Patents

Literature

625results about How to "Reactive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyzer used for low carbon alkane catalytic dehydrogenation and method of manufacturing propylene by paraffin hydrocarbons catalytic dehydrogenation with the same as catalyzer

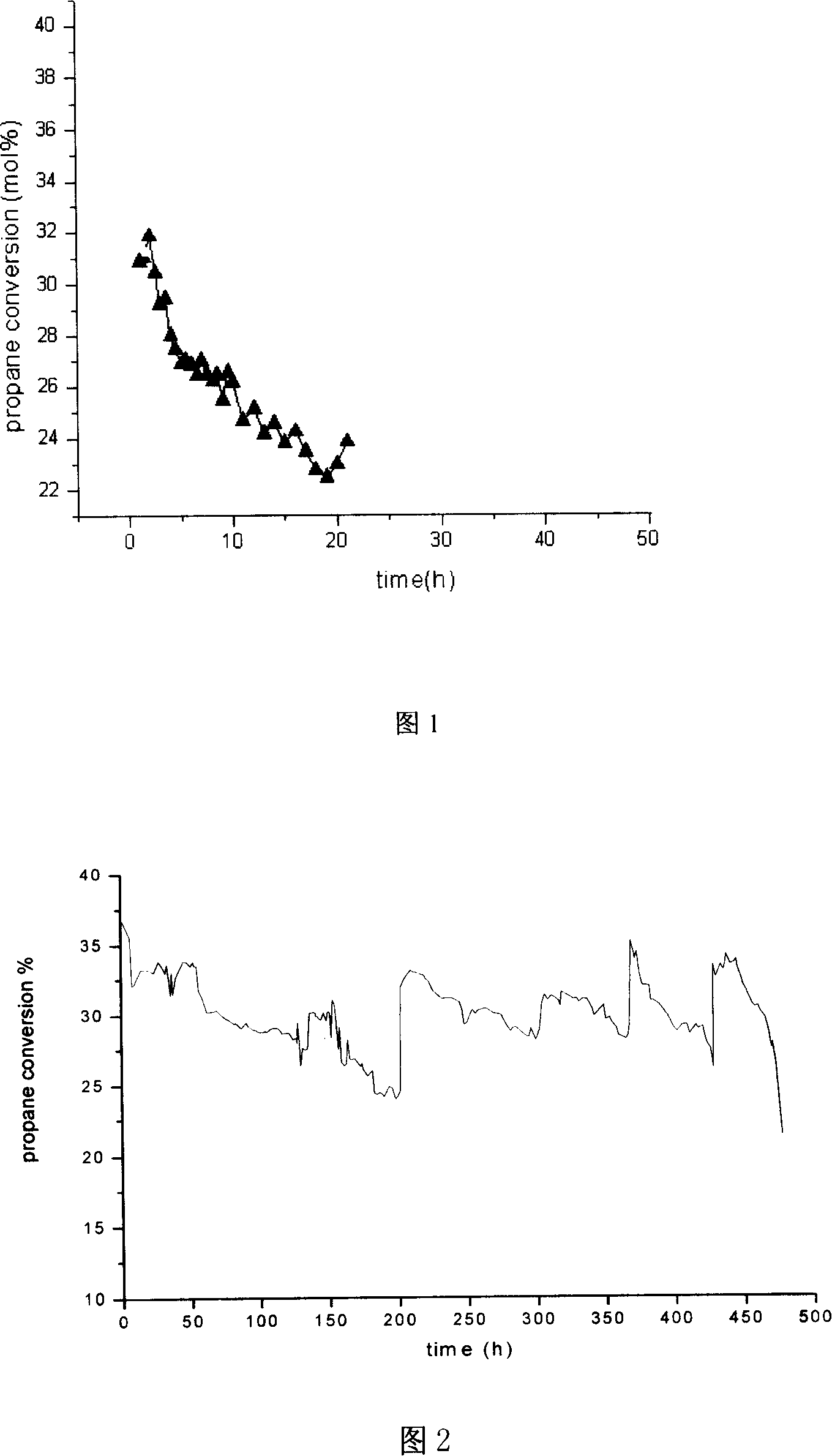

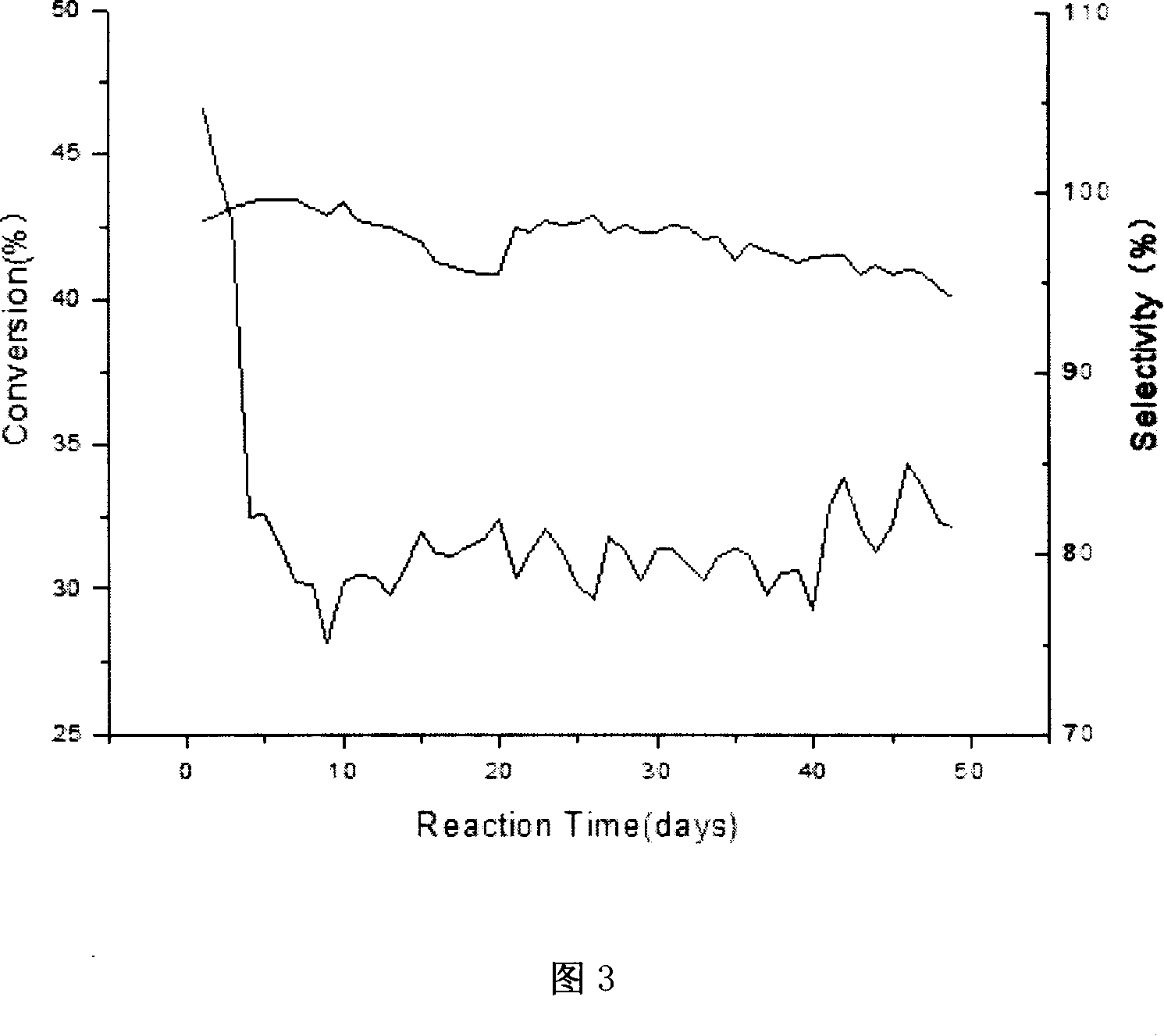

InactiveCN101108362AReactiveMitigation of heightened demandMolecular sieve catalystsHydrocarbonsAlkaneReaction temperature

The invention relates to a catalyst used for catalyzing and dehydrogenation of low-carbon alkane and the method of producing propylene by alkane catalyzing and dehydrogenation with the catalyst. The former catalyst used for catalyzing and dehydrogenation of low-carbon alkane, each molecule of the hydrocarbon has about 2 to 8 carbon atom, which is characterized in that: the catalyst makes a molecular sieve the carrier, the Pt family metal is loaded on the carrier as the active component, makes the IVA family metal element and alkalinity metal element as additional agent and high temperature standing inorganic oxide as connection agent; when the catalyst is used in producing propylene by alkane catalyzing and dehydrogenation, the reaction temperature is 500 to 700 DEG C., the pressure is 0 to 0.2Mpa, the quality air speed is 2 to 5h to 1, the regenerating temperature of the catalyst is 500 to 700 DEG C., the air speed is 100 to 1000h to 1, the pressure is 0 to 1.0MPa. With adopting the invention, the reaction of producing propylene by alkane catalyzing and dehydrogenation is good, the average transforming rate is 30 per cent, the selectivity above 95 per cent can keep for 50 days.

Owner:SINOPEC JINLING PETROCHEMICAL CO LTD

Modified hot setting resin and preparation method thereof

The invention discloses a modified hot setting resin and a preparation method thereof. In parts by weight, the modified hot setting resin is obtained by evenly mixing 100 parts of hot setting resin, 0-100 parts of curing agent, 0-1 part of curing catalyzer, and 1-100 parts of hyperbranched silicon resin containing active functional groups at the temperature of 30-200 DEG C. The modified hot setting resin has high storage stability, processability and reactiveness and sufficiently integrates the performance advantages of hyperbranched polymer and polysiloxane, and thereby the obtained modified hot setting resin has high tenacity, more prominent thermostability and excellent dielectrical property as well as damp heat resistance. The preparation method of the modified hot setting resin has wide applicability, simple operating process and easy molding.

Owner:SUZHOU UNIV

Method for preparing modified white carbon black

The invention discloses a method for preparing modified white carbon black, which comprises the following steps of: under the protection of nitrogen, heating and activating white carbon black for 4 to 5 hours; mixing the activated white carbon black and toluenediisocyanate, wherein the use amount of the toluenediisocyanate is 10 to 20 percent of that of the white carbon black; adding anhydrous dimethylbenzene into the mixture, wherein the ratio of the volume of the anhydrous dimethylbenzene to the mass of the white carbon black is 5-8:1; under the protection of nitrogen, stirring and dispersing at room temperature, and heating to the temperature of between 60 and 85 DEG C; and filtering and drying to obtain the modified white carbon black.

Owner:甘肃银光聚银化工有限公司

Method for improving solid content of catalytic cracking catalyst slurry

ActiveCN101134906ASimple structureHigh solid contentCatalytic crackingCatalyst activation/preparationMolecular sieveColloid

The present invention is method of raising solid content in catalytic cracking catalyst slurry. The method includes mixing clay, molecular sieve slurry, aluminum-containing binder, pseudo boehmite and inorganic acid to form catalyst slurry and the subsequent spray drying. It features that the addition of inorganic acid before adding pseudo boehmite and the molecular sieve, and the addition of inorganic acid after adding kaolin and aluminum-containing binder or into the aluminum-containing binder. The present invention can raise the solid content in catalyst slurry to over 40 % to short the colloid forming time greatly, raise the catalyst producing efficiency and lower catalyst producing cost while ensuring the wear strength of catalyst. At the same time, the catalyst has great pore volume, high micro reaction activity and improved comprehensive reaction performance.

Owner:PETROCHINA CO LTD

Ecological dyeing method for dyeing cotton fabric with mulberry red natural dye

InactiveCN101851868AImprove protectionNo allergic reactionDyeing processVegetal fibresEngineeringNatural dye

The invention relates to an ecological dyeing method for dyeing a cotton fabric with mulberry red natural dye, comprising the following steps: preprocessing the cotton fabric and then dyeing the preprocessed cotton fabric with the mulberry red natural dye; adding metal salt for fixation; and soaping the fabric after fixation and then fixing colors to obtain the dyed fabric with even color, wherein washing fastness can reach 3-4degrees. The ecological dyeing method has simple dyeing process, high dye-uptake, good pigment stability and wide market prospect.

Owner:CHANGZHOU GOLDEN SPRING TEXTILE +1

Co-Zr catalyst for Fischer-Tropsch synthesis and its prepn and application

InactiveCN1398669AImprove stabilityReduced inactivation rateCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsMetalChemistry

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

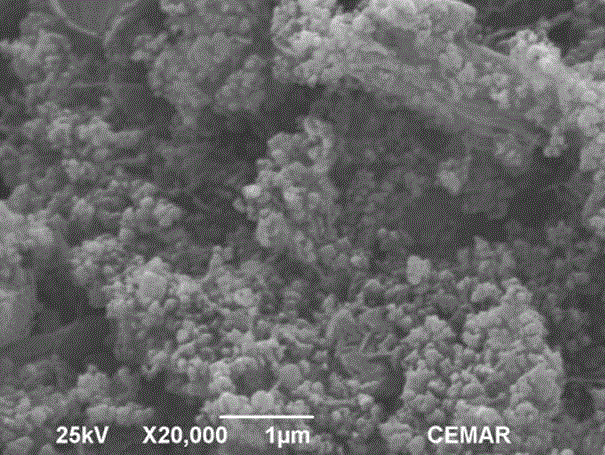

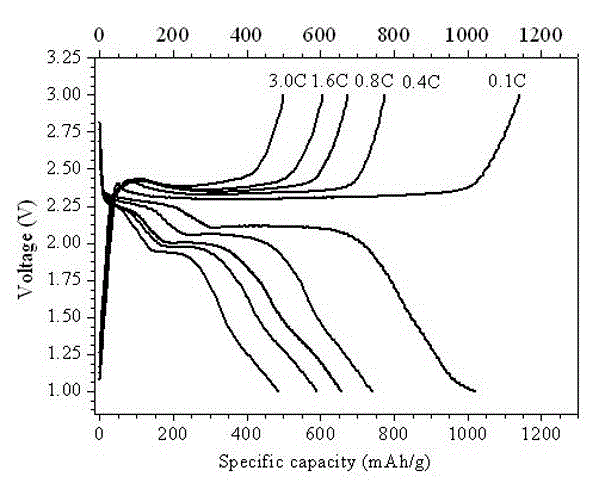

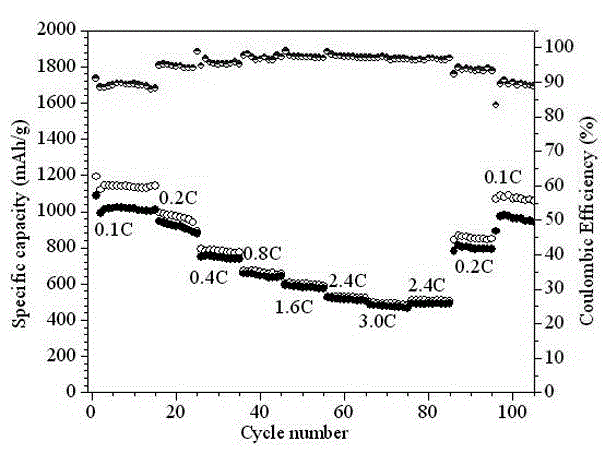

Preparation method of novel porous skeleton MIL-101(Cr)@S/graphene composite material for cathode of lithium sulfur battery

InactiveCN102751494AImprove adhesionImprove cycle performanceCell electrodesElectrical batteryLithium–sulfur battery

