Patents

Literature

120results about How to "Good decontamination performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

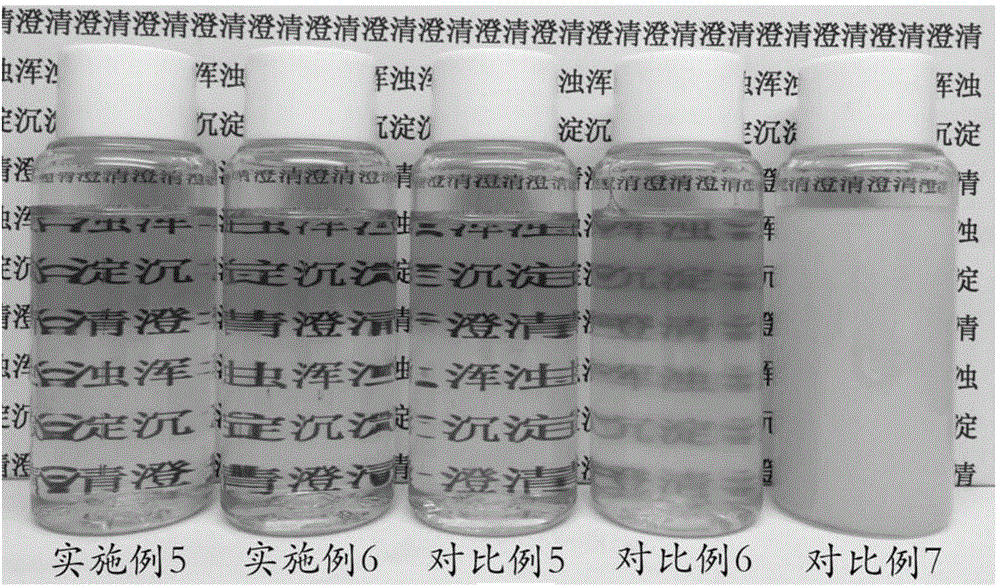

Preparation method of modified cation waterborne polyurethane emulsion containing hydrophilic and hydrophobic side long chains and product thereof

The invention relates to a preparation method of modified cation waterborne polyurethane emulsion containing hydrophilic and hydrophobic side long chains and a product thereof. The method comprises the following steps that raw materials are prepared; polyester glycol dehydration pretreatment is carried out; polyester glycol obtained after dehydration pretreatment is subjected to a prepolymerization reaction with an end alkyl polysiloxane linear body, a nonionic chain extender, a functionality chain extender and diisocyanate under catalyzing of a polymerization catalyst so that a prepolymer can be obtained; the prepolymer reacts with a nonionic chain extender and a part diluent to prepare an intermediate; the intermediate reacts with a silane coupling agent, and is emulsified to prepare the modified cation waterborne polyurethane emulsion. The product is a polyester type cation waterborne polyurethane high-polymer material containing hydrophilic and hydrophobic side long chains, wherein polysiloxane is embedded into a main chain of the material, a side chain is grafted with long-chain polyether and long-chain alkyl, and the silane coupling agent is connected into the tail end of the material; the film-forming ability is high, and serving as a film, the emulsion has obvious water-repellent, antifouling and easy dirt-removing abilities, is excellent in compatibility with a cation softening agent, and has an excellent low-temperature soft feature; the product is safe, environmentally friendly and convenient to use.

Owner:HUBEI DAYA BIOLOGICAL TECH CO LTD

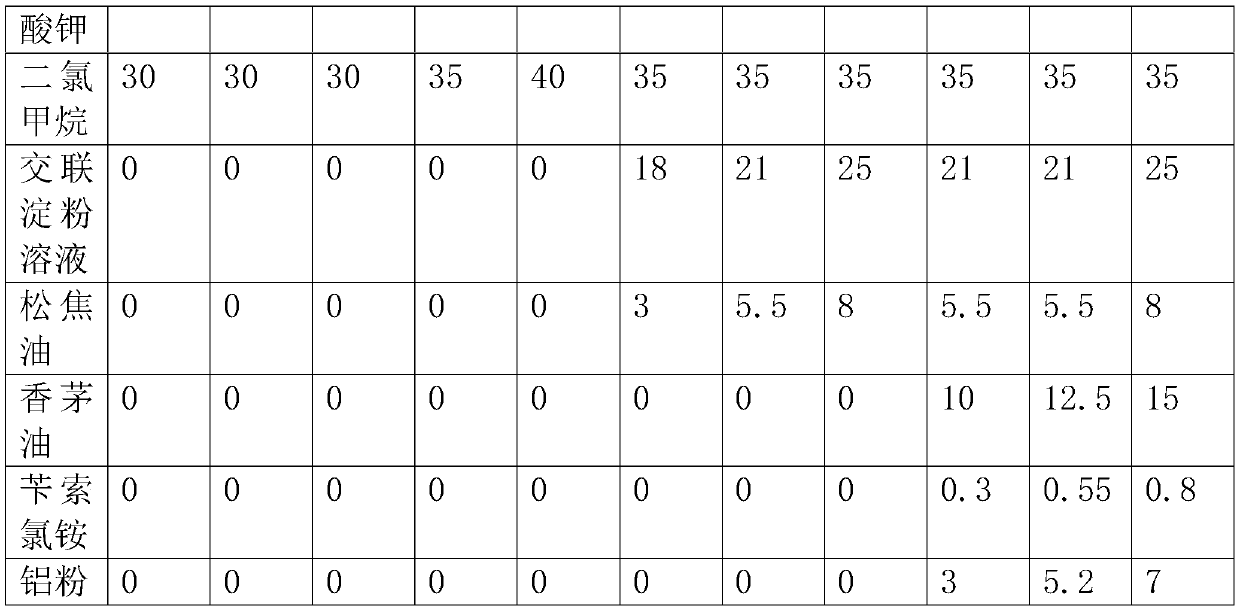

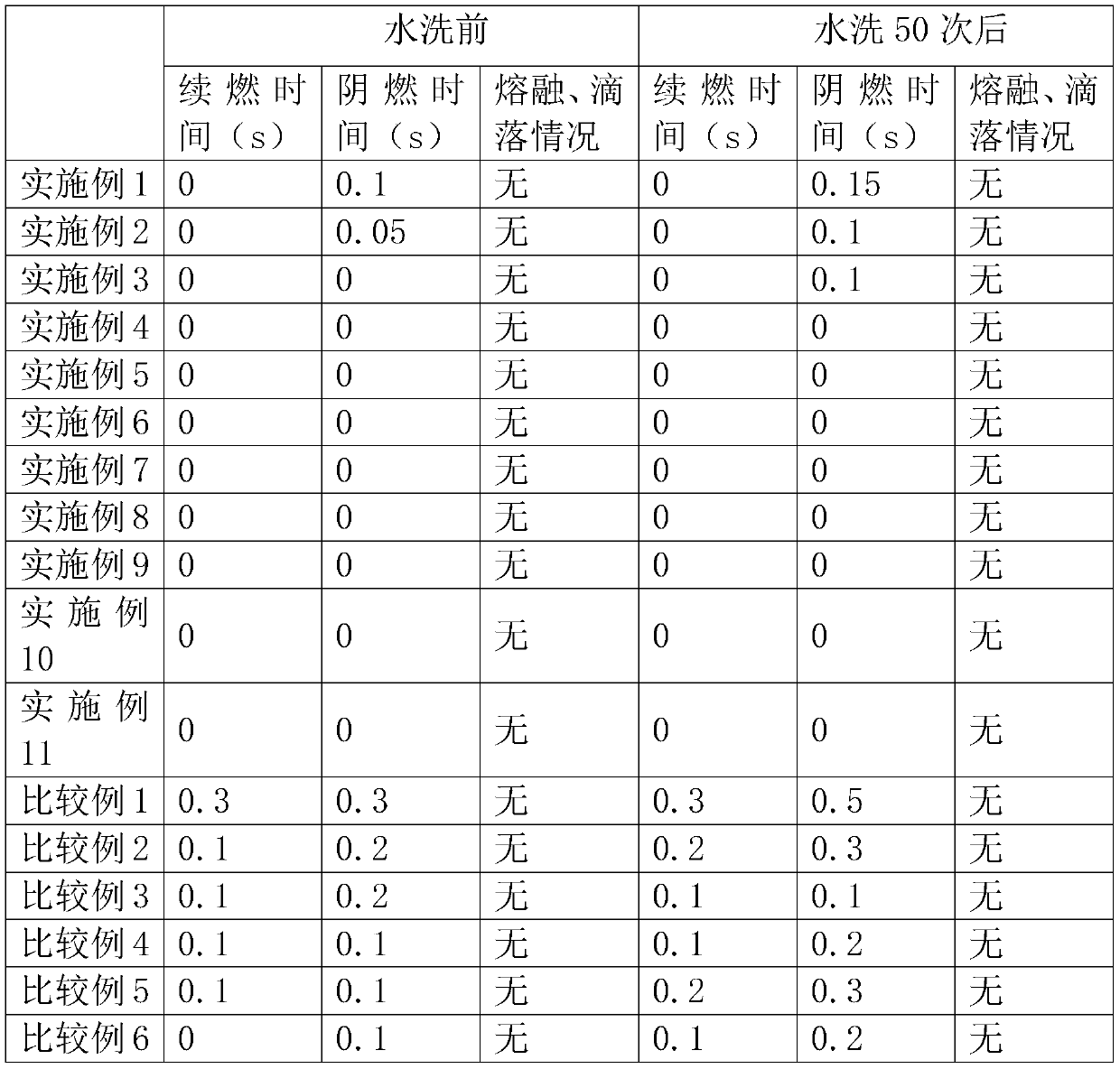

Preparation method of washable three-proofing and easy-decontamination antibacterial fabric

InactiveCN111535026AMeet environmental protection requirementsImprove washing resistanceStain/soil resistant fibresBiochemical fibre treatmentProcess engineeringCross linker

The invention discloses a preparation method of a washable three-proofing and easy-decontamination antibacterial fabric. The preparation method is characterized by comprising the following steps of: soaping, to be specific, after desizing, scouring, bleaching and mercerizing the fabric in advance, removing impurities on the cloth cover by a soaping process, and then drying; and performing one-bathprocess washable three-proofing and easy-decontamination antibacterial finishing, to be specific, shaping and processing the soaped and dried fabric on a shaping machine, drying, baking and finishing, thereby obtaining the washable three-proofing and easy-decontamination antibacterial fabric. A working solution which simultaneously contains a C6 durable three-proofing finishing agent, a purifiedcotton durable fluorine-free waterproof agent, a durable crosslinking agent, an antibacterial agent and a special waterproof penetrant is contained in a rolling groove of the shaping machine, and thefabric is subjected to padding, then is dried and baked to obtain the washable three-proofing and easy-decontamination antibacterial fabric. The preparation method solves the contradiction between thethree-proofing and the easy decontamination, and also solves the problems between the three-proofing and the bacteria prevention; and meanwhile the fabric is endowed with the function of washing resistance, and can meet the overall actual needs for functional fabrics in actual situations.

Owner:江苏康乃馨纺织科技有限公司

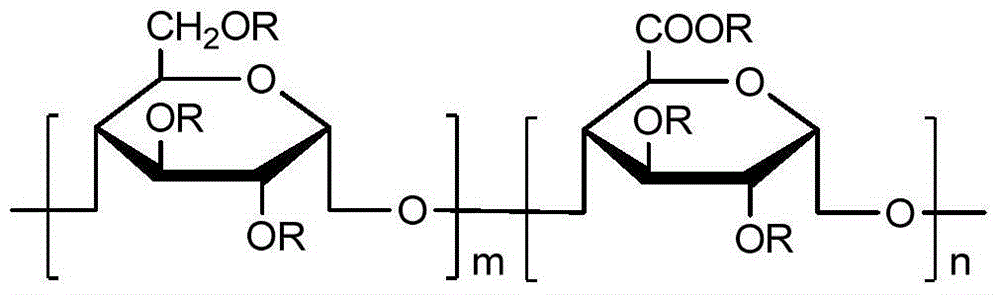

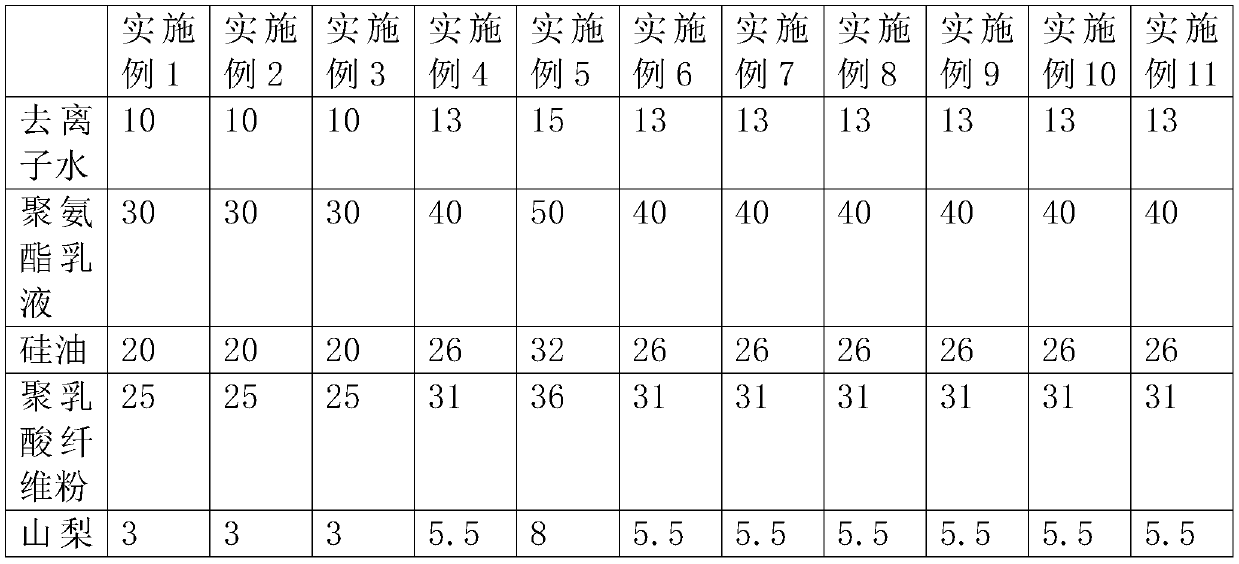

Soil-releasing finishing agent for cotton-polyester blended fabric and preparation method of soil-releasing finishing agent

