Porous carbon material and preparation and application thereof

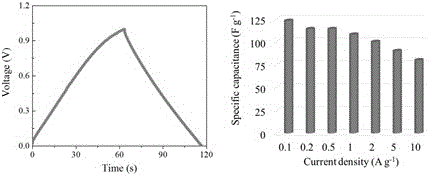

A technology of porous carbon and raw materials, applied in the fields of nanomaterial technology and energy science, can solve the problems of low specific surface area of carbon materials, equipment corrosion, etc., and achieve great application value, avoid process steps, and process clean effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of a porous carbon material, comprising the following steps:

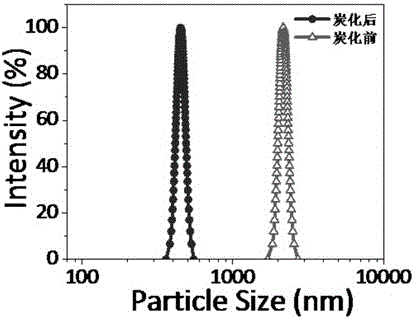

[0036] (1) Break the coconut shell into small pieces first, then put it into a high-energy ball mill, and perform ball milling at room temperature for 4 hours, that is, pulverize into micron powder;

[0037] (2) Place the micron powder prepared in step (1) under a nitrogen atmosphere with a flow rate of 600mL / min, raise the temperature to 900°C at a heating rate of 5°C / min, carbonize at a constant temperature for 9 hours, and cool down naturally to room temperature to obtain a porous carbon material .

Embodiment 2

[0039] A preparation method of a porous carbon material, comprising the following steps:

[0040] (1) The coconut shell is first broken into small pieces, then put into a high-energy ball mill, and ball milled for 1 hour at room temperature, that is, pulverized into micron powder;

[0041] (2) Place the micron powder prepared in step (1) under a nitrogen atmosphere with a flow rate of 600mL / min, raise the temperature to 900°C at a heating rate of 5°C / min, carbonize at a constant temperature for 6 hours, and cool down naturally to room temperature to obtain the porous carbon material.

Embodiment 3

[0043] A preparation method of a porous carbon material, comprising the following steps:

[0044] (1) The coconut shell is first broken into small pieces, then put into a high-energy ball mill, and ball milled for 6 hours at room temperature, that is, pulverized into micron powder;

[0045] (2) Place the micron powder prepared in step (1) under a nitrogen atmosphere with a flow rate of 600mL / min, raise the temperature to 900°C at a heating rate of 5°C / min, carbonize at a constant temperature for 12 hours, and cool down naturally to room temperature to obtain the described Porous carbon materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

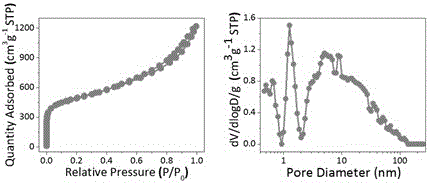

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com