Patents

Literature

170 results about "Green cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Green cleaning refers to using cleaning methods and products with environmentally friendly ingredients and procedures which are designed to preserve human health and environmental quality. Green cleaning techniques and products avoid the use of products which contain toxic chemicals, some of which emit volatile organic compounds causing respiratory, dermatological and other conditions. Green cleaning can also describe the way residential and industrial cleaning products are manufactured, packaged and distributed. If the manufacturing process is environmentally friendly and the products are biodegradable, then the term "green" or "eco-friendly" may apply.

Green disinfection/sanitization compositions and processes of making thereof

ActiveUS20100136148A1Provide benefitsImproved profileBiocideInorganic active ingredientsFlavorEmulsion

Cleaning and disinfecting compositions containing one or more “green” surfactants are disclosed. The compositions may be present as micro-emulsions that generally include green disinfecting agents, green surfactants, and water. The composition may also contain other green ingredients such as linkers, pH adjusting agents, natural fragrances, natural insecticides, and other natural organic actives such as natural oils. The composition may be used as a green cleaning and disinfecting composition with performance comparable or superior to conventional cleaning and disinfecting products with less desirable ecological profiles.

Owner:SC JOHNSON & SON INC

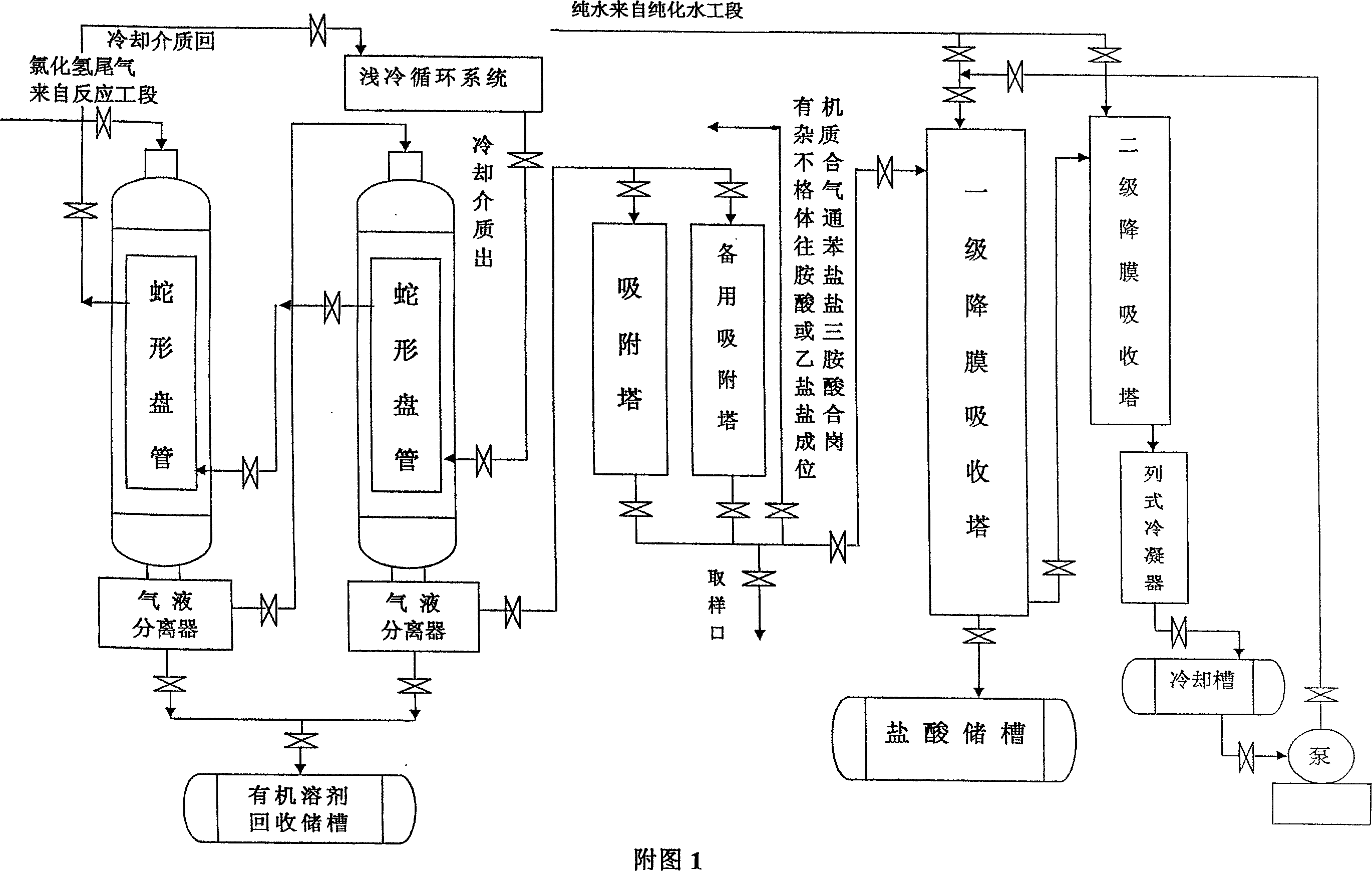

Process for preparing high purity hydrochloric acid by circularly absorbing hydrogen chloride by-product

InactiveCN1951801ASatisfied with the resultExpand the range of industrial applicationsChlorine/hydrogen-chloride purificationActive particlesPolypropylene

The invention discloses a preparing method of high-purity alcaine technology through circulating and adsorbing by-product of hydrogen chloride, which comprises the following steps: aerating hydrogen chloride gas with organic impurity in the condenser at -10- -40 deg.c and gas-liquid separator; adsorbing gas with little impurity through active particle charcoal; aerating adsorbed gas into one-grade and two-grade graphite falling-film; adsorbing through pure water to obtain the high-purity alcaine; adsorbing non-adsorbed hydrogen chloride through cold water; putting hydrogen chloride and diluted acid in the graphite polypropylene falling-film adsorbing tower into cooling groove; utilizing circulating pump to transmit the inlet of one-grade falling-film adsorbing tower; circulating the adsorption.

Owner:ZHEJIANG UNIV OF TECH

Green cleaning energy-saving antiwear hydraulic oil and production process thereof

InactiveCN1597886AAvoid wear and tearObvious effect of drag reduction and energy savingAdditivesBase-materialsCombustionToxic material

The invention discloses a green clean energy-saving antwear hydraulic oil, composed of hydrofined II-type mineral basic oil, refined plant oil and synthetic hydrocarbon as well as compound additive, applied to electric liquid servo hydraulic systems in the trades of sugar manufacturing, drug making, daily chemicals, light industry, food, sanitation, etc, and especially applied to the limitation to solid particles in oil and the nontoxic use environment in related trades. It mainly makes the bubbling and weeping in the use and storage and transport course of the related trades unable to destroy the quality of corresponding products, unable to cause mutagenic substances and chemical toxic substances and uneasy to cause pollution and has better internal-combustion degradability.

Owner:广西飞日能源集团有限公司

Water-activated green cleaning wipe

ActiveUS8278260B2Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsWet wipeGreen cleaning

Owner:SC JOHNSON & SON INC

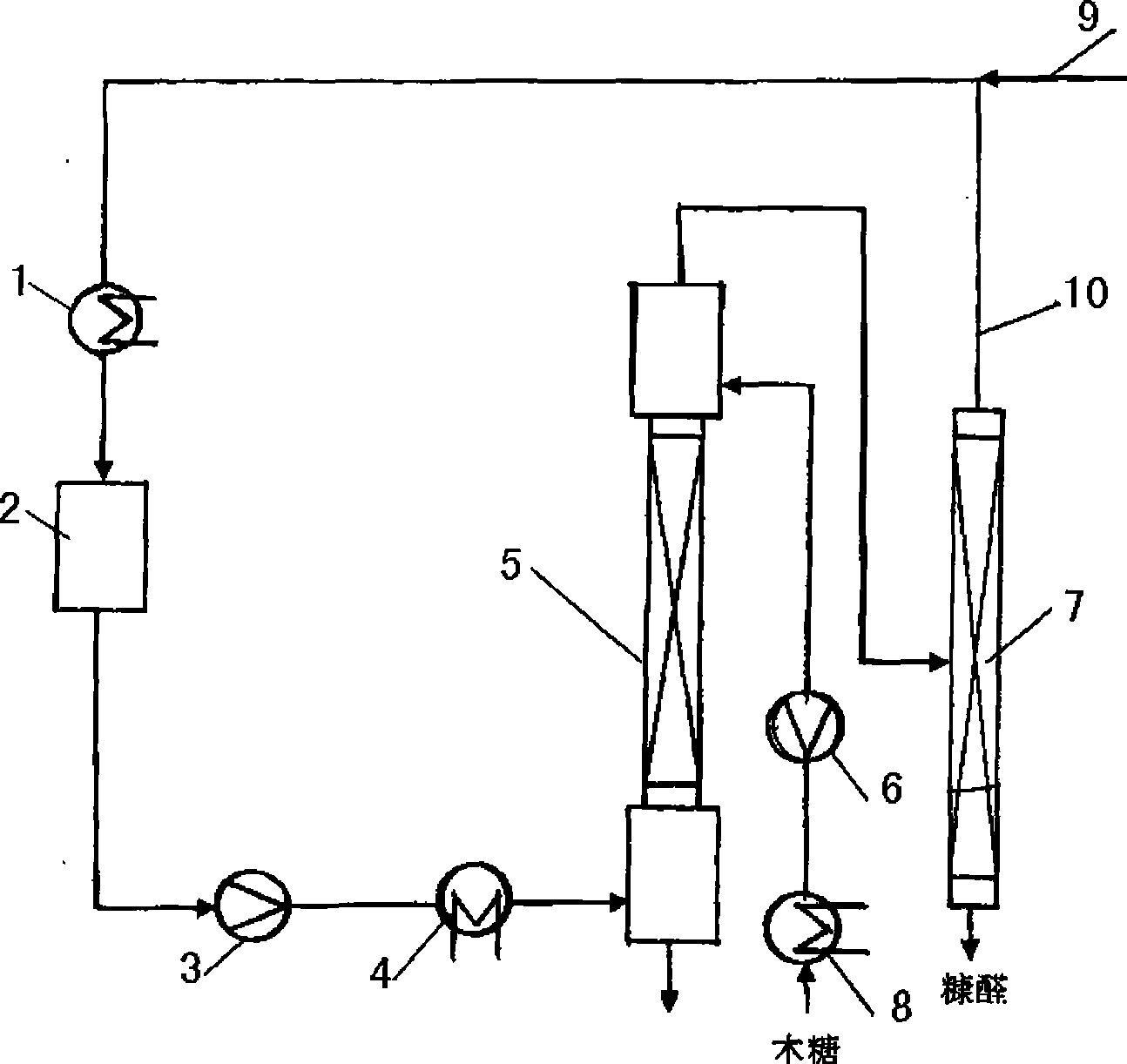

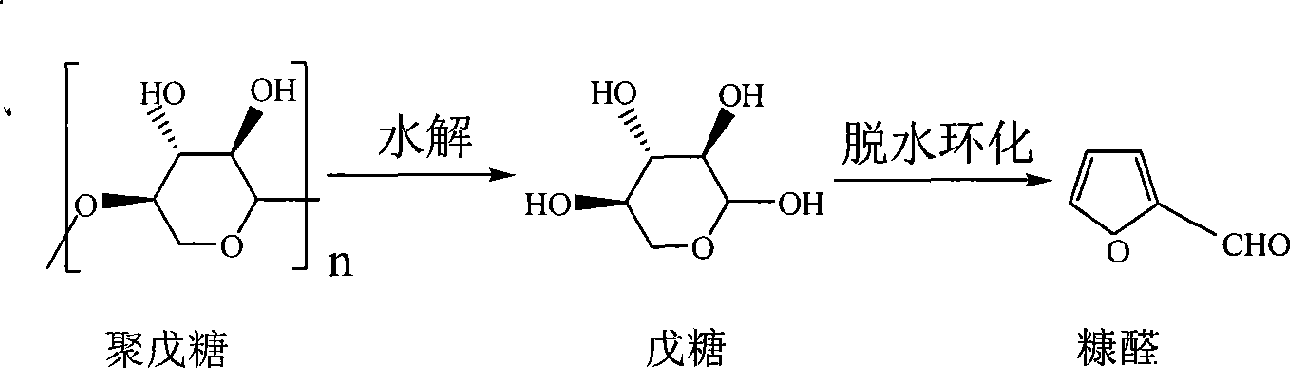

Solid acid catalysis and supercritical extraction coupled furfural preparation and apparatus

InactiveCN101486695AEasy to separateReduce pollutionOrganic chemistryMolecular sieve catalystsSolubilitySolid acid

The invention discloses a solid-acid catalysis and supercritical extraction coupling preparation method of furfural and a device thereof, pertaining to the technical field of the preparation of biobased chemicals. The method adopts solid acid as a catalyst, such as superacid or molecular sieve, and uses supercritical CO2 (SCCO2) for on-line extraction and separation of products. In the whole preparation process of the furfural, raw material aqueous phase and supercritical fluid phase successively enter a tower for realizing the countercurrent contact multiple-extraction which is carried out in a catalysis filling extracting tower. In the whole process, the solid acid is easily separated from the product, can be recycled and has little corrosion to equipment. Discharge amount of the three wastes is small and operation is convenient and safe. Furthermore, the SCCO2 has low cost, no toxicity, good diffusivity performance and easily controllable solubility, and such a defect as mass transmission efficiency reduction in a heterogeneous catalytic reaction after the use of the solid acid can be overcome when the SCCO2 is used for on-line extraction of the furfural, so as to immediately remove coking precursors from a catalyst pore passage, thereby deferring the inactivation of the catalyst, realizing green and clean production technology and wide application prospect.