InactiveCN103668989AGood decontamination performanceWash thoroughlyVegetal fibresCarboxymethyl cellulosePolyester

The invention provides a soil-releasing finishing agent for cotton-polyester blended fabric and a preparation method of the soil-releasing finishing agent. The soil-releasing finishing agent for the cotton-polyester blended fabric comprises raw materials in parts by mass as follows: 15-18 parts of carboxymethylcellulose, 5-6 parts of water soluble silicone oil, 20-25 parts of a water-based acrylic ester copolymer emulsion, 20-25 parts of glycerine and 80-90 parts of water. The soil-releasing finishing agent for the cotton-polyester blended fabric can effectively improve soil release performance of the cotton-polyester fabric, so that the cotton-polyester blended fabric can be completely cleaned when contaminated by oil stain; and a formula is reasonable and can be popularized and applied.

Owner:NANTONG TONGZHOU DISTRICT CHUANJIANG TOWN SUNWORLD DYNASTY HOME TEXTILE DESIGN STUDIO

Organic and inorganic composite self-cleaning finishing agent and its uses

The invention involves a organic and inorganic composite self-cleaning finishing agent and its application method on fiber products, the organic and inorganic composite self-cleaning finishing agent includes 40% component A and 60%B component (weight percentage), its application method on fiber products includes: (1) freshly preparing component A and B organic and inorganic composite self-cleaning finishing agent, (2) slop padding work solution and fiber products, drying and curing, (3) characterizing the self-cleaning property of textiles through the water repellency, oil repellency and soil release property. The organic and inorganic composite self-cleaning finishing agent in the invention has good stability and repeatability, it has good water repellency, oil repellency and soil release property when it is applied in fiber products, it can meet the needs of developing various fiber high-grade self-cleaning rib fabrics.

Owner:DONGHUA UNIV +1

After-finishing process of shrink-proof, anti-wrinkling, moisture absorption and quick-drying shirt collar support

The invention discloses an after-finishing process of a shrink-proof, anti-wrinkling, moisture absorption and quick-drying shirt collar support. The process comprises the following steps of: preparing a 30-40 g / l modifier of polyethylene siloxane serving as a quick-drying hygroscopic agent of an after-finishing agent, resin of a certain concentration and a Cat.D catalyst into a padding liquid of which the pH value is 4.5; and putting a fabric to be finished into the padding liquid, and performing pre-baking and baking steps when the padding rate is 80 percent. In the padding finishing liquid, the modifier of the polyethylene siloxane plays a role in absorbing moisture and drying quickly and is suitable for moisture absorption and quick-drying finishing of cotton, terylene and a blended fabric thereof, and the fabric is endowed with extremely good soft handfeel. The modifier of the polyethylene siloxane can be used separately with a padding method, and can be used together with initial condensation bodies such as a shrink-proof and anti-wrinkling agent, stiff resin and the like, so that the swelling ratio of a fiber pore canal is lowered, and better moisture absorption and quick-drying effects are achieved.

Owner:南通海盟实业股份有限公司

Atmospheric plasma processing method used for fabric topical finish

InactiveCN101117764AEasy to operateShort processUltrasonic/sonic fibre treatmentRegenerating fibersEngineering

A normal-pressure plasma treating method for post-finishing of fabrics is disclosed by the present invention, which relates, in particular, to a normal-pressure plasma treating method for softening and decontaminating finishing of fabrics without chemical assistants and belongs to the technical field of textile processing. The present invention is characterized in that a fabric is positioned between electrodes of a plasma device and treated with corona or glow discharge for 3s-20min by voltage application after the power is switched on,. The fabric can be a natural fiber fabric, a synthesized fabric, a regenerated fiber fabric, a blended fabric of the above fabrics or an interwoven fabric of the above fabrics. The present invention has simple operation and short process and is free of the troublesome steps including padding, pre-baking and baking; without use of chemical assistants or water, the present invention is conducive to environment protection; the fabrics finished with the present invention feels soft and smooth.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH

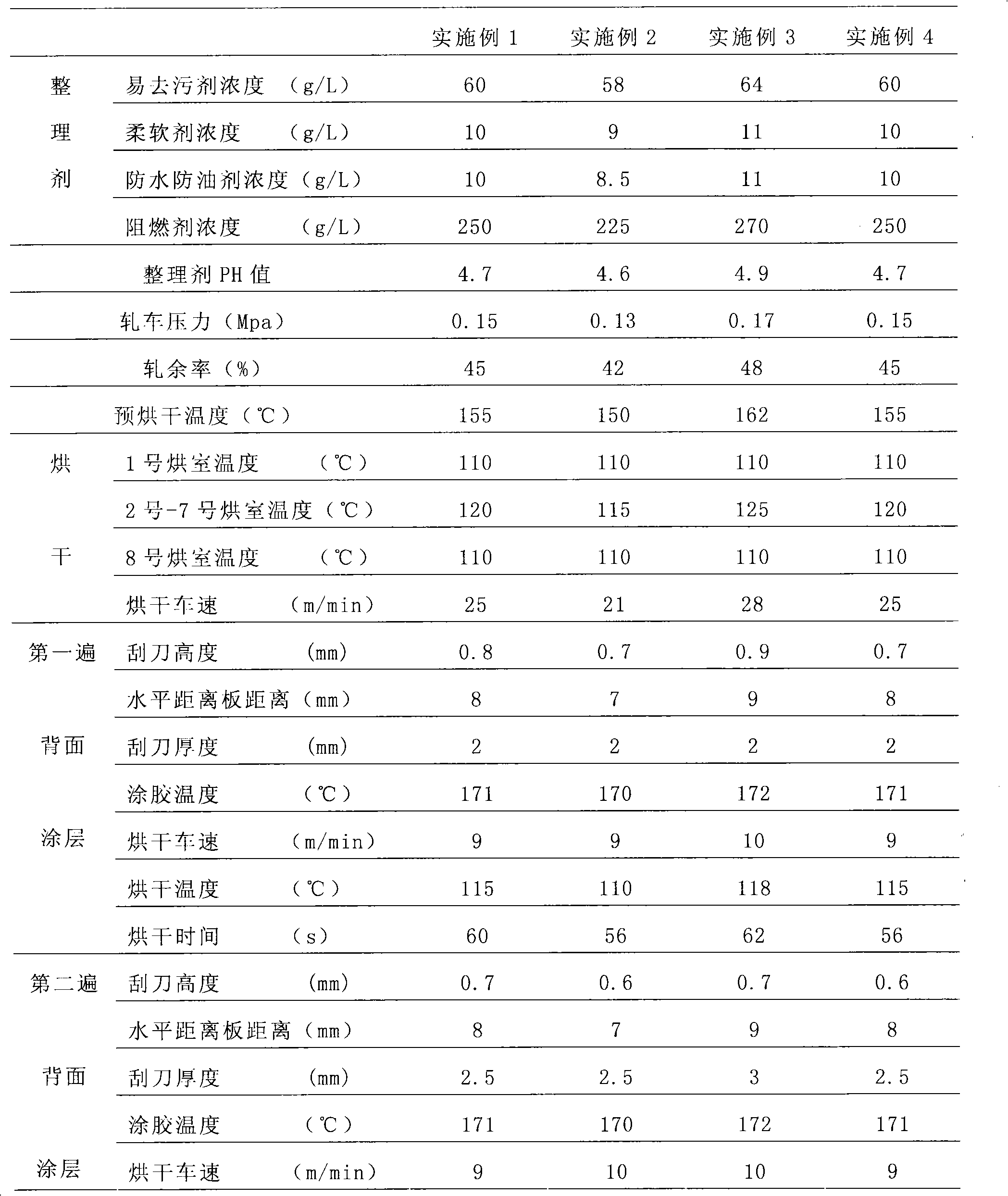

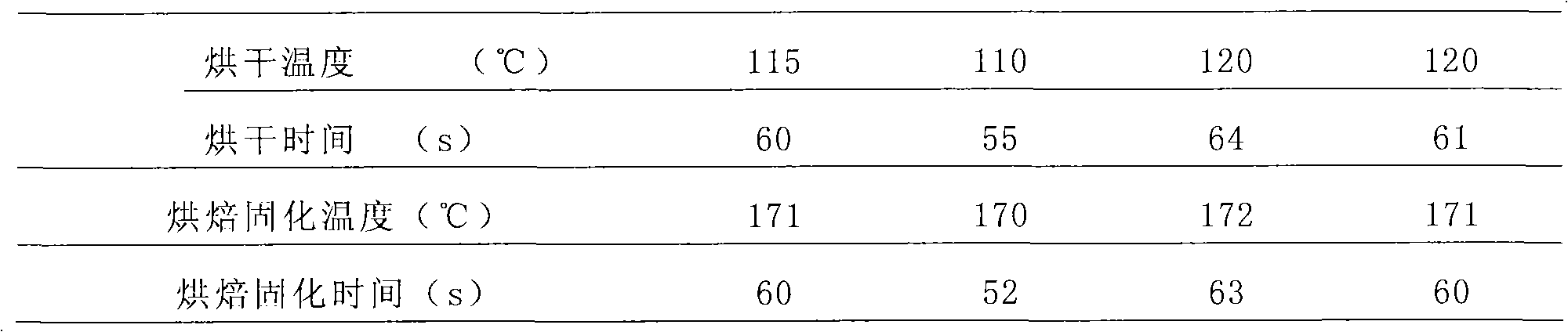

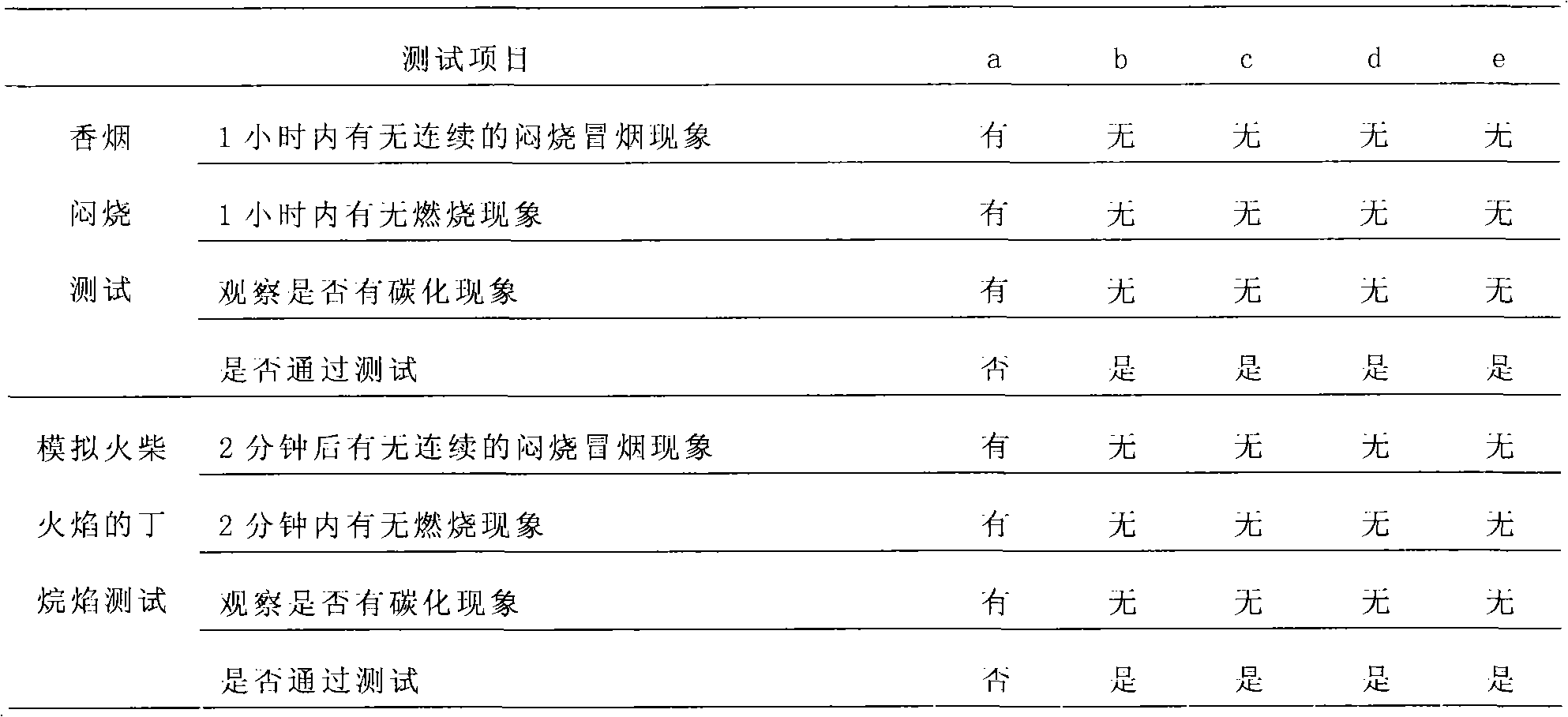

Finishing method of flocking fabric

ActiveCN101798759AImprove flame retardant performanceImprove waterproof performanceFibre treatmentPulp and paper industryAirplane

