Fluid Container

a technology for liquid containers and containers, applied in the field of storage devices, can solve the problems of increasing volume, affecting the environment, disintegration, etc., and achieve the effect of reducing volume and preventing involuntary crushing or collapsing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

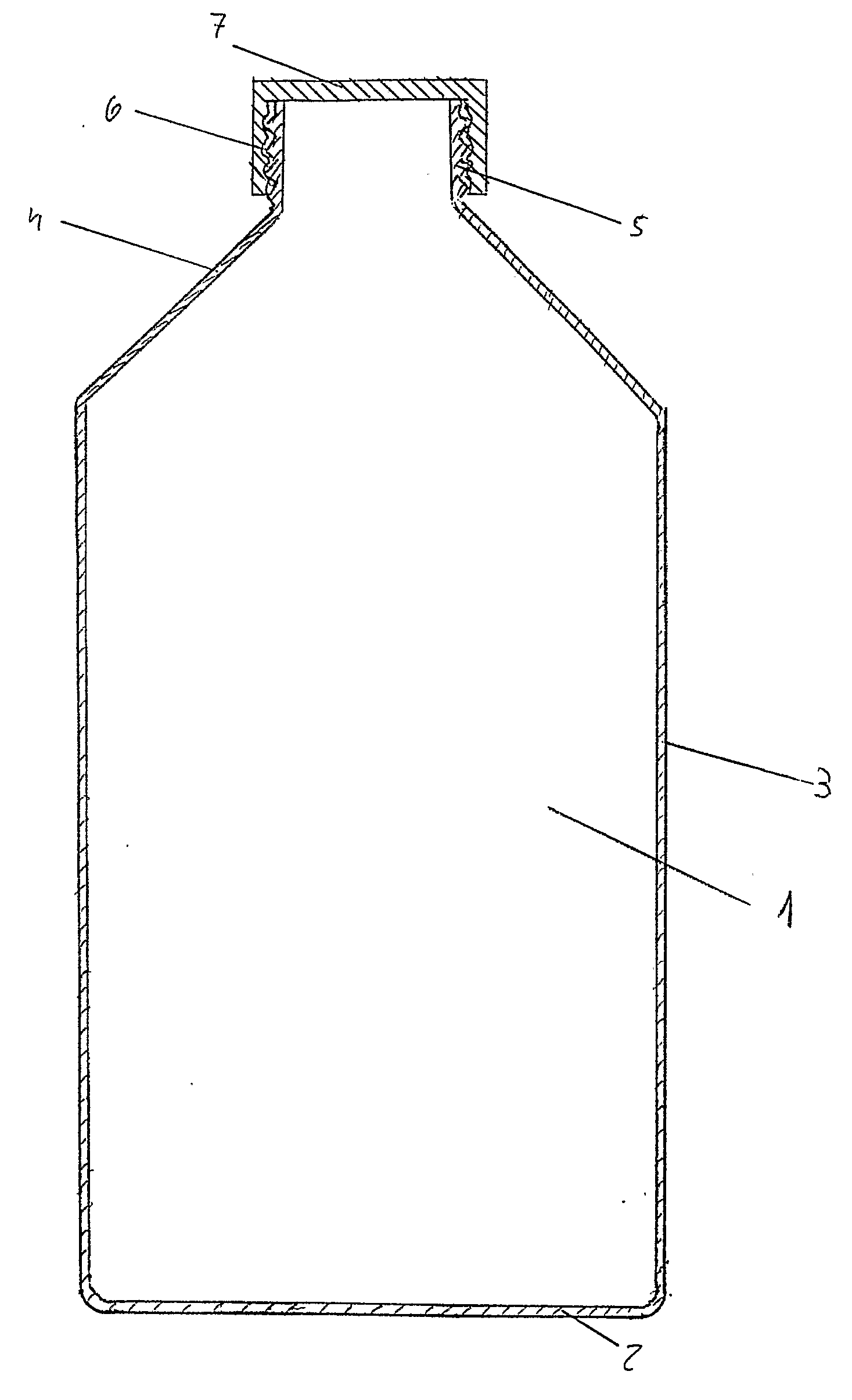

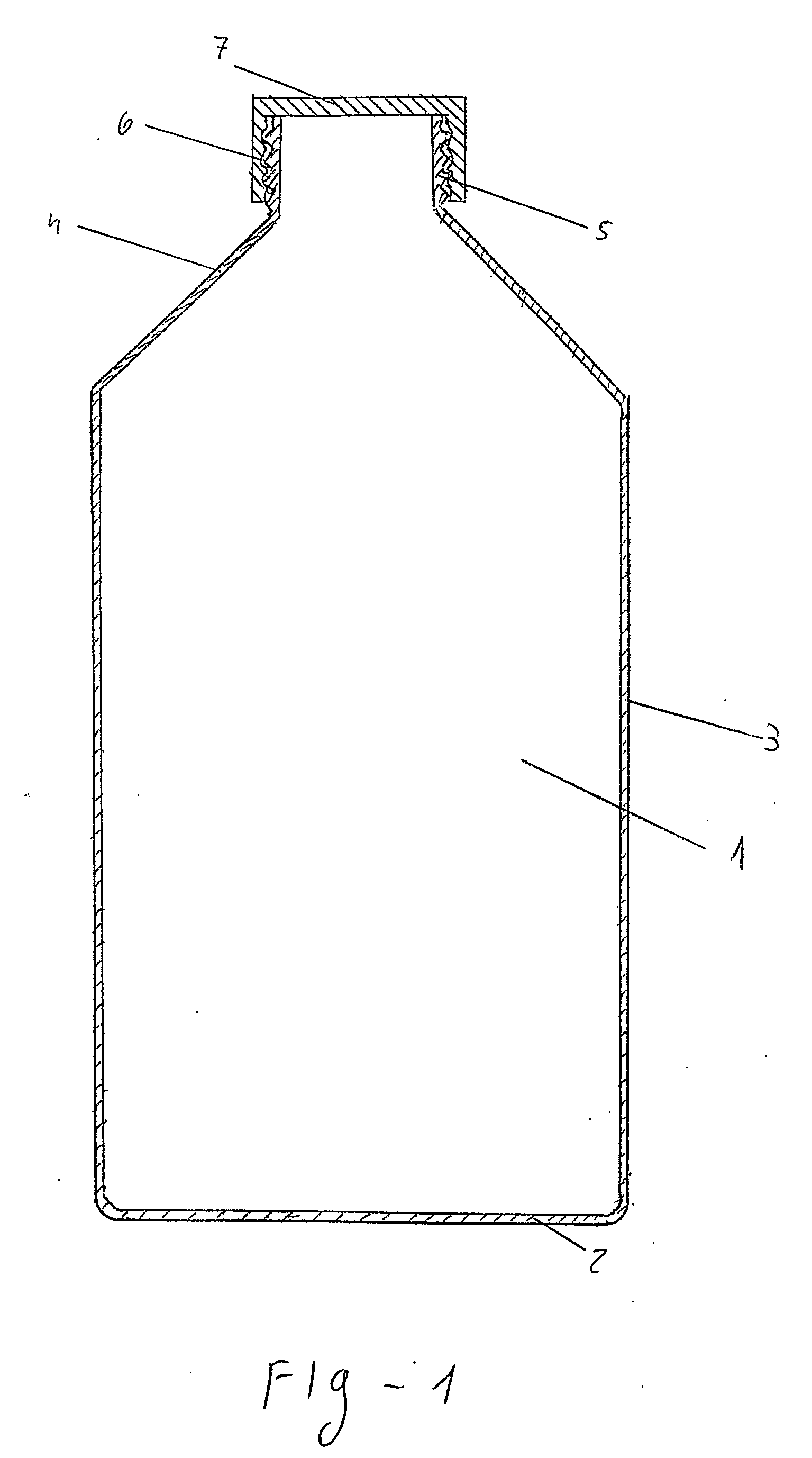

[0076]FIG. 1 illustrates the structure of an ordinary bottle 1 which already exists today. The bottle includes base 2, envelope 3, an upper part 4 with a neck 5, threading 6 and a cup 7.

