Patents

Literature

333results about How to "Chemical resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dual-curing coating and preparation method thereof

InactiveCN102181192ACuring shrinkage is smallIncrease crosslink densityCoatingsInformation layerCoating system

The invention discloses a dual-curing coating. The coating contains ultraviolet curing resin monomers, a low polymer, a photo-initiator, polymer resins, an adjuvant and an organic solvent. In the invention, the dual-curing coating is prepared by synergistic copolymerization of an ultraviolet curing coating system and a solvent-based polymer system. The preparation method of the coating comprises the following steps: firstly thermocuring, and then processing information layers and photocuring at the same time; or firstly photocuring, then processing the information layers, and finally heating with an oven or infrared-heating for further cross-linking curing. Therefore, the dual-curing coating has better comprehensive performances such as fast curing speed, small film-coating cure shrinkage and high crosslinking density so as to achieve the characteristics of chemical corrosion resistance, strong wear resistance, strong high temperature resistance, excellent flexibitity, excellent adhesive force and the like; and the coating can be used for laser anti-counterfeit marks of plastics, cosmetic preparations, ceramic materials, glass, paper, leather, wooden products and metal products as well as production of pigment preparations and the like.

Owner:SHANGHAI HONGDUN ANTI COUNTERFEIT MATERIAL

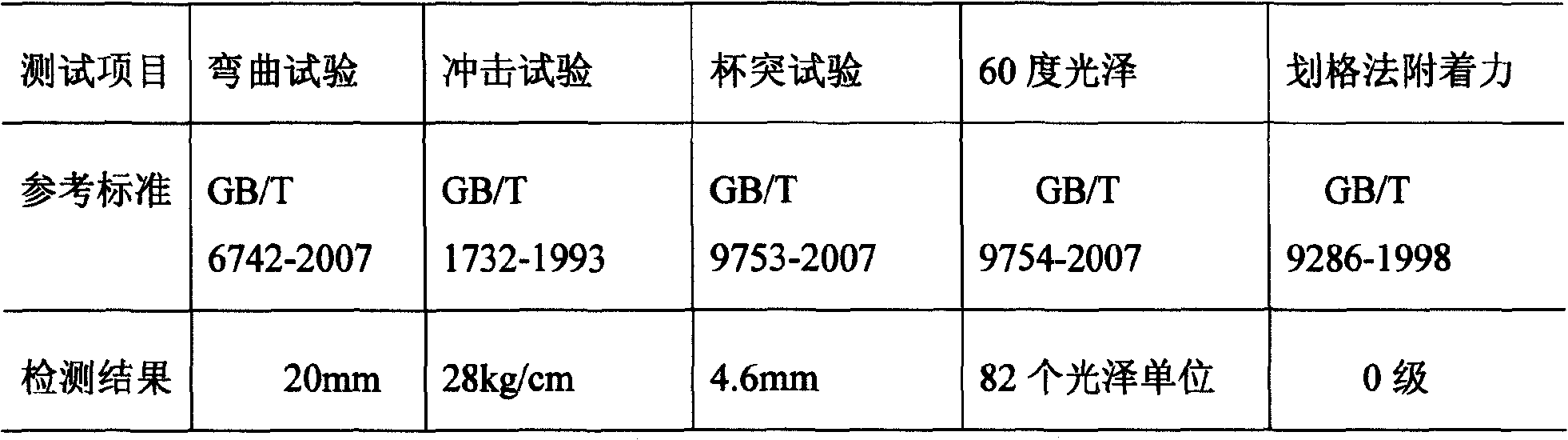

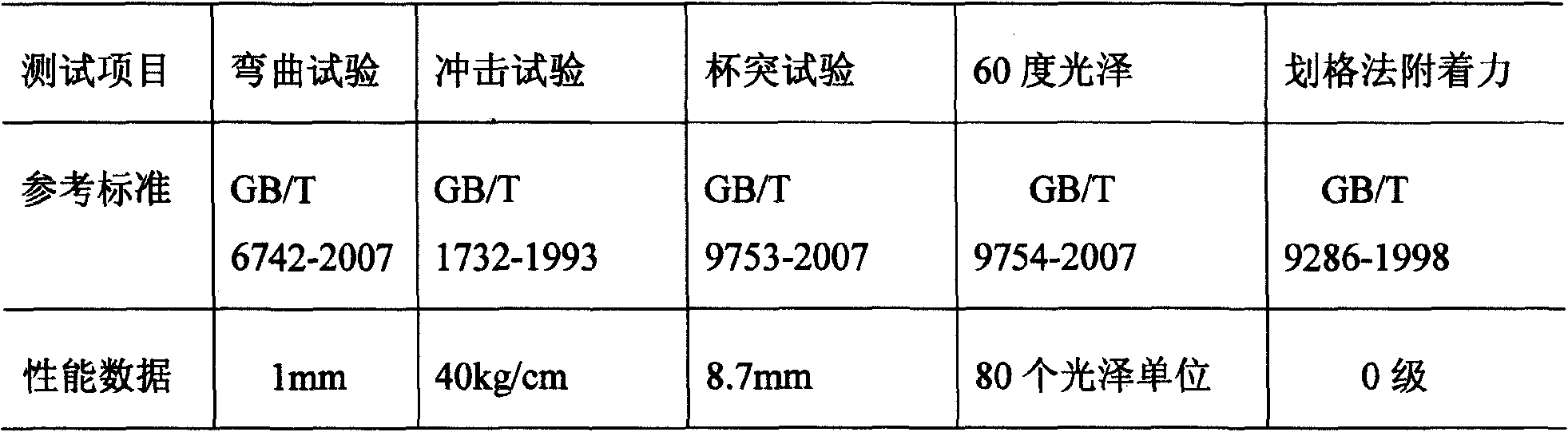

Powder coating with super-weathering resistance, preparation method and application thereof

InactiveCN101671518AWith super weather resistanceThe ratio is scientific and reasonablePowdery paintsPolyester coatingsPliabilityUltraviolet

The invention discloses powder coating with super-weathering resistance, a preparation method and an application thereof. The powder coating comprises the following raw materials in parts by weight: 40-90 parts of weather-resistant polyester resin, 3-30 parts of thermosetting fluorocarbon resin, 4-50 parts of curing agent, 0.1-1.5 parts of flatting agent, 0.2-0.8 part of degasifying agent, 0-4.5 parts of defoaming agent and 4-45 parts of pigment and filler. The powder coating with super-weathering resistance provided by the invention has scientific and reasonable proportioning in the aspects of raw material composition and raw materials, fine comprehensive properties such as flexibility, hardness, adhesive force and the like, stable chemical property, easy storage, performances of acid rain, ozone, ultraviolet ray and chemical medicine resistance and the like in long-term outdoor use, environment protection and wide application range. The preparation method provided by the invention has reasonable processes, strong operability, high qualified rate of finished products and capability of realizing industrialized production.

Owner:TIGER DRYLAC TAICANG

Photocuring/thermosetting inkjet composition and printed wiring board using same

The invention provides a photocurable and thermosetting composition for inkjet, which contains: (A) a monomer having an acryl group or a methacryloyl group and a thermosetting functional group in the molecule; (B) a weight average molecular weight of 700 or less of the photoreactive diluent and (C) photopolymerization initiator other than the component (A), and the viscosity of the composition is 150 mPa·s or less at 25°C. The composition is used to directly draw a solder resist pattern on a printed circuit board with an inkjet printer, and is cured once by irradiating active energy rays, and then further heated and cured.

