Patents

Literature

262 results about "Pulsed laser device" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

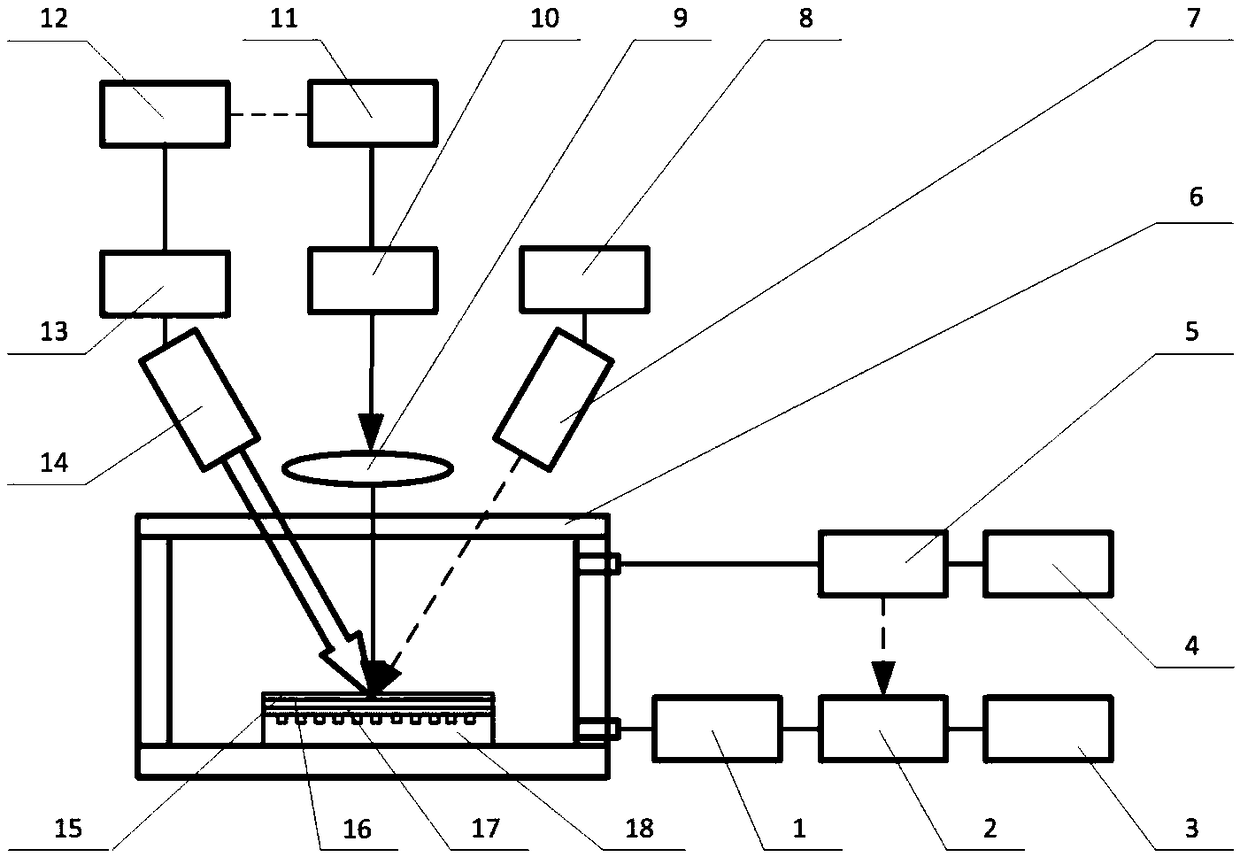

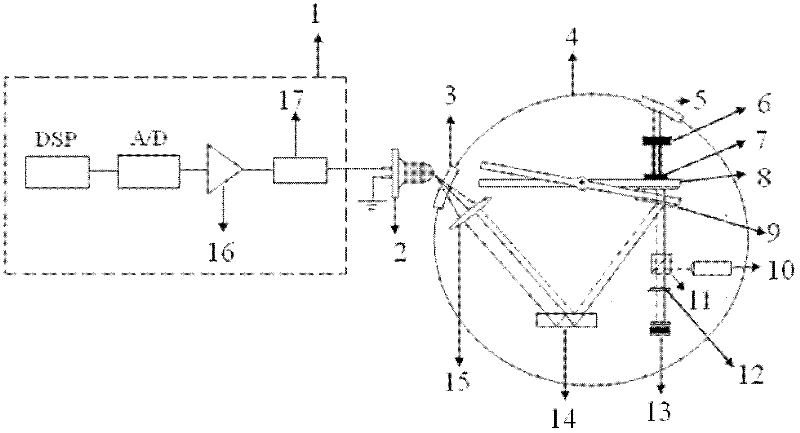

Integrated laser-induced enhanced plasma spectrum acquisition system

InactiveCN102841078AAccurate measurementIncrease production capacityAnalysis by material excitationLaser-induced breakdown spectroscopyHigh pressure

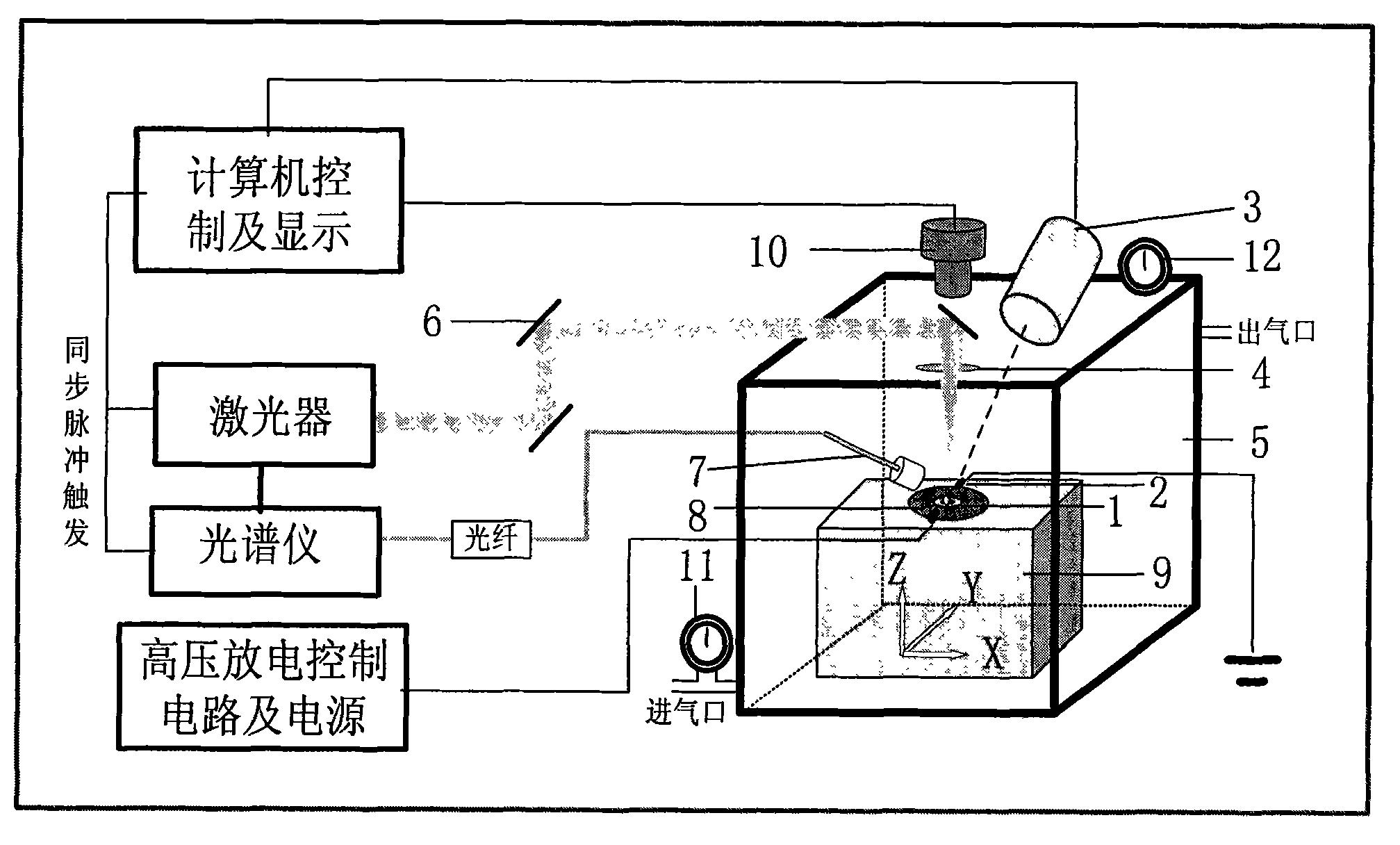

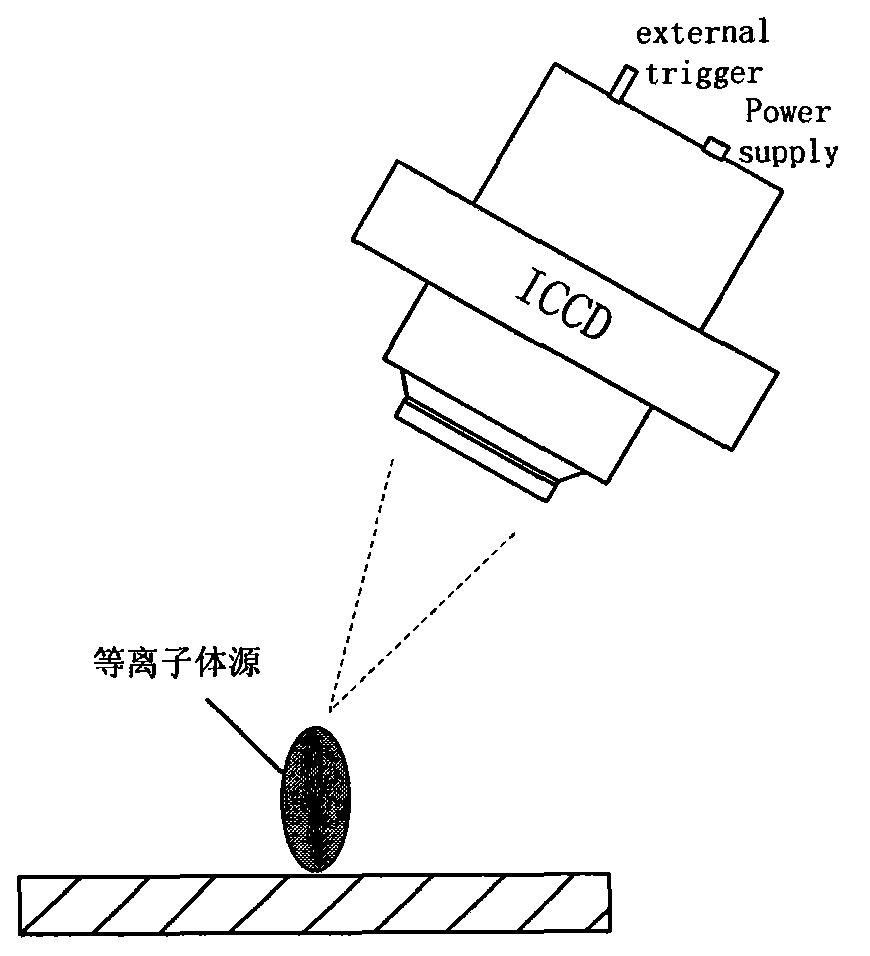

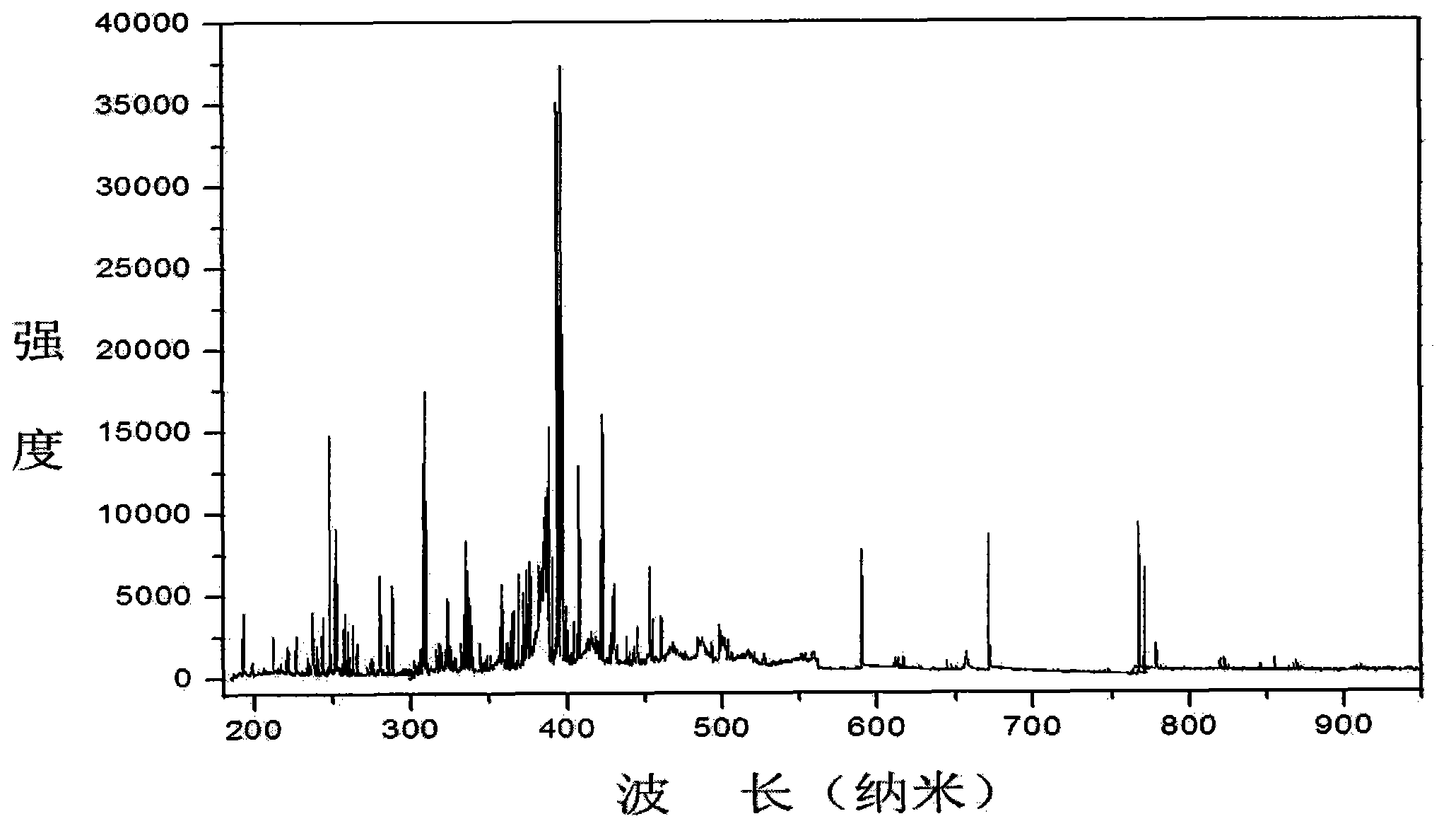

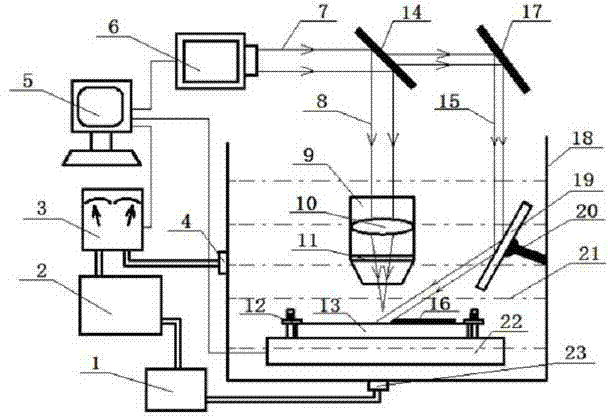

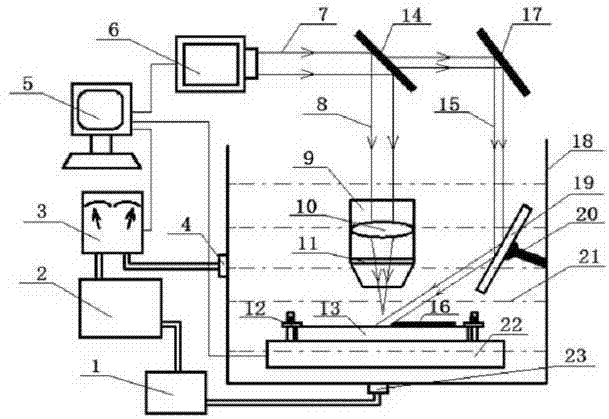

The invention relates to an integrated laser-induced enhanced plasma spectrum acquisition system and belongs to the field of laser plasma spectrum detection. The integrated laser-induced enhanced plasma spectrum acquisition system comprises a pulse laser device, a light beam lifter, a spectrometer, a domain limiting loop, a high voltage discharge electrode, an ICCD (Intensified Charge Coupled Device) camera, a focusing lens, a sample chamber, a reflector, an adjustable optical fiber optical receiving system, a sample to be detected, a three-dimensional electric control translation platform, an imaging CCD (Charge Coupled Device), a gas flow meter and a gas pressure meter. According to the integrated laser-induced enhanced plasma spectrum acquisition system, different LIBS (Laser-induced Breakdown Spectroscopy) signals are collected by utilizing control and synchronous control of internal environments of smaller independent sealed spaces so that integration is realized; a high voltage discharge enhanced and loop limited domain synchronous enhanced LIBS system with the functions of spectrum acquisition, dynamic image analysis and the like is integrated; and more accurate measurement are realized by utilizing environment stress around the sample and control of protection gas; and the system is quick and convenient, and is favorable for industrial production and application.

Owner:刘瑞斌

Laser cleaning system for rubber module

InactiveCN102886363AEasy to cleanIncrease laser output powerCleaning processes and apparatusCoupling lossEngineering

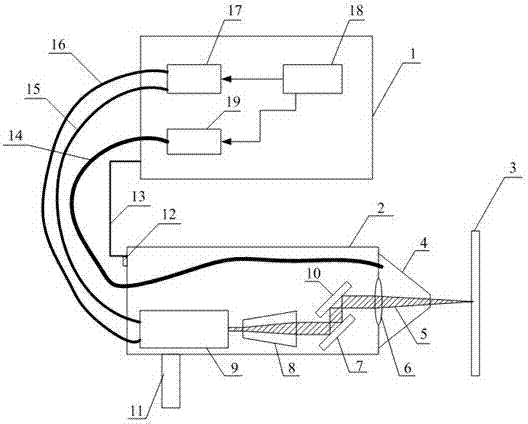

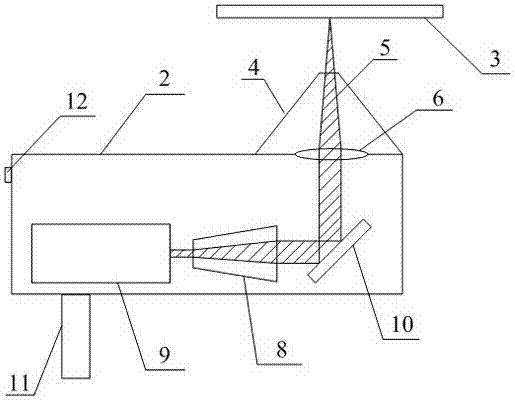

The invention provides a laser cleaning system for a rubber module, and the laser cleaning system comprises a laser cleaning head and a laser control system, wherein the laser cleaning head comprises a laser device and a beam expander, a scanning galvanometer is arranged in the output light direction of the beam expander, a focusing lens is arranged on the reflecting light path of the scanning galvanometer, and the light path output end of the focusing lens is used for cleaning articles; the laser device comprises a total reflector, an acousto-optic Q-switch, a semiconductor pumping module and an output mirror which are sequentially arranged on the light path; and the light-emitting switch of the laser device, the Q-switching drive module of the acousto-optic Q-switch, the power supply of the semiconductor pumping module, and the drive unit of the scanning galvanometer are controlled by a laser control system respectively. According to the invention, the semiconductor pumping solid pulse laser device is adopted and integrated on a cleaning machining head, the output power of laser is increased by means of acousto-optic Q-switching, and the coupling loss caused by optical fibre transmission is avoided, so that portable-type machining in a handheld mode or a manipulator clamping mode can be realized, and efficient cleaning for the rubber module can be finished.

Owner:NO 717 INST CHINA MARINE HEAVY IND GRP

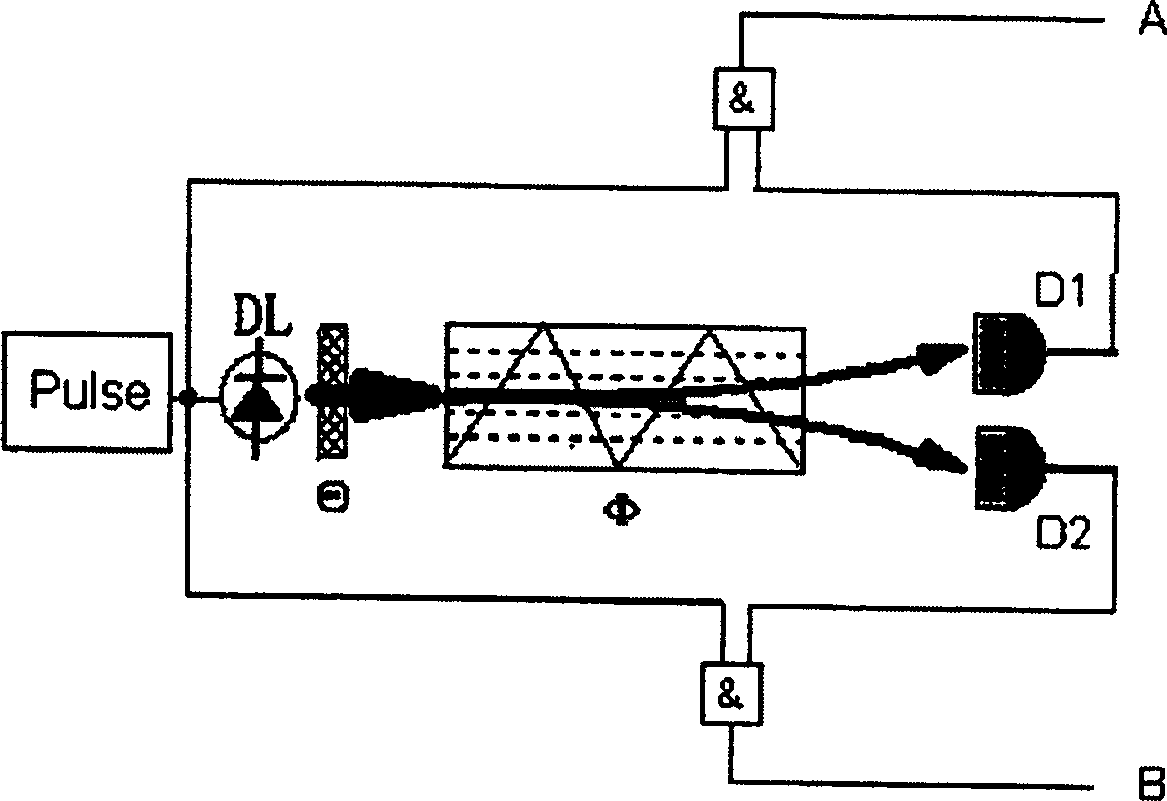

Single-light-source dual-wavelength LIBS (laser-induced breakdown spectroscopy) measurement device and method

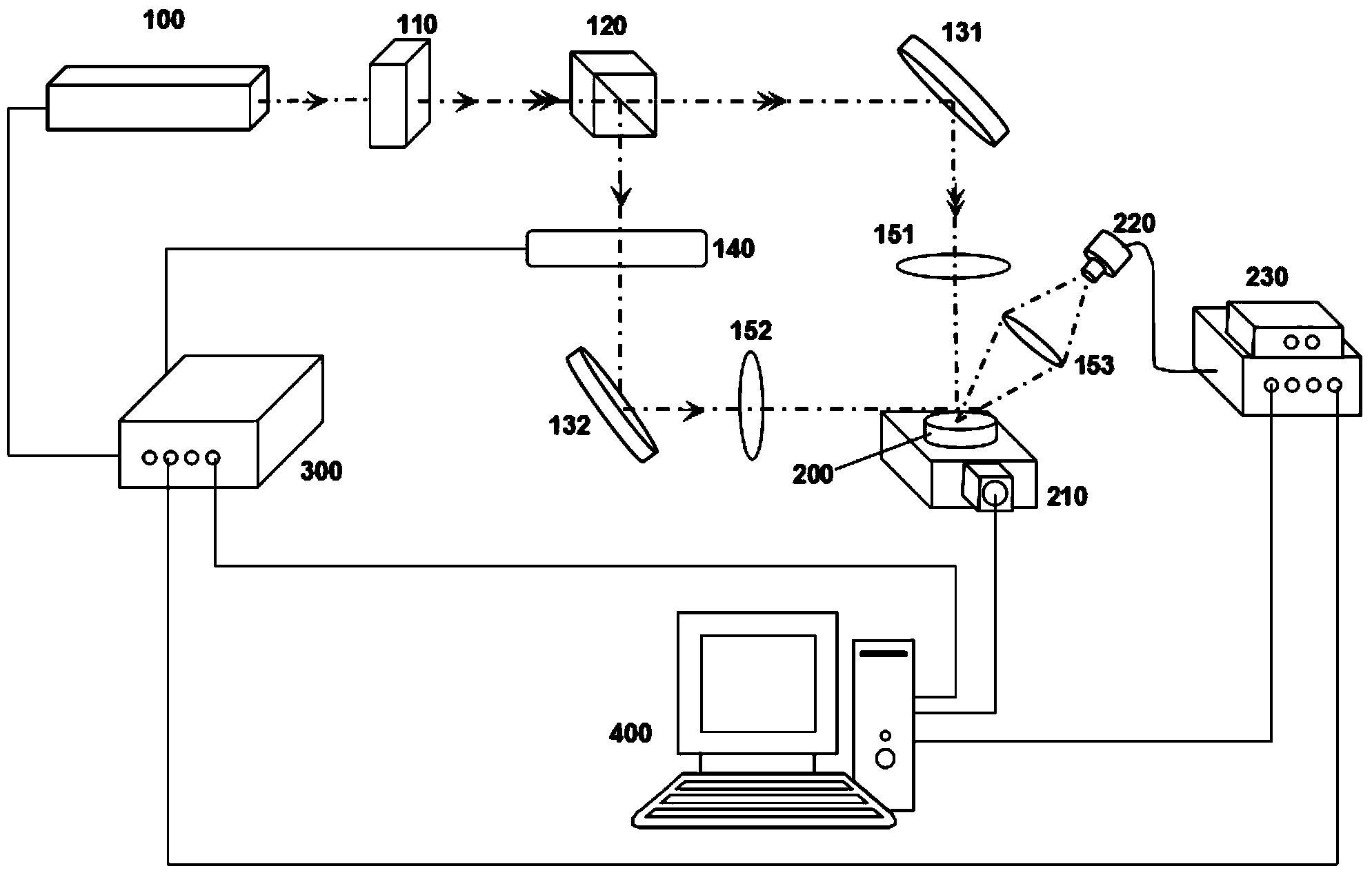

InactiveCN103529000AHigh detection sensitivitySimple structureAnalysis by material excitationMeasurement deviceSpectrograph

The invention discloses a single-light-source dual-wavelength LIBS (laser-induced breakdown spectroscopy) measurement device and method. The device mainly comprises a pulsed laser device, a frequency multiplying crystal, a light splitter, a first total reflector, a second total reflector, a light shutter, a spectrograph and a synchronous delay controller, wherein laser generated by the pulsed laser device passes through the frequency multiplying crystal, and then is divided into fundamental frequency light and frequency multiplying light, and is irradiated to the light splitter; the frequency multiplying light is reflected by the first total reflector, and is vertically irradiated to the surface of a to-be-detected sample; the fundamental frequency light passes through the light shutter, then is reflected by the second total reflector, and then is irradiated above the surface of the to-be-detected sample by 1-5mm in parallel; spectrum signals generated by a plasma stimulated from the to-be-detected sample are converged to an optical fiber collecting head, and are transmitted to the spectrograph. The single-light-source dual-wavelength LIBS measurement device provided by the invention has the advantages of simple structure, compact volume and low price while achieving dual-pulse LIBS high detection sensitivity, and can be widely applied to the technical field of laser diagnosis and spectrum analysis.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

