Epoxy resin composition for transformers and process for casting transformer by composition

A technology of epoxy resin and transformer, applied in the field of resin, can solve the problems of increased partial discharge and blooming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

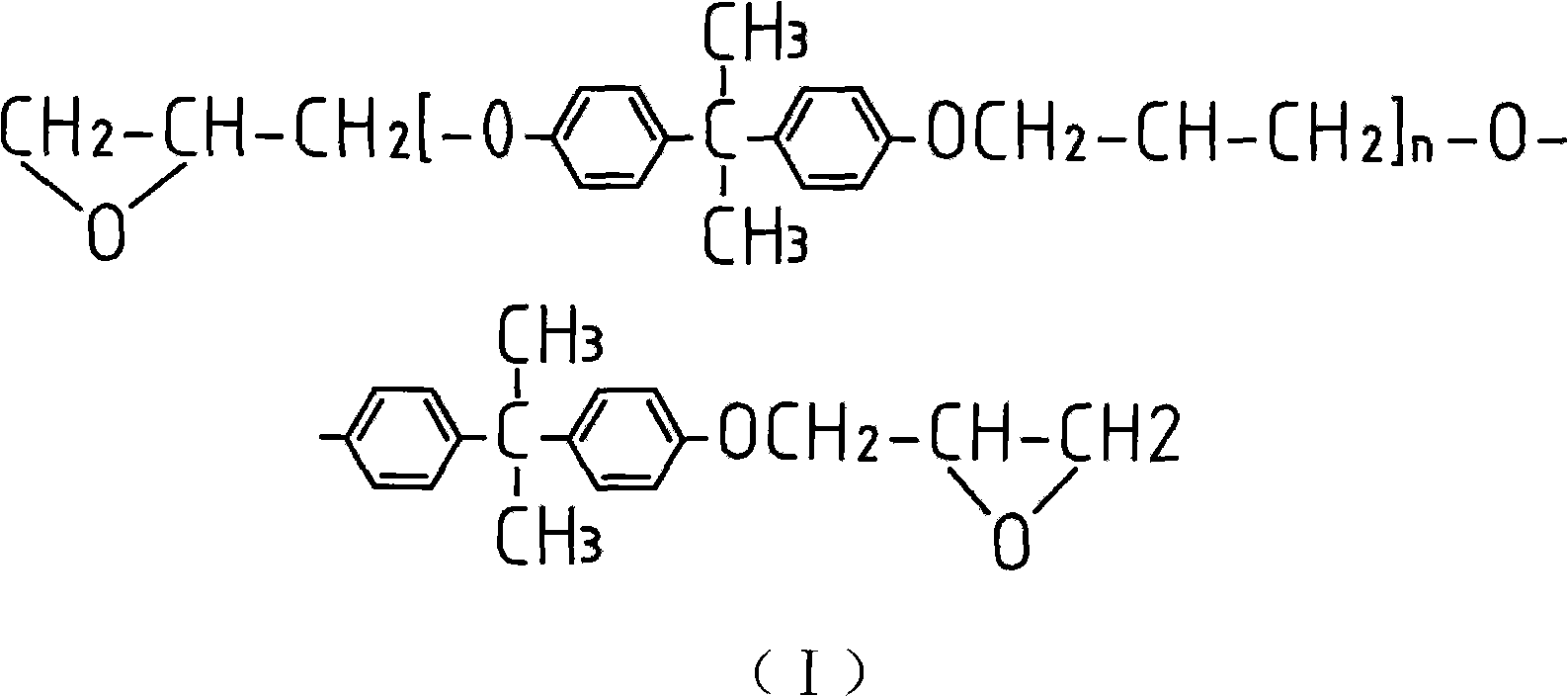

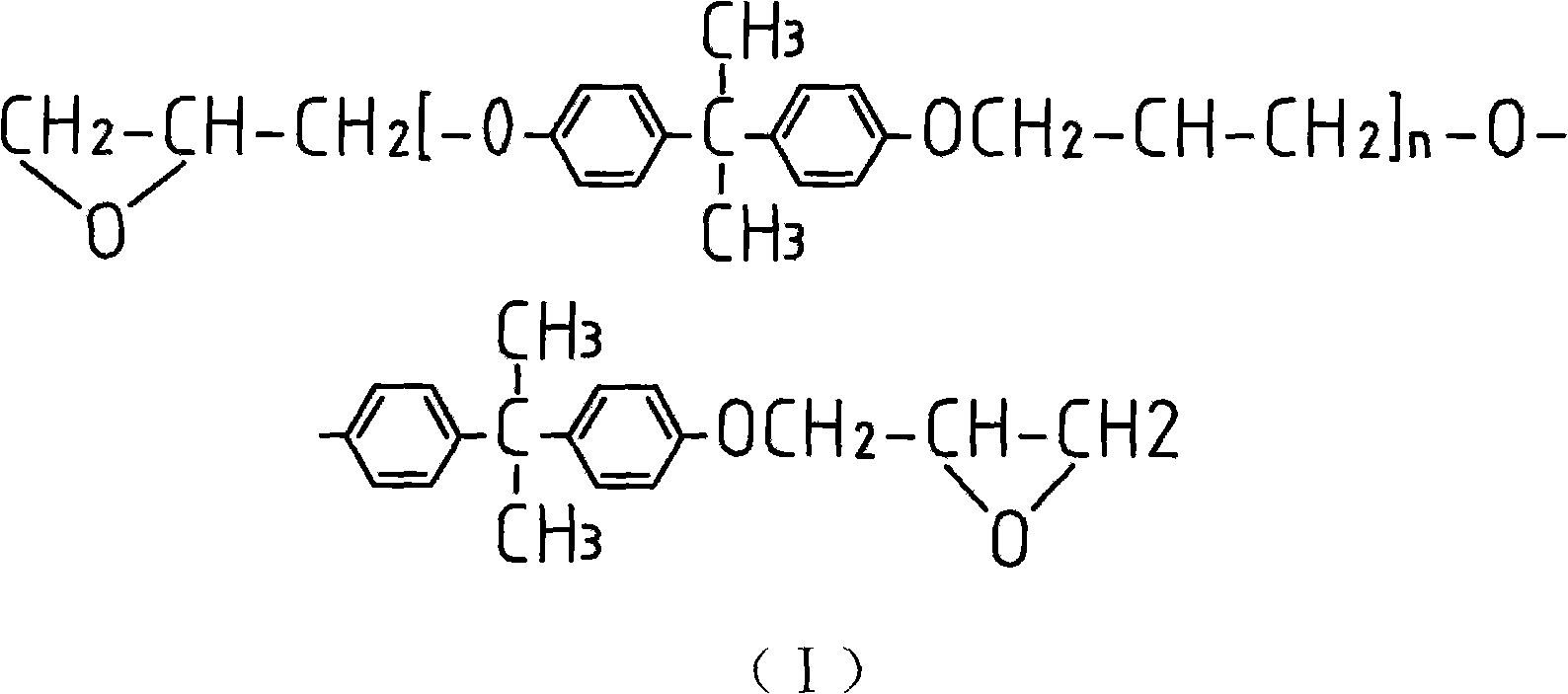

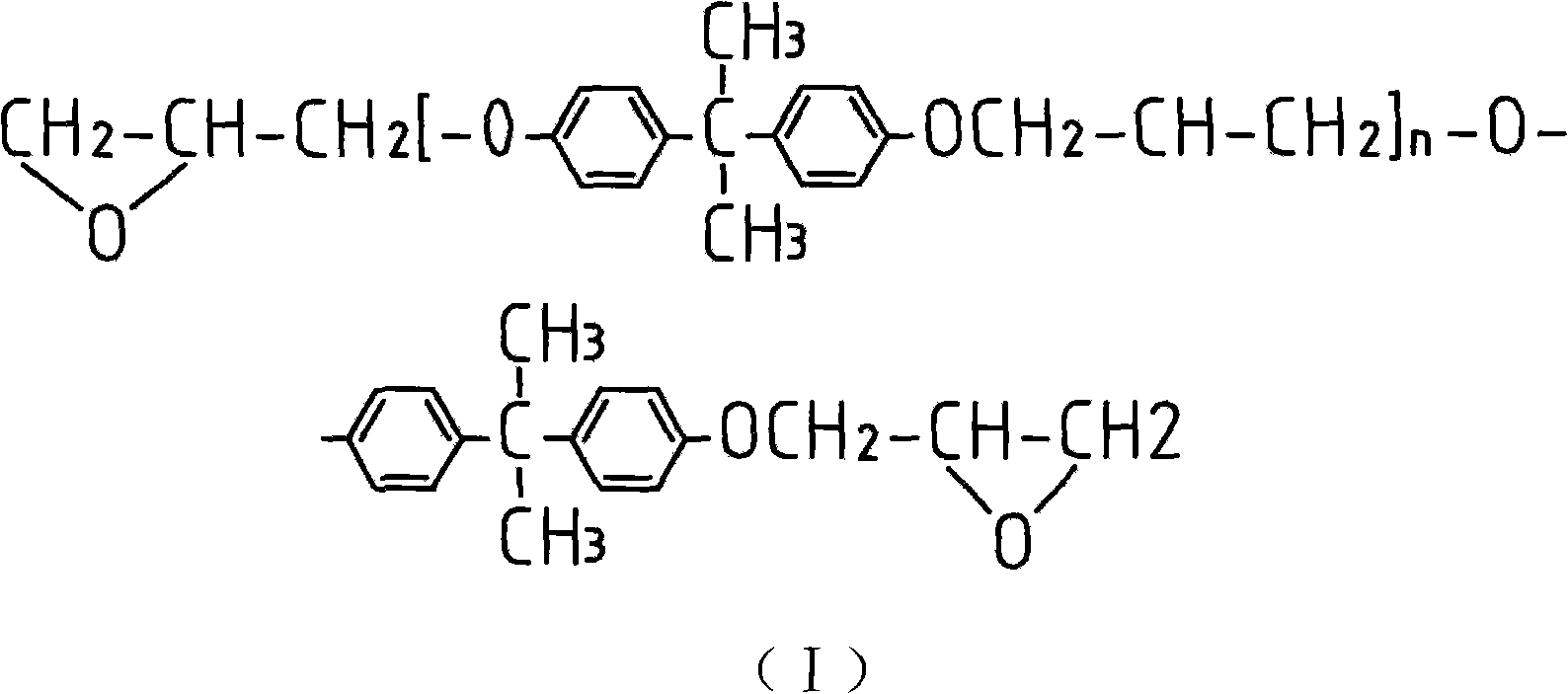

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1, the raw material of epoxy resin composition comprises following component, and content (weight part) is:

[0041] epoxy resin 100

[0042] Hardener 100

[0043] Toughener 10

[0044] Accelerator 0.05.

[0045] The technological process of pouring the transformer with the epoxy resin composition of the present embodiment is:

[0046] A. Pre-bake the epoxy resin, curing agent, toughener and accelerator at 75°C for 2.5 hours, and the coil at 105°C for 9.5 hours;

[0047] B. Put the pre-baked mold into the pouring tank after inspection, close the feeding valve, start the power supply of the pouring equipment, turn on the air compressor and water pump, and then start the heating system of the pouring tank to check whether there is any abnormality in the equipment. , and then preheat the mixer to 65°C in advance, and the pouring tank to 75°C;

