Laser detection apparatus and method for in-furnace information

A laser detection and laser technology, used in measuring devices, optical devices, optical testing flaws/defects, etc., can solve problems such as inability to comprehensively observe the operation of equipment in the furnace, the charging process and the condition of the material surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

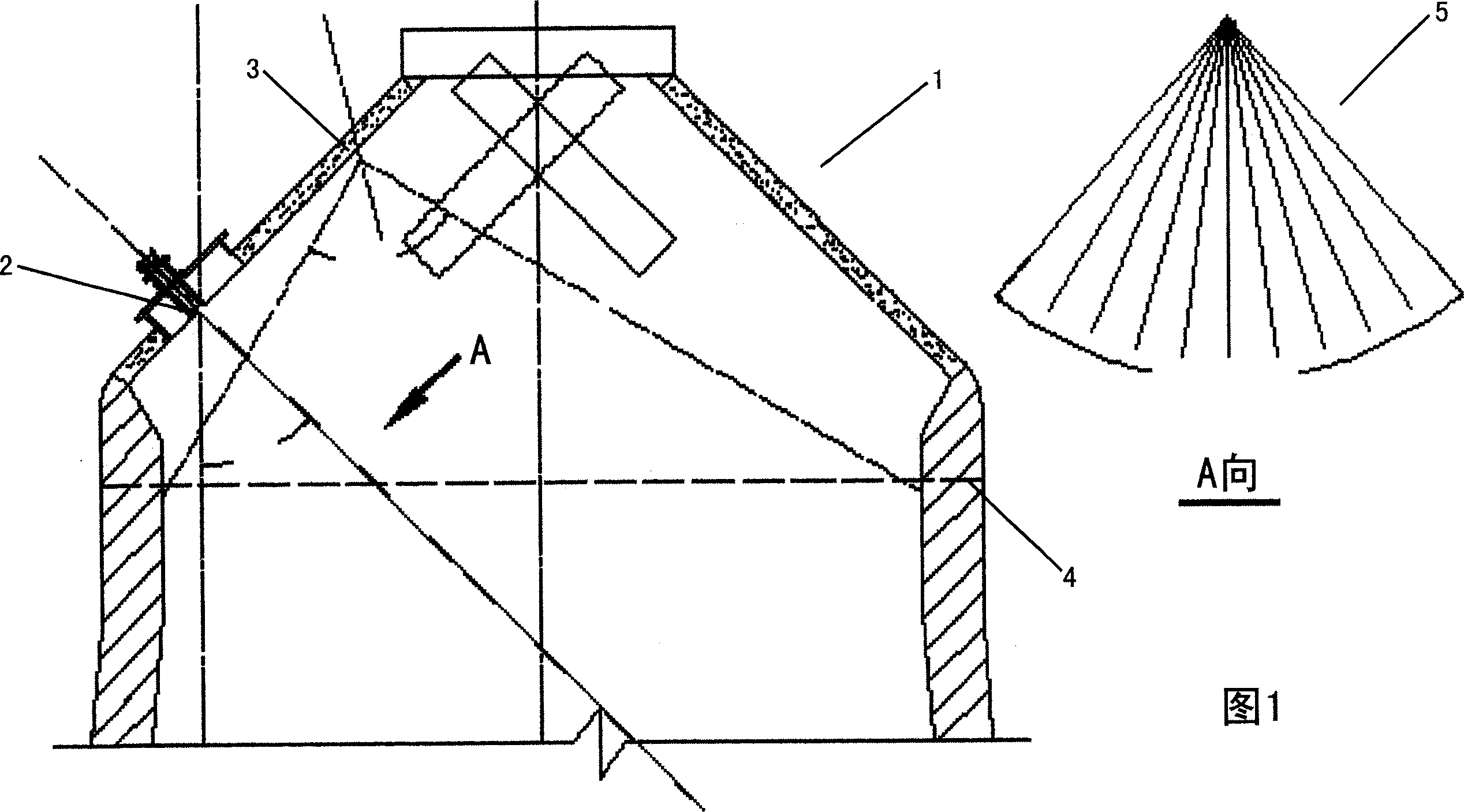

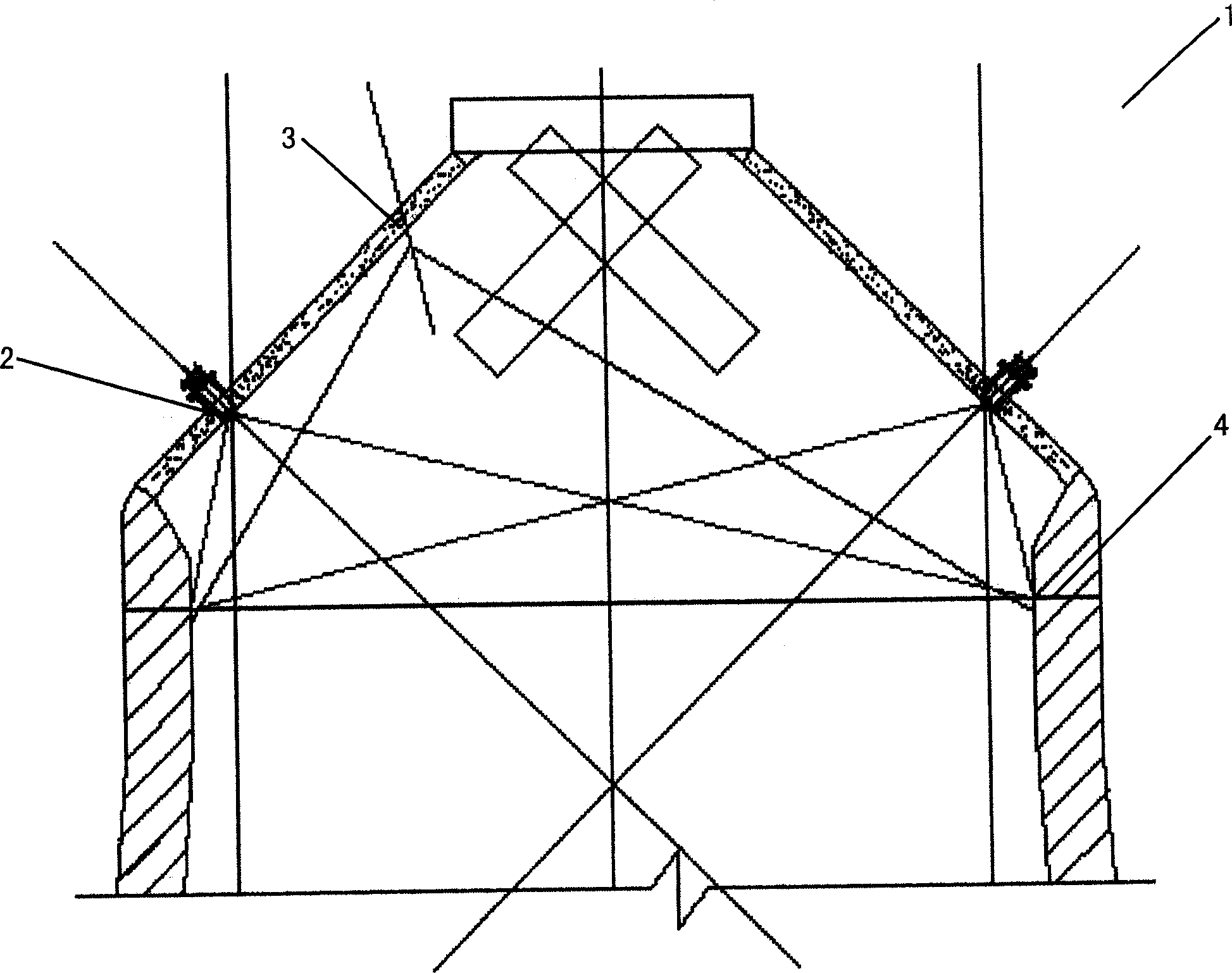

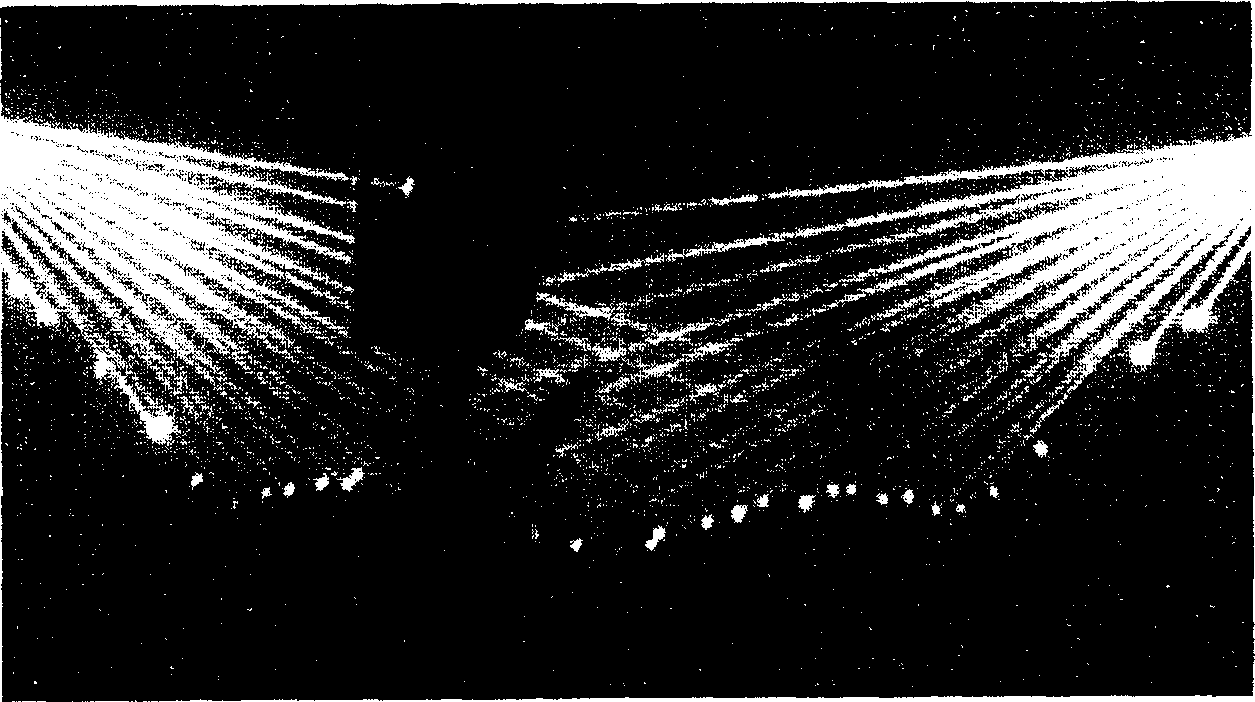

[0013] See Figure 1 and figure 2 , an industrial furnace such as a blast furnace 1 is provided with a laser inlet 2 and a camera 3 above the reference material surface 4, and the laser inlet 2 and the camera 3 are arranged on the blast furnace 1 in an appropriate manner, that is, under normal circumstances, the inside of the blast furnace will not pass The laser entrance 2 and the video camera 3 are in communication with the outside world, and the video camera 3 can acquire the required images inside the furnace formed by the laser 5 . One or more laser entrances 2 and / or cameras 3 can be provided as required. It should be noted that the laser (not shown) can be arranged outside the blast furnace 1, but also inside it. Due to the high temperature, high pressure, high dust, high humidity and other environments inside the blast furnace, ordinary camera methods cannot obtain information in the furnace at all. However, according to the different production conditions inside the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com