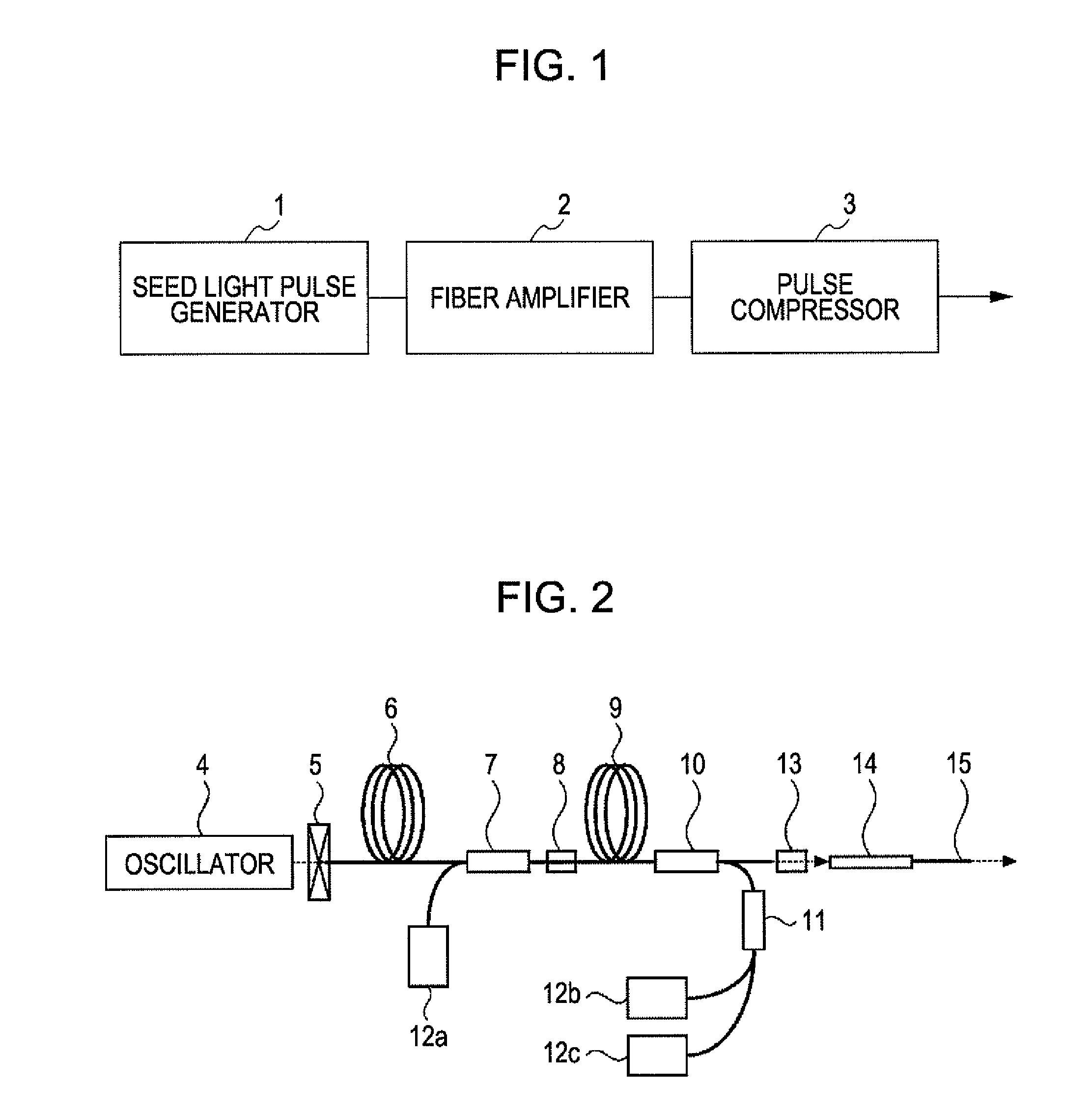

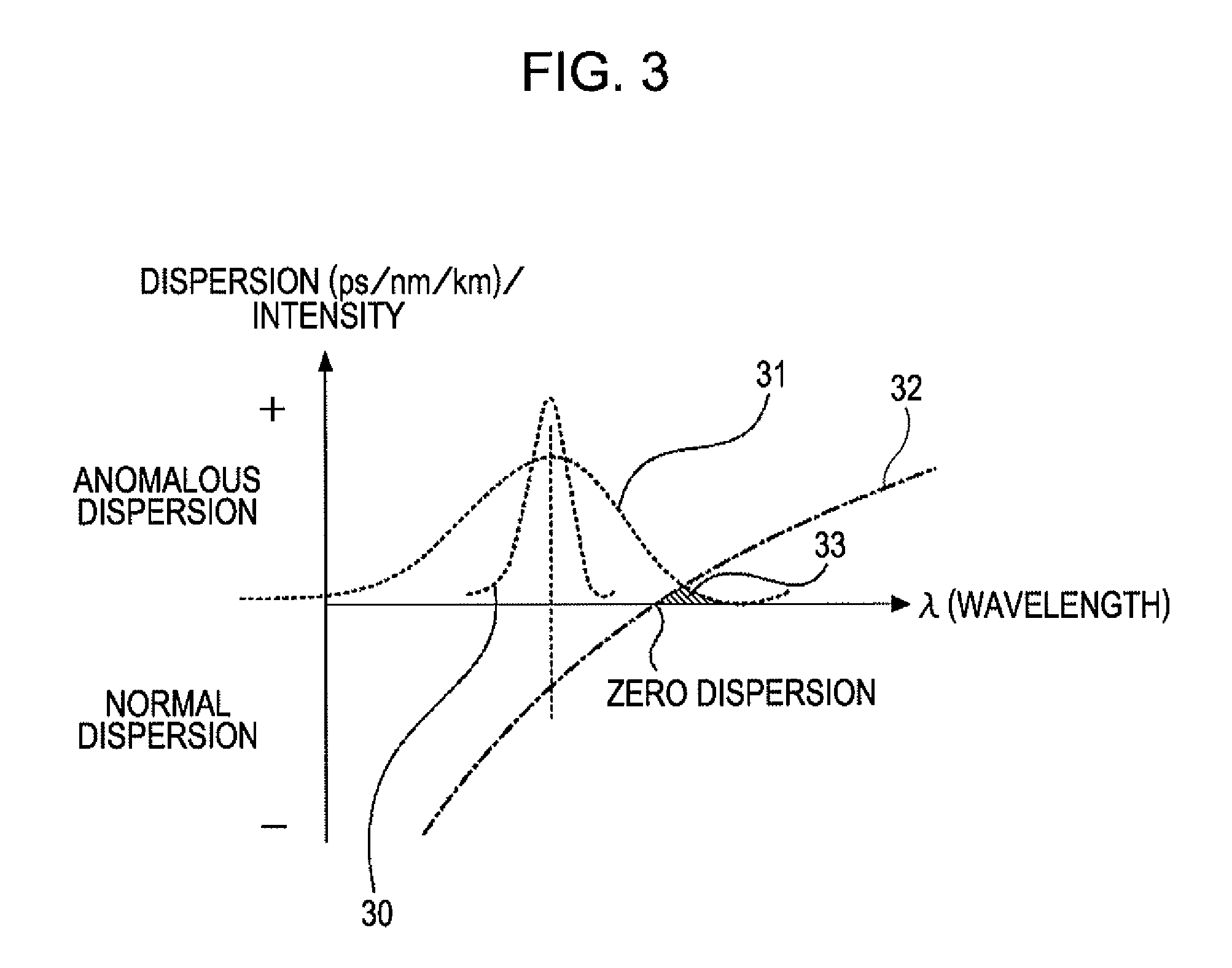

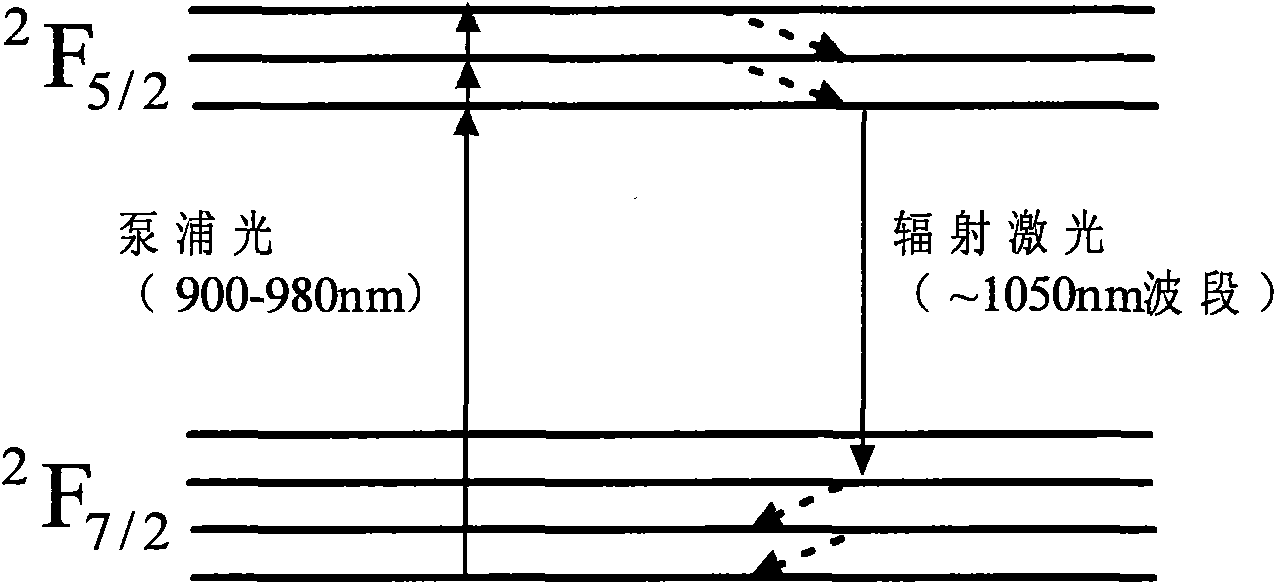

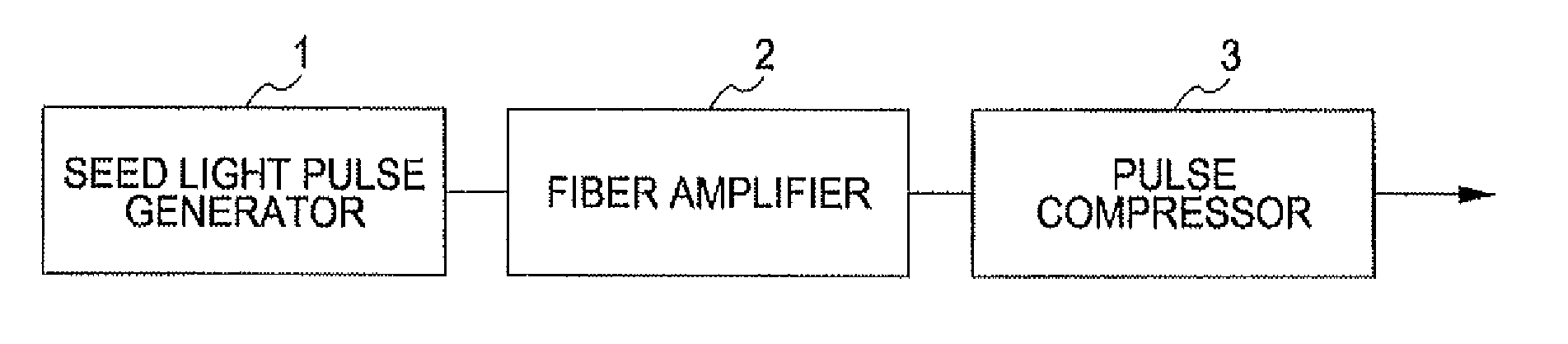

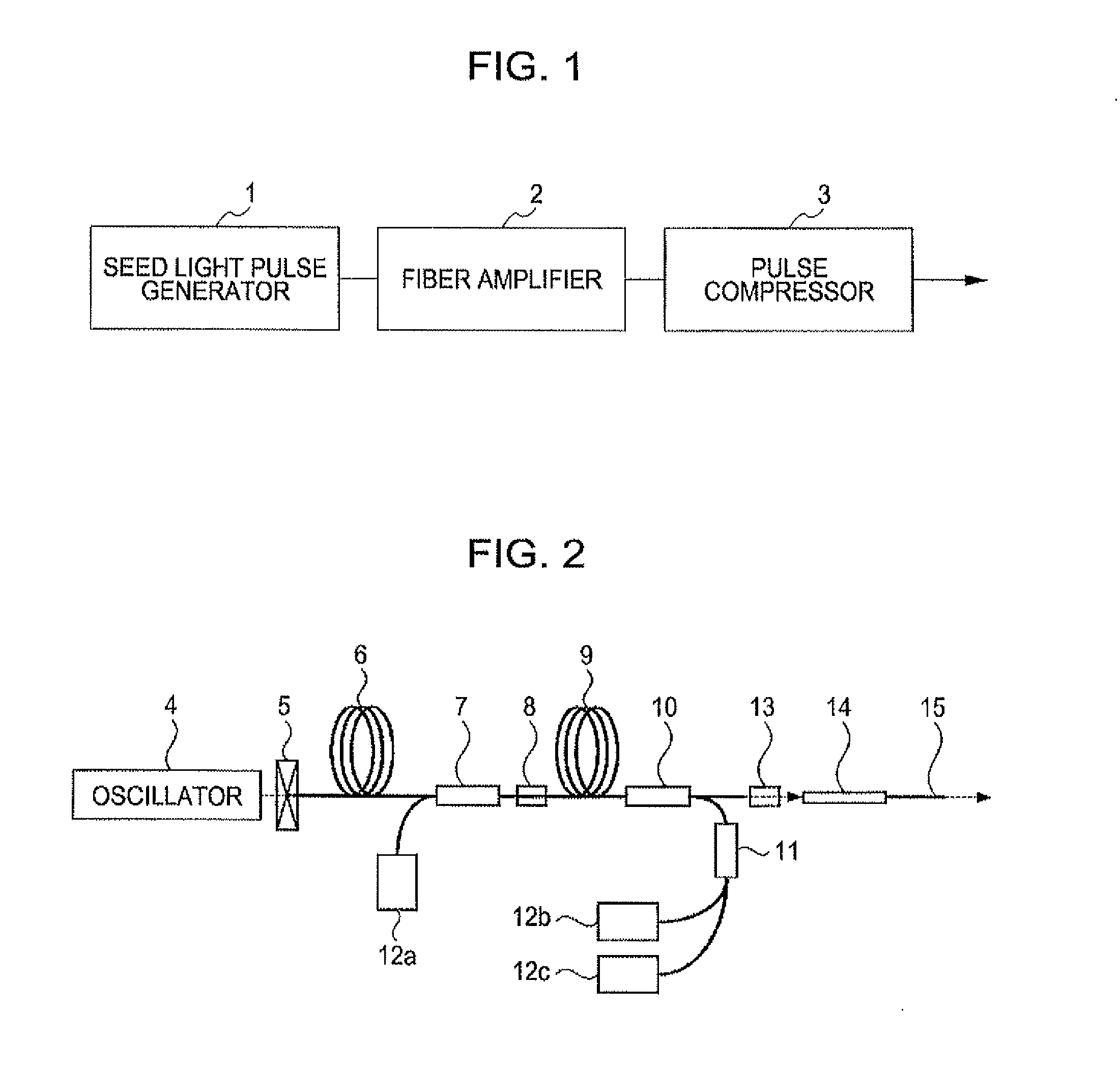

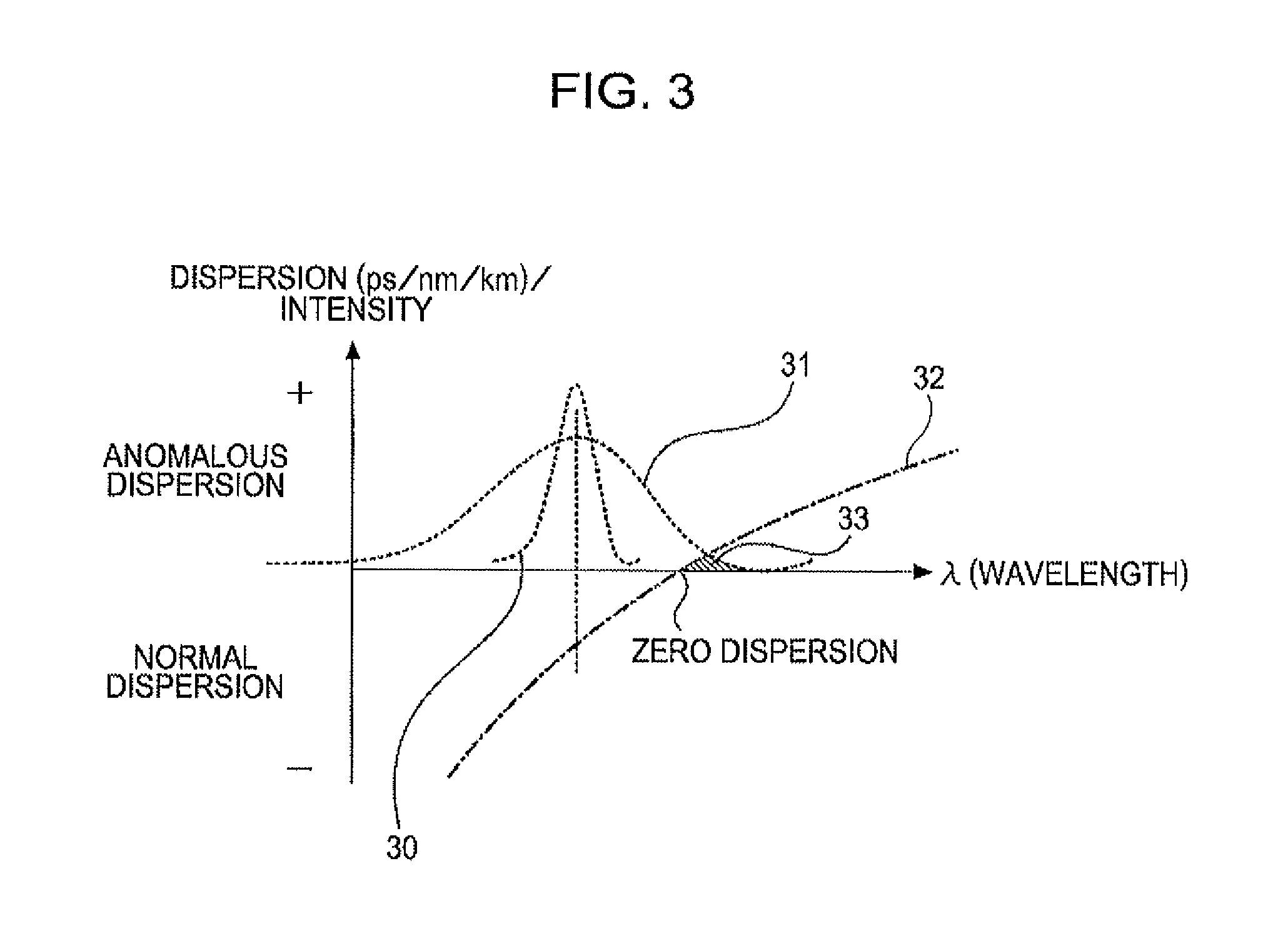

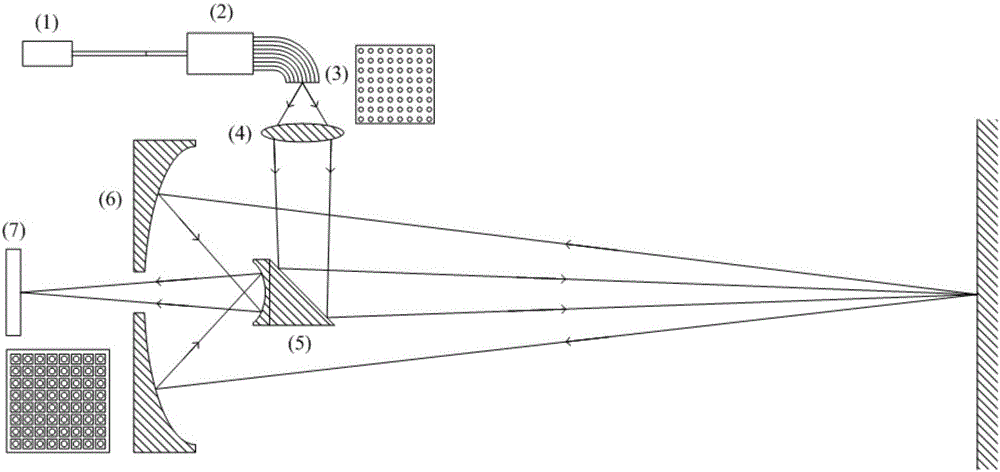

Pulse laser apparatus, terahertz measuring apparatus, and terahertz tomographic apparatus

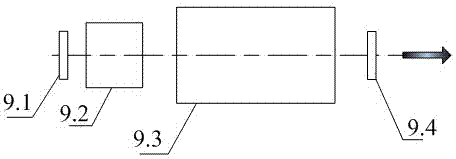

InactiveUS20090213880A1Low generationLaser using scattering effectsSolid masersFiberZero-dispersion wavelength

A pulse laser apparatus includes a laser configured to generate a pulse of a laser beam, a fiber amplifier, and a pulse compressor. The fiber amplifier includes a rare-earth doped fiber that exhibits normal dispersion at a wavelength of the laser beam generated from the laser. The pulse laser apparatus further includes a unit configured to give a loss to energy portions in a wavelength region corresponding to a zero-dispersion wavelength of the rare-earth doped fiber and / or a wavelength region longer than the zero-dispersion wavelength within a wavelength spectrum of the laser beam having been chirped in the fiber amplifier.

Owner:CANON KK

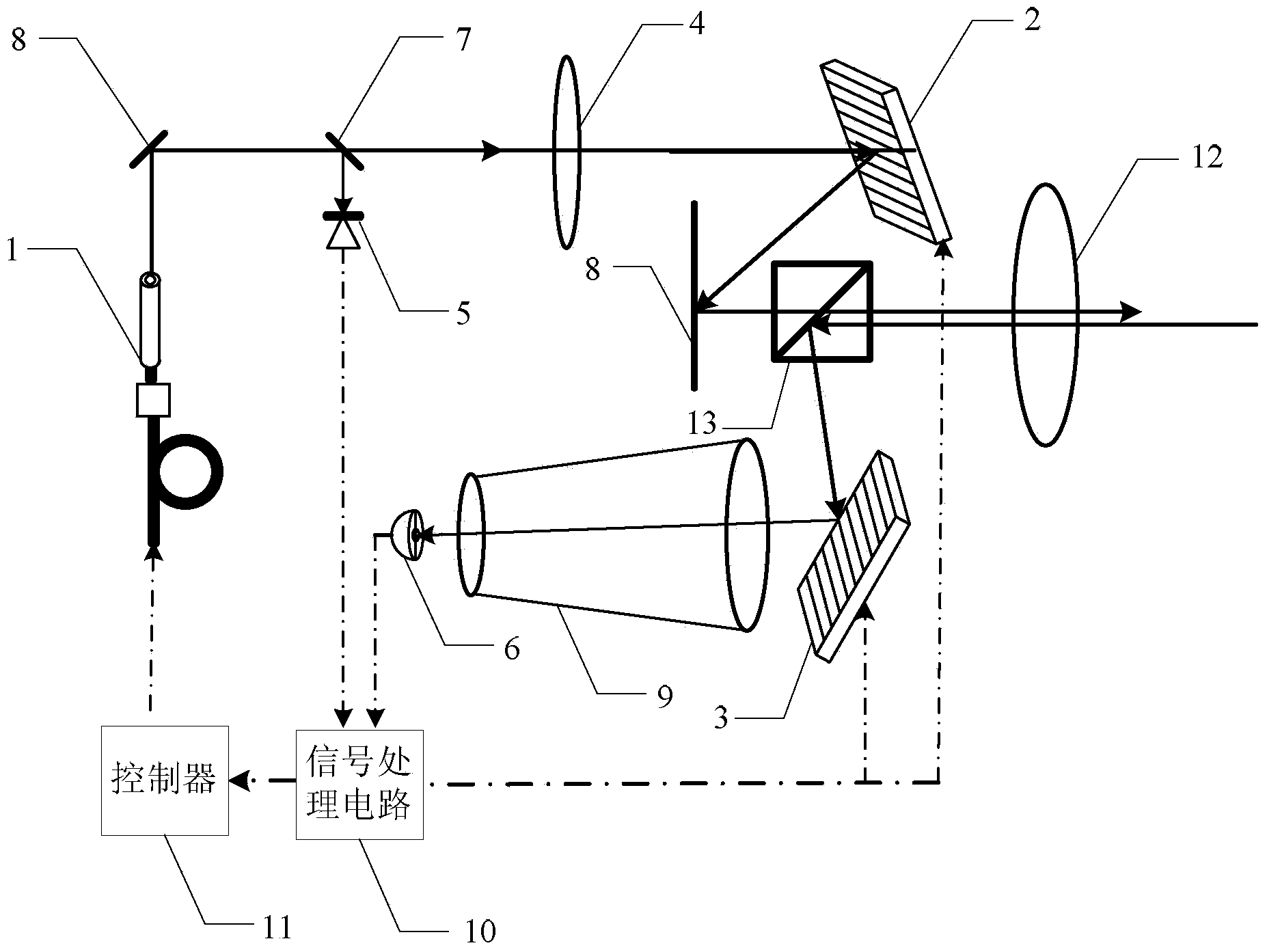

Double-electric-control scanning laser phased array radar

InactiveCN103645470AEliminate distractionsReduce false alarmsElectromagnetic wave reradiationBeam splitterSignal processing circuits

A double-electric-control scanning laser phased array radar relates to laser phased array radars and is used for solving the problem of signal receiving interference due to large unit dimension and large amount of sidelobe of emitted laser beams of existing phase array antennas. According to the double-electric-control scanning laser phased array radar, pulse laser emitted by a pulse laser device is emitted to an optical splitter through a reflector, reflected light is emitted into a detector PIN, transmission light is emitted into a polarizer and then to a two-dimensional liquid crystal phase modulator, the reflected light is emitted into a beam splitter through the reflector, transmission light is emitted to a transmitting / receiving optical element to be emitted off, echo signals are transmitted to the beam splitter through the transmitting / receiving optical element, reflected light is emitted to a two-dimensional micromirror array and then to a telescope, transmission light is emitted to a detector APD (avalanche photodiode), the detector PIN and the detector APD convert light signals into electric signals for outputting to a signal processing circuit, and a controller controls the two-dimension liquid crystal phase regulator, the two-dimensional micromirror array and the pulse laser device. The double-electric-control scanning laser phased array radar is applicable to laser radars tracking multiple high-speed motion targets.