Owner:TSINGHUA UNIV

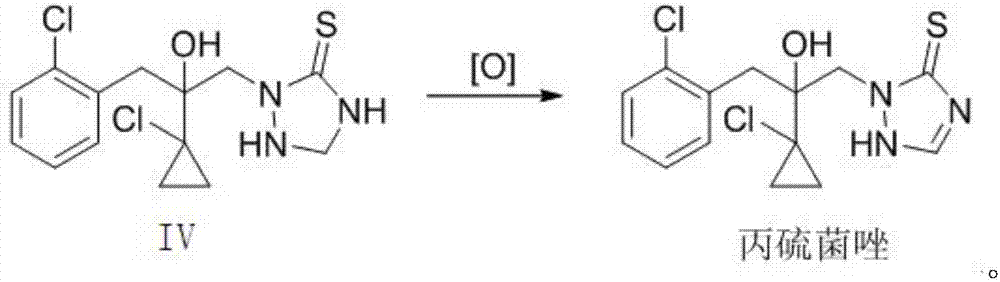

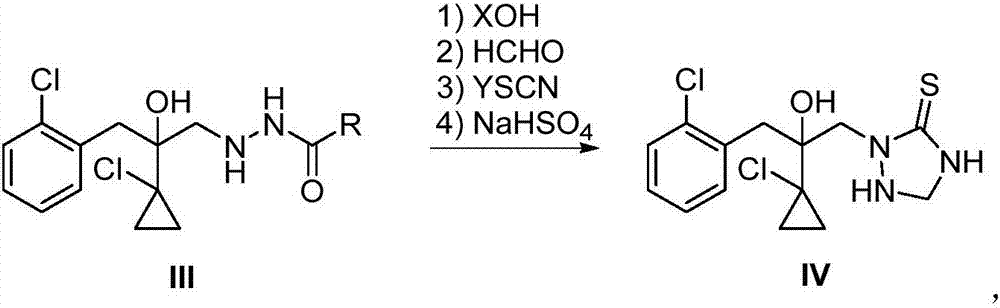

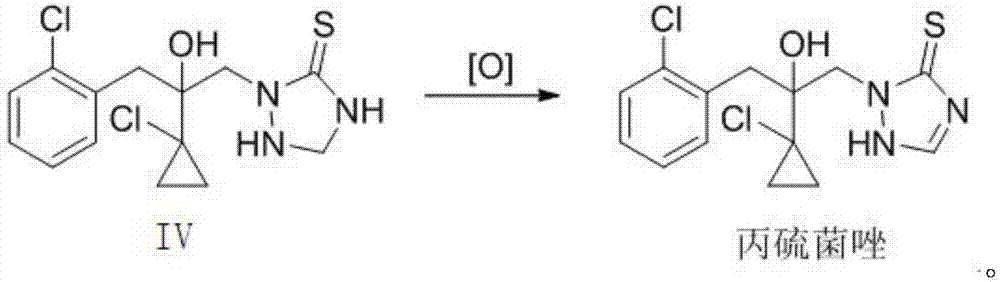

Preparation method of prothioconazole

The invention relates to a preparation method of prothioconazole. The preparation method comprises that a compound IV undergoes a reaction at 20 to 120 DEG C in the presence of an oxidizing agent and a solvent, and after the reaction, the product is treated to form prothioconazole. The preparation method has mild reaction conditions, utilizes cheap and easily available raw materials, has simple processes, is environmentally friendly and clean in regents and reaction processes, greatly reduces three wastes, is suitable for industrial production, and realizes a high yield of a final product and high content.

Owner:JIANGSU SEVENCONTINENT GREEN CHEM CO LTD

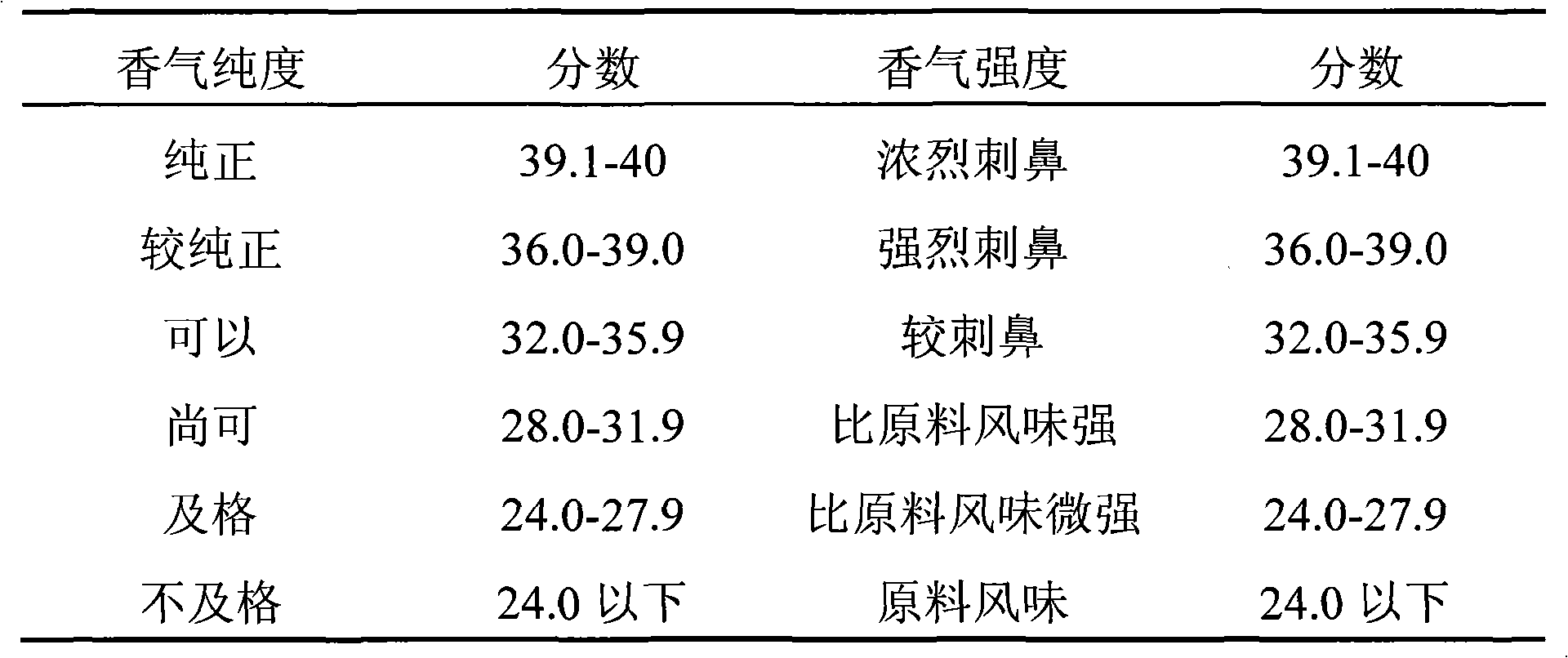

Natural milk flavored essence base material prepared by hydrolyzing milk fat by using lipase and production method thereof

ActiveCN102067977APlay a role in flavoringIntrinsic quality improvement and enhancementFood preparationFlavorHydrolysate

The invention discloses a natural milk flavored essence base material prepared by hydrolyzing milk fat by using lipase and a production method thereof. The method comprises the step of adding the lipase into a milk fat system to hydrolyze to obtain a hydrolysate, and is characterized in that the milk fat system is prepared by a method comprising the steps of: adding the milk fat into water or enzymolysis buffer solution, mixing the milk fat and the water or the enzymolysis buffer solution, raising the temperature to be between 70 and 90 DEG C, keeping the temperature for 15 to 40 minutes, reducing the temperature to be between 35 and 55 DEG C, adjusting the pH value of solution to be between 4.5 and 7.5, and then performing mechanical emulsification. The invention improves a method for producing a milk flavored essence base material by taking cream as a raw material and utilizing the hydrolysis of the lipase, and obtains the milk flavored essence base material with stronger, fuller and more impressive milk flavor, more natural and softer fragrance, and more natural trend by improving reaction conditions. Compared with products prepared by the conventional process, the natural milkflavored essence base material can increase the fragrance by 100 to 200 times, and remarkably improve the inner quality of fragrance-increased products. Moreover, the natural milk flavored essence base material has the advantages of low production cost, simple process, high edible safety, and 'pollution-free' production process.

Owner:BRIGHT DAIRY & FOOD

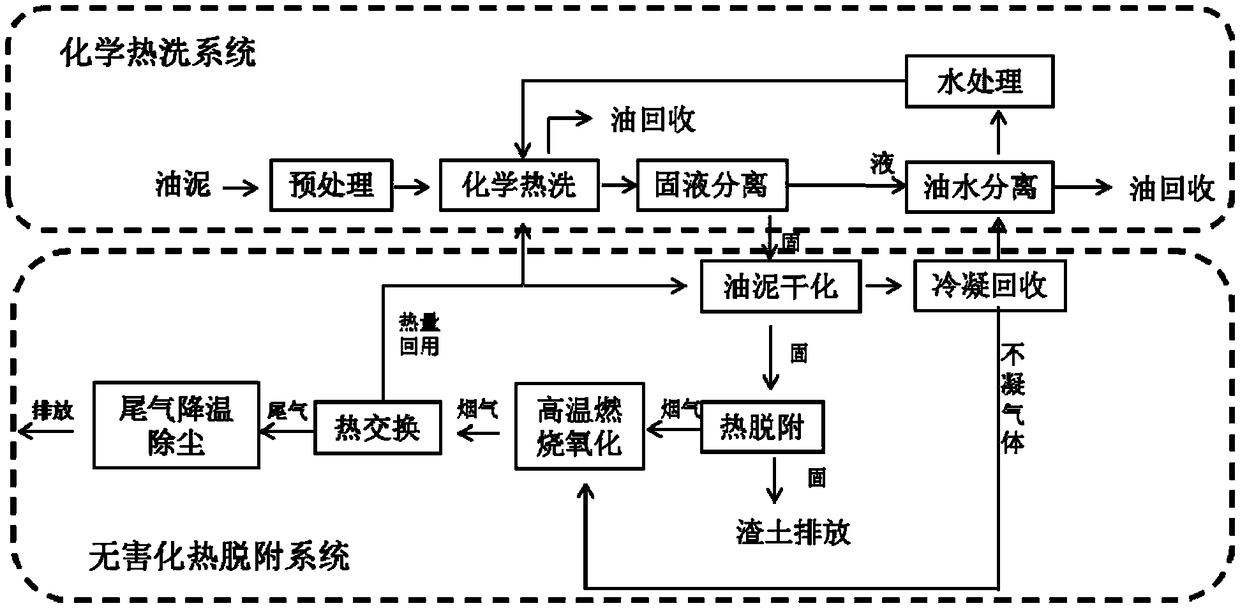

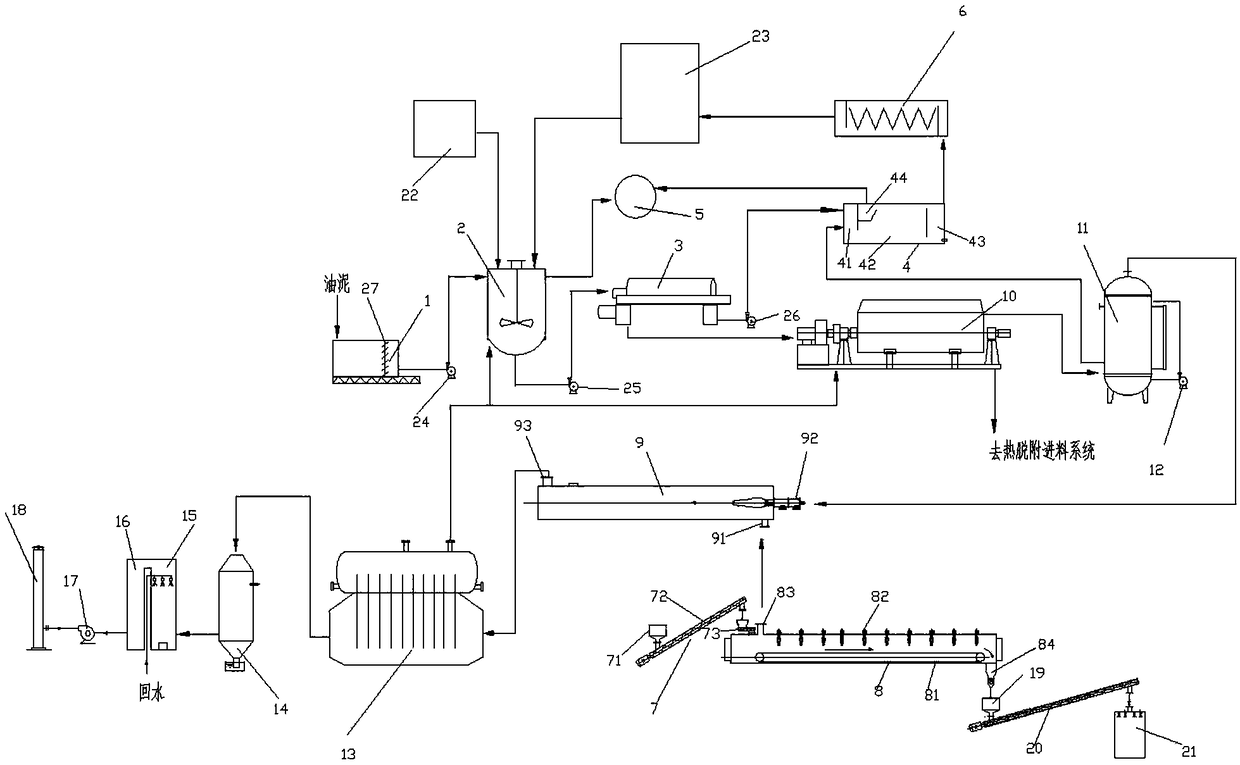

Green cleaning-thermal desorption integrated technology treatment method and treatment system for high-concentration petroleum sludge

ActiveCN108996859ALayering efficiency is fastHigh recovery rateSludge treatment by de-watering/drying/thickeningFatty/oily/floating substances removal devicesHigh concentrationWater storage tank