[0048] C. Feeding, according to the process formula (parts by weight): put 100 parts of epoxy resin, 100 parts of ...

Embodiment 2

[0055] Embodiment 2, the raw material of epoxy resin composition comprises following component, and content (weight part) is:

[0056] epoxy resin 100

[0057] Hardener 100

[0058] Toughener 8

[0059] Accelerator 0.001.

[0060] The technological process of pouring the transformer with the epoxy resin composition of the present embodiment is:

[0061] A. Pre-bake the epoxy resin, curing agent, toughener and accelerator at 65°C for 1.5 hours, and the coil at 95°C for 8.5 hours;

[0062] B. Put the pre-baked mold into the pouring tank after inspection, close the feeding valve, start the power supply of the pouring equipment, turn on the air compressor and water pump, and then start the heating system of the pouring tank to check whether there is any abnormality in the equipment. , and then preheat the mixer to 55°C in advance, and the pouring tank to 65°C;

[0063] C. Feeding, according to the process formula (parts by weight): put 100 parts of epoxy resin, 100 parts of c...

Embodiment 3

[0068] Embodiment 3, the raw material of epoxy resin composition comprises following component, and content (weight part) is:

[0069] epoxy resin 100

[0070] Hardener 100

[0071] Toughener 9

[0072] Accelerator 0.025.

[0073] The technological process of pouring the transformer with the epoxy resin composition of the present embodiment is:

[0074] A. Pre-bake the epoxy resin, curing agent, toughening agent and accelerator at 70°C for 1 hour, and pre-bake the coil at 100°C for 9 hours;

[0075] B. Put the pre-baked mold into the pouring tank after inspection, close the feeding valve, start the power supply of the pouring equipment, turn on the air compressor and water pump, and then start the heating system of the pouring tank to check whether there is any abnormality in the equipment. , and then preheat the mixer to 60°C in advance, and the pouring tank to 70°C;

[0076] C. Feeding, according to the process formula (parts by weight): put 100 parts of epoxy resin, 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com