Owner:HARBIN INST OF TECH

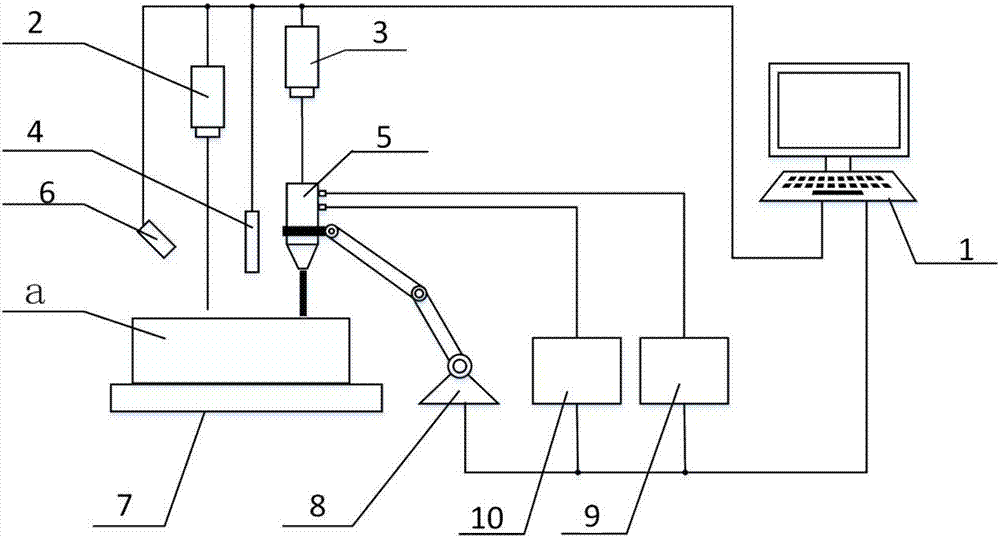

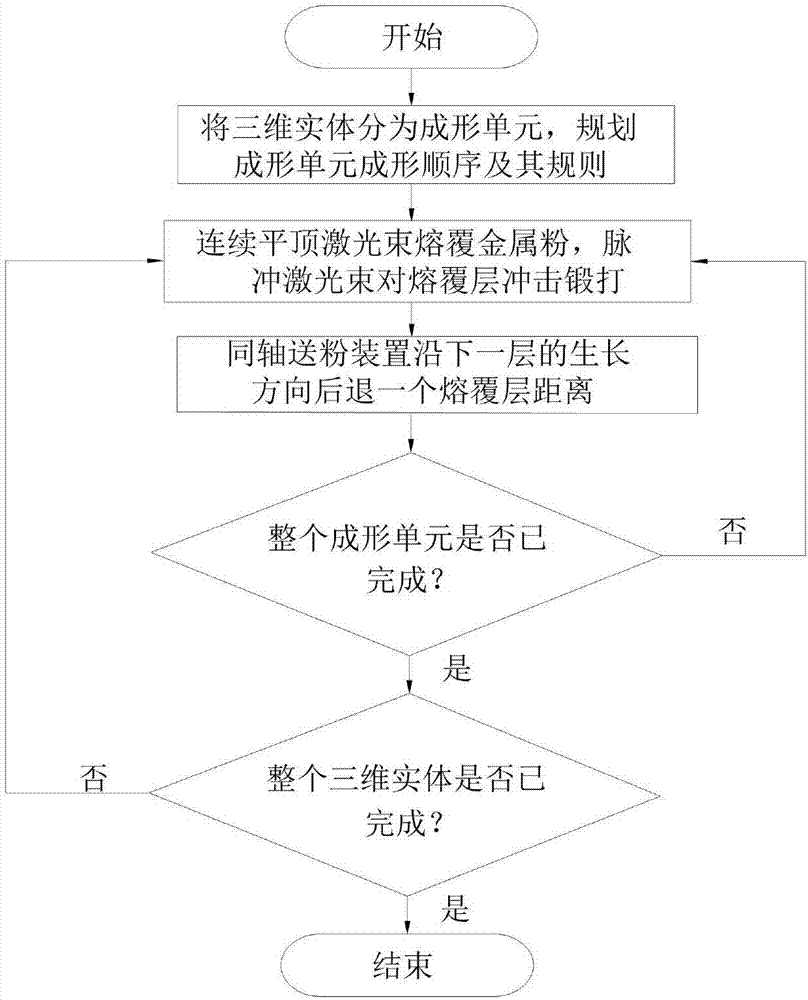

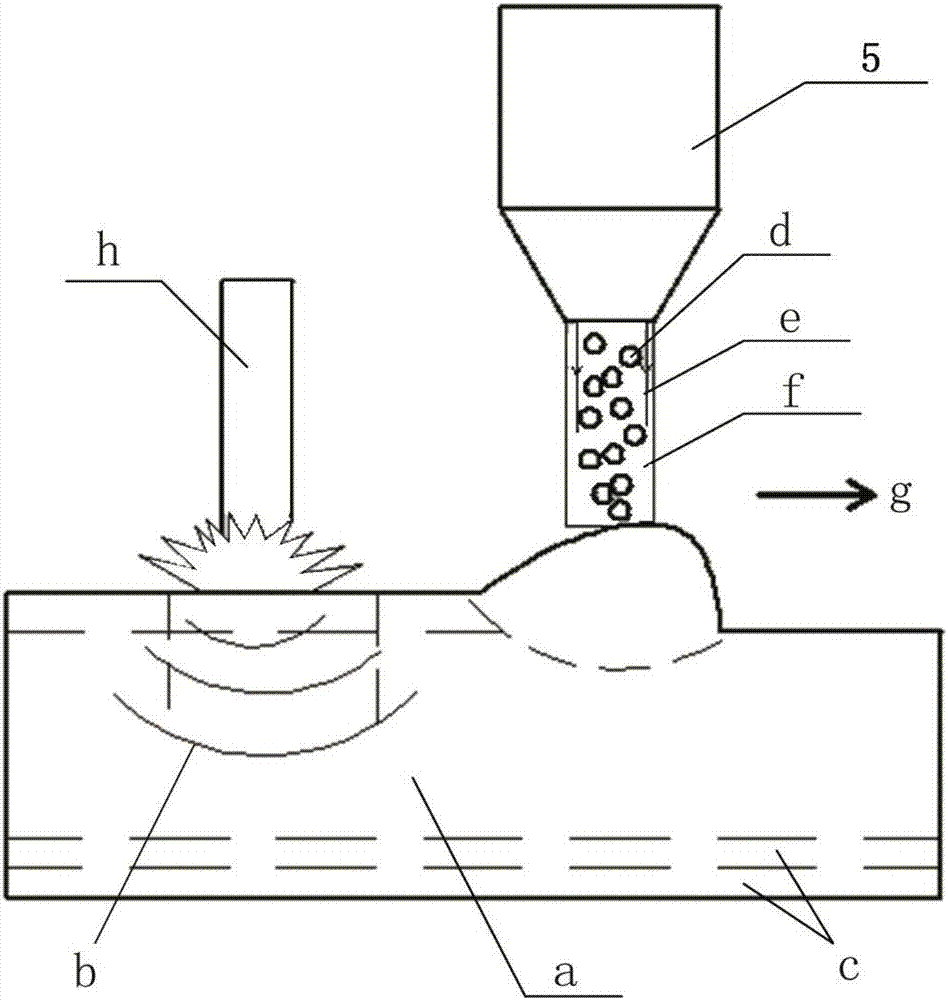

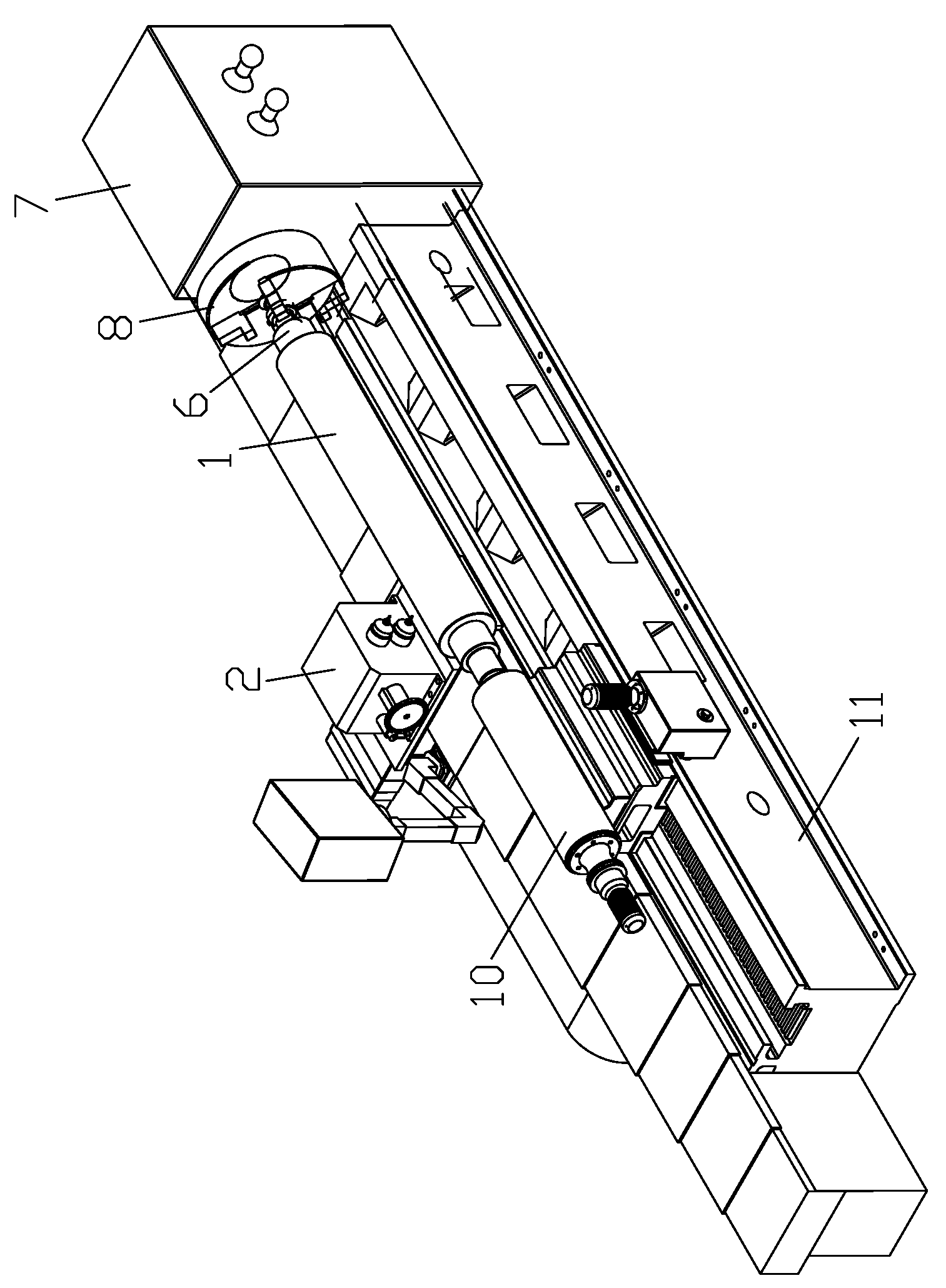

Inside-laser coaxial powder feeding laser impacting and forging composite machining forming device and method

ActiveCN107262713ASolve undermeltSolve the problem of impenetrabilityAdditive manufacturing apparatusIncreasing energy efficiencyOptoelectronicsInductor

The invention relates to an inside-laser coaxial powder feeding laser impacting and forging composite machining forming device and method. The device comprises a master controller, a pulse laser device, a continuous laser device, a temperature inductor, a coaxial powder feeding device, a visual tracking system, a workbench, a mechanical arm, a metal powder container and a gas container. The pulse laser device, the continuous laser device, the temperature inductor and the visual tracking system are all arranged above the workbench. The mechanical arm tightly clamps the coaxial powder feeding device, so that the coaxial powder feeding device is located between the continuous laser device and the workbench, and is coaxial with the continuous laser device. The coaxial powder feeding device communicates with the metal powder container and the gas container. The pulse laser device, the continuous laser device, the temperature inductor, the visual tracking system, the mechanical arm, the metal powder container and the gas container are all connected with the master controller. The inside-laser coaxial powder feeding laser impacting and forging composite machining forming device and method can solve the problems of insufficient fusion and incomplete fusion of the Gaussian light spot edges, inner defects of gas holes, incomplete fusion, cracks and shrinkage are effectively eliminated, and the inner stress state of a formed part is greatly improved.

Owner:GUANGDONG UNIV OF TECH

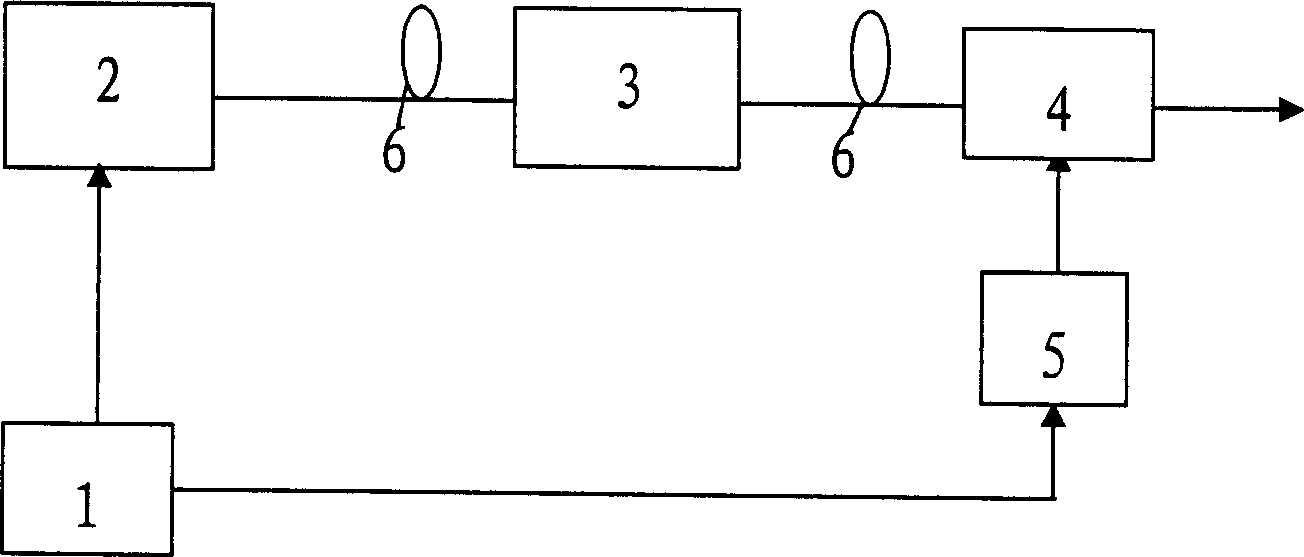

Method and device for producing true random numbers

InactiveCN1780145AQuality improvementImprove anti-interference abilityRandom number generatorsSecuring communicationAttenuation coefficientOptical attenuator

A method for generating true random number includes such steps as controlling laser device by signal generator to generate laser pulses, attenuating them by adjustable light attenuator, and regulating the attenuation coefficient of said attenuator to make that 10 pulses contain a photon and the interval between photons is randomly distributed. Its system is composed of signal generator, pulse laser device, adjustable light attenuator, single photon detector, time-amplitude converter, optical fiber, signal delay unit and multi-channel analyzer.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

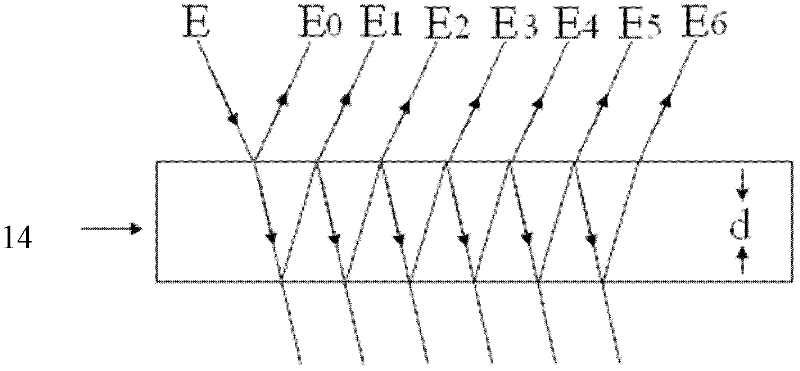

Filamentary cutting of brittle materials using a picosecond pulsed laser

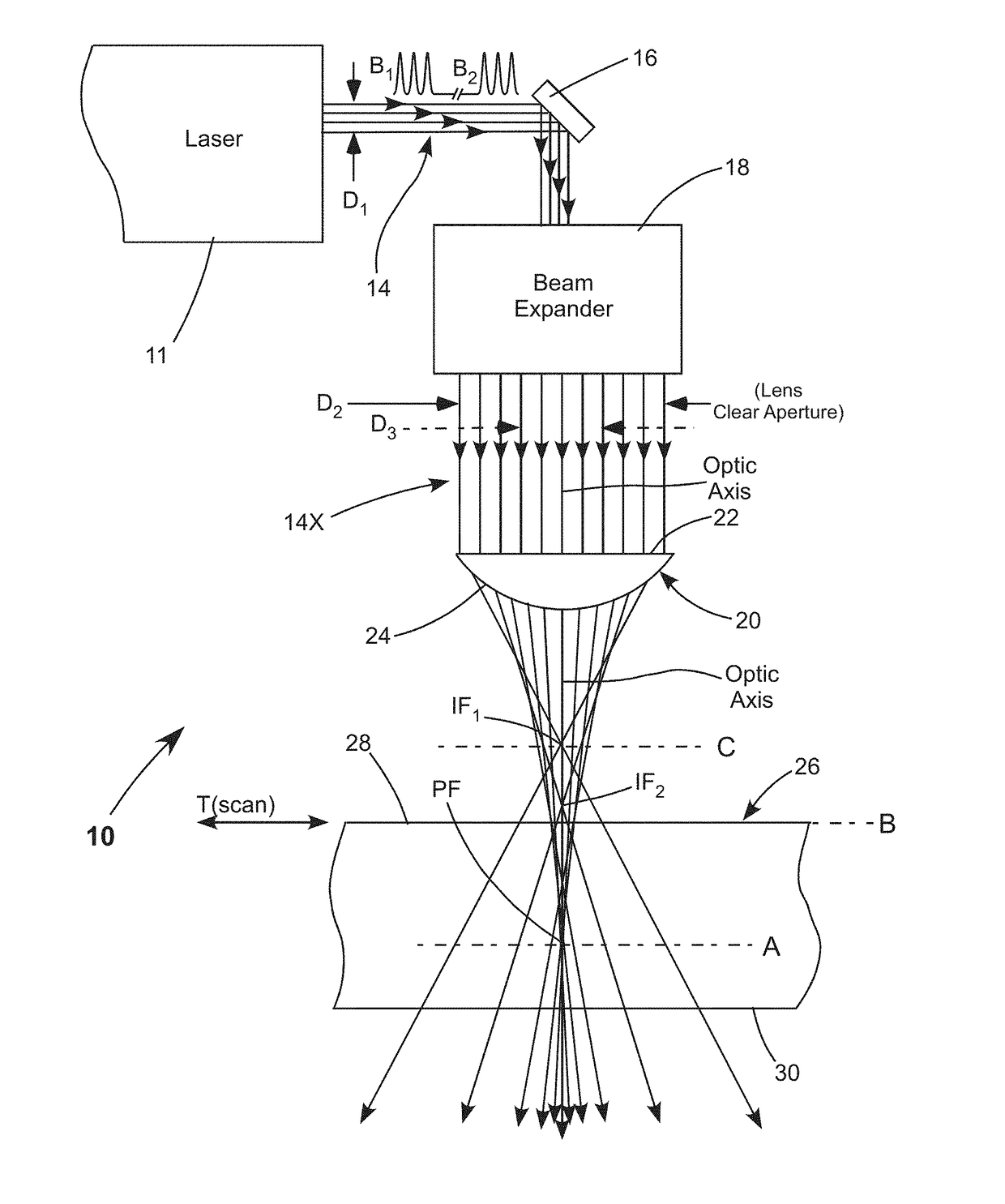

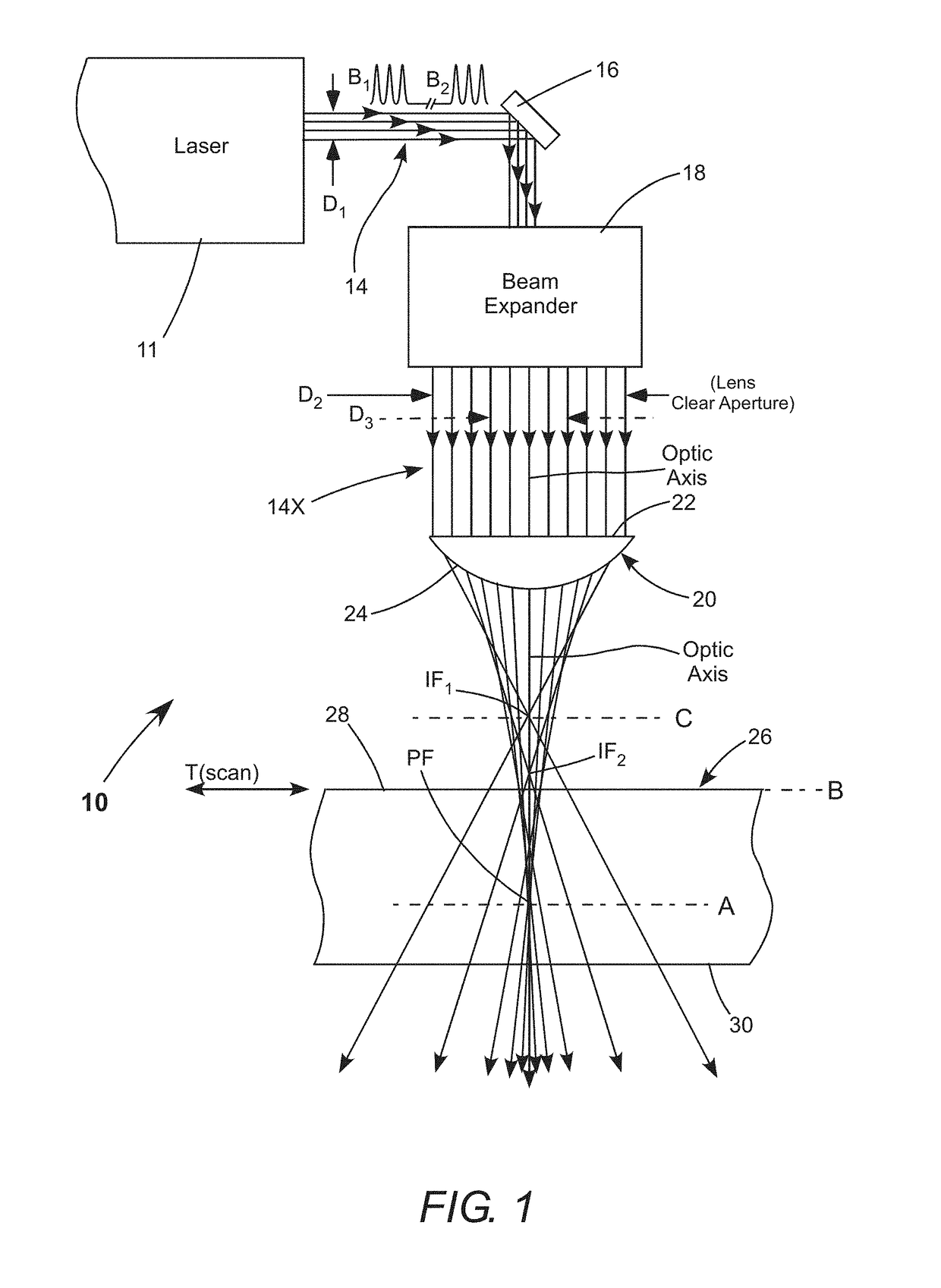

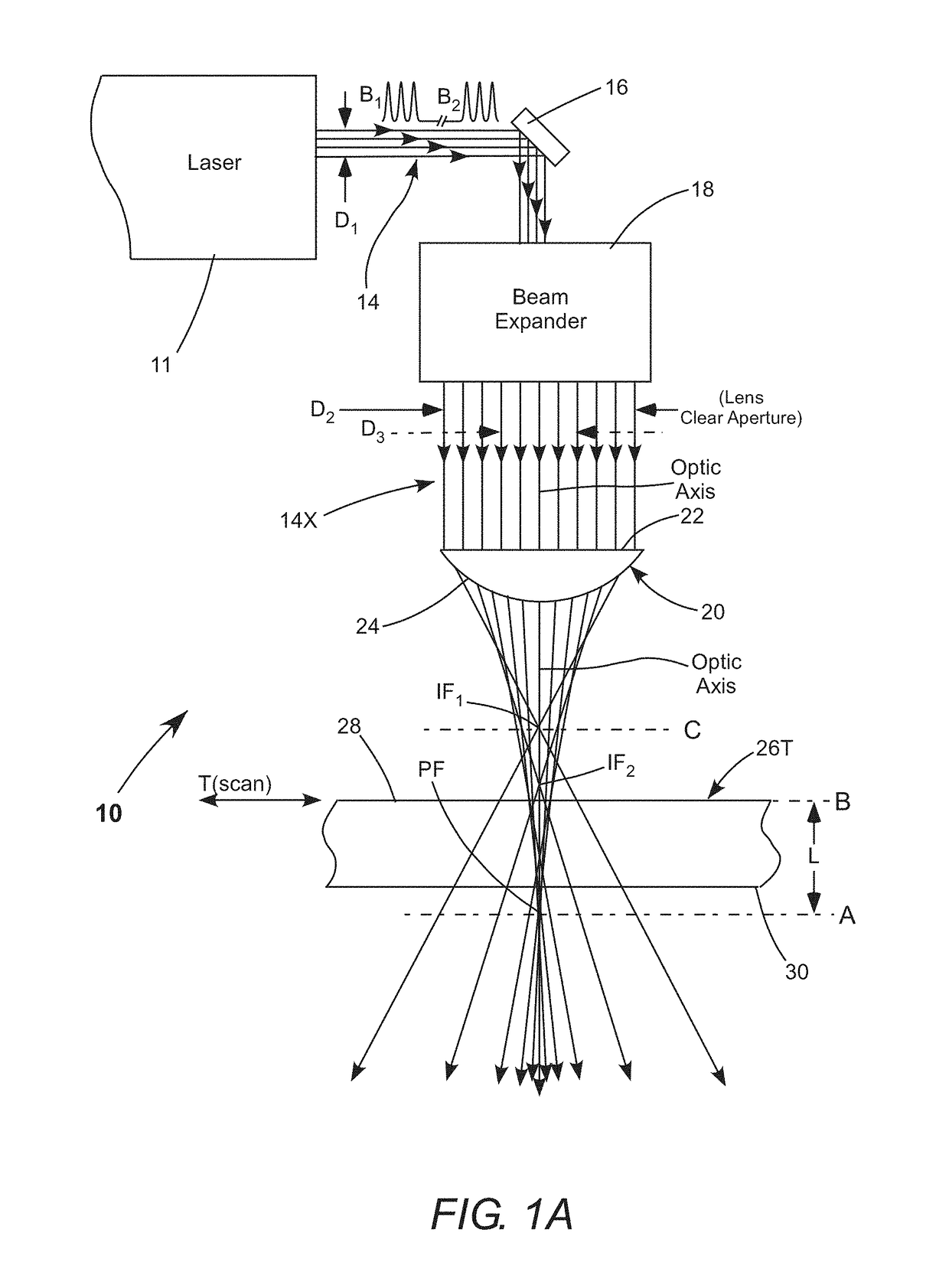

ActiveUS9873628B1Increase the diameterGlass severing apparatusLaser beam welding apparatusPicosecond pulsed laserLight beam

In pulsed-laser apparatus for filamentary cutting a glass-sheet, a laser-beam is focused by a plano-convex focusing lens into the glass-sheet through a first surface of the sheet to a point close to a second surface of the sheet. Pulses from the laser are delivered in repeated bursts. The laser-beam fills the clear-aperture of the lens such that uncorrected spherical aberration in the focusing lens causes radial modulation of the beam between the lens and the focus point. This provides that each burst of pulses generates a filament extending between the first and second surfaces of the sheet.