The invention discloses a preparation method of a metal organic skeleton MIL-101(Cr)@S / graphene composite material as the cathode material of a lithium sulfur battery. The preparation method comprises the following steps of: evenly loading sulfur into a three-dimensional pore channel of MIL-101(Cr) by a melting diffusing method, and mixing with graphene, so that the MIL-101(Cr)@S / graphene composite material can be prepared. The metal organic skeleton crystal material in the composite material is has superhigh specific surface area and pore volume and has a skeleton structure which has medium-mirco double pores, so that the dual effects of dispersing and fixing the sulfur grains can be played, and the whole electrical conductivity of the composite material can be improved due to graphene, so that the polarization of the material can be weakened, the discharge multiplying power performance can be improved, the coulomb efficiency can be improved and the like. The electrochemical performance test shows that the discharge specific capacity of the MIL-101(Cr)@S / graphene composite material prepared by the method can reach 1087mAh / g under the condition that the multiplying power is less than 0.1C, and the discharge specific capacity of the MIL-101(Cr)@S / graphene composite material prepared by the method is respectively kept at 807 and 387mAh / g under the condition that the multiplying power is 0.8C and 2.4C when the circulation times is 116 and 150. The preparation method has the advantages that the preparation method has the characteristics of being simple in process, convenient to operate, good in material performance and the like, and is suitable for large-scale industrial production.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

Preparation method for activated carbon special for removal of low-concentration formaldehyde in room

InactiveCN103769053AReduce productionMild conditionsOther chemical processesDispersed particle separationActivated carbonRoom temperature

The invention discloses a preparation method for activated carbon special for the removal of low-concentration formaldehyde in a room. The preparation method is characterized by comprising the following steps of pre-treating commercial activated carbon serving as a raw material, and performing modification, washing, filtering and drying to prepare an activated carbon material for removing the formaldehyde at room temperature. The obtained modified activated carbon is high in low-concentration formaldehyde removal efficiency, low in cost and easy to operate; when the concentration of the formaldehyde is 20ppm, 85 to 95 percent of formaldehyde can be adsorbed by the material.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

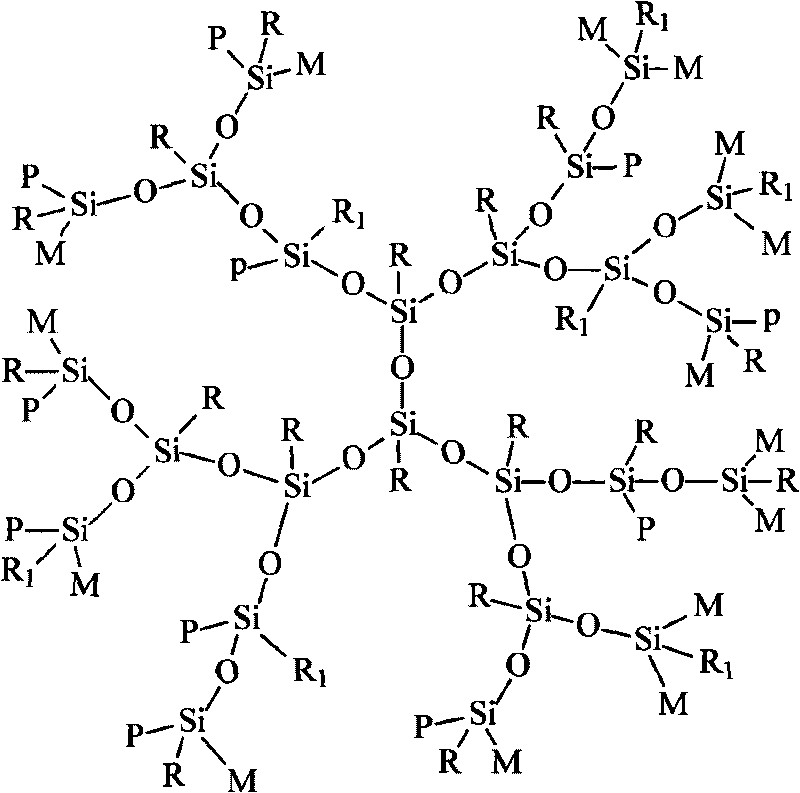

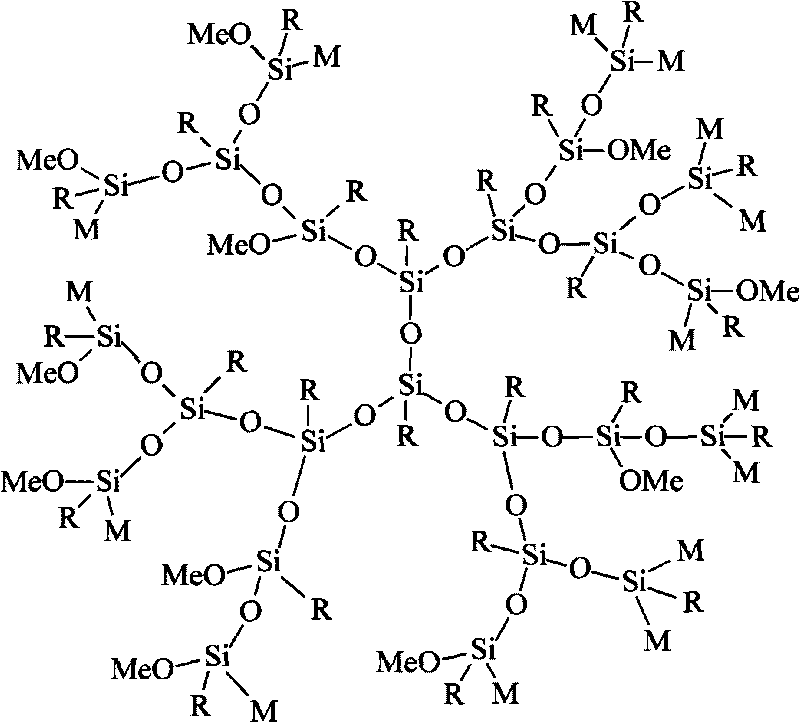

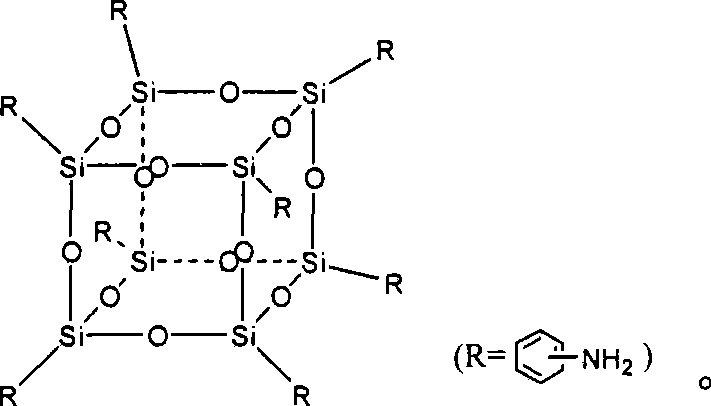

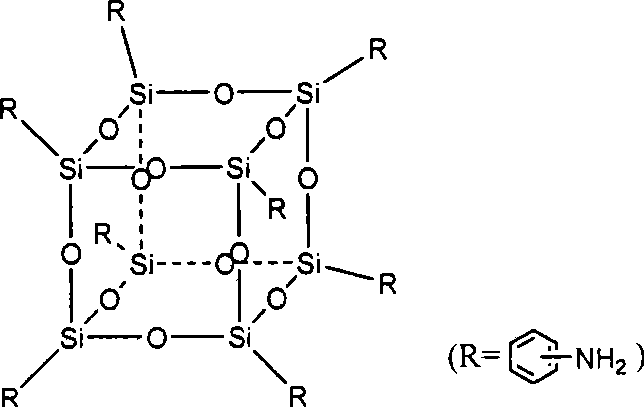

Low dielectric coefficient polyimide/oligomeric silsesquioxane nano hybrid film and preparation thereof

The invention discloses a polyimide / oligomeric silsesquioxane nano-hybrid film with low dielectric constant, which consists of diacid anhydride monomers, diamine monomers and oligomeric silsesquioxane, wherein, the mass content of the oligomeric silsesquioxane is 0.1%-30%, and the mol ratio of the diamine monomers to the diacid anhydride monomers is 1:1-1.1. The polyimide / oligomeric silsesquioxane nano-hybrid film has the advantages of low dielectric constant and maintaining the original excellent properties of the polyimide matrix resin. The preparation method of the invention can obviously improve the miscibility among the oligomeric silsesquioxane, the reactant and the polymer matrix, which causes the oligomeric silsesquioxane to be easily and evenly dispersed in the polyimide resin by nano size to obtain organic-inorganic hybrid materials with excellent comprehensive properties; and the polyimide / oligomeric silsesquioxane nano-hybrid film has wide application prospect in the aspects of electrical engineering, electron, information, military, aeronautics, astronautics, etc.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

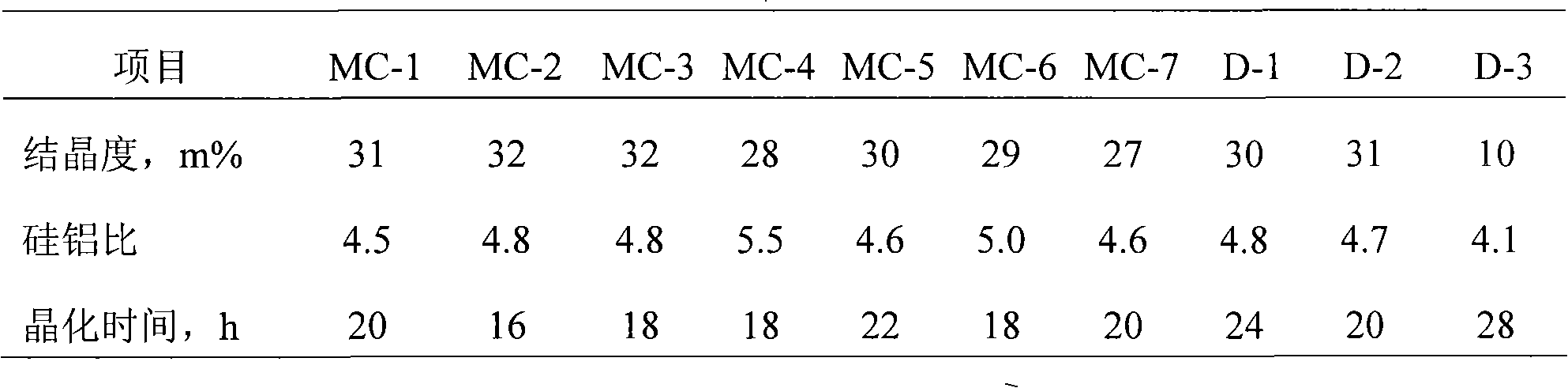

Method for preparing in situ crystallization type catalytic cracking catalyst

ActiveCN101537368AReduce build timeShort build timeMolecular sieve catalystsCatalyst activation/preparationMolecular sieveIn situ crystallization