The invention discloses a green cleaning-thermal desorption integrated technology treatment method and treatment system for high-concentration petroleum sludge. The treatment method includes the treatment steps of homogeneous impurity removal pretreatment, chemical thermal washing treatment, solid-liquid separation and oil-water separation, oil sludge thermal desorption and high temperature combustion oxidation, heat exchange and tail gas cooling and dust removal. The treatment system includes an oil sludge chemical thermal washing system and an oil sludge harmless thermal desorption system. The oil sludge chemical thermal washing system is formed by connecting an oil sludge homogenization slot, an oil sludge chemical thermal washing tank, a high efficiency solid-liquid separator, an oil-water separator, a sewage integrated treatment system and a water storage tank successively. The oil sludge harmless thermal desorption system mainly consists of a sludge dryer, a condensation recoverysystem, a thermal desorption feeding system, a thermal desorption system, a high temperature combustion oxidation system, a waste heat boiler and a discharging system. With adopting of the combined application of the chemical thermal washing technology and the thermal desorption technology, multiple functions such as resource recovery and utilization of petroleum materials and heat, reduction ofoily sludge, harmlessness and the like can be simultaneously realized.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

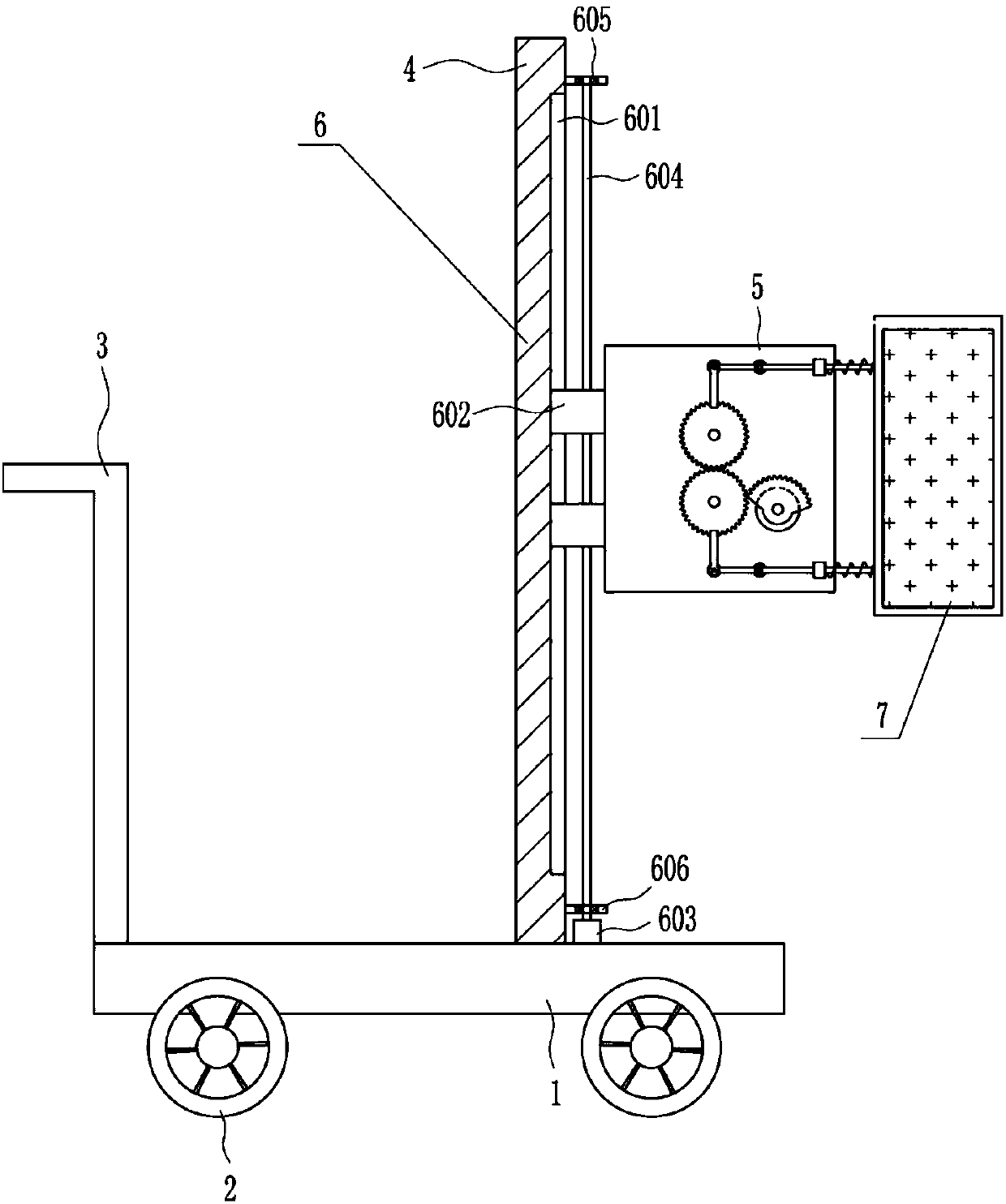

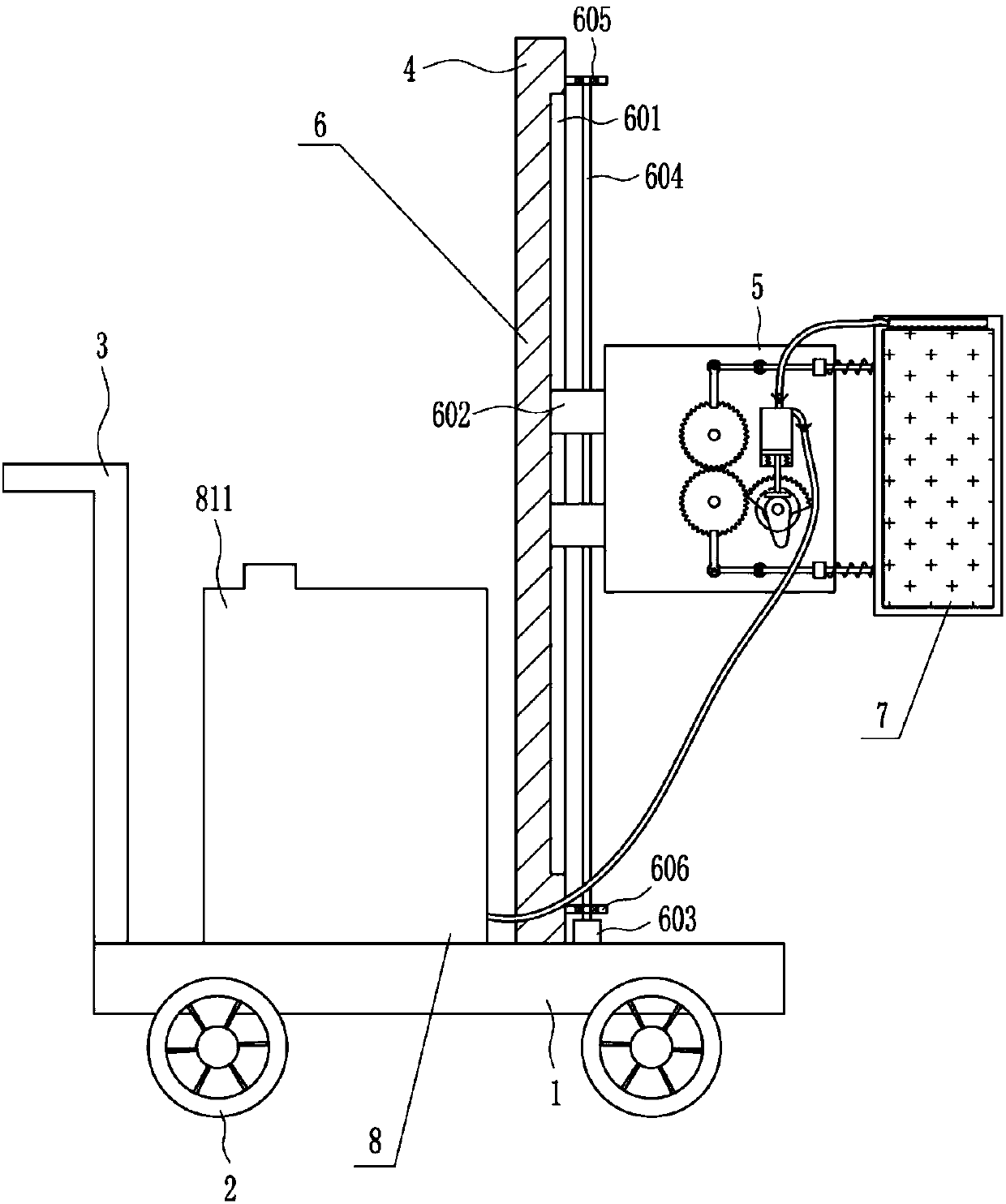

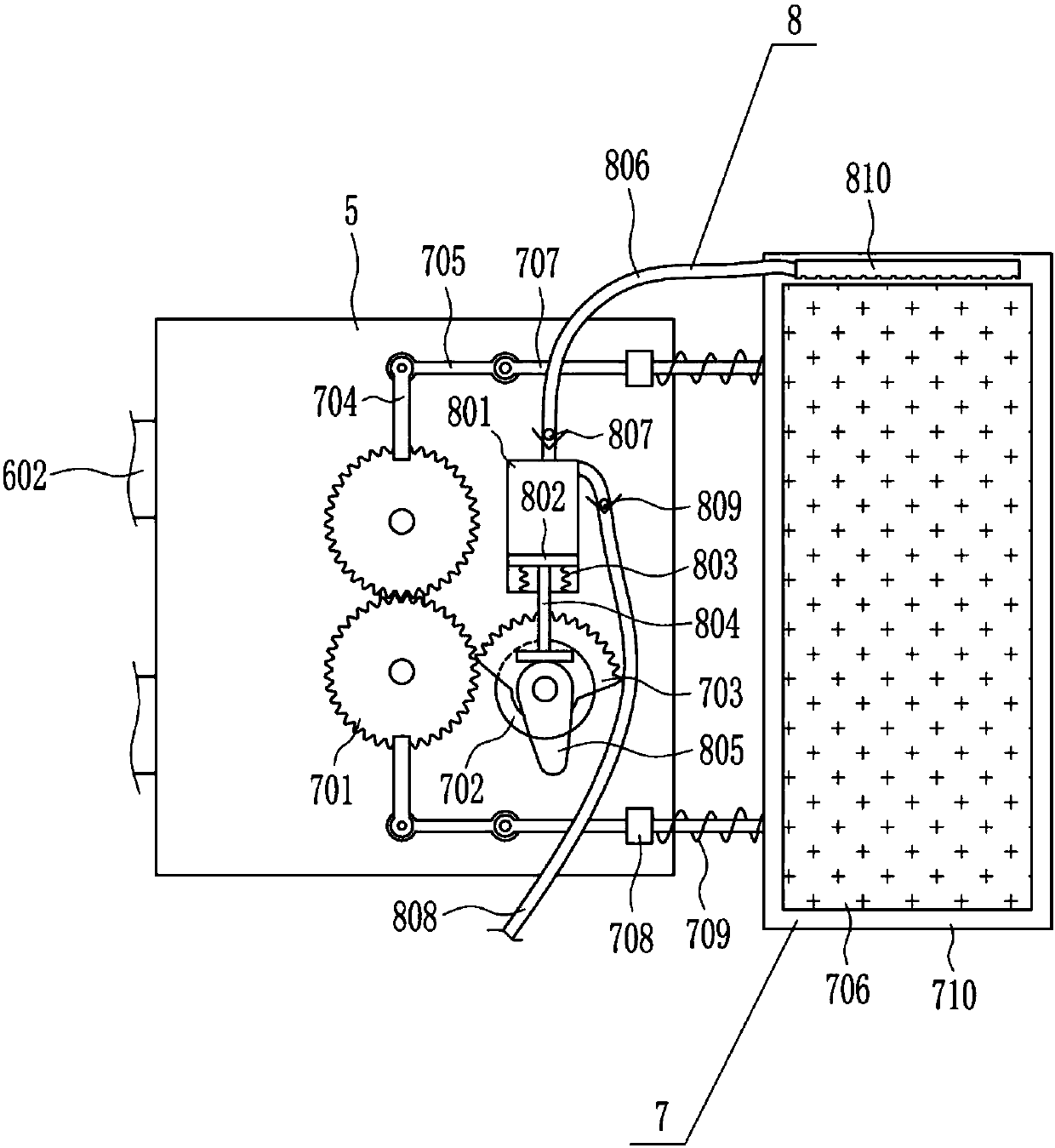

Municipal fence green cleaning car

The invention relates to a green cleaning car, in particular to a municipal fence green cleaning car. The invention aims to provide a municipal fence green cleaning car with a good cleaning effect, which is labor-saving and has high efficiency. In order to achieve the aim, the invention provides such a municipal fence green cleaning car, which comprises a trolley board and the like, wherein wheelsare arranged at the bottom of the trolley board, and a pushing handle is connected to the leftmost side of the top of the trolley board; the right side of the top of the trolley board is connected with a vertical board, and a lifting device is arranged at the right side of the vertical board; a lifting component of the lifting device is connected with a mounting board, and a brushing device is arranged at the front side of the mounting board. According to the municipal fence green cleaning car provided by the invention, the height of the brushing device is adjusted by the lifting device, so that various parts of the wall surface can be conveniently cleaned; the surface of the fence can be brushed by the brushing device, so that the wall surface can be cleaned; spraying water by a water spraying device can further improve the cleaning effect, so that the wall surface is well cleaned.

