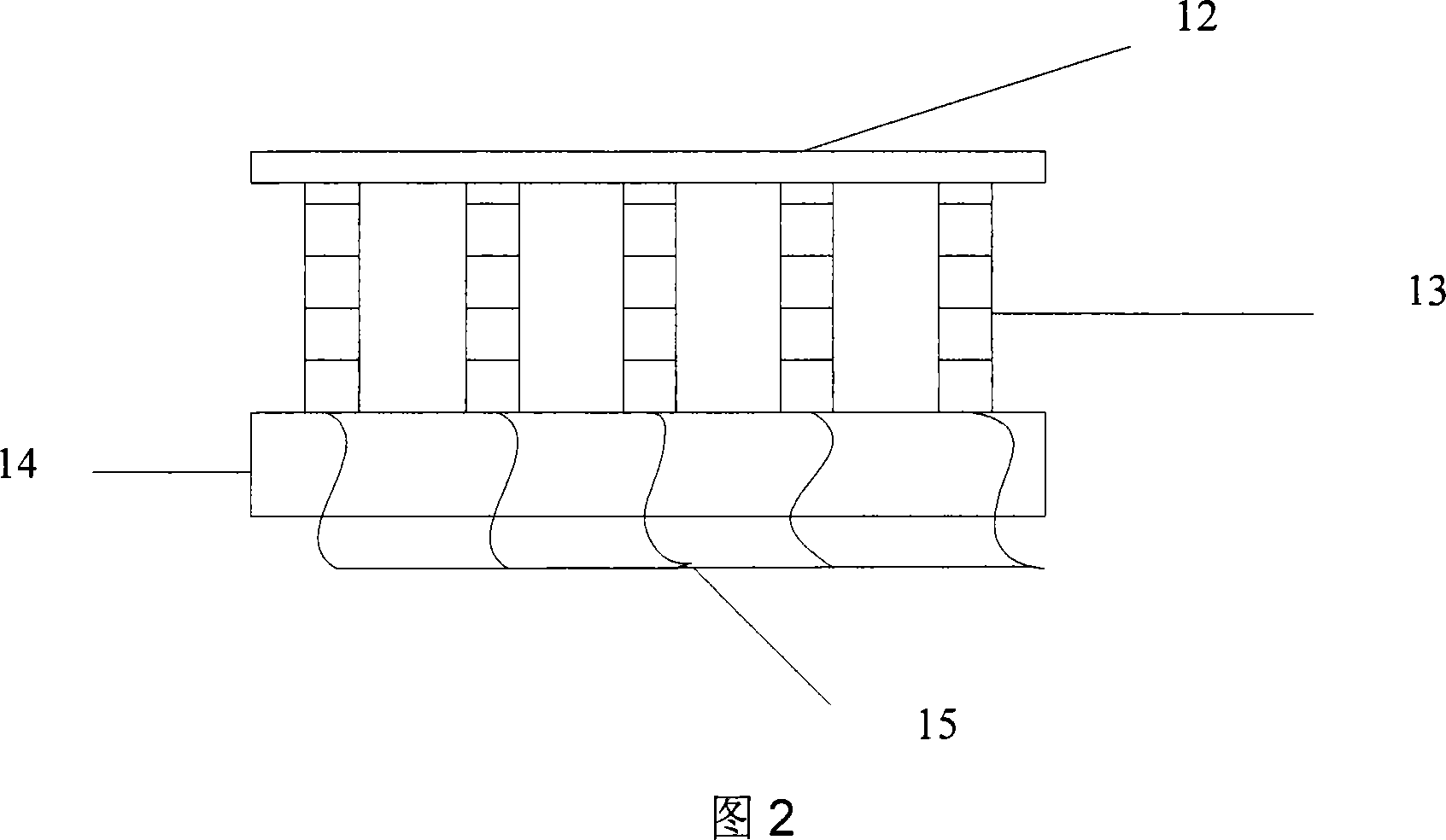

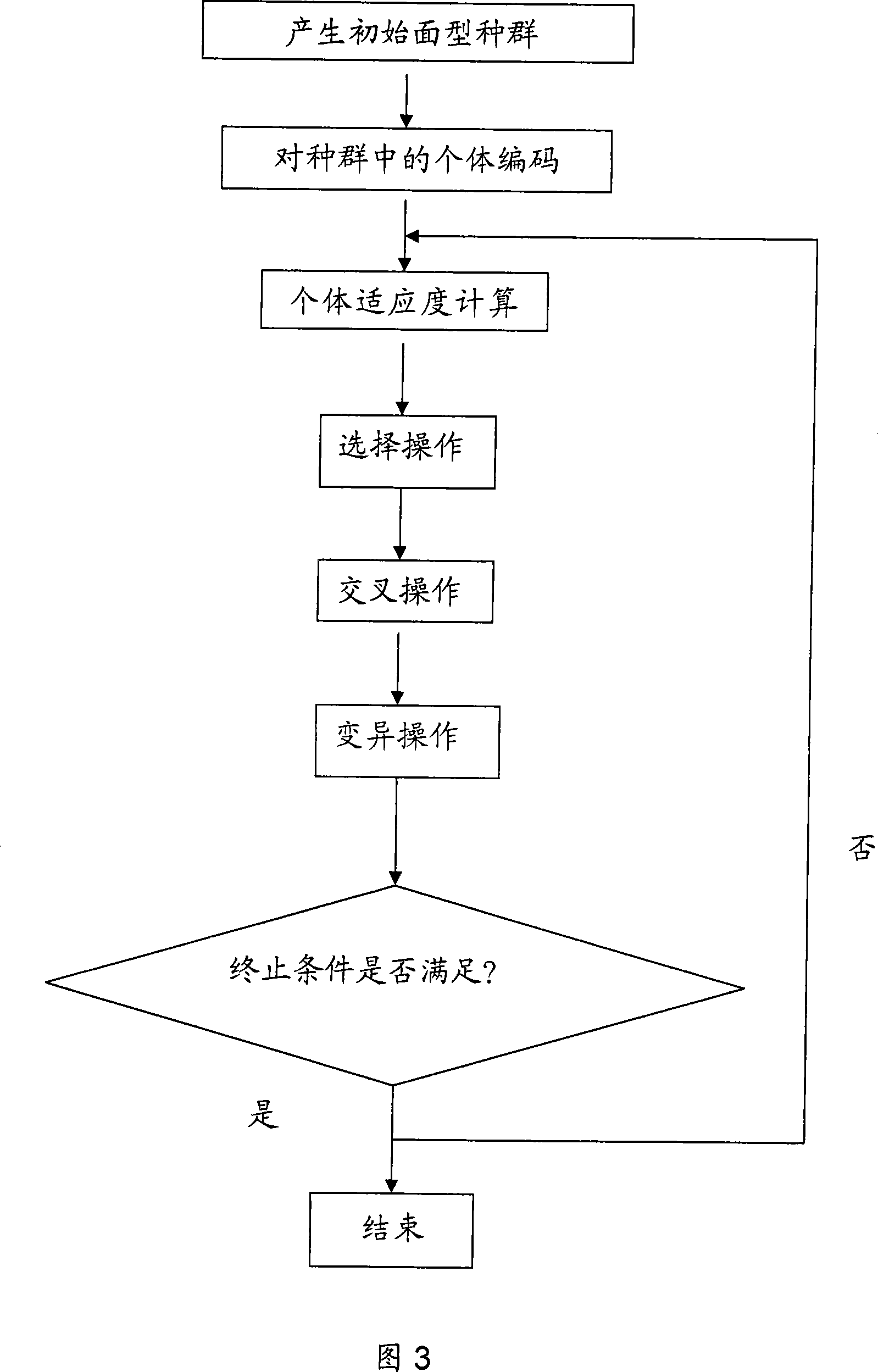

Solid laser resonance cavity system with automated optimization laser mode

ActiveCN101079530AQuality improvementIncrease brightnessOptical resonator shape and constructionSpecial data processing applicationsBeam splitterHigh pressure

The invention discloses a solid laser resonator system of automatic optimizing laser pattern, which comprises the following parts: output cavity lens, reflective deforming lens, gain dielectric, narrow-band filter, facular detector, beam splitter, power meter, high-pressure amplifier, main control computer, telescope, image gathering card, focal lens and control algorism. The invention utilizes reflective deforming lens with high reflectance to replace common plane reflective lens as reflective end lens of resonator, which generates kinds of high-low stepped optical aberration to inhibit high-step laser, in order to output high-brightness basic mould. The invention possesses simple structure to be controlled conveniently, which improves the quality of output beam without reducing the output power.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com