Owner:COHERENT KAISERSLAUTERN

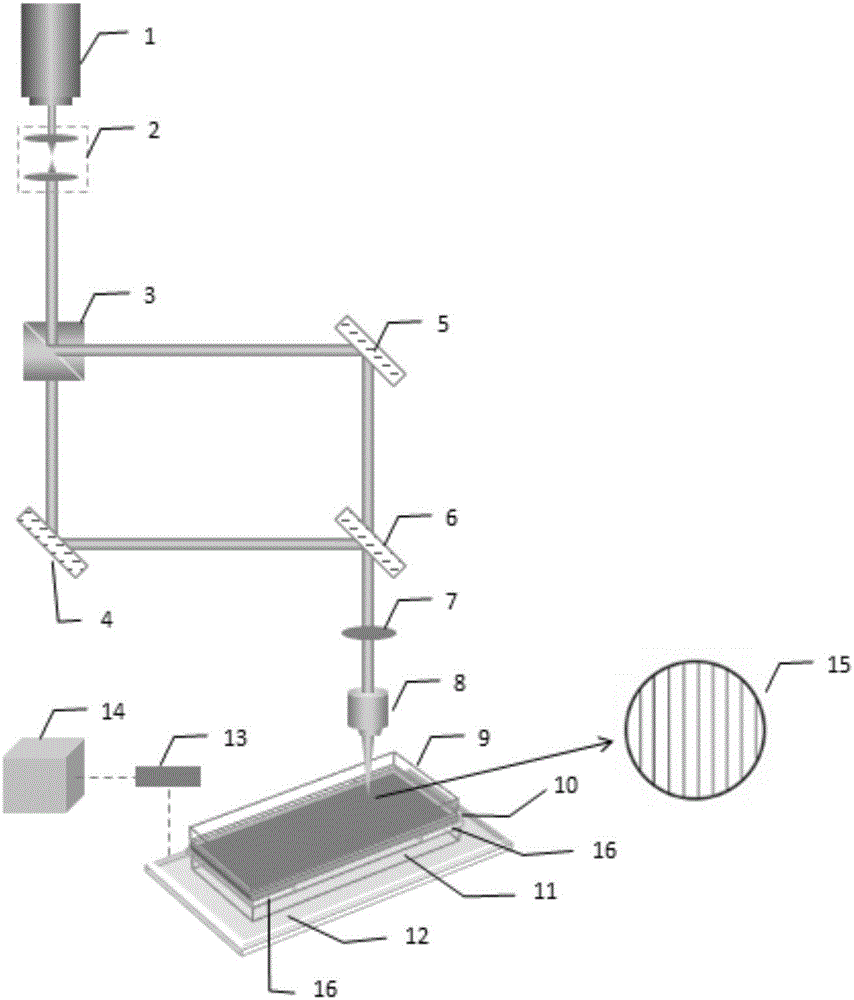

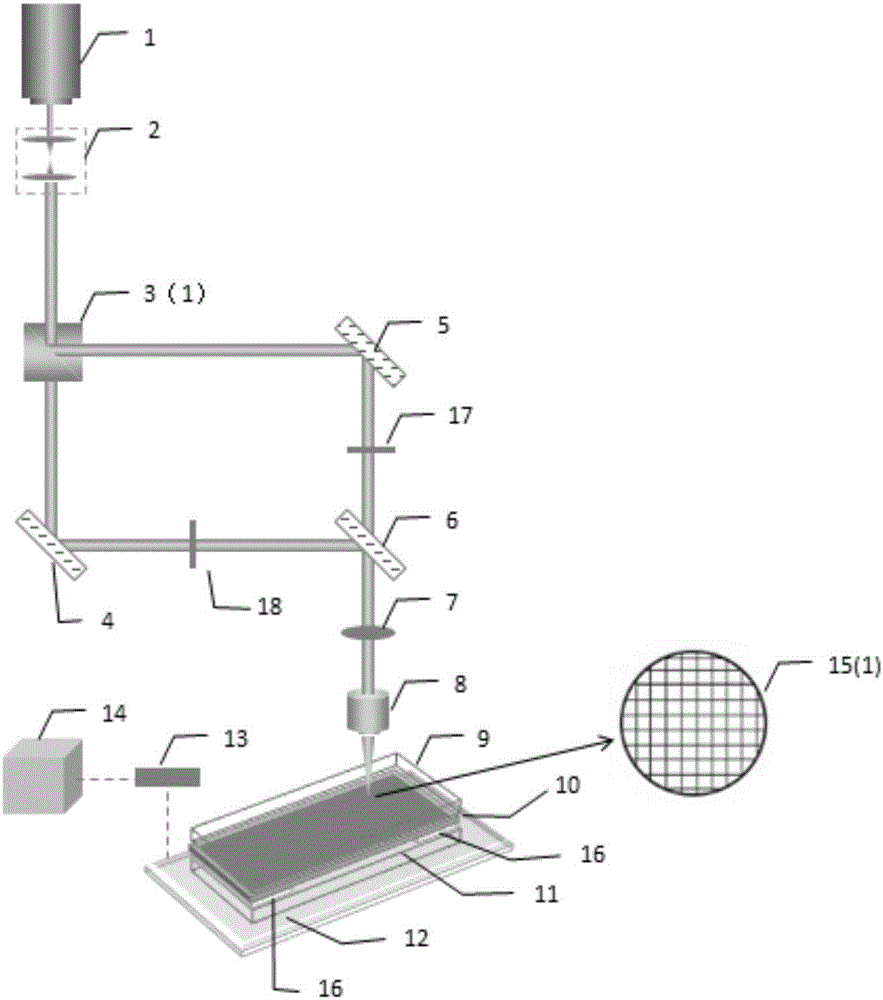

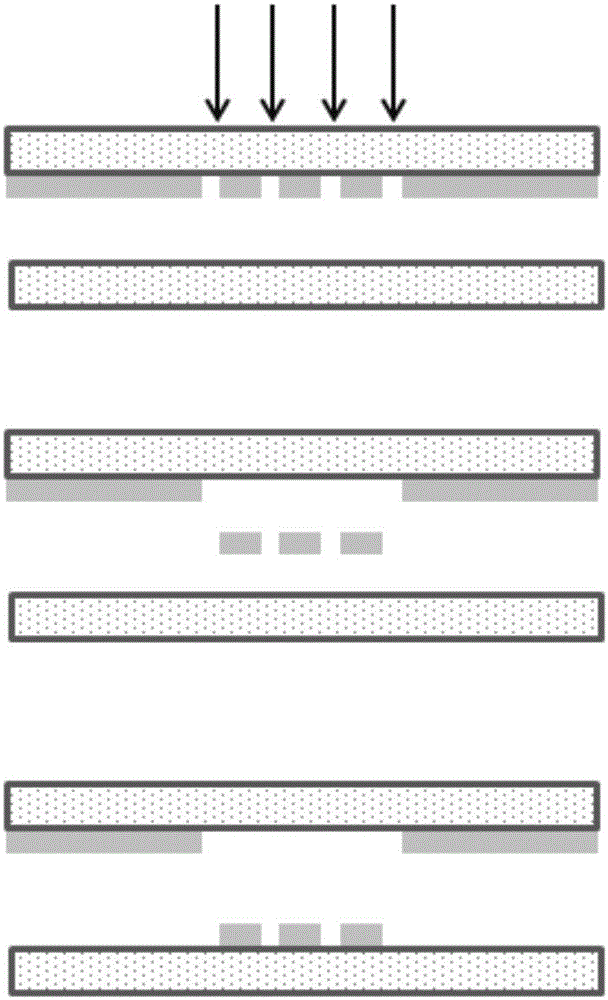

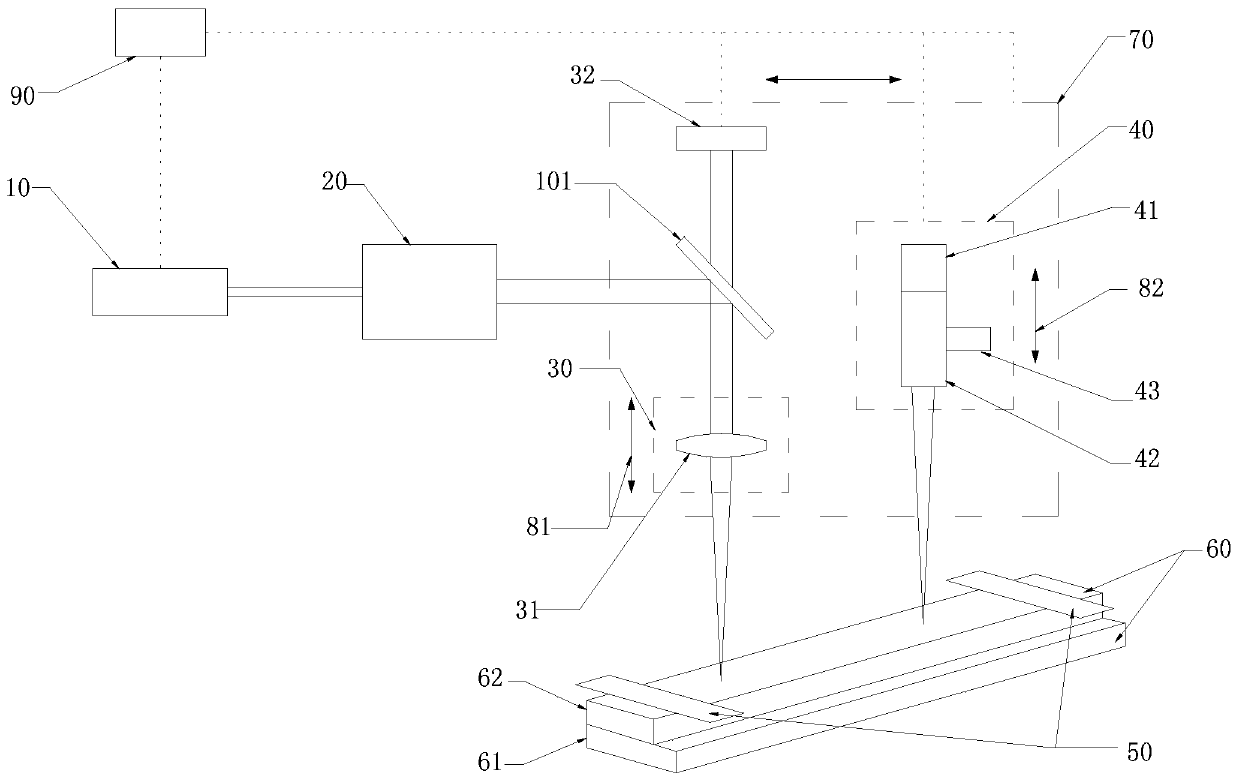

System and method for preparing patterned metal thin layer through pulse laser-induced forward transfer

ActiveCN106825915APrecise Control of Local MetastasisPrecise Control of DepositionLaser beam welding apparatusOptical elementsManufacturing cost reductionOptoelectronics

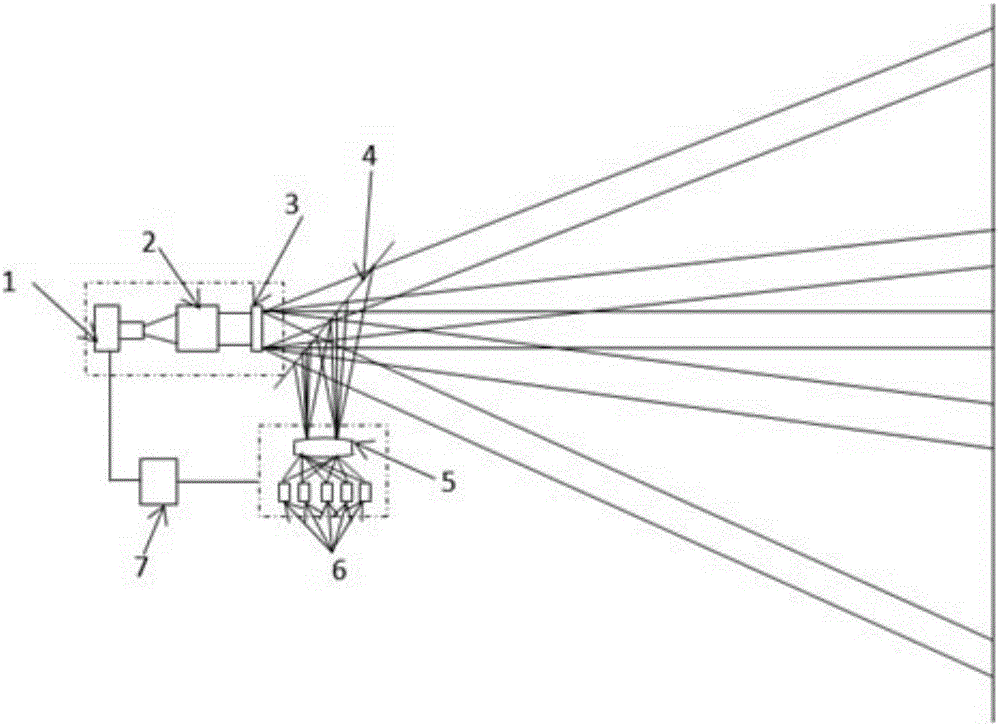

The invention discloses a system and method for preparing a patterned metal thin layer through pulse laser-induced forward transfer, and belongs to the technical field of laser application and printing electronics. The system comprises a laser light source, a light path adjusting system and a two-dimensional precise motion system, wherein the laser light source is connected with the light path adjusting system; the two-dimensional precise motion system is located below the light path adjusting system; the laser light source is a pulse laser device; the light path adjusting system comprises a collimating beam expander lens assembly and a light splitting element connected with the collimating beam expander lens assembly; the light splitting element is connected with two reflectors at 90 degrees separately; the two reflectors are connected with a beam combiner separately; the beam combiner is connected with an objective lens through a focusing lens; the two-dimensional precise motion system comprises an electric platform, a motion controller and a computer; the computer is connected with an electric platform through the motion controller; and the electric platform is used for putting an initial substrate and a receiving substrate. Fast, high-precision and large-format pattern transfer can be achieved, the manufacturing cost is greatly reduced and the manufacturing cycle is greatly shortened.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

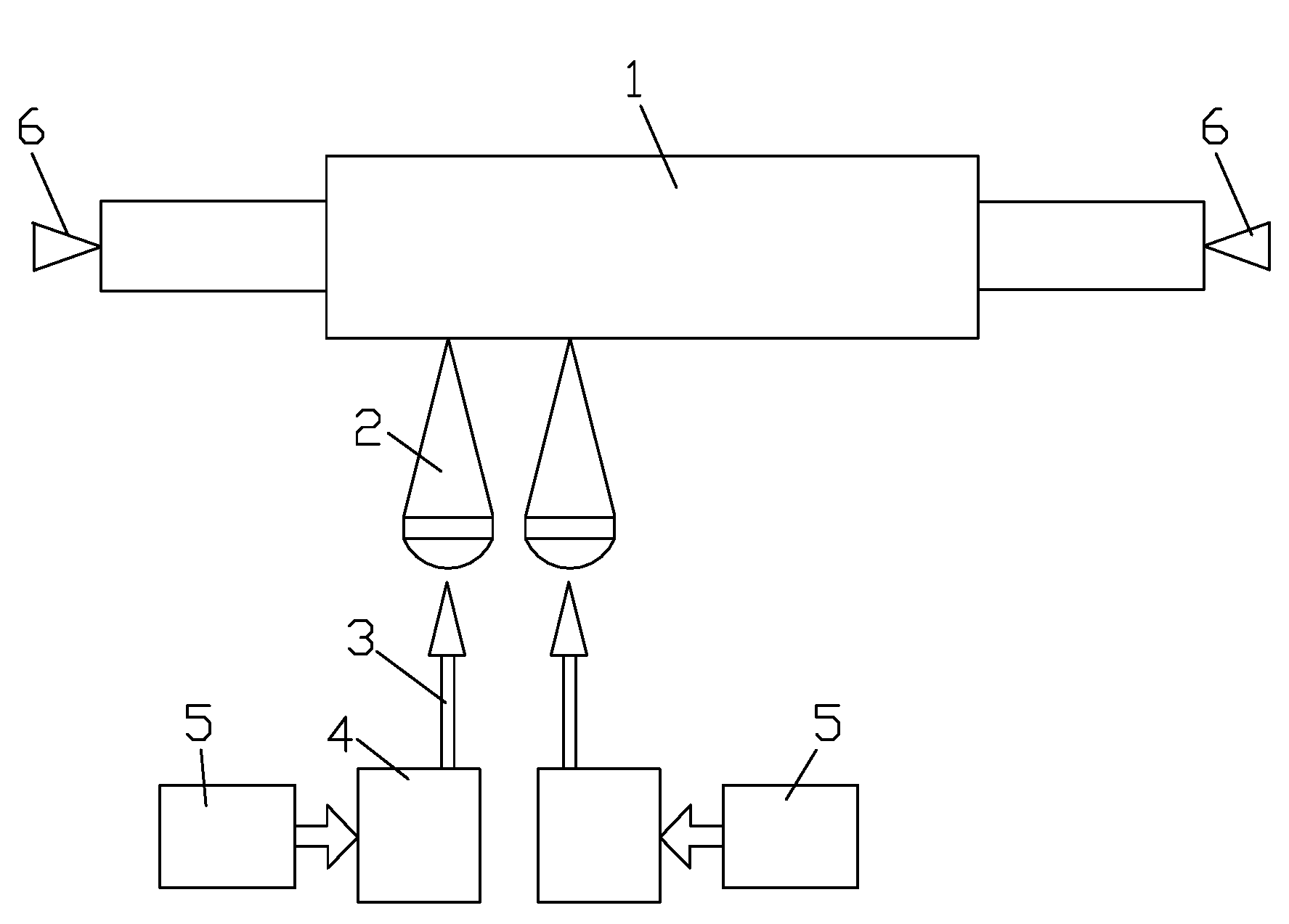

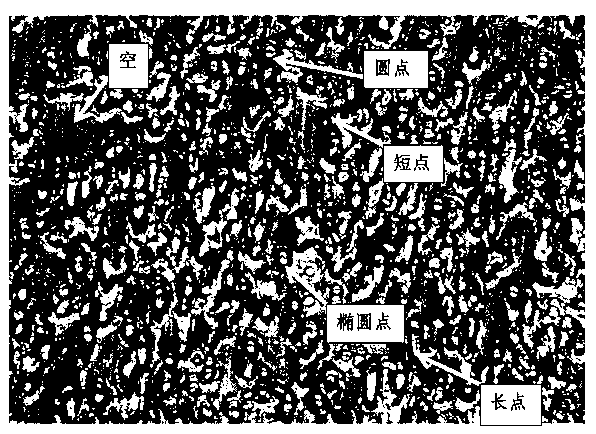

Method and device for processing multi-head laser disordered and textured roller surface

ActiveCN102699524AHigh hardnessIncrease the amount of steelLaser beam welding apparatusNumerical controlPulse beam

The invention relates to a method and a device for processing a multi-head laser disordered and textured roller surface. The method comprises the steps: controlling each pulse laser device to generate a plurality of disordered pulse laser beams by a plurality of random signal generators, and processing a plurality of spiral lines without an overlapped track on the roller surface after focusing, wherein the distance between two adjacent spiral lines is smaller than 150% of a diameter value of a laser speckle; a helical pitch of the spiral line is equal to a numerical value obtained from the distance between the adjacent spiral lines multiplied by quantity of the spiral lines, and the pulse laser device follows a random variable emitted by each random signal generator and changes the duty ratio and frequency of each laser pulse beam at random. The processing device comprises a numerical control roller machine tool, a plurality of lasers and a plurality of laser processing heads; and axial uniform movement are carried out by the the laser processing heads along a lateral bus of the roller. By the scheme, the roller which really accords with disordered requirements can be manufactured; the method for processing the roller surface by laser has the advantages of high disordered rough surface hardness and low production cost without pollution, and the steel quantity of the roller is greatly improved.

Owner:WUHAN HGLASER ENG CO LTD

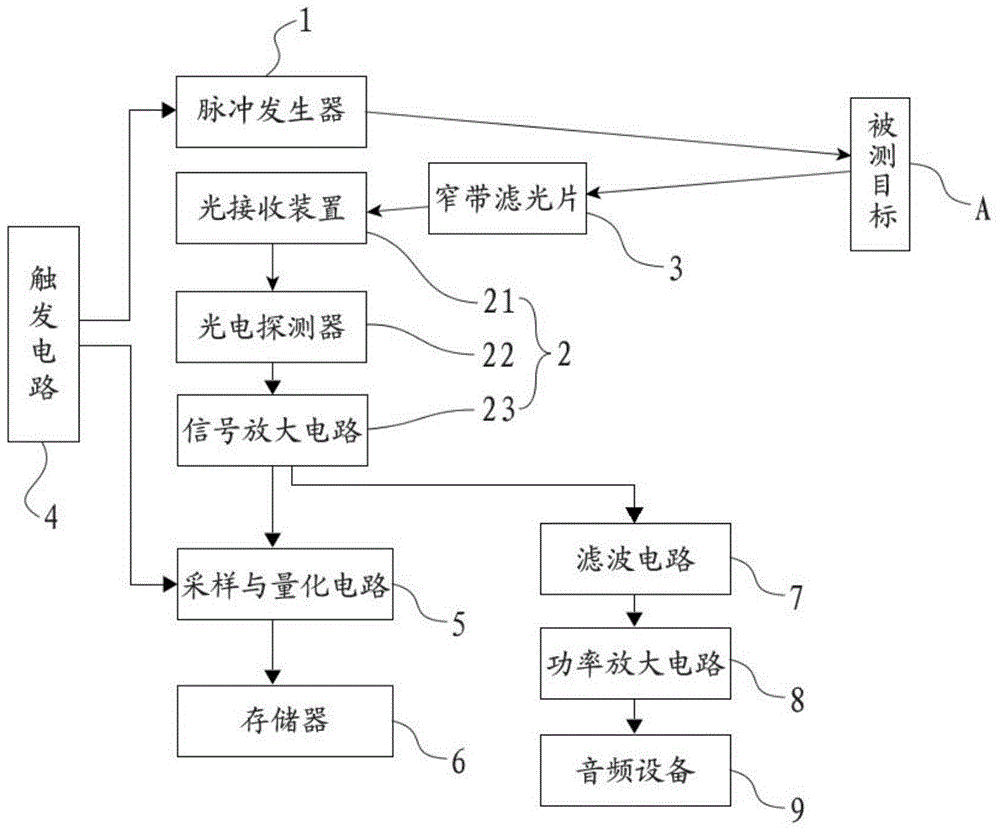

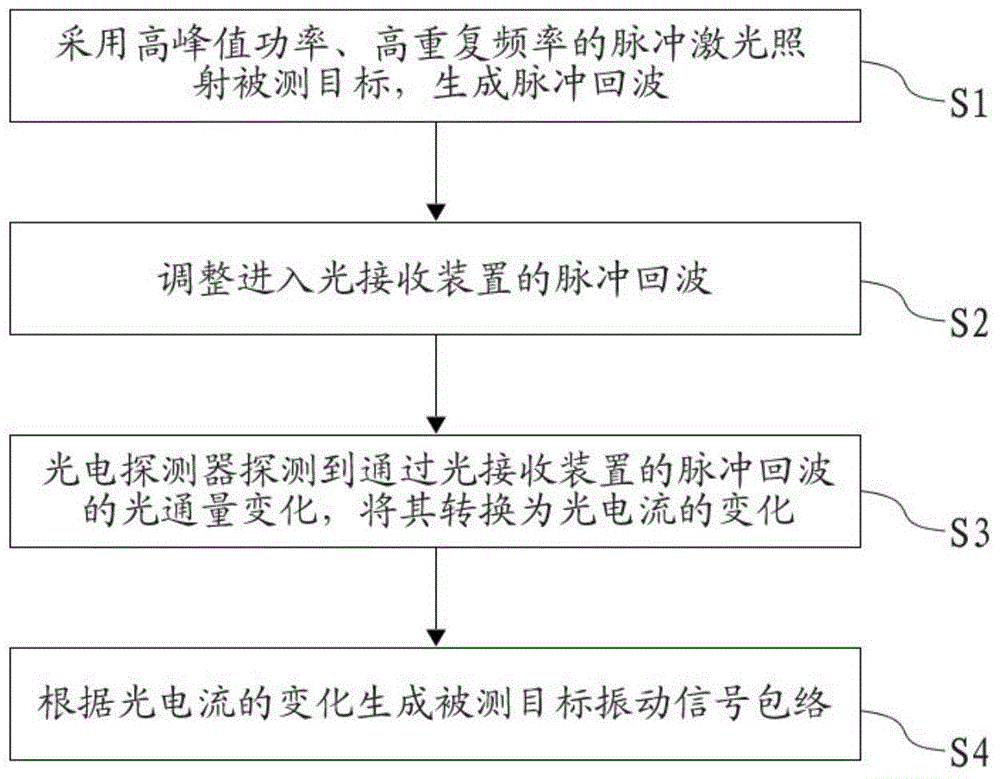

Micro vibration measuring system and measuring method based on long-distance pulse laser speckles

ActiveCN103983340AIncrease echo powerRealize micro-vibration measurementSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansDiffuse reflectionOptoelectronics

The invention discloses a micro vibration measuring system based on long-distance pulse laser speckles. The system comprises a pulse laser device and an optical detection unit, wherein the pulse laser device is used for sending pulse laser which is high in peak power and repetition frequency to illuminate a target to be measured; the optical detection unit is used for receiving the speckles, generated by diffuse reflection of the target to be measured, of the pulse laser. The pulse laser light source with high peak power and repetition frequency takes the place of a continuous wave laser light source, so that on the premise that measurement safety is guaranteed, namely average laser emission power is low, echo power fed back by the target to be measured is greatly improved, micro vibration measuring of the long-distance target can be achieved, and the method has very important actual application value in the fields of bridge and building health monitoring, security protection system, detection and antiterrorism, disaster rescue and the like.