Owner:TAIYO HLDG CO LTD

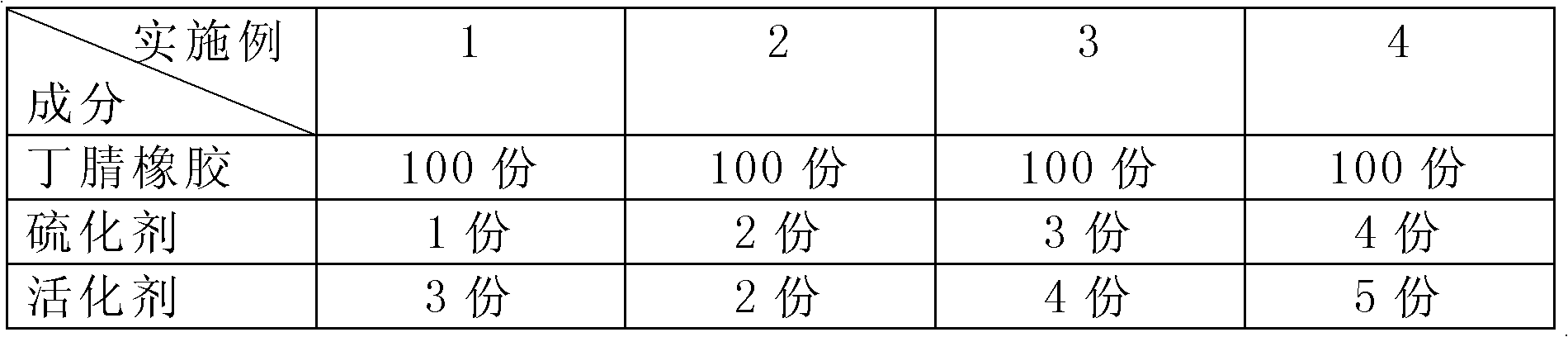

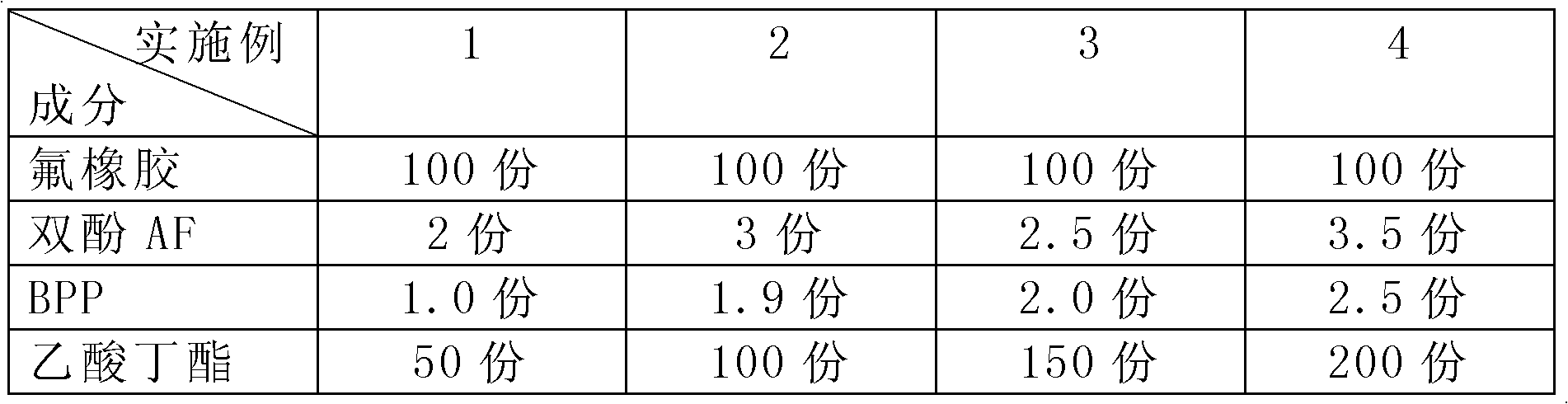

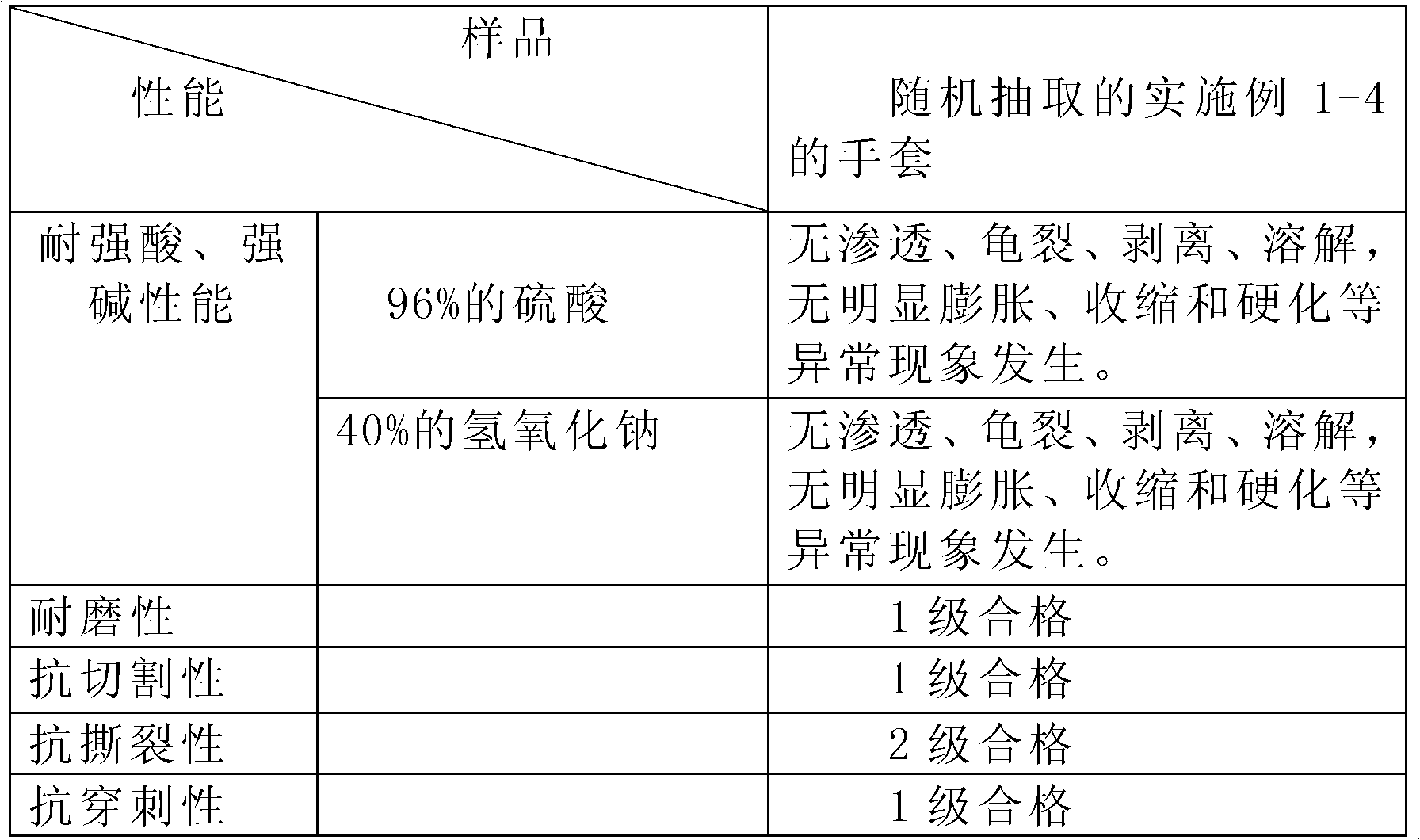

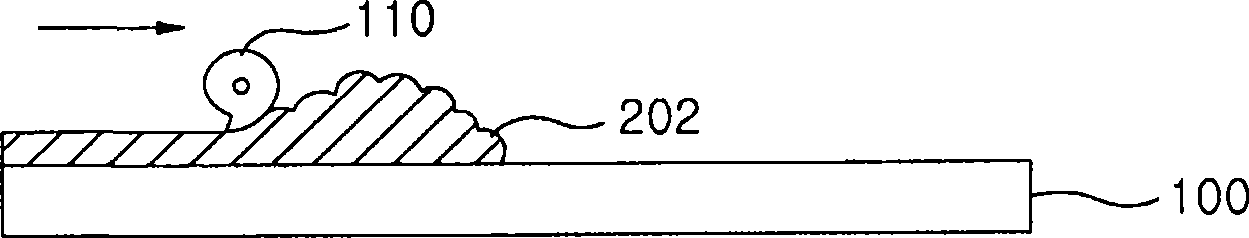

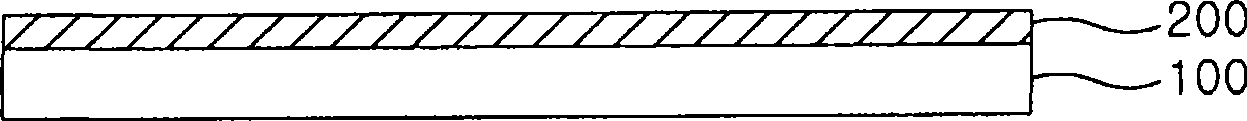

Fluorine/butadiene rubber composite glove and manufacturing method thereof

The invention relates to a fluorine / butadiene rubber composite glove and a manufacturing method thereof, belonging to the technical field of labour protection appliances. The glove comprises a fiber glove lining, the surface of the fiber glove lining is coated with a butyronitrile emulsion layer, the surface of the butyronitrile emulsion layer is coated with a fluorine rubber layer, and fluorine rubber particles are sprayed on the surface of the fluorine rubber layer, wherein the butyronitrile emulsion layer comprises the components such as butyronitrile rubber, a vulcanizer and an activator,and the fluorine rubber cement comprises the components of the fluorine rubber, the vulcanizer, a vulcanization accelerator and an ester solvent. The method for manufacturing the glove comprises three steps burdening, soaking cement and pouring cement. The glove and the manufacturing method in the invention have the following advantages: the performances of resistances to chemicals, strong acid, strong alkali and corrosion are achieved, and the cost is lower; and meanwhile, the method for manufacturing the glove adopts a flow line production manner during the production process, the product process is simple, the cost is lowers, and the glove is applicable to large-scale industrialized production.

Owner:台州达顿安防科技有限公司

Reinforced PA6/ABS(Polyamide 6/Acrylonitrile-Butadiene- Styrene) alloy material and preparation method thereof

InactiveCN102558849AFix stability issuesSolve the disadvantage of easy warpingGlass fiberHeat resistance

The invention relates to a reinforced PA6 / ABS(Polyamide 6 / Acrylonitrile-Butadiene- Styrene) alloy material, belonging to the technical field of polymer materials. The reinforced PA6 / ABS alloy material is characterized by comprising the following components in percentage by weight: PA6 30-70, ABS 10-50, anti-impact modifier 5-15, glass fiber 10-40, compatilizer 1-10, antioxidant 0.2-1 and lubricant 0.3-0.8. The reinforced PA6 / ABS alloy material has the characteristics of stable size, high strength, high fluidity, chemical resistance, wear resistance, good heat resistance performance,etc. The reinforced PA6 / ABS alloy material can be used for injection molding automotive interior parts, automobile wheel covers, printer gears, sports equipment and other motor products.

Owner:徐州腾飞工程塑料有限公司

Pressure sensitive adhesive composition for transferring flexible substrate

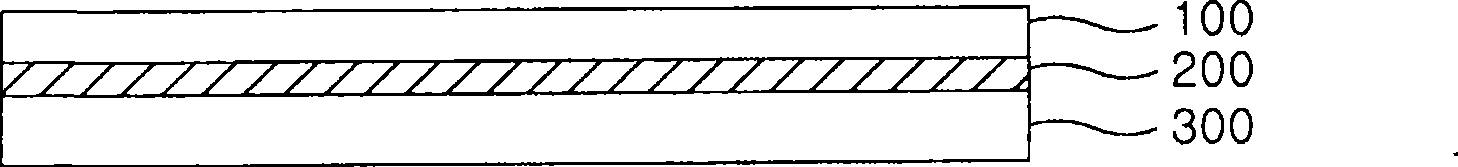

ActiveCN101443429AHeat resistantChemical resistantTemperatue controlAdhesive articlesAntistatic agentLiquid-crystal display

Disclosed herein is an adhesive composition for transporting a flexible substrate, which is used to manufacture a flexible display device using a flexible substrate such as a plastic substrate by using a conventional line for manufacturing a liquid crystal display device comprising a glass substrate. The present invention provides an adhesive composition for transporting a flexible substrate, which includes 100 parts by weight of an adhesive for transporting a flexible substrate and 0.001 to 5 parts by weight of an antistatic agent, an adhesive sheet containing the composition, and a method of transporting a flexible substrate using the same.

Owner:LG CHEM LTD

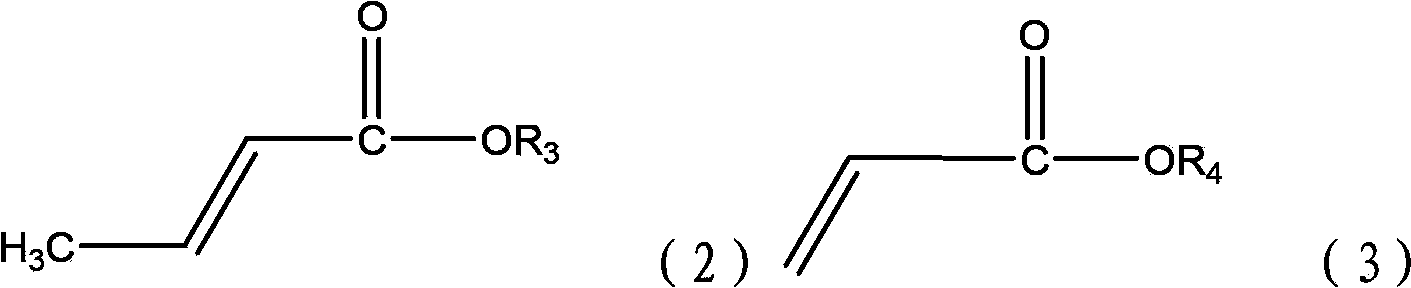

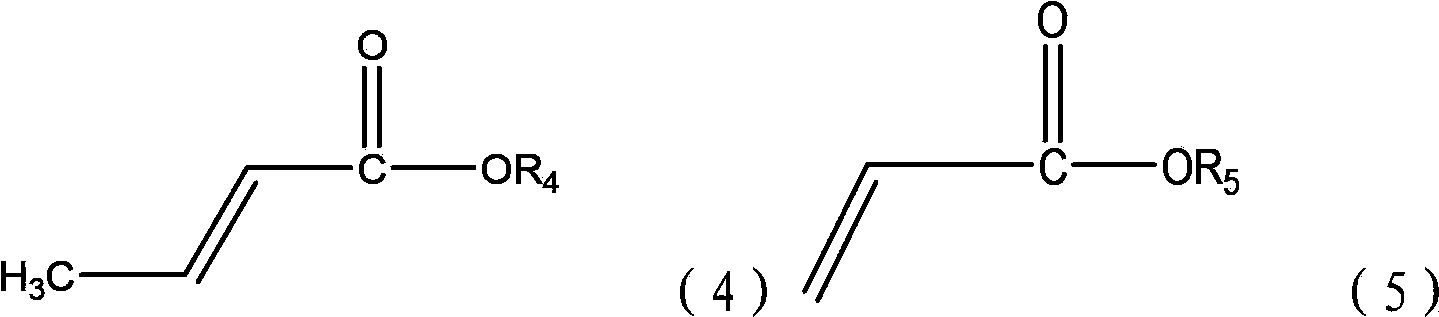

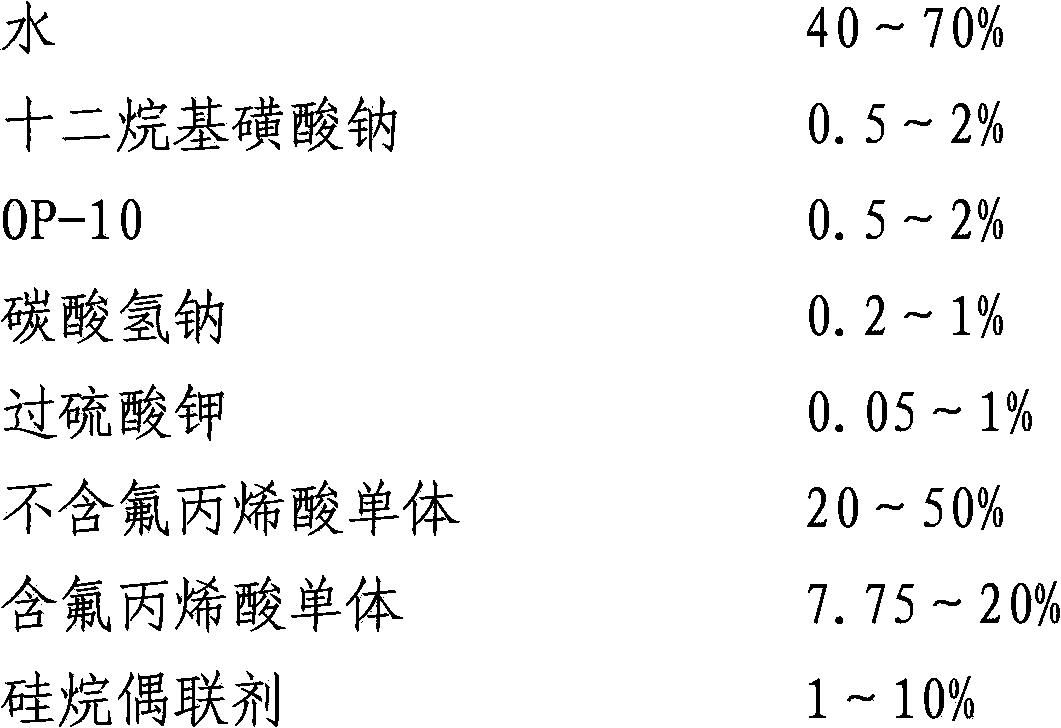

Preparation method of super-hydrophobic coating with phase change function

ActiveCN103666159AMaintain phase change abilityEasy to use in large areaCoatingsMicroballoon preparationMicro nanoWater based

The invention discloses a preparation method of a super-hydrophobic coating with a phase change function applied to the fields of a building exterior wall and a thermal insulation pipeline, and relates to the technical fields of coatings and general heat insulation. The super-hydrophobic phase-change coating with a micro-nano secondary structure is built by a composite water-based fluorine silicone acrylic emulsion, an organic phase-change microcapsule and nano particles. The fluorine silicone acrylic emulsion, the organic phase-change microcapsule, the nano particles, a defoamer and water are evenly mixed, and then dispersed by adopting a high-speed disperser or an ultrasonic crusher for 0.3-2 hours, so as to obtain the super-hydrophobic coating. The preparation method disclosed by the invention is simple, the prepared super-hydrophobic coating has heat-insulating and self-cleaning properties, and large-area construction is facilitated.

