Production process of moisture-absorbing and sweat-releasing fabric capable of removing stains easily

A technology of moisture absorption and perspiration, production process, applied in the direction of yarn, dyeing, textile and paper making, etc., to achieve the effect of excellent moisture absorption and perspiration, enhanced antistatic performance, and easy decontamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The production process of the easy-to-decontaminate moisture-absorbing and sweat-wicking fabric is as follows: weaving→pretreatment→dyeing→dehydration→cutting→drying→setting→finished product,

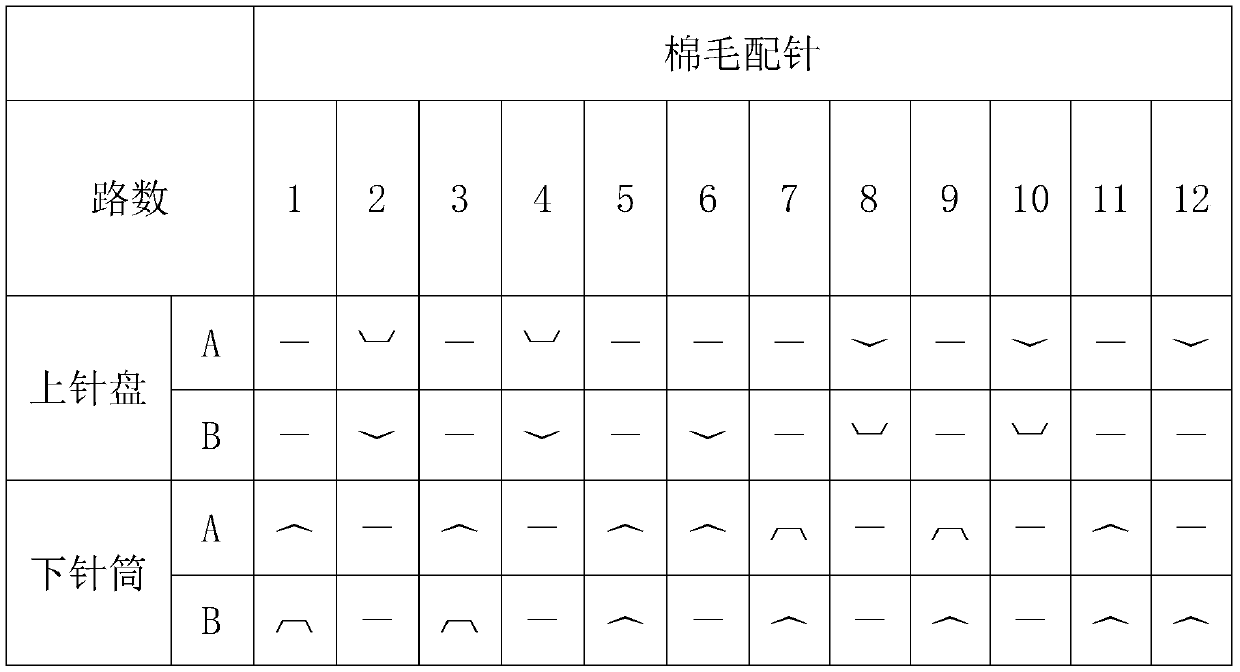

[0018] (1) During weaving: the fabric is woven from blended yarn with a fineness of 50S and 75D Coolplus fiber on a Lida double-sided circular knitting machine with an ultra-fine gauge of 34 inches and 32G. The grammage of the knitted fabric is 200g / m 2High-elastic style fabrics, the mass proportion of blended yarn in the fabric is 61%, the blended yarn is made of modal fiber and cotton fiber, and the mass proportion of modal fiber in the blended yarn is 45%; the fabric pattern cycle It has two coil wales and twelve coil courses, of which: the first, third, fifth, seventh, ninth and eleventh routes are for blended yarn feeding; the second, fourth, sixth, eighth, tenth and twelfth routes Feed yarn for Coolplus fiber; the knitting method is: the first way: the blended yarn is kni...

