Cement raw material quality online laser detection device and method

A cement raw material and laser detection technology, applied in the direction of material excitation analysis, fluorescence/phosphorescence, etc., can solve the problems of ineffective application in industrial sites and inaccurate analysis results, so as to achieve accurate and reliable detection results, ensure production quality, and improve precision degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

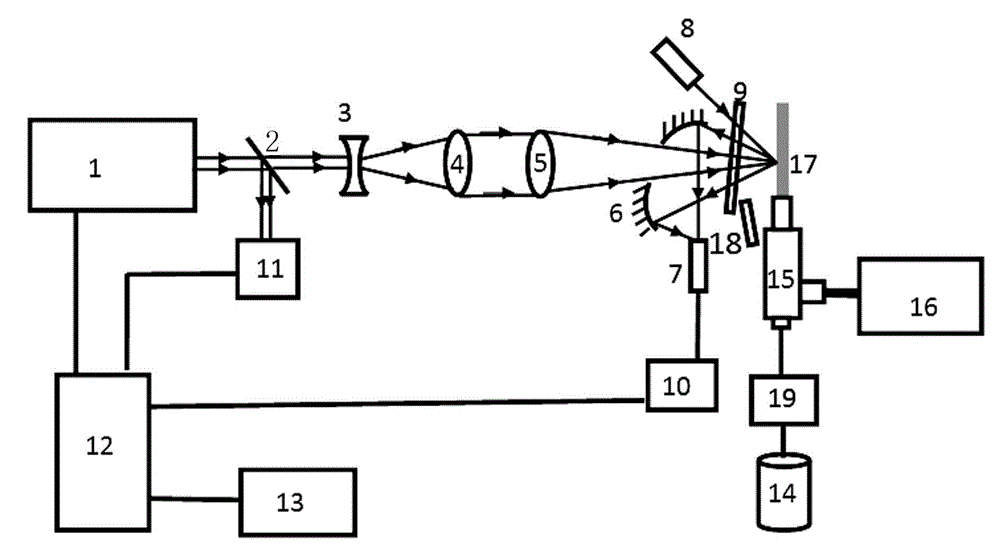

[0023] An on-line laser detection device for cement raw meal quality, comprising a pulse laser 1, a converging lens group sequentially arranged on the output light path of the pulse laser 1, and a concave mirror 6 with a center hole; the concave side of the concave mirror 6 with a center hole is provided with Quartz lens 9, high-pressure gas tank 14 and jet device 15; the feed port of jet device 15 is connected with cement raw material conveying pipe 16, and high-pressure gas tank 14 is connected with the air inlet of jet device 15; concave mirror with middle hole A continuous laser 8 is also provided beside the 6; an optical fiber focusing head 7 is arranged on the reflected light path of the concave surface mirror 6 with a center hole, and the optical fiber focusing head 7 is connected with a spectrometer 10 through an optical fiber, and the spectrometer 10 is connected with an industrial computer 12, and the signal of the industrial computer 12 The output end is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com