Owner:PIPECHINA SOUTH CHINA CO

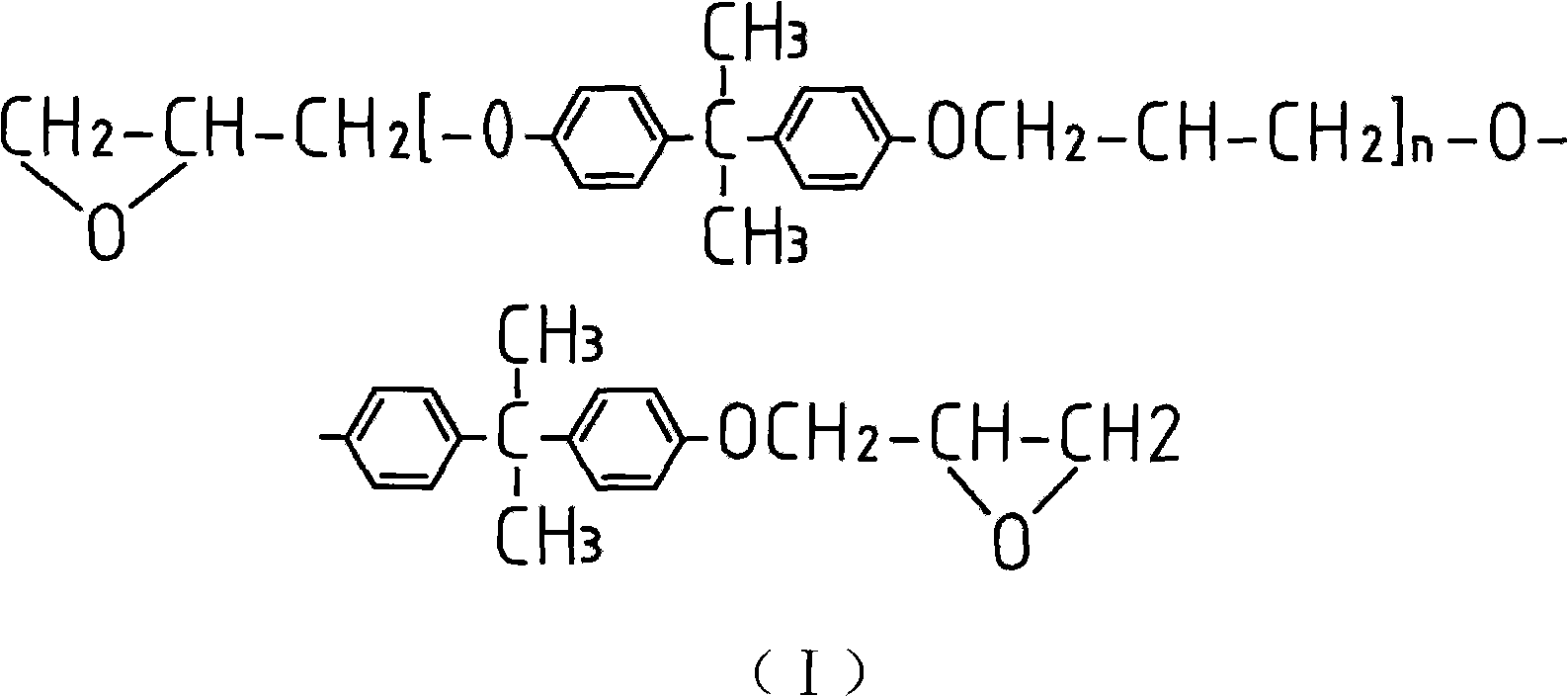

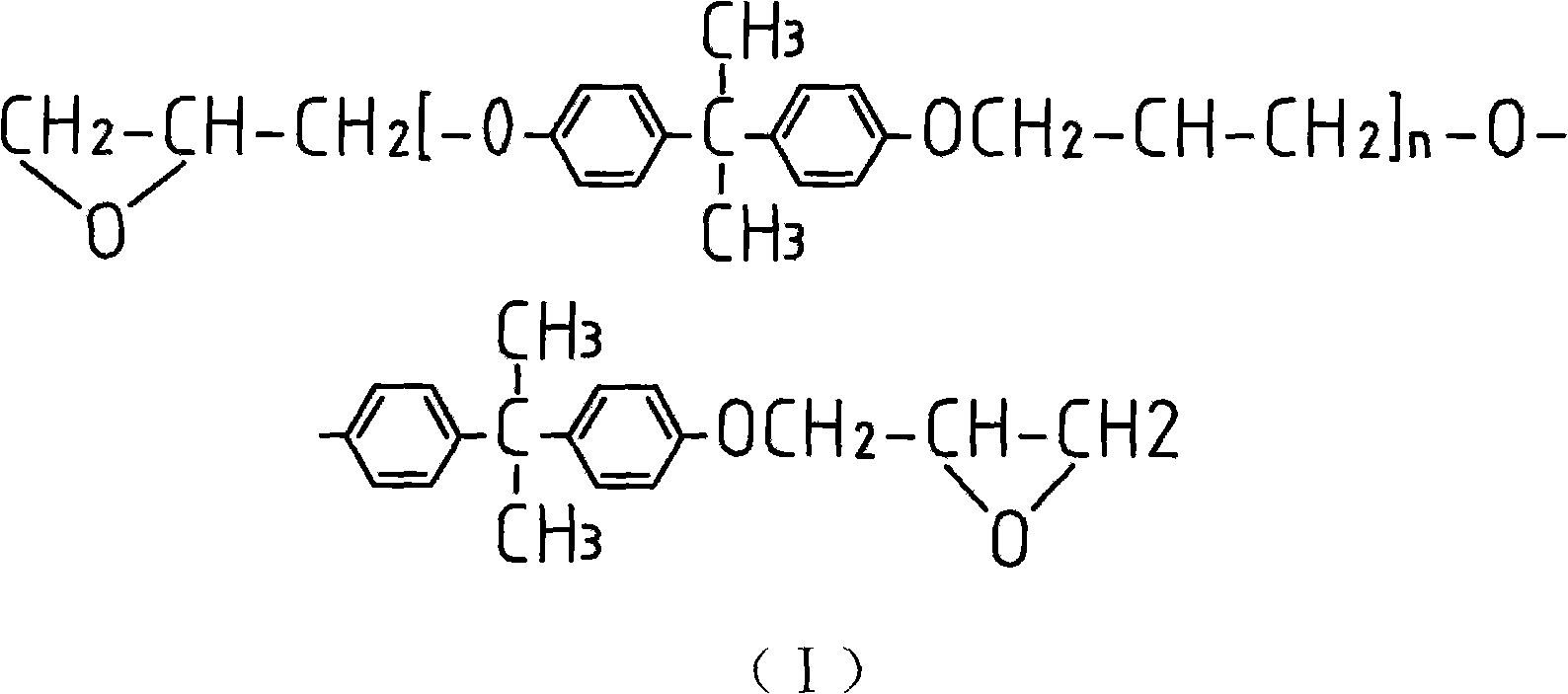

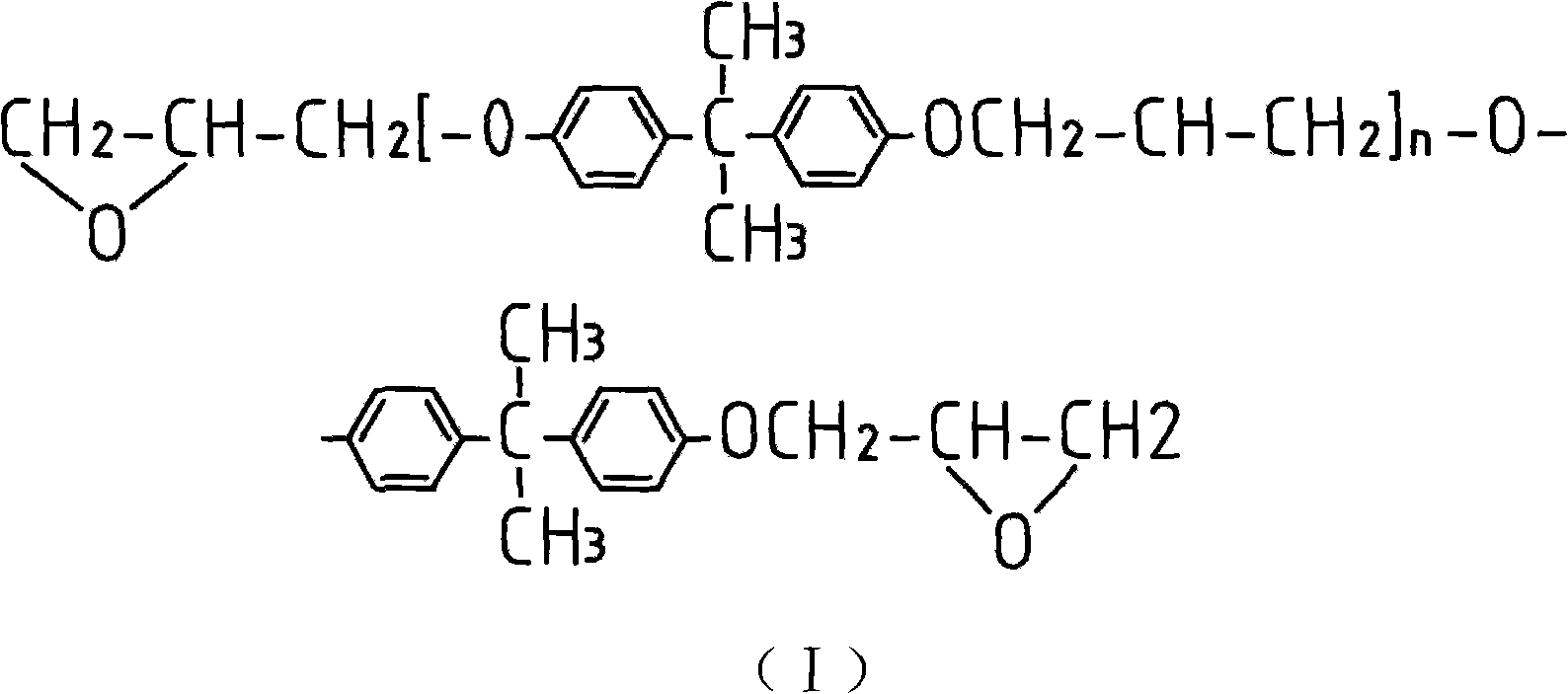

Epoxy resin composition for transformers and process for casting transformer by composition

The invention relates to the technical field of resin, in particular to an epoxy resin composition for transformers and a process for casting a transformer by the composition. The composition comprises epoxy resin, a curing agent, a toughening agent and an accelerating agent, the epoxy resin is a mixture of general formula (I), the epoxy groups on both terminals have reactive activity in the composition unit of the general formula (I), bisphenol A framework provides strong toughness and thermal endurance, a methylene chain has flexibility, ether bond has chemical resistance, and hydroxyl has reactivity and adhesiveness. Brominated epoxy resin of halogenated epoxy resin is taken as an fire retardant, and can be reactive fire retardant and also as flame retardant epoxy resin, thus fire resistance of the cast coil is good, and local discharge is small.

Owner:广东康德威电气股份有限公司

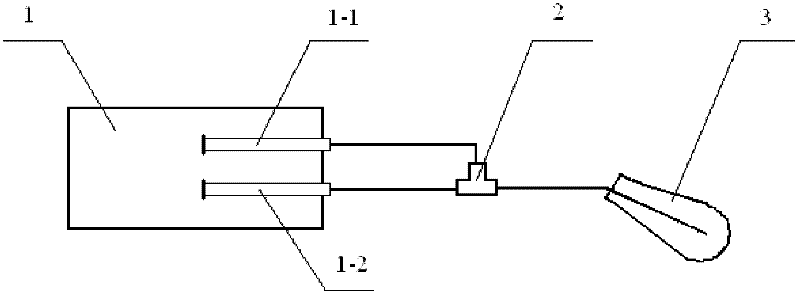

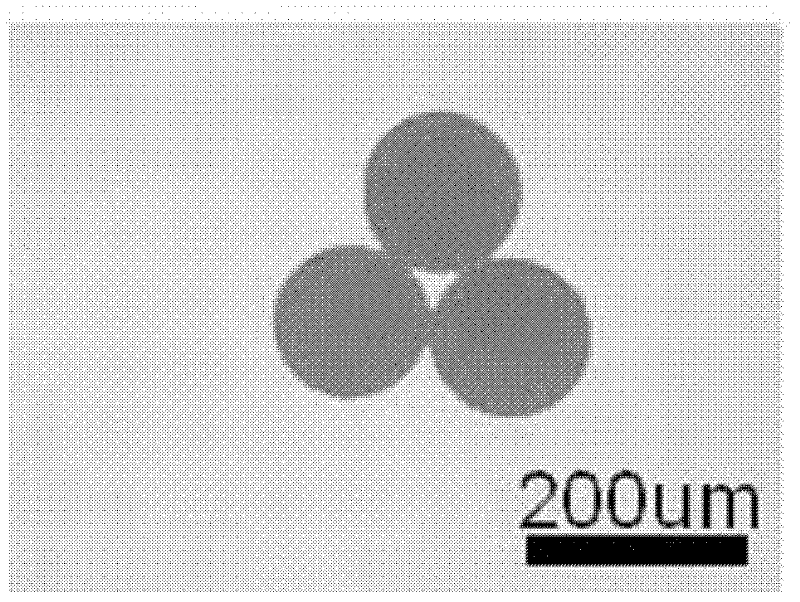

Microfluidic-control preparation method for microsphere of polymethylmethacrylate-coated cadmium telluride (CdTe) quantum dot

InactiveCN102504822AUniform shapeConsistent and uniform sizeLuminescent compositionsInjectorQuantum dot

The invention relates to a microfluidic-control preparation method for a microsphere of a polymethylmethacrylate-coated cadmium telluride (CdTe) quantum dot, and relates to a preparation method for the microsphere of a polymethylmethacrylate-coated CdTe quantum dot. The microfluidic-control preparation method for the microsphere of the polymethylmethacrylate-coated (CdTe) quantum dot aims to solve the problems that the surface of the quantum dot needs to be modified and the quantum dot is easy to dissolve by the microsphere of the polymethylmethacrylate-coated CdTe quantum dot by adopting a traditional preparation method for the microsphere of the polymethylmethacrylate-coated CdTe quantum dot. The method comprises the following steps: preparing a sodium hydrogen telluride solution; preparing a CdTe quantum dot; preparing a polymer solution; connecting a microfluidic-control system; respectively putting the polymer solution and silicone oil into injectors A and B of the microfluidic-control system; setting the propulsion speed of the injectors A and B; after starting, formed liquid beads flow into a rotary evaporator; and curing and evaporating the silicone oil to obtain the microsphere of the polymethylmethacrylate-coated CdTe quantum dot. In the microfluidic-control preparation method for the polymethylmethacrylate-coated CdTe quantum dot, the polymethylmethacrylate-coated CdTe quantum dot is selected, therefore, fluorescence is stable, and the microsphere can be adjusted in size and can be used for field of fluorescent display and the like.

Owner:HEILONGJIANG UNIV

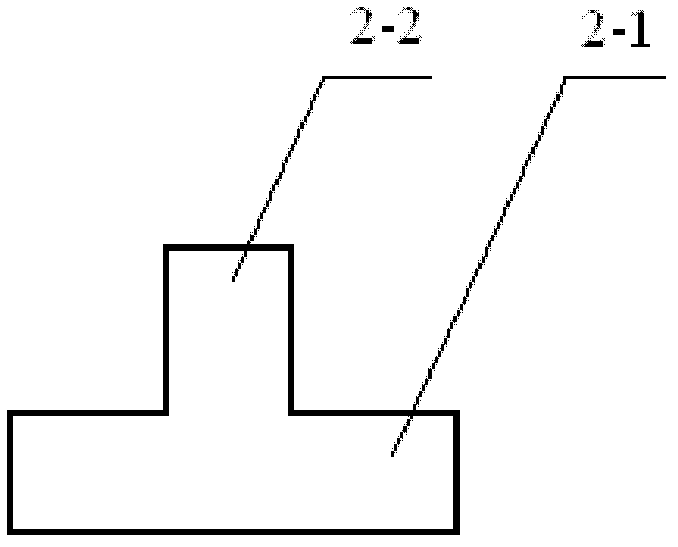

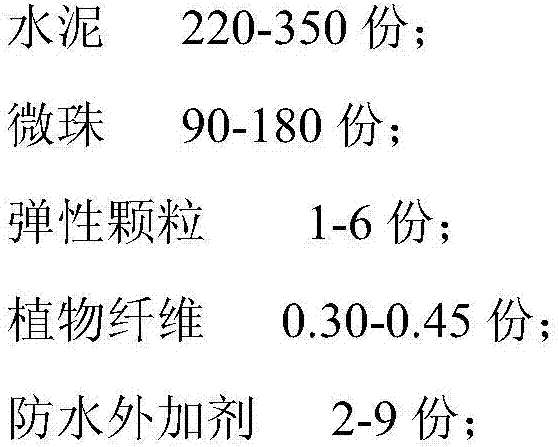

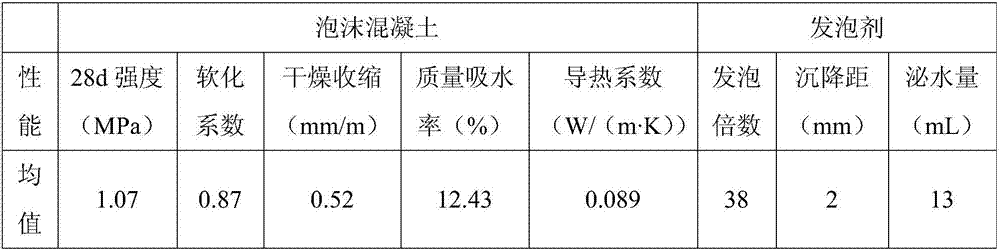

Waterproof crack-resistant foam concrete and manufacture method

The invention discloses waterproof crack-resistant foam concrete and a manufacture method thereof. The waterproof crack-resistant foam concrete is formed by mixing and stirring of raw materials including, by weight, 220-350 parts of cement, 90-180 parts of microspheres, 1-6 parts of elastic particles, 0.30-0.45 parts of palm filaments, 60-160 parts of water, 2-9 parts of waterproof admixtures and foam. The waterproof crack-resistant foam concrete and the manufacture method thereof have the advantages that the raw materials such as industrial by-products, tailings powder or waste rubber powder and the palm filaments are adopted, and the multi-scale toughening principle on compounding of the elastic particles and fibers is followed, so that strength and crack resistance of the foam concrete are improved, and waste resource utilization is benefited; the adopted waterproof admixtures are highly compatible with other materials, and accordingly, water resistance and durability of the foam concrete are improved effectively; by the prepared foam which is fine, uniform and high in stability, anti-permeability and thermal performance of the foam concrete are improved; the foam concrete is applicable to heat insulation of building walls and roofs and roadbed refilling materials for highways in regions with soft soil and high water level.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