Embodiment 2

[0028] The production process of the easy-to-decontaminate moisture-absorbing and sweat-wicking fabric is as follows: weaving→pretreatment→dyeing→dehydration→cutting→drying→setting→finished product,

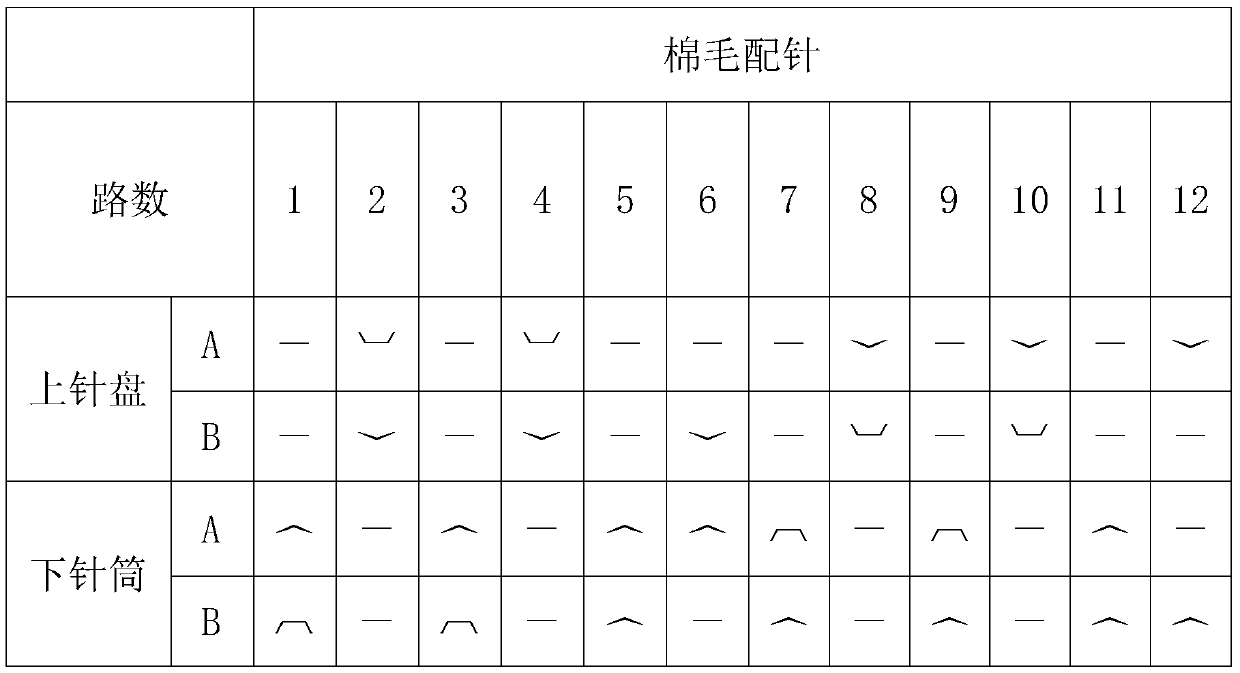

[0029] (1) During weaving: the fabric is woven from blended yarn with a fineness of 60S and 100D Coolplus fiber on a Lida double-sided circular knitting machine with an ultra-fine gauge of 34 inches and 32G. The grammage of the knitted fabric is 180g / m 2 The high-elastic style fabric, the mass proportion of blended yarn in the fabric is 67%, the blended yarn is made of modal fiber and cotton fiber, and the mass proportion of modal fiber in the blended yarn is 55%; the fabric pattern cycle It has two coil wales and twelve coil courses, of which: the first, third, fifth, seventh, ninth and eleventh routes are for blended yarn feeding; the second, fourth, sixth, eighth, tenth and twelfth routes Feed yarn for Coolplus fiber; the knitting method is: the first way: the blended yarn i...