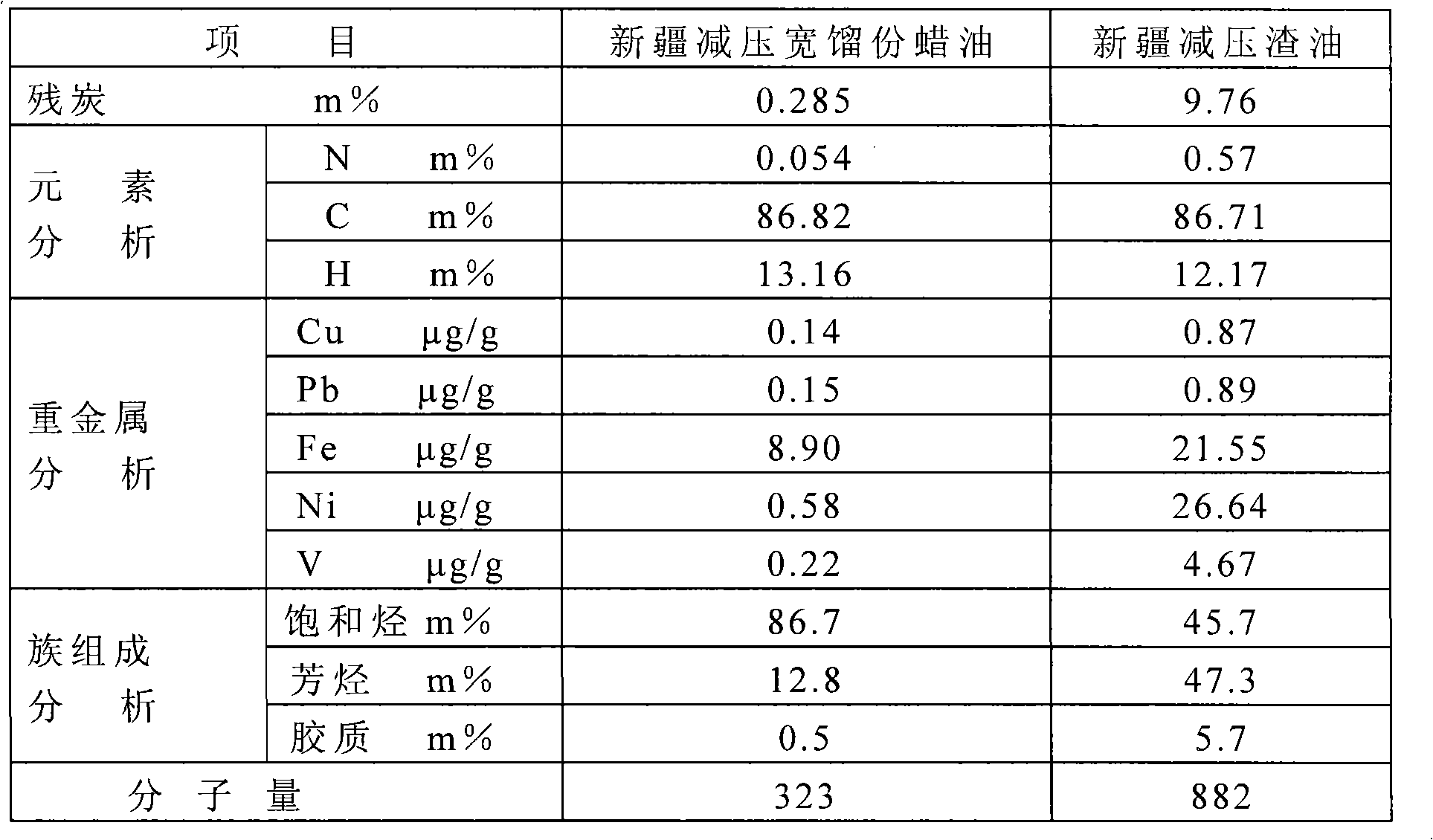

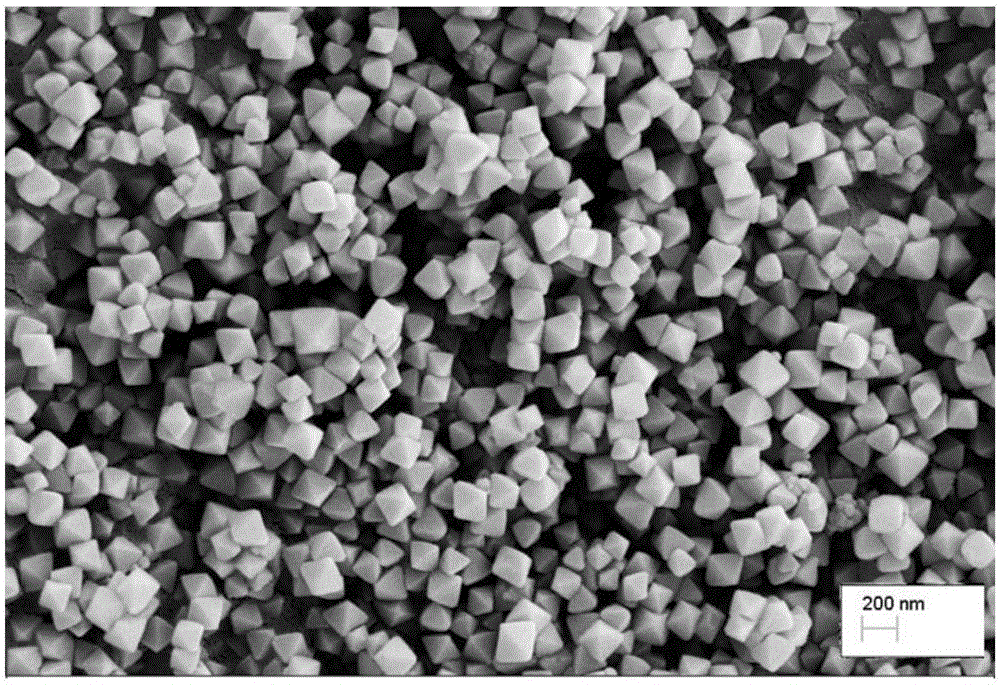

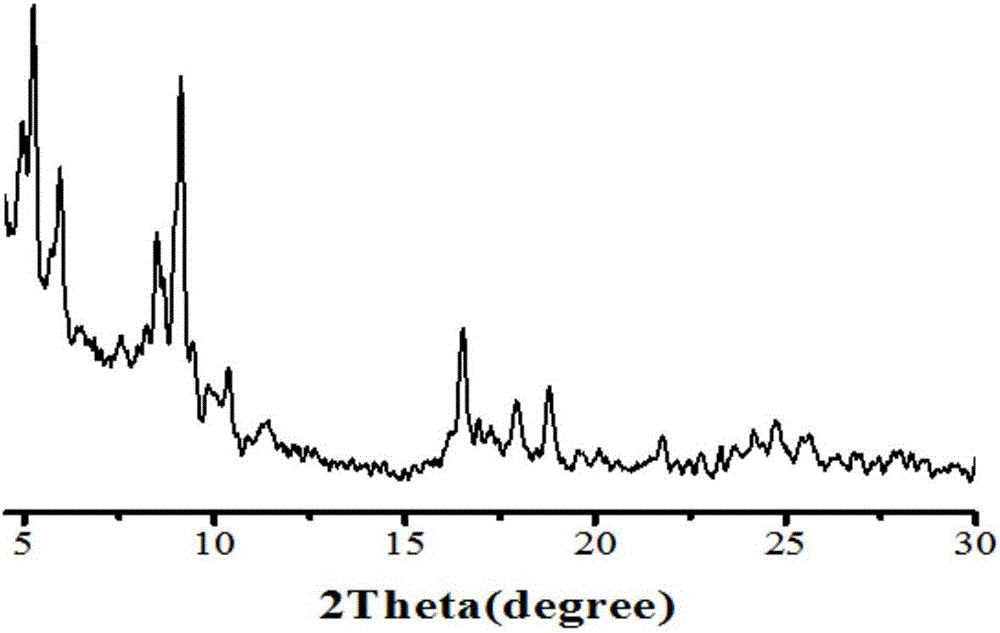

The invention provides a method for preparing an in situ crystallization type catalyst by adding components with a silicon-aluminum structure unit in a certain proportion. The method is characterized in that: kaoline with meso position grain diameter used as a raw material is added with water to form a pulp, the pulp undergoes spray forming to form an earth ball, and the earth ball is roasted to form a roasted earth ball. The roasted earth ball undergoes the crystallized reaction with sodium silicate, the components with the silicon-aluminum structure unit, a guiding agent and the like to from a crystallized product of which the content of NaY zeolite is between 15 and 60 percent and the silicon-aluminum ratio is 3.5-5.5; and the crystallized product is exchanged and roasted to obtain the catalyst needed. Because the components with the silicon-aluminum structure unit are used as sources of partial silicon, aluminum and sodium, the method has the advantages of realizing the preparation of the in situ crystallization type molecular sieve in a short period of time, further shortening flow, improving yield and lowering production cost.

Owner:PETROCHINA CO LTD

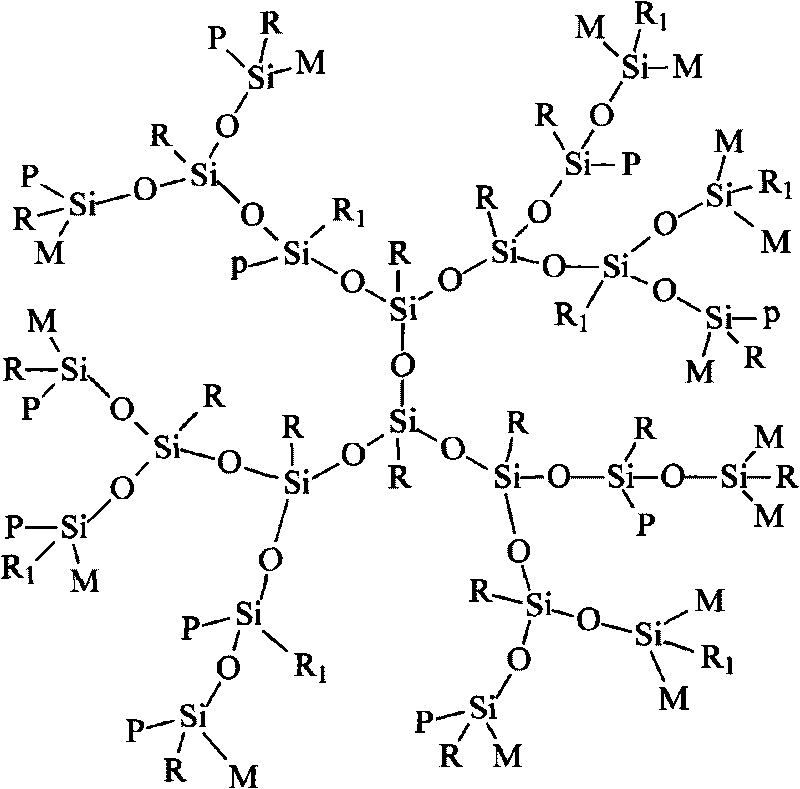

Catalyst for catalytic dehydrogenation of alkane and preparation method and application thereof

InactiveCN102698750AMitigation of heightened demandReactiveHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkanePtru catalyst

The invention relates to a catalyst for catalytic dehydrogenation of low-carbon alkane. The gamma-Al2O3 is used as the carrier, wherein the carrier has the bulk density of 0.4-0.6g / ml and the specific surface area of 100-300m<2> / g; the active component which is Pt is supported on the carrier; the Sn, the Na and the La are used as assistants, and the Cl is used as a modifier; the content of the Pt accounts for 0.3-0.5% of the mass of the catalyst, the content of the Sn accounts for 0.6-1.0%, the content of the Na accounts for 0.75-1.0%, the content of the La accounts for 0.8-1.0%, and the content of the Cl accounts for 0.1-0.2%. The process for preparing the corresponding olefin by using the catalyst for dehydrogenation of low-carbon alkane comprises the following steps: adding the precursor of the catalyst into a reactor, introducing hydrogen, reducing the precursor of the catalyst for 1-10 hours at 400-600 DEG C, introducing preheated mixture of low-carbon alkane, hydrogen and steam, and carrying out the dehydrogenation reaction of low-carbon alkane at 500-700 DEG C. The isobutene prepared by adopting the process and the catalyst through dehydrogenation of isobutene has the average conversion rate of more than 30% and the selectivity of more than 95% and can retain for more than 40 days.

Owner:南京沃来德能源科技有限公司

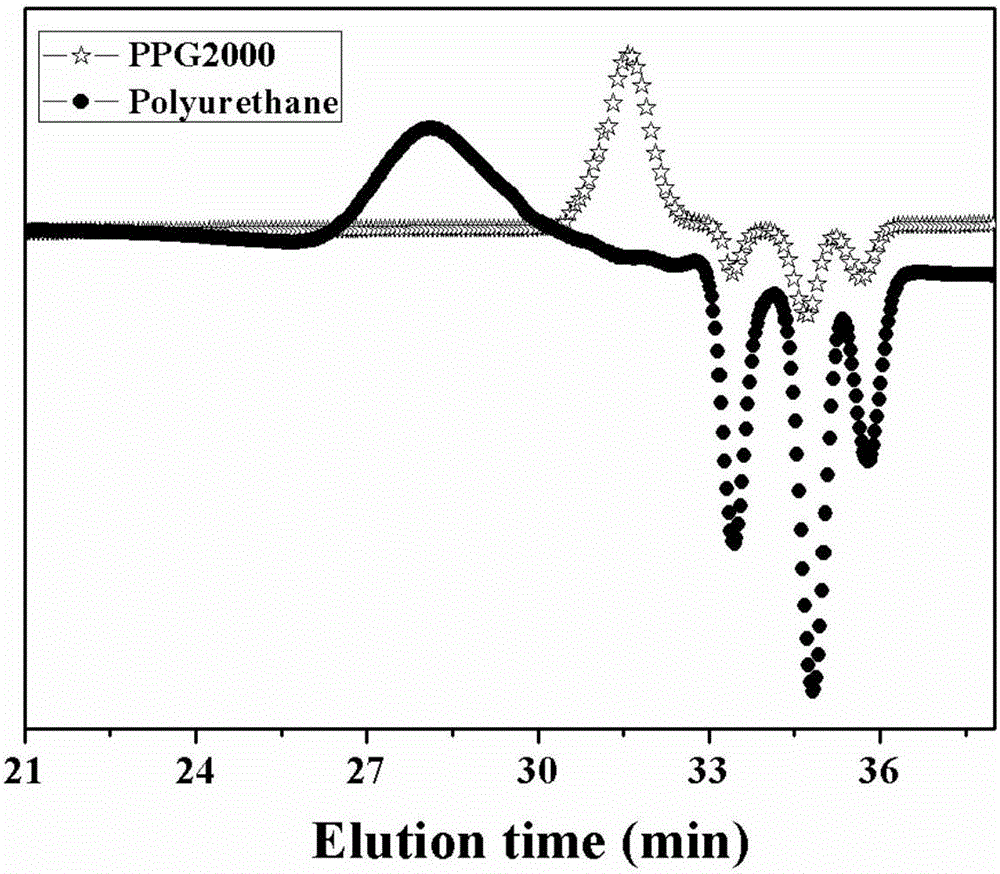

Metal-organic framework nanocrystal loaded polyurethane foam as well as preparation and application thereof

ActiveCN106366636AGood dispersionOvercoming the defects of difficult processingCarboxylic acid nitrile preparationOrganic compound preparationChemical industryMetal-organic framework

The invention discloses a metal-organic framework nanocrystal loaded polyurethane foam as well as a preparation and an application thereof. Polyurethane prepolymer and active amino on MOFs (Metal-Organic Frameworks) are taken to perform chemical doping, the great challenge that MOFs materials are difficult to process is overcome, MOFs nanoparticles are uniformly loaded in the polyurethane foam, a foam reactor is obtained by means of in-situ forming, a new process of building a complex mesoporous-microporous assembly based on microporous metal-organic skeleton nanoparticles as structural units is provided to observe catalysis of the MOFs nanoparticles on knoevenagel condensation; as water serves as a foaming agent and a green chemical method is adopted to prepare an integral flow-by foam reactor to catalyze an organic reaction, aftertreatment of a catalyst is simplified, loss of the catalyst is avoided, continuous flow-by cyclic catalyzation can also be performed, and a new method is provided for the treatment of environmental pollution and chemical industry.

Owner:SHANDONG NORMAL UNIV

Kettle type catalytic hydrogenation of C5 and C9 petroleum resin for removing color and foreign flavour

Owner:DALIAN UNIV OF TECH

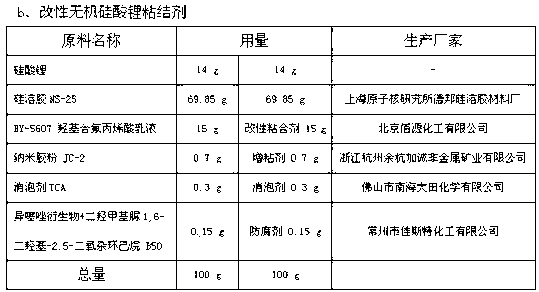

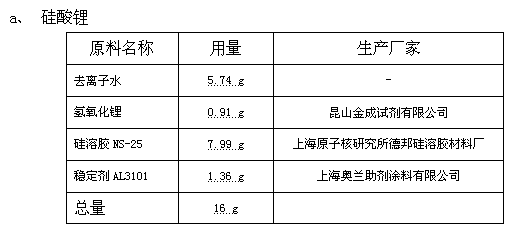

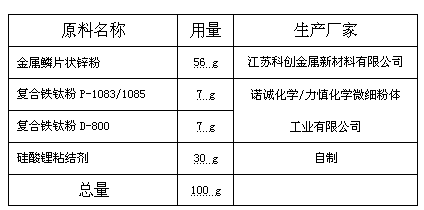

Modified water-based inorganic zinc rich coating and preparation method thereof

ActiveCN103305041ALow viscosityEasy to dryAlkali metal silicate coatingsAlkali metal silicatesWater basedAluminium

The invention relates to a modified water-based inorganic zinc rich coating and preparation thereof. The modified water-based inorganic zinc rich coating is produced by mixing a composite powder with a water-based inorganic binder in a weight ratio of (65-75): (35-25), wherein the composite powder comprises 40-70 parts of metal zinc powder, 3-15 parts of composite iron-titanium powder and 0-15 parts of an antirust agent; the water-based inorganic binder is a lithium silicate binder and comprises 10-25 parts of lithium silicate binder, 60-75 parts of silica sol, 10-15 parts of modified binder and 0.6-3 parts of other auxiliaries; and the modified binder is organic fluorine and / or an organic silicon modified acrylic emulsion. The water-based inorganic lithium silicate binder is used as the base stock of the modified water-based inorganic zinc rich coating, so that the coating is quick in air-drying, nontoxic, tasteless and non-combustible, and has excellent abrasive resistance, flexibility, impact resistance, bending resistance, high / low temperature resistance, electric welding resistance and chemical corrosion resistance, as well as high binding strength, resistance to heat and humidity, salt water resistance and long salt fog resistance time; therefore, the coating is suitable for various building steel structure as a heavy corrosion protective primer, and also can be used as a paint for closure of thermally sprayed zinc, thermally sprayed aluminium anticorrosion layers.