Owner:XIAMEN UNIV

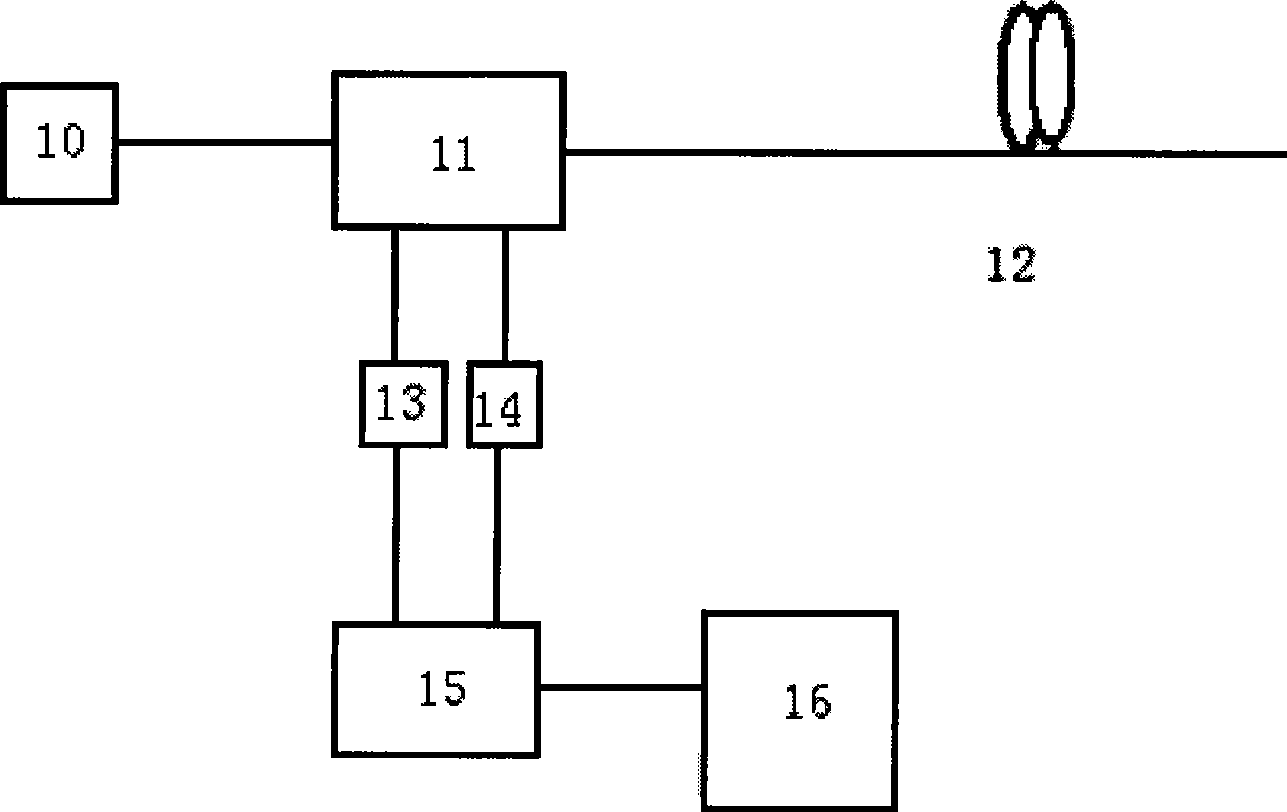

Distributed optical fiber Raman temperature measurement system

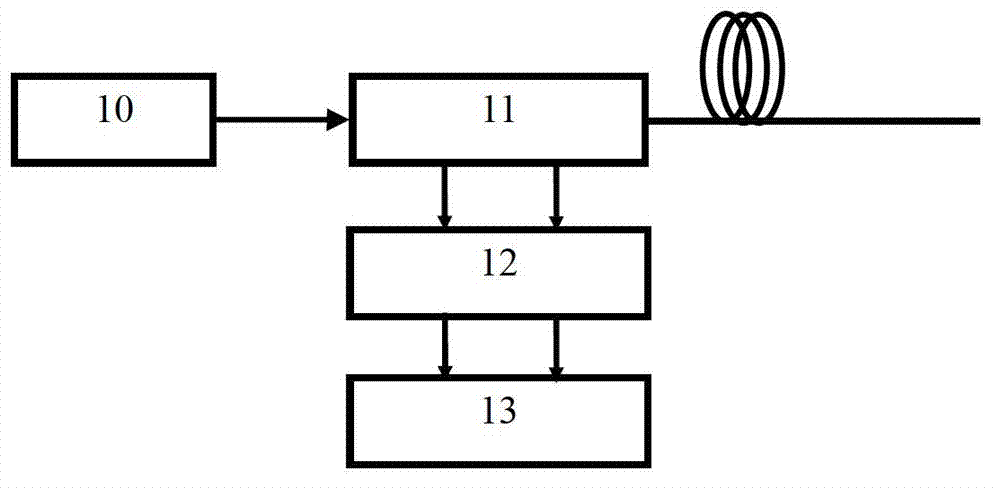

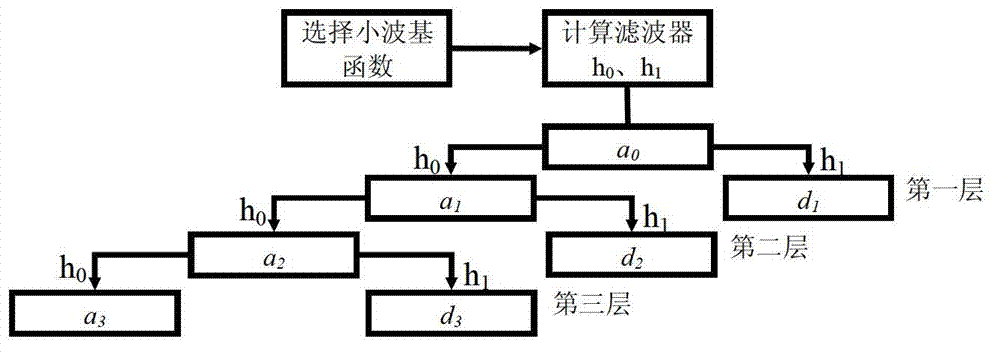

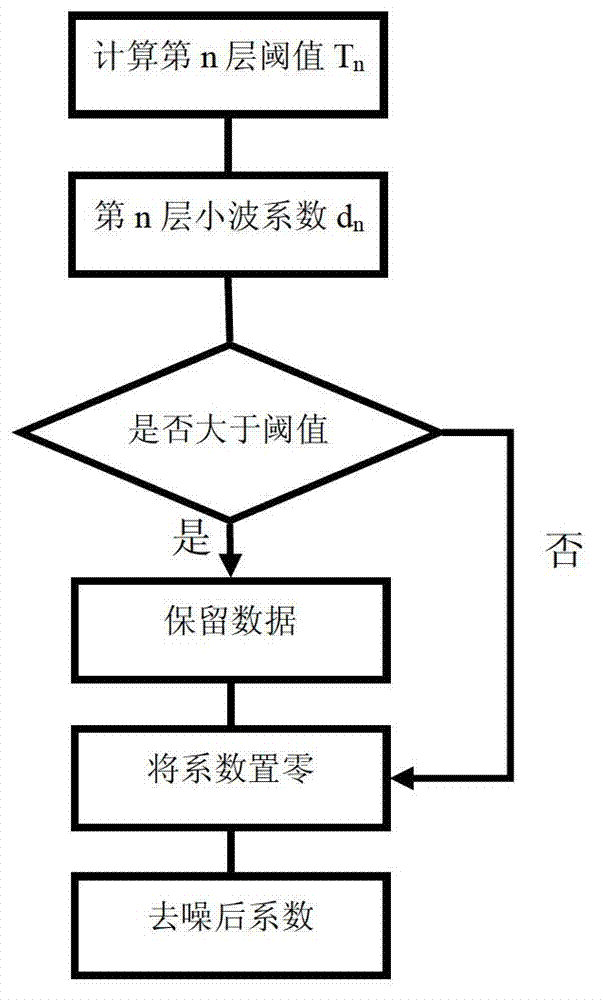

ActiveCN103115693ARealize wavelet denoisingProcessing speedThermometers using physical/chemical changesWavelet denoisingPulsed laser device

The invention relates to the field of distributed optical fiber temperature measurement systems, and discloses a distributed optical fiber Raman temperature measurement system. The system comprises a pulse laser device, a wavelength division multiplexer, a sensor optical fiber, a double-channel avalanche photodiode, and a digital signal processor (DSP). The whole optical fiber laser device emits pulse lasers, the pulse lasers enter into a to-be-tested sensor optical fiber after passing through the wavelength division multiplexer, the pulse lasers continuously generate backscattering inside the optical fiber in the spreading process, and then backscattering light returns back to the wavelength division multiplexer, after the backscattering light passes through the wavelength division multiplexer, Stokes scattering light and anti-Stokes Raman scattering light are respectively filtered out and enter the double-channel avalanche photodiode to be conducted photovoltaic conversion, and after an electrical signal of the double-channel avalanche photodiode is processes by the DSP, a temperature signal is obtained. The high-speed DSP is used for achieving wavelet denoising, and therefore processing speed is quick, and real time performance of temperature measurement is not influenced on the premise that precision is guaranteed.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

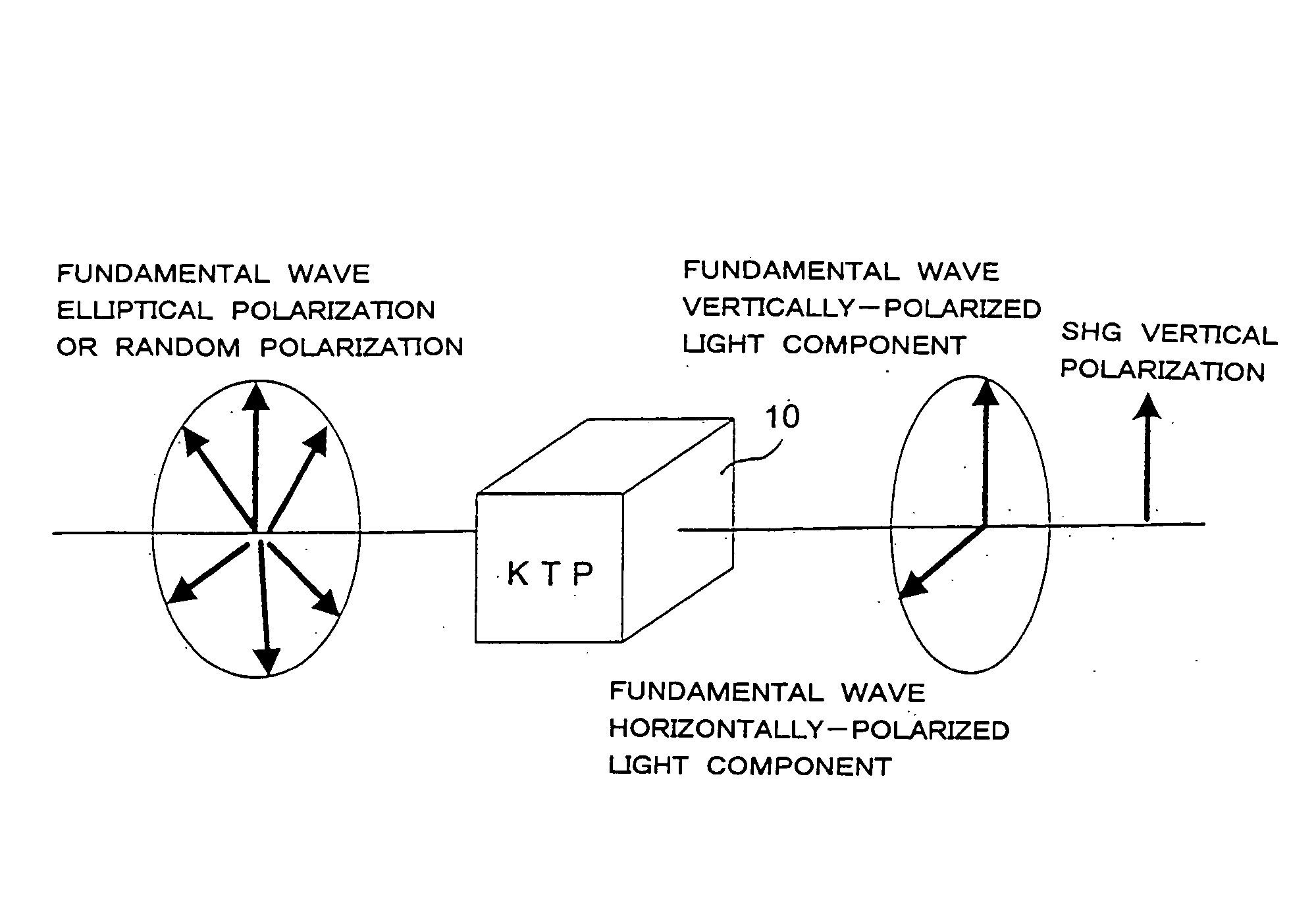

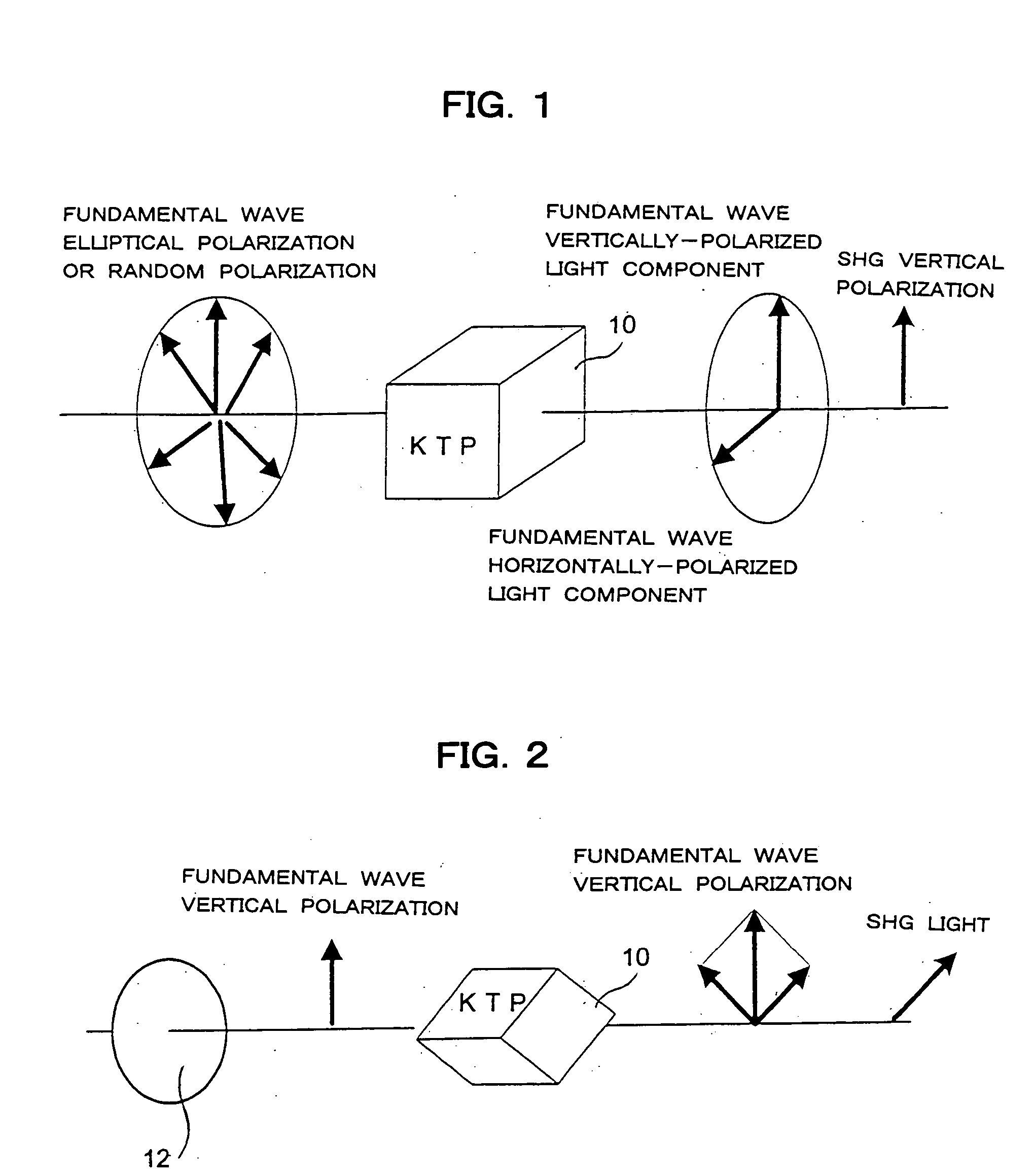

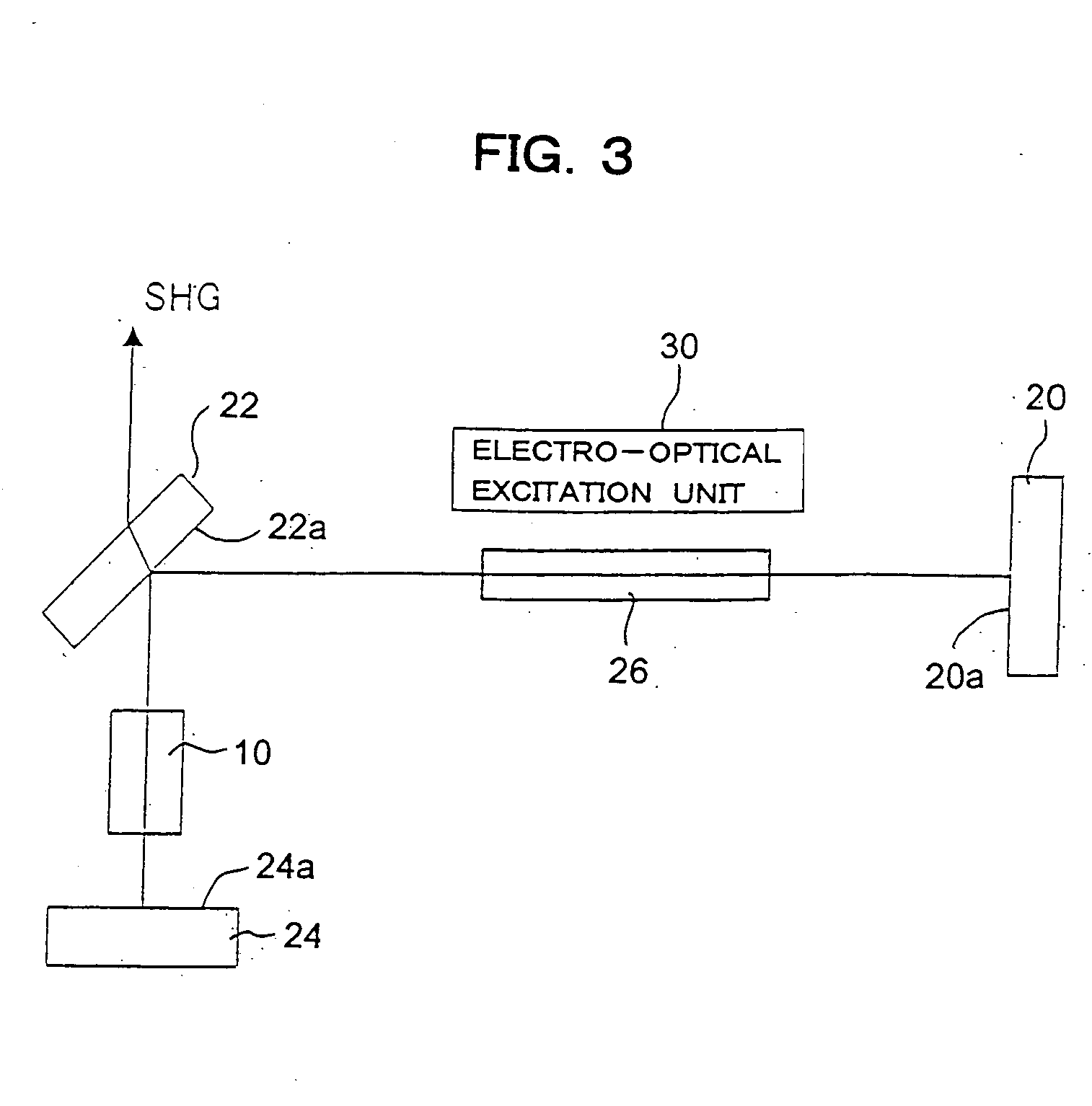

Harmonic pulse laser apparatus, and method for generating harmonic pulse laser beams

ActiveUS20050163174A1Get stableImprove wavelength conversion efficiencyWeft knittingCurtain accessoriesLaser processingHarmonic

A KTP crystal is irradiated by a long-pulse fundamental wave pulse laser beam having a pulse width of 100 μs or longer typically output from a solid-state pulse laser such as YAG pulse laser. In the KTP crystal, wavelength conversion is performed to generate a second harmonic pulse laser beam with a two times higher frequency, which long-pulse second harmonic pulse laser beam is in turn output for laser processing such as welding etc.

Owner:MIYACHI TECHNOS CORP

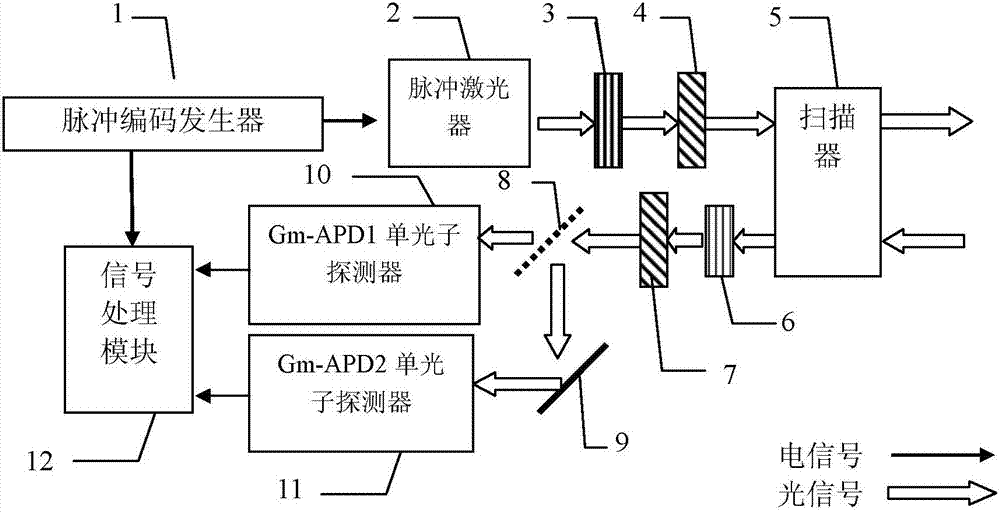

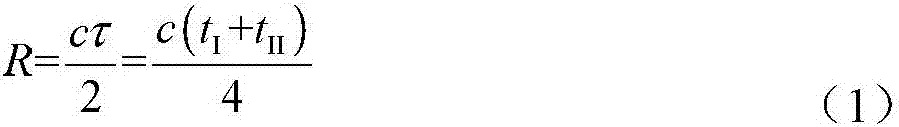

High sensitivity polarization laser radar system based on Gm-APD

ActiveCN107272020AImprove responsivenessEffective resolutionElectromagnetic wave reradiationRadar systemsPolarizer

The invention relates to a high sensitivity polarization laser radar system based on Gm-APD, relates to the laser radar technology field and solves problems of incapability of detecting weak signals and incapability of distinguishing a target from a shielding object in the prior art. A modulation pulse laser device is driven by a pulse code generator to generate a laser signal pulse sequence, the laser signal pulse sequence is modulated through a polarizer and a first one-quarter wave plate, and the target is irradiated through a scanner; a returned laser signal through the scanner sequentially realizes incidence to a narrowband optical filter, a second one-quarter wave plate and a polarization splitter, the incident laser signal is divided by the polarization splitter into two paths of laser signals, the two paths of laser signals are respectively received by two single-photon detectors, detection signals outputted by the two single-photon detectors are inputted to a signal processing module, and the signal processing module is used for carrying out correlation of a reference signal and the two paths of detection signals to acquire a distance, intensity and a polarization degree of corresponding pixel points on a detected object. The method is advantaged in that the method is suitable for detecting the weak signals.

Owner:HARBIN INST OF TECH

Pre-welding laser cleaning method and device capable of efficiently removing aluminum alloy oxidation film

InactiveCN108031687AEfficient ConcentrationImprove cleaning qualityCleaning processes and apparatusShock waveLight beam

The invention provides a pre-welding laser cleaning method and device capable of efficiently removing an aluminum alloy oxidation film. The method includes the steps that S1, a material to be cleanedis prepared, and the oxidation film with the film layer thickness being d0 is arranged on the surface of the material to be cleaned; S2, the material to be cleaned is put onto a three-dimensional moving platform and further located on the focal plane of a focusing lens; S3, the laser beam direction is adjusted to be parallel to the normal direction of the surface of the material to be cleaned; S4,laser parameters are set, laser energy is set and the laser overlap rate is determined; and S5, laser cleaning of the material to be cleaned is conducted, a pulsed laser device emits pulsed lasers toscan the surface of the material to be cleaned, light beams emitted by the laser device pass through the focusing lens and then are absorbed by the oxidation film on the surface of the material to becleaned, matter of the oxidation film is converted into rapid expansion plasmas and is made away from the surface to be removed, and meanwhile shock waves are generated and can turn the oxidation film into fragments to be removed. The aluminum alloy oxidation film can be removed efficiently and effectively.

Owner:JIANGSU UNIV

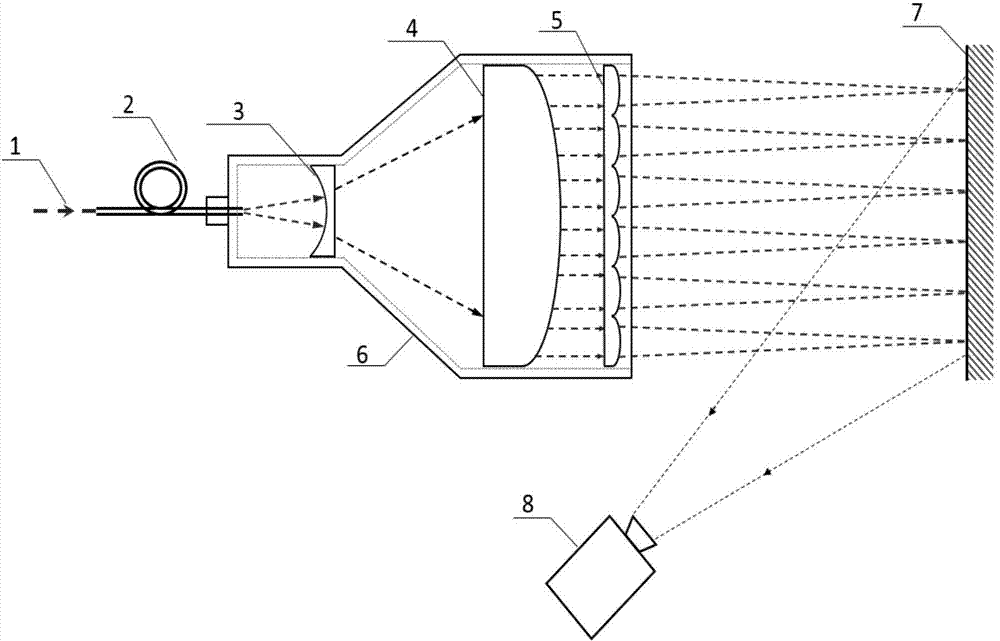

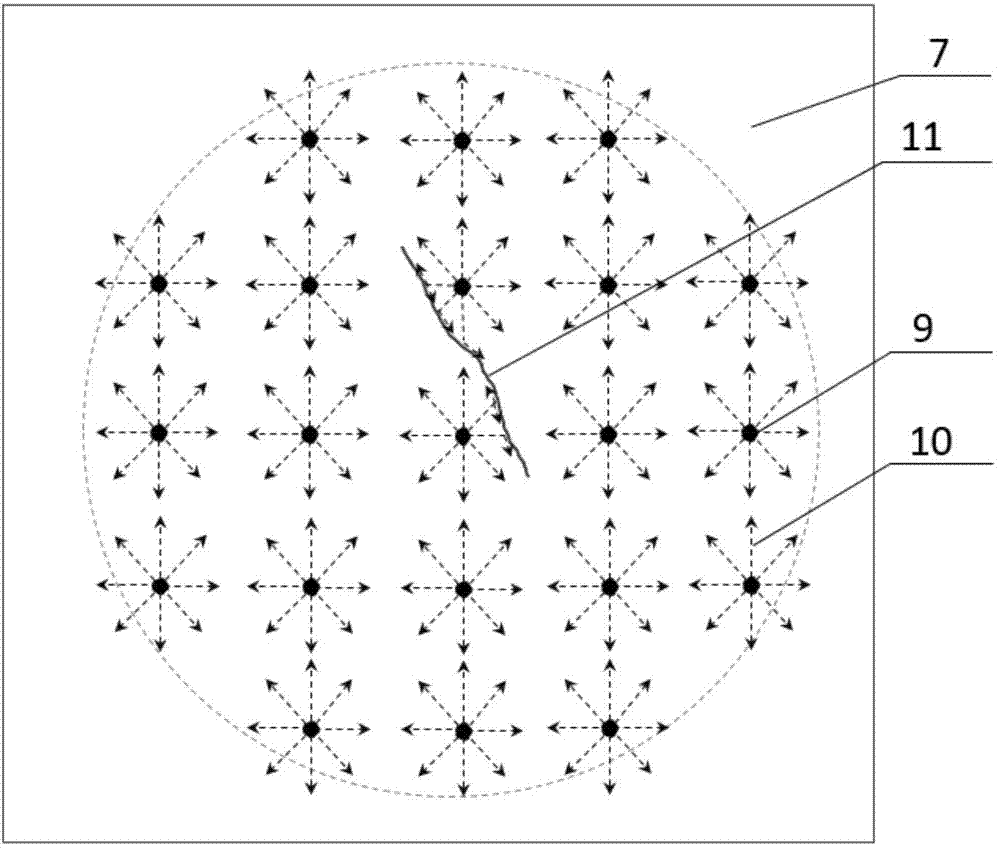

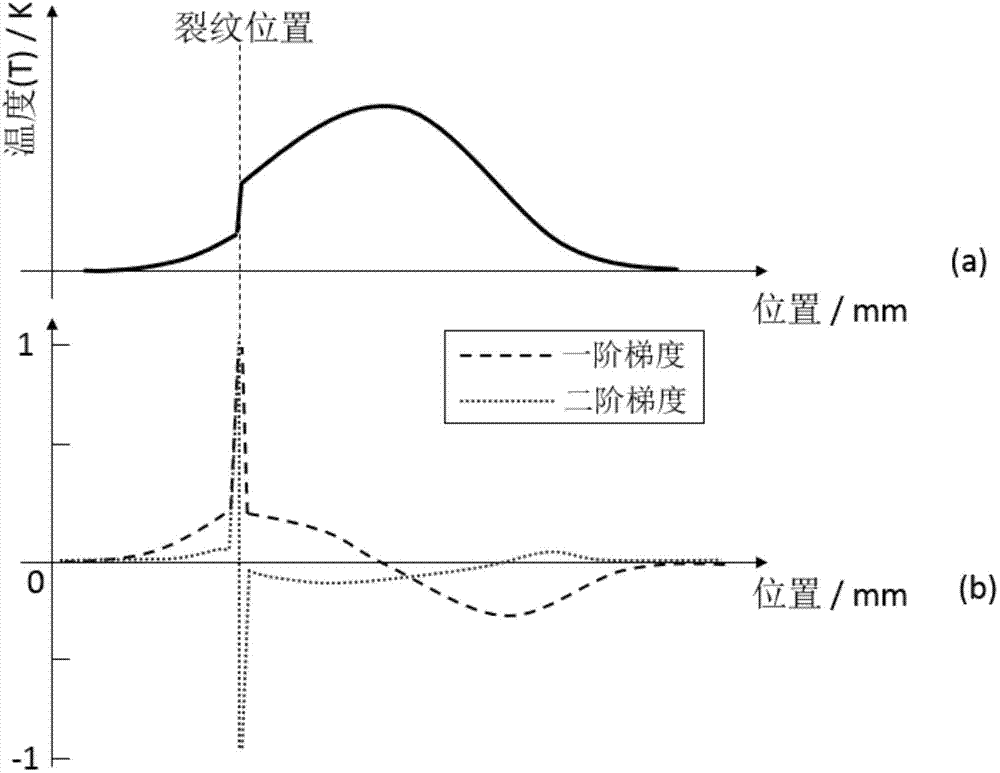

Infrared nondestructive testing and imaging method based on array laser source and used for structure surface cracks

InactiveCN104502409AEasy to implementEasy to operateMaterial flaws investigationDistance detectionOptoelectronics

The invention discloses an infrared nondestructive testing and imaging method based on an array laser source and used for structure surface cracks. The method comprises the following steps: expanding the beam of a laser source generated by a pulse laser device into a collimation laser beam with the diameter of several centimetres by virtue of a laser beam expander at first, and then focusing the laser beam onto the surface of the tested piece by virtue of m*n array convex lenses to form array laser spots with radiuses of less than 1mm and uniformly distributed, and then monitoring the temperature field distribution change condition of the surface of the tested piece irradiated by the array pulse laser source by using an infrared camera; when cracks exist in the irradiated area of the surface of the tested piece, the cracks block the diffusion of the heat of the laser irradiation on the surface, thus forming a high temperature difference at the both sides of each crack. Therefore, the cracks on the surface of the tested piece can be tested and imaged through the temperature gradient field of the irradiated area. The method disclosed by the invention has the advantages of being simple in system structure, easy to realize and operate, high in testing speed, high in sensitivity, intuitive in result, capable of realizing remote testing, and the like.