Owner:王静娴

Green disinfection/sanitization compositions and processes of making thereof

ActiveUS8778860B2Provide benefitsImproved profileInorganic/elemental detergent compounding agentsBiocideEmulsionGreen cleaning

Cleaning and disinfecting compositions containing one or more “green” surfactants are disclosed. The compositions may be present as micro-emulsions that generally include green disinfecting agents, green surfactants, and water. The composition may also contain other green ingredients such as linkers, pH adjusting agents, natural fragrances, natural insecticides, and other natural organic actives such as natural oils. The composition may be used as a green cleaning and disinfecting composition with performance comparable or superior to conventional cleaning and disinfecting products with less desirable ecological profiles.

Owner:SC JOHNSON & SON INC

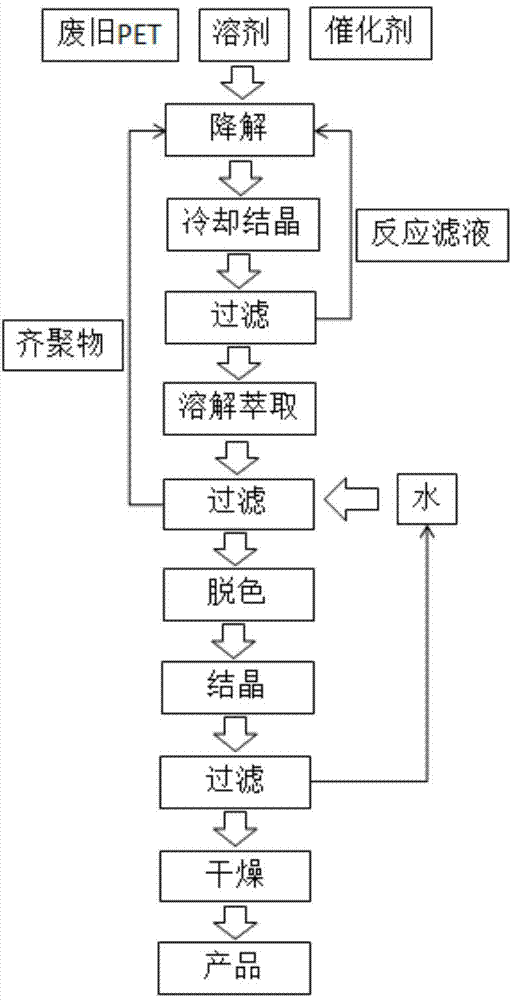

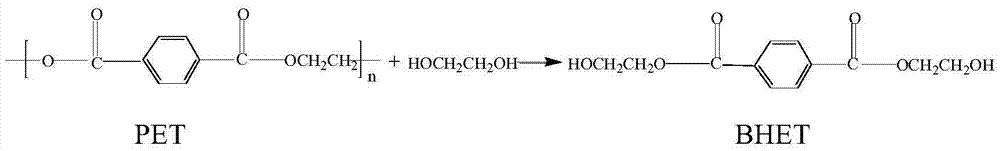

Recycling method for catalytic degradation of waste PET

InactiveCN104774153AAvoid mixingReduce manufacturing costOrganic compound preparationCarboxylic acid esters separation/purificationSocial benefitsDistillation

The invention relates to a recycling method for catalytic degradation of waste PET, and is characterized in that the recycling method comprises the process steps: degradation reaction, cooling crystallization, filtration, dissolution, decoloration, crystallization, drying and the like. The method is composed of two circulations of degradation and separation recovery, an alcoholysis agent is not contacted with dissolving water, large amount of energy consumption and great production costs generated in distillation separation of water and an alcoholysis liquid are saved, the amount of a solvent and the circular degradation cycle are reduced, production costs are significantly decreased, and the method is green, clean, fast and efficient. Scale production for alcoholysis recycling of the waste PET is achieved, and considerable social benefits and economic benefits are brought.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

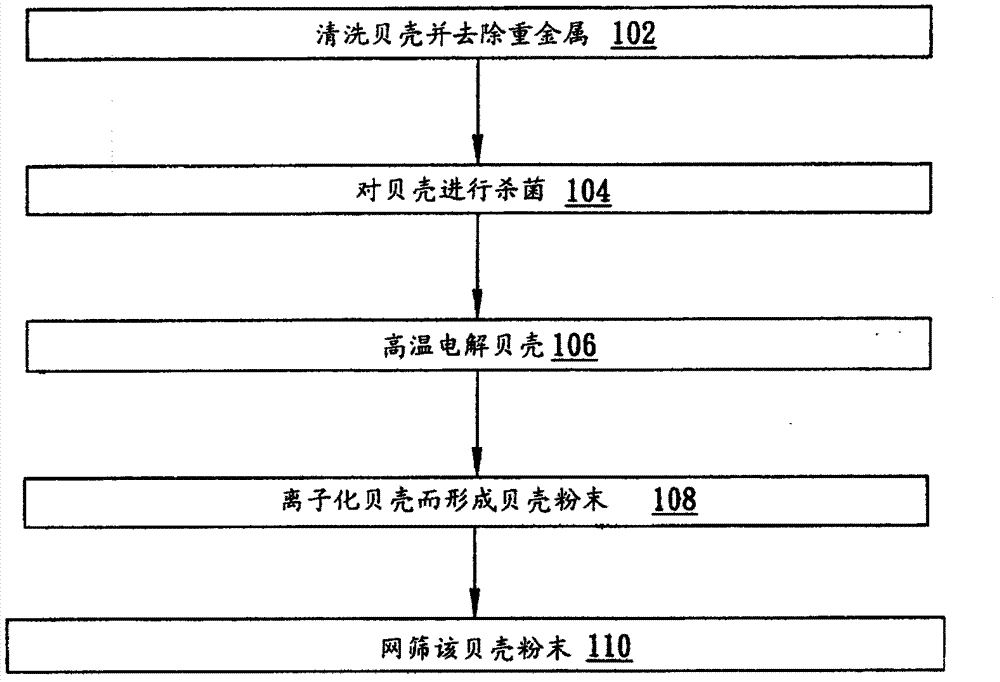

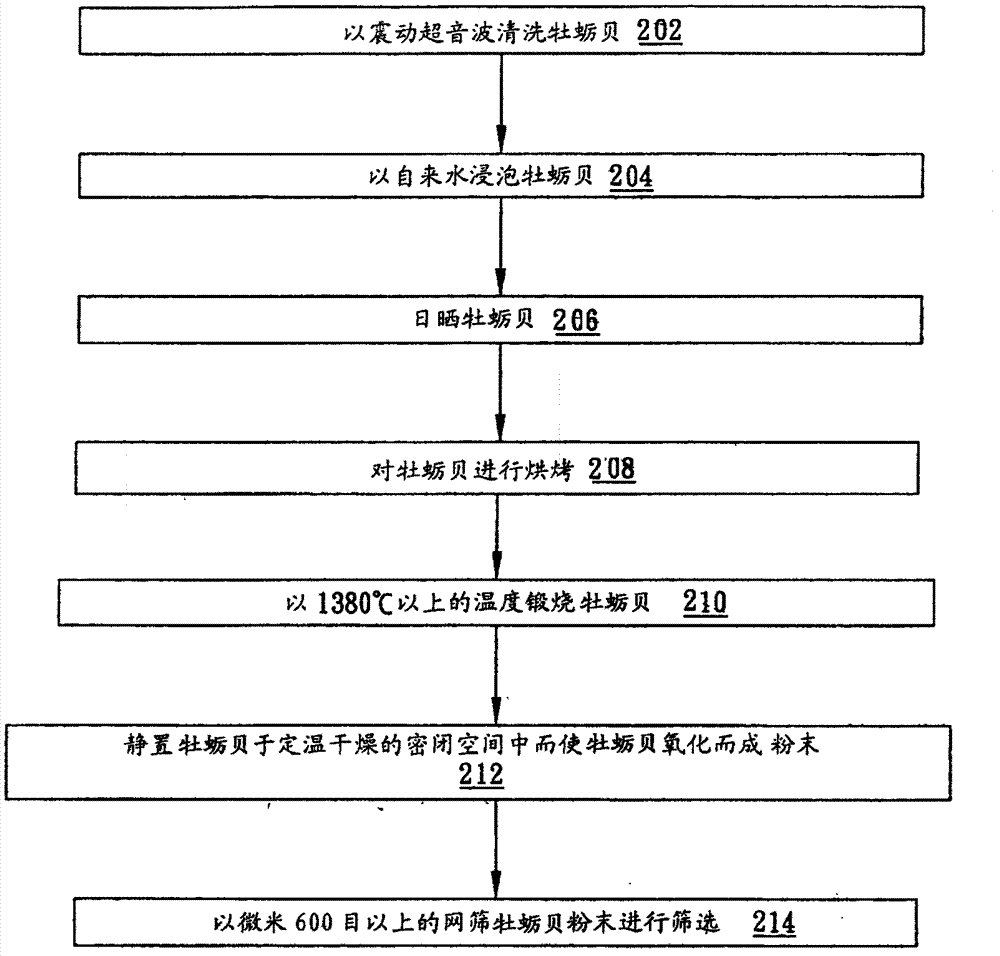

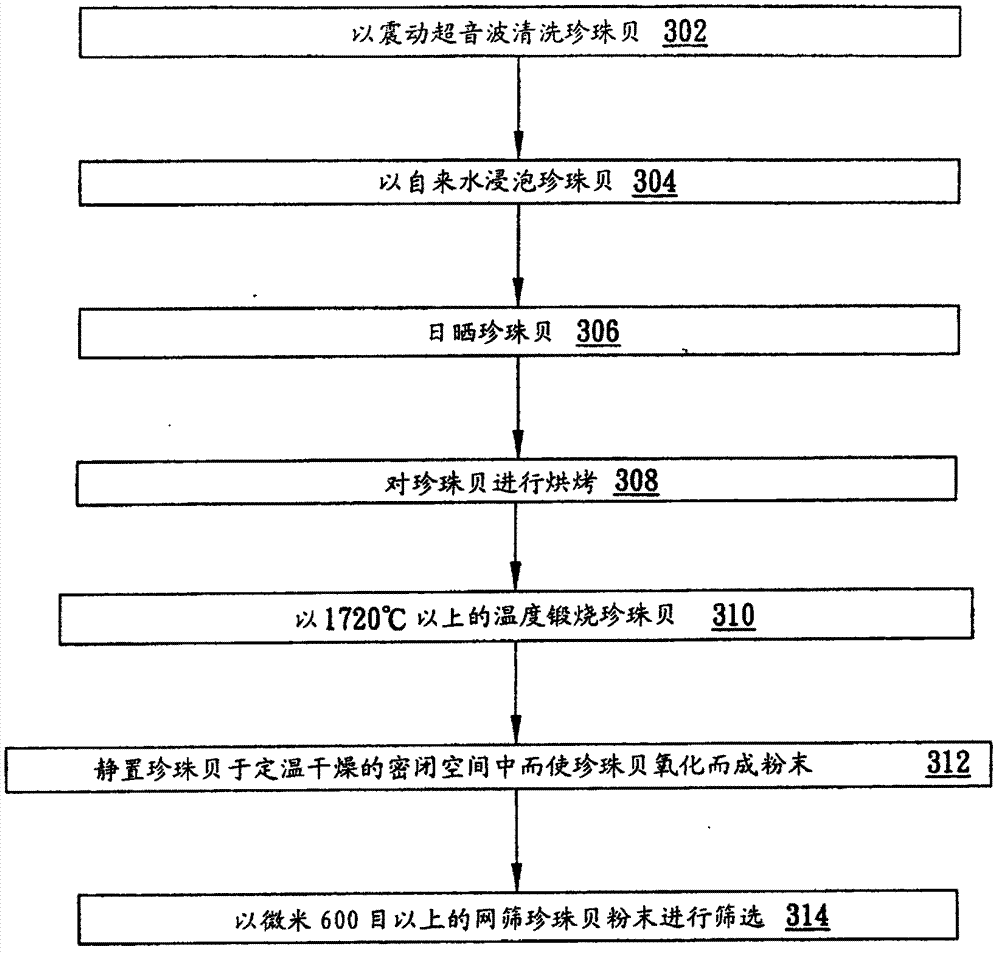

Natural cleaning agent for removing residual pesticide on fruit and vegetable surfaces and preparation method

InactiveCN103087846AHealth hazardNon-irritatingNon-surface-active detergent compositionsDetergent mixture composition preparationEcological environmentIrritation

The invention relates to a natural cleaning agent for removing residual pesticides on fruit and vegetable surfaces and a preparation method; the preparation method of the cleaning agent comprises the following steps: cleaning shells, removing heavy metal, sterilizing the shells, performing high temperature electrolysis and ionization of the sterilized shells to form solid powder, and refining with a mesh sieve to prepare nanometer powder; the cleaning agent comprises one or more than one natural shells according to certain weight ratios. The cleaning agent of the invention not only can remove residual toxic materials on fruit and vegetable surfaces, such as pesticides, sulfur dioxide and aflatoxin, prevent toxic materials from entering human body by eating of the fruit and vegetable, thus prevent continuous accumulation of the toxic materials in the body to damage human body health, but also has no toxicity or irritation to human skin, causes no secondary pollution of ecological environment, meets the development trend of green cleaning agents, and has good application prospects.

Owner:曾皇铭

Novel method for synthesizing finasteroid

The invention provides a new synthetic method of finasteride, belonging to the technical field of drug synthesis. The method comprises the following steps of: a. synthesis of dihydro finasteride iodo complex; and b. synthesis of finasteride; the synthesis method can transform dihydrotestosterone finasteride (F9) into the finasteride with a theoretic volume, avoids the use of harmful and toxic chemicals which are sensitive to the environment, has the advantages of total two-step reaction yield of more than 90%, purity of over 99.0%, good product yield, high purity, easy refining, simple operation, low cost, and less three-waste, conforms with the requirements of green chemical synthesis, and can achieve the requirements of high yield, high purity, green cleaning and industrial production of the finasteride.