The invention provides a finishing method of a flocking fabric, which comprises the following steps that: static flocking fabric is impregnated in a finishing agent, and the finishing agent comprises a decontaminating agent, a waterproof and oil-proofing agent, a softening agent and a fire retardant; and the static flocking fabric after being impregnated is baked and cured after the back surface of the flocking fabric is coated with flame-retardant coat rubber. The static flocking fabric which is undertaken the functional finishing has high flame resistance, good water and oil resistance, easy decontamination and softer and more smooth hand touch. The performance of the flocking fabric can satisfy the requirements of the decoration fabric of the home furnishings and the cloth for inner ornaments of car, train, airplane and the like, so the static flocking fabric which is finished with the method has wider application range.

Owner:YUYUE HOME TEXTILE

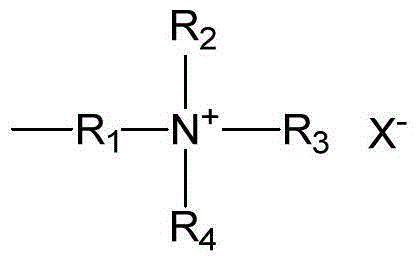

Liquid textile washing agent composition and method for improving color protection performance of liquid textile washing agent composition

ActiveCN104531406AGood color protectionReduce cross-color phenomenonDetergent mixture composition preparationSurface-active non-soap compounds and soap mixture detergentsWhitening AgentsOptical brightener

The invention discloses a liquid textile washing agent composition and a method for improving a color protection performance of the liquid textile washing agent composition. The composition contains a cation hydroxypropyl oxidized starch derivative; and the cation substitution degree is 0.20-1.00 and the number-average molecular weight of a polymer is 1000000-4000000. The cation hydroxypropyl oxidized starch derivative has a textile color fixing effect and also can prevent an anti-cross-color phenomenon from occurring between colored textiles. More importantly, cation hydroxypropyl oxidized starch has good compatibility with an anion surfactant and a fluorescent whitening agent; and the liquid textile washing agent composition has a good washing and stain-removing capability. According to the liquid textile washing agent composition and the method for improving the color protection performance of the liquid textile washing agent composition, disclosed by the invention, the washing function can be provided for a consumer, the color loss of the textiles and the mutual color crossing between the textiles are remarkably reduced, and the colors of the textiles keep bright.

Owner:GUANGZHOU LIBY

After-finishing process of shrink-proof, anti-wrinkling, moisture absorption and quick-drying shirt collar support

The invention discloses an after-finishing process of a shrink-proof, anti-wrinkling, moisture absorption and quick-drying shirt collar support. The process comprises the following steps of: preparing a 30-40 g / l modifier of polyethylene siloxane serving as a quick-drying hygroscopic agent of an after-finishing agent, resin of a certain concentration and a Cat.D catalyst into a padding liquid of which the pH value is 4.5; and putting a fabric to be finished into the padding liquid, and performing pre-baking and baking steps when the padding rate is 80 percent. In the padding finishing liquid, the modifier of the polyethylene siloxane plays a role in absorbing moisture and drying quickly and is suitable for moisture absorption and quick-drying finishing of cotton, terylene and a blended fabric thereof, and the fabric is endowed with extremely good soft handfeel. The modifier of the polyethylene siloxane can be used separately with a padding method, and can be used together with initial condensation bodies such as a shrink-proof and anti-wrinkling agent, stiff resin and the like, so that the swelling ratio of a fiber pore canal is lowered, and better moisture absorption and quick-drying effects are achieved.

Owner:南通海盟实业股份有限公司

Finishing agent for water and oil proofing of fabric

InactiveCN103469585AImprove waterproof performanceGood decontamination performanceVegetal fibresElastomerPolyester

The invention discloses a finishing agent for water and oil proofing of a fabric. The finishing agent comprises the following components in parts by weight: 80-100 parts of polyether ester elastomer, 20-30 parts of stearic acid propylene isopropyl enol ester, 5-10 parts of dimethyl hydrogen-containing polysiloxane and 1-3 parts of aluminium zirconium acid ester coupling agent. The finishing agent for water and oil proofing of the fabric, which is provided by the invention, can be used for waterproof and oilproof finishing of various fabrics, and is particularly suitable for cotton fabrics or cotton-polyester blended fabrics, so that the fabric surface has favorable performance about water proofing and high easiness in oil contamination removing, and the finishing agent has better effects in the aspects of water proofing, oil proofing and fouling resistance.

Owner:KUNSHAN TIENIU SHIRT FACTORY

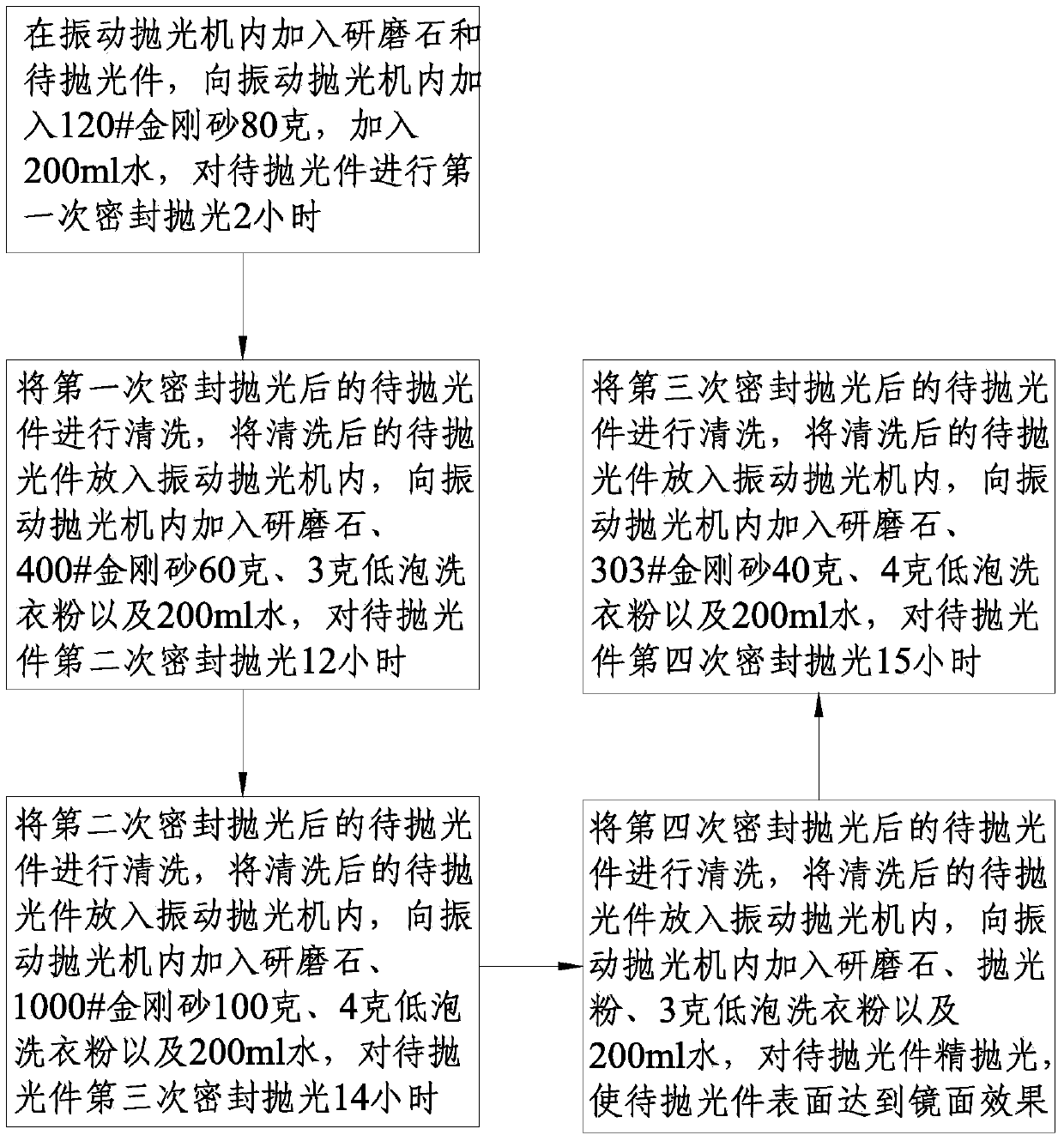

Polishing technology

InactiveCN104191345AImprove polishing effectGood decontamination performanceEdge grinding machinesPolishing machinesSludgePulp and paper industry

The invention relates to a polishing technology, and relates to the field of jadeware polishing. The polishing technology mainly aims to solve the technical problem that because sludge adheres to the surface of a to-be-polished piece in the prior art in the polishing process, the polishing effect is poor. According to the main technical scheme, the polishing technology includes the following steps that a to-be-polished piece and emery are added into a polishing machine, and the to-be-polished piece is subjected to sealing polish for the first time; the to-be-polished piece having been polished for the first time, emery and low-foaming detergent are added into the polishing machine, and the to-be-polished piece is subjected to sealing polish for the second time; the to-be-polished piece having been polished for the second time, emery and low-foaming detergent are added into the polishing machine, and the to-be-polished piece is subjected to sealing polish for the third time; the to-be-polished piece having been polished for the third time, emery and low-foaming detergent are added into the polishing machine, and the to-be-polished piece is subjected to sealing polish for the fourth time; the to-be-polished piece having been polished for the fourth time, emery and low-foaming detergent are added into the polishing machine, and the to-be-polished piece is subjected to finishing polish.

Owner:新疆布尔津县友谊峰玉石加工厂

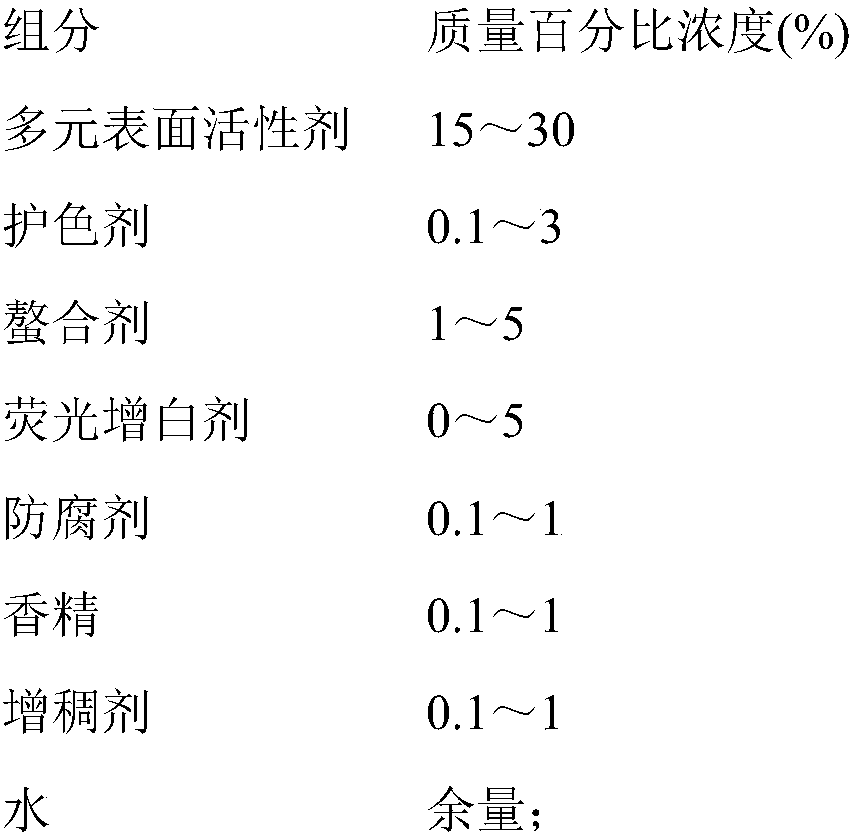

Highly-efficient color-protecting liquid laundry detergent and preparation method thereof