Owner:XI AN JIAOTONG UNIV

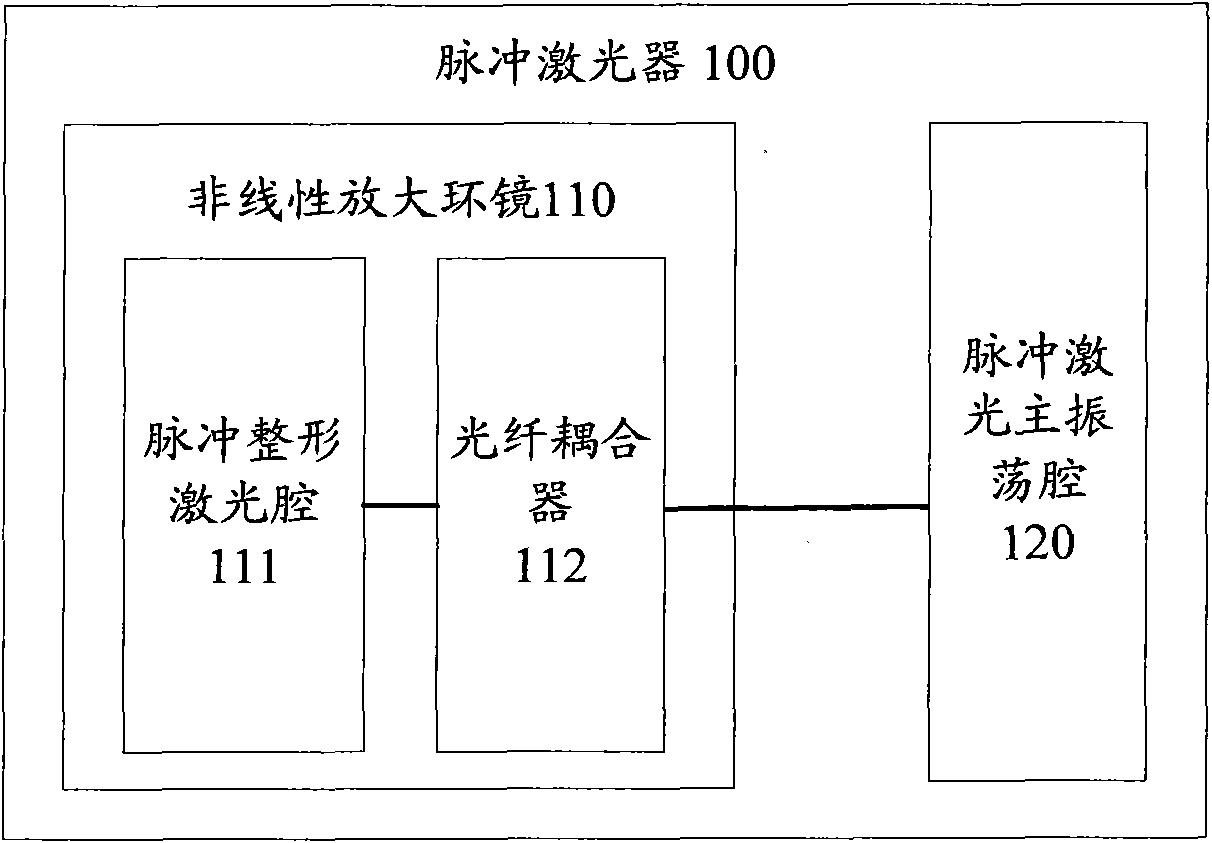

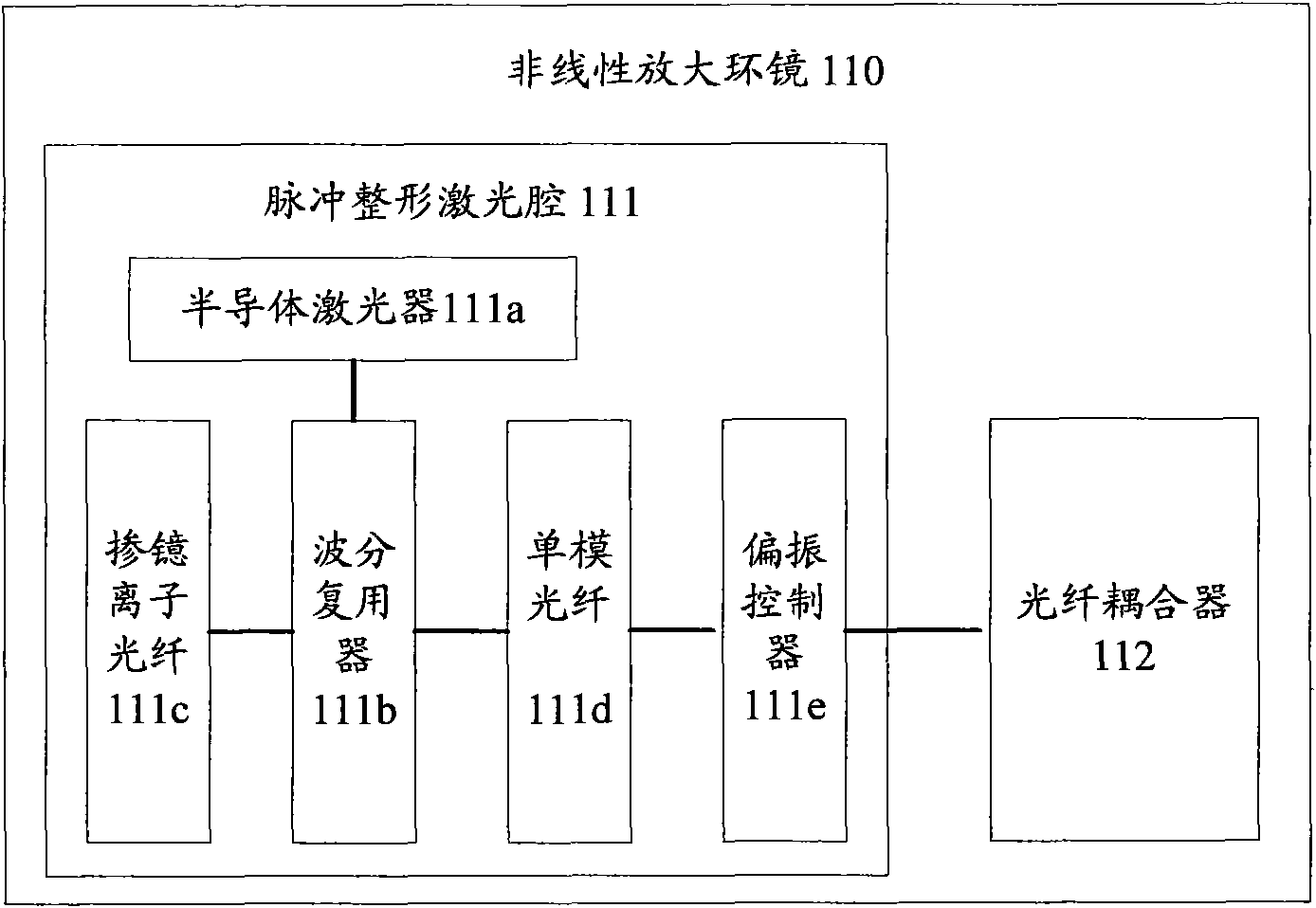

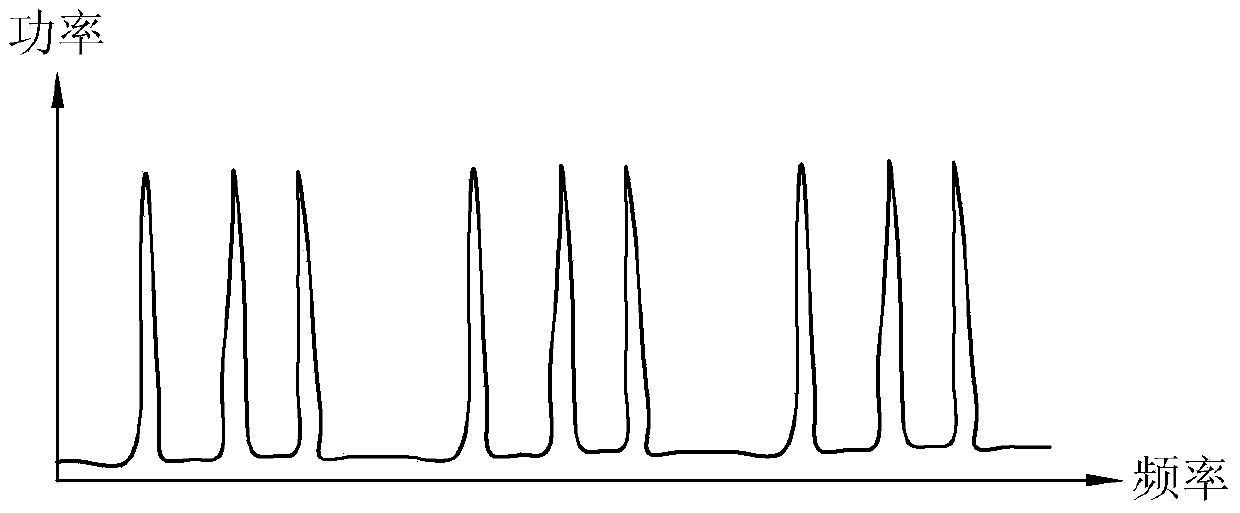

Square-wave pulse laser device and square-wave pulse laser generating method

InactiveCN101820129ASimple structureStable structureActive medium shape and constructionSquare waveformOptoelectronics

The invention provides a square-wave pulse laser device, which comprises a nonlinear amplification environment NALM and a pulse laser main oscillation cavity, wherein the nonlinear amplification environment NALM is used for performing intra-cavity pulse shaping on laser pulse; and the pulse laser main oscillation cavity is used for circularly oscillating a square-wave laser pulse sequence in the nonlinear amplification environment NALM and the pulse laser main oscillation cavity and generating and outputting square-wave laser pulse. The invention also provides a square-wave pulse laser generating method, which comprises the following steps of: inputting continuous laser to excite a working substance to generate primary laser pulse; and performing intra-cavity pulse shaping on the primary laser pulse through the nonlinear amplification environment NALM, and circularly oscillating the primary laser pulse in the nonlinear amplification environment NALM and the pulse laser main oscillation cavity to generate the square-wave laser pulse. According to the pulse laser device and the method provided by the embodiment of the invention, the pulse laser device can directly output the square-wave laser pulse and has the characteristics of self start and simple adjustment.

Owner:UNIV OF SCI & TECH OF CHINA

Method for measuring width of subsurface defect based on laser ultrasonic surface waves

ActiveCN107688051AAvoid secondary clampingLow efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesUsing subsonic/sonic/ultrasonic vibration meansLaser probeSurface acoustic wave

The invention discloses a method for measuring the width of a subsurface defect based on laser ultrasonic surface waves. The method comprises the following steps: (1) a pulsed laser probe and an ultrasonic probe are placed on one side of the subsurface defect of a workpiece, and pulsed laser is located between the subsurface defect and the ultrasonic probe; (2) a pulsed laser device excites surface acoustic waves on the surface of the workpiece, and the ultrasonic probe detects a direct surface wave signal R1 and a surface wave signal RR1 reflected by the defect; (3) the ultrasonic probe is taken down, a two-dimensional displacement platform is controlled to move, the pulsed laser is located on the other side of the subsurface defect, the ultrasonic probe is placed, and the pulsed laser islocated between the subsurface defect and the ultrasonic probe; (4) the step (2) is repeated, and the ultrasonic probe detects a direct surface wave signal R2 and a surface wave signal RR2 reflectedby the defect; and (5) in accordance with the reaching time of the direct surface wave signal and the defect echo signal, which is twice measured by ultrasonic probe, the movement displacement d of the three-dimensional movement platform and a surface wave echo time compensation factor alpha, the width of the subsurface defect is calculated. The method can be used for on-line measurement, and canaccurately measure the widths of subsurface defects with different depths and internal shapes.

Owner:ZHEJIANG UNIV

Distributed type optical fiber Raman photon temperature sensing fire disaster detector

InactiveCN101393677AImprove signal-to-noise ratioImprove reliabilityThermometers using physical/chemical changesFire alarm electric actuationDisplay devicePulsed laser device

The invention discloses a distributed optical fiber Raman photon temperature sensing fire detector. The detector is a fire detector produced on the basis of integrated optical fiber wavelength division multiplex technology by utilizing the principle that the strength of the optical fiber anti-Stokes Raman photon is modified by the temperature of the optical fiber and the principle of optical time domain reflection. The fire detector comprises a light pulse laser device, an integrated optical fiber wavelength division multiplexer, intrinsic temperature sensing optical fiber, two avalanche photodiodes, a digital signal processor and a display or an alarm. The intrinsic temperature sensing optical fiber laid in the fireproof site is uncharged, electromagnetic interference resistant, radiation resistant and corrosion resistant, and is both a transmission media and a sensing media. The fire detector has the advantages of low cost, long service life, simple structure, good signal-to-noise ratio and good reliability, thereby being suitable for medium range and short range temperature sensing and fire detection within 100 meters-15 kilometers.

Owner:山西关铝集团有限公司

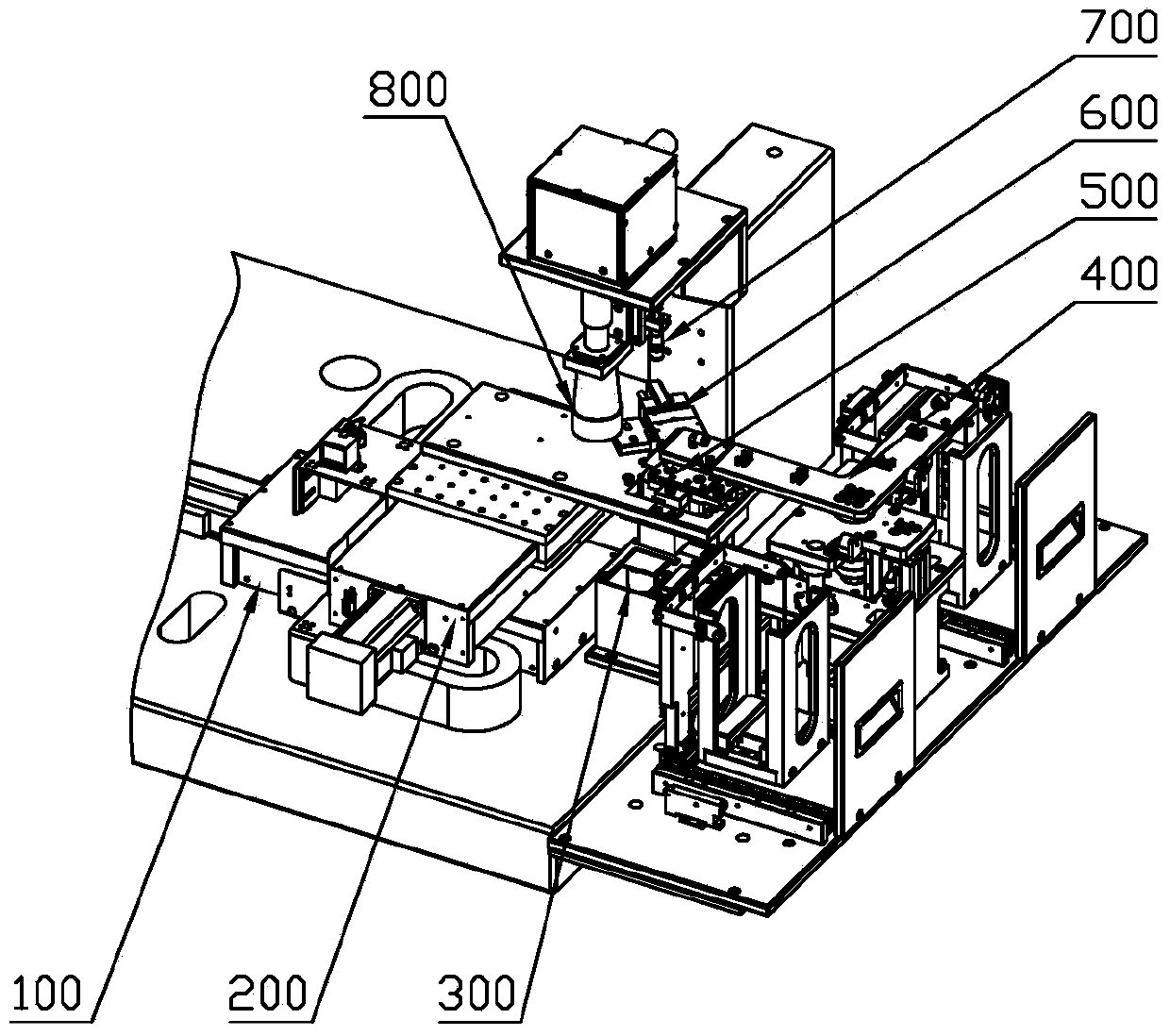

Laser cutting processing method and system of ceramic substrate

ActiveCN103433624AImprove cut qualityImprove yield rateLaser beam welding apparatusLaser cuttingCcd camera

The invention relates to a laser cutting processing method of a ceramic substrate. The laser cutting processing method comprises the following steps: using a pulse laser device, recombining the laser frequency to enable multiple laser pulses to be located at the same point of a machined workpiece, achieving doting scoring or imaginary line scoring on the ceramic substrate, and carrying out separation in a splintering mode at the later period. The invention further relates to a laser cutting system of the ceramic substrate workpiece. The laser cutting system comprises an X-axis displacement table, a Y-axis displacement table, a CCD camera, a feeding-discharging system, a workpiece suction disc, a locating system, a Z-axis displacement table and a laser focusing assembly, wherein the laser focusing assembly is arranged above the workpiece suction disc, the workpiece suction disc is connected with the Y-axis displacement table, the Z-axis displacement table is arranged above the workpiece suction disc and connected with the laser focusing assembly, the CCD camera is arranged below the workpiece suction disc, and the feeding-discharging system comprises a 90-degree supporting plate, a suction disc A, a suction disc B, a feeding box and a discharging box and is used for completing automatic feeding-discharging motions of the machined workpiece. Both the notch quality and the yield are greatly improved.