Owner:ZHEJIANG XIANJU JUNYE PHARM CO LTD

Natural, mild and green cleaning agent

ActiveCN101165151AZero pollutionEnsure drinking water healthInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSodium metasilicateMirabilite

The natural mild green detergent consists of composite surfactant 1 (in weight portions, the same below), sodium carbonate 15-21.428, mirabilite 17-24.28, sodium percarbonate 6-8.58, sodium metasilicate 15-21.428, citric acid 10-14.28, sodium carboxymethyl ellulose 2-2.86, EDTA 2-2.86, stuffing 10-14.28 and water 3-4.28. It has the advantages of environment friendship, no pollution to underground water, high detergency, no harm to skin, natural sterilizing capacity and no toxicity.

Owner:SHANGHAI TEDIWANG AGRI TECH

Low-foam green CIP bactericidal concentrated cleaning agent

ActiveCN107937171APromote degradationEfficient removalInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsProduction lineFood industry

The invention discloses a low-foam green CIP bactericidal concentrated cleaning agent, and relates to the field of CIP engineering cleaning agents. The cleaning agent aims to solve the technical problems that the time of a cleaning process is long, industrial wastewater is easy to cause environmental pollution, and green cleaning standards are not met in the existing food industry. The cleaning agent is prepared from an active component, an assistant, a chelating agent, a penetrating agent, an antifoaming agent, a bactericide, a pH regulator and residual deionized water. The cleaning agent isapplicable to the cleaning of food production line CIP, has excellent hard water resistance and dirt-removing power, adopts a nonionic / anionic surfactant with excellent biological degradability, belongs to an efficient CIP green cleaning agent integrating low foam and bactericidal activity, and can effectively remove various food dirt.

Owner:HEILONGJIANG HEIKE TECH CO LTD

Golf course green debris removal device

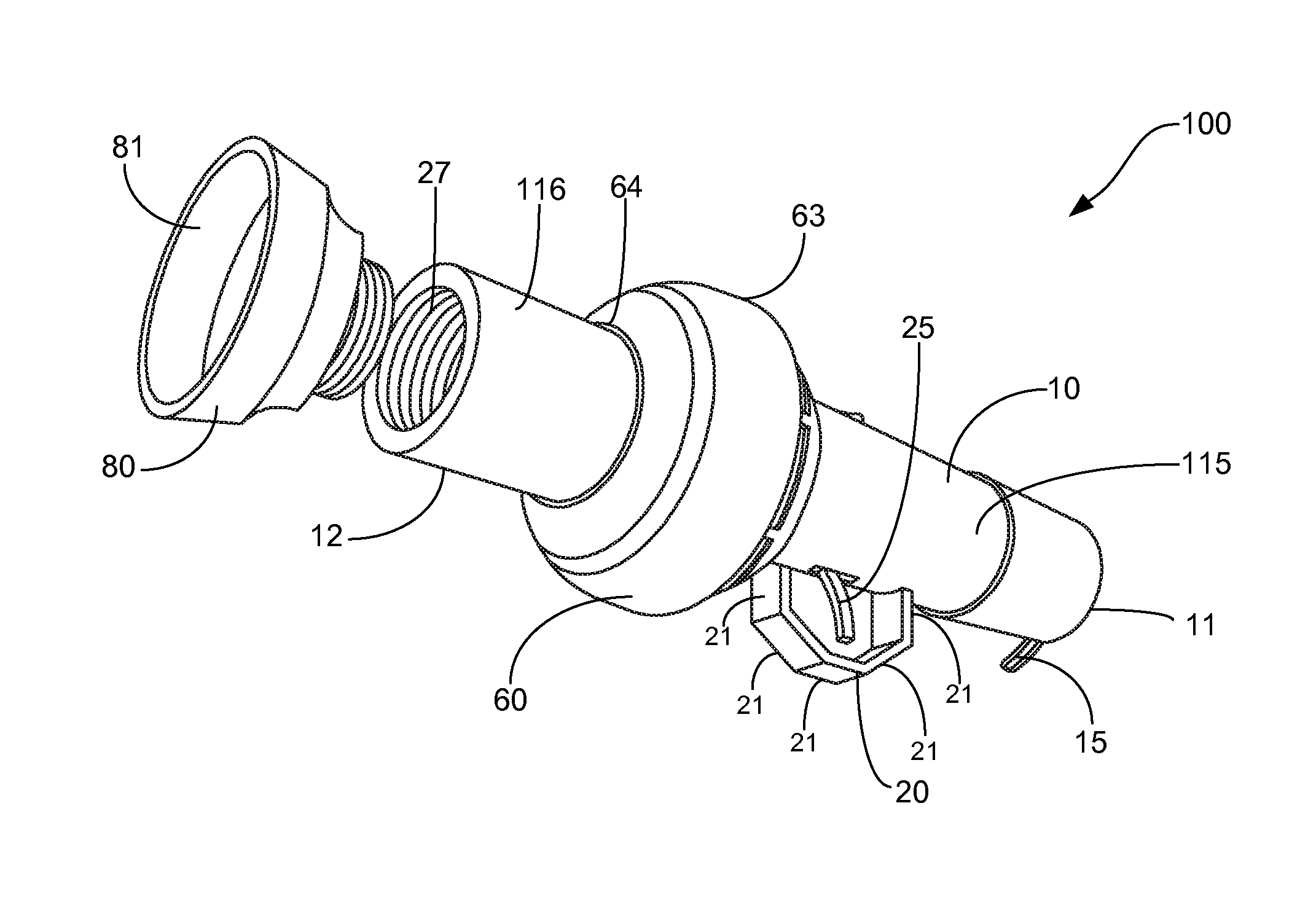

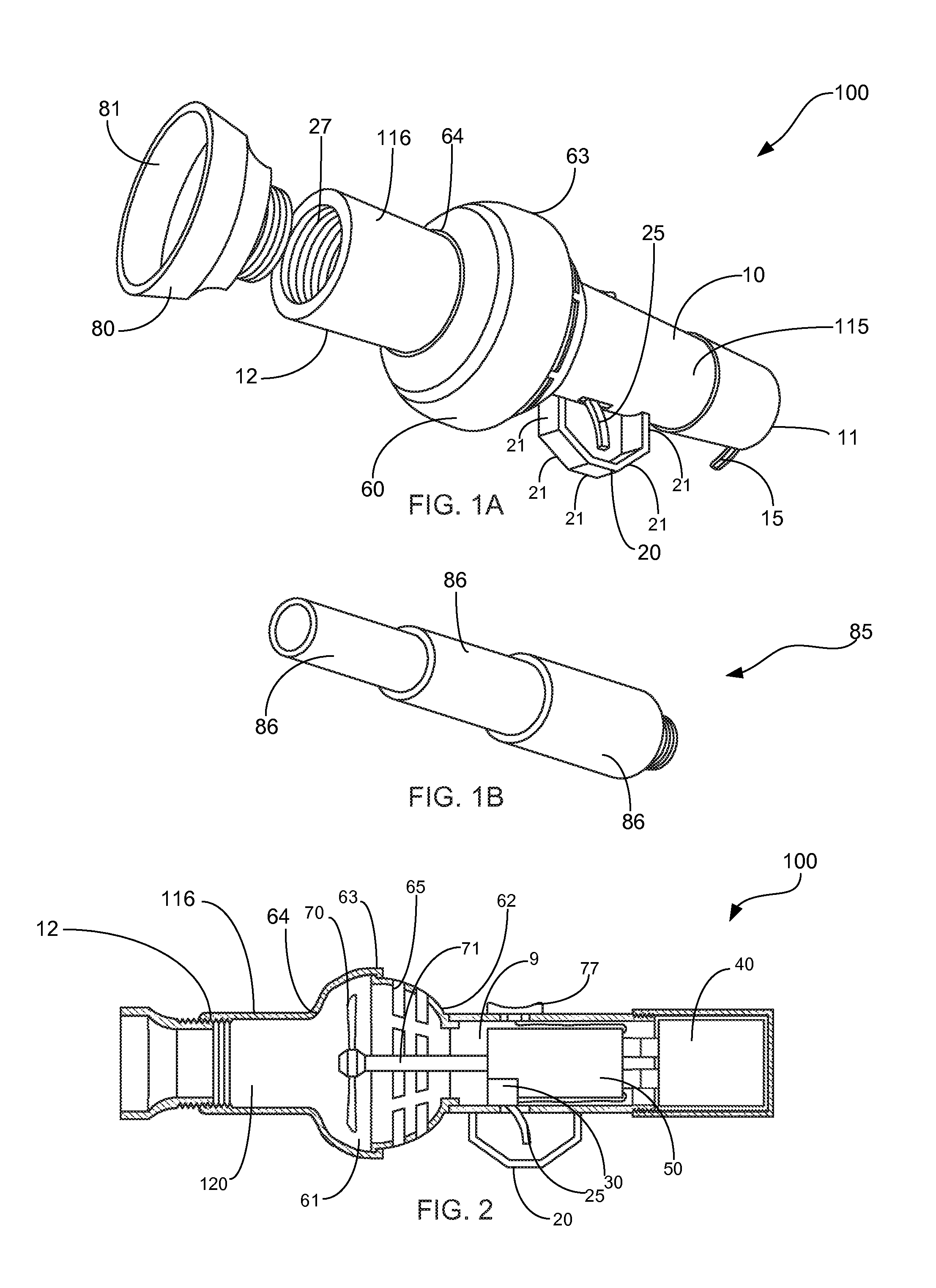

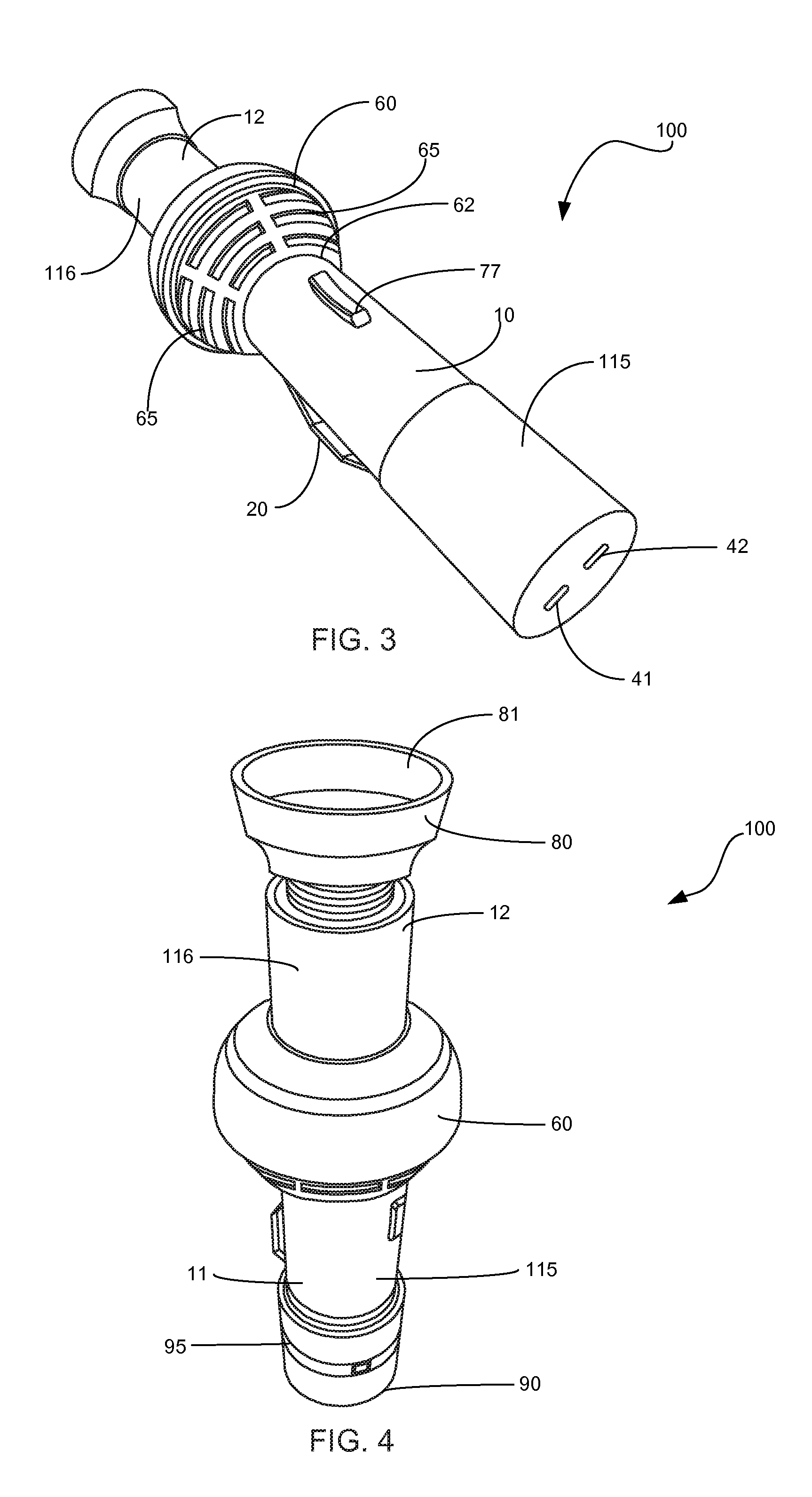

InactiveUS7941894B1Quickly remove debrisEasy to remove debrisSuction nozzlesGolfing accessoriesGolf course turfSpray nozzle

A golf course green cleaning device configured to remove debris from the predicted putting path of a golf ball. The golf course green cleaning device further includes a housing having three contiguous portions. The first portion is generally cylindrical in shape and has disposed therein a rechargeable power supply. The second portion is spherical in shape and is substantially hollow. The second portion has a fan an motor assembly therein configured to generate an airflow. The third portion is operably coupled to the second portion and is cylindrical in shape having an internal air passage to receive the airflow from the second portion. Removably attached to the third portion distal from the second portion is a nozzle that directs the airflow exiting the third portion so as to remove debris from the predicted putting path of a golf ball.