PendingCN108130199AExcellent color protectionProtect colorInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPreservativeWhitening Agents

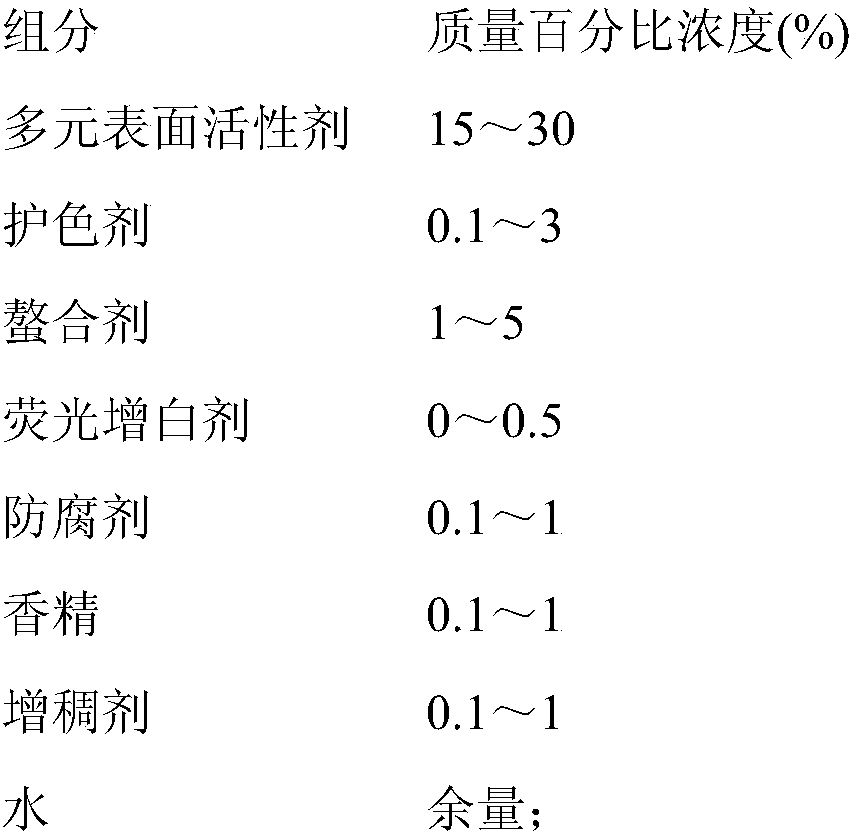

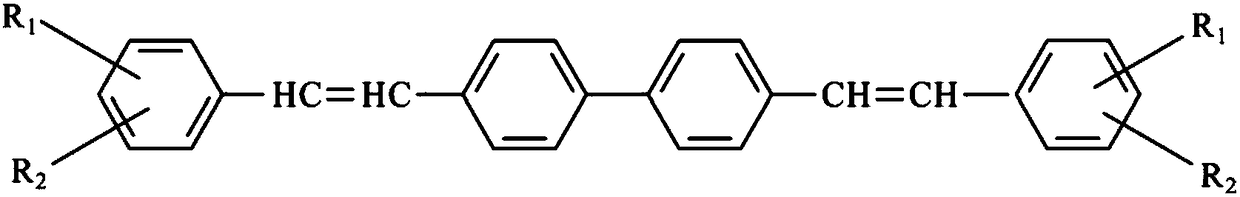

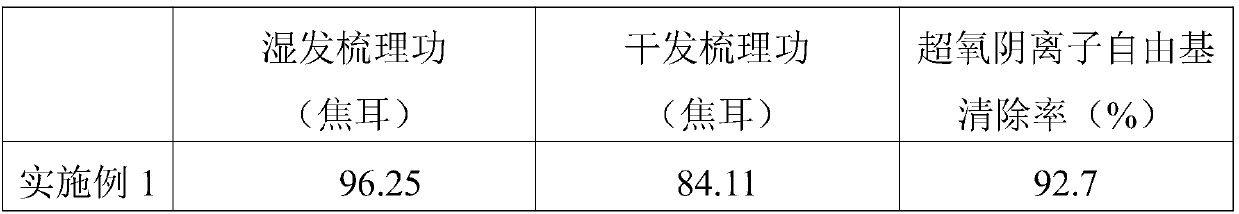

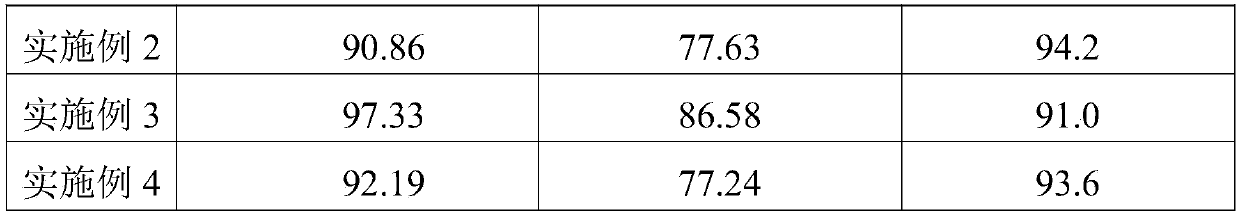

The invention mainly relates to the field of washing compositions with a surface active compound as a base material, specifically to a highly-efficient color-protecting liquid laundry detergent and apreparation method thereof. The highly-efficient color-protecting liquid laundry detergent is characterized by being prepared from the following components by uniform mixing in terms of mass percent concentration (%): 15% to 30% of a multi-element surfactant, 0.1% to 3% of a color-protecting agent, 1% to 5% of a chelating agent, 0% to 5% of a fluorescent whitening agent, 0.1% to 1% of a preservative, 0.1% to 1% of an essence and 0.1% to 1% of a thickening agent, with the balance being water. The highly-efficient color-protecting liquid laundry detergent provided by the invention has good washing effect, reduces the loss of fabric color, and prevents colors from crossing in fabric washing.

Owner:SHANGHAI BAIMAO

Organic infant hair and body wash and preparation method thereof

InactiveCN107669551AFull of nutritionGood decontamination performanceCosmetic preparationsHair cosmeticsHair washingChemistry

The invention discloses an organic infant hair and body wash and a preparation method thereof. The preparation method includes the following steps: (1) water is heated to 65 DEG C to 85 DEG C, cocamidopropyl betaine, sodium laureth sulfate, sodium lauroamphoacetate, glycerol, a nonionic surfactant and lavender oil are sequentially added and uniformly stirred and mixed, so that a mixture is obtained; (2) the mixture is cooled to 45 DEG C to 55 DEG C, then a matricaria chamomilla flower / leaf / stem extract, an oat kernel extract, Curacao aloe leaf juice powder and sodium chloride are sequentiallyadded and uniformly stirred and mixed, and thereby the organic infant hair and body wash is obtained. The organic infant hair and body wash disclosed by the invention contains rich plant essences, caneffectively moisturize the tender hair and skin of infants, and can provide richer nutrition. The organic infant hair and body wash has excellent cleaning property, a good effect in use and both a hair-washing function and a bathing function, is mild and non-irritating, and is convenient to carry.

Owner:温迪熊(上海)儿童用品股份有限公司

Preparation method of environment-friendly multifunctional textile washing and finishing agent

ActiveCN104313883AGood decontamination performanceAntistaticSurface-active detergent compositionsFibre treatmentPolyethylene glycolOleic Acid Triglyceride

The invention discloses a preparation method of an environment-friendly multifunctional textile washing and finishing agent. The preparation method comprises the steps of enabling methoxy polyethylene glycol and hydroxyl silicone oil to have esterification reaction with animal oleic acid to obtain complex ester formed by the animal oleic acid and the methoxy polyethylene glycol and hydroxyl silicone oil, and compounding the complex ester which is adopted as a main component with soluble chitosan, lauryl sodium sulfate, sodium citrate, isopropanol and fragrance agent to obtain the environment-friendly multifunctional textile washing and finishing agent. The environment-friendly multifunctional textile washing and finishing agent prepared by the method has the characteristics of good washing decontamination performance, softness and comfort of washed fabric, electrostatic resistance, sterilization, moth prevention and the like and is applicable to natural and synthesized fiber textiles.