Owner:WUHAN DR LASER TECH CORP LTD

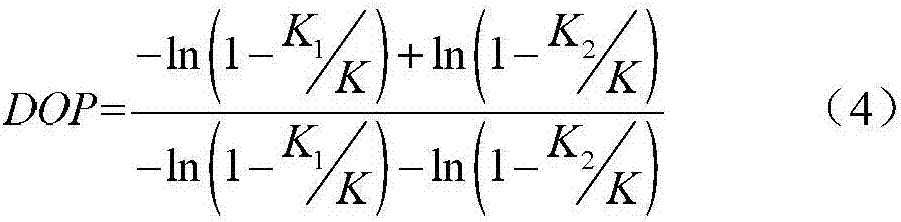

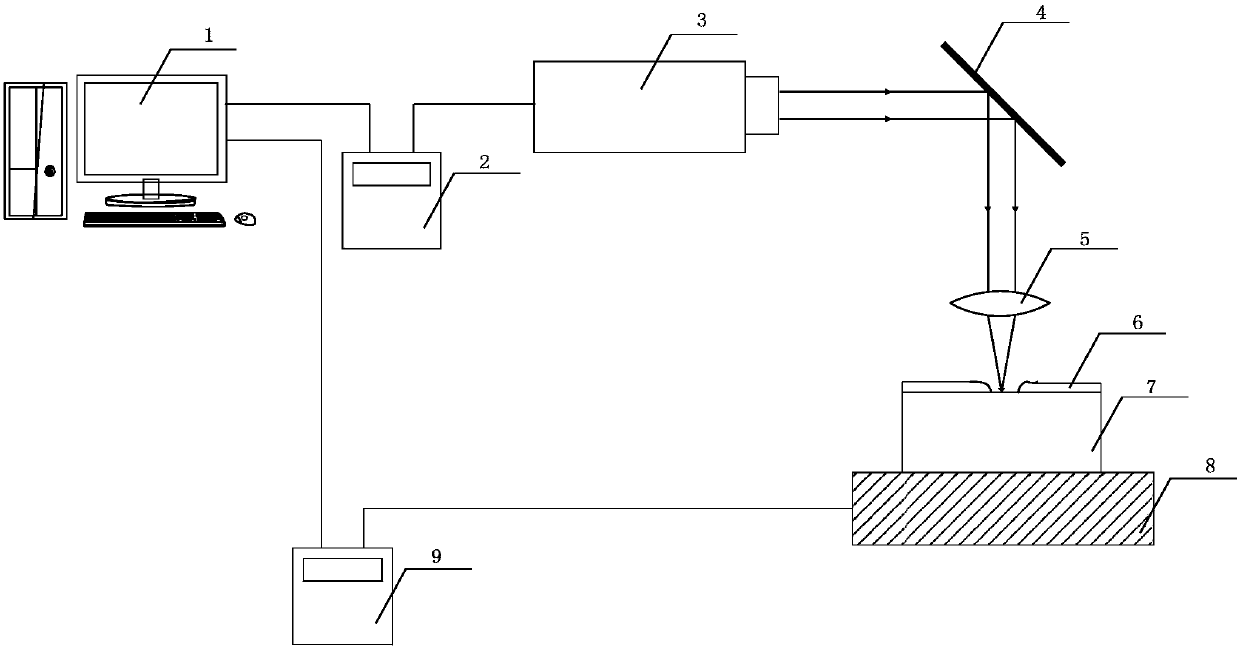

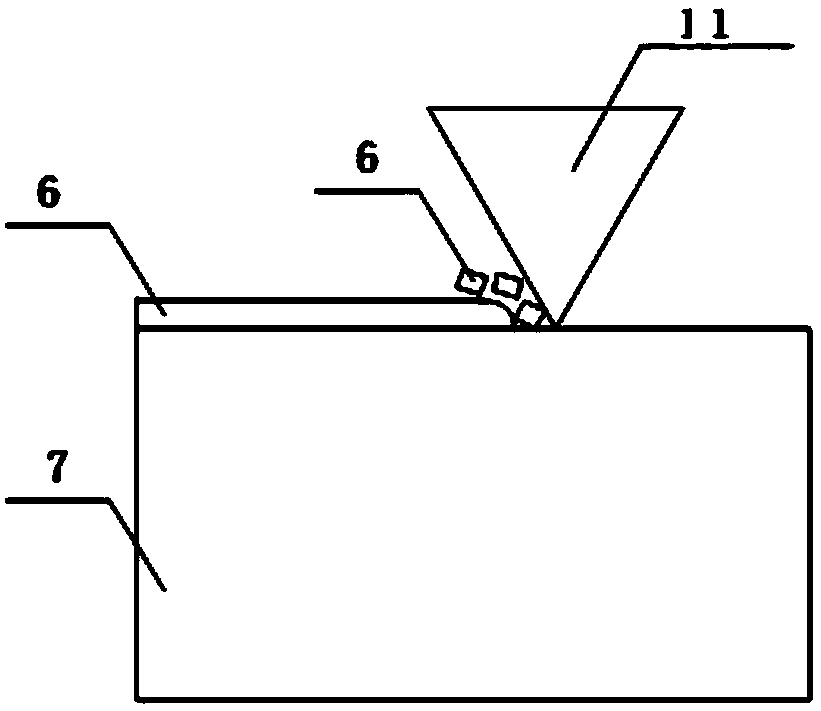

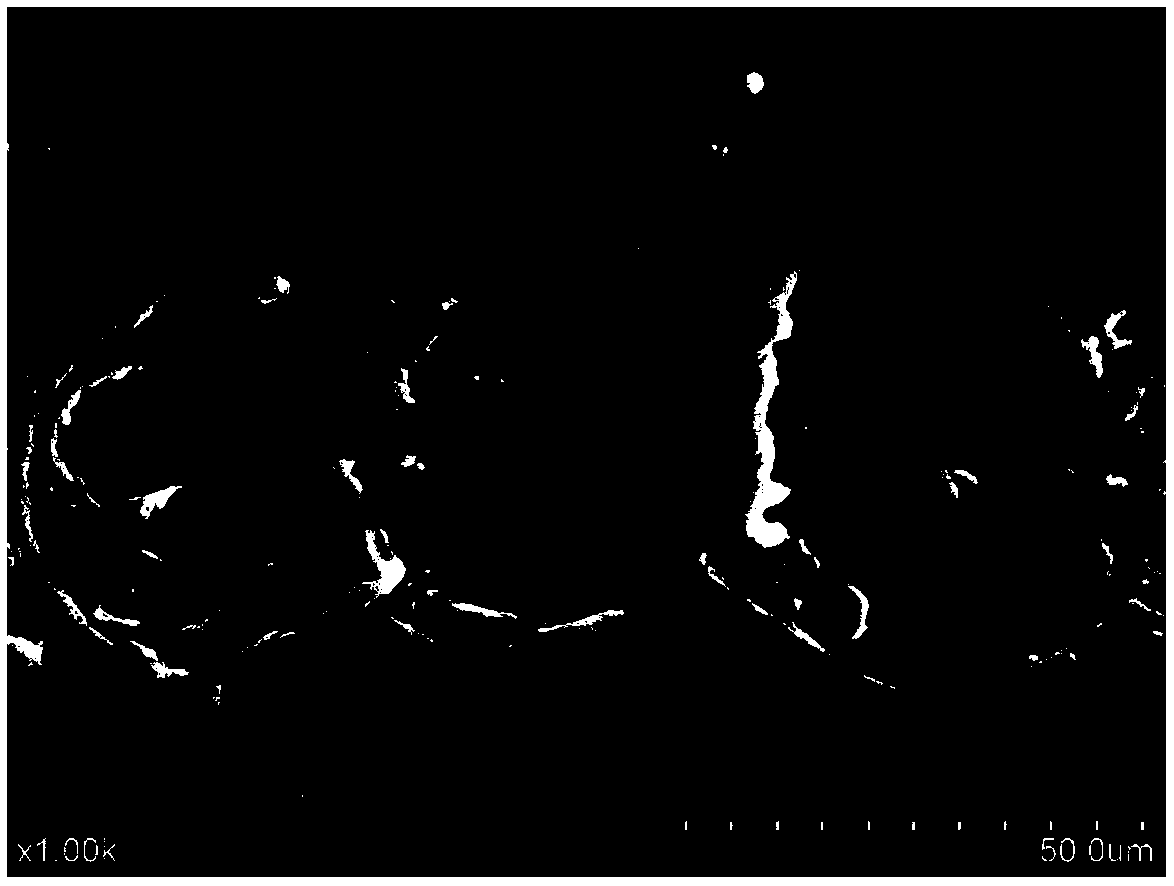

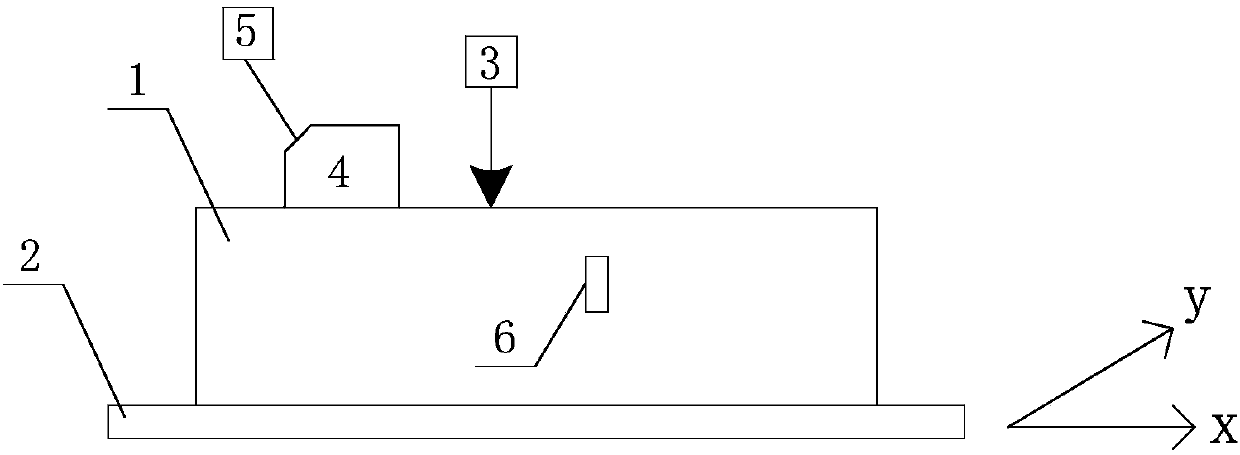

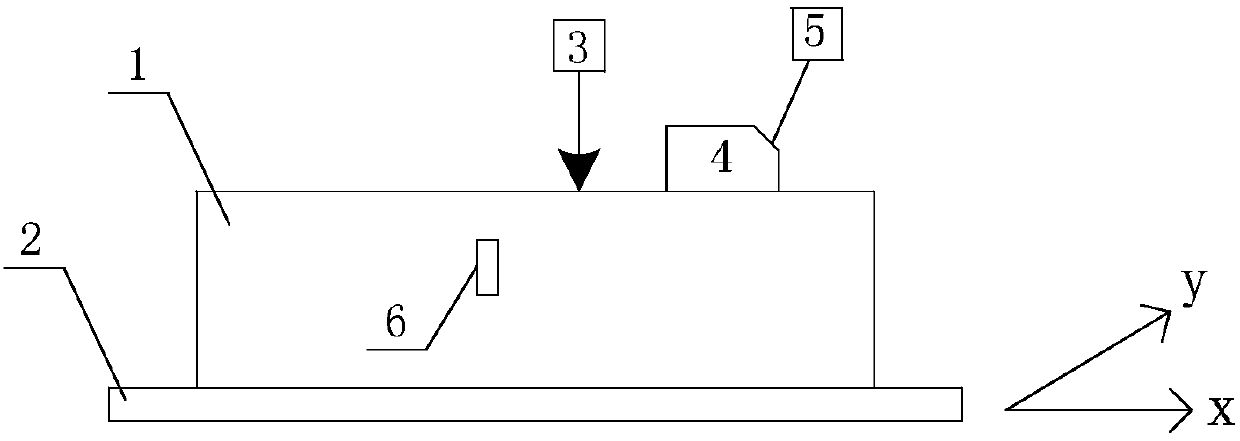

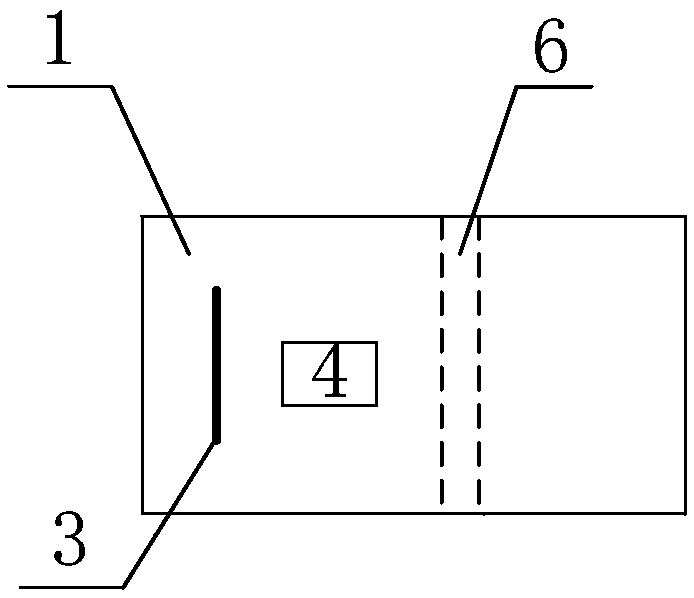

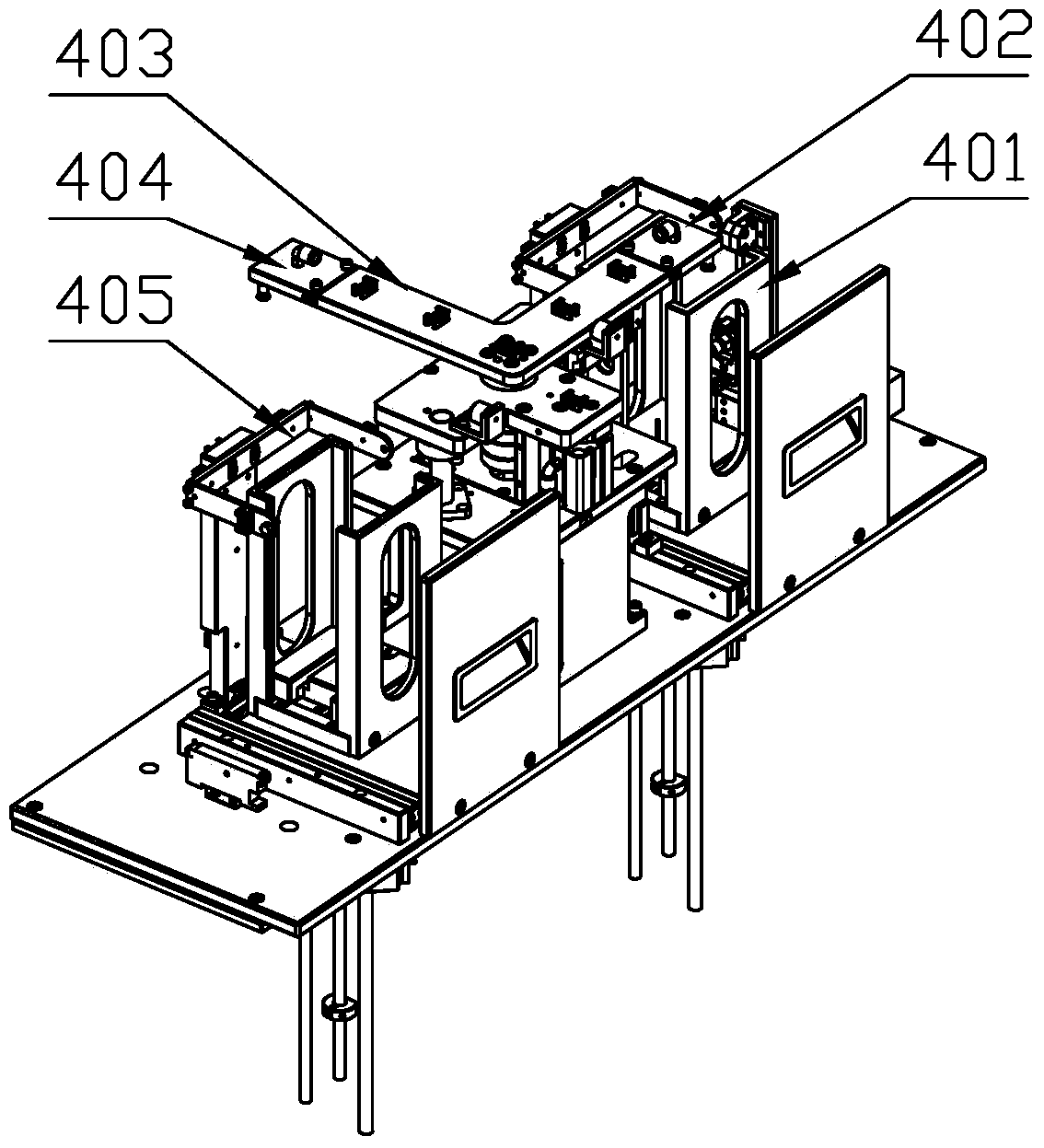

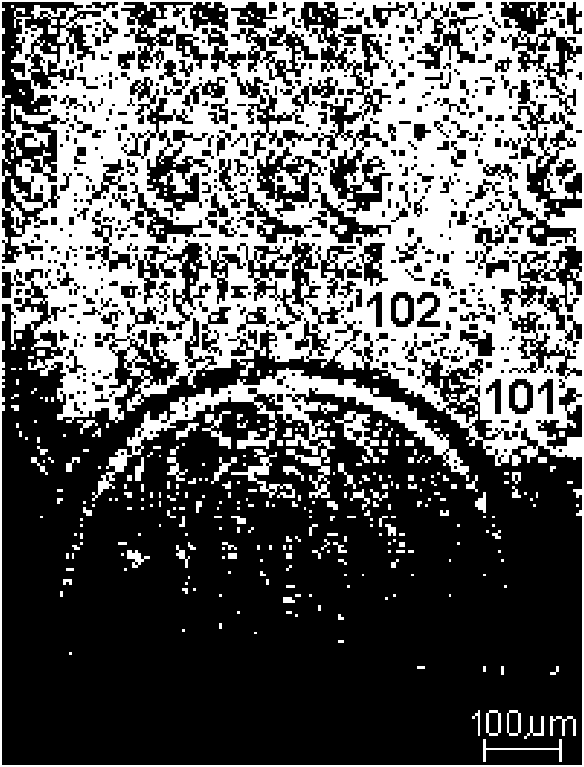

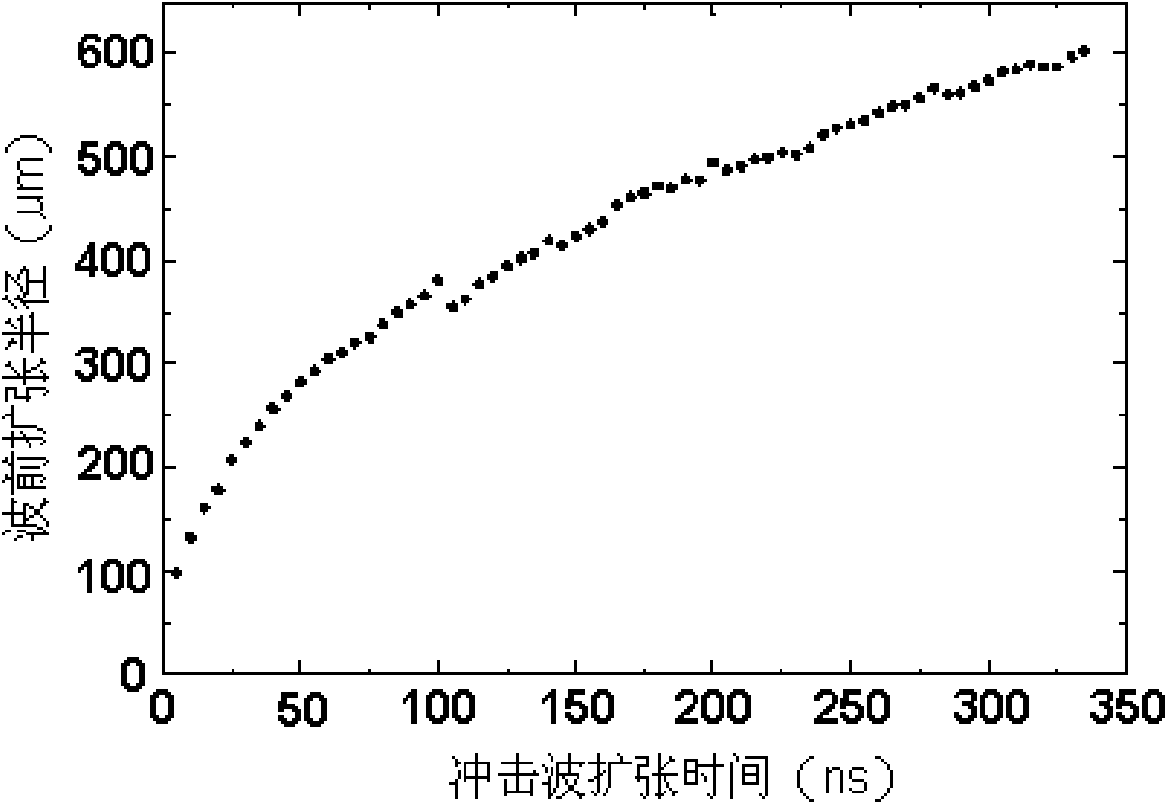

Laser processing method and device for non-through hole

The invention discloses a laser processing method and a laser processing device for a non-through hole. The method comprises the following steps of: focusing a pulse laser beam 4 emitted by a pulse laser device 401 on a to-be-perforated position of a workpiece 404 through a perforating optical system 403 to implement perforating; and when the pulse laser device 401 emits laser pulse, trigging a synchronous time delay module 405, trigging a shock wave photographing system 406 after certain time delay, photographing shock wave 407 produced by the interaction of the laser pulse and the workpiece 404, inputting photo data into a control computer 409 through an image acquisition module 408, analyzing and processing a shock wave photo by the control computer 409, obtaining the real-time depth of a processed hole by consulting processing reference data stored in the control computer 409, and judging whether the hole depth meets the requirement so as to control the pulse laser device 401 to continue or terminate perforating. The method and the device perform closed-loop control on the perforated hole depth during laser perforating so as to greatly improve the laser processing precision and efficiency of the non-through hole.

Owner:王晓东

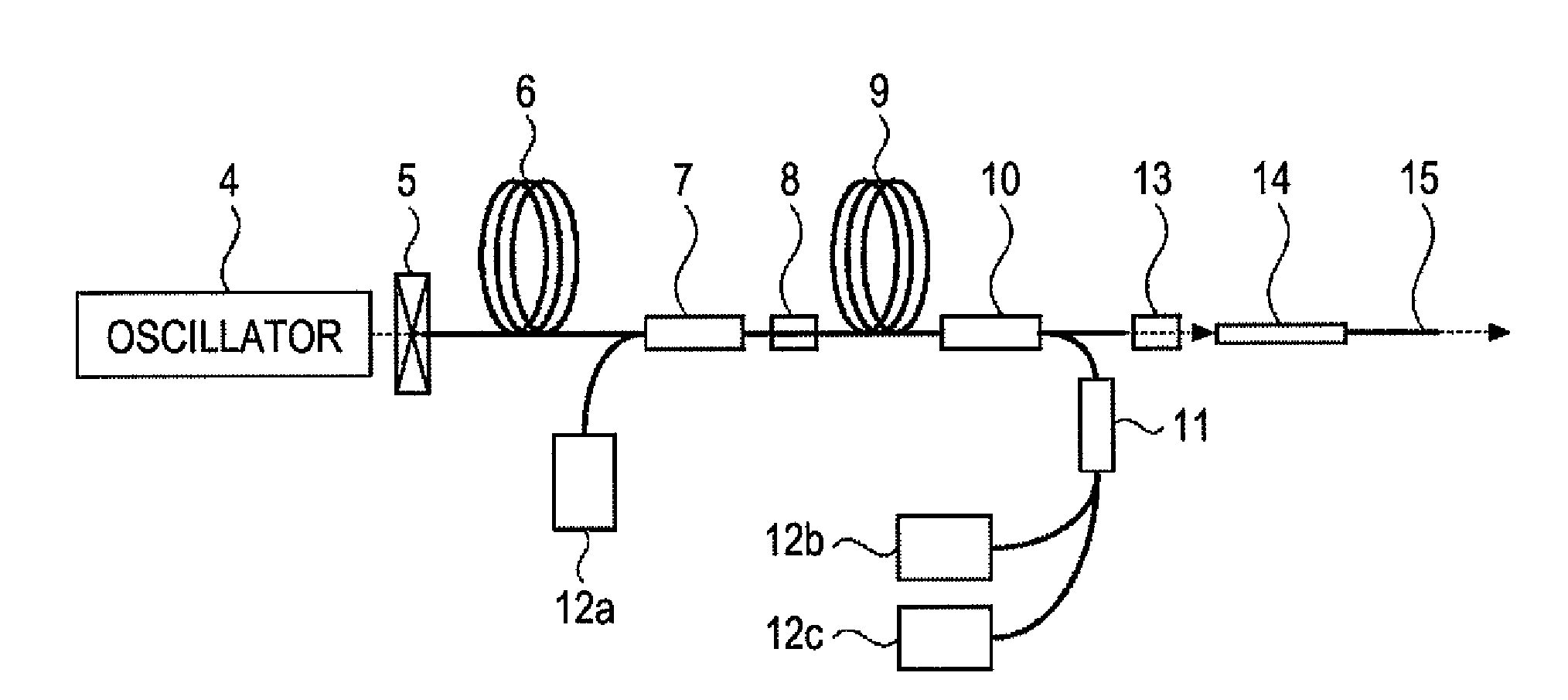

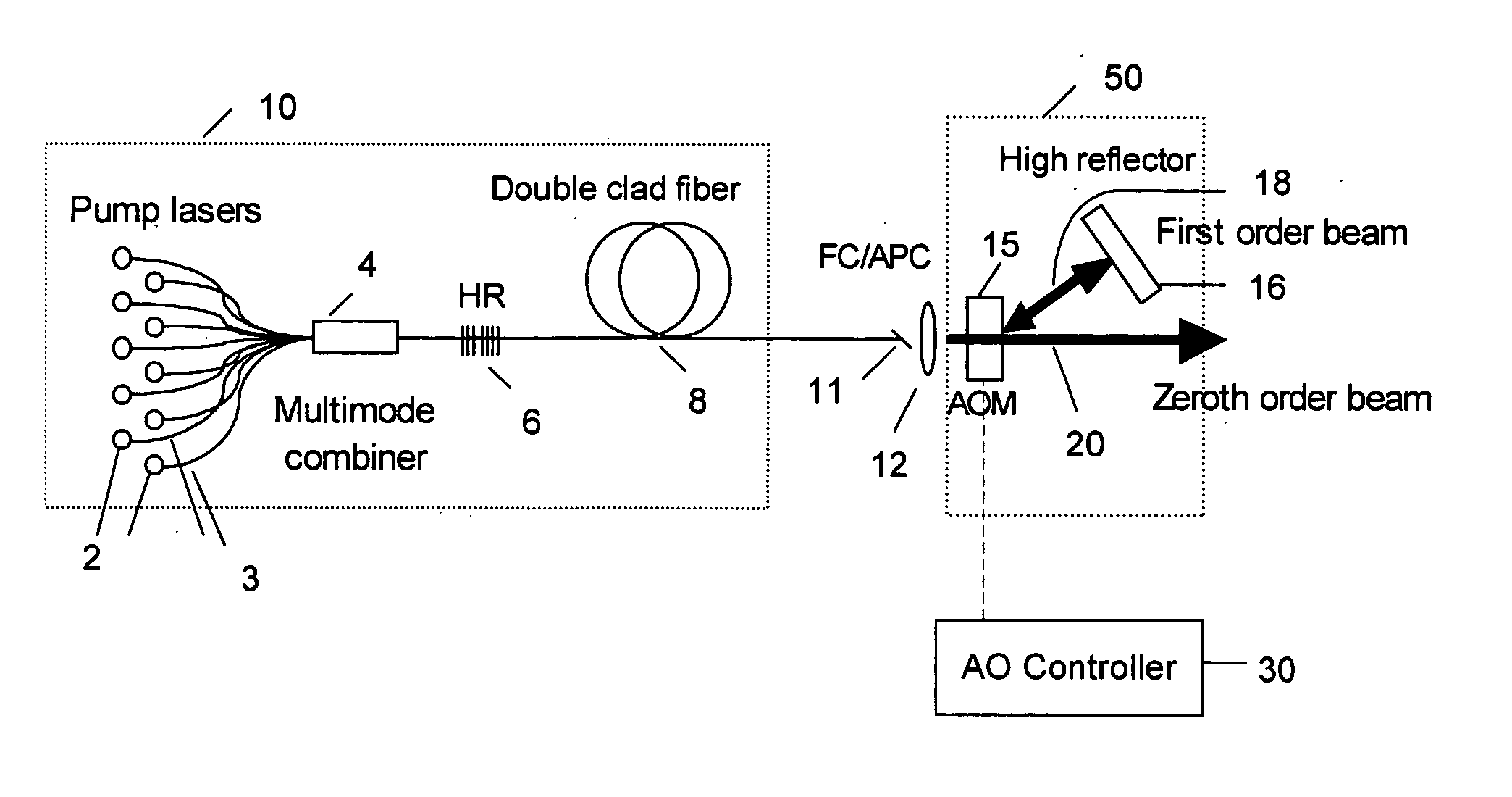

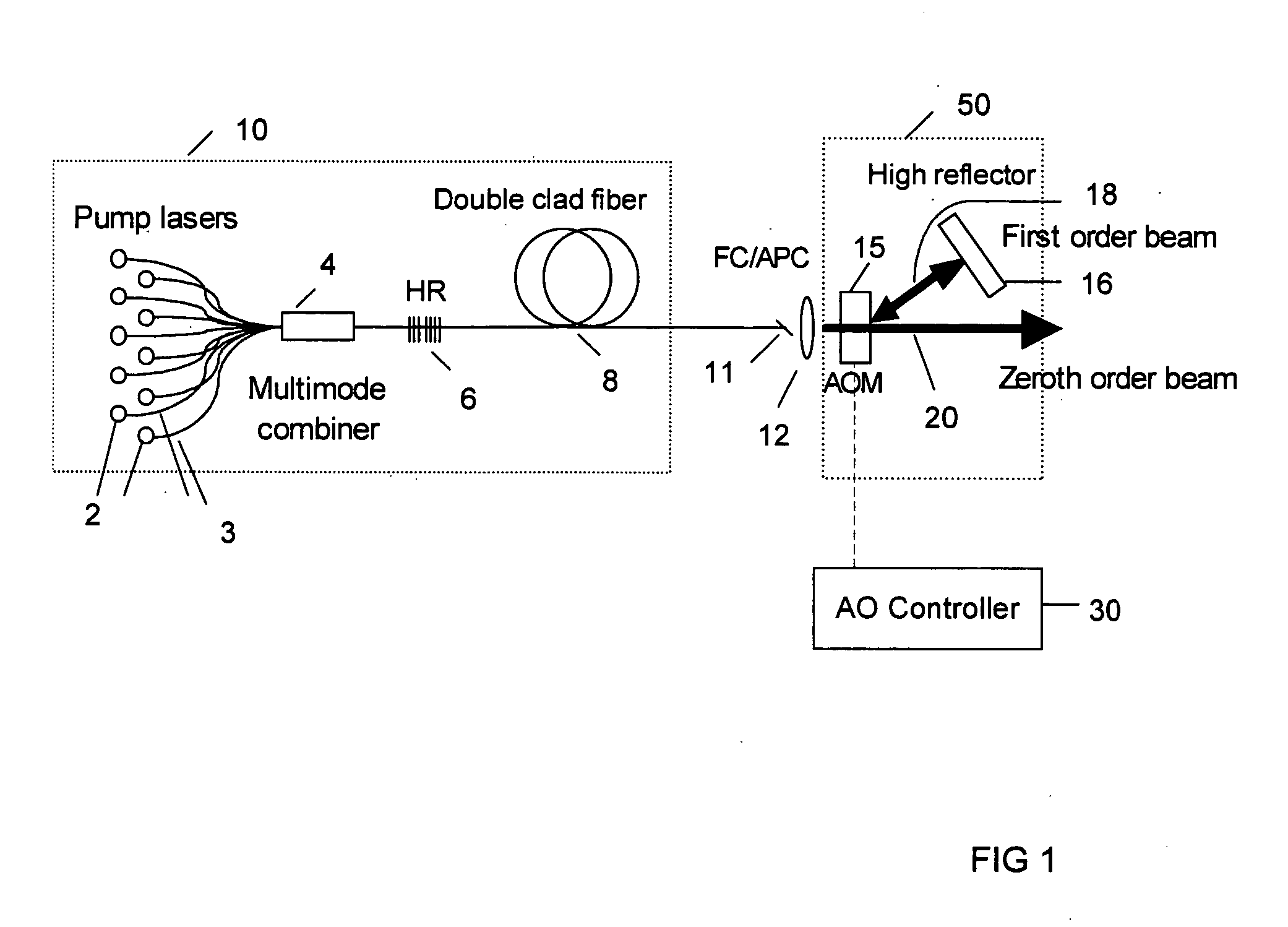

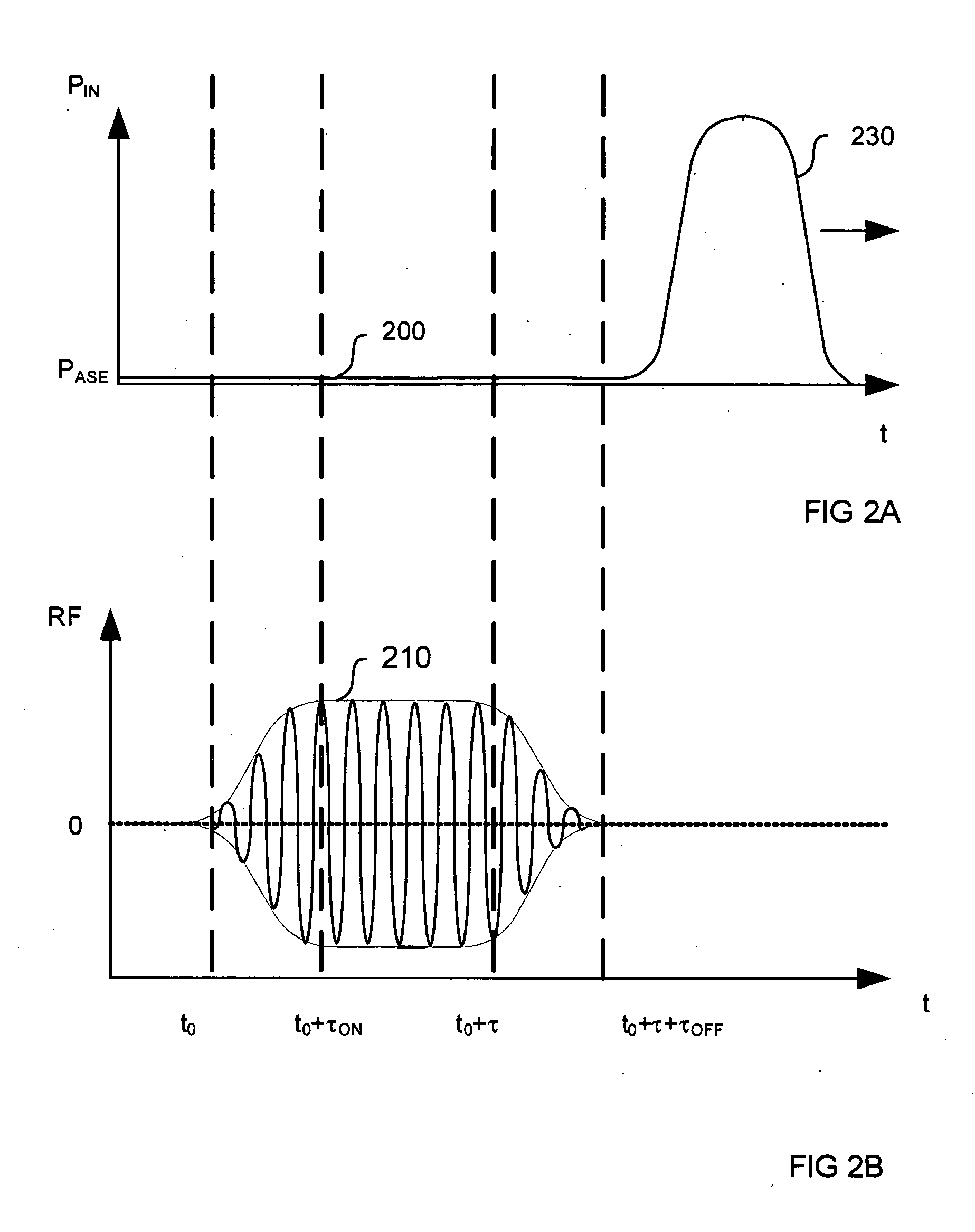

Pulsed laser apparatus and method

A laser apparatus for generating optical pulses is disclosed, said laser apparatus has a reflecting gain element preferably including a fiber gain medium. The reflecting gain element is coupled to a controllable reflecting / transmitting module having a reflecting state and a transmitting state, wherein the controllable reflecting / transmitting means are operable to switch from the transmitting state to the reflecting state to initiate a build-up of an optical pulse, and to switch back to the transmitting state for outputting the optical pulse before it reaches the reflecting / transmitting means after a cavity roundtrip. In a preferred embodiment, the controllable reflecting / transmitting module includes an acousto-optic switch at an output end of a laser operable to output the optical pulse in zeroth diffraction order.

