Bio-based nylon fabric, and preparation method and product thereof

A bio-based nylon and bio-based technology, applied in the field of textile fabrics, can solve the problems of nylon composite fabrics such as the decline in mechanical properties, poor moisture absorption and perspiration effects, and poor wearing comfort, and achieve good moisture absorption and perspiration effects and moisture permeability. High and long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A kind of bio-based nylon fabric, described bio-based nylon fabric is blended by bio-based nylon fiber, cotton fiber and polytetrafluoroethylene fiber, then made through knitting or weaving process;

[0056] In parts by weight: 80-90 parts of bio-based nylon fiber, 12-15 parts of cotton fiber and 6-9 parts of polytetrafluoroethylene fiber;

[0057] The bio-based nylon fiber is made from raw materials comprising the following parts by weight:

[0058] 80-90 parts of bio-based polypentamethylene adipate,

[0059] 14-18 parts of polypentamethylene adipate,

[0060] 5-7 parts of carboxymethyl cellulose,

[0061] 6-8 parts of sepiolite powder,

[0062] Fumed silica 4-6 parts,

[0063] 4-5 parts of dispersant;

[0064] The bio-based polypentamethylene adipate is made from bio-based 1,5-pentanediamine and petroleum-based adipic acid.

[0065] In this embodiment, the bio-based nylon fabric is blended with bio-based nylon fibers, cotton fibers and polytetrafluoroethylene fib...

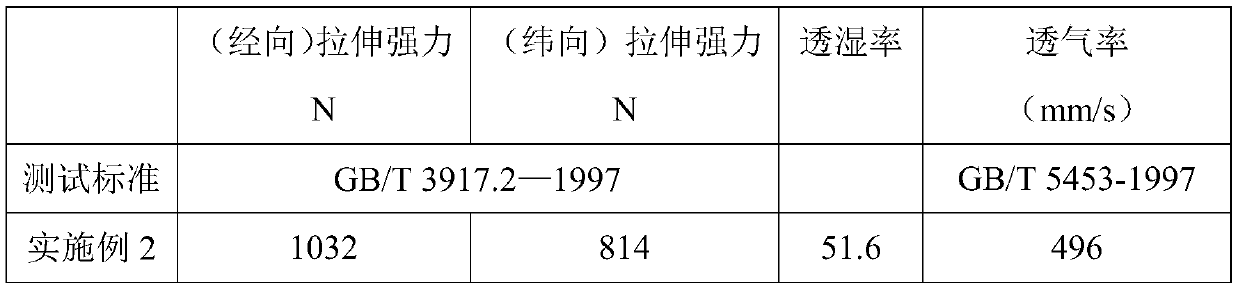

Embodiment 2

[0087] A kind of bio-based nylon fabric, described bio-based nylon fabric is blended by bio-based nylon fiber, cotton fiber and polytetrafluoroethylene fiber, then made through knitting or weaving process;

[0088] In parts by weight: 80 parts of bio-based nylon fiber, 15 parts of cotton fiber and 9 parts of polytetrafluoroethylene fiber;

[0089] The bio-based nylon fiber is made from raw materials comprising the following parts by weight:

[0090] 80 parts of bio-based polypentamethylene adipate,

[0091] 14 parts of polypentamethylene adipate,

[0092] Carboxymethylcellulose 5 parts,

[0093] 6 parts of meerschaum powder,

[0094] Fumed silica 4 parts,

[0095] 4 parts of dispersant;

[0096] The bio-based polypentamethylene adipate is made from bio-based 1,5-pentanediamine and petroleum-based adipic acid.

[0097] In this embodiment, the particle size of the sepiolite powder is 5000 mesh.

[0098] In this embodiment, the dispersant is an amide type polycarboxylic ac...

Embodiment 3

[0110] A kind of bio-based nylon fabric, described bio-based nylon fabric is blended by bio-based nylon fiber, cotton fiber and polytetrafluoroethylene fiber, then made through knitting or weaving process;

[0111] In parts by weight: 90 parts of bio-based nylon fiber, 12 parts of cotton fiber and 6 parts of polytetrafluoroethylene fiber;

[0112] The bio-based nylon fiber is made from raw materials comprising the following parts by weight:

[0113] 90 parts of bio-based polypentamethylene adipate,

[0114] 18 parts of polypentamethylene adipate,

[0115] Carboxymethylcellulose 7 parts,

[0116] 8 parts of meerschaum powder,

[0117] Fumed silica 6 parts,

[0118] 5 parts of dispersant;

[0119] The bio-based polypentamethylene adipate is made from bio-based 1,5-pentanediamine and petroleum-based adipic acid.

[0120] In this embodiment, the particle size of the sepiolite powder is 6000 mesh.

[0121] In this embodiment, the dispersant is an amide type polycarboxylic ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com