Owner:李双峰

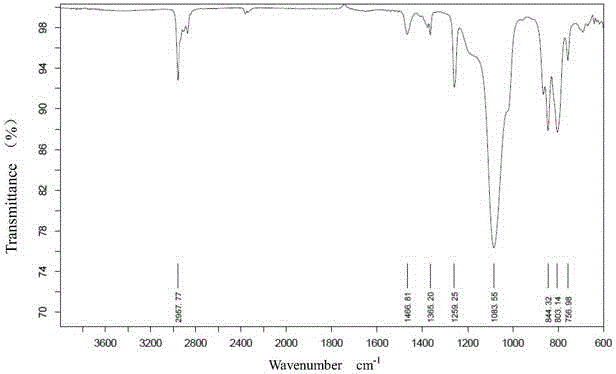

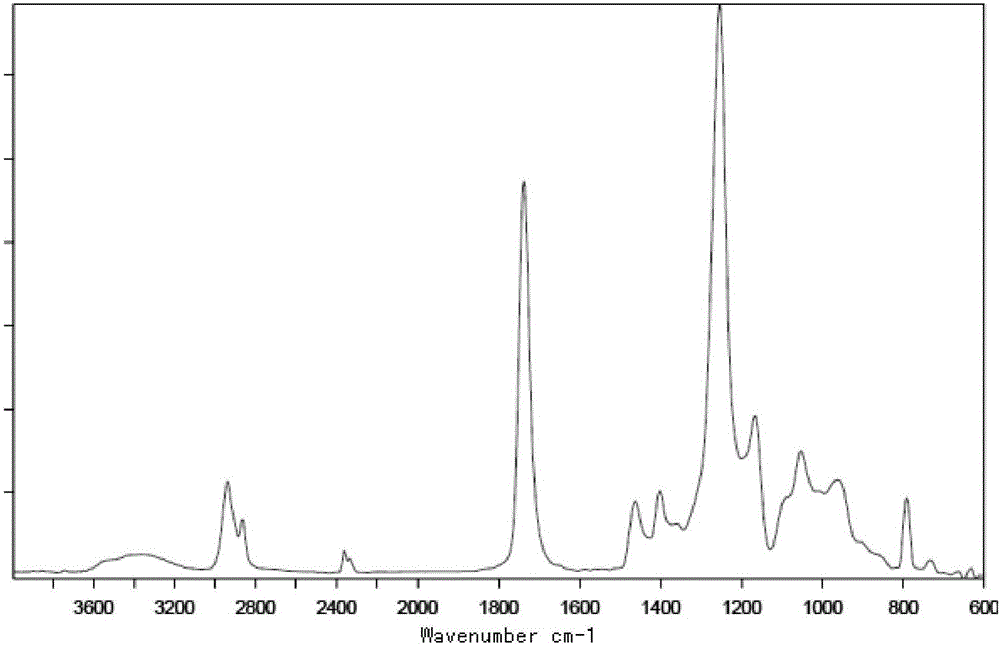

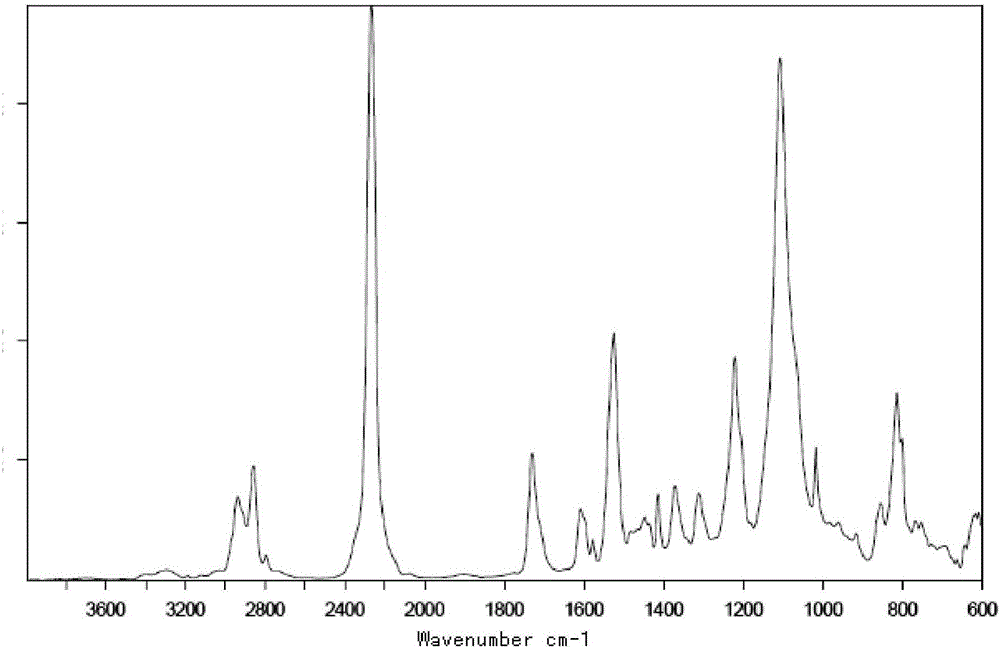

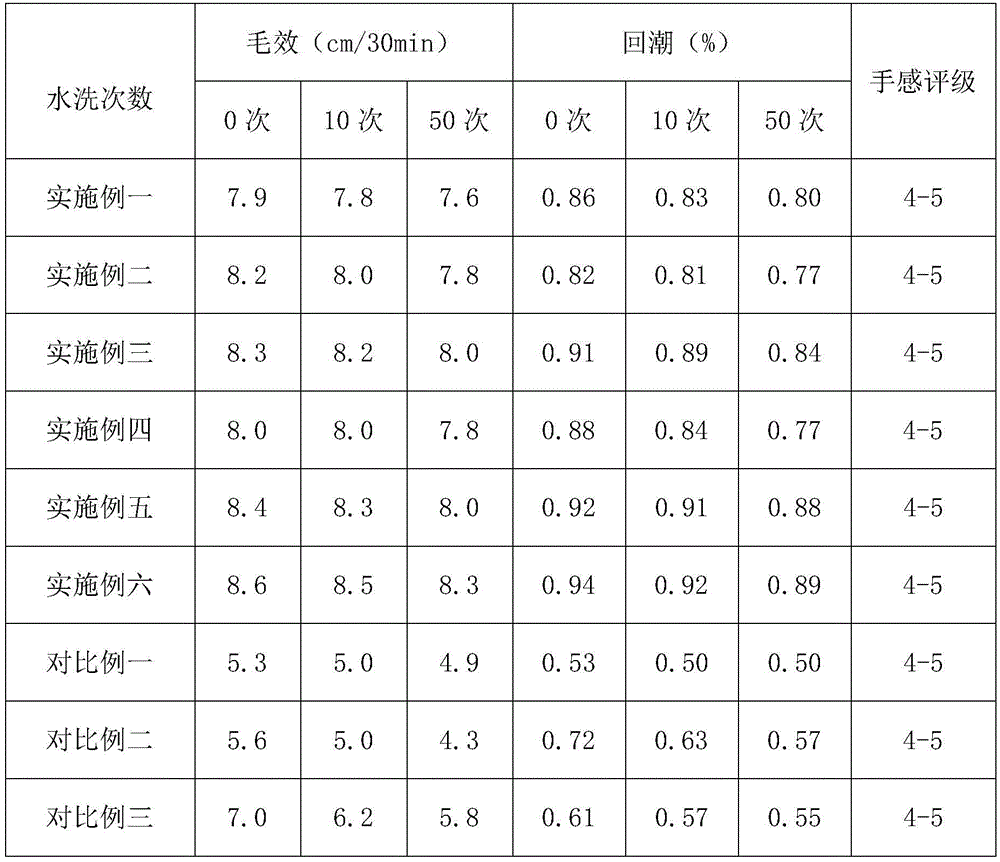

Novel hydrophilic soil-releasing finishing agent and preparation method thereof

The invention discloses a novel hydrophilic soil-releasing finishing agent. The novel hydrophilic soil-releasing finishing agent is prepared from, by weight, 10-15 parts of methyl acrylate, 10-20 parts of ethyl acrylate, 5-10 parts of methacrylic acid, 6-12 parts of bis(2-ethylhexyl) sulfonyl sodium succinate, 2-5 parts of water-soluble silicone oil, 3-7 parts of carboxymethylcellulose, 5-8 parts of polyethylene oxide / polypropylene oxide block polyether, 0.5-1 part of tourmalineline powder, 0.02-0.05 part of a dispersing agent, 1-2 parts of an initiating agent and 30-50 parts of deionized water. The invention further discloses a preparation method of the novel hydrophilic soil-releasing finishing agent. Accordingly, the soil-releasing property of a fabric is effectively improved, and the processed fabric is excellent in washing resistance and good in physical property and mechanical property; the novel hydrophilic soil-releasing finishing agent is free of poison and harmless to a human body and the environment, and the preparation method is simple and low in production cost.

Owner:嘉兴纳科新材料有限公司

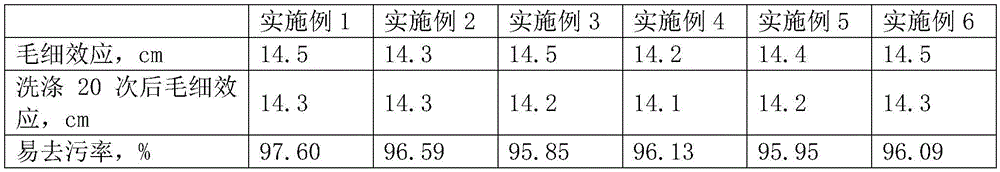

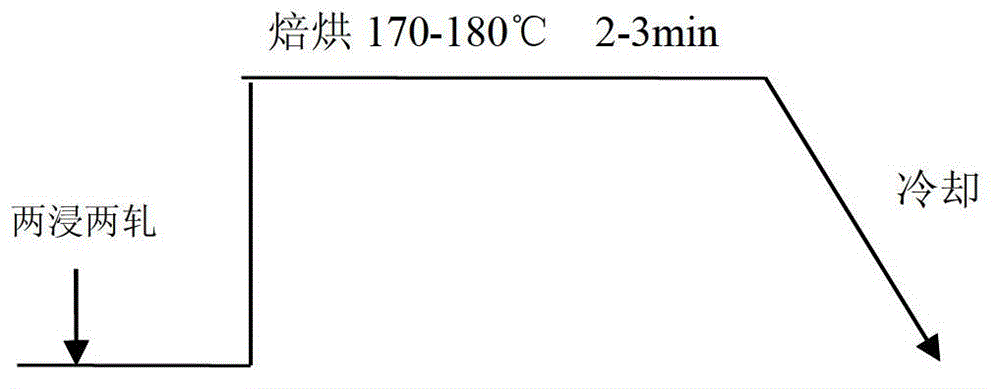

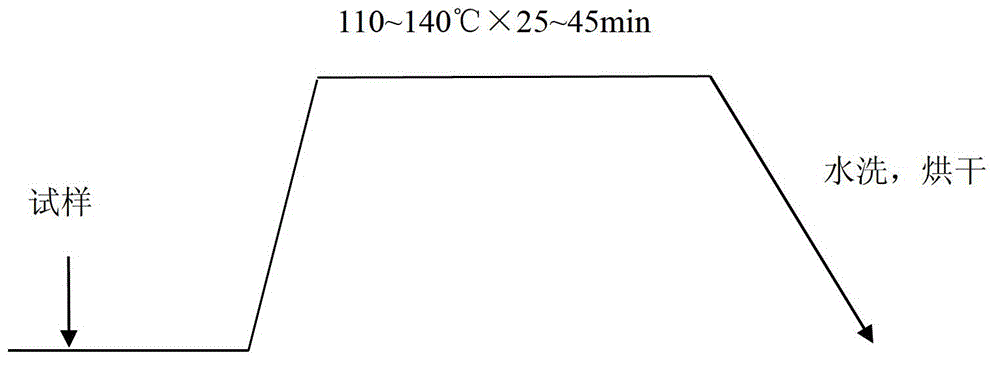

Hydrophilic soil release finish method for fabrics

InactiveCN102864626AImprove hydrophilicityGood decontamination performanceFibre typesFiberSoil science

The invention discloses a hydrophilic soil release finish method for fabrics. The method comprises using a soil release finish agent SR produced by Dahua Japan company limited to conduct soil release finish; adopting a padding method to manufacture, enabling using amount of the soil release finish agent SR to be 25-35g / L, enabling rolling remaining rate to be 70-90%, enabling baking temperature to be 170-180 DEG C, and enabling baking time to be 2-3min; or adopting an impregnation method to manufacture, enabling using amount of the soil release finish agent SR to be 3-5%(owf.), enabling impregnation temperature to be 110-140 DEG C, and enabling impregnation time to be 25-45min. The hydrophilic soil release finish method for fabrics uses a chemical hydrophilic modified agent which does not return fluorine to serve as the hydrophilic soil release finish agent, and is low in cost, simple in treatment process and capable of giving excellent hydrophily and easy soil release performance of chemical fibers.

Owner:SHANGHAI JIALE

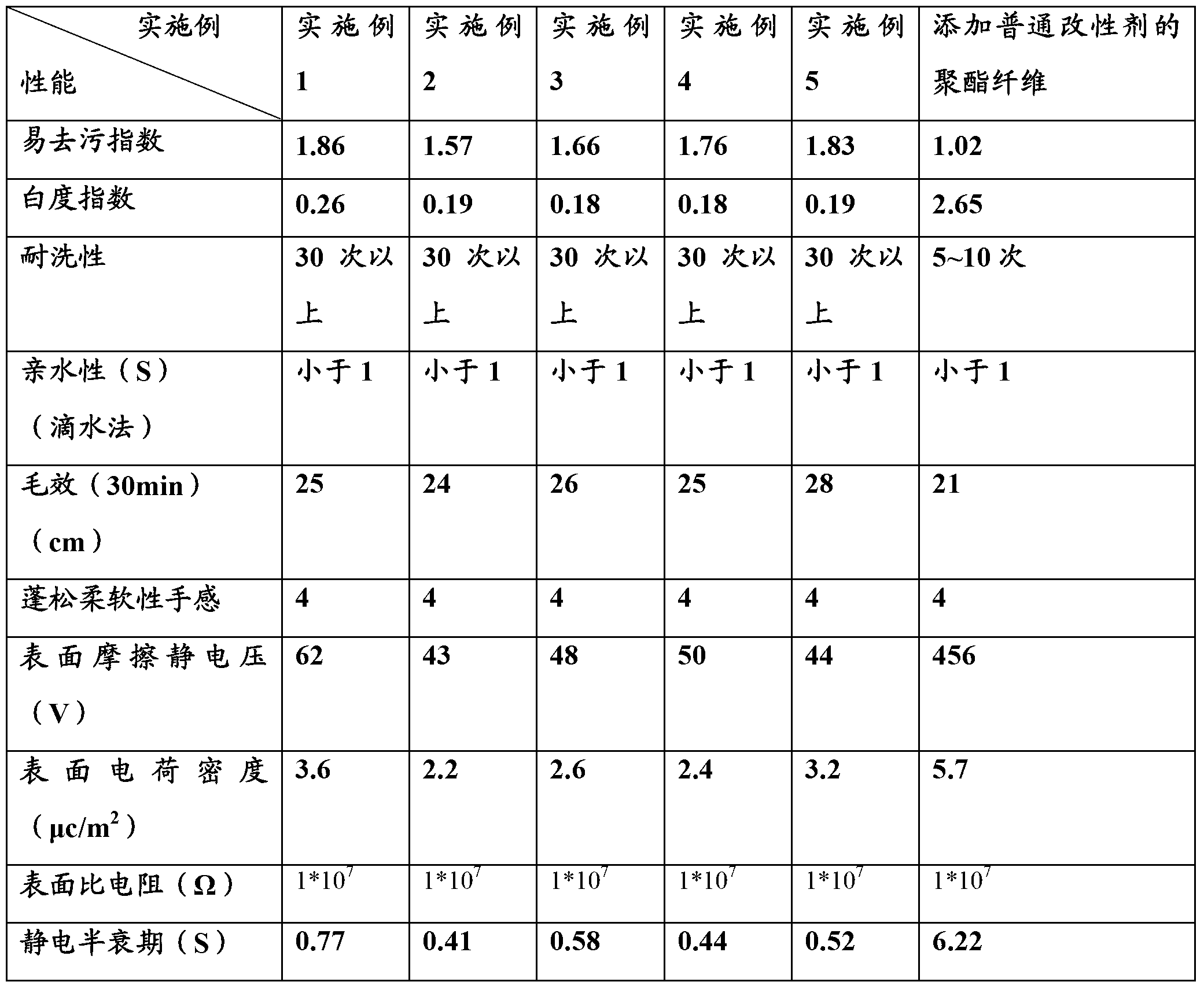

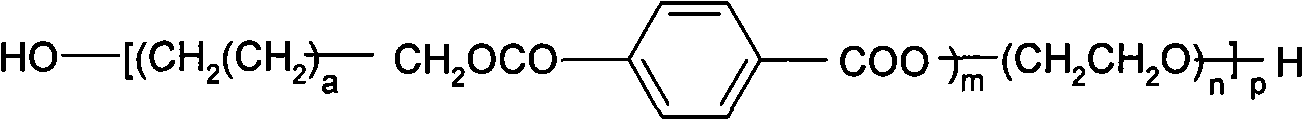

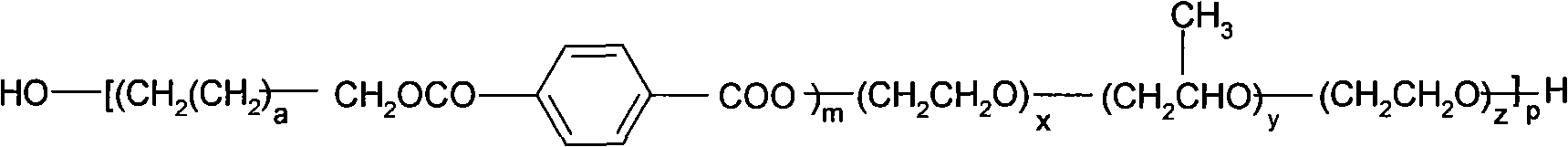

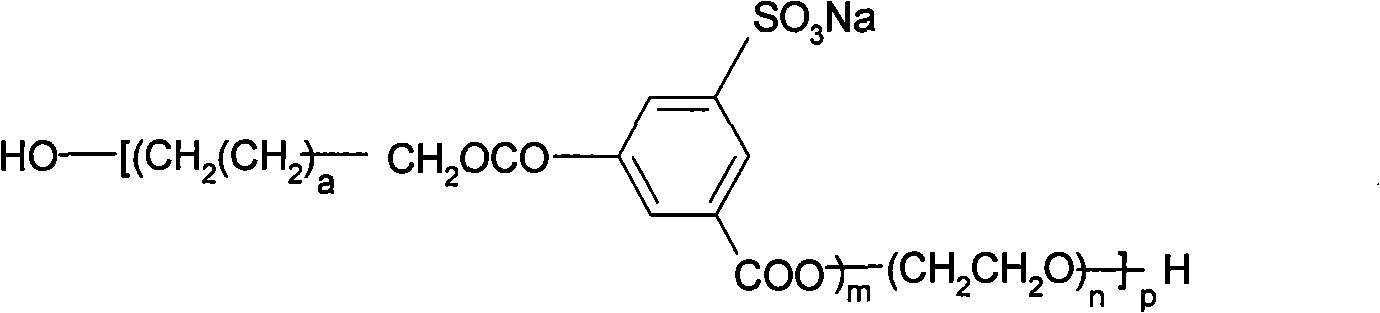

Decontamination finishing agent used for polyester fiber, and preparation method thereof