Owner:LUMENTUM OPERATIONS LLC

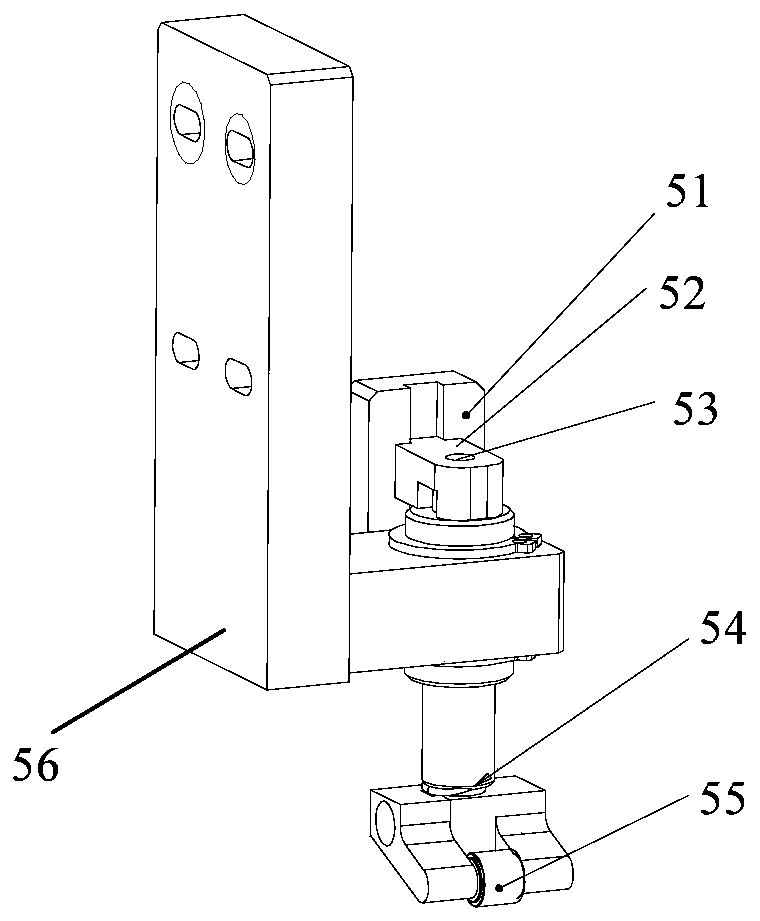

Micronano-scale high-temperature laser impact imprinting device and method

PendingCN109226970AImprove mechanical propertiesImprove manufacturing precisionLaser beam welding apparatusExhaust valveOxygen sensor

The invention discloses a micronano-scale high-temperature laser impact imprinting device and method, and relates to the technical field of laser impact imprinting. The device comprises an atmosphereprotection module, a high-temperature laser impact imprinting module, a monitoring module and a clamp module; the atmosphere protection module comprises a target chamber, the target chamber is provided with an air inlet and an air outlet, and the air inlet is sequentially connected with an air inlet valve, an air pump and an air storage system through pipelines; the air outlet is connected with anoxygen sensor and an exhaust valve through pipelines; the oxygen sensor is connected with the air pump; the high-temperature laser impact imprinting module is formed by connecting a focus lens, a pulse laser device, a pulse laser controller, a pulse delay generator, an infrared laser controller and an infrared laser device in sequence; the monitoring module is formed by sequentially connecting aCCD and a computer; the clamp module is composed of a constraint layer, an absorption layer, a sample and a mold from top to bottom in sequence; the clamp module is arranged in the target chamber. Laser impact imprinting and rapid manufacturing of a high-precision micronano complex structure on the surface of a metal material are achieved.

Owner:XUZHOU UNIV OF TECH

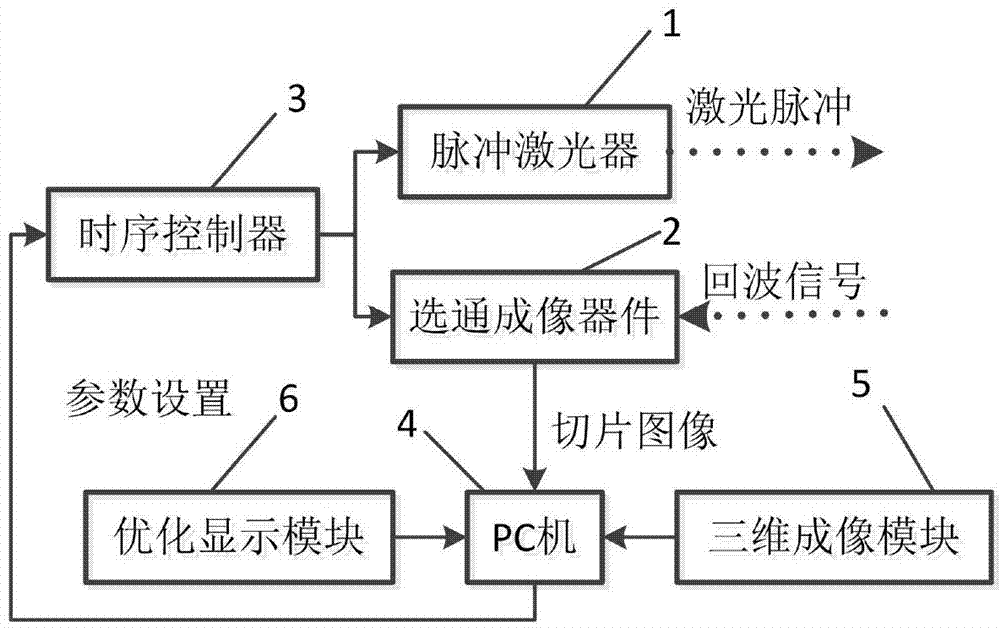

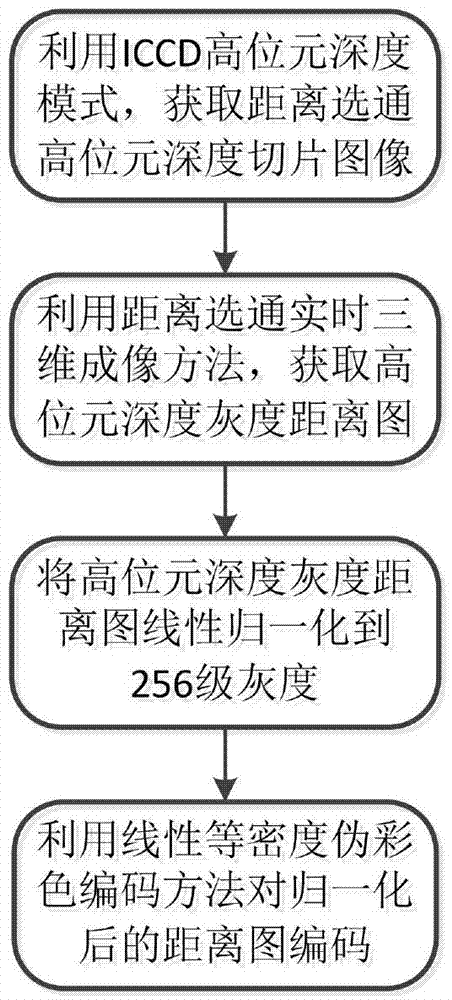

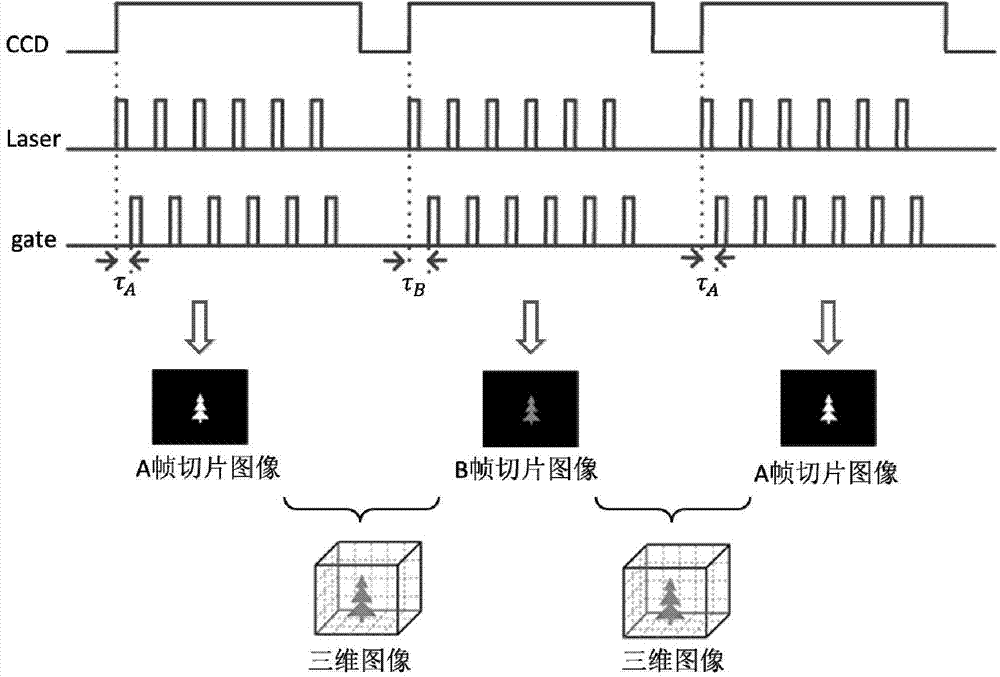

Optimized display device and optimized display method for range-gating super-resolution three-dimensional imaging distance map

InactiveCN104748729AIsodensity pseudo-color coding implementationEasy to observePicture taking arrangementsImage resolutionDisplay device

The invention discloses an optimized display device and an optimized display method for a range-gating super-resolution three-dimensional imaging distance map. The device comprises a pulse laser device, a gating and imaging apparatus, a time sequence controller, a PC (personal computer), a three-dimensional imaging module and an optimized display module. Based on the device, the invention discloses the optimized display method for the range-gating super-resolution three-dimensional imaging distance map, wherein a slice image with low bit depth is replaced with a slice image with high bit depth to obtain a three-dimensional grey distance map with high bit depth, and the distance resolution is improved; in order to vividly show more details, during pseudo-color processing of the distance map with high bit depth, the distance map with high bit depth is linearly normalized to 256-level grey level, and equal-density pseudo-color coding is performed. On the basis of improving the three-dimensional imaging distance resolution to the greatest extent, equal-density pseudo-color coding display of the range-gating super-resolution three-dimensional imaging technology is realized.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Pulse laser apparatus, terahertz measuring apparatus, and terahertz tomographic apparatus

ActiveUS20110210252A1Radiation pyrometryLaser using scattering effectsFiberZero-dispersion wavelength

A pulse laser apparatus includes a laser configured to generate a pulse of a laser beam, a fiber amplifier, and a pulse compressor. The fiber amplifier includes a rare-earth doped fiber that exhibits normal dispersion at a wavelength of the laser beam generated from the laser. The pulse laser apparatus further includes a unit configured to give a loss to energy portions in a wavelength region corresponding to a zero-dispersion wavelength of the rare-earth doped fiber and / or a wavelength region longer than the zero-dispersion wavelength within a wavelength spectrum of the laser beam having been chirped in the fiber amplifier.

Owner:CANON KK

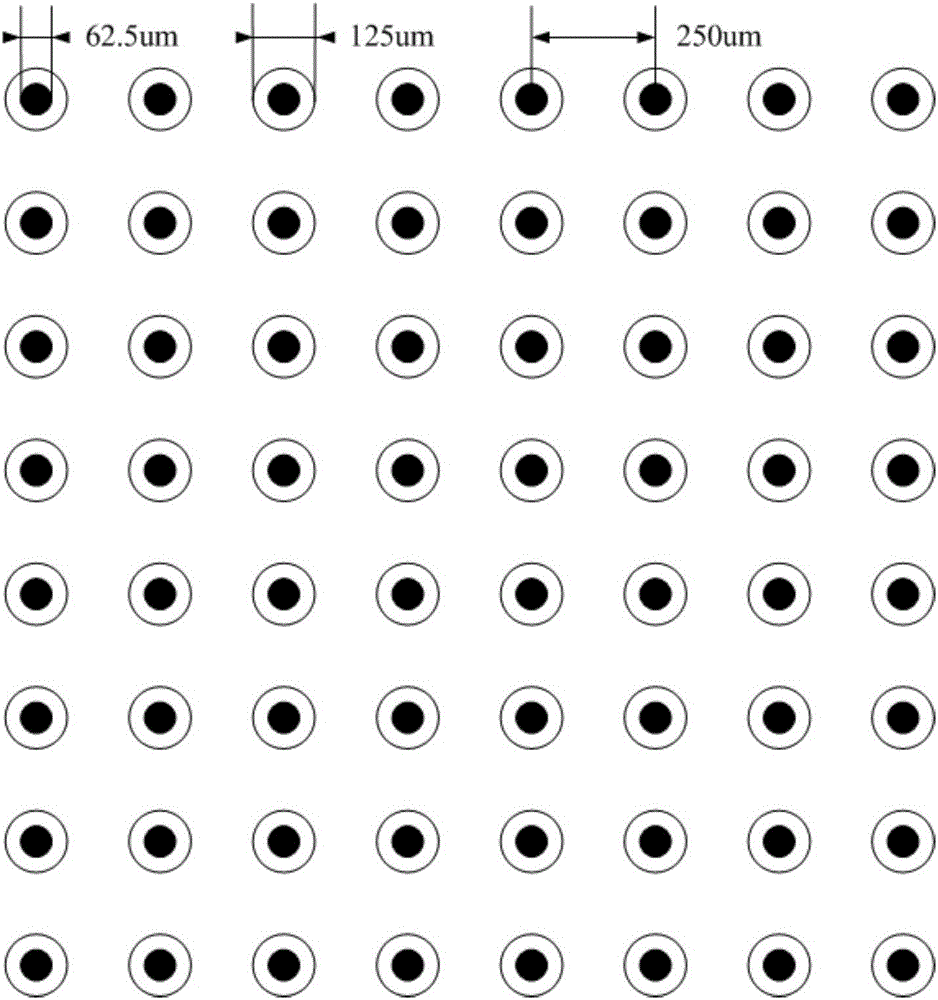

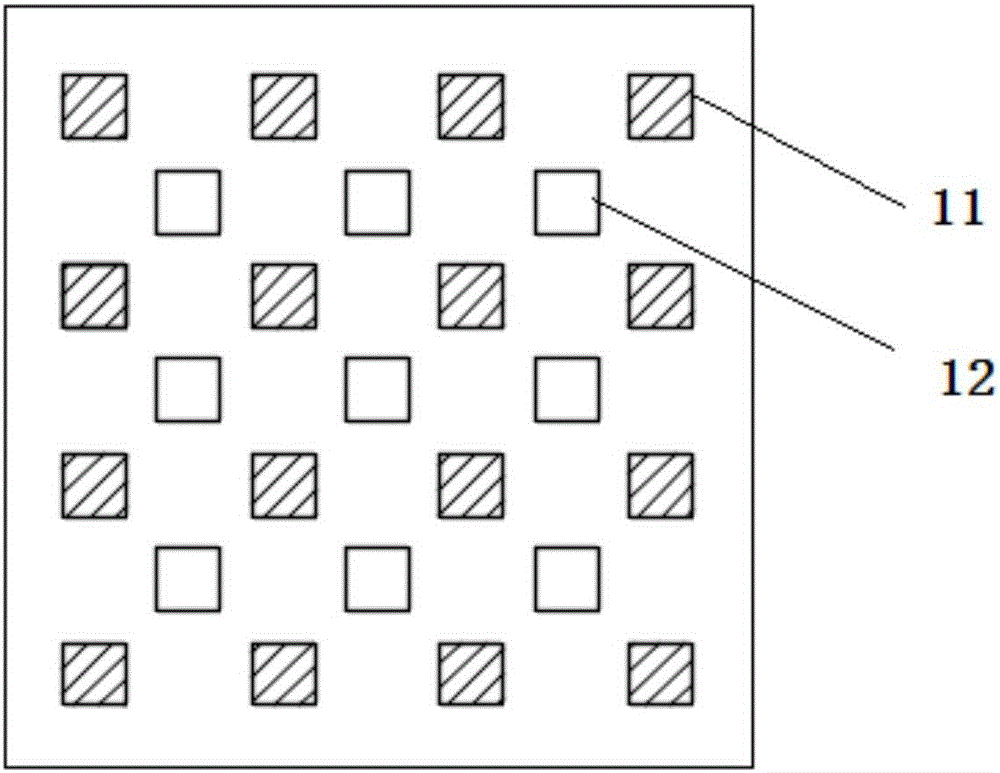

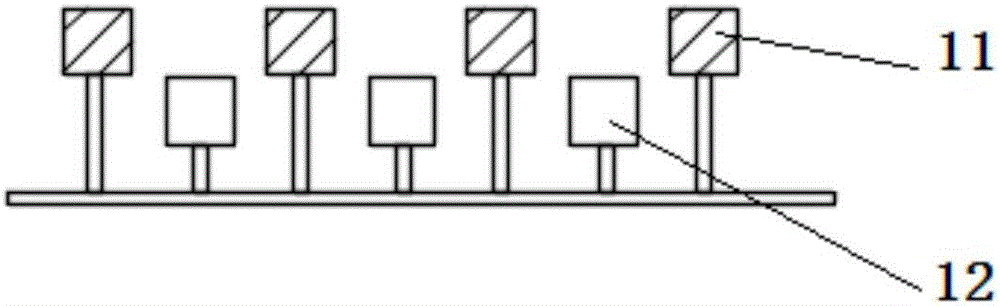

Dot matrix emitting and receiving system for non-scanning laser imaging

InactiveCN106093911ASolve for uniformitySolve UtilizationElectromagnetic wave reradiationDot matrixLaser light

The invention relates to a dot matrix emitting and receiving system for non-scanning laser imaging and belongs to the technical field of photoelectric imaging. The device comprises an optical fiber pulse laser device, an optical fiber branching device, an optical fiber array, an emitting optical system, a planar reflecting mirror, a receiving optical system and an APD plane array detector. The optical fiber pulse laser device is used for emitting a narrow pulse infrared laser beam, 64 paths of laser beams that are the same in energy are emitted out after the narrow pulse infrared laser beam goes through the optical fiber branching device, each path of the laser beam is emitted out from the optical fiber array, an end face of the optical fiber array becomes a 8*8 dot matrix pulse laser light source, the laser beams which are emitted out are imaged on an object after going through the emitting optical system and the planar reflecting mirror, and the laser beams that are reflected via the object are imaged on the APD plane array detector after being received by the receiving optical system. A problem that a non-scanning laser imaging radar illumination system is not uniform enough in light intensity distribution and low in energy utilization rate is solved, and system detection distance can be increased via the dot matrix emitting and receiving system.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method and device for continuously synthesizing diamond membrane by radiating carbon nanotube with strong laser

InactiveCN102409292AHigh purityPrevent thinningVacuum evaporation coatingSputtering coatingBeam splitterMacroscopic scale

The invention relates to a method and device for continuously synthesizing a diamond membrane by radiating a carbon nanotube with strong laser. The device for continuously synthesizing the diamond membrane is characterized by consisting of a laser generating system, a working system and an auxiliary system. Laser emitted by a high-power pulse laser device is reflected and split by a spectroscope to generate a laser beam G1 and a laser beam G2, the laser beam G1 is focused at an appropriate position over the upper surface of a substrate, and carbon nanotube powder in a solution is gasified and ionized momentarily by absorbing laser energy to generate a large quantity of high-speed plasmas; and meanwhile, a momentary high-temperature and high-pressure micro-zone is formed on the surface of the substrate under the compounding action of laser G2, and the high-speed plasmas bombard the surface of the substrate to form the diamond membrane. According to the method and the device, the problems of low synthesis efficiency, special reaction condition, difficulty in operating equipment and high equipment price are solved, continuous synthesis of the diamond membrane at the macroscopically normal temperature and under the macroscopically normal pressure is realized innovatively, and a large-thickness high-purity diamond membrane is obtained.

Owner:JIANGSU UNIV

Laser radar multipoint distance measurement system on basis of diffraction optical components

ActiveCN106353766AGuaranteed normal transmissionEnsure reasonable arrangementElectromagnetic wave reradiationRadarLight beam

The invention relates to the technical field of machinery, and discloses a laser radar multipoint distance measurement system on the basis of diffraction optical components. The laser radar multipoint distance measurement system comprises a laser signal transmitting device, a laser signal receiving device and a signal processing system. The signal processing system is connected with the laser signal transmitting device and the laser signal receiving device, the laser signal transmitting device comprises a pulse laser device, and a collimation system, a beam expansion system, a diffraction grating and a half-transmitting and half-reflecting mirror are sequentially arranged in a light emitting direction of the pulse laser device; the light emitting direction of the pulse laser device is positioned in a transmitting direction of the half-transmitting and half-reflecting mirror, and the laser signal receiving device is arranged in a reflecting direction of the half-transmitting and half-reflecting mirror. The laser radar multipoint distance measurement system has the advantages that laser light transmitted by the pulse laser device can be divided into a plurality of light beams at equal angles or unequal angles by the diffraction grating, and the light beams can be transmitted via the half-transmitting and half-reflecting mirror, then face media at to-be-measured distances, can be reflected by the media at the to-be-measured distances and then can be reflected to the laser signal receiving device by the half-transmitting and half-reflecting mirror.

Owner:SHANGHAI NOVA OPTICS TECH

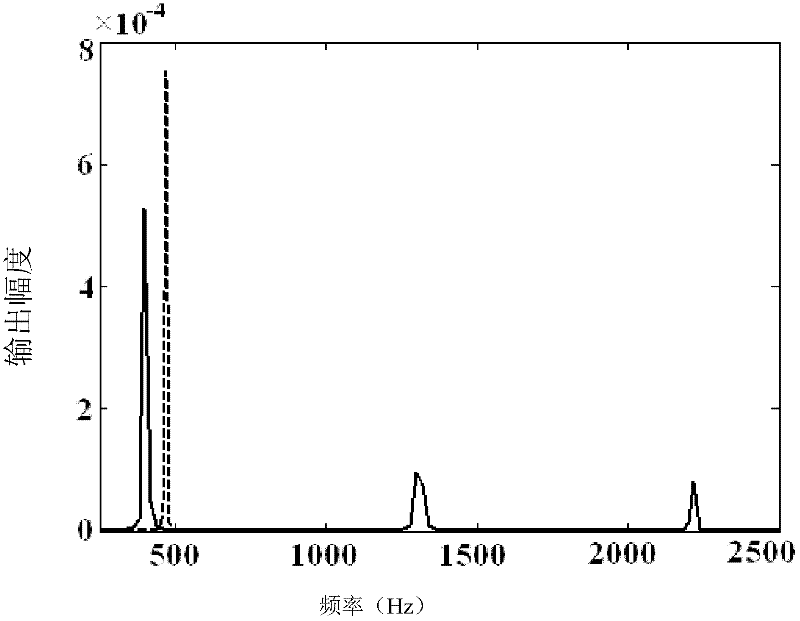

Device and method for measuring micro impulse by torsional pendulum method for modulating multi-beam laser heterodyne by using doppler galvanometer sine

InactiveCN102305682AHigh precisionHigh measurement accuracyApparatus for force/torque/work measurementDigital signal processingPendulum system

The invention relates to a device and a method for measuring a micro impulse by a torsional pendulum method for modulating multi-beam laser heterodyne by using doppler galvanometer sine, and belongs to the technical field of micro impulse measurement. By the device and the method, the problem that the measurement precision of parameter values to be measured is low because only one single parameter value to be measured can be acquired by the conventional heterodyne interference method for measuring the micro impulse of a micro thrustor is solved. The device consists of a digital signal processing system, a photoelectric detector, a pulse laser device, a torsional pendulum system, an H0 solid laser device, a polarization beam splitter (PBS), a quarter wave plate, a galvanometer, a plane standard lens and a convergent lens. The method comprises the following steps of: switching on driving power supplies of the H0 solid laser device and the galvanometer; exciting a working medium target by using pulse laser emitted by a pulse laser device, and making the working medium target produce plasma ejection to make the beam of a standard beam rotate; and acquiring signals emitted by the photoelectric detector by using the digital signal processing system, and processing the signals to acquire the micro impulse I' of the beam of the standard beam. The device and the method are suitable formeasuring the micro impulse of the micro thrustor.

Owner:HARBIN INST OF TECH

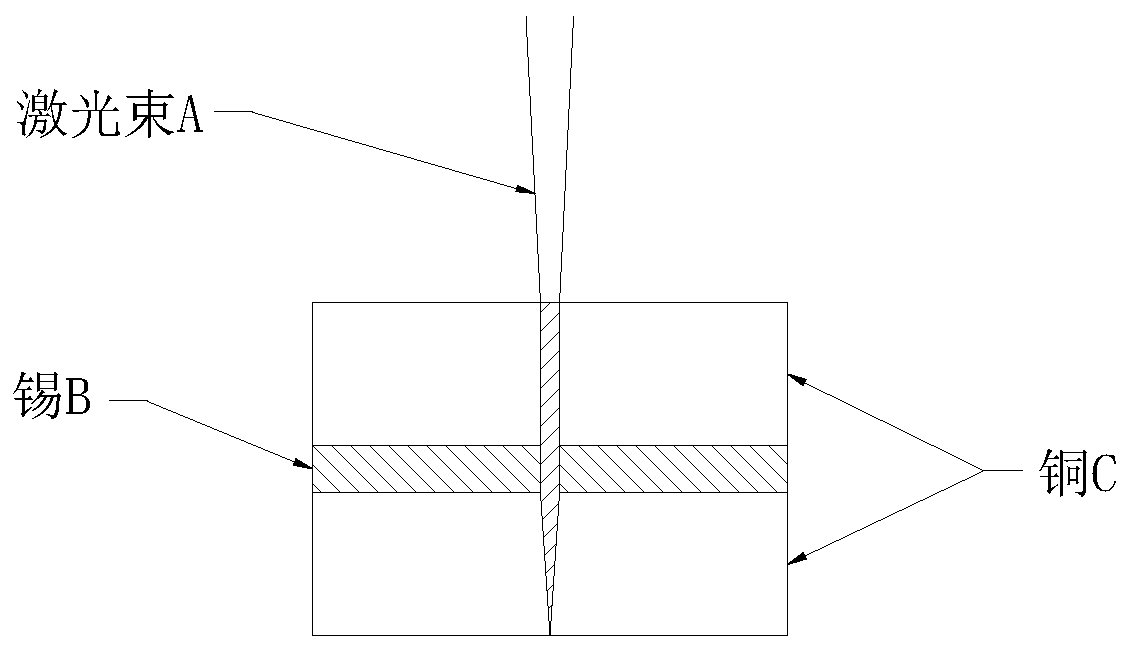

Penetrating type laser welding method of solar cell bus bars

PendingCN109986205AImprove heating efficiencySimplify the welding processLaser beam welding apparatusBeam expanderSurface layer

The invention relates to a penetrating type laser welding method of solar cell bus bars. The method comprises the following steps: outputting a laser beam through a pulse laser device, carrying out beam expansion control on diameter of the laser beam through a beam expander, focusing the laser beam subjected to beam expansion on a welding sample through a laser welding head, and enabling the laserwelding head to horizontally move up and down to adjust the size of a laser focal point and a laser welding spot; applying pre-pressure to a position near an area to be welded through a pre-pressingmechanism to enable two layers of welding strips to be in full contact with each other; receiving thermal radiation reflection laser in the welding process through a temperature feedback system, collecting a welding thermal radiation laser beam and converting the welding thermal radiation laser beam into temperature information, and calibrating the temperature of the welded area; enabling a visualimage system to move up and down to adjust a visual image focal point and identifying position information of the welding sample; focusing pulse laser on the welding strips, forming extremely high laser energy density in an action area, directly gasifying tin on the surface layers and copper on the inner sides of the welding strips, forming cavities in the materials and enabling the materials tobe tightly occluded with each other, and directly carrying out fusion welding of copper layers of the two layers of welding strips. The welding quality is high.

Owner:江阴德龙能源设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com