Owner:JIUQING PAINT SHANGHAI

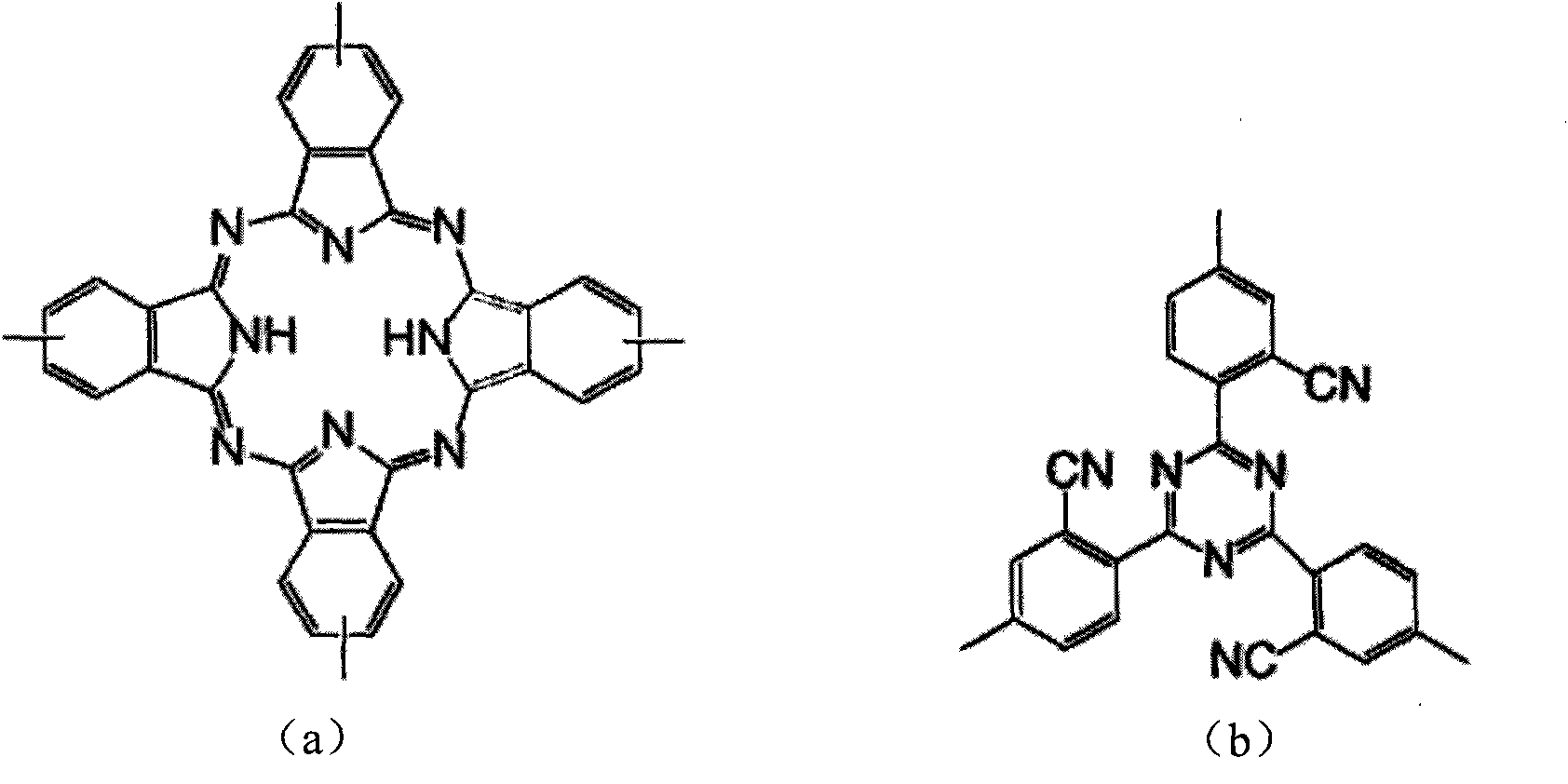

Nitrile resin monomer, nitrile resin polymer and preparation method of nitrile resin monomer and nitrile resin polymer

InactiveCN102976972ALow viscosityReduce liquidityCarboxylic acid nitrile preparationOrganic compound preparationPolymer scienceResin matrix

The invention discloses a nitrile resin monomer, a nitrile resin polymer and a preparation method of the nitrile resin monomer and the nitrile resin polymer, belonging to the technical field of organic polymer materials. The nitrile resin monomer is a tetraphthalonitrile resin monomer containing benzoxazine cycle, and the nitrile resin polymer is a product obtained by heating polymerization of the nitrile resin monomer. The nitrile resin monomer has a low viscosity, a good mobility and the processing performances of low-temperature curing and the like at a low temperature. The nitrile resin polymer has the good curing performances of self-flame resistance, adhesion, heat stability and the like. The resin monomer has the good processing performances of benzoxazine resins, and the resin polymer has the high-temperature resistance of nitrile resins, thus reducing the curing processing temperature and being capable of being used in a high-temperature temperature, namely, having the advantages of low temperature processing, medium temperature formation and high temperature use; and the resin monomer and the resin polymer can be used in the fields of coatings, adhesives, electronic packaging materials, aeronautics, astronautics, ships, resin matrix composites and the like. The preparation method is simple and easy to control, low in reaction temperature, energy-saving, and suitable for industrialized production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

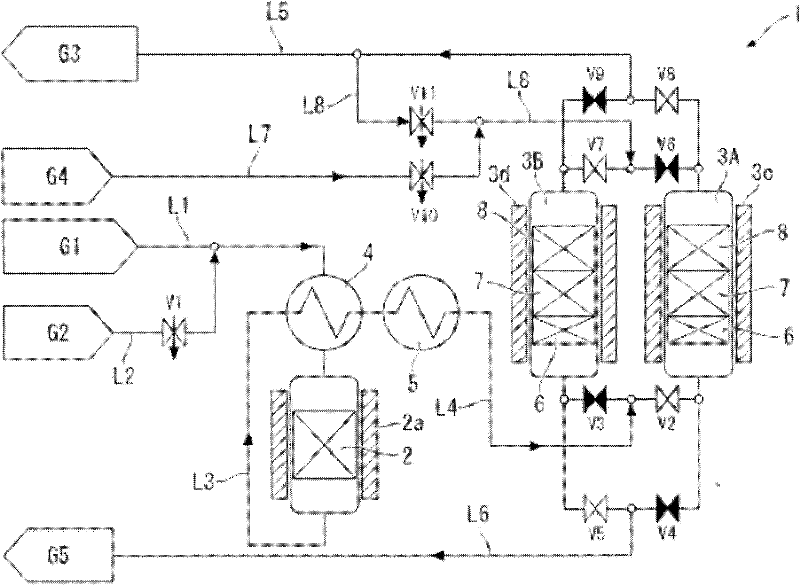

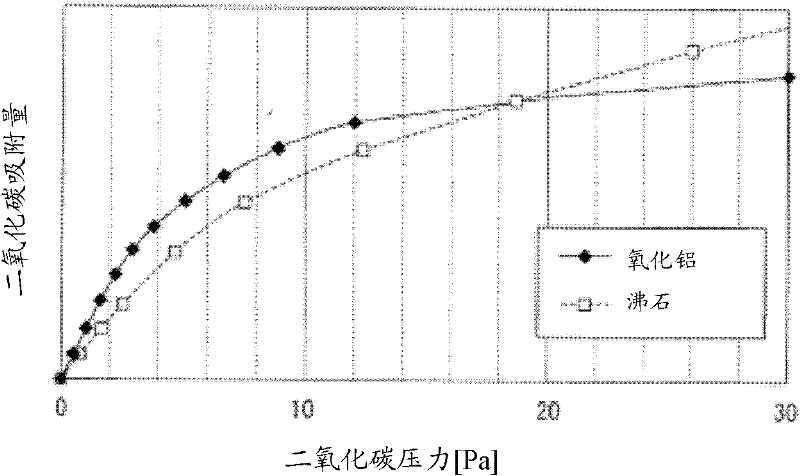

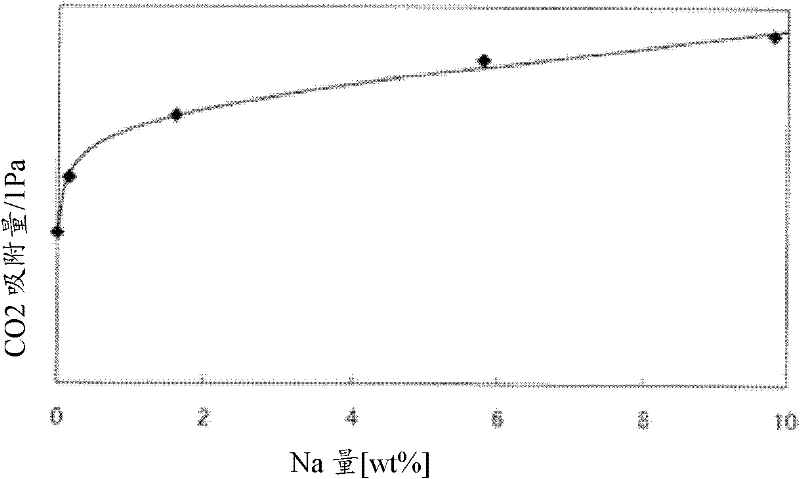

Gas purifying method and gas purifying apparatus

InactiveCN102380313AReactiveCheap and readily availableNitrogen purification/separationProductsNoble gasPurification methods

The present invention provides a gas purifying method, characterized by comprising the steps of contacting a raw material gap with a catalyst to form carbon dioxide and water; contacting the raw material gas after contacting with the catalyst with a water adsorbent for removing the water; contacting the raw material gas with the water removed with a nickel catalyst for removing reaction residuum oxygen; and contacting the raw material gas with the oxygen removed with an aluminum oxide containing 0.1-10 wt% sodium for removing the carbon dioxide. According to the present invention, the gas purifying method and the gas purifying apparatus can remove hydrocarbon, hydrogen, carbon monoxide, carbon dioxide, oxygen and water contained in the raw material gas containing nitrogen or rare gas, thereby enabling the purifying apparatus to be miniaturized, reducing the filling amount of the costly nickel catalyst, and reducing the purification cost.

Owner:NIPPON SANSO CORP

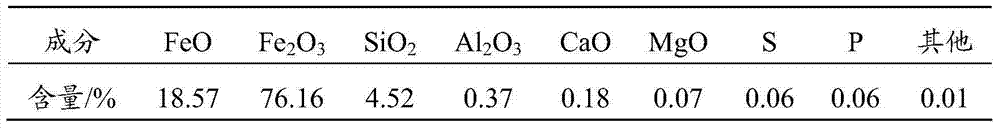

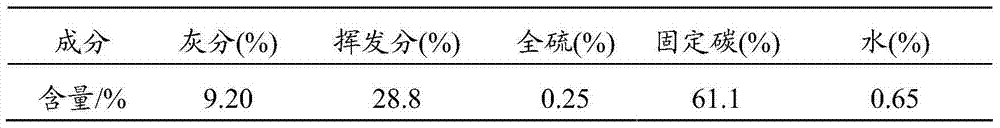

Hot briquetted iron coke for iron-making and preparation method thereof

The invention belongs to the technical field of iron-making and specifically relates to hot briquetted iron coke for iron-making and a preparation method thereof. The hot briquetted iron coke is composed of the following raw materials in percentage by mass: 10%-30% of iron ore powder, 60%-80% of pulverized soft coal and 10%-20% of pulverized blind coal. The preparation method comprises the following steps: thoroughly and evenly mixing the raw materials to obtain a mixture, heating the mixture in a heating furnace to 200-350 DEG C, performing instant hot briquetting on the mixture to obtain a hot briquetted iron coke green ball, putting the hot briquetted iron coke green ball in a tunnel kiln and performing high-temperature destructive distillation and carbonization at a certain temperature increased previously at a certain rate, and then taking out the braised material for cooling, thereby obtaining the hot briquetted iron coke. The prepared hot briquetted iron coke has excellent compressive strength, abrasive resistance, reactivity and post-reaction strength; the hot briquetted iron coke is used for blast furnace iron-making instead of partial coke, and therefore, the adaptability of blast furnace iron-making to fuels is improved. The preparation method of the hot briquetted iron coke is wide in raw material source, low in production cost, simple in process flow and free from the use of a binder, and has wide industrial application prospect.

Owner:NORTHEASTERN UNIV

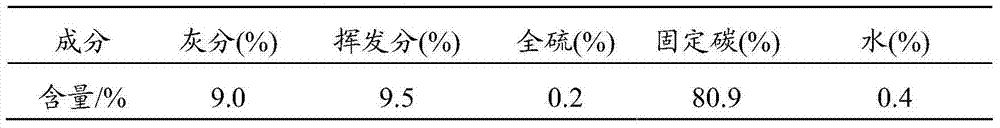

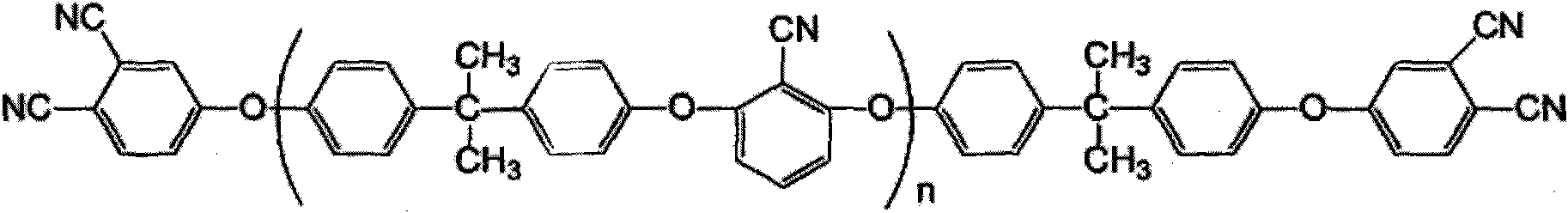

Bisphenol A type bis-phthalonitrile resin with aryl ether nitrile segments, cured product and preparation method thereof

InactiveCN101914038ALow water absorptionImprove curing effectCarboxylic acid nitrile preparationOrganic compound preparationPhthalonitrileSolvent

The invention discloses a bisphenol A type bis-phthalonitrile resin with aryl ether nitrile segments, a cured product and a preparation method thereof and belongs to the field of polymer materials. Raw materials of bisphenol A and 2,6-dichlorobenzonitrile are subjected to nucleophilic substitution reaction, anhydrous potassium carbonate and anhydrous sodium carbonate are used as a catalyst, a hydroxyl-terminated bisphenol A type oligomer intermediate is formed in mixed liquor of a strong polar solvent and toluene, and then hydroxyl groups are substituted by 4-nitrophthalonitrile, thus obtaining the resin. A cure-crosslinking agent, the mass of which is equal to 5 percent of the resin, is added into the resin, and then after pre-curing at 220-240DEG C and heat treatment at 375DEG C at least, the cured product of the resin can be obtained. The bis-phthalonitrile resin provided by the invention has different chain lengths and the aryl ether nitrile segments as well as a low melting point and wider curing process temperature, and the cured product is of a net structure which comprises a phthalocyanine ring and a triazine ring and has excellent heat stability. The manufacturing methods of the resin and the cured product are simple and controllable and are suitable for industrial production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

