Micronano-scale high-temperature laser impact imprinting device and method

A laser shock and micro-nano-scale technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of performance degradation of micro-nano devices, small depth and width of micro-nano structures, and poor replication accuracy, so as to avoid The effect of surface oxidation, large imprint depth, and high manufacturing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

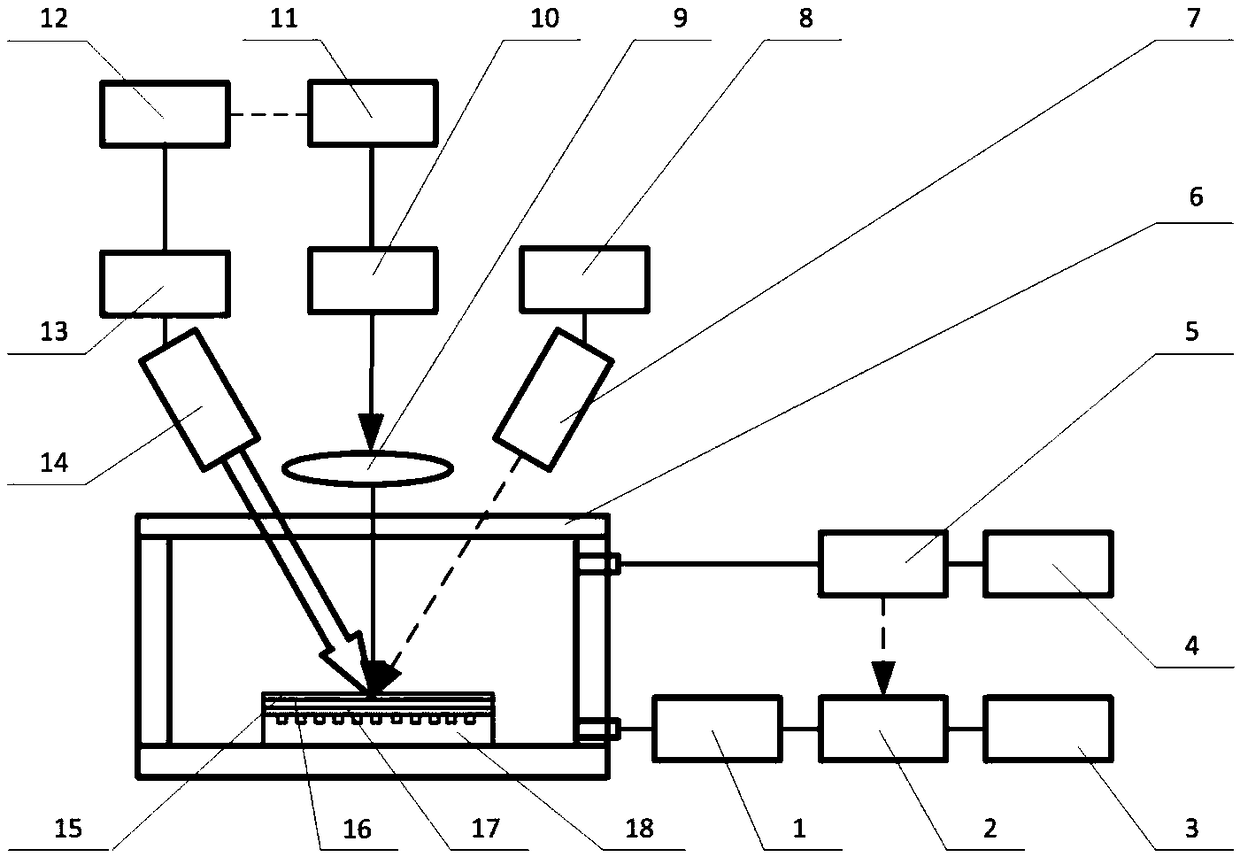

[0027] like figure 1 As shown, a micro-nano-scale high-temperature laser shock imprinting device includes an atmosphere protection module, a high-temperature laser shock imprinting module, a monitoring module and a fixture module. Wherein, the atmosphere protection module includes a target chamber 6. The target chamber 6 has an air inlet and an exhaust port. The oxygen sensor 5 is connected with the exhaust valve 4; and the oxygen sensor 5 is connected with the air pump 2. The high-temperature laser shock embossing module is composed of a focusing mirror 9, a pulse laser 10, a pulse laser controller 11, a pulse delay generator 12, an infrared laser controller 13, and an infrared laser 14; the monitoring module is connected by a CCD 7 and a computer 8 in sequence; The fixture modules are constrained layer 15 , absorbing layer 16 , sample 17 and mold 18 from top to bottom; the fixture module is set in the target chamber; the high-temperature laser shock embossing module is set ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com