Micro vibration measuring system and measuring method based on long-distance pulse laser speckles

A pulsed laser, measurement system technology, applied in measurement devices, measurement of ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of the reduction of the echo power reaching the photodetector, adverse effects of measurement, etc., and avoid the large-scale echo power. The effect of reducing, ensuring quality, and increasing echo power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

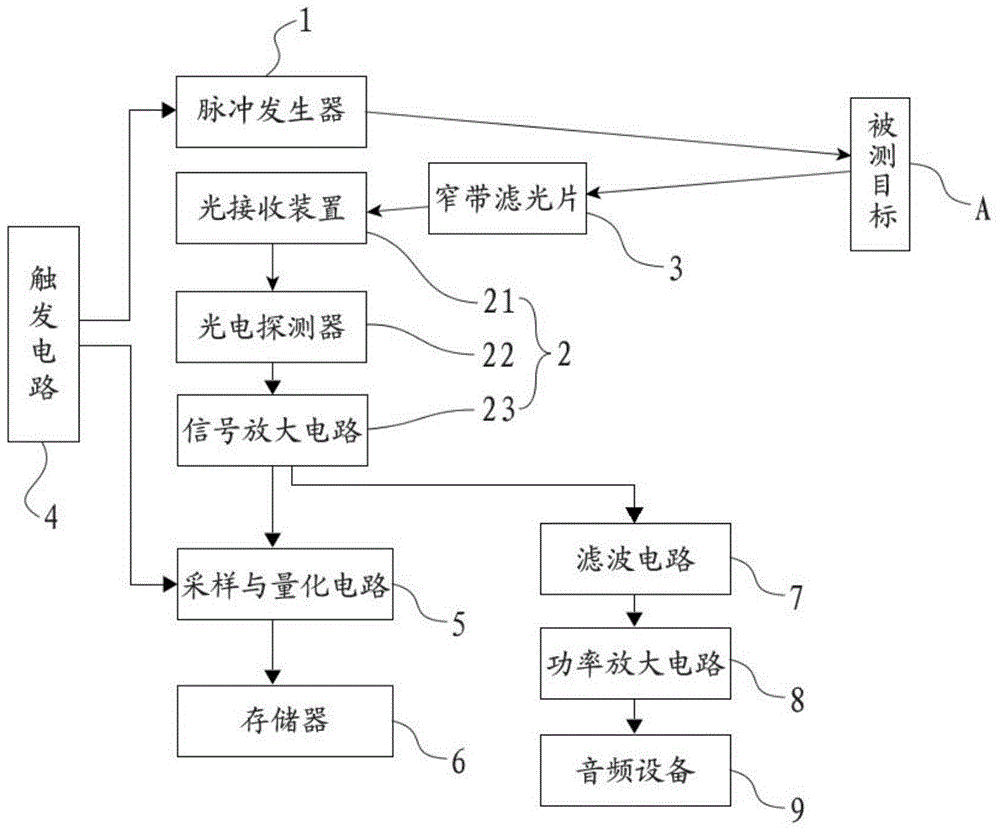

[0027] see figure 1 , a micro-vibration measurement system based on long-distance pulse laser speckle, including pulse laser 1, light detection unit 2, narrow-band filter 3, trigger circuit 4, sampling and quantization circuit 5, memory 6, filter circuit 7, power Amplifying circuit 8 and audio equipment 9, wherein:

[0028] The pulsed laser 1 is used to emit pulsed laser with high peak power and high repetition rate to irradiate the measured target A, and the emission wavelength can be visible light wavelength or infrared wavelength. In this embodiment, the pulsed laser 1 is a Q-switched laser.

[0029] refer to figure 1 As shown, the light detection unit 2 includes a light receiving device 21, a photodetector 22 and a signal amplification circuit 23, wherein:

[0030] The light receiving device 21 is used to receive the speckle generated by the diffuse reflection of the pulsed laser light by the measured target A, and has a certain receiving aperture. In this embodiment, ...

Embodiment 2

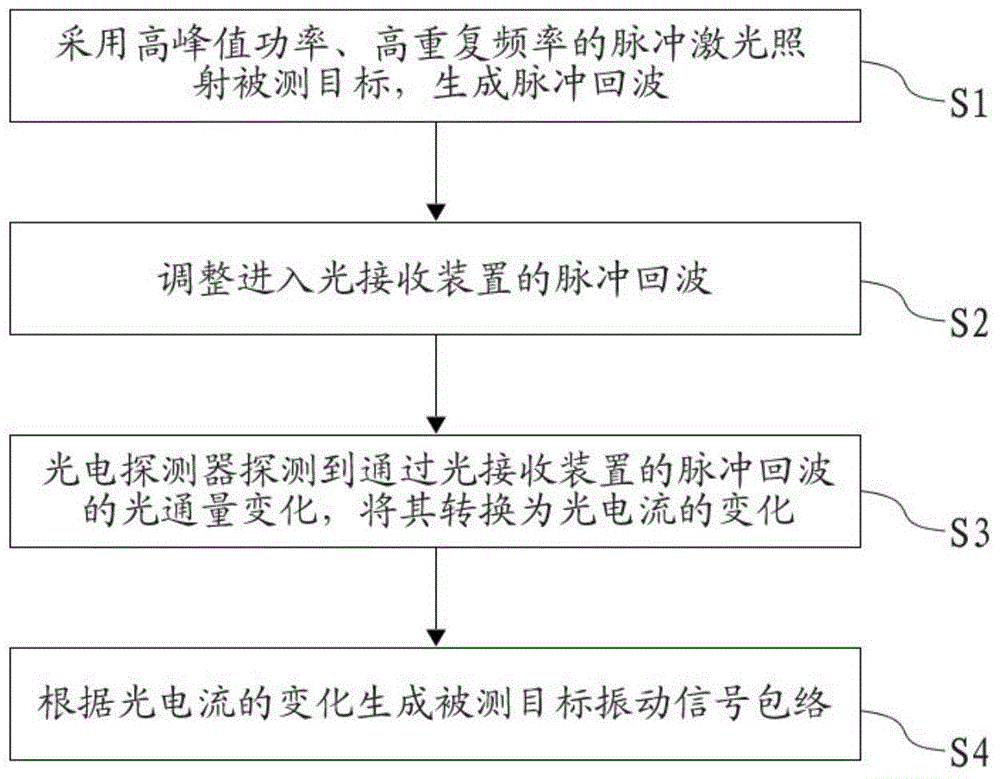

[0039] see figure 1 with figure 2 As shown, a micro-vibration measurement method based on long-distance pulsed laser speckle, including the following steps:

[0040] S1. Pulse laser 1 emits pulsed laser light with high peak power and high repetition frequency to irradiate the target A to be measured and generate pulse echo. The repetition frequency of the pulse laser should be greater than twice the highest vibration frequency of the target A to be measured. The "pulse echo" mentioned here refers to the speckle generated after the pulsed laser is diffusely reflected by the target A under test.

[0041] S2. Adjust the pulse echo entering the light receiving device 21 so that the variation of its luminous flux and the vibration amplitude and frequency of the measured target A are optimally matched. This step is specifically implemented by the following methods:

[0042] By adjusting the spot size of the pulsed laser 1 irradiating the target A to be measured and the receiving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com