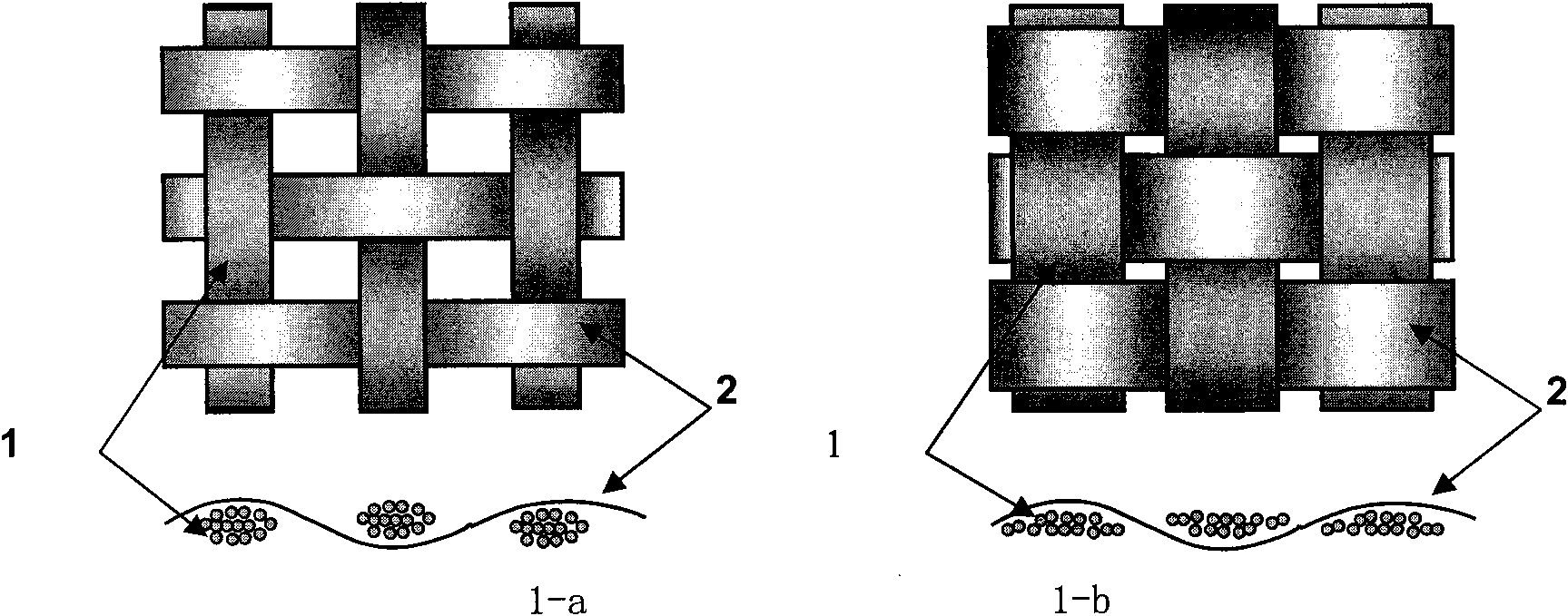

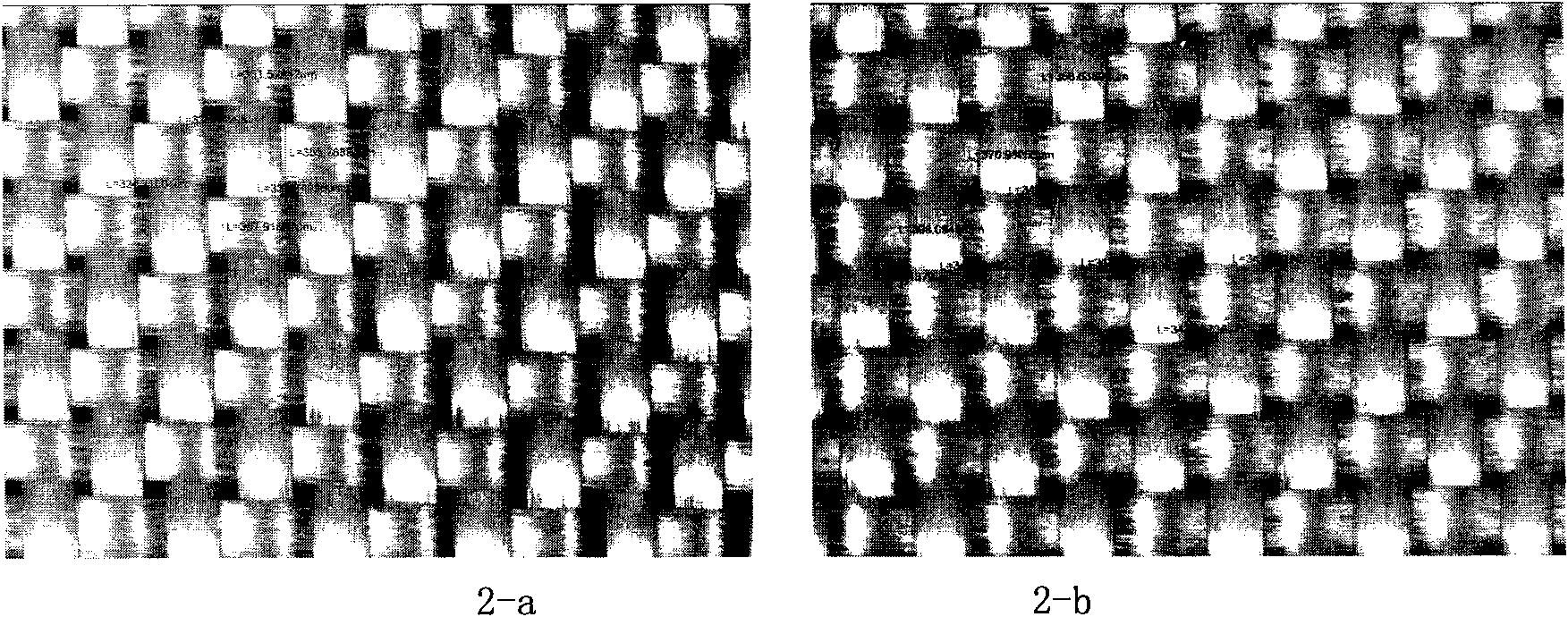

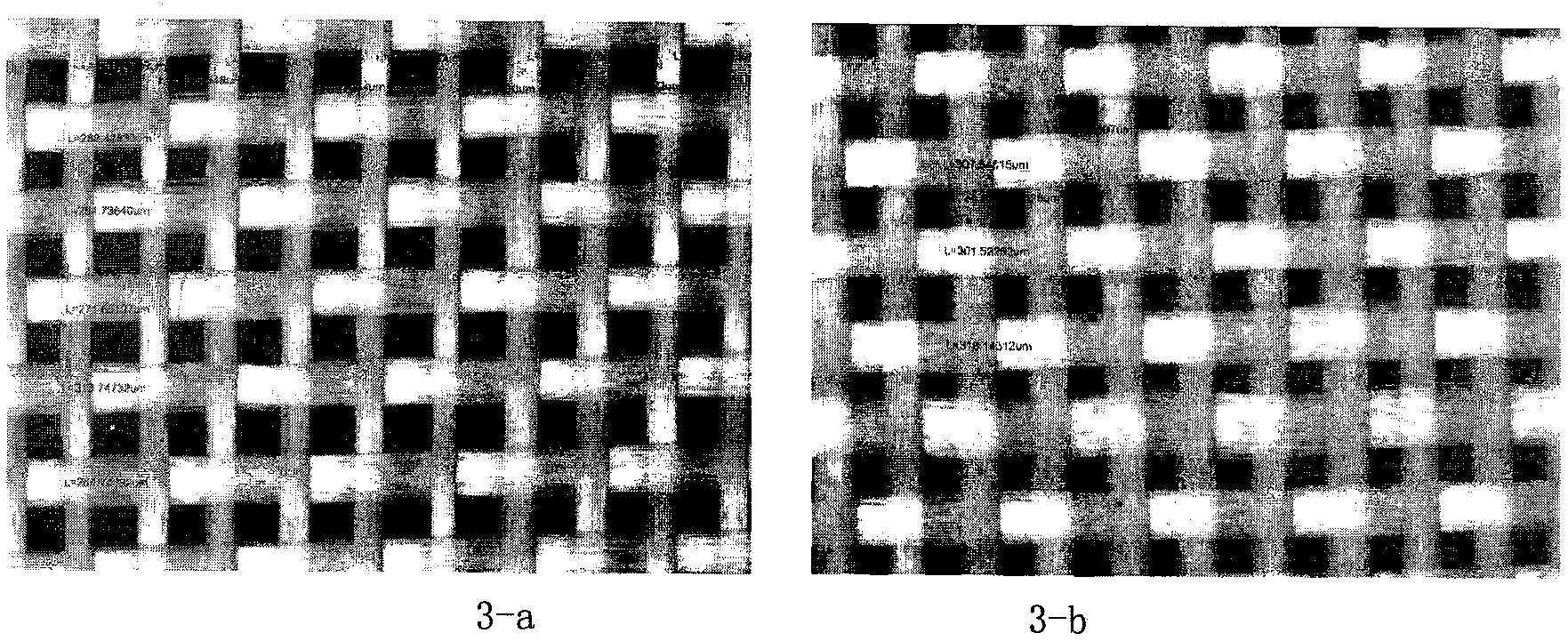

Fiber opening process of electronic grade glass fiber cloth and size used in same

The invention relates to a fiber opening process of electronic grade glass fiber cloth and size used in the same. The fiber opening process is applied to the technical field of electronic grade glass fibers and is characterized by preparing and boiling the size: in particular, firstly weighing a certain amount of main size PVA and then pouring the PVA into a size boiling barrel, adding a certain amount of deionized water, stirring the mixture and raising the temperature to dissolve the PVA, then adding the weighed leavening agent after the PVA is completely dissolved and becomes transparent and clear solution, and preserving heat for half an hour after stirring the mixture until the PVA is completely dissolved, thus the size can be used. The size comprises the following components in percentage by mass: 5-10% of main size PVA, 0.5-1% of added leavening agent and the balance water. The invention provides the fiber opening technology of the electronic grade glass fiber cloth suitable for printed-circuit boards with high precision, high uniformity and high performance. The electronic grade glass fiber cloth prepared by the fiber opening technology is thin and uniform, has faster resin impregnation, is suitable for the insulation enhanced materials of the printed-circuit boards and is extensively applied to the high-end products such as mobile phone boards, notebook computers, automotive sheets, digital cameras, digital players, navigation equipment and the like.

Owner:SHANGHAI GRACE FABRIC

Process for preparing ethylene glycol by ethylene oxide catalytic hydration

InactiveCN1566050AGood hydrothermal stabilityReactiveOrganic compound preparationHydroxy compound preparationThermal energyHydration reaction

The invention relates to a process for preparing ethylene glycol by ethylene oxide catalytic hydration, wherein the solid acid catalyst employs niobium compounds as the main active components, at least one of germanium, tin, lead, antimony, phosphor, sulfur, ferrum and cobalt is used as the auxiliary agent for preparing ethylene alcohol at rather low water ratio conditions, the thermal energy needed for processing reacting excess water can be reduced substantially, the catalyst used possesses not only good activity, selectivity, but also fine steadiness.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polymer modified asphalt and preparation method thereof

InactiveCN101531817AImprove performanceHigh softening pointBuilding insulationsPolymer sciencePolymer modified

The invention relates to polymer modified asphalt and a preparation method thereof. The modified asphalt consists of base asphalt, maleic anhydride grafted ethylene-vinyl acetate copolymer (M-EVA), styrene-butadiene rubber (SBR) and a tackifier. The preparation method comprises the following steps: heating the base asphalt to completely smelt; and then, slowly adding the maleic anhydride grafted ethylene-vinyl acetate copolymer (M-EVA) modifying agent into the base asphalt by stirring; and cutting and blending the mixture at high speed to prepared the polymer modified asphalt. When the maleic anhydride grafted ethylene-vinyl acetate copolymer (M-EVA) is used for the modified asphalt, a maleic anhydride group reacts with functional groups in the asphalt, so that the polymer and the asphalt perform crosslink to a certain extent, compatibility of the ethylene-vinyl acetate copolymer (EVA) and the asphalt can be improved, the high and low temperature performance of the asphalt is improved, and the polymer modified asphalt is a perfect material for road.

Owner:NORTHWEST NORMAL UNIVERSITY

Functional admixture used for early tensioning prestressed structural concrete and purposes of functional admixture

InactiveCN102584063AImprove early strengthHigh early modulusSolid waste managementPre stressUltimate tensile strength

The invention relates to a functional admixture used for early tensioning prestressed structural concrete. The functional admixture comprises the following materials in percent by weight: 5%-95% of carbonate stone powder and mineral admixture; the carbonate stone powder is obtained by processing carbonate ores through processes such as breaking and fine grinding. A preparation process comprises the following steps of: grinding the carbonate ores into fine powder, and uniformly mixing with other mineral powders according to the proportion to obtain the functional admixture. The prepared functional admixture is applied in preparation of cast-in-situ beam concrete; the concrete capable of meeting fast tensioning requirement can be prepared under the premise without increasing the design strength of the concrete; and the problems that the conventional in-cast-situ beam concrete is long in prestressed age and long in construction period are solved.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