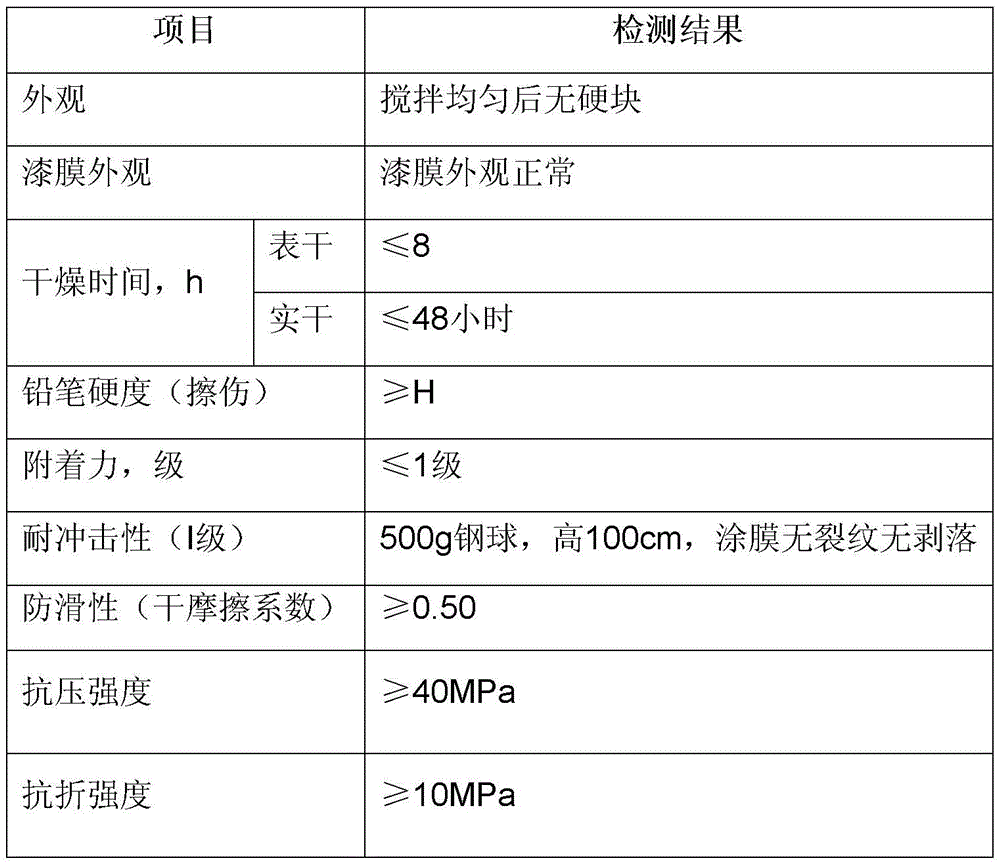

Aqueous epoxy coating for terraces, and preparation method thereof

The invention discloses an aqueous epoxy coating for terraces, and a preparation method thereof. The aqueous epoxy coating for terraces comprises 1.2-1.3 parts of an aqueous epoxy curing agent, 1 part of bisphenol A liquid epoxy resin, and 7-8 parts of a third component, wherein the third component is prepared through mixing 20-30 parts of high grade cement, 15-20 parts of coarse quartz sand, 40-50 parts of fine quartz sand, 0.1-0.2 parts of a water reducer, 0.1-0.3 parts of an antifoaming agent and 0.1-0.3 parts of cellulose. The aqueous epoxy coating for terraces, disclosed in the embodiment of the invention, has good strong acid, strong alkali, wear, pressure, impact, mildew, water, dust and skid resistance, has the advantages of simple preparation method and long service life, avoids obvious connection seams between an original coating layer and a new repairing coating layer as a maintaining and repairing material, and keeps good cracking resistance, flexural strength and compressive strength in the repairing position.

Owner:FIRST NEW MATERIAL TECH DEV

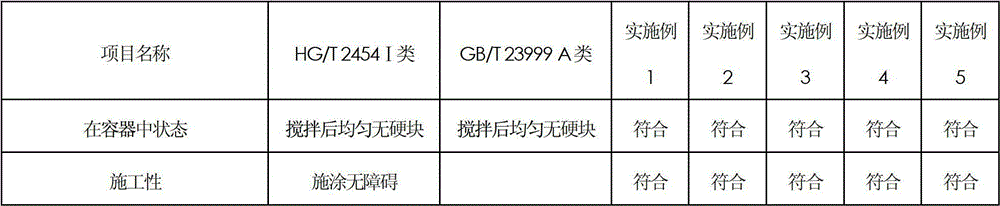

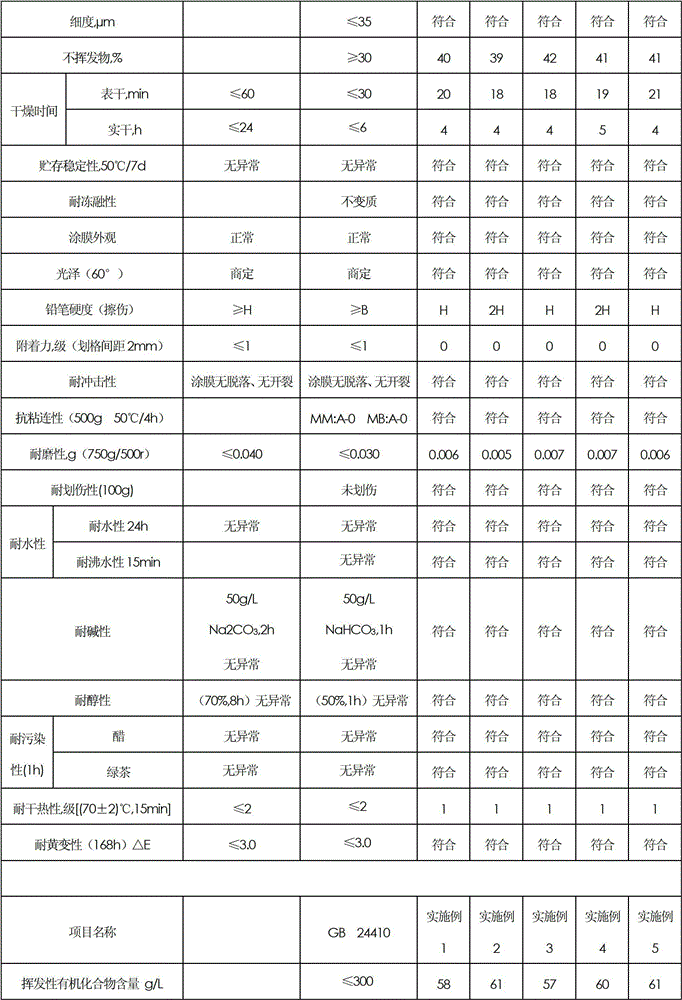

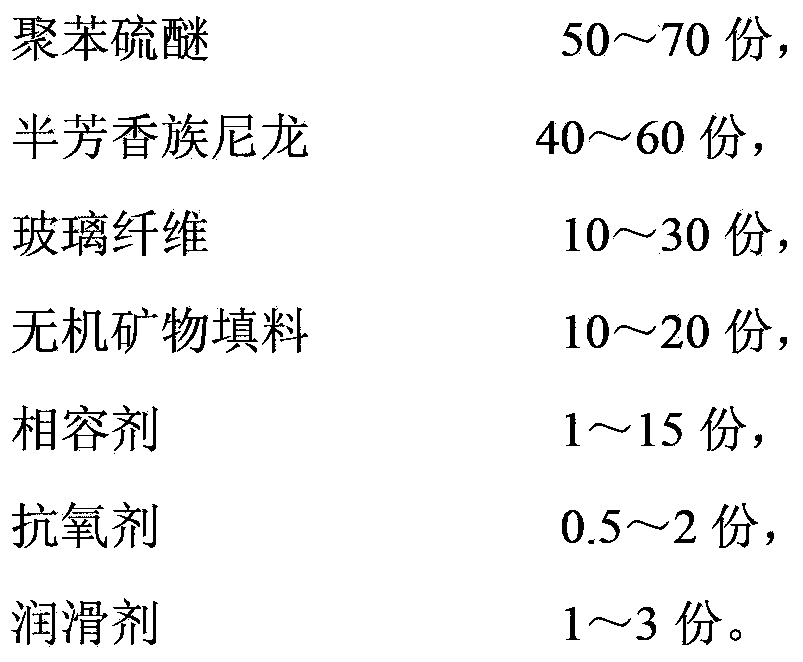

Monocomponent wear-resistant aqueous polyurethane wood floor coating for container and preparation method thereof

ActiveCN102746777AAdhesiveChemical resistantPigmenting treatmentPolyurea/polyurethane coatingsPolymer scienceCoating system

The invention discloses monocomponent wear-resistant aqueous polyurethane wood floor coating for containers and a preparation method thereof. The coating is composed of deionized water, aqueous fatty group polyurethane resin, nanometer alumina slurry, wetting dispersant A, wetting dispersant B, a pH regulator, a composite film-forming auxiliary agent, an antifoaming agent and a thickening agent. According to the invention, the nanometer alumina is effectively dispersed in the aqueous coating system through the preparation of the nanometer alumina slurry, enabling the coating to have excellent combination properties such as wear resistance, high hardness, high gloss and good adhesion, and both the quality and performance of the coating reach and go far beyond the GB / T 23999-2009 type A standard. With simple and convenient application, safety storage and stable performance, the product obtained through the invention contains no harmful substances such as benzene series, glycol ether and ester thereof, free formaldehyde and soluble heavy metals, and has excellent environmental protection performance which is significantly better than solvent coating, and reach and go far beyond the GB 24410-2009 standard,.

Owner:GUANGZHOU JOINTAS CHEM

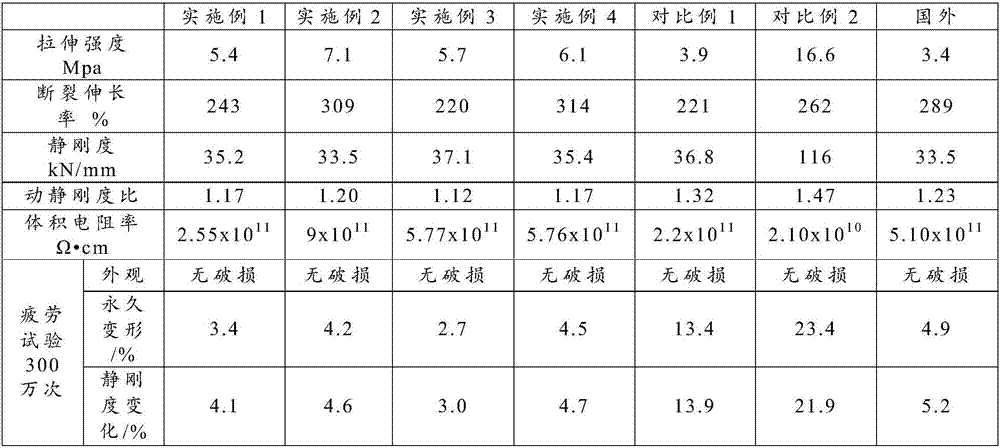

Polyurethane micropore elastomer composite material of low spring rate ratio for urban rail and preparation method thereof

The invention provides a polyurethane micropore elastomer composite material of low spring rate ratio for urban rail and a preparation method thereof, and belongs to the field of polyurethane materials. The material has the excellent performance of high strength, wear resistance, flex resistance, low temperature resistance and oil resistance, chemical resistance and the like, and has the characteristics of low buffer stress, stable damping, short response time and the like. The polyurethane micropore elastomer composite material of low spring rate ratio for urban rail comprises a polyurethane main material, the polyurethane main material is prepared by mixing a component A and a component B, the component A is prepared by the following materials: 75-90% of polyether polyol, 8-18% of a chain extender, 0.5-1% of an anti-oxidant, 0.5-1% of an amine catalyst, 0.1-0.5% of a foaming agent, 1-4% of an organosilicon foam stabilizer, and 0.1-0.5% of color paste. The materials are uniformly mixed at 100-120 DEG C, the water content in the mixture is below 0.05%, and that is the component A; the component B is obtained by a reaction of 30-60% of isocyanate and 40-70% of polyol at 80-90 DEG C for 3-4 hours.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