The invention relates to a decontamination finishing agent used for polyester fiber, and a preparation method thereof. The finishing agent comprises, by weight, 1-5% of a polyester-polyether-polyamide block copolymer, 2-5% of glycerol or ethylene glycol or fluorine resin, and balance of water. The polyester-polyether-polyamide block copolymer is prepared from the raw materials of, by weight: 60-160 parts of polyethylene glycol, 13-40 parts of glycol, 14-26 parts of dimethyl terephthalate, 15-100 parts of polyamide, and 0.2-1 parts of metal acetate as a catalyst. With the in-bath crease-resisting agent provided by the invention, the polyester fiber is provided with good decontamination performance. Also, fluffy and soft texture, antistatic property, hydrophilic smoothness, and the like of polyester fiber can be improved. The decontamination finishing agent has excellent washing resistance, and does not fail after at least 30 times of washing.

Owner:DUPLUS CHEM OF ZHANGJIAGANG CITY

Jade polishing process

InactiveCN107350955AImprove polishing effectGood decontamination performanceEdge grinding machinesPolishing machinesSludgeMaterials science

The invention relates to a jade polishing process and relates to the field of jade polishing. The main purpose of the invention is to solve the technical problem in the prior art that the polishing effect is poor due to mud attached to the surface of a piece to be polished during the polishing process. The main technical solution is: a jade polishing process, including the following steps: adding the piece to be polished and corundum into the polishing machine, sealing and polishing the piece to be polished for the first time; adding the polished piece to the polishing machine after the first polishing Parts, emery and low-foaming washing powder, seal and polish the parts to be polished for the second time; add the parts to be polished, emery and low-foaming washing powder after the second polishing into the polishing machine, and seal and polish the parts to be polished for the third time; Add the workpiece to be polished after the third polishing, corundum and low-foaming washing powder into the polishing machine, and seal and polish the workpiece for the fourth time; add the workpiece to be polished, polishing powder and low-foaming detergent after the fourth polishing into the polishing machine Washing powder, for fine polishing of polished parts.

Owner:如皋市明德包装有限公司

Three-proofing finishing method for elastic tencel blended fabrics

ActiveCN103409959AImprove performanceGood decontamination performanceSucessive textile treatmentsSolvent-treatmentTextile technologyOrganic chemistry

The invention belongs to the textile technical field and particularly relates to a production method for elastic tencel blended fabrics. A three-proofing finishing method for elastic tencel blended fabrics is characterized by adding 5-20g / L of softening agents 3305, 20-40g / L of chlorine washing resistant improvers, 10-30g / L of finishing agents CP-SLA, 10-30g / L of finishing agents 7713, 10-30g / L of soil release finishing agents CP-R and 1-20g / L of improvers LK-30. When elastic tencel blended fabrics are subjected to three-proofing finishing through the method, the three-proofing finishing and soil release amount is adjusted in the pretreatment process of tencel to improve the performance of the tencel; the tencel treated by the method has a good soil release property, the good soil release property is provided for heavy oil difficult to be washed away, and the soil release property is good after washing for 50 times, so that the washing durability is outstanding.

Owner:HUAFANG

Polyester fabric-containing multifunctional washing assistant, preparation and use thereof

InactiveCN101323822AImprove efficacyImprove hydrophilicityOrganic detergent compounding agentsPolyesterAntioxidant

The invention discloses a multifunctional cleaning assistant for polyester containing textile and a preparation method thereof. The multifunctional cleaning assistant for polyester containing textile is polyester-polyether block copolymer with molecule containing polyester chain segment and polyether chain segment. The preparation method comprises the following steps: 1) 100 weight portions of diatomic ester, 70 to 80 weight portions of diatomic alcohol and 0.2 to 0.6 weight portions of transesterification catalyst are added into a reaction kettle, nitrogen is pumped in and the reaction kettle is heated until the temperature rises to 150 DEG C; stirring is carried out, after diatomic ester is totally melted, the temperature is raised gradually to the reaction temperature of transesterification reaction of 180 to 220 DEG C and the transesterification reaction lasts 2.5 to 3 hours; 2) when the steamed methanol steamed reaches a theoretical quantity of 90 to 95 percent, 60 to 926 weight portions of polyether, 0.1 to 0.5 weight portion of polycondensation catalyst, 2 to 4 weight portions of antioxidant are added, heating is continued until the temperature reaches that of polycondensation reaction of 230 to 280 DEG C and polycondensation lasts 0.5 to 1.5 hours after vacuum-pumping. The multifunctional cleaning assistant of the invention is applied to the cleaning or rinsing working procedure during the course of household cleaning with an amount of 0.5 to 1g / L, can provide polyester containing textile with multiple functions such as hydrophile, anti-static electricity, and being easy to decontaminate, etc. and has excellent washability.

Owner:ZHEJIANG SCI-TECH UNIV

Preparation method of wear-resisting anti-fouling solvent-free polyurethane automobile leather

InactiveCN106436331AImprove wear resistanceGood decontamination performanceRoad vehiclesCoatingsSolventChemistry

The invention discloses a preparation method of wear-resisting anti-fouling solvent-free polyurethane automobile leather. The surface of release paper is uniformly coated with a surface layer sizing agent, and drying is performed to obtain a surface layer leather film; the surface layer leather film is uniformly coated with a foaming layer sizing agent, drying is performed till the coatings have the certain adhesive property; all the coatings and synthetic leather base cloth are laminated, drying and curing are performed, and then the release paper is peeled off to obtain a dry method semi-finished product; the front face of the dry method semi-finished product is coated with an anti-fouling coating, and drying and solidification are performed to obtain a finished product. The method has the environmental protection property and functionality, no solvent is adopted in the production technological process, no solvent remains in the product, and the wear-resisting anti-fouling solvent-free polyurethane automobile leather is high in wear-resisting property and excellent in anti-fouling performance.

Owner:ANHUI ANLI MATERIAL TECH

Hydrophilic modification method for polyester fibers with bromoethane and PVA

The invention discloses a hydrophilic modification method for polyester fibers with bromoethane and PVA and belongs to the technical field of macromolecules. According to the method, a sodium hydroxide solution is added to the polyester fibers, the mixture is stirred, heated and preprocessed, the surfaces of the polyester fibers are damaged, and subsequent modification processing is facilitated; a bromoethane solution is added to the polyester fibers, the mixture is stirred and heated and subjected to modification treatment, then a PVA solution with the mass ratio being 4-5.5% is added to the polyester fibers, the mixture is stirred and heated, and the polyester fibers obtained after hydrophilic modification is obtained. According to the method, after the sodium hydroxide solution is added for preprocessing the polyester fibers, the bromoethane solution and the PVA are utilized to conduct modification processing on the polyester fibers, and the polyester fibers good in hydrophilia and antistatic performance are obtained. The method is easy and convenient to operate, the reaction speed and the reaction temperature are easy to control, the amount of organic solvent added in the reaction process is small, low toxin, low pollution and low emission are achieved, subsequent operation is easy and convenient to conduct, industrialized popularization are facilitated, and high economic benefits are achieved.