Owner:SKORPUT TONY

Preparation method of cleaning agent for kitchen

ActiveCN104293498AImprove surface activityGood decontamination performanceInorganic/elemental detergent compounding agentsSurface-active detergent compositionsMethacrylateAmylase

The invention discloses a preparation method of a green cleaning agent for a kitchen. The preparation method comprises the following steps: degrading corn starch in water by using high-temperature alpha-amylase, then carrying out graft copolymerization reaction with polyoxyethylene ether methacrylate under the action of an initiating agent to prepare a green starch-based surface active agent, and then compounding with soluble chitosan, sodium tripolyphosphate and sodium carbonate to obtain the green cleaning agent for the kitchen. The green cleaning agent for the kitchen, which is obtained by adopting the method, can be used for cleaning tableware, fruits, vegetables and the like and has the characteristics of good washing detergence property, sterilization, environmental friendliness and the like.

Owner:青岛美洁尔智能科技有限公司

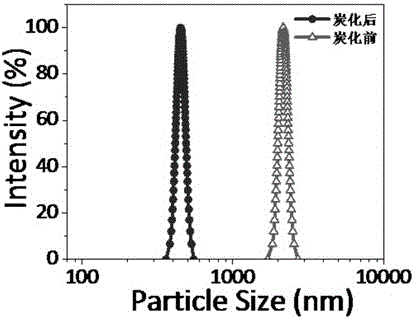

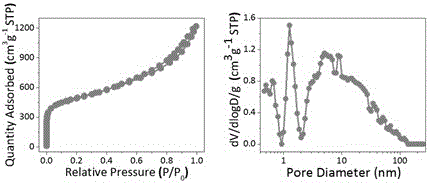

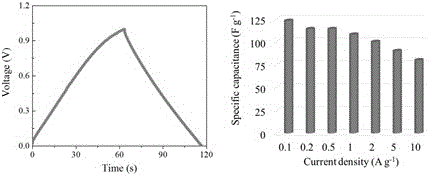

Porous carbon material and preparation and application thereof

InactiveCN106315547AIncrease the areaLarge hole volumeCarbon preparation/purificationMicro nanoPorous carbon

The invention relates to a porous carbon material and preparation and application thereof. The preparation method of the porous carbon material comprises the steps of grinding the carbon raw material into micrometer powder, feeding the micrometer powder into the inert gases and heating to 800 to 1000 DEG C, and carbonizing for 6 to 19 hours to acquire the porous carbon material with high surface area. The preparation method provided by the invention can prepare a carbon material with high surface area and high pore capacity which possesses the micro-nano structure and can be directly used to the energy storage, adsorbing and medical purposes; further the preparation method provided by the invention doesn't require any chemical reagent and at the same time avoids the complex physical or active chemical processing. The operation is simple. The invention is an environment-friendly and clean preparation method.

Owner:SUN YAT SEN UNIV

Method for cleaning filter element of filter at normal temperature

InactiveCN108187408AReduce viscosityEmission reductionFilter regenerationCleansing AgentsGreen cleaning

The invention discloses a method for cleaning a filter element of a filter at the normal temperature. The method comprises the following steps: (1) evenly mixing an ionic liquid and a cosolvent proportionally to prepare a cleaning agent; (2) immersing the to-be-cleaned filter element in the cleaning agent for 2-16 hours at the temperature of 20-50 DEG C; (3) taking out the filter element, furtherwashing with water to wash the ionic liquid and the organic solvent; (4) drying the above filter element. After being dried, the filter element is detected by a stereoscopic microscope and is subjected to bubble detection. The cleaning method is low in washing energy consumption and has a good cleaning effect, the service life of the filter element is prolonged, the cleaning liquid can be recycled, the pollutant discharge is reduced, and the green cleaning is realized.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

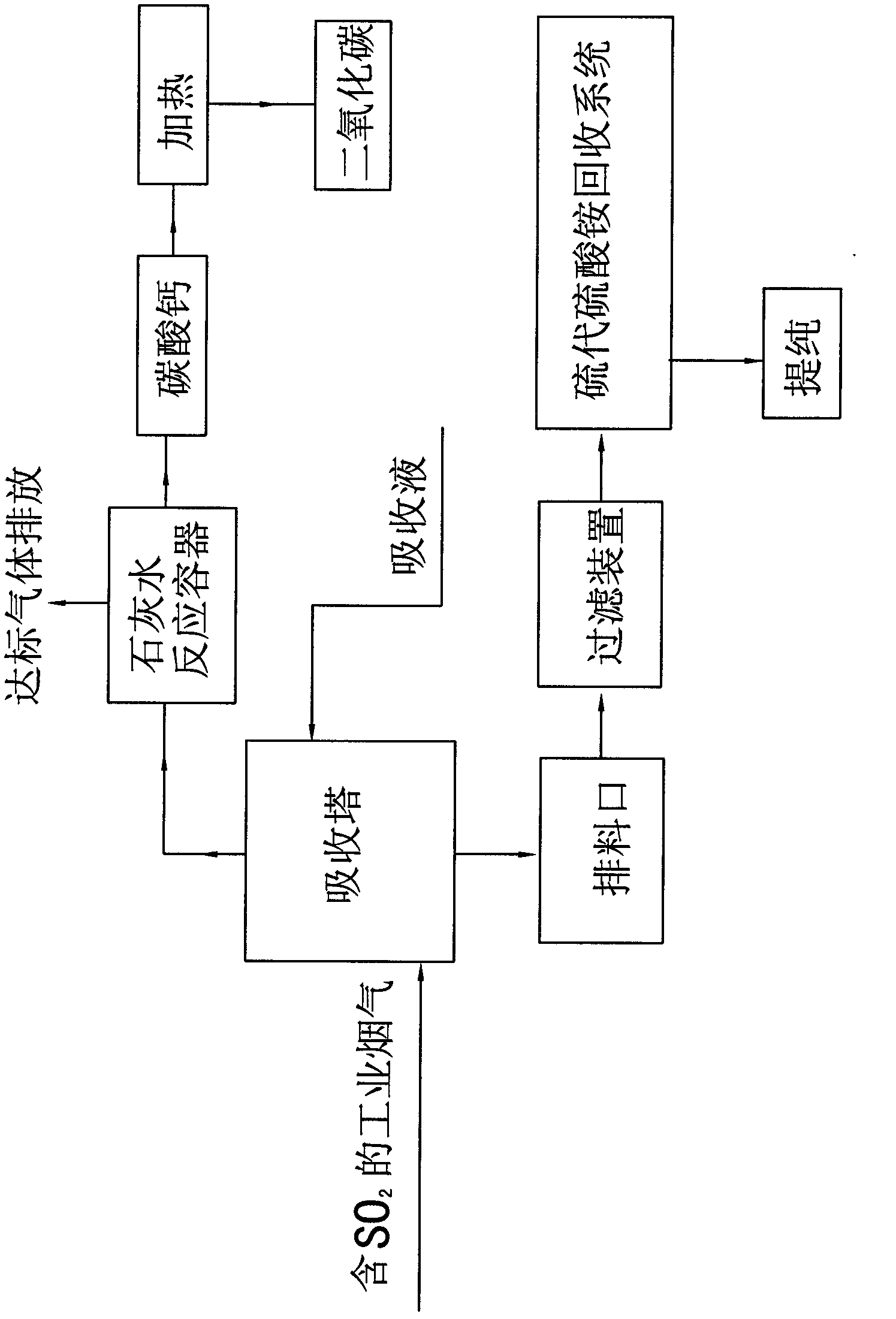

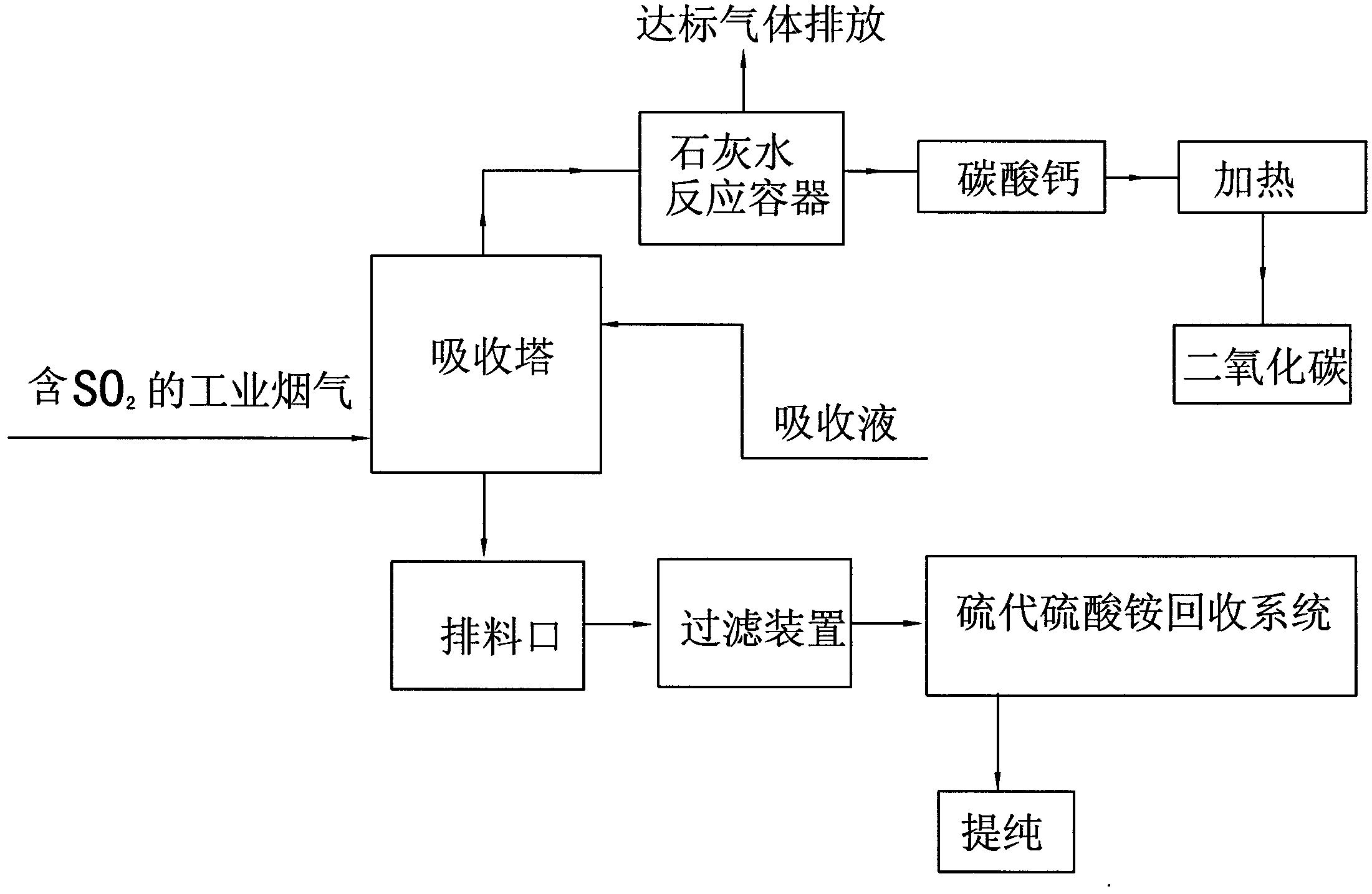

Method for producing thiosulfate and recovering carbon dioxide by utilizing industrial flue gas

The invention relates to a method for producing thiosulfate and recovering carbon dioxide by utilizing industrial flue gas. The method comprises the steps of: contacting a bicarbonate solution serving as an absorption liquid with exhaust gas to absorb SO2 in the exhaust gas and to generate sulfite and carbon dioxide, adding enough sulfur to the generated sulfite solution, heating and boiling for reaction, then filtering, evaporating, cooling and crystallizing, and centrifugally separating to prepare a thiosulfate finished product. According to the invention, sulfur dioxide in the flue gas and inexpensive bicarbonate are utilized to produce an expensive thiosulfate product, the air is purified and the reutilization of sulfur resources is realized, the SO2 utilization rate is high, after purification, SO2 in the flue gas is almost completely removed, and the recovered thiosulfate and carbon dioxide have low cost and high quality; and any secondary pollution is not generated, thus the method for producing thiosulfate by utilizing industrial flue gas is a green and clean process technique capable of protecting environment and recycling wastes and has wide market prospects.