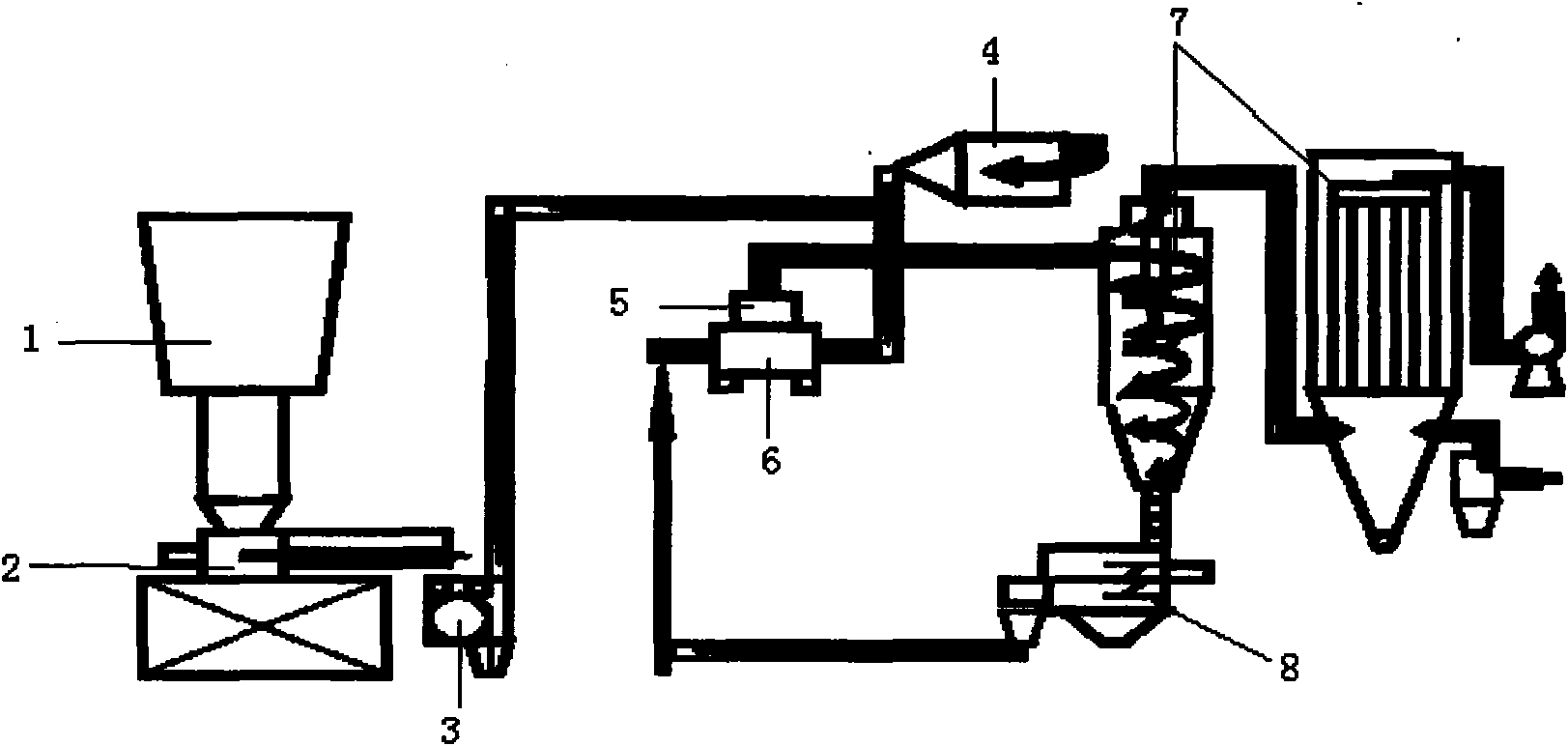

Method for manufacturing high-performance polyphenylene sulfide fibre dust removal felt cloth

InactiveCN101177917AGood thermal dimensional stability at high temperatureChemical resistantFiltration separationNon-woven fabricsFiberFiltration

The invention discloses a manufacturing method of a high performance polyphenylene sulfide (PPS) fibre dedusting felt, adopting the steps that: treatment of short fibre, material feeding, grooming, base cloth setting, needling, idle needling, high temperature thermal compression molding and finishing and molding technique. PPS short fibre with a length ranging from 8 to 130mm is treated by spinning oil and is groomed into a fibre net; the fibre net is needled by needling machine on a base cloth woven by 15 to 25 percent of poly (tetrafluoethylene), 20 to 30 percent of ceramics fibre and about 60 percent of PPS filament, then idle needled and high temperature thermal compression molded, and finally finished and produced into high performance PPS fibre dedusting felt. Since 20 to 30 percent of ceramics fibre and 15 to 30 percent of poly (tetrafluethylene) fibre are added, the base cloth has good thermal size stability in high performance, chemical resistance, abrasion resistance, and excellent dust collecting and elimination effect, which is suitable for acted as professional filtration material in the thermal power generation plant, the rubbish burning furnace and the metallurgy industry.

Owner:SICHUAN DEYANG CHEM

Polyurethane microporous elastomer with characteristics of rubber and preparation method thereof

The invention discloses a polyurethane microporous elastomer with characteristics of rubber and a preparation method thereof. The preparation method comprises the following steps: heating and mixing polyester polyol A1, polyester polyol A2, polyester polyol A3, a chain extender, tertiary amine or organic metal catalyst, an organosilicon foam stabilizer and a foaming agent in a reaction kettle to obtain a component A; mixing diisocyanate, polyester polyol B1, polyester polyol B2, polyester polyol B3 and a side reaction inhibitor in a reaction kettle to react, thereby obtaining a component B; and thoroughly mixing the components A and B, and reacting to obtain the polyurethane microporous elastomer. The polyurethane microporous elastomer with characteristics of rubber is suitable to be used as a sole material, and has the advantages of excellent processability, mechanical properties, hydrolysis resistance and low-temperature resistance. The prepared sole is light and comfortable; and meanwhile, a double-component system and a cast molding technique which are used are simple and easy to control, thereby enhancing the competitive power of the traditional sole materials, such as polyurethane microporous elastomer materials, rubber and the like.

Owner:ZHEJIANG HUAFON NEW MATERIALS CO LTD

Process for spraying fluorocarbon wood grains on surface of sectional material

InactiveCN101596519AWeather resistantResist supernatural powersPretreated surfacesSpecial surfacesWeather resistanceMetallurgy

The invention provides a process for spraying fluorocarbon wood grains on the surface of a sectional material. At first, first PVDF fluorocarbon powder is sprayed on the surface of the sectional material and is roasted at the intermediate temperature of 150+ / -10 DEG C for 15+ / -3min, so that the PVDF fluorocarbon powder forms a gelling state on the surface of the sectional material; after cooling, the sectional material is sprayed with PVDF fluorocarbon render face-colour powder for the second time and is roasted at the intermediate temperature of 150+ / -10 DEG C for 15+ / -3min to form a gelling state, and is fully integrated with first-layer spraying powder; after the sectional material is sprayed with PVDF fluorocarbon powder for twice, the liquid PVDF fluorocarbon paint is sprayed on the wood grain of the sectional material according to the principle of PU roll printing and is roasted at the high temperature of 220+ / -10 DEG C for 40+ / -3min so that the solid PVDF fluorocarbon powder and liquid PVDF fluorocarbon paint are fully integrated and cured; finally, fluorocarbon wood grain effect is obtained on the surface of the sectional material. The fluorocarbon wood grain has the characteristics of strong weather resistance, heat resistance, low temperature resistance, chemical resistance, and low friction.

Owner:梁志华

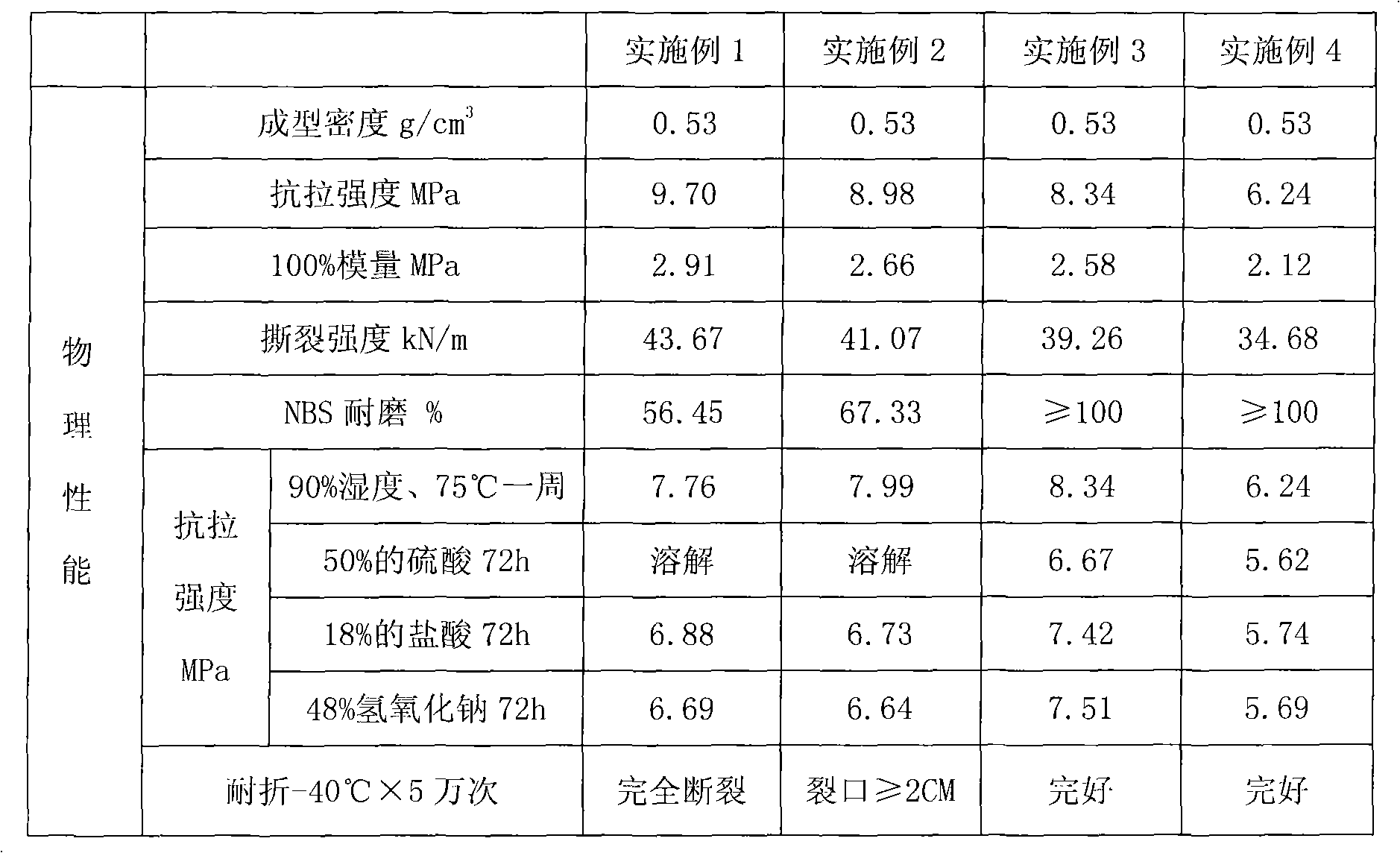

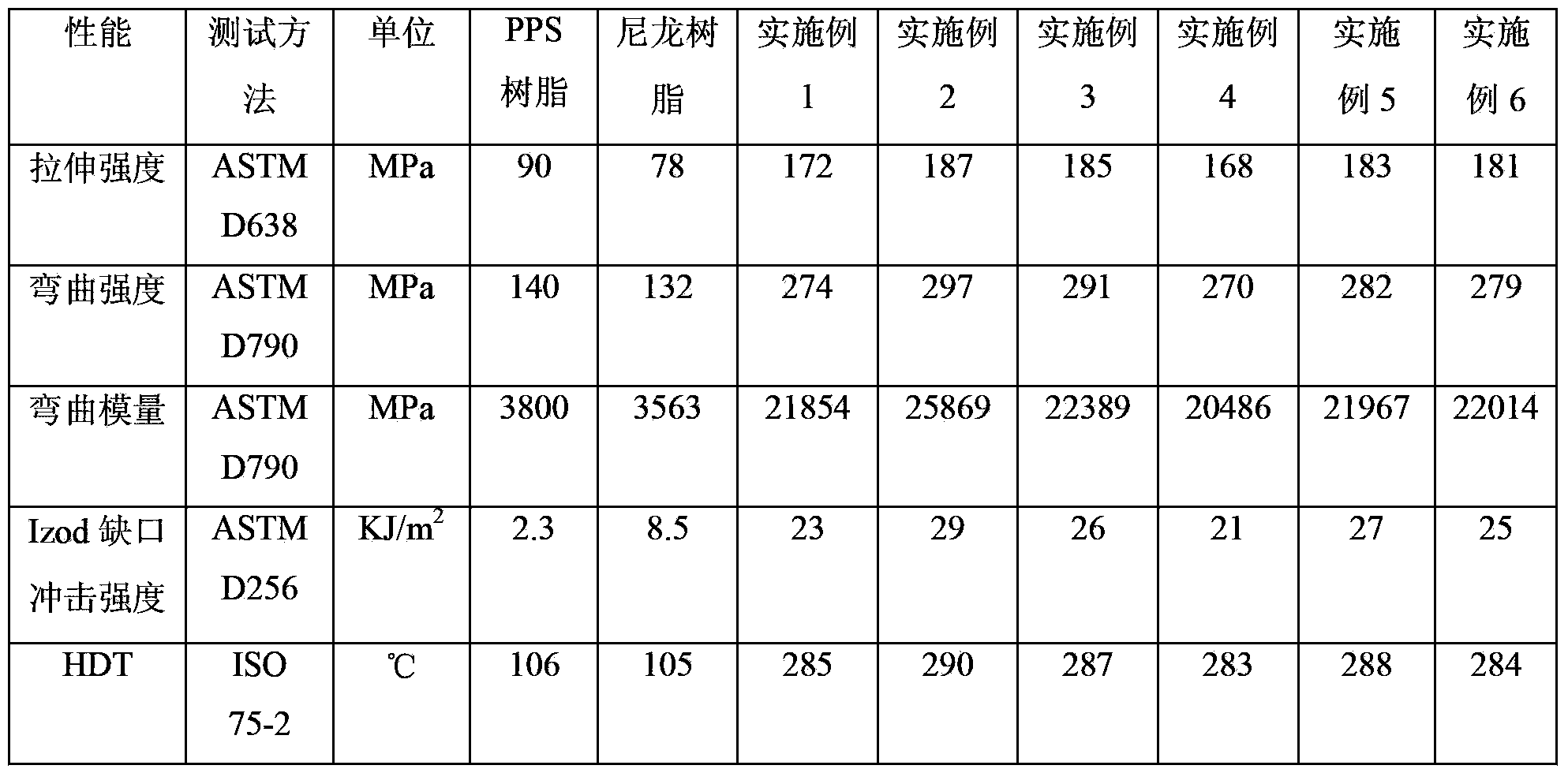

Polyphenylene sulfide/semi-aromatic nylon composite material and preparation method thereof

InactiveCN104277459AHigh mechanical strengthGood thermal stabilityTemperature resistanceHigh polymer

The invention belongs to the technical fields of high-molecular material processing and modification, and relates to a polyphenylene sulfide / semi-aromatic nylon composite material and a preparation method thereof. The composite material is prepared by using the following components, by weight, 50-70 parts of polyphenylene sulfide, 40-60 parts of semi-aromatic nylon, 10-30 parts of a glass fiber, 10-20 parts of an inorganic mineral filler, 1-15 parts of a compatilizer, 0.5-2 parts of an antioxidant and 1-3 parts of a lubricant. The material disclosed in that invention has the advantages of low molding shrinkage, good dimension stability, high toughness, excellent high temperature resistance and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Novel cold-resistant and wear-resistant rubber

The invention discloses novel cold-resistant and wear-resistant rubber which is prepared from following raw materials: 60-100 parts of natural rubber, 40-60 parts of silicone robber, 3-7 parts of melamine resin, 2-4 parts of an anti-aging agent, 2-3 parts of aromatic hydrocarbon oil, 3-8 parts of white carbon black, 3-5 parts of ferric oxide, 1-1.3 parts of stearic acid, 70-85 parts of a cold-resistant agent, 10-15 parts of calcium carbonate, 1-1.5 parts of an accelerant, 3-5 parts of a plasticizer, 1-2 parts of a softener and 1-1.3 parts of a vulcanizing agent. Compared with conventional rubber, the novel cold-resistant and wear-resistant rubber is excellent in cold-resistant performance and is improved in wear-resistant performance, so that the rubber is greatly prolonged in service life. In addition, the novel cold-resistant and wear-resistant rubber has weather resistance and chemical resistance, is high in strength and is good in insulating performance and corrosion resistance. The novel cold-resistant and wear-resistant rubber can be used in a cold severe environment. The rubber is simple in production technology. The raw materials are easy to obtain. The rubber is low in cost.