Owner:苏州东奕盛材料科技有限公司

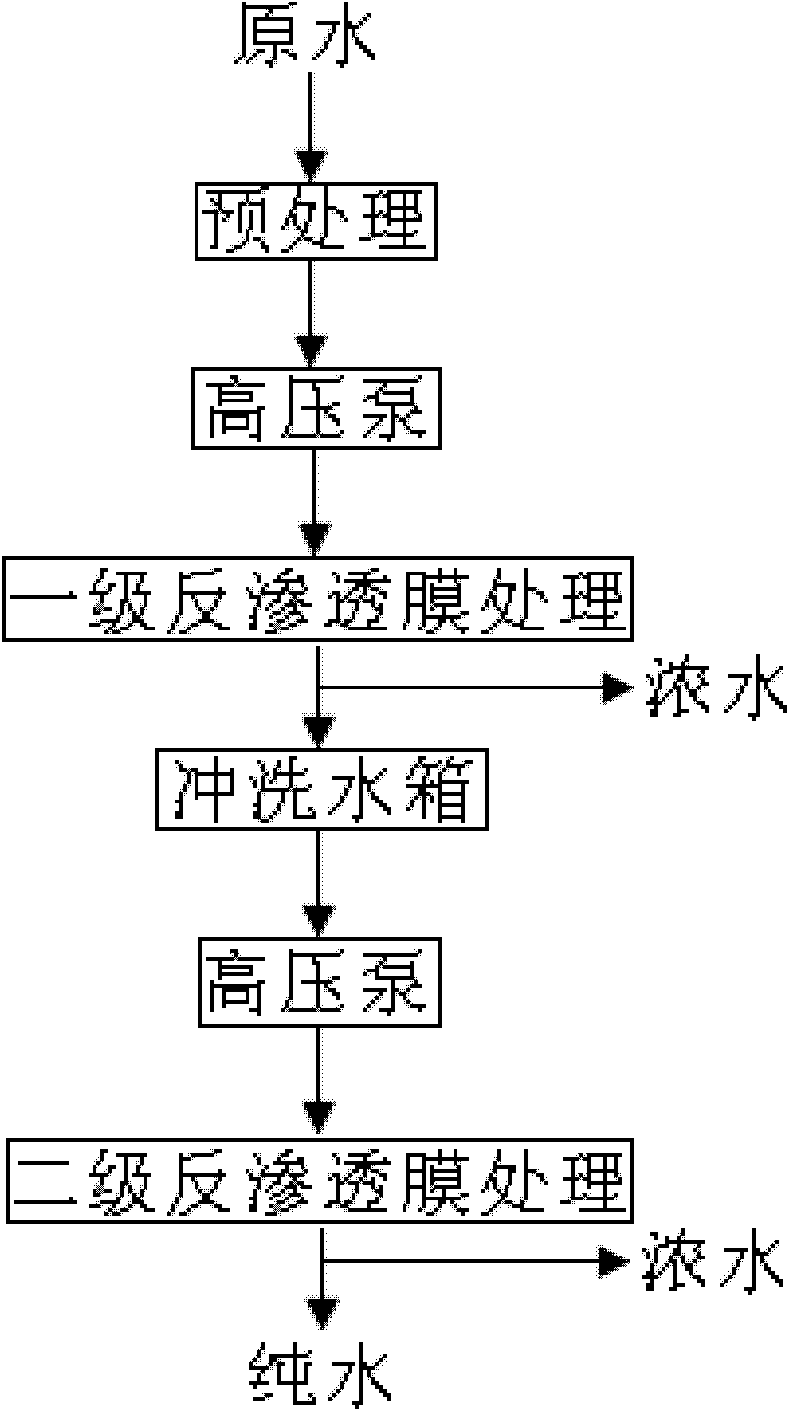

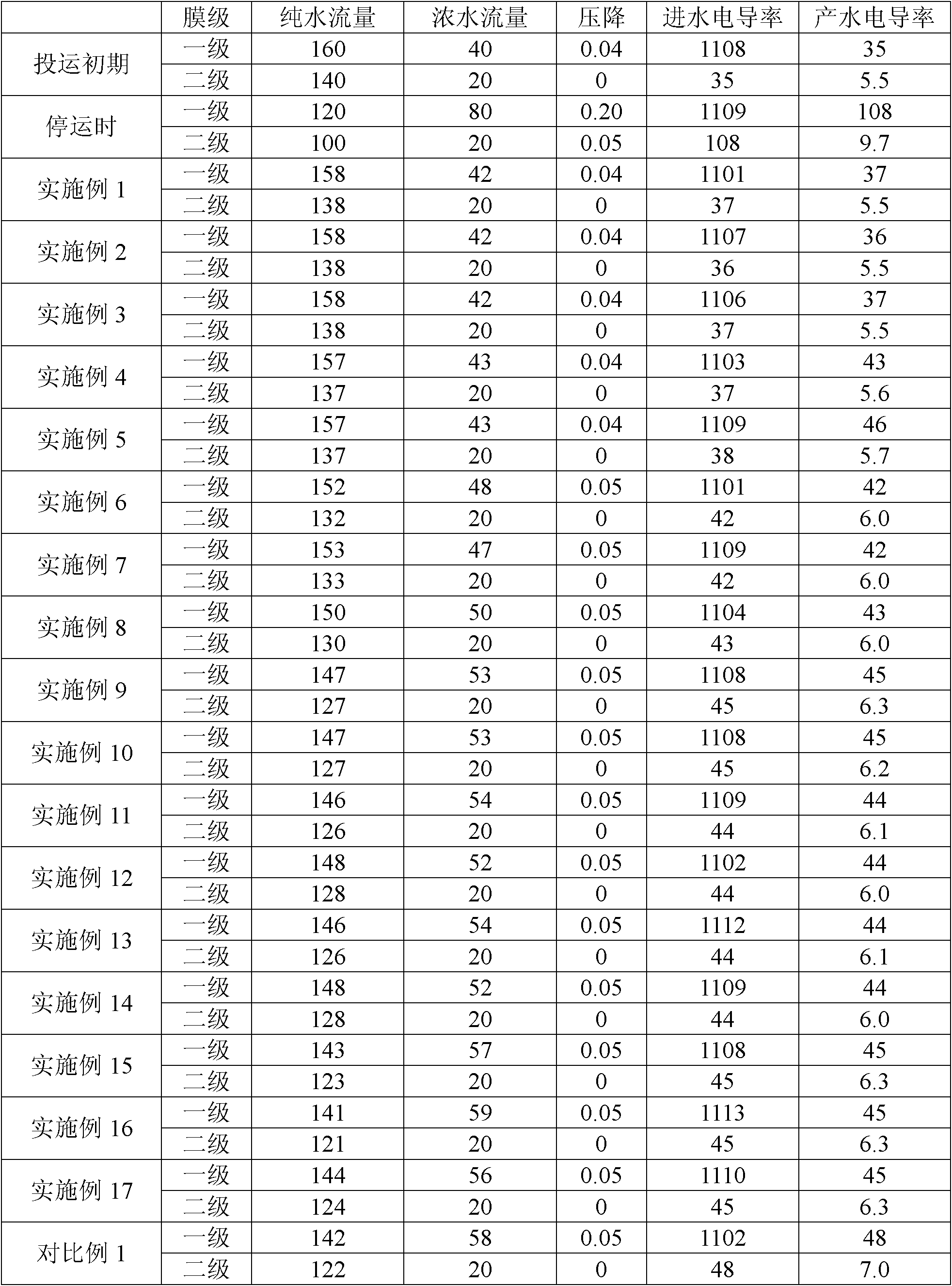

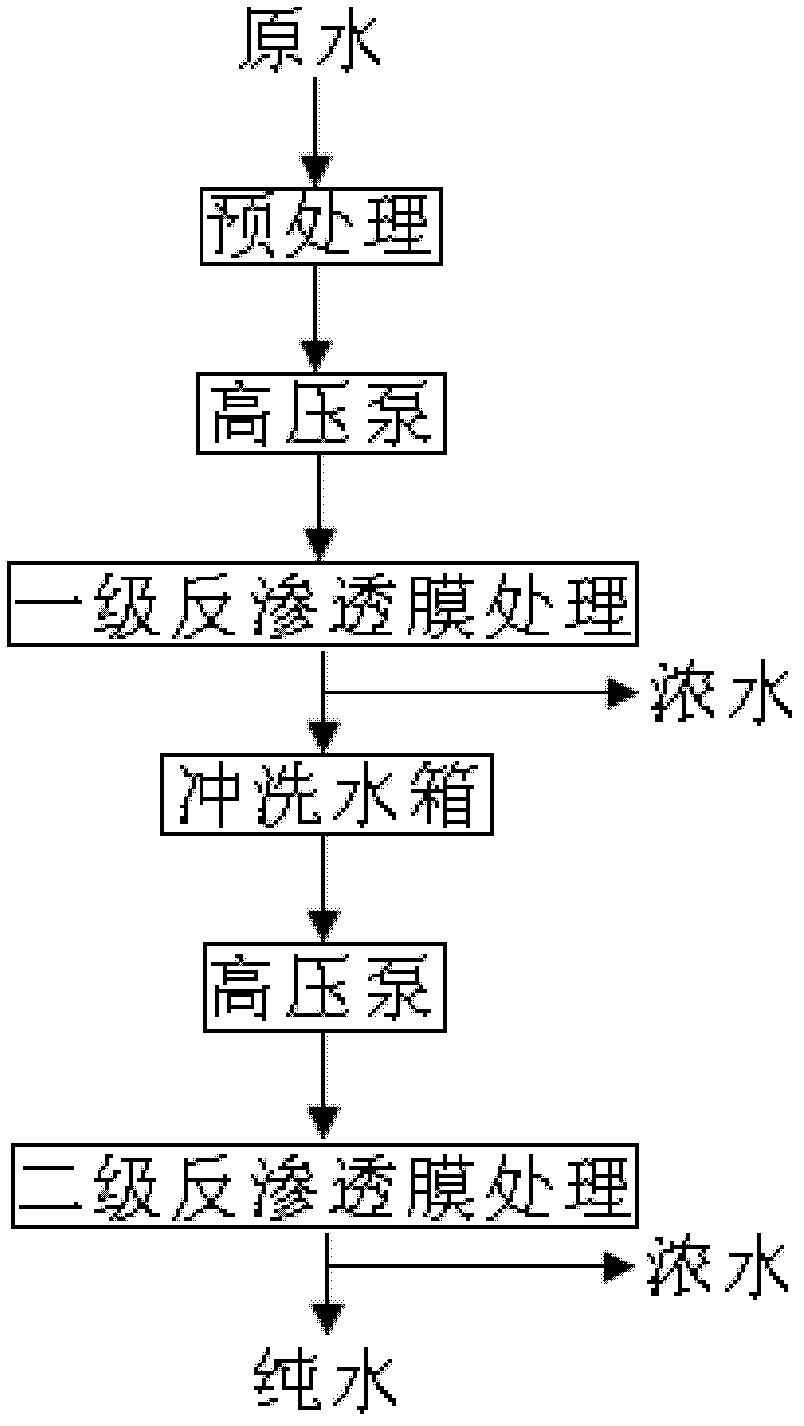

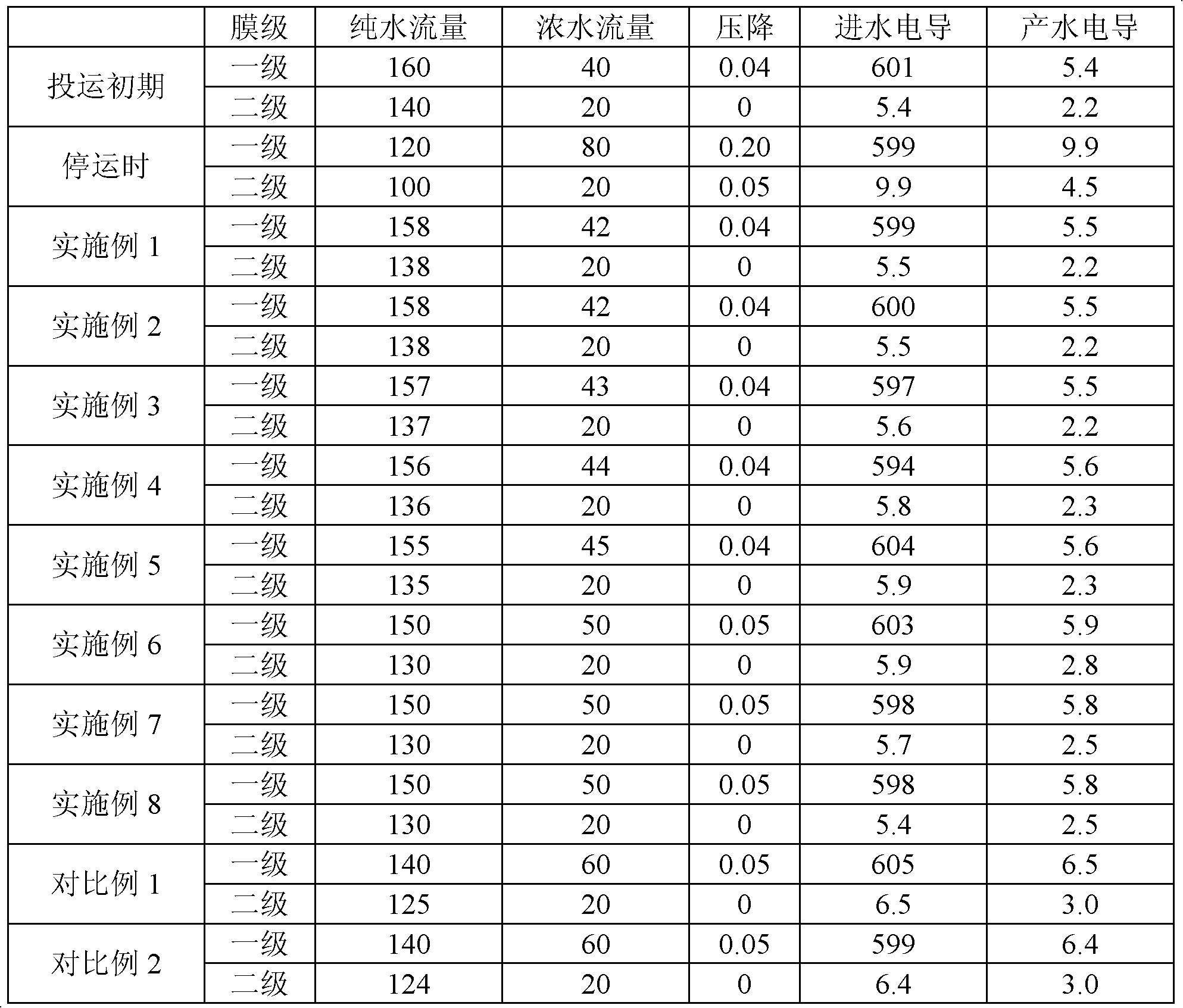

Cleaning agent composition and cleaning method for reverse osmosis membrane

ActiveCN103143261AImprove lipophilicityReduce foamingSemi-permeable membranesReverse osmosisEthylene Homopolymers

The invention relates to a cleaning agent composition, comprising an A agent and a B agent. The A agent and the B agent are stored independently. The A agent comprises a non-ionic surfactant and a dispersing agent, wherein the non-ionic surfactant is a fatty alcohol-polyoxyethylene ether; and the dispersing agent is selected at least one from an organic phosphonic acid, a poly-aspartic acid, a polyepoxysuccinic acid and a co-polymer and / or a homopolymer obtained by polymerization of at least one of an unsaturated organic acid, an unsaturated organic acid ester and an unsaturated organic acid anhydride. The B agent contains a foaming agent. The invention also relates to a method for cleaning a reverse osmosis membrane by using the above cleaning agent composition. A cleaning liquid prepared by the cleaning agent composition can clean the reverse osmosis membrane effectively, makes water yield of a reverse osmosis system restore basically, and can significantly reduce front-and-back pressure difference of the reverse osmosis membrane and reduce conductivity of produced water.

Owner:CHINA PETROLEUM & CHEM CORP +1

Manufacture method of self-cleaning fabric

ActiveCN105568426AImprove stabilityGood repeatabilityWeft knittingFilament/thread formingMolten stateEpoxy

The invention relates to a manufacture method of a self-cleaning fabric. The manufacture method comprises the following steps: uniformly mixing polyvinyl chloride, polyoxyethylene-polyoxypropylene block copolymer, epoxy resin, nanometer titania, towel gourd juice, nanometer mica powder and polystyrolsulfon acid, heating to a molten state, adding benzyl butyl phthalate, cellulose ester, nanometer chitin and residual components, uniformly mixing to obtain a modified spinning melt, performing spinning and postprocessing to obtain ultrafine denier fibers, and spinning the spinning fibers to obtain the self-cleaning fabric. By virtue of blending spinning of the combined materials, a hierarchical structure combining a micron structure with a nanometer structure is formed on the surface of the fabric, so that the surface roughness of the fabric is enhanced, and the self-cleaning property and the water and oil repellent performance of the fabric are improved greatly.

