Pre-welding laser cleaning method and device capable of efficiently removing aluminum alloy oxidation film

A technology of laser cleaning and oxide film, which is applied in the direction of cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of slow cleaning speed, low overlap rate, failure to meet preparation requirements, etc., to improve cleaning quality and facilitate welding , the effect of high surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

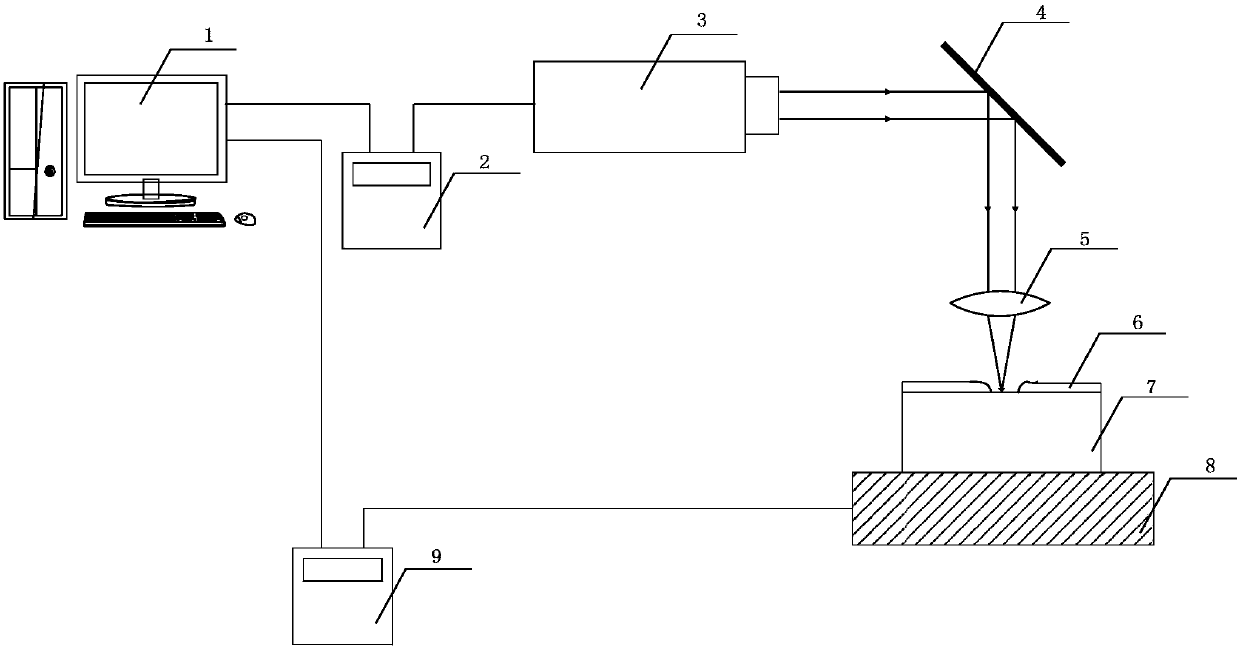

[0054] Select the material 7 to be cleaned to be 6061 aluminum alloy, adopt sulfuric acid anodization in the anodic oxidation method, and coat a layer of film thickness d on the surface of the aluminum alloy 0 = 4μm oxide film 6, oxide film 6 is Al 2 o 3 , place the material 7 to be cleaned on the three-dimensional mobile platform 8, and place the focal length of the focusing lens 5. The direction of the laser beam is adjusted by the scanning galvanometer 4 so that it is parallel to the normal direction of the upper surface of the aluminum alloy of the material 7 to be cleaned.

[0055] According to the thickness of the oxide film 6, the measured laser cleaning threshold power is J 0 =15W, set the laser cleaning power to J through the laser control board 0 , take △J=0, from η=△J×10 -7 Calculated η = 0, due to D = 50μm, f = 100kHz, according to Set the scanning speed ν=5000mm / s.

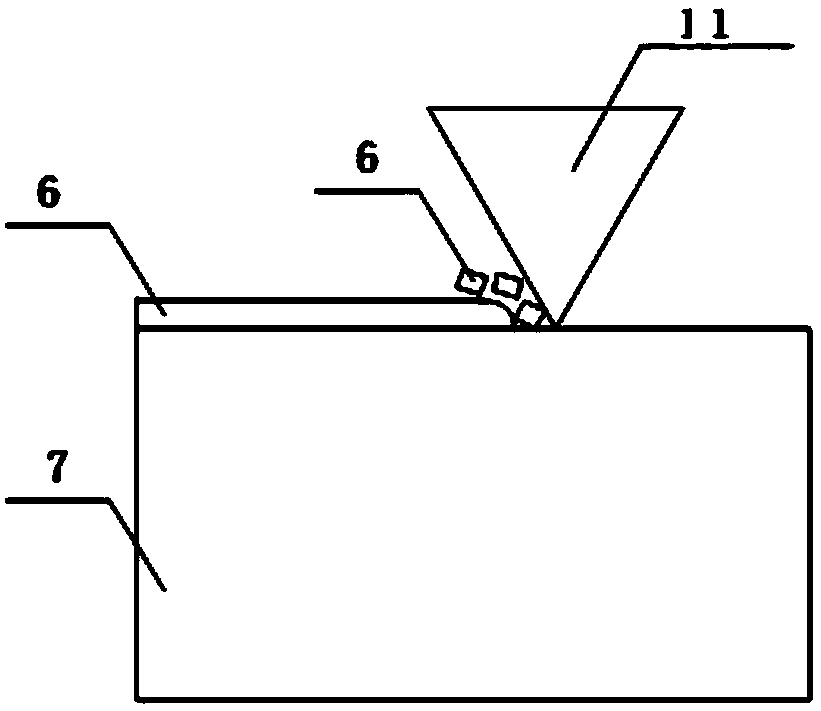

[0056] like figure 2 As shown, the pulsed laser 3 emits a pulsed laser and scans the uppe...