Owner:QINGDAO DTCN NEW MATERIAL TECH DEV

Water-based lotus-leaf-structured hydrophobic over-printing varnish for wallpaper and preparation method of over-printing varnish

The invention specifically relates to water-based lotus-leaf-structured hydrophobic over-printing varnish for wallpaper and a preparation method of the over-printing varnish, and belongs to the technical field of ink. The technical problem to be solved is to provide an over-printing varnish by using which the surface of a wallpaper product can be smooth, bright and wear-proof and the lotus leaf type waterproof and moisture-roof effects can be realized, and a preparation method of the over-printing varnish. In order to solving the technical problem, the technical scheme adopted is as follows: the water-based lotus-leaf-structured hydrophobic over-printing varnish for the wallpaper is prepared from raw materials including a modified organic silicon polymer emulsion, a non-film-forming acrylate emulsion, an styrene-acrylic emulsion, neutralizing amine, propylene glycol, a water-based coalescing agent, a water-based leveling wetting agent, a mineral defoamer, a water-based nanoscale organosilicon waterproofing agent, a waterborne polyurethane thickening agent, deionized water and an organic silicon defoamer; the raw materials are stirred and mixed in a specific order to form the over-printing varnish.

Owner:山西金博雅油墨科技有限责任公司

Fireproof flame-retarding polystyrene foam and production method thereof

The invention relates to fireproof flame-retarding polystyrene foam which is technically characterized in that an inorganic flame retardant, a water-soluble adhesive, an inorganic dispersing agent, a strength enhancer, water and a foaming agent are added into polystyrene foam plastic granules, extracted from waste polystyrene foam plastics, and ordinary polystyrene foam plastic granules. The invention further provides a production method of the fireproof flame-retarding polystyrene foam. The fireproof flame-retarding polystyrene foam disclosed by the invention has the physical and chemical properties of light weight, cushioning, heat insulation, chemical resistance and the like, and further has the characteristics of simple process, low cost, wide application range, long service life and the like.

Owner:SHENYANG YONGFENG BAINA BUILDING MATERIALS

Nanometer cross-linking PVDF/PU blending hollow fiber ultrafiltration membrane and preparation method

InactiveCN102151498AImprove compatibilityToughness and hydrophilicitySemi-permeable membranesPolyvinylidene fluorideHollow fibre

The invention discloses a nanometer cross-linking PVDF / PU (Polyvinylidene Fluoride / Polyurethane) blending hollow fiber ultrafiltration membrane and a preparation method thereof, wherein the nanometer cross-linking PVDF / PU blending hollow fiber ultrafiltration membrane mainly contains the ingredients of polyvinylidene fluoride (PVDF), polyurethane (PU), nanometer cross-linking agent and solvent, and the nanometer cross-linking PVDF / PU blending hollow fiber ultrafiltration membrane prepared according to the method of the invention integrates the characteristics of two high polymers and nanometer material, and has the advantages of large strength, good tenacity and thermal resistance, excellent pollution resistance, large flux and the like.

Owner:何善媛

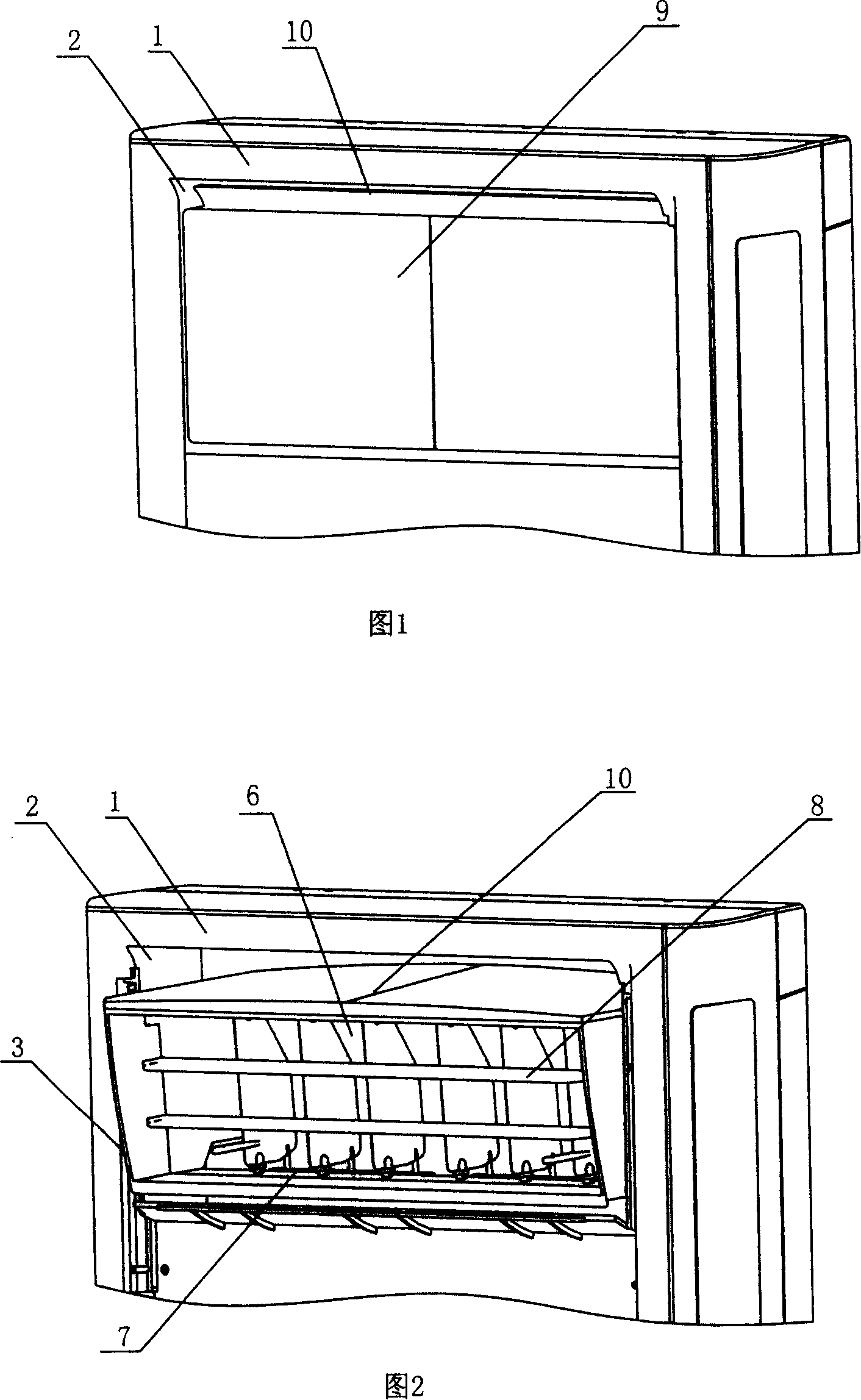

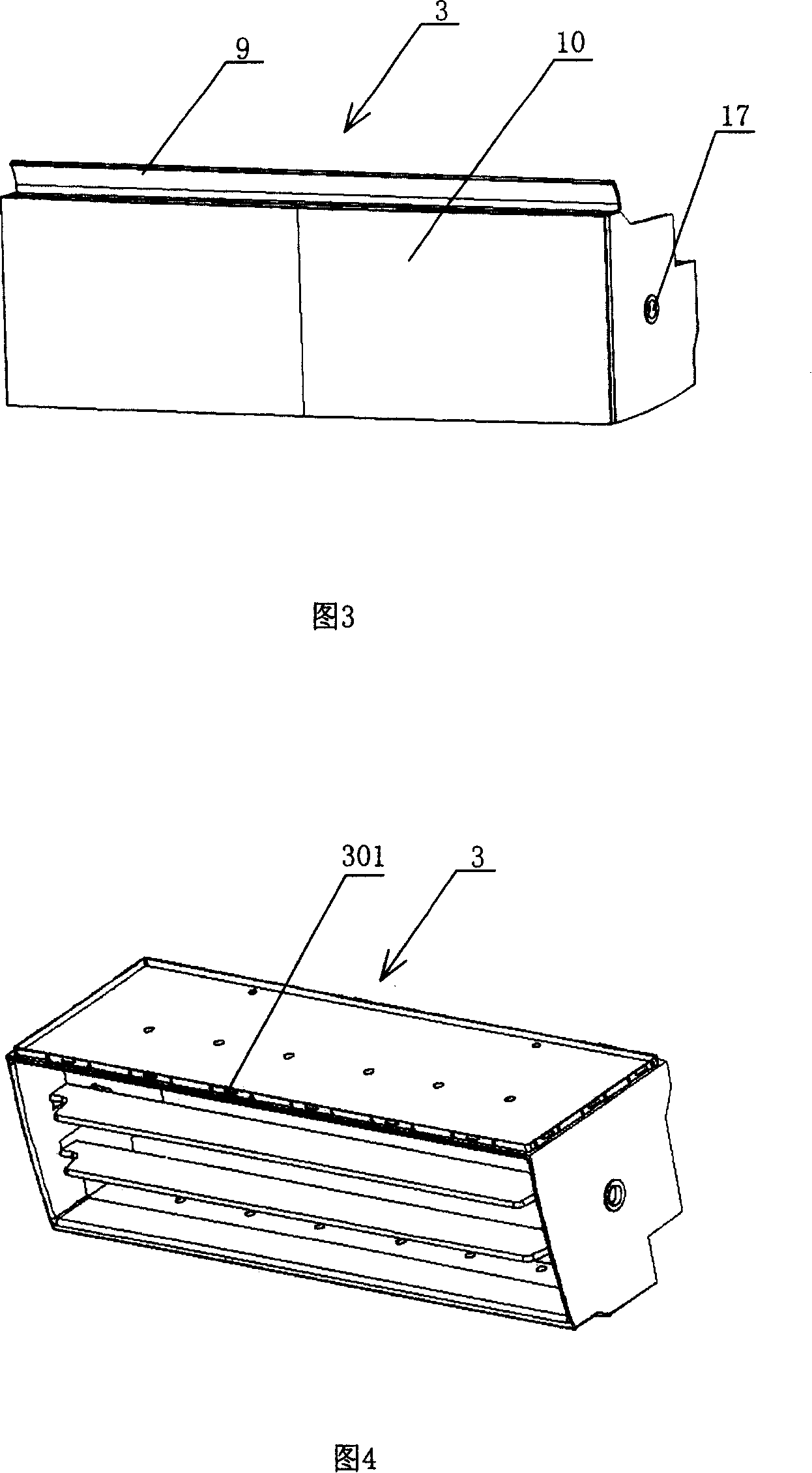

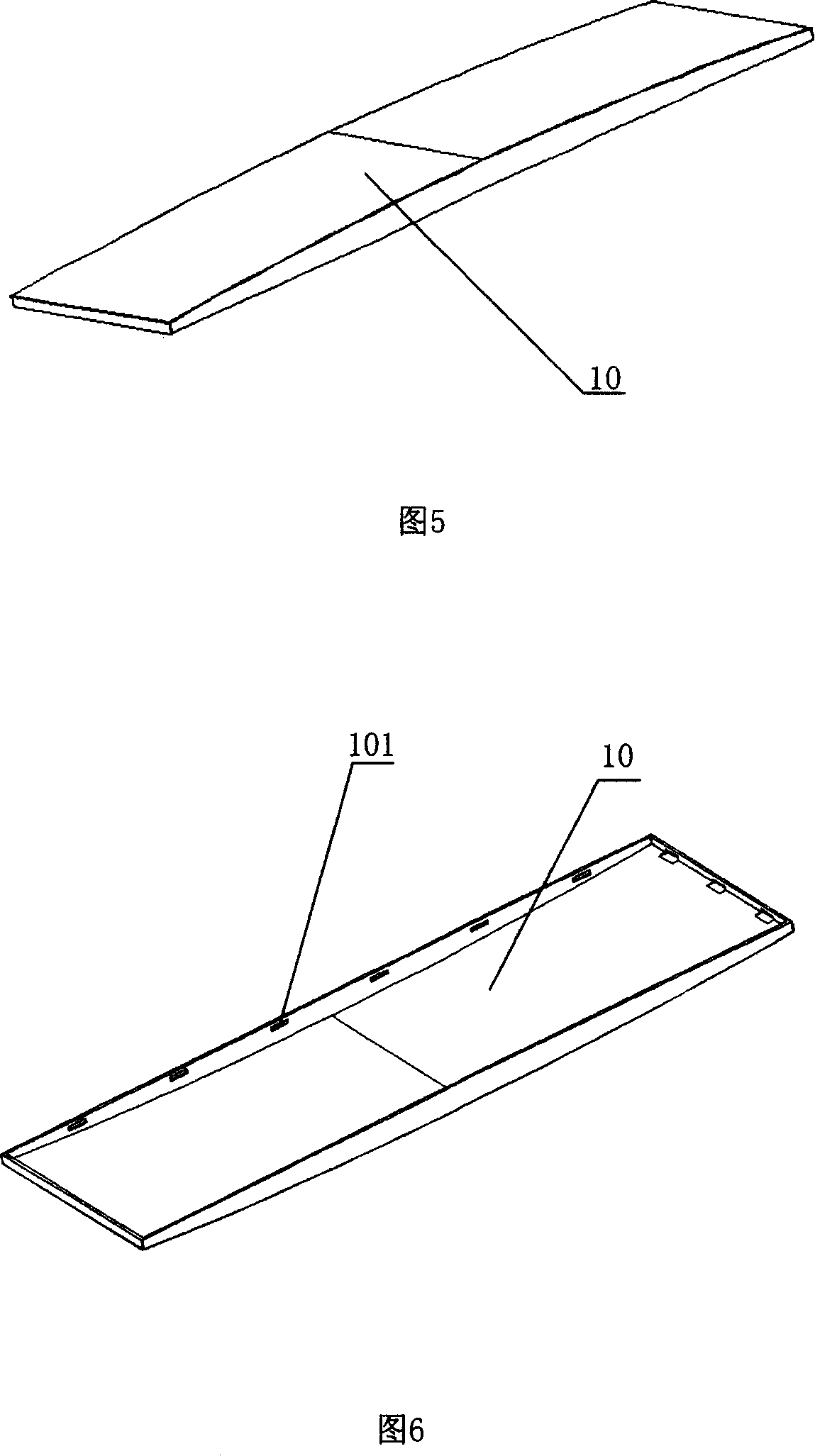

Air conditioner decorative sheet adopting novel technique of transcribing in model and its technique

ActiveCN101153737AAppearance coordinationFashionable and beautiful appearanceLighting and heating apparatusAir conditioning systemsCompression moldingWear resistant

The present invention discloses an air conditioner decorative plate adopting novel technique of transcribing in mold and the technologic method thereof, wherein, the decorative plate is arranged on an air outlet frame inside an air outlet frame of a front panel; the air outlet frame is pivoted inside the air outlet frame, can swing up and down around a shaft to supply air, and can also obstruct an air outlet to prevent dust from entering when an air conditioner is turned off. The decorative plate adopts a novel technique of transcribing in mold, and the technologic method comprises the following steps: firstly, membrane making, which comprises selection of materials for making membrane and printable materials, pattern printing in printed region and drying after making; secondly, positioning and membrane feeding, which comprise membrane feeding of a membrane feeding device, die positioning on the decorative plate and membrane fixing; thirdly, compression molding, which comprises heating for softening the membrane and molding; fourthly, injection molding, which comprises selection of castingresin corresponding to the membrane materials, corresponding to the resin temperature regulation and resin injection; fifthly, post treatment, which comprises taking-out, shearing and processing. The present invention executes silver luster treatment to the whole surface of the decorative plate; thereby the decorative plate is beautiful and stylish in exterior appearance, wear resistant and scratch resistant.