Owner:东台市天地经纬织品有限公司

Cleaning agent composition and cleaning method for reverse osmosis membrane

ActiveCN103143264AImprove wettabilityImprove washing effectSemi-permeable membranesReverse osmosisEthylene Homopolymers

The invention relates to a cleaning agent composition, comprising a non-ionic surfactant and a dispersing agent, wherein the non-ionic surfactant is a fatty alcohol-polyoxyethylene ether; and the dispersing agent is a (methyl)acrylic homopolymer and / or a (methyl)acrylic acid copolymer. The invention also relates to a method for cleaning a reverse osmosis membrane by using the above cleaning agent composition. The method comprises the steps of preparing the cleaning agent composition into a cleaning liquid with a pH value of 10.5-11.5 and cleaning the reverse osmosis membrane by using the cleaning liquid. The cleaning liquid prepared by the cleaning agent composition can clean the reverse osmosis membrane effectively, makes water yield of a reverse osmosis system restore basically, and can significantly reduce front-and-back pressure difference of the reverse osmosis membrane and reduce conductivity of produced water.

Owner:CHINA PETROLEUM & CHEM CORP +1

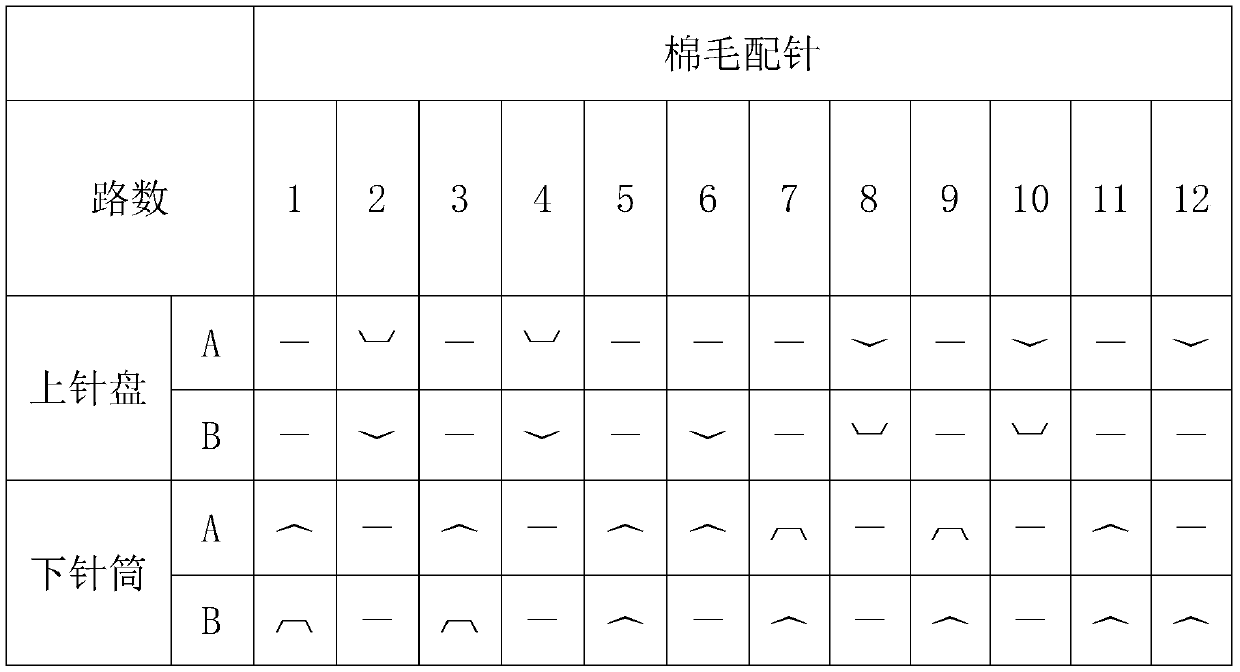

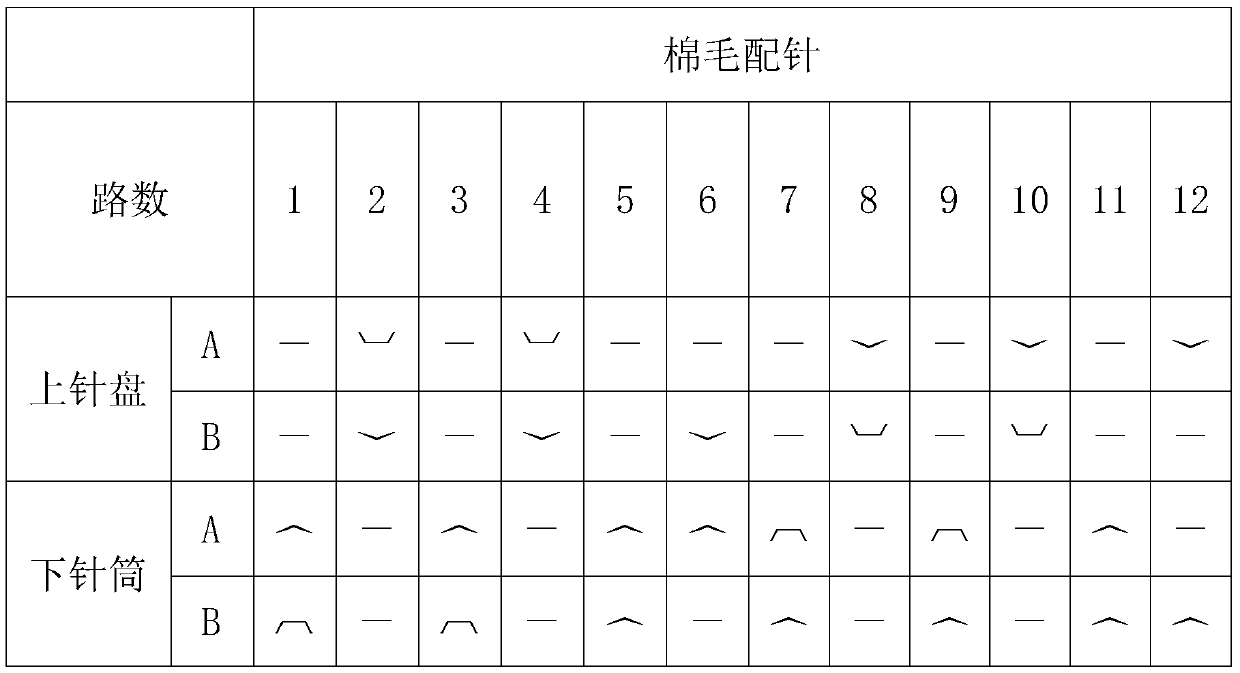

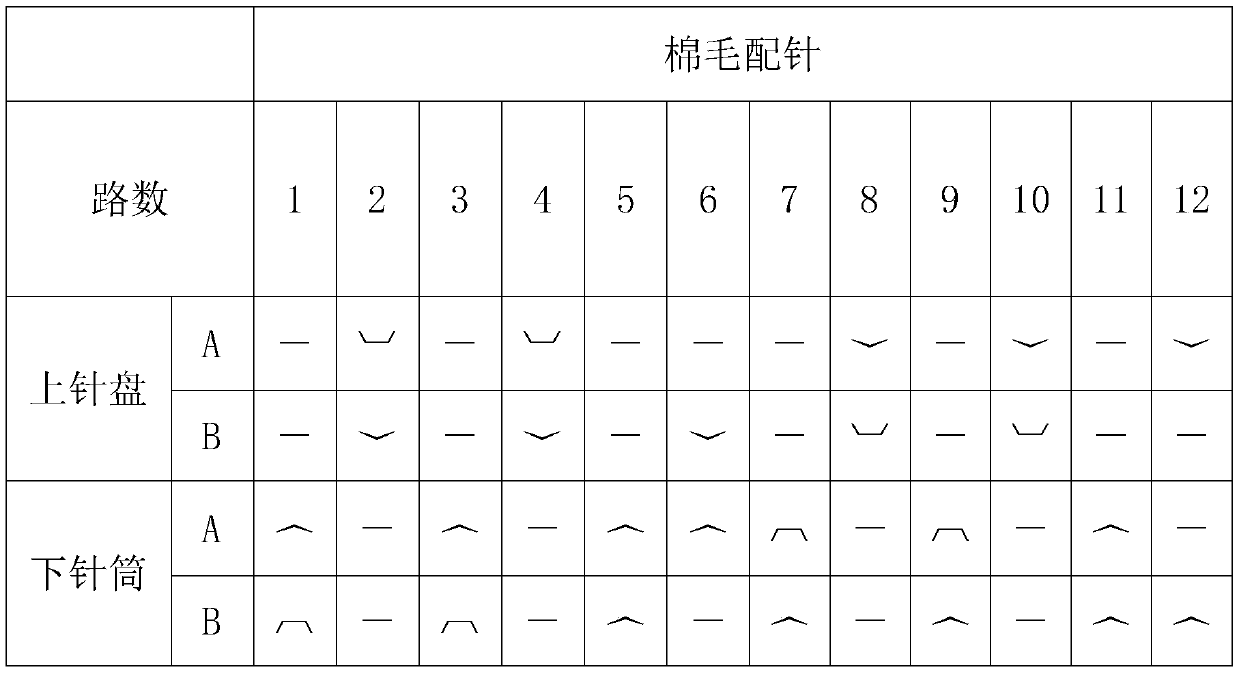

Knitted underwear rib 'three opening' self-cleaning finishing method

InactiveCN101067271AEasy to operateIncreased durabilityFibre treatmentLiquid/gas/vapor removalFiberEngineering

The self-cleaning finish process for collars of ribbing knitted underwear includes the following steps: 1. compounding self-cleaning finish liquid mixture and regulating pH value; and 2. padding ribbing knitted underwear in the finish liquid, stoving and roasting. The self-cleaning performance of the fabric is characterized with water repellency, oil repellency and detergency. The process is simple, makes the finished fabric possess lasting self-cleaning function, and may be applied for various kinds of high grade ribbing knitwear.

Owner:DONGHUA UNIV +1

Production process of moisture-absorbing and sweat-releasing fabric capable of removing stains easily

InactiveCN111118715AGood moisture absorption and perspirationExcellent decontamination effectWeft knittingDyeing processEcologyCotton fibre

The invention discloses a production process of a moisture-absorbing and sweat-releasing fabric capable of removing stains easily. The fabric is formed by weaving 50-60S of blended yarn and 75-100 D Coolplus fibers on a knitting double-sided large circular machine, wherein the mass proportion of the blended yarn in the fabric is 60-67%, the blended yarn is formed by blending modal fibers and cotton fibers, and the mass proportion of the modal fibers in the blended yarn is 45-55%; and the production process comprises the steps of carrying out weaving, pretreatment, dyeing, dehydration, cutting,drying, shaping, and finished product obtaining. According to the production process of the moisture-absorbing and sweat-releasing fabric capable of removing stains easily, the fabric is comfortable,soft and not prone to being deformed by virtue of the moisture absorption and conduction effect of the core of the Coolplus fibers and the moisture-absorbing and sweat-releasing performance of the blended yarn; and in addition, the surface of the fabric is subjected to soil release finish, so that the fabric is excellent in effect of removing stains easily, the antistatic performance is enhanced,wearing is comfortable, the harm of static electricity to human bodies is reduced, and the fabric conforms to the consumption concept of ecological environmental protection and health.

Owner:JIANGSU DONGYUAN TEXTILE SCI & TECH IND

Detergent for down jacket

InactiveCN106833985AGood decontamination performanceLess foamSurface-active non-soap compounds and soap mixture detergentsWaxHand washing

The invention relates to the technical field of detergent compositions, in particular to a detergent for down garments. It is made of the following raw materials in parts by weight: 0.05-0.5% of dioctadecyldimethylammonium chloride, 4-6% of glutamine, 3-4% of polyoxyethylene abietic acid, 3- 4%, sodium laurate 1-2%, sodium citrate 0.01-0.5%, polyisobutylene 2-3%, propylene glycol 0.5-2%, antibacterial agent 0.01-0.05%, silicone softener 3-4, essence 0- 0.1%; the pH value of the down jacket detergent is 5.8-7. The down jacket detergent of the present invention has good decontamination performance, less foam and easy rinsing; the neutral-weak acid formula will not make the down jacket hard and brittle due to excessive degreasing; A hydrophobic protective film is formed on the surface of the fiber to prevent damage to the wax on the surface of the down and keep the down fluffy and warm; the dispersion performance is good, and it can be washed in cold water, hot water, machine wash, or hand wash.

Owner:QINGDAO HUANAN SHENGYUAN FRUIT IND CO LTD

Flame-retardant clothing and preparation process thereof

InactiveCN110042592AImprove cleanlinessGood flexibilityFlame-proof filament manufactureBiochemical fibre treatmentEngineeringPre treatment

The invention relates to the field of textile products, in particular to flame-retardant clothing and a preparation process thereof. The preparation process comprises the following steps of S1, pretreatment; S2, preparation of a finishing solution; S3, soft sterilization finishing; S4, dewatering, wherein a soft bactericidal flame-retardant fabric obtained in S3 is dewatered; S5, drying; S6, shaping. The preparation process has the advantages that soft sterilization finishing is carried out on the flame-retardant fabric so that the flame-retardant clothing made of the flame-retardant fabric can be applied to chef clothing in the daily life, and the chef clothing not only has good flame resistance but also has good comfort and air permeability.

Owner:深圳市帝邦服装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com