Method of performing oxidation treatment on waste lithium ion batteries

A lithium-ion battery, oxidation treatment technology, applied in the direction of battery recycling, recycling of waste collectors, improvement of process efficiency, etc., can solve the problems of high energy consumption, complicated procedures, and complicated operations in the process, and achieve low operating costs and ease of operation The effect that the burden and operation safety are high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

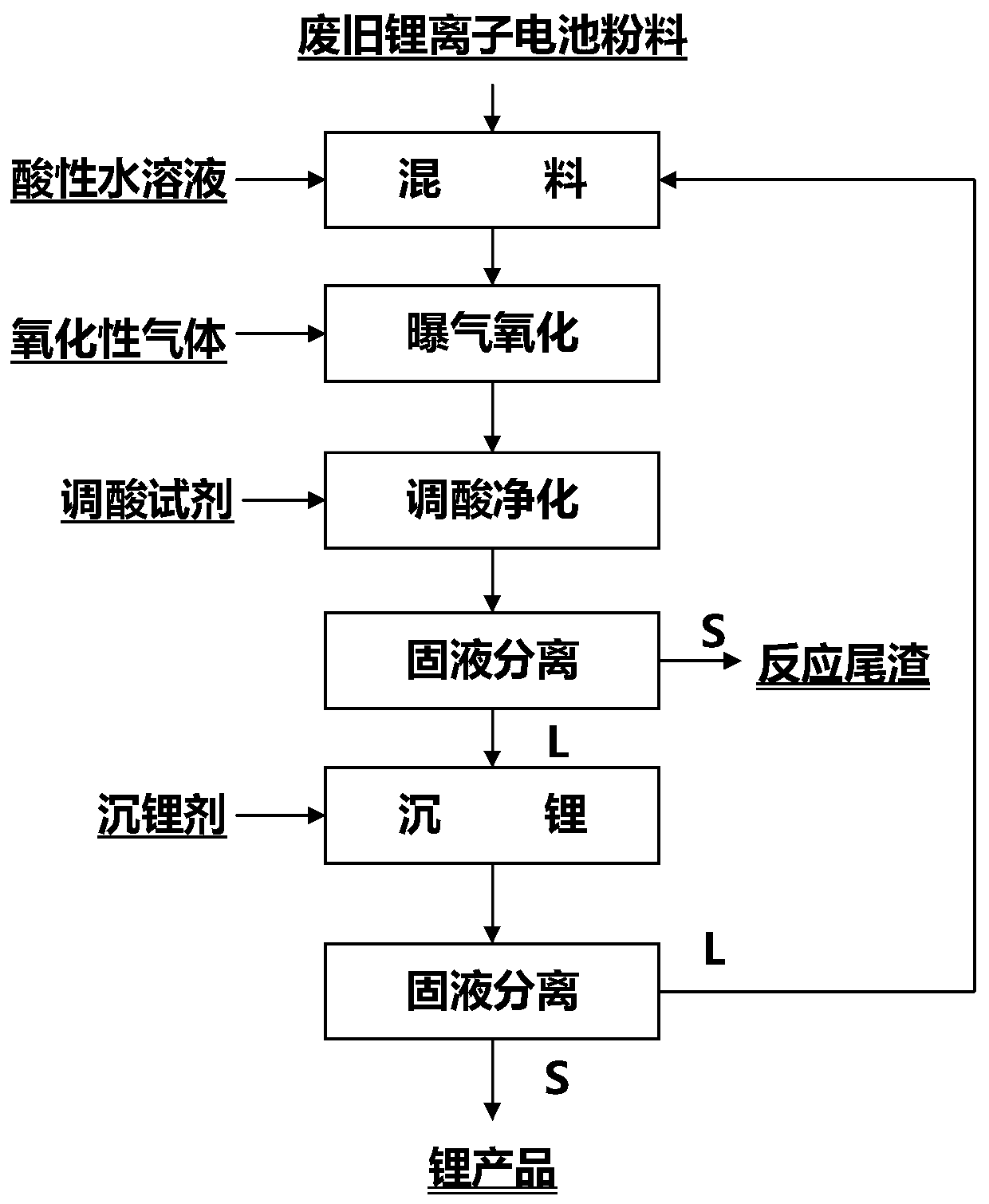

Method used

Image

Examples

Embodiment 1

[0044] 1) Mixing preheating: Add the lithium cobalt oxide positive electrode material that has been mechanically crushed to a size below 200 mesh into dilute sulfuric acid aqueous solution with a concentration of 0.05mol / L, and heat to 75°C to prepare a mixed slurry with a solid-to-liquid ratio of 10g / L;

[0045] 2) Aeration oxidation: use a titanium rod-shaped microporous aeration device to introduce oxygen into the mixed slurry obtained in step 1), the diameter of the aeration micropores is 10 μm, the gas flow rate is controlled to 0.1L / min, and magnetic stirring is applied. 400rpm, carry out aerated oxidation for 10h, add 1mol / L NaOH to the system to adjust the pH of the solution to 10.34 after the reaction is completed, and obtain the reaction slurry;

[0046] 3) Solid-liquid separation: The reaction slurry obtained in step 2) is subjected to solid-liquid separation to obtain cobalt-rich reaction tailings and a lithium-containing purification solution. ICP was used to me...

Embodiment 2

[0049] 1) Mixing preheating: add the lithium manganate positive electrode material that is mechanically crushed to below 200 mesh into the dilute sulfuric acid aqueous solution with a concentration of 0.25mol / L, and heat to 90°C to prepare a mixed slurry with a solid-to-liquid ratio of 20g / L;

[0050] 2) Aeration and oxidation: use a titanium rod-shaped microporous aeration device to pass air into the mixed slurry obtained in step 1), the diameter of the aeration micropores is 25 μm, the gas flow rate is controlled to 1.2 L / min, apply mechanical stirring, and the stirring rate 500rpm, carry out aerated oxidation 5.5h, add ammoniacal liquor to the system after the reaction finishes and adjust the solution pH to 8.0, obtain reaction slurry;

[0051] 3) Solid-liquid separation: The reaction slurry obtained in step 2) is subjected to solid-liquid separation to obtain manganese-rich reaction tailings and a lithium-containing purification solution. ICP was used to measure the cont...

Embodiment 3

[0054] 1) Mixing preheating: add the NCA111 powder after alkali leaching treatment to dilute hydrochloric acid with a concentration of 0.50mol / L, and heat it to 60°C to prepare a mixed slurry with a solid-to-liquid ratio of 15g / L;

[0055] 2) Aeration oxidation: use a plate-shaped microporous aeration device made of PTFE to pass a mixture of oxygen and ozone into the mixed slurry obtained in step 1), the diameter of the aeration micropores is 50 μm, and the gas flow rate is controlled to 1.5L / min. The volume ratio of oxygen to ozone is 19:1, apply mechanical stirring, the stirring rate is 350rpm, carry out aerated oxidation for 2.0h, add Na to the system after the reaction is completed 2 CO 3 And NaOH solid solution pH is adjusted to 9.8, obtains reaction slurry;

[0056] 3) Solid-liquid separation: The reaction slurry obtained in step 2) is subjected to solid-liquid separation to obtain reaction tailings rich in nickel, cobalt and aluminum and a lithium-containing purificati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com