Owner:HAIER GRP CORP +1

Nano silicon salt filler zinc-aluminum composite thermal-insulation coating and preparation method thereof

InactiveCN104673034ASelf-lubricatingWith wear resistanceFireproof paintsEpoxy resin coatingsEpoxyPowder talc

The invention discloses a nano silicon salt filler zinc-aluminum composite thermal-insulation coating. The coating comprises, in parts by mass, 18-24 parts of a silicone-acrylate emulsion, 12-14 parts of rutile type titanium dioxide, 2-4 parts of an aid, 55-60 parts of functional filler, 3-4 parts of propylene glycol, 10-15 parts of PPESK (poly(phthalazinone ether sulphone ketone)) modified resin, 15-25 parts of silicon carbide micro-powder, 15-20 parts of fluorinated graphite and 30-35 parts of a coupling agent, wherein the PPESK modified resin comprises, in parts by mass, 40-70 parts of epoxy resin and 20-35 parts of PPESK; the particle size of the silicon carbide micro-powder is 6 mu m; the particle size of the fluorinated graphite is in a range of 5-10 mu m; the functional filler comprises nano-montmorillonite type silicate and barrier type functional filler in the mass ratio of 1:1.5; the barrier type functional filler comprises, in parts by mass, 2-6 parts of hollow glass beads, 10-15 parts of graphite, 20-35 parts of black silicon carbide, 25-30 parts of fine-grained aluminum oxide, 5-10 parts of molybdenum disulfide, 1-5 parts of zinc oxide and 3-6 parts of talc powder. The invention further designs a preparation method of the nano silicon salt filler zinc-aluminum composite thermal-insulation coating.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

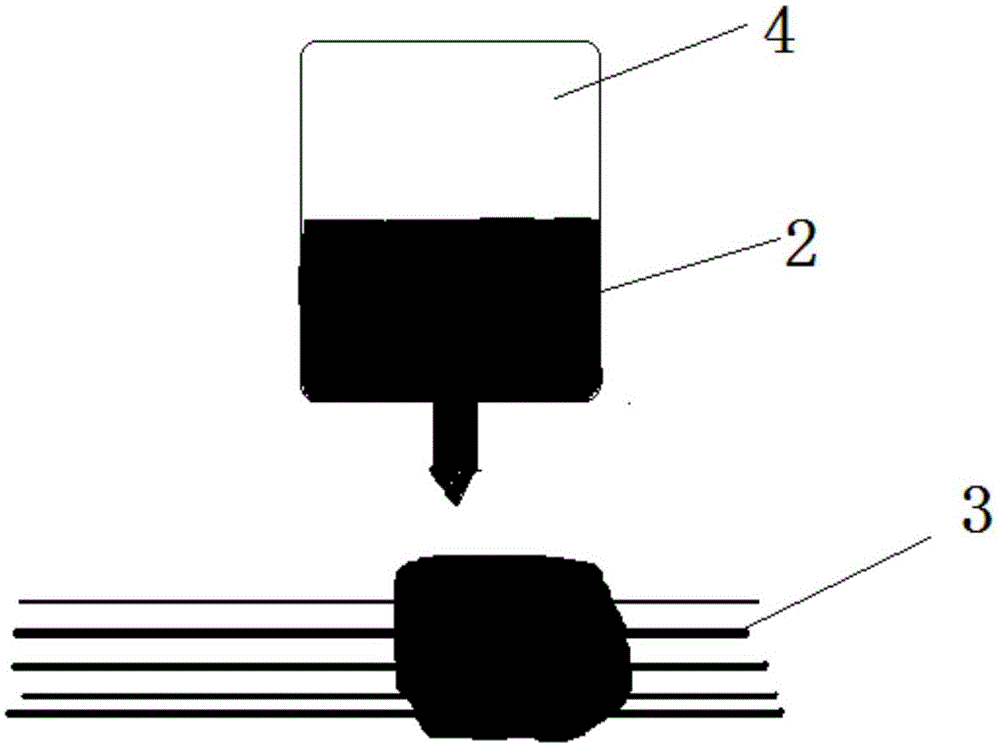

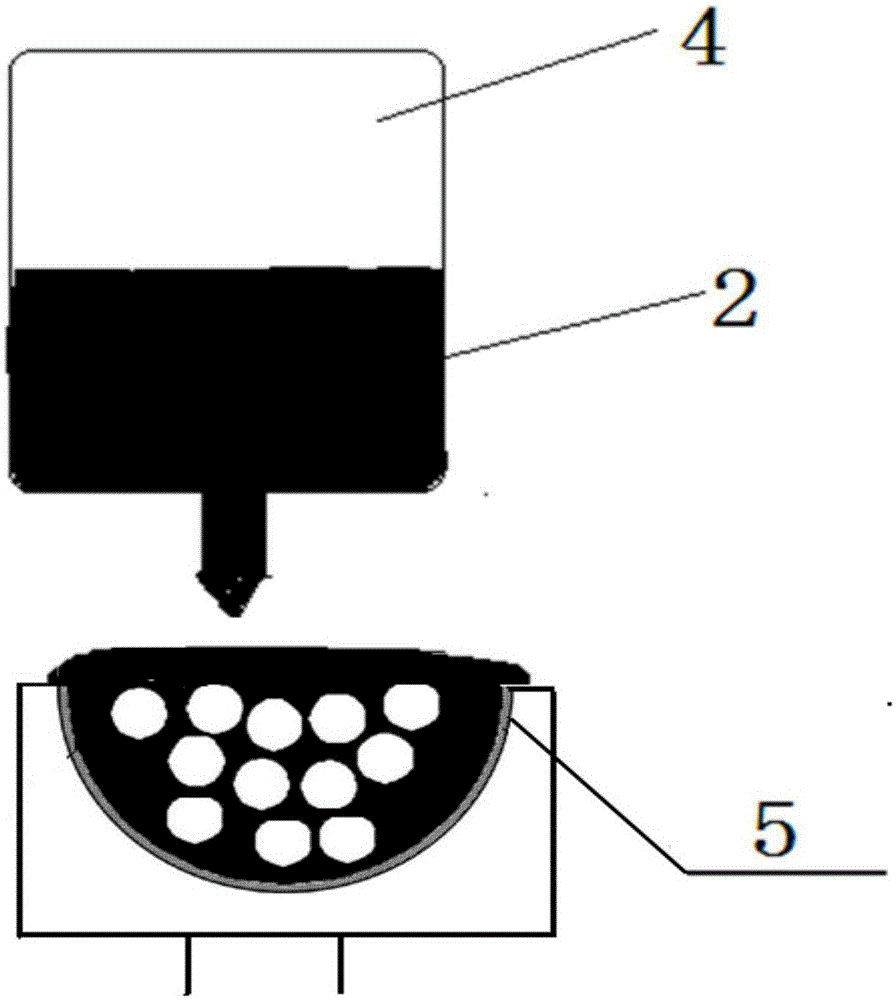

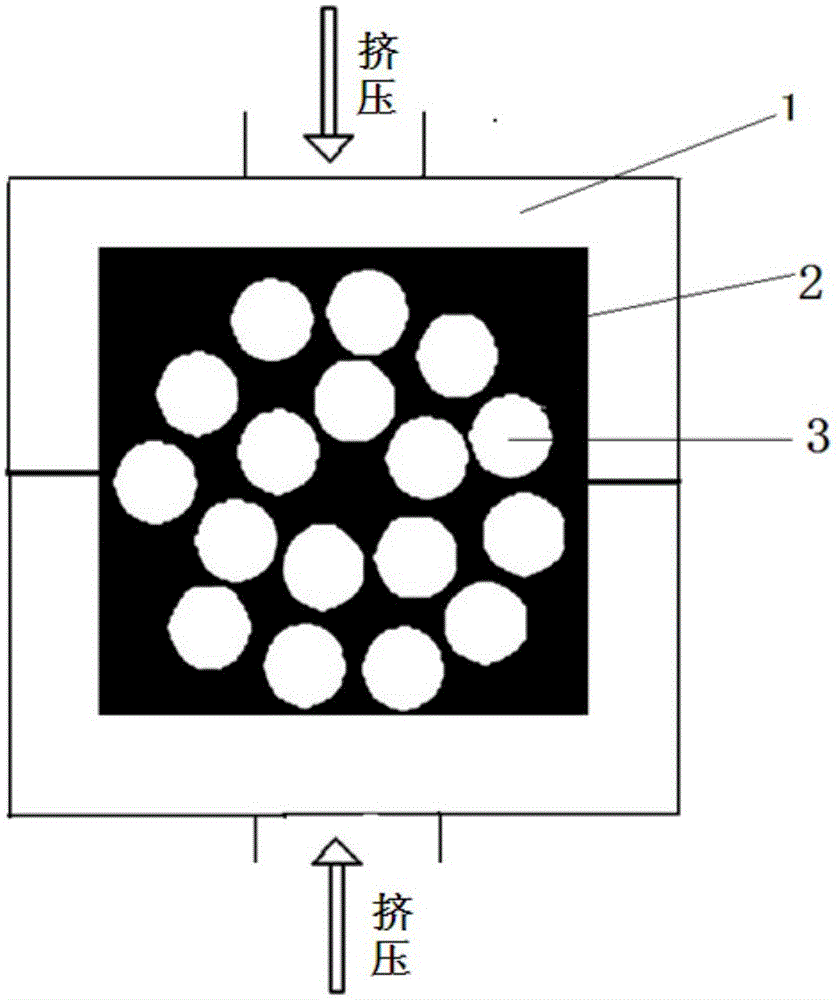

Internal filled waterproof wire bundle and fabrication method thereof

InactiveCN105097100AExtended service lifePrevent infiltrationInsulated cablesManufacturing wire harnessesChemical corrosionMaterials science

The invention aims at providing a simple, convenient, fast and reliable internal filled waterproof wire bundle and a fabrication method thereof. The internal filled waterproof wire bundle is characterized by comprising wire bundle bodies and a solid filler, wherein gaps among the wire bundle bodies are fully filled with the solid filler. The fabrication method comprises the following steps: heating and melting the solid filler; coating the wire surfaces with the molten filler; putting the wires soaked with the filler into a mold, and closing the mold for cooling; and cooling and curing the wires, opening the mold, and taking out the wire bundle bodies, so as to obtain the internal filled waterproof wire bundle. The internal filled waterproof wire bundle fabricated by the method has the properties such as waterproofness, anti-leakage property, insulating property and chemical corrosion resistance; and the service life of the wire bundle can be greatly prolonged.

Owner:GUILIN LYUYUAN TECH CO LTD

Double-ingredient epoxy seam beautifying glue

InactiveCN106381117AEasy to operateSafe and non-toxicNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyCrack resistance

The invention relates to seam beautifying glue, in particular to double-ingredient epoxy seam beautifying glue. An ingredient A is prepared from the following ingredients in percentage by weight: 60 to 90 percent of epoxy resin, 0 to 30 percent of plasticizers, 0 to 3 percent of anti-freezing agents, 0 to 15 percent of glitter powder, 1 to 10 percent of thixotropic agents, 0.01 to 1 percent of antifoaming agents and 0 to 20 percent of filling materials; an ingredient B is prepared from the following ingredients in percentage by mass: 65 to 95 percent of curing agents, 1 to 20 percent of thixotropic agents, 0 to 30 percent of plasticizers and 0 to 15 percent of glitter powder. The ingredient A and the ingreeinet B are respectively packaged after the preparation; the ingredient A and the ingredient B can be used after being uniformly mixed according to the weight ratio of 1:1. The construction operation is convenient; the advantages of safety, non-toxicity, wear resistance, waterproof performance, mildewproof performance, stain prevention, chemical medicine resistance, anti-cracking performance, fine crack resistance, yellowing resistance, rich color and the like are realized; the seam beautifying glue can be used as the seam beautifying glue by replacing the existing cement and can be used for performing color matching on ceramic tiles in different colors so as to achieve the decoration effect.