Owner:NINGBO JINYUANDONG PETROCHEM ENG TECH

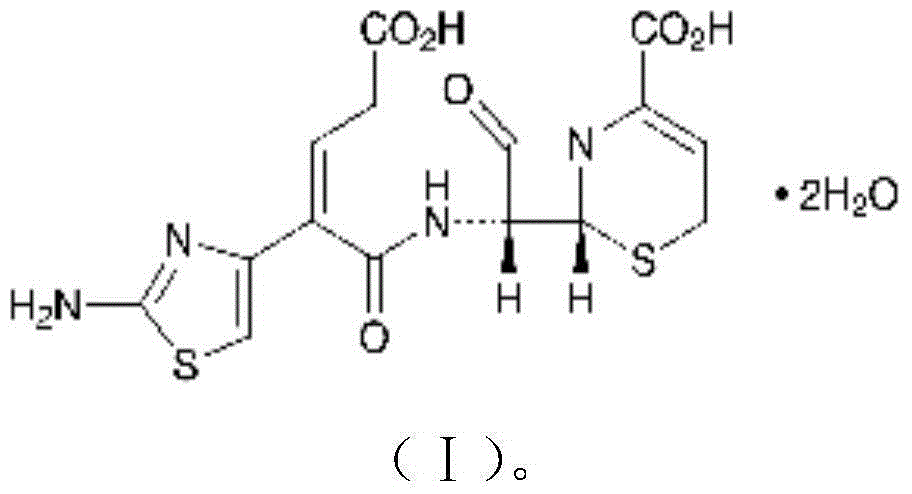

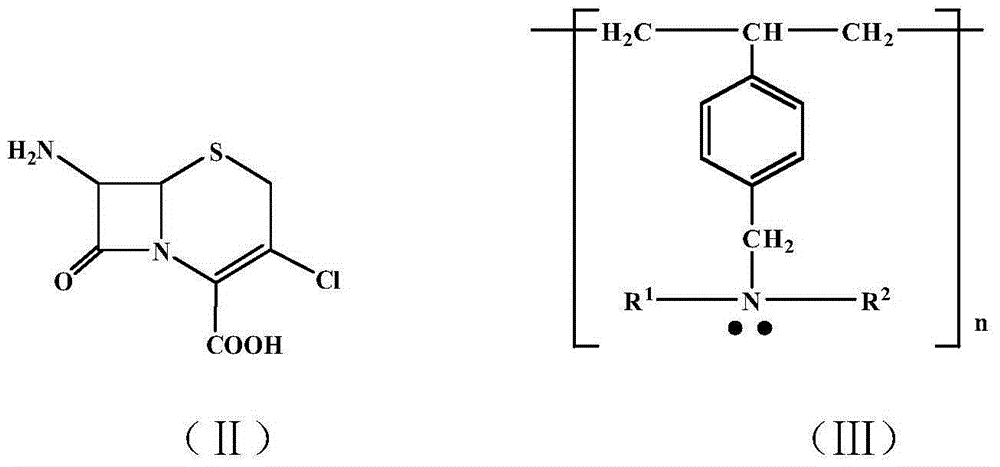

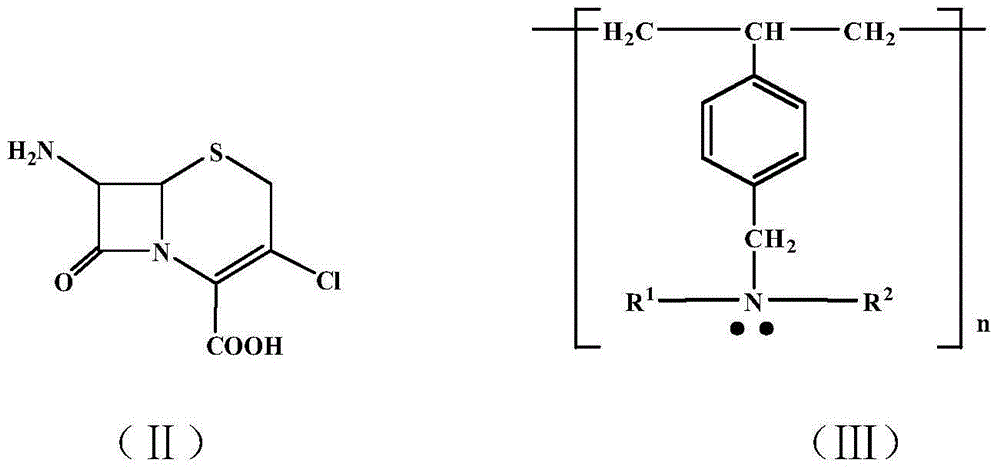

Preparation method of ceftibuten

The invention provides a preparation method of ceftibuten. The preparation method comprises the steps of adding cefaclor nucleus, methyltetrahydrofuran and magnesium powder into a reactor, and reacting until the magnesium powder disappears; then, adding a proper quantity of distilled water, stirring, standing for layering, separating out an organic layer, and drying by using anhydrous magnesium sulfate; after filtering, adding D301 week basic ion exchange resin and 2-(2-carbobenzoxy-aminothiazole-4-yl)-5-carbobenzoxy-2-pentenoic acid, and reacting at a certain temperature for a certain time; after ending the reaction, filtering to remove the week basic ion exchange resin; and then, hydrolyzing to obtain a target product, namely ceftibuten. The method is a novel preparation method of ceftibuten, is high in product yield and purity as well as simple and convenient in operation, is a green and clean production process and is suitable for industrial production on a certain scale; and the cefaclor nucleus is a main product in the company, and a sustainable development technology of the company is to prepare ceftibuten serving as a mainly developed variety in the Tenth Five-year Plan period from the product of the company.

Owner:山东昌邑四方医药化工有限公司

Method for extruding in-situ grafting modified cellulose through twin screws with ionic liquid serving as solvent

The invention relates to a method for extruding in-situ grafting modified cellulose through twin screws with ionic liquid serving as a solvent. The method comprises the following steps: (1) drying the cellulose and a grafting monomer in vacuum; (2) uniformly mixing the following raw materials by weight percent: 4 to 8% of cellulose, 30 to 40% of grafting monomer, 51.84 to 65.92% of ionic liquid, 0.04 to 0.08% of initiator, and 0.04 to 0.08% of catalyst; and (3) extruding the mixture by a co-rotating twin-screw extruder, so as to obtain the in-situ grafting modified cellulose. By adopting the method, high flowing property is provided on the basis that the original performances of the cellulose are remained; the cellulose grafting copolymer, which is easily processed and formed, and efficient, green and clean, can be obtained; and the development on novel cellulosic fibers, which are low in energy consumption, economic and feasible and environmentally friendly, can be promoted.

Owner:DONGHUA UNIV

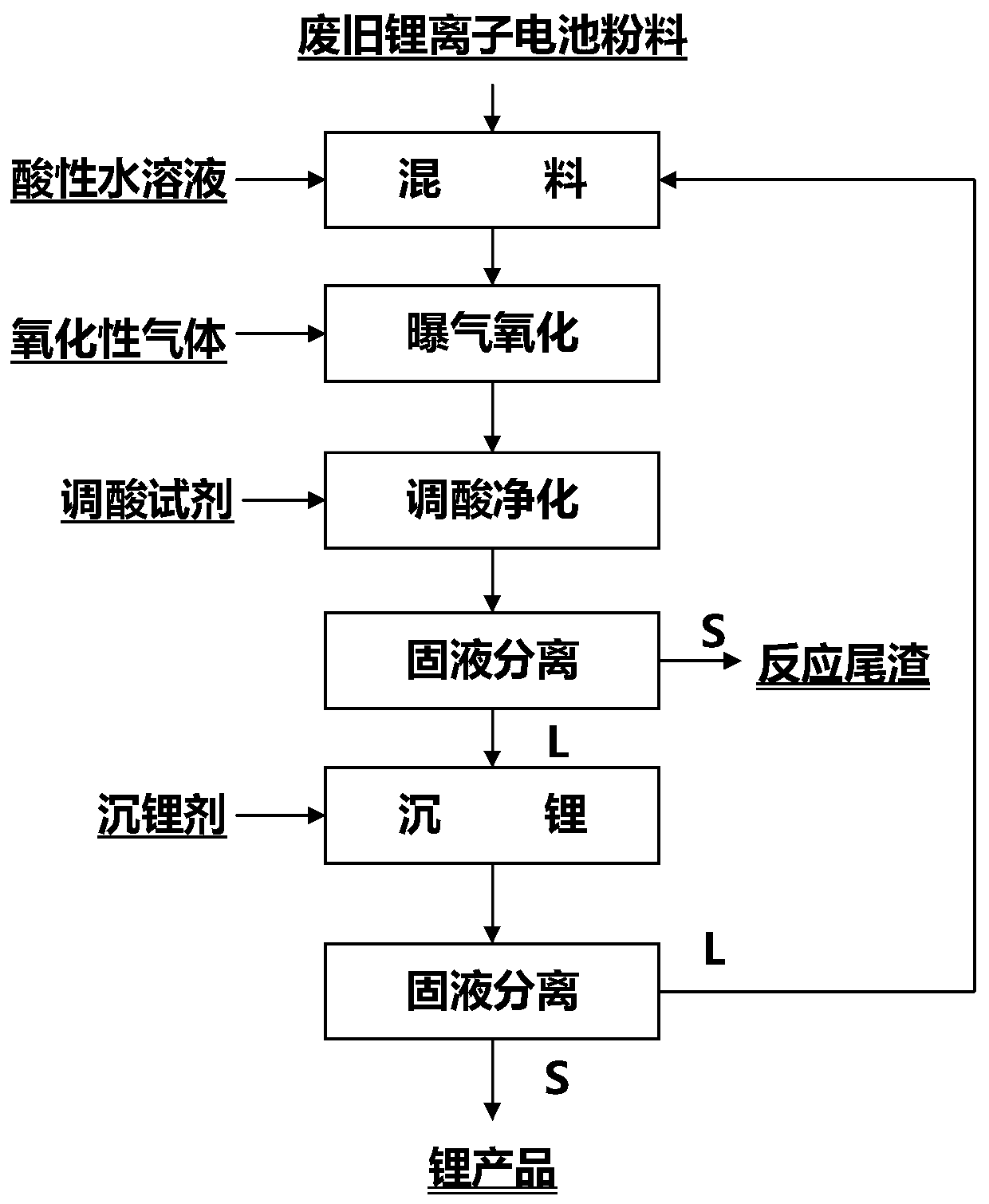

Method of performing oxidation treatment on waste lithium ion batteries

InactiveCN109852807ASolve lossAddress effectivenessWaste accumulators reclaimingProcess efficiency improvementSlurryLithium-ion battery

The invention relates to a method of performing oxidation treatment on waste lithium ion batteries, and belongs to the technical field of environment. The method comprises the following steps of adding waste lithium ion battery powder into an acidic water solution to obtain mixed slurry; inputting oxidizing gas to the mixed slurry with an aerating device, and performing oxidizing leaching; after areaction is completed, regulating the pH of the reaction slurry with an acid regulating reagent to remove few valuable metal ions in lixivium, and then performing solid-liquid separation to obtain lithium-enriched purifying liquid and reaction tailings; and then performing lithium sinking and solid-liquid separation on the purifying liquid so as to obtain lithium carbonate products or lithium phosphate products. Through the adoption of the method disclosed by the invention, through an aeration means, under a milder condition, high-selectivity extraction of lithium elements in the waste lithium ion batteries is realized; the reaction process is green and clean, simple and easy to operate, and wide in application range; and the lithium extraction rate is 85% or above, and the extracting selectivity is 95% or above, so that the problem that in a conventional processing method, lithium resources cannot be economically and effectively recovered can be solved from the source.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing fuel oil from waste paper waste residue

The invention discloses a method for preparing fuel oil from waste paper waste residue, which comprises the following steps: pretreating waste residue generated after papermaking with waste paper; by using the pretreated waste paper waste residue as the raw material and bamboo charcoal sulfonated solid acid as a catalyst, carrying out cracking reaction at 100-500 DEG C for 0.5-10 hours; and after the reaction finishes, distilling the cracking liquid, and collecting the 40-330 DEG C fraction as the fuel oil. The method for producing fuel oil by using the solid acid catalyst does not generate solid waste, and thus, is environment-friendly; and the method disclosed by the invention is suitable for large-scale industrial production, is a green and clean production technique capable of changing wastes into valuable substances, and has no application reports of industrial production at present.

Owner:ZHONGRONG TECH CORP LTD

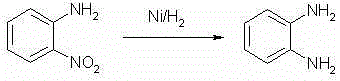

Green synthetic method of preparing o-phenylenediamine by reducing o-nitroaniline

ActiveCN105130821ARealize green and clean productionHigh reaction yieldOrganic compound preparationAmino compound preparationGreen cleaningO-nitroaniline

The invention relates to a green synthetic method of preparing o-phenylenediamine by reducing o-nitroaniline, wherein the method includes following steps: with o-nitroaniline as a substrate, dissolving the o-nitroaniline in water or in a mixed liquid composed of water and a co-solvent, and adding a supported catalyst under a carbon monoxide atmosphere, wherein the supported catalyst includes a supporter and a catalyst body supported thereon, and performing a reaction to prepare the o-phenylenediamine at 30-150 DEG C. In the method, the supported catalyst is used for preparing the o-phenylenediamine through reduction. The catalyst is high in selectivity and reaction yield and is mild in reaction condition. The method is environment-friendly in production system and less in treatment load of waste water, waste gas and solid waste, achieves green and clean production of the o-phenylenediamine, and is suitable for large-scale popularization.

