Method for preparing catalytic cracking catalyst containing pseudo-boehmite

A pseudo-boehmite and catalytic cracking technology, which is applied in the field of preparation of high-heavy oil conversion catalytic cracking catalysts, can solve the problems of catalyst slurry solid content decrease, viscosity increase, and impact on catalyst output, etc., to achieve superior reaction performance, increase content, Effect of improving coke selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

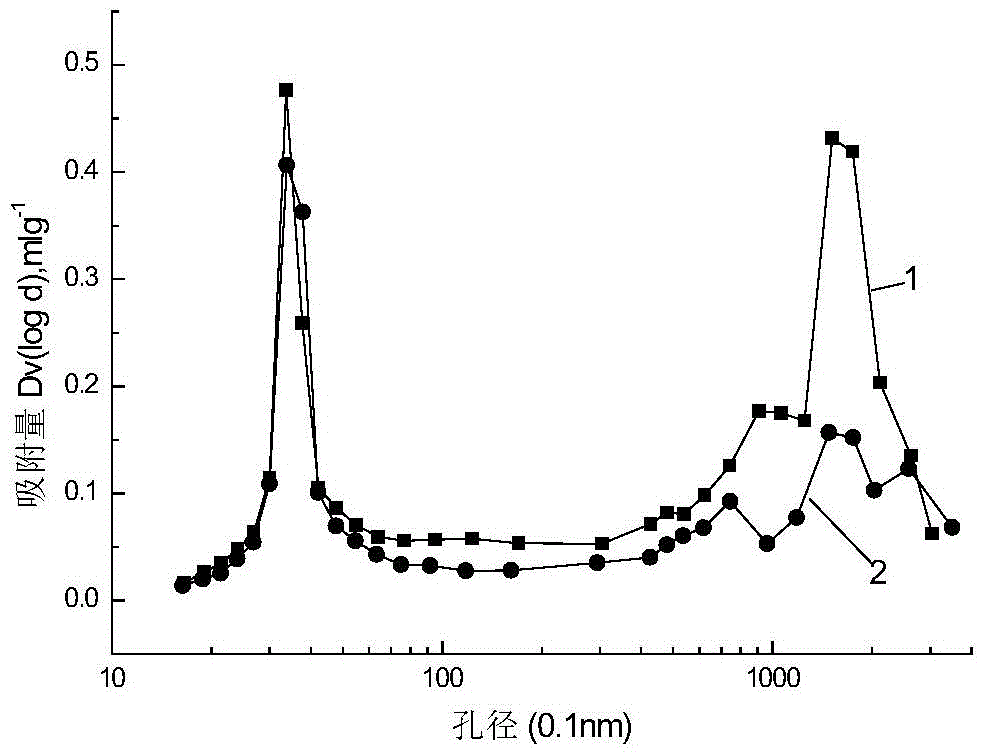

Image

Examples

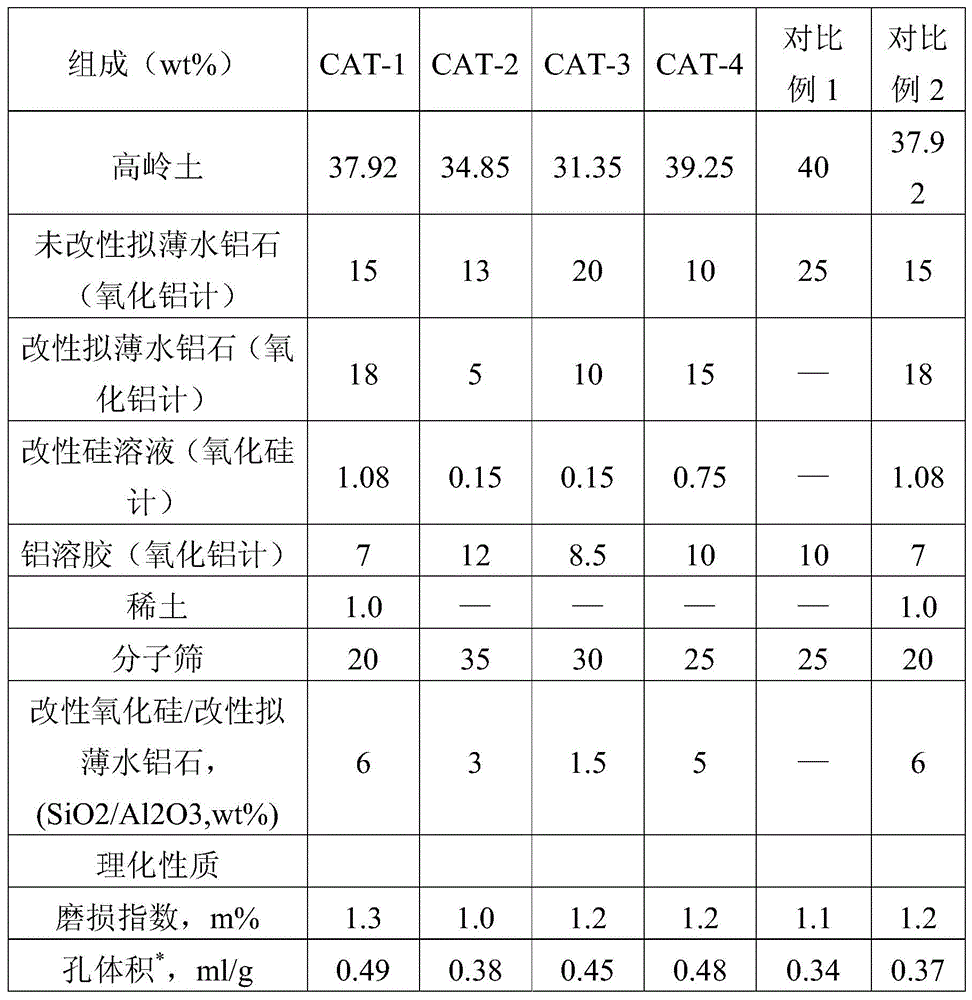

Embodiment 1

[0041] Take by weighing 2.769 kilograms of pseudo-boehmite (solid content 65.0%, Shanxi Aluminum Factory product, the same below), add 15.601 kilograms of deionized water, add 547 milliliters of water glass (SiO 2 250g / l, Na 2 (088g / l, produced by Lanzhou Petrochemical Company, the same below), after continuing to stir for 30 minutes, add 2.308 kilograms of pseudo-boehmite, 4.546 kilograms of kaolin (dry basis, industrial products of China Kaolinshi Company, the same below), aluminum sol 3.608 kg (including Al 2 o 3 19.4wt%, produced by Lanzhou Petrochemical Company Catalyst Factory, the same below), rare earth solution 346.3ml (content is 288.75gL -1 , La, Ce mixed rare earth, collected from Lanzhou Petrochemical Catalyst Factory, the same below) and stirred for two hours, then added 700 ml of 37% by weight hydrochloric acid, stirred for 1 hour, and aged at 50 ° C for 2 hours.

[0042] 2.361 kg of REUSY molecular sieves (solid content 84.7%, Na 2 O content 1.1 wt%, RE 2 ...

Embodiment 2

[0046] Weigh 0.769 kg of pseudo-boehmite, add 4.0 kg of deionized water, add 55.73 ml of ethyl orthosilicate under stirring, continue stirring for 30 minutes, add 2.0 kg of pseudo-boehmite, 4.178 kg of kaolin, aluminum sol 6.186 kg, stirred for two hours, then added 500 ml of 37% by weight hydrochloric acid, stirred for 1 hour, and aged at 60°C for 2 hours.