Owner:三友(天津)高分子技术有限公司

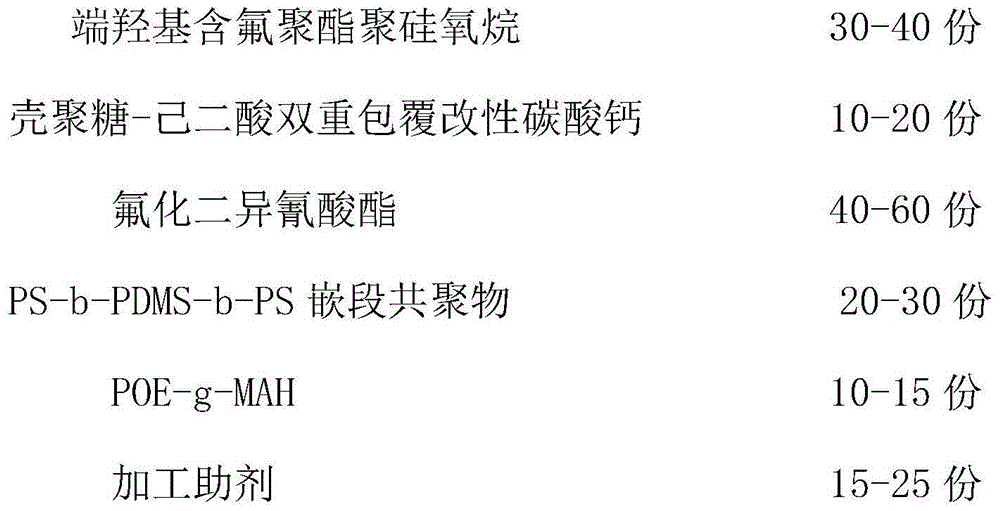

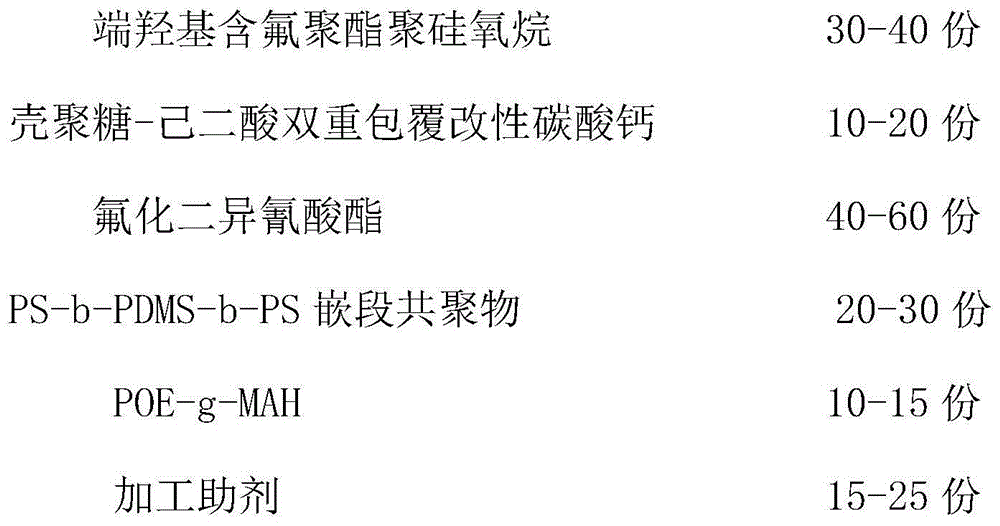

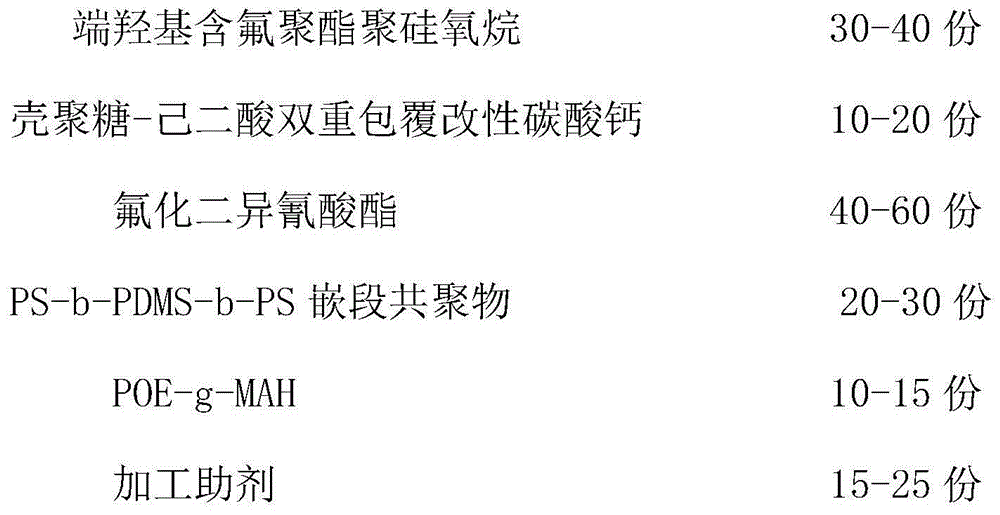

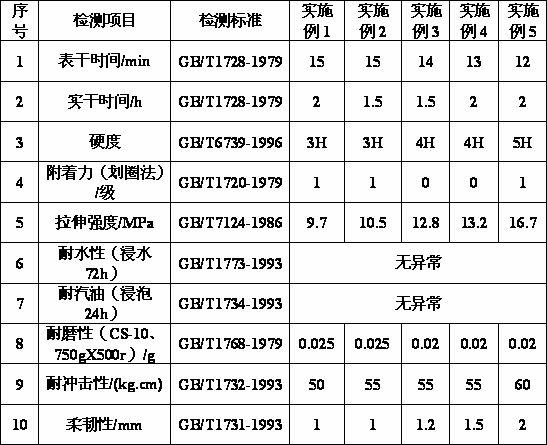

Self-cleaning material for signal lines and preparation method thereof

ActiveCN104403301AChange the disadvantage of easy to get dirtyReduce surface tensionPolyesterProcedure Agents

The invention discloses a self-cleaning material for signal lines. The self-cleaning material is prepared from the following ingredients, by weight, 30-40 parts of hydroxyl-terminated fluorine-containing polyester polysiloxane, 10-20 parts of chitosan- adipic acid dual coating modified calcium carbonate, 40-60 parts of diisocyanate fluoride, 20-30 parts of a PS-b-PDMS-b-PS segmented copolymer, 10-15 parts of POE-g-MAH and 15-25 parts of a processing aid. The invention also discloses a preparation method of the self-cleaning material for signal lines. The product has characteristics of low surface tension of fluoroalkyl-containing and siloxane-containing structures, hydrophobicity, oleophobicity and the like. When the product is applied to signal lines, the product has advantages of self-cleaning function, high anti-pollution ability, flexibility, good elasticity, good hand feeling, good weatherability, chemicals resistance, antibacterial property and the like, and is not easy to scratch or leave a trace. When in use, the product can keep bright in appearance for a long time. thus, the defect that most existing fluorine-containing materials have high hardness and inflexible molecular chain and are not applicable to signal lines is overcome.

Owner:DONGGUAN YINGTONG WIRE +1

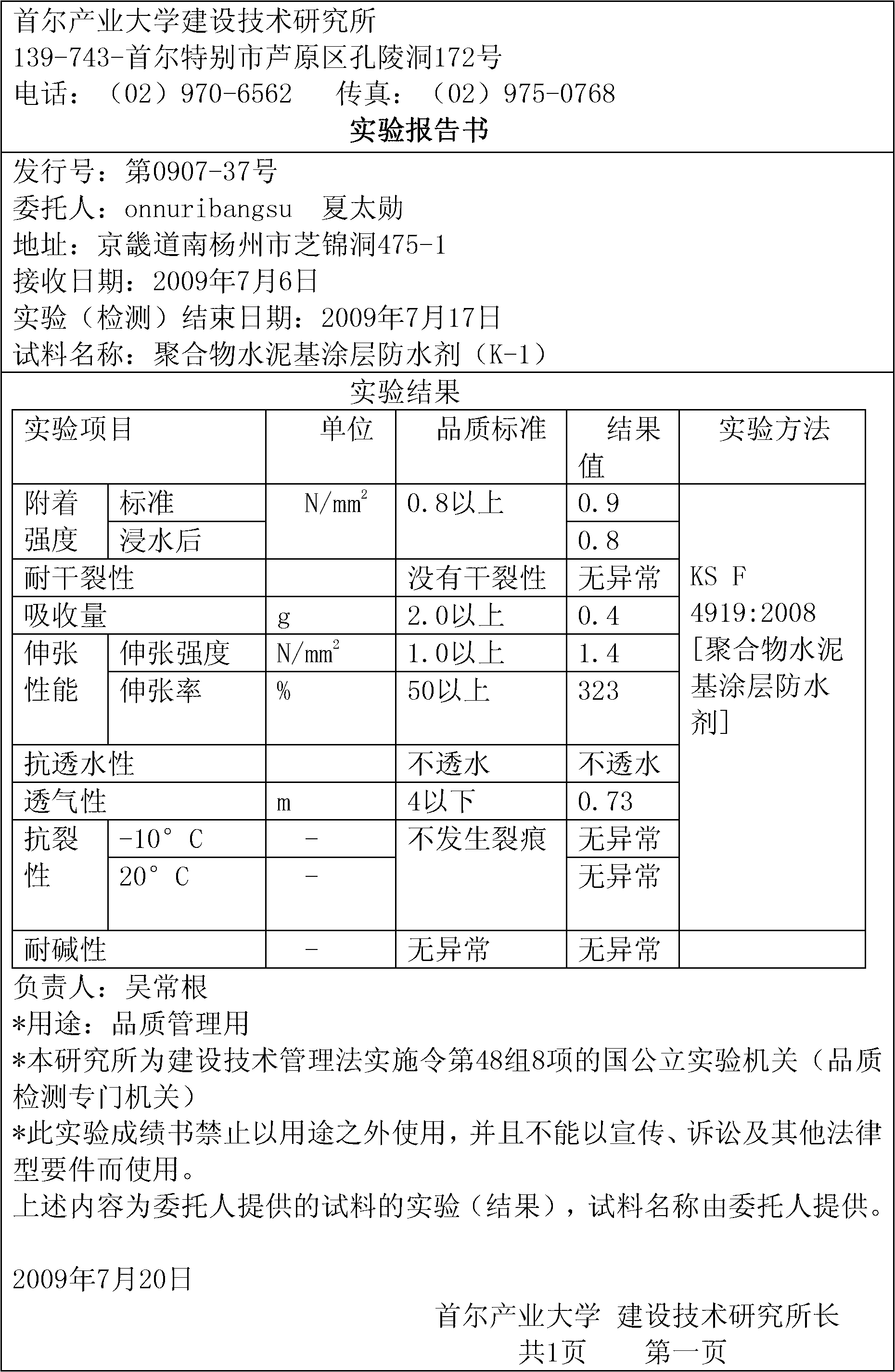

Polymer-based film waterproofing agent mixed with cement, and preparation method thereof

InactiveCN102762678AHigh tensile strengthChemical resistantBuild-up roofsProtective foundationCrack resistanceWater leakage

The present invention relates to a polymer-based film waterproofing agent mixed with cement which is coated on a structure requiring waterproofing and water leakage prevention so as to show excellent chemical resistance, weather resistance, crack resistance and impact resistance and high tensile strength in addition to waterproofness by preventing penetration of water into the structure, and a preparation method thereof. The polymer-based film waterproofing agent mixed with cement of the present invention comprises: 65-75 wt% of an acrylic emulsion; 12-20 wt% of micro-cement; 10-18 wt% of quicklime; 0.02-0.2 wt% of a superplasticizer; 0.02-0.2 wt% of an antifoaming agent; and 0.02-0.2 wt% of an expansion agent. The preparation method comprises: the first step of preparing 65-75 wt% of an acrylic emulsion in a liquid state in a first circular container; the second step of preparing 12-20 wt% of micro-cement in a powder state, 10-18 wt% of quicklime, 0.02-0.2 wt% of a superplasticizer, 0.02-0.2 wt% of an antifoaming agent, and 0.02-0.2 wt% of an expansion agent in a second circular container; and the third step of pouring the contents prepared in the second circular container into the first circular container to dilute the same with an electric mixer.

Owner:河泰薰

Method for preparing epoxy acrylate modified waterborne polyurethane coating

The invention discloses a method for preparing epoxy acrylate modified waterborne polyurethane coating and belongs to the technical field of chemical coatings. The method comprises the following steps: A) synthetizing modified epoxy acrylate; B) preparing an epoxy acrylate modified waterborne polyurethane emulsion; and C) preparing the finished product epoxy acrylate modified waterborne polyurethane coating. The epoxy acrylate modified waterborne polyurethane coating has the advantages of excellent bondability of epoxy resin, high modulus, high strength, high adhesive force, low shrink rate, water resistance and chemistry resistance. The epoxy acrylate modified waterborne polyurethane coating has excellent water resistance, physical property and weather resistance of acrylate ester; the raw materials are easy to obtain and have low cost; and the epoxy acrylate modified waterborne polyurethane coating has good physical performance and cold resistance of waterborne polyurethane and has environment protection property.

Owner:常熟市协新冶金材料有限公司

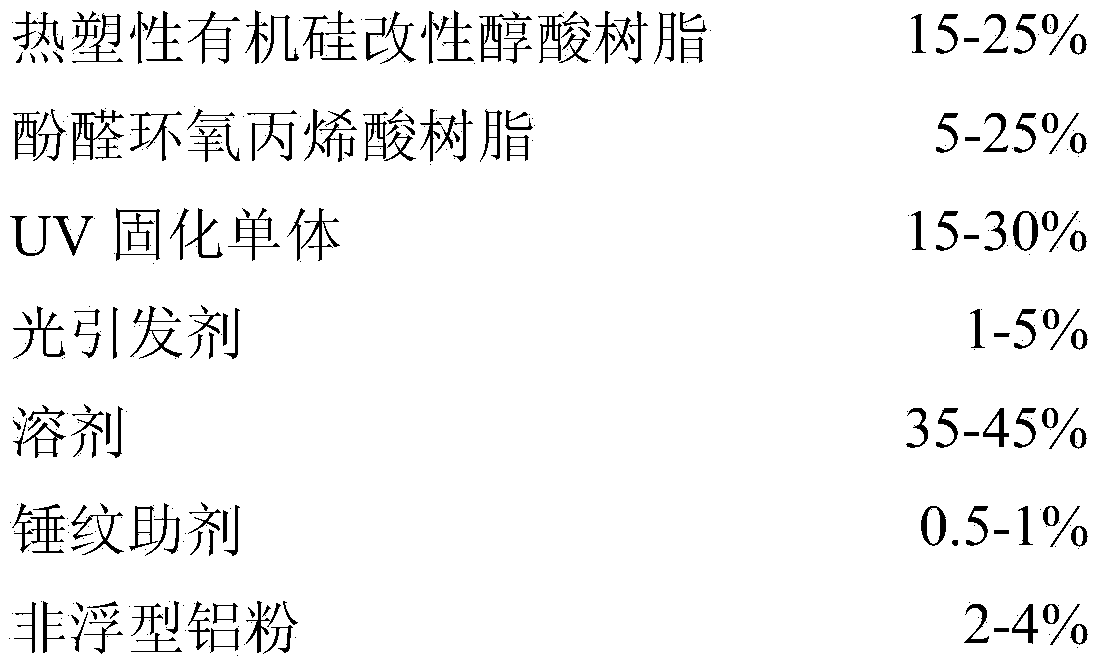