Owner:江阴市华亚化工有限公司

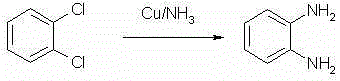

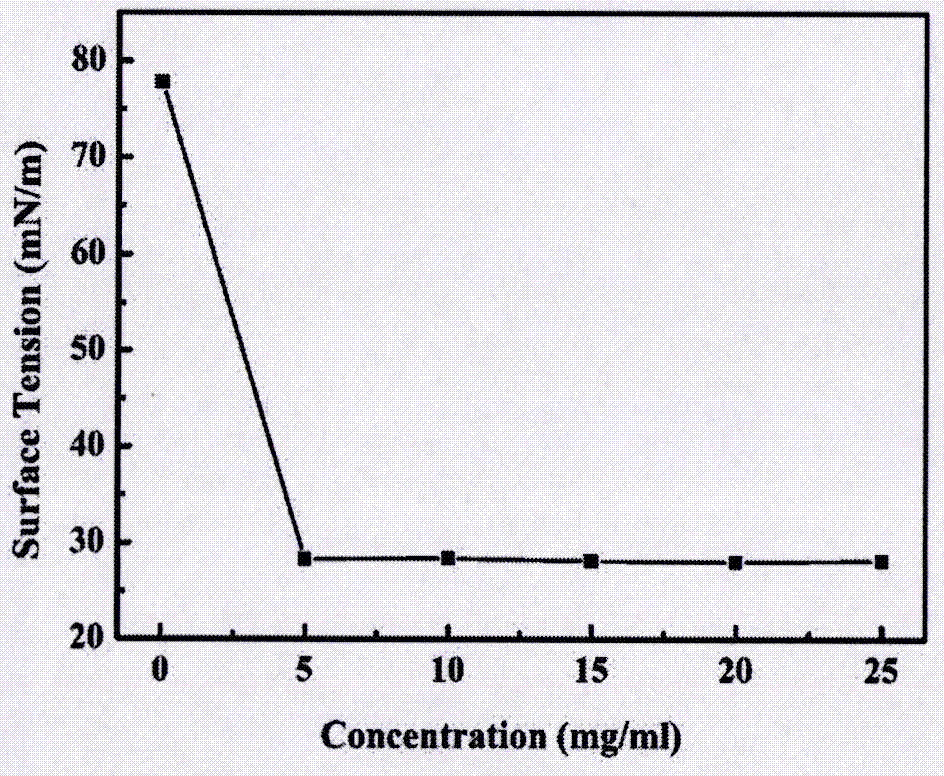

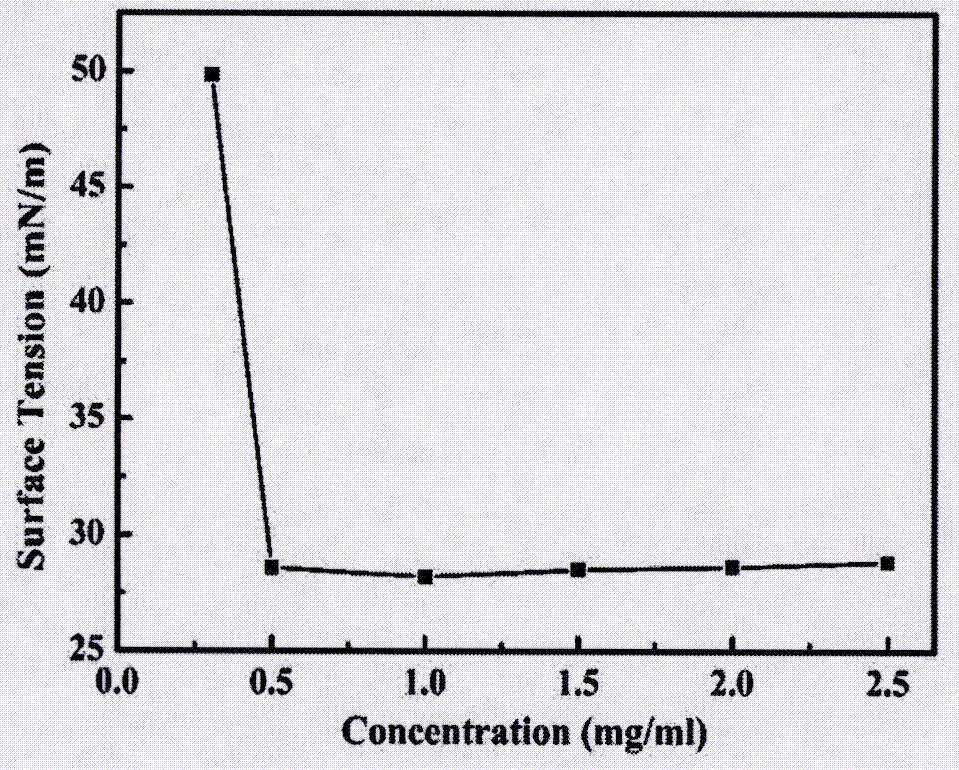

Synthesis of quasi chitosan-fatty acid salt and development of green surfactant

The invention relates to a novel method for simply producing a novel green cleaning detergent in an aqueous solution system. Green detergent series products which are prepared from mixed fatty acid and quasi chitosan biomass amino compounds and have high surface activity are developed, surface tension of an aqueous solution is reduced to 28-29 mN / m, critical micelle concentration is 0.38-0.40 mg / ml, and the products are far better than sodium dodecyl sulfate and soap. According to the technology, biomass raw materials are widely sourced, the cost is low, and the prepared products are good in biological degradability, safe and environment-friendly.

Owner:XIAMEN UNIV

Cellulose in-situ urea modified plastification melt spinning method

InactiveCN102965752AEasy to processBreaking hydrogen bondsSpinning head liquid feederArtificial filaments from cellulose derivativesCellulose fiberGreen cleaning

The invention relates to a cellulose in-situ urea modified plastification melt spinning method comprising the following steps of: (1) drying the cellulose and the urea under a vacuum condition; (2) uniformly mixing 10-20wt% of cellulose, 50-70wt% of ionic liquid and 10-40wt% of urea; (3) extruding the mixture by a co-rotating twin screw extruder, defoaming, filtering and ejecting from a spinneret port; (4) drawing and coiling the quickly solidified fiber to form cellulose fiber. The method can be used for get the cellulose grafted copolymer which is easy to process, high-efficiency, green and clean, and can prompt development of the novel cellulose fiber which is low in energy consumption, economical, practical and environmentally-friendly.

Owner:DONGHUA UNIV

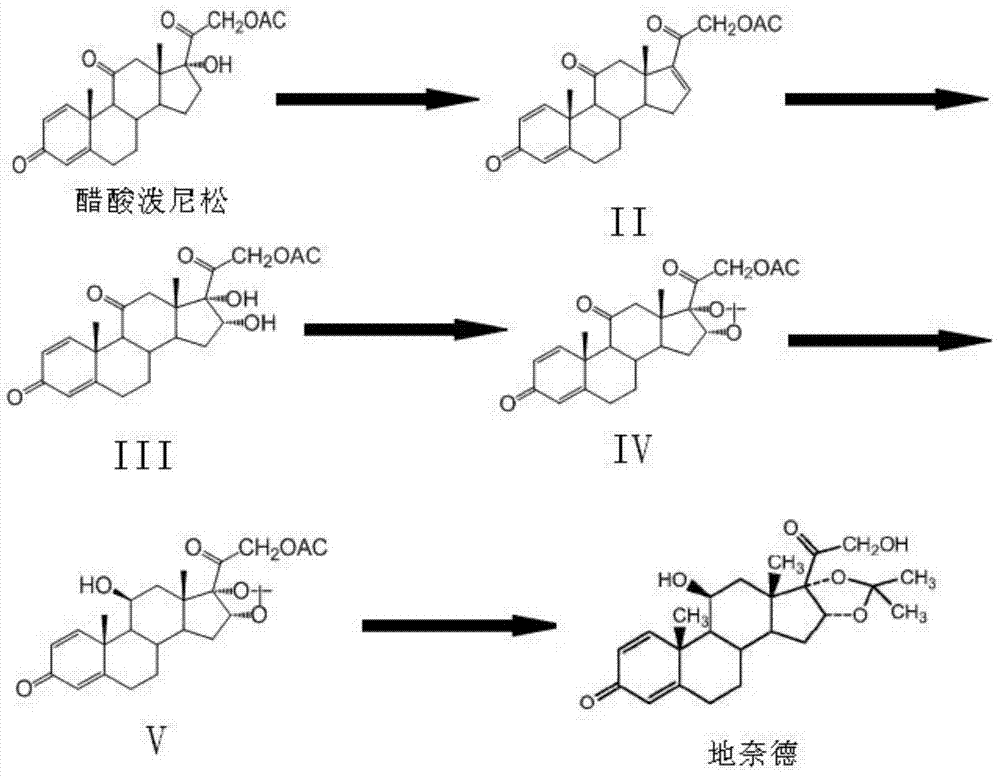

Synthetic method of desonide

The invention discloses a synthetic method of desonide. The synthetic method is characterized by carrying out elimination reaction on prednisone acetate by using sulfur dioxide in the presence of a first catalyst and an inert gas, then carrying out oxidation reaction on a product after elimination by using an oxidant in the presence of a second catalyst, then carrying out condensation treatment on a product after oxidation by using acetone in the presence of a third catalyst, carrying out selective reduction on a product after condensation in the presence of a fourth catalyst and finally carrying out hydrolysis reaction on a product after reduction in the presence of a fifth catalyst, thus preparing desonide. The synthetic method has the beneficial effects that desonide can be obtained by using prednisone acetate as the raw material and carrying out elimination, oxidation, condensation, reduction and hydrolysis; all the solvents in the synthetic process are recycled and reused, heavy metals do not participate in reaction in the reaction process, the technical process is mild and the energy consumption is low, so that the synthetic method is environment-friendly and clean.

Owner:ZHEJIANG XIANJU JUNYE PHARM CO LTD

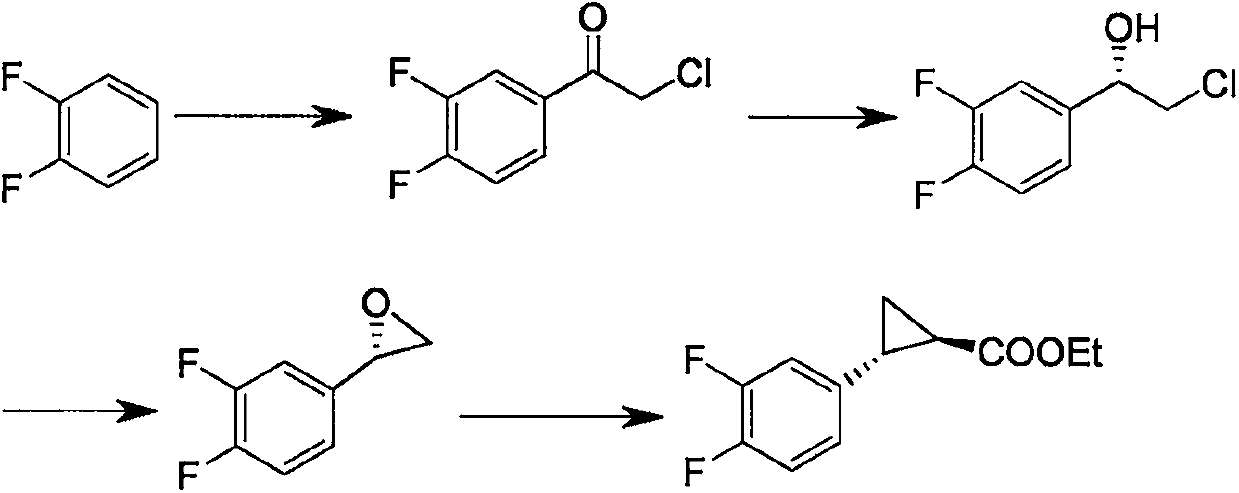

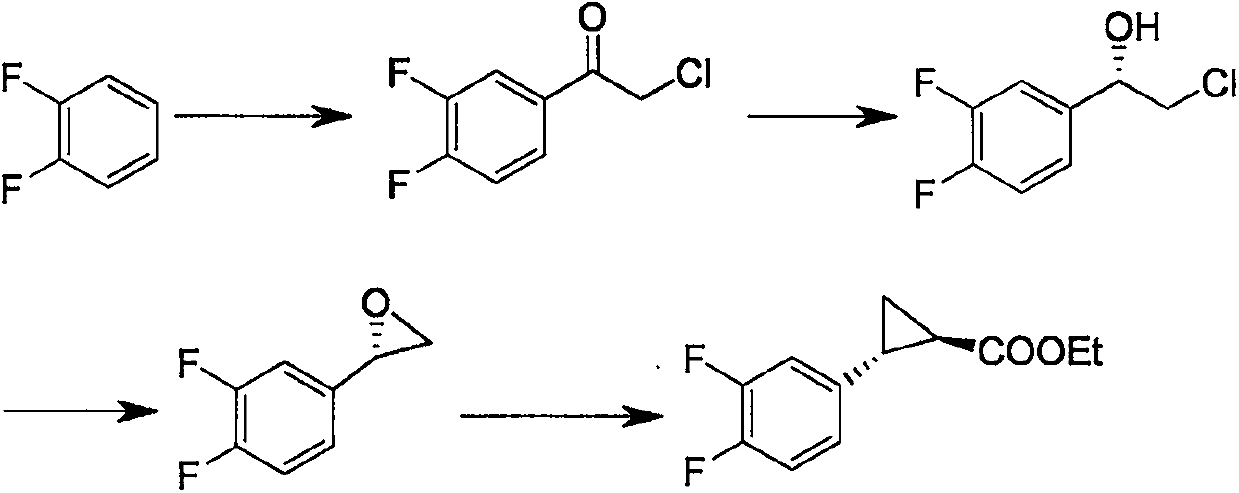

Method for preparing ticagrelor intermediate

InactiveCN107686447AReduce transit lossFew stepsOrganic compound preparationOrganic chemistry methodsTicagrelorGreen cleaning

The invention discloses a method for preparing a ticagrelor intermediate. The method comprises the following steps: taking o-difluorobenzene and chloroacetyl chloride as initial raw materials, carrying out an F-K reaction, a bio-enzyme fermentation technology asymmetric reduction reaction, a ring-closure reaction and a cyclopropanation reaction, so as to obtain the key intermediate (1R, 2R)-2-(3,4-difluorophenyl) cyanocyclopropane carboxylate of the ticagrelor at high yield, high enantioselectivity and high purity. The method can realize industrialized production. The method is low in energy consumption, less in pollution, green, clean, high in yield and high in purity, the cost is reduced, the product quality is stable, and the method is suitable for large-scale stable industrial production.

Owner:XUCHANG HENGSHENG PHARMA

Clean production process for simultaneously extracting lipid and collagen from animal fat tissues

InactiveCN104531334AHigh yieldImprove effective utilizationConnective tissue peptidesPeptide preparation methodsWastewaterGreen cleaning

The invention belongs to the technical field of livestock and poultry processing, and in particular relates to a clean production process for simultaneously extracting lipid and collagen from animal fat tissues. The clean production process provided by the invention is simple, convenient and efficient, is low in cost and high in added value and is used for processing and utilizing the animal fat tissues, and by using the process, collagen can be industrially extracted from the animal fat tissues on a large scale, and animal fat can be obtained at the same time. Compared with the prior art, by using the process provided by the invention, the animal fat tissues are used as a raw material for extracting collagen, high-quality collagen and animal fat can be obtained on the premise that wastewater is not generated, green and clean utilization of the animal fat tissues are realized, a big pollutant source of the livestock and poultry processing industry is eliminated, and meanwhile, the added value of the animal fat tissues is also greatly improved, so that the clean production process has a wide application prospect in the field of livestock and poultry processing.

Owner:JIANGNAN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com