Embodiment 2

[0059] The above process of preparing the material 7 to be cleaned remains unchanged, and the material 7 to be cleaned is still selected from 6061 aluminum alloy, and the thickness of the film layer is d 0 = 4 μm. The laser energy J=15W, 20W, and 25W are set to act on the aluminum alloy surface through the laser control board 2, f=100kHz, η=-5%, because D=50μm, according to Therefore, the scanning speed ν=4750mm / s.

[0060] After cleaning, use such as Image 6 The schematic diagram of the oxygen content test on the surface of the aluminum alloy with different laser energies of η=-5% is shown, point A is the center of the laser spot, point B is the center of the adjacent spot, and the test direction is from point A to point B. The result is as Figure 7 The oxygen content curves on the surface of the aluminum alloy with different laser energies of η=-5% are shown. It can be seen from the figure that when J=15W, the oxygen content is higher than that on both sides at the ove...

Embodiment 3

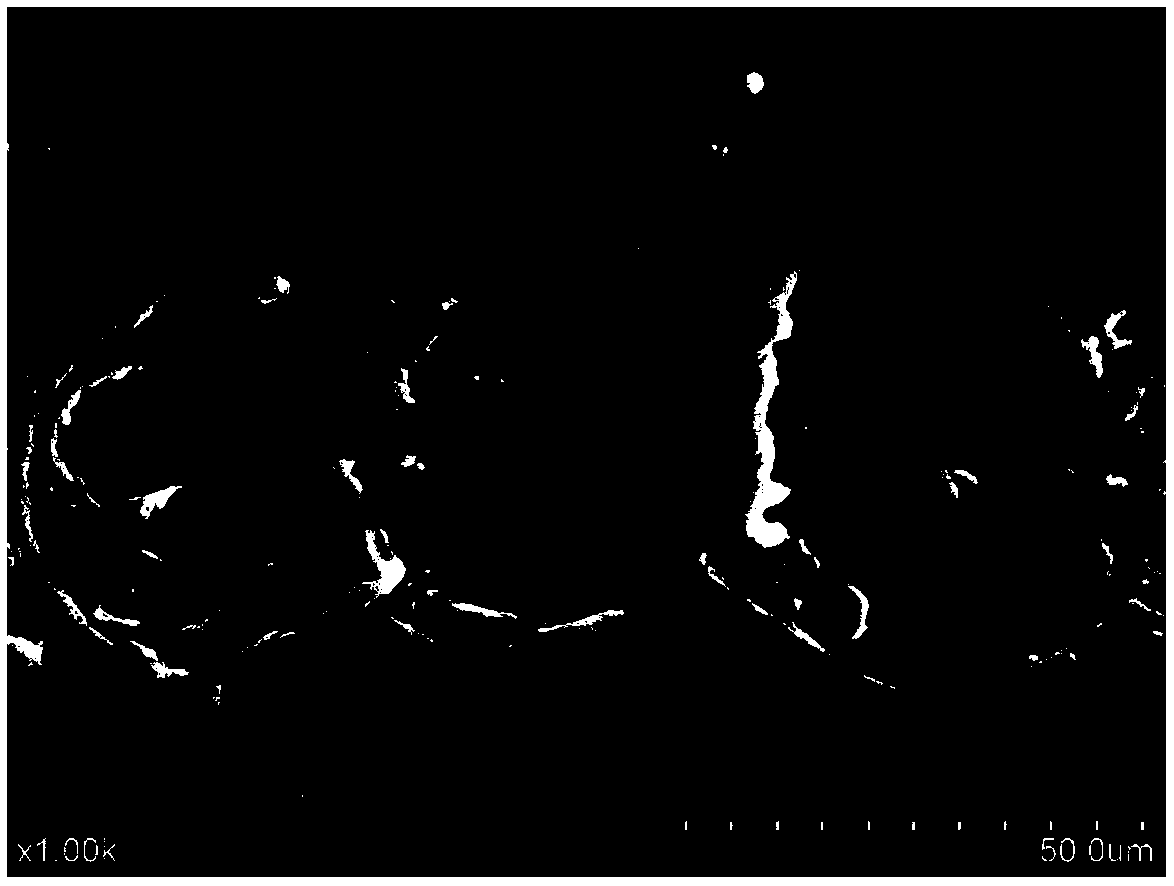

[0062] The material is the same as the previous two examples. Set the laser energy J=25W to act on the aluminum alloy surface through the laser control board 2, f=100kHz, take △J=50×10 4 W / cm 2 , by η=△J×10 -7 Calculated η = 5%, since D = 50μm, according to Therefore, the scanning speed ν=5250mm / s. like Figure 8 Shown is the surface microtopography of the η=5% laser cleaning oxide film according to the present invention. From the figure, it is found that the oxygen content of the laser active area is 0, indicating that the oxide film has been completely removed, and no new oxide layer has been formed; the oxygen content of the unaffected areas of the two adjacent laser spots is also 0, indicating that the oxide film has also been removed. Meet the pre-weld preparation requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com