[0047] 4.132 kg of REUSY molecular sieve and 7.138 kg of deionized water were mixed and beaten for 2 hours, then added to the first step of the beating tank after mixing, beating homogenized for 4 hours, and then spray-dried.

[0048] The catalyst obtained by spray drying was calcined at 650°C for 2 hours, then stirred in aqueous hydrochloric acid solution with pH=2.8 for 20 minutes, filtered, and dried at 120°C for 6 hours to obtain the cracking catalyst CAT-2 provided by the present invention.

[0049] The composition of the catalyst CAT-2 is: based on the catalyst mass as 100%, 34.85% by weight of kaolin, 13% by weight o...

Embodiment 3

[0051] Take by weighing 1.538 kilograms of pseudo-boehmite, add 10.0 kilograms of deionized water, add 76 milliliters of water glass under stirring, after continuing to stir for 30 minutes, add 3.077 kilograms of pseudo-boehmite, 3.759 kilograms of kaolin, 4.381 kilograms of aluminum sol, stir After two hours, 400 ml of 37% by weight hydrochloric acid was added, stirred for 1 hour, and aged at room temperature for 2 hours.

[0052] 3.542 kg of REUSY molecular sieves (solid content 84.7%, Na 2 O content 1.1 wt%, RE 2 o 3 Content 4.3wt%, produced by Lanzhou Petrochemical Company Catalyst Factory, the same below) and 4.692 kg of deionized water were mixed and beaten for 2 hours, then added to the first step beating tank after mixing, beating homogenized for 4 hours, and then spray-dried.

[0053] The catalyst obtained by spray drying was calcined at 550°C for 2 hours, then stirred in aqueous hydrochloric acid solution with pH=3.2 for 40 minutes, filtered, and dried at 120°C for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com