Embodiment 3

[0039] The production process of the easy-to-decontaminate moisture-absorbing and sweat-wicking fabric is as follows: weaving→pretreatment→dyeing→dehydration→cutting→drying→setting→finished product,

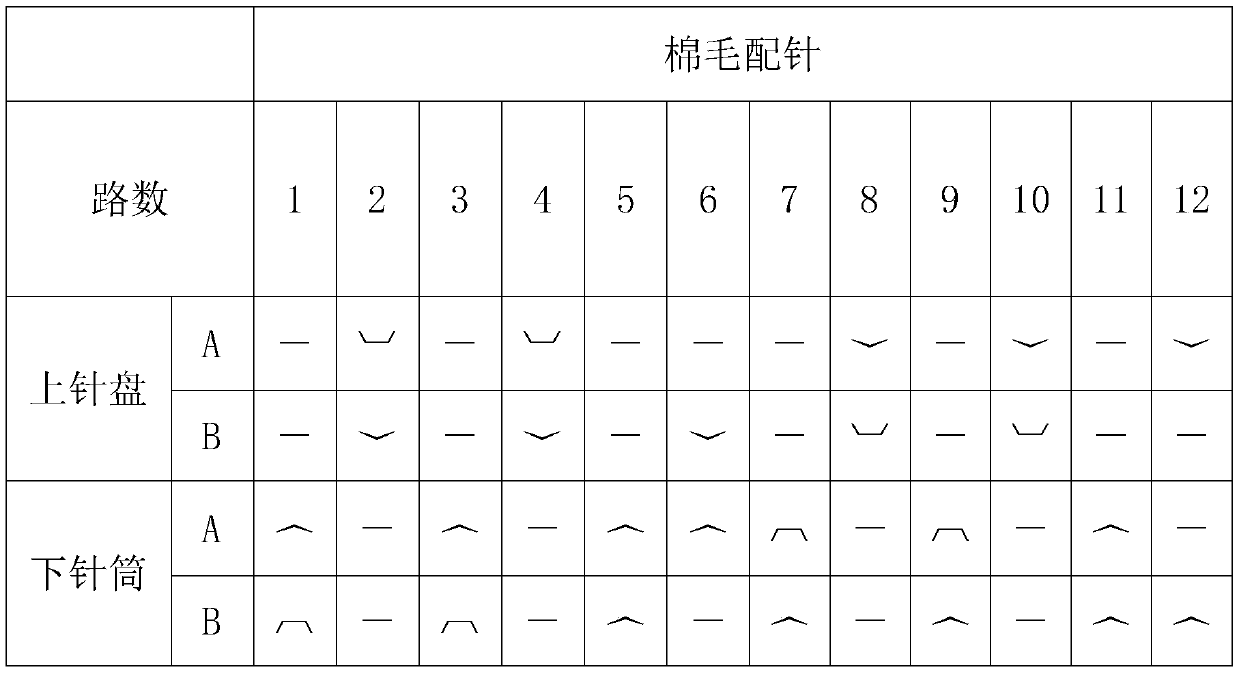

[0040] (1) During weaving: the fabric is woven from blended yarn with a fineness of 60S and 100D Coolplus fiber on a Lida double-sided circular knitting machine with an ultra-fine gauge of 34 inches and 32G. The grammage of the knitted fabric is 190g / m 2 The high-elastic style fabric, the mass proportion of blended yarn in the fabric is 65%, the blended yarn is made of modal fiber and cotton fiber, and the mass proportion of modal fiber in the blended yarn is 50%; the fabric pattern cycle It has two coil wales and twelve coil courses, of which: the first, third, fifth, seventh, ninth and eleventh routes are for blended yarn feeding; the second, fourth, sixth, eighth, tenth and twelfth routes Feed yarn for Coolplus fiber; the knitting method is: the first way: the blended yarn i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Wicking height | aaaaa | aaaaa |

| Evaporation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com