Laser processing method and device for non-through hole

A laser processing method and non-through hole technology, which are used in laser welding equipment, metal processing equipment, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further clarify the method and device adopted by the present invention to achieve the intended invention purpose, the laser drilling method and device proposed by the present invention and its specific implementation methods, steps and features will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

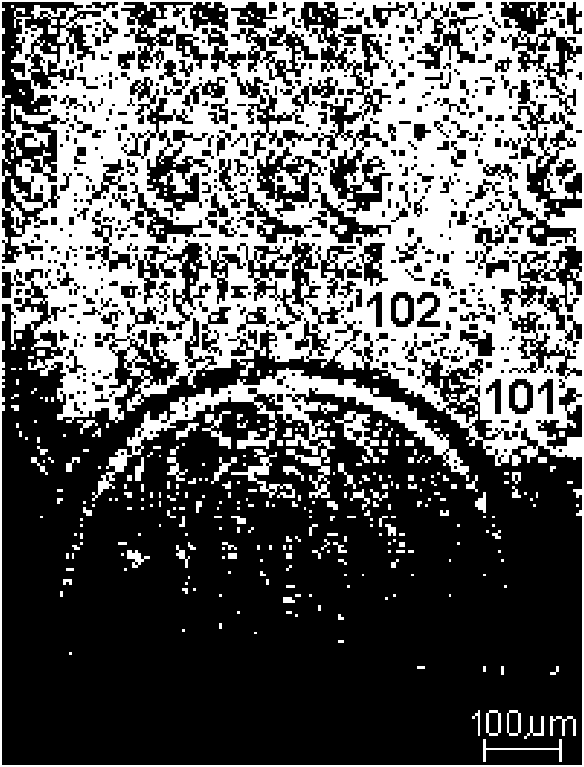

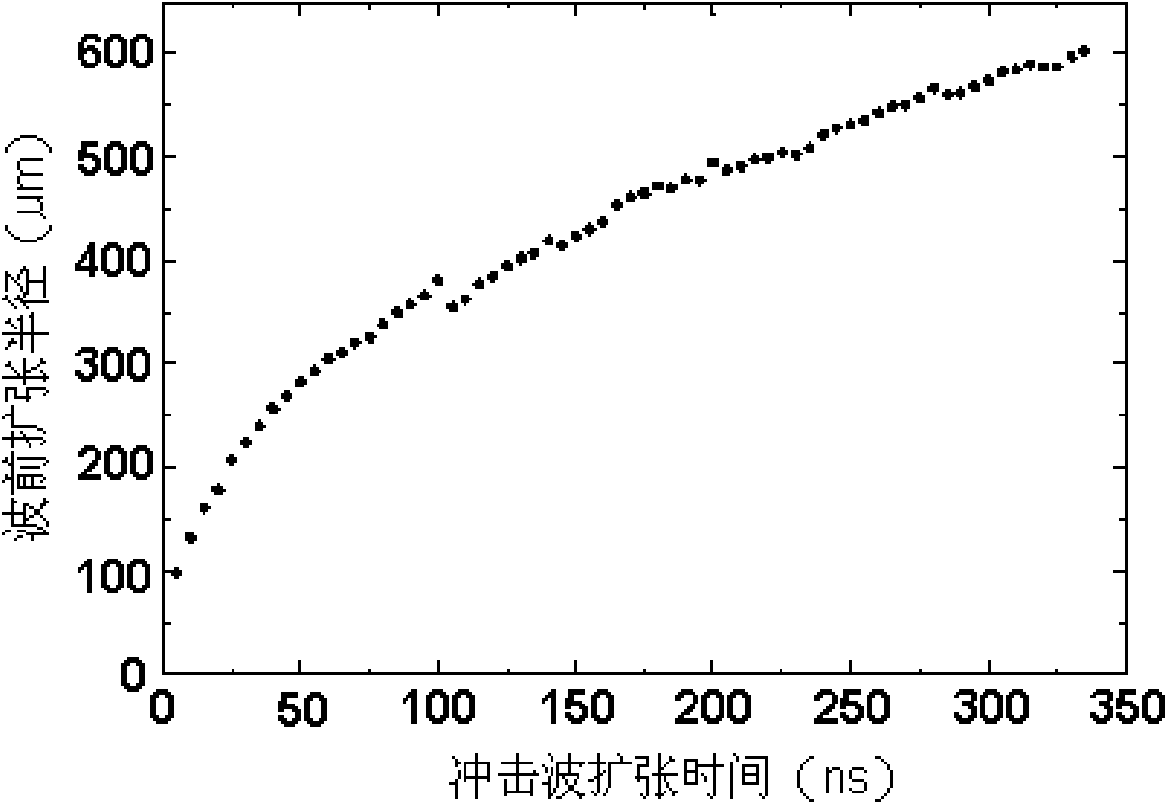

[0024] High-intensity laser pulses are irradiated on the surface of the material, when the power density is greater than about 2×10 8 W / cm 2 When the surface layer of the material is explosively vaporized, the laser-supported detonation wave (LSDW) phenomenon occurs. The high-temperature and high-pressure material gas plasma and air plasma rapidly expand outward from the laser action area to form laser shock waves 101, such as figure 1 As shown, the hemispherical laser shock wave front 102 expands toward the outside atmosphere with the laser action point as the center. The high temperature, high pressure, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com