Preparation method of moisture-absorbing sweat-releasing PLA/PET side-by-side compound fiber

A composite fiber, moisture-absorbing and sweat-wicking technology, applied in fiber processing, melt spinning, filament/thread forming, etc., to achieve the effect of improving moisture-wicking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

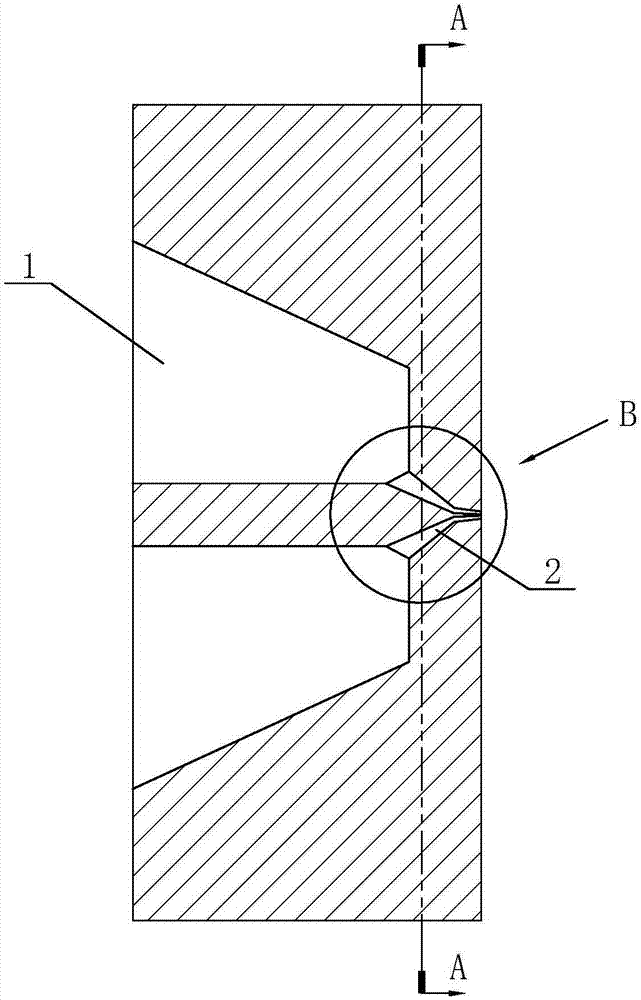

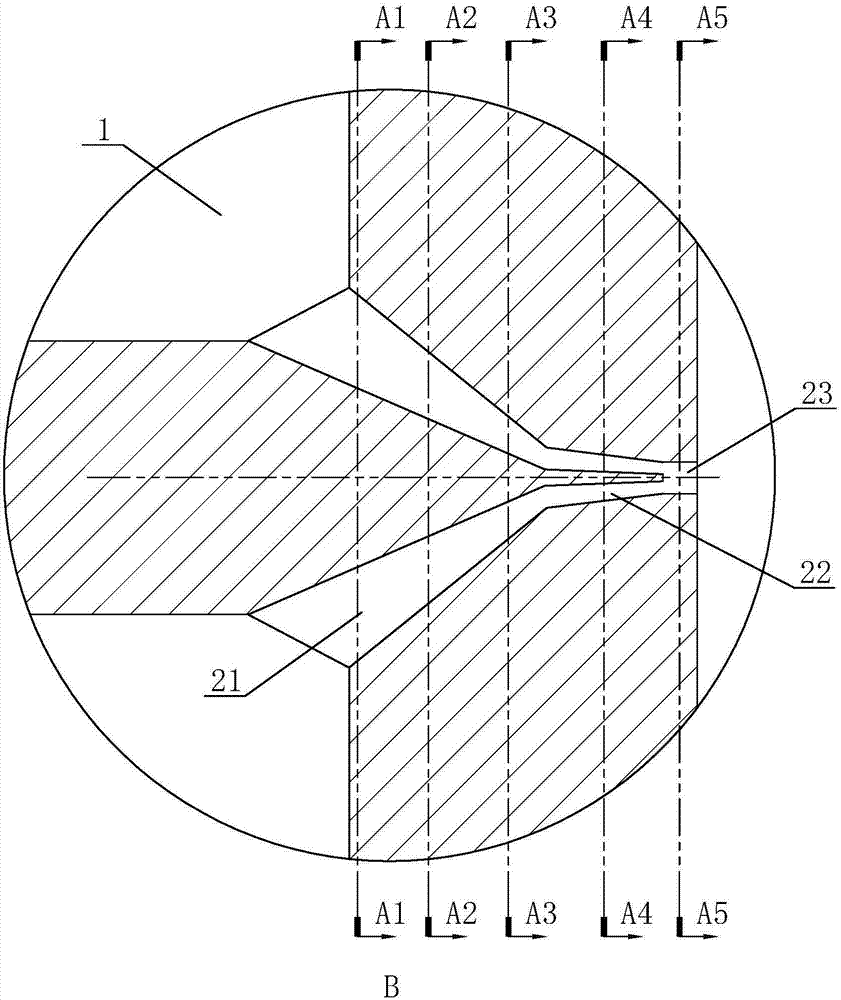

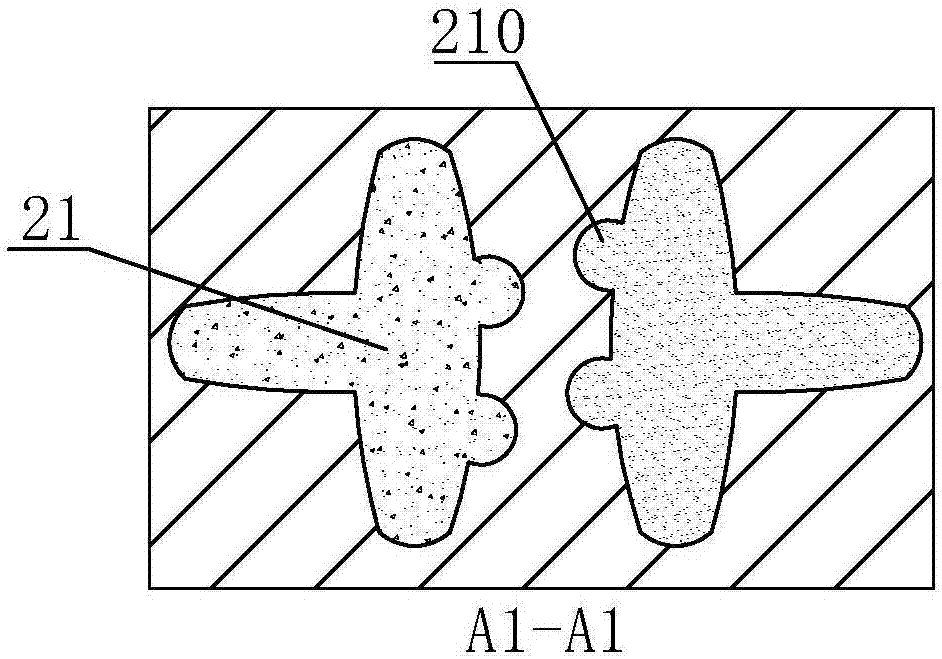

Method used

Image

Examples

Embodiment 1

[0061] The raw material has an intrinsic viscosity of 1.0dl / g of PLA, an intrinsic viscosity of 0.6dl / g of PET, and the mass ratio of PLA to PET is 80:20.

[0062] A preparation method of PLA / PET side-by-side composite fiber capable of absorbing moisture and wicking sweat specifically includes the following steps:

[0063] The PLA slices are dried through three-stage drying to obtain dried PLA slices with a moisture content of less than 0.005%. The dried PLA chips are extruded at low temperature and high temperature by the screw, metered into the side-by-side composite assembly, undergo side-by-side composite distribution, and are side-by-side composite with PET at the composite spinneret. The PET chips are dried in three stages to obtain dried PET chips with a moisture content of less than 0.005%. The dried PET chips are extruded at low temperature and high temperature by the screw, and then measured into the parallel composite assembly for parallel composite distribution, and pa...

Embodiment 2

[0068] The raw material has PLA with an intrinsic viscosity of 1.0 dl / g and PET with an intrinsic viscosity of 0.6 dl / g. The mass ratio of PLA to PET is 50:50.

[0069] A preparation method of PLA / PET side-by-side composite fiber capable of absorbing moisture and wicking sweat specifically includes the following steps:

[0070] The PLA slices are dried through three-stage drying to obtain dried PLA slices with a moisture content of less than 0.005%. The dried PLA chips are extruded at low temperature and high temperature by the screw, metered into the side-by-side composite assembly, undergo side-by-side composite distribution, and are side-by-side composite with PET at the composite spinneret. The PET chips are dried in three stages to obtain dried PET chips with a moisture content of less than 0.005%. The dried PET chips are extruded at low temperature and high temperature by the screw, and then measured into the parallel composite assembly for parallel composite distribution, a...

Embodiment 3

[0075] The raw material has PLA with an intrinsic viscosity of 1.5dl / g and PET with an intrinsic viscosity of 0.8dl / g. The mass ratio of PLA to PET is 80:20.

[0076] A preparation method of PLA / PET side-by-side composite fiber capable of absorbing moisture and wicking sweat specifically includes the following steps:

[0077] The PLA slices are dried through three-stage drying to obtain dried PLA slices with a moisture content of less than 0.005%. The dried PLA chips are extruded at low temperature and high temperature by the screw, metered into the side-by-side composite assembly, undergo side-by-side composite distribution, and are side-by-side composite with PET at the composite spinneret. The PET chips are dried in three stages to obtain dried PET chips with a moisture content of less than 0.005%. The dried PET chips are extruded at low temperature and high temperature by the screw, and then measured into the parallel composite assembly for parallel composite distribution, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curvature | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| Curvature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com