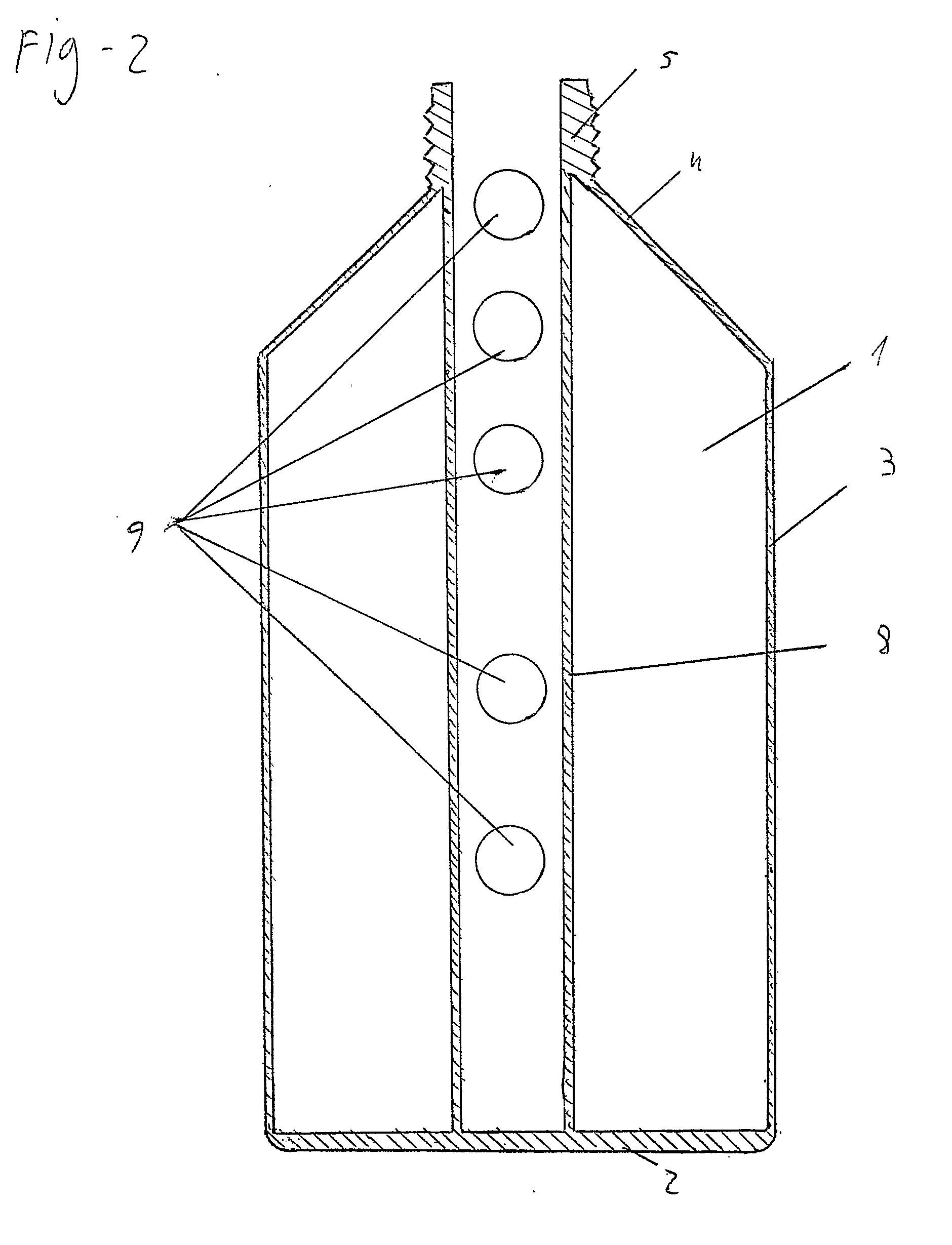

[0077]FIG. 2 is a section view of s a bottle-like storage device 1, includes a thin envelope 3, a fixed hollow sleeve 8 which joins the base of the bottle 2 and its upper part 4. The sleeve 8 includes bores 9 along its length, mainly at the part that is closer to the bottle's neck 4, thus allowing the passage of the bottle's contents into sleeve 8 and subsequently outside the bottle. In bottle 1 the thickness of bottle's envelope 3 has been reduced to a feasible minimum, similar to the thickness of a milk bag. The bottle base 2 and the upper part 4, which includes neck 5 and cup 7, are made of a thicker and more solid substance. The result of such a structure is a kind of bag having a stable base and a stable upper part. In order to give strength and stability to the bottle's wall, i.e. envelope 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com