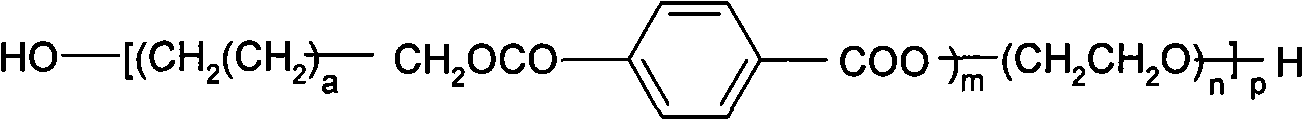

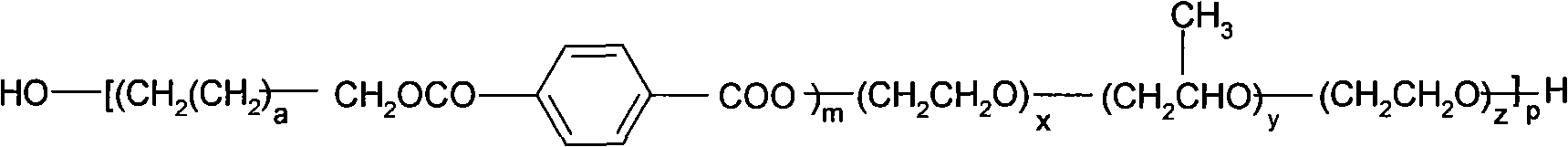

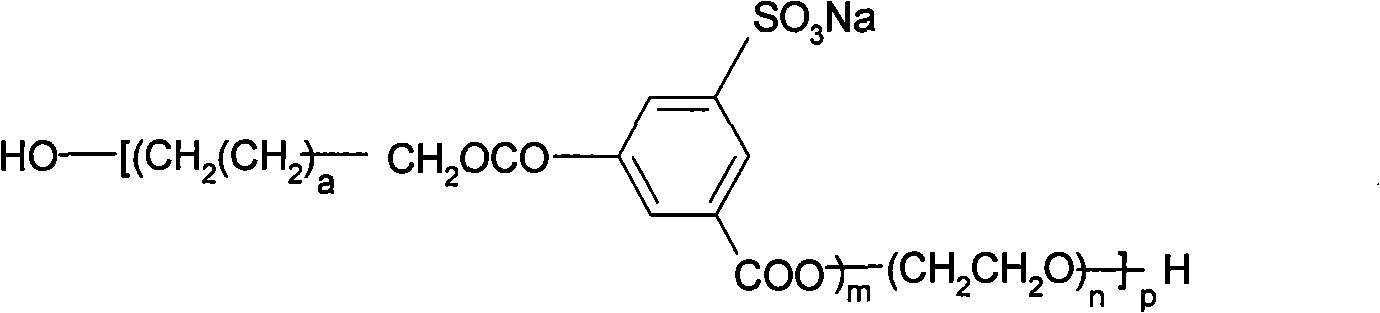

Polyester fabric-containing multifunctional washing assistant, preparation and use thereof

A washing aid and multi-functional technology, applied in the direction of organic washing compositions, etc., can solve the problems of unsatisfactory, poor washing resistance, large dosage, etc., and achieve the effect of improving efficacy, good washing resistance, and improving enrichment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In a 250ml reactor, put 24.3g DMT, 18.6g ethylene glycol, 0.05g zinc acetate, and heat to 150°C under the protection of nitrogen. After the DMT melts, start stirring and continue to heat up. The temperature rises to 180°C, and methanol begins to evaporate. out, continue to heat up to 195°C, and react for 3 hours. When the amount of methanol evaporated reached 90% to 95% of the theoretical amount, PEG, 0.025g polycondensation catalyst and 0.5ml antioxidant triphenyl phosphite were dropped into 56.3g molecular weight of 1500, and the temperature was continued to rise to 260°C. MPa) in polycondensation for 1 hour to obtain the polyester polyether block copolymerization type multifunctional detergent builder. Add 0.75g / L of this detergent additive in the washing process in the household washing process. After the treatment, the polyester fabric has a capillary effect of 11.3cm / 15min and a surface resistance of 7.0×10 8 Ω, half-life 3.28s, easy decontamination rate 85.8%; a...

Embodiment 2

[0028] Put 24.3g of DMT, 22.8g of propylene glycol, and 0.05g of zinc acetate into a 250ml reactor, and heat it to 150°C under the protection of nitrogen. After the DMT melts, stir and continue to heat up to 200°C, and react for 2.5 hours. When the amount of methanol distilled out reaches 90%~95% of the theoretical amount, drop into 56.3g molecular weight as PEG of 1500, 0.025g polycondensation reaction catalyst and 0.5ml antioxidant triphenyl phosphite, continue to be warming up to 250 ℃, in vacuum ( 0.04MPa) in polycondensation for 1.5 hours to obtain the polyester polyether block copolymerization type multifunctional detergent builder. Add 0.75g / L of this detergent additive in the household washing and rinsing process of polyester fabrics. After treatment, the wool effect of polyester fabrics is 10.4cm / 15min, and the surface resistance is 7.9×10 8 Ω, the half-life is 4.18s, and the decontamination rate is 80.8%.

Embodiment 3

[0030] Put 24.3g of DMT, 27.0g of butanediol, and 0.05g of zinc acetate into a 250ml reactor, heat it to 150°C under nitrogen protection, start stirring after the DMT melts and continue to heat up to 220°C, and react for 2.5 hours. When the amount of methanol distilled reaches 90% to 95% of the theoretical amount, drop in 56.3g of PEG with a molecular weight of 1500, 0.025g of polycondensation catalyst and 0.5ml of triphenyl phosphite, and continue to heat up to 270°C. ) in polycondensation for 0.5 hour to obtain the polyester polyether block copolymerization type multifunctional detergent builder. Add 0.75g / L of this detergent additive in the household washing and rinsing process, the polyester fabric capillary effect after treatment is 9.6cm / 15min, and the surface resistance is 8.5×10 8 Ω, the half-life is 4.52s, and the decontamination rate is 79.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| half-life | aaaaa | aaaaa |

| half-life | aaaaa | aaaaa |

| half-life | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com