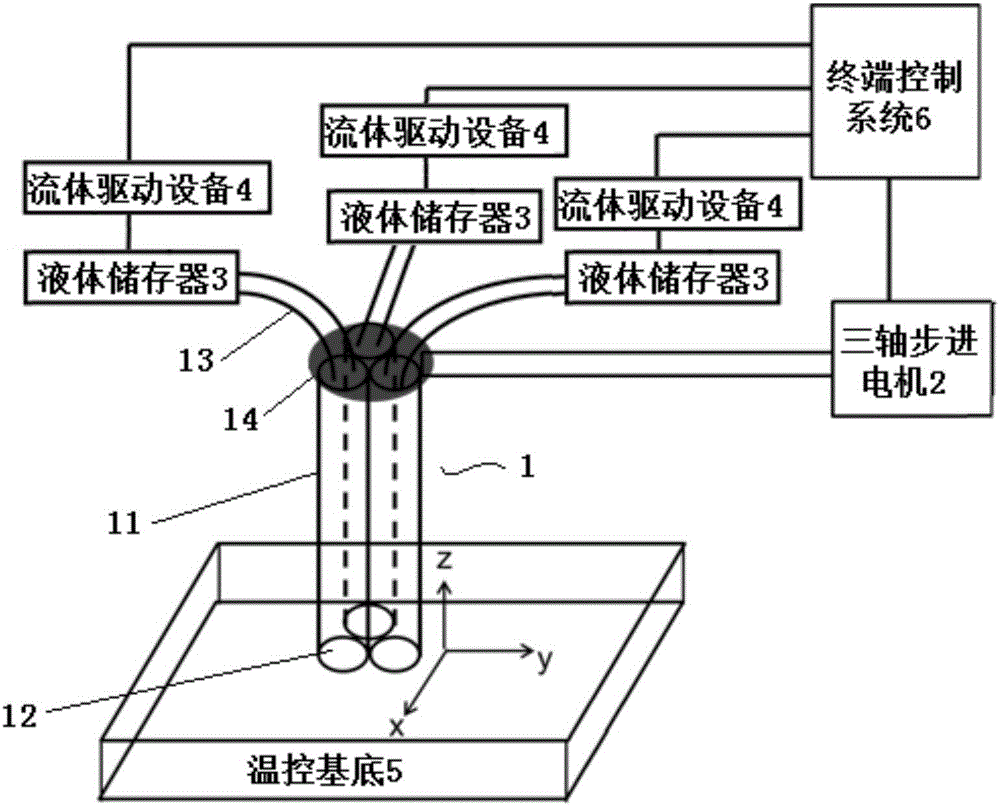

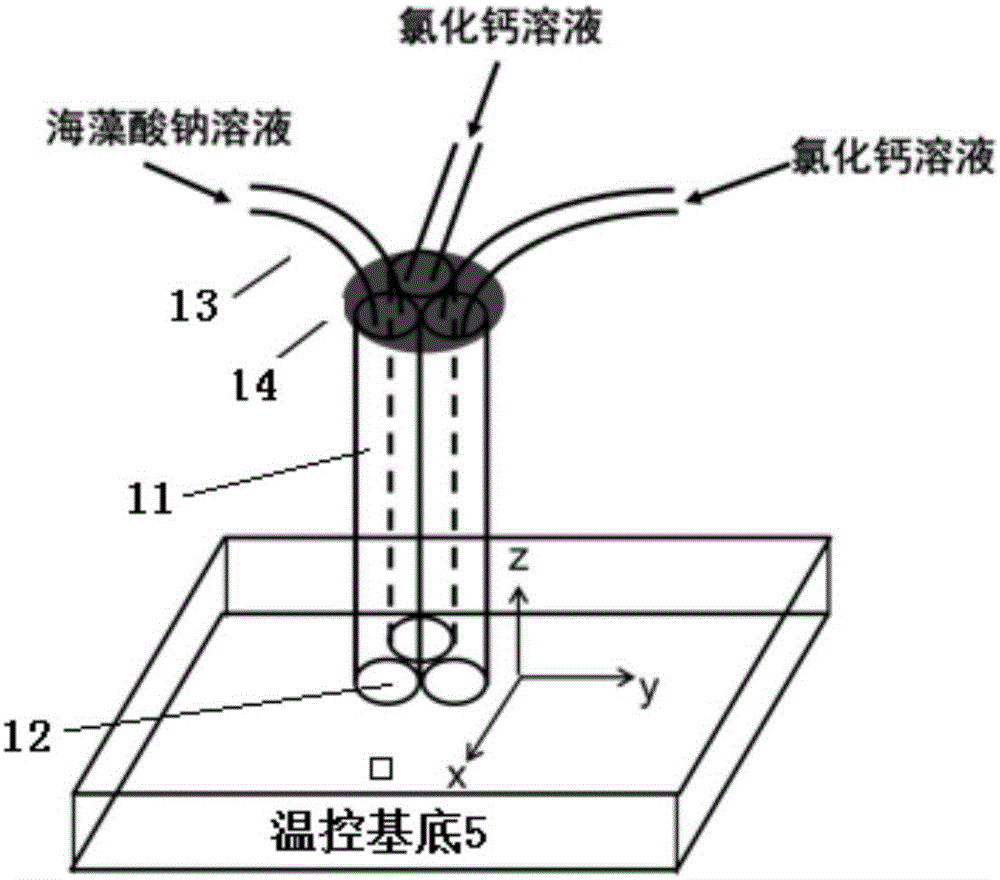

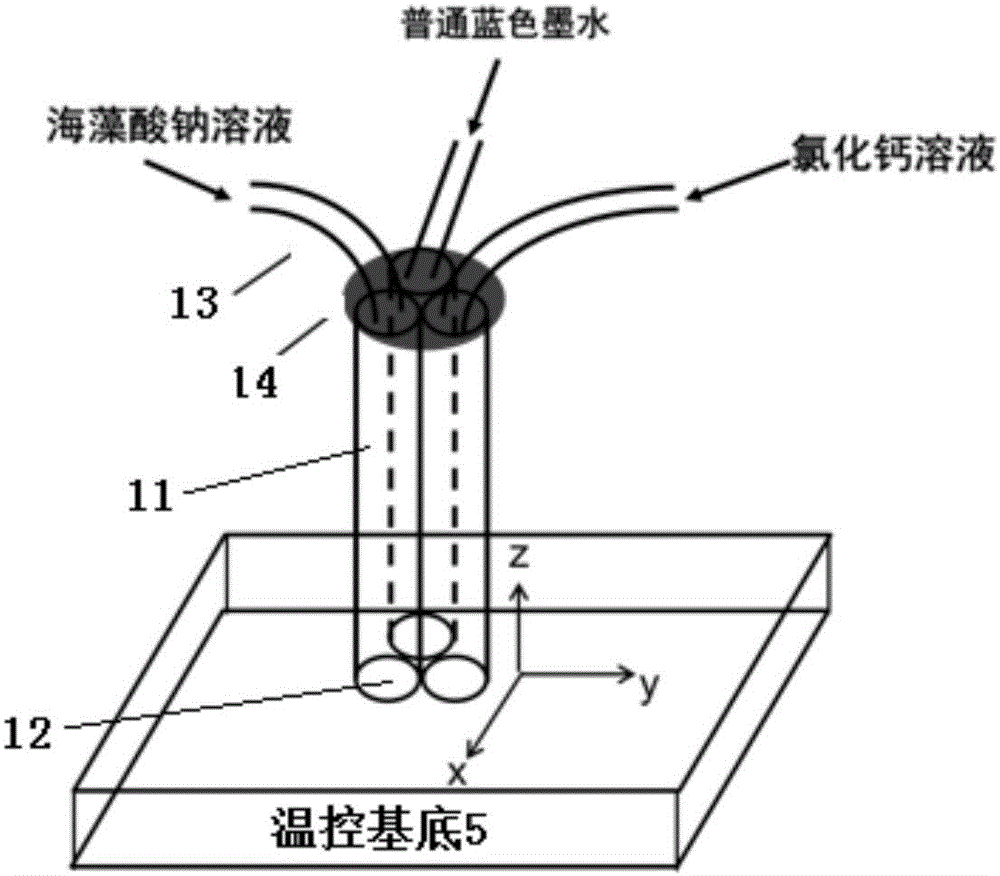

Multicomponent three-dimensional organism printing device and method based on multi-channel nozzle

InactiveCN106510898AReactiveAchieve conversionAdditive manufacturing apparatusProsthesisTemperature controlControl system

The invention relates to a multicomponent three-dimensional organism printing device and method based on multi-channel nozzle. The device comprises a multi-channel nozzle which is located on a three axis stepper motor. The multi-channel mozzle is made of multiple nozzles arranged in parallel. One end of all micro-channels is aligned to form the nozzle, and the other end is connected with all liquid storage containers through Teflon pipes. All liquid drive devices are connected with all the liquid storage containers to drive the liquid in the liquid storage containers. A terminal control system controls the three axis stepper motor, all the liquid drive devices and temperature control devices to make the multi-channel nozzle move correspondingly and eject ink, thus achieving the three dimensional printing on a temperature control substrate. The device can precisely adjust the proportion of different ink types through controlling the ink feeding speed of all the channels. The printed artificial tissues and cells are more close to the actual tissues or organs, thus making the device have a broader application prospect compared with the prior art of tissue engineering.

Owner:RENMIN UNIVERSITY OF CHINA

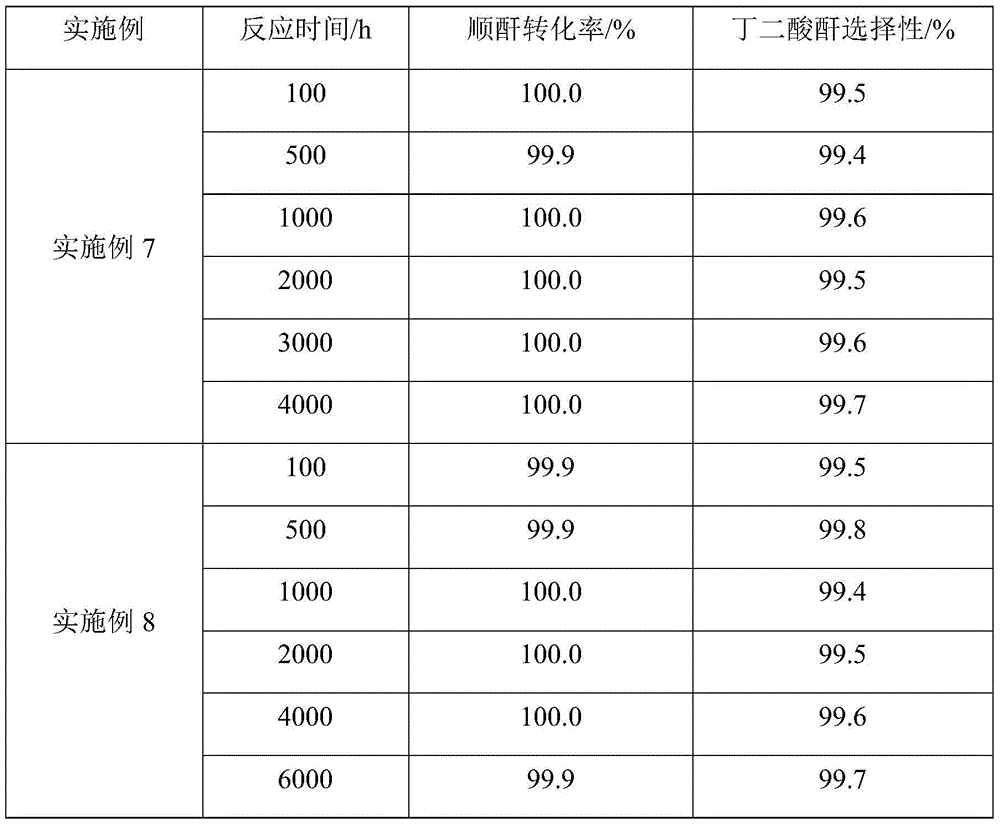

Catalyst and method of reaction for preparing butanedioic anhydride from maleic anhydride through liquid phase hydrogenation

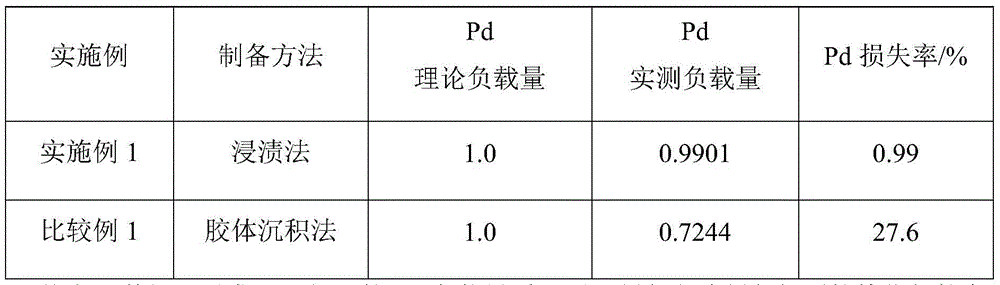

InactiveCN105597742ASolution to short lifeReduce manufacturing costOrganic chemistryMolecular sieve catalystsBULK ACTIVE INGREDIENTActive ingredient

The invention relates to a catalyst and method of the reaction for preparing butanedioic anhydride from maleic anhydride through liquid phase hydrogenation. The problems that in the prior art, the Pd loss rate is high and the maleic anhydride conversion rate and butanedioic anhydride selectivity are low are mainly solved. The catalyst is prepared through a dipping method, carriers or carriers with active auxiliaries are formed into strip-shaped, spherical or special-shaped particles through forming auxiliaries, Pd is the active ingredient, the problems are well solved through the technical scheme of the method for spraying a solution with Pd metal compounds on the forming particle carriers through the dipping method, and the catalyst and the method can be used for the reaction for preparing butanedioic anhydride from maleic anhydride through liquid phase hydrogenation.

Owner:SHANGHAI HUAYI GRP CO

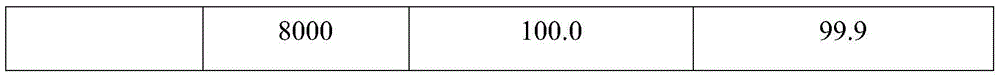

Modified polymer material and preparation method thereof

The invention discloses a modified polymer material and a preparation method of the modified polymer material. The modified polymer material is obtained by uniformly mixing 100 parts by weight of thermosetting resin, 0 to 100 parts by weight of a curing agent, 1 to 100 parts by weight of hyperbranched polyborosiloxane with functional groups and 0 to 1 part by weight of a curing catalyst at the temperature of 30 to 400 DEG C, has excellent storage stability, manufacturability and reactivity, and fully integrates performance advantages of a hyperbranched polymer, polysiloxane and polyboroxane, thereby not only having higher toughness, higher flame retardancy, higher thermal stability and higher dielectric properties and wet-heat resistance, but also having high cost performance. The preparation method of the modified polymer material disclosed by the invention has the advantages of wide applicability, simple operation process, easiness in molding and the like.

Owner:QUANZHOU NORMAL UNIV

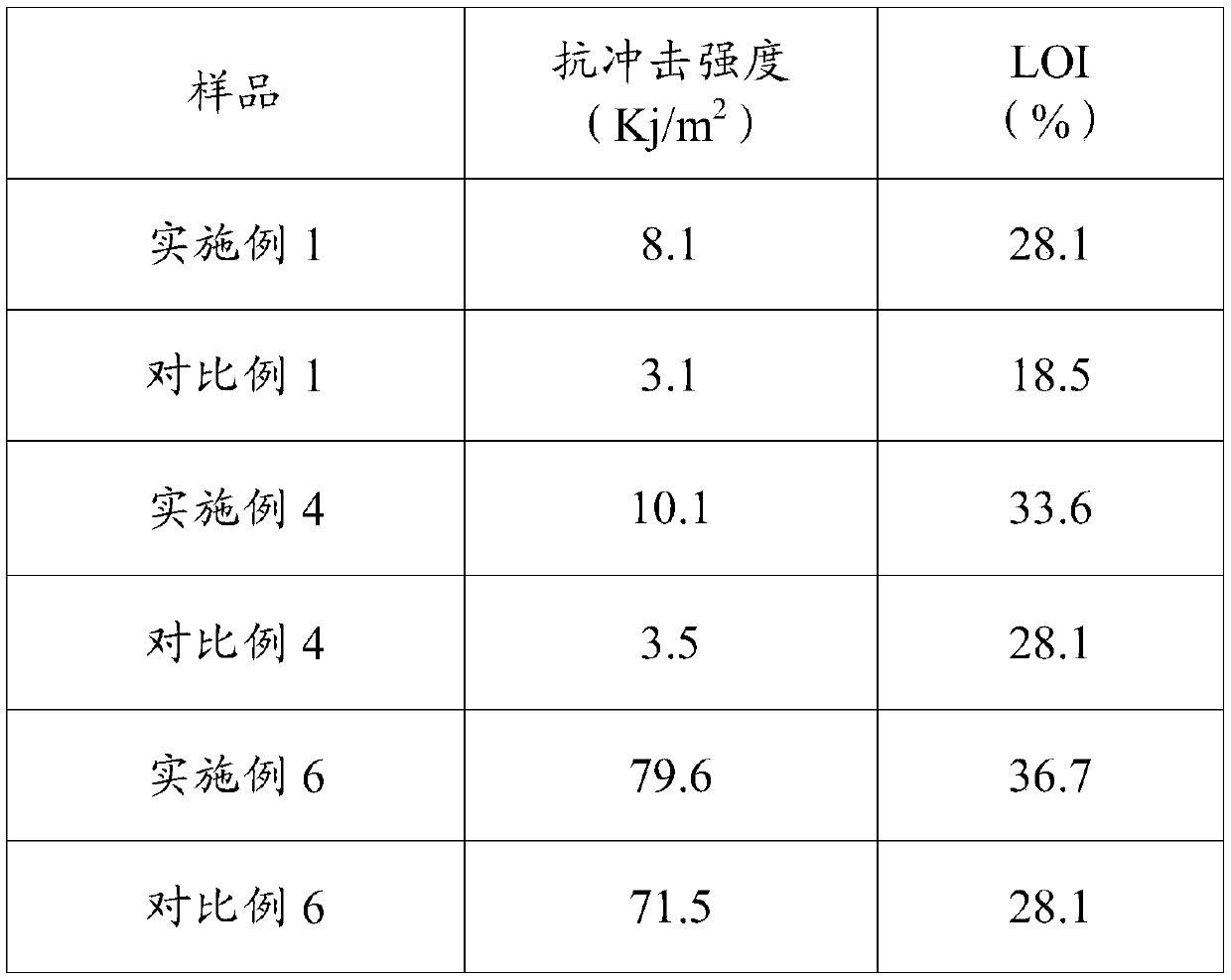

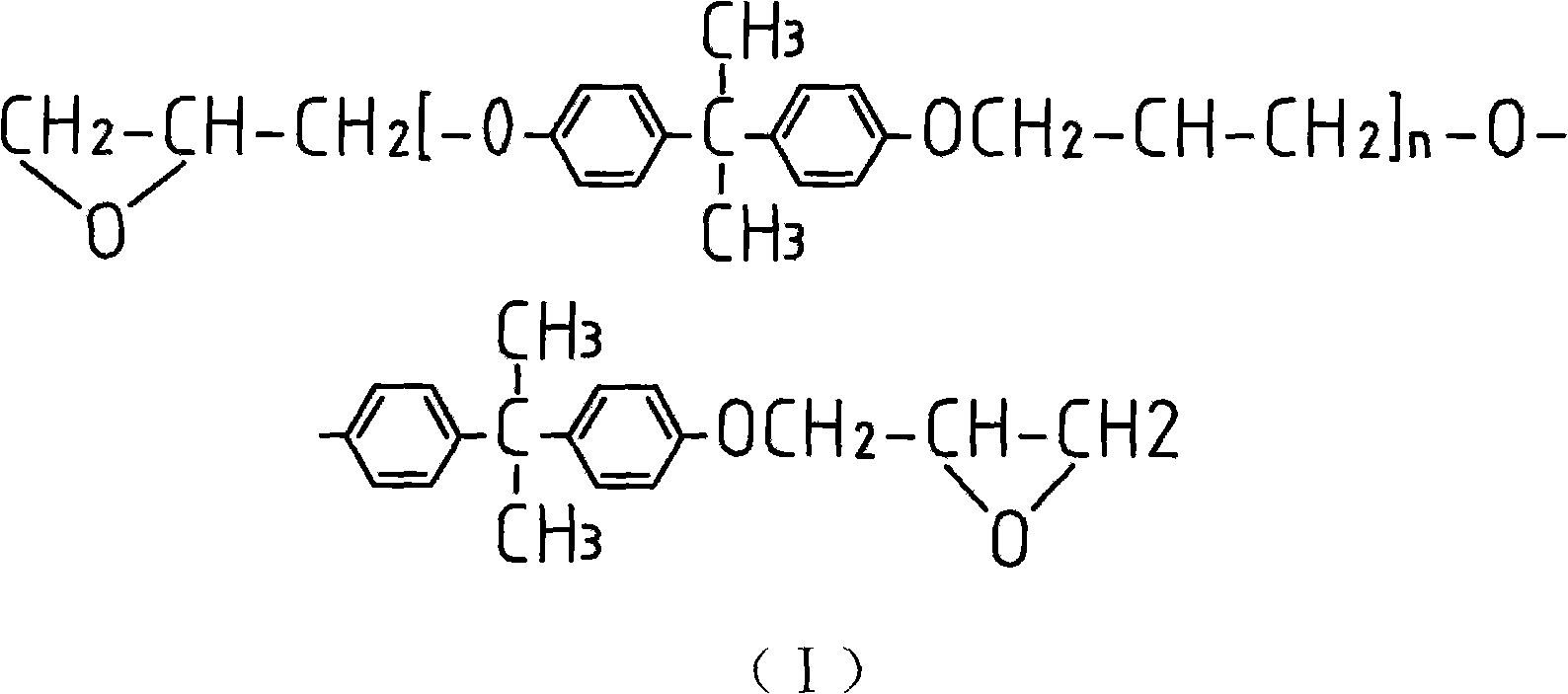

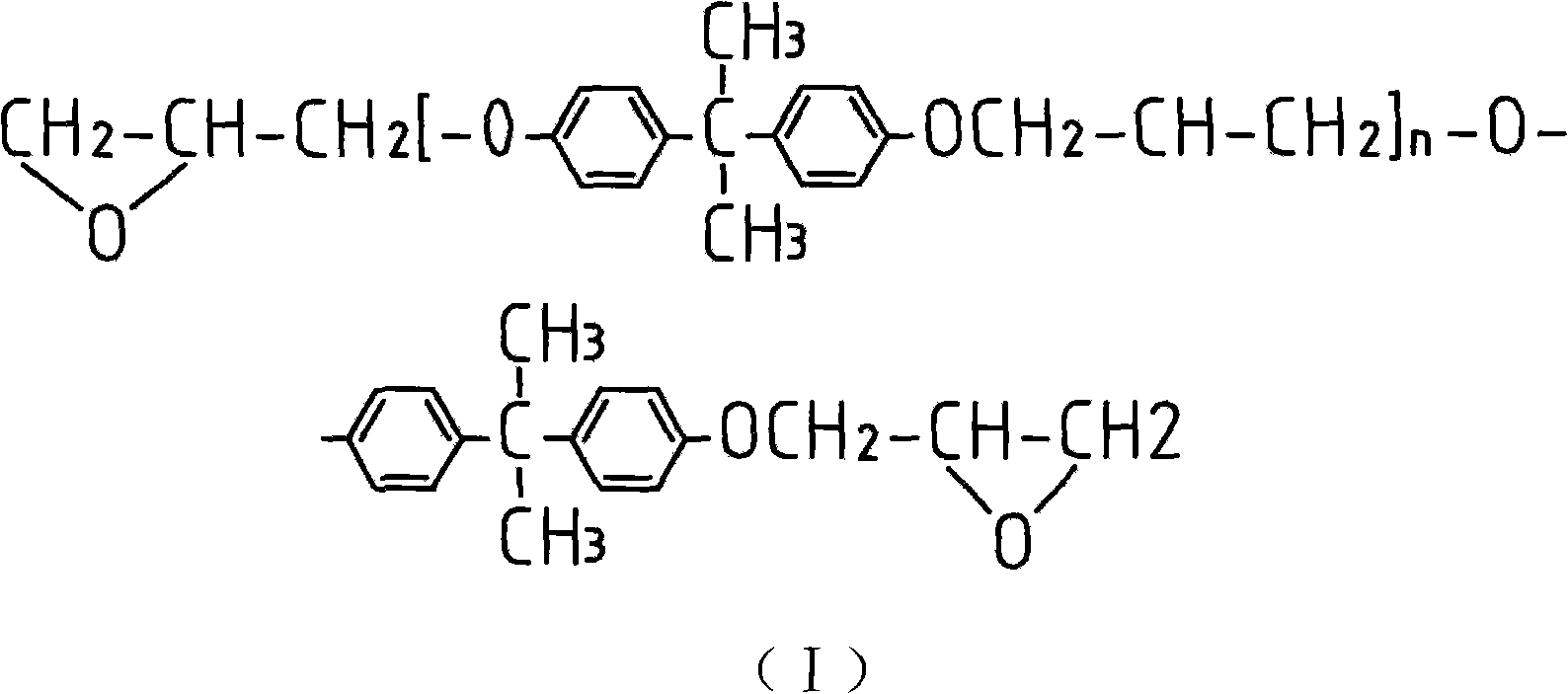

Epoxy resin composition for transformers and process for casting transformer by composition

The invention relates to the technical field of resin, in particular to an epoxy resin composition for transformers and a process for casting a transformer by the composition. The composition comprises epoxy resin, a curing agent, a toughening agent and an accelerating agent, the epoxy resin is a mixture of general formula (I), the epoxy groups on both terminals have reactive activity in the composition unit of the general formula (I), bisphenol A framework provides strong toughness and thermal endurance, a methylene chain has flexibility, ether bond has chemical resistance, and hydroxyl has reactivity and adhesiveness. Brominated epoxy resin of halogenated epoxy resin is taken as an fire retardant, and can be reactive fire retardant and also as flame retardant epoxy resin, thus fire resistance of the cast coil is good, and local discharge is small.

Owner:广东康德威电气股份有限公司

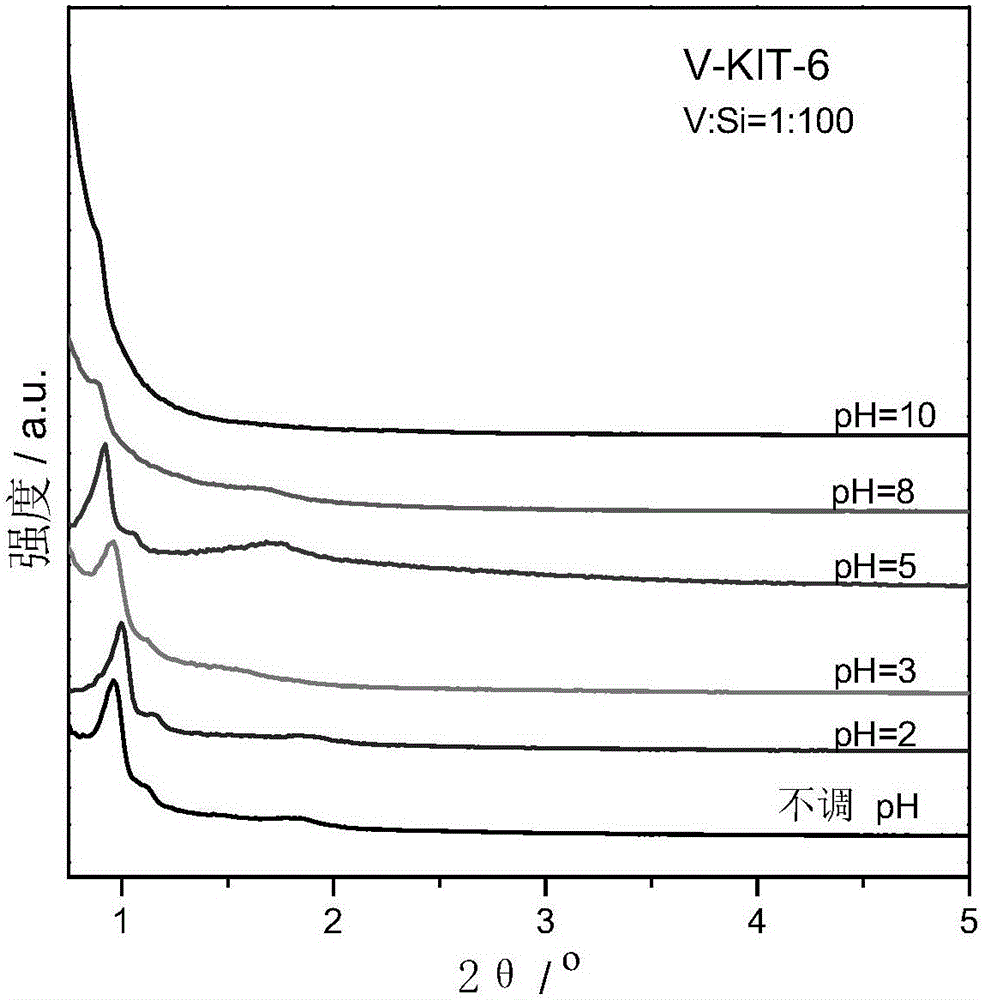

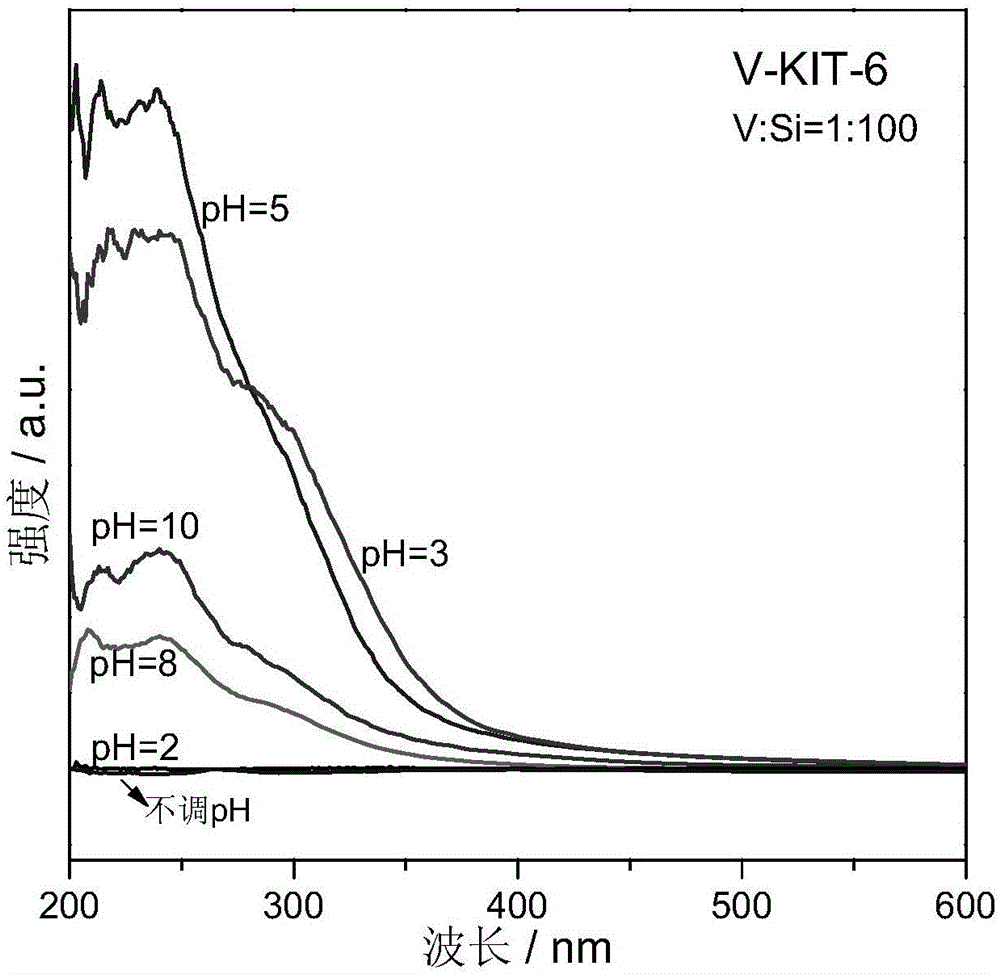

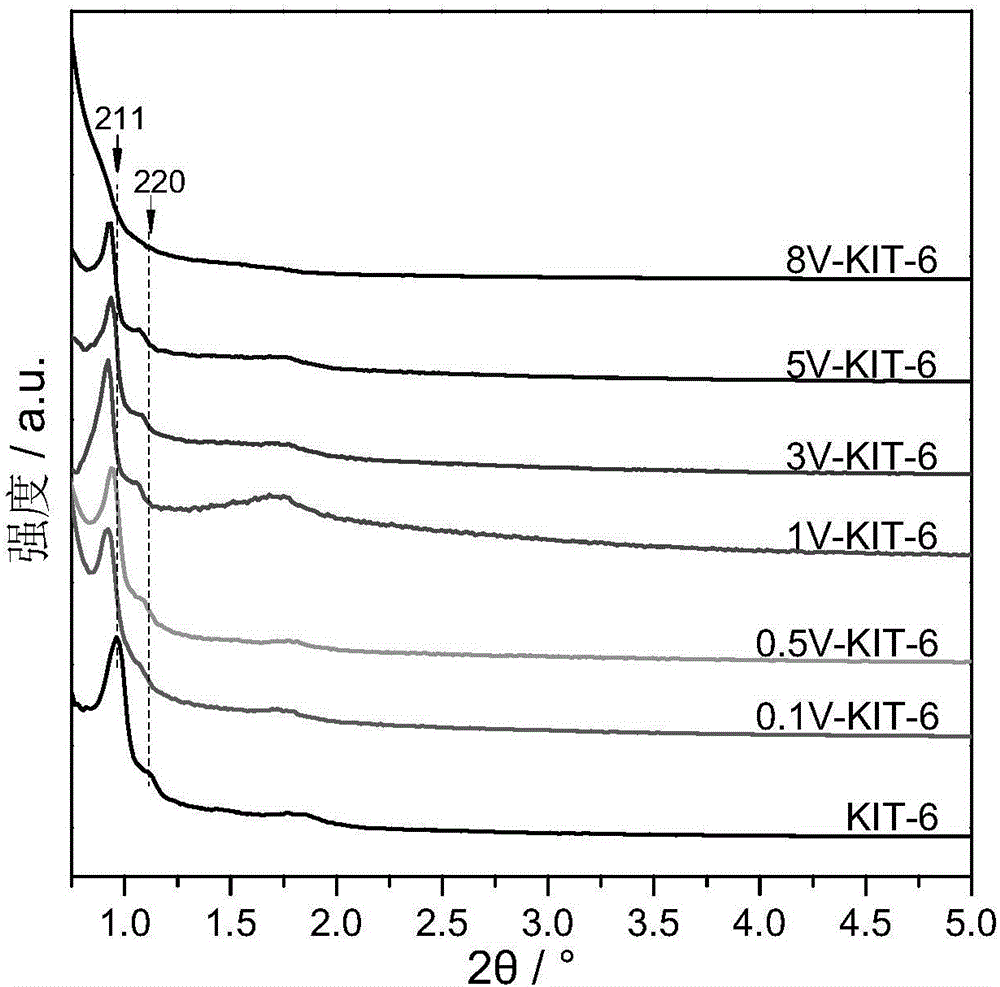

Vanadium-doped silicon oxide-based mesoporous molecular sieve catalyst, as well as preparation method and application thereof

ActiveCN105728013APore structure maintenanceNo change in ratioMolecular sieve catalystsHydrocarbonsDispersityMolecular sieve

The invention provides a vanadium-doped silicon oxide-based mesoporous molecular sieve catalyst, as well as a preparation method and application thereof. According to the catalyst, a pure silicon mesoporous molecular sieve KIT-6 is taken as a carrier, vanadium oxide is taken as an active ingredient, and is doped into a framework of the pure silicon mesoporous molecular sieve KIT-6, and the molar ratio of V to Si is 0.1:100 to 8:100. The invention further provides the preparation method for the catalyst and the application of the catalyst to selective oxidative dehydrogenation of propane for production of olefin. According to the vanadium-doped silicon oxide-based mesoporous molecular sieve catalyst, the dispersity of the active ingredient vanadium is higher, the concentration of an active site is higher, and the stability of the active site is higher, so that the catalytic activity of the catalyst is higher. When the catalyst is applied to reaction of selective oxidative dehydrogenation of the propane for production of the olefin, the molar recovery rates of products propene and olefin of selective oxidation reaction of the propane can reach 35.6 percent and 38.6 percent respectively.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

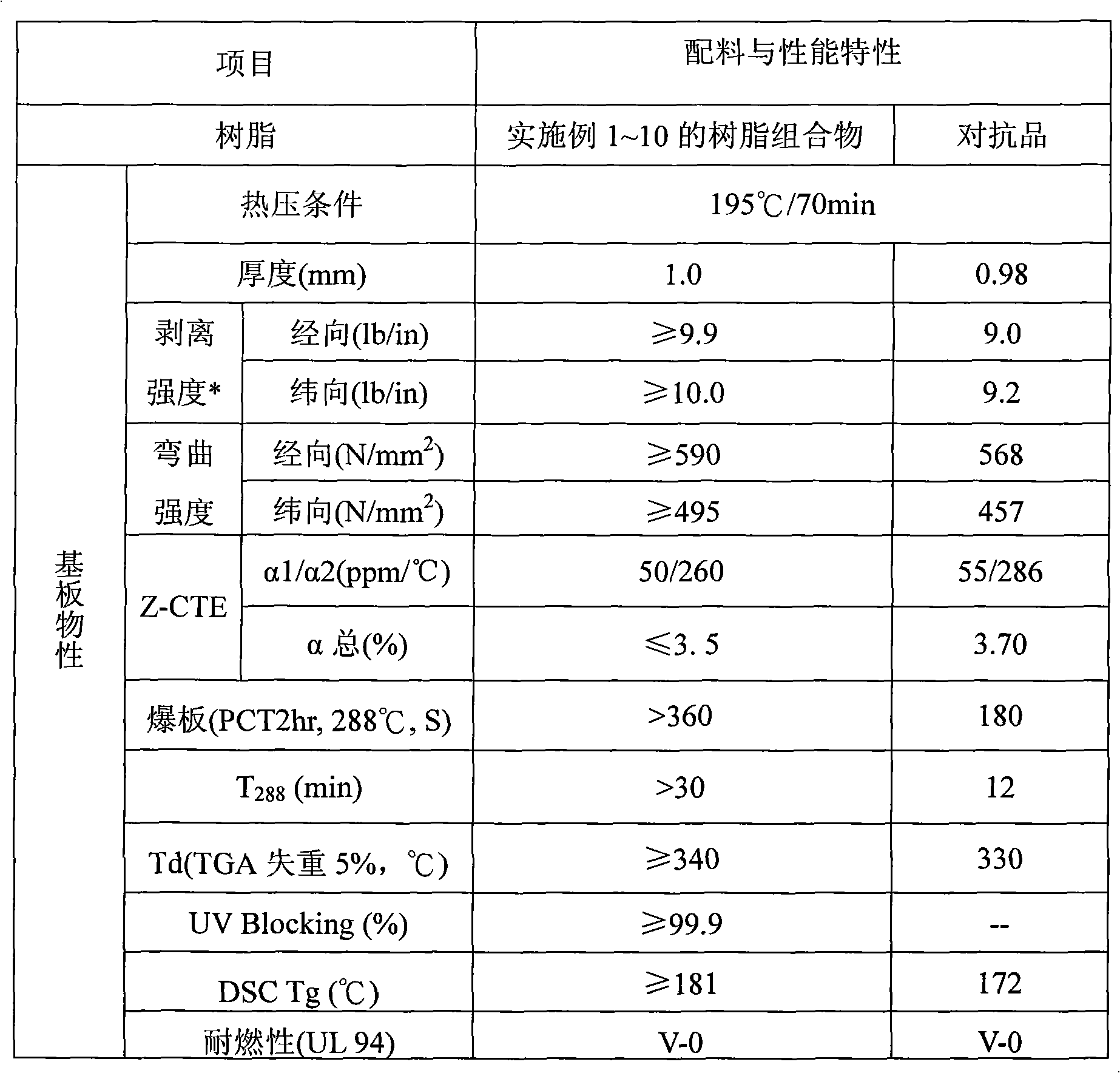

Epoxy resin composition for printed circuit copper-clad plate

ActiveCN101864146AHigh glass transition temperatureImprove heat resistanceCircuit susbtrate materialsMetal layered productsHeat resistanceThermal expansion

The invention discloses an epoxy resin composition for a printed circuit copper-clad plate, which consists of the following components in part by weight: 130 to 140 parts of butane solution containing modified epoxy resin, 60 to 70 parts of composite phenolic aldehyde curing agent or 4.5 to 6.5 parts of dicyandiamide curing agent, 0.02 to 0.04 part of curing catalyst, 30 to 40 parts of solvent and 25 to 30 parts of filler, wherein the butane solution containing the modified epoxy resin is prepared by modifying bis-functional epoxy resin, brominated bisphenol epoxy resin, multi-functional novolac epoxy resin and linear novolac epoxy resin. The epoxy resin composition has the characteristics of low viscosity, easy impregnation, convenient operation, good reactivity and high Tg; and the printed circuit copper-clad plate made of the epoxy resin composition has good reliability and workability, excellent heat resistance and Z-axis thermal expansion coefficient and other comprehensive performance.

Owner:EPOXY BASE ELECTRONICS MATERIAL

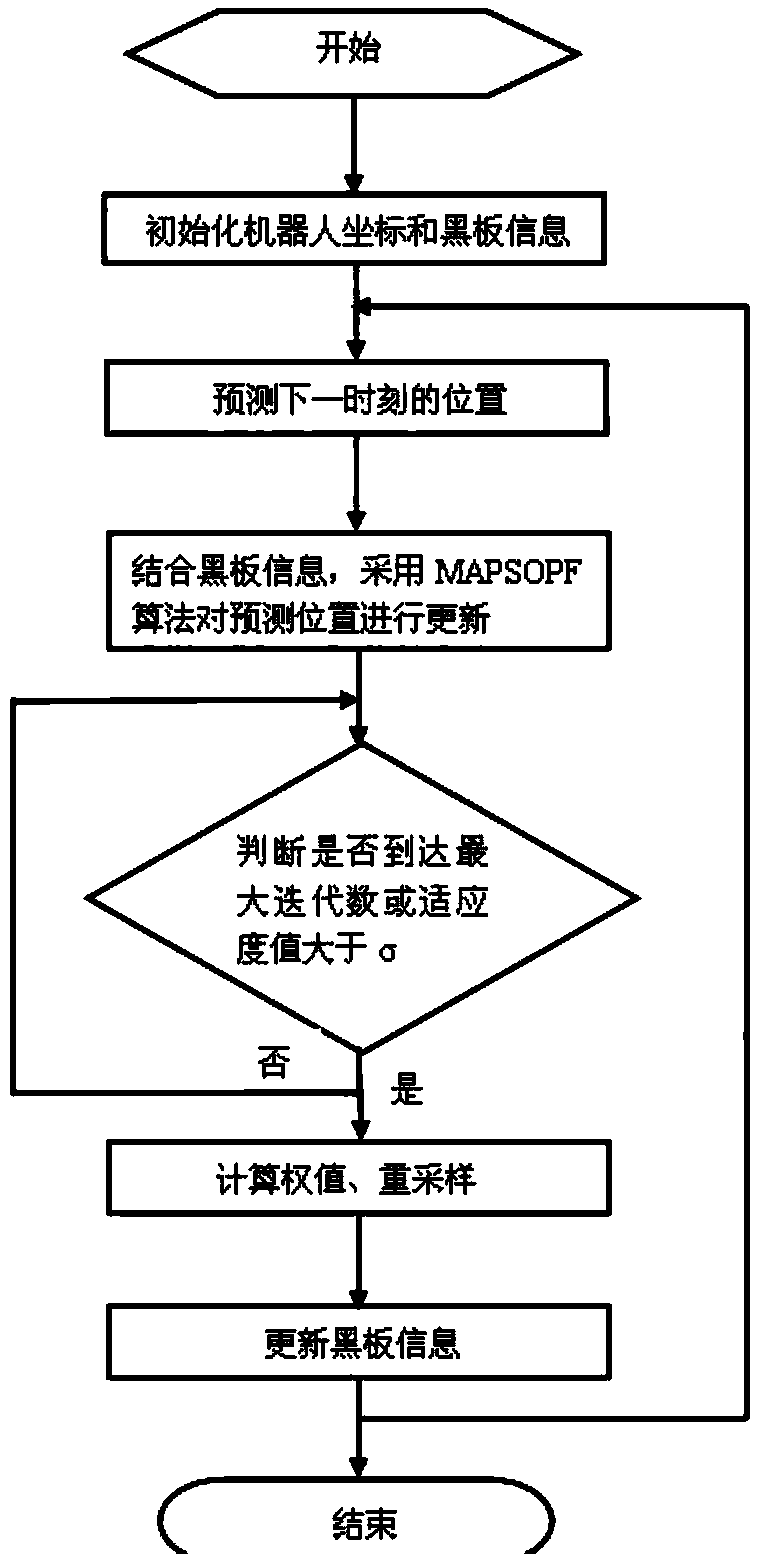

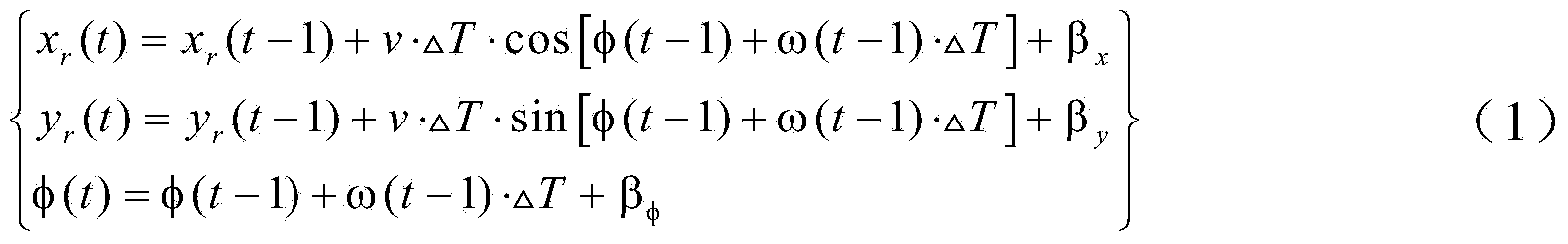

Multi-mobile-robot cooperation positioning method based on filtering of MAPSO particle optimization filtering

InactiveCN103970135AEasy to observeReasoningPosition/course control in two dimensionsLearning factorRelevant information

The invention discloses a multi-robot cooperation positioning method based on an MAPSOPF algorithm. The method includes the steps that an actual operating environment is abstracted into a planar graph, and according to the position of a road sign and the paths of robots, an environmental map is built; relevant information and blackboard information of the robots are initialized; the MAPSOPF algorithm is adopted, the subsequent positions of the robots are predicted according to a fitness value, the predicted positions and the blackboard information are updated, and accurate positioning is completed. By adjusting weighing coefficients and learning factors, a competition mechanism is introduced so that the optimization effect of the algorithm can be improved, and finally, multi-robot coordination positioning accuracy is improved.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

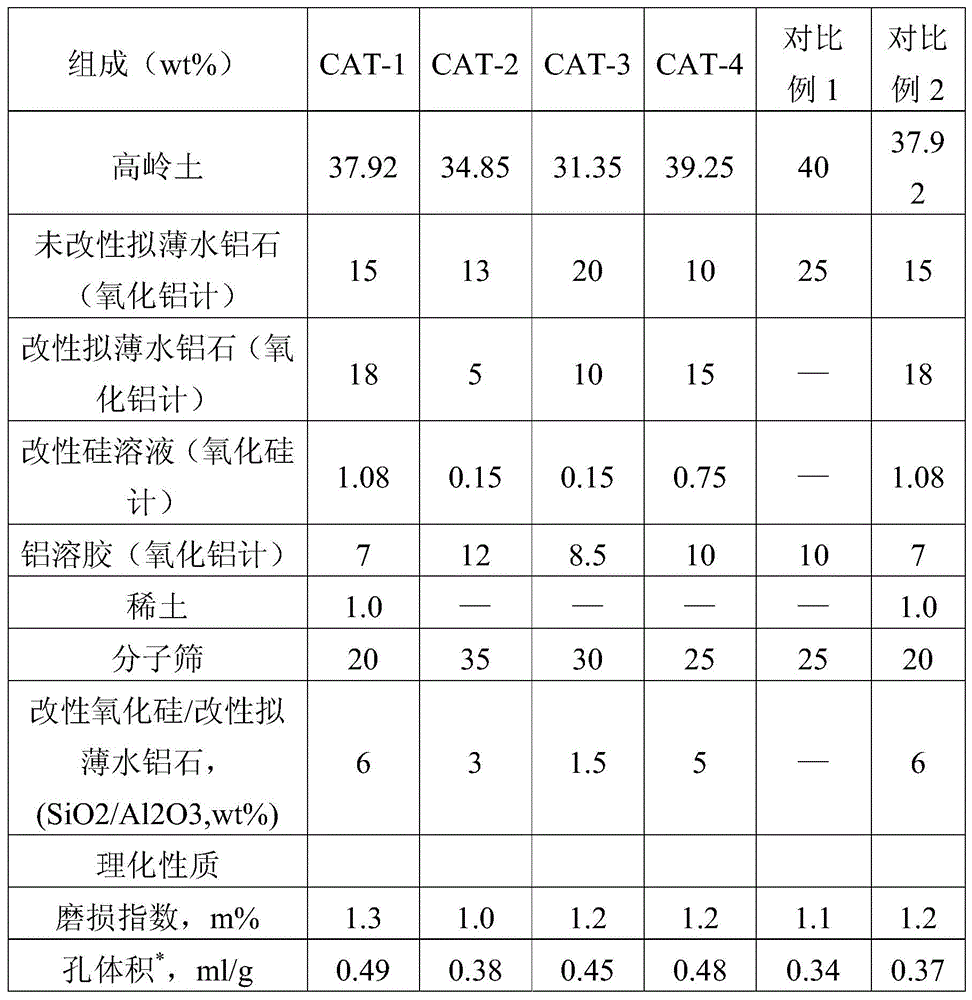

Method for preparing catalytic cracking catalyst containing pseudo-boehmite

ActiveCN105688977AIncrease contentLarge specific surface areaMolecular sieve catalystsIon exchangeBoehmite

The invention discloses a method for preparing a catalytic cracking catalyst containing pseudo-boehmite.The method comprises the steps of mixing and stirring part of pseudo-boehmite and silica solution for over 15 min to prepare modified pseudo-boehmite A, the modified pseudo-boehmite A, residual pseudo-boehmite B and clay are mixed and pulped to prepare matrix size containing pseudo-boehmite, the matrix size and molecular sieve size are mixed, homogenized, formed and dried, and ion exchange is conducted to obtain the catalytic cracking catalyst, wherein the dry basis mass ratio of the modified pseudo-boehmite A to the residual pseudo-boehmite B is 0.2-2.5, and the add amount of silica solution is that SiO2 accounts for 0.5-8% of the dry basis weight of the modified pseudo-boehmite A.The catalyst prepared with the method has a high abrasion index, a large pore volume and high heavy oil conversion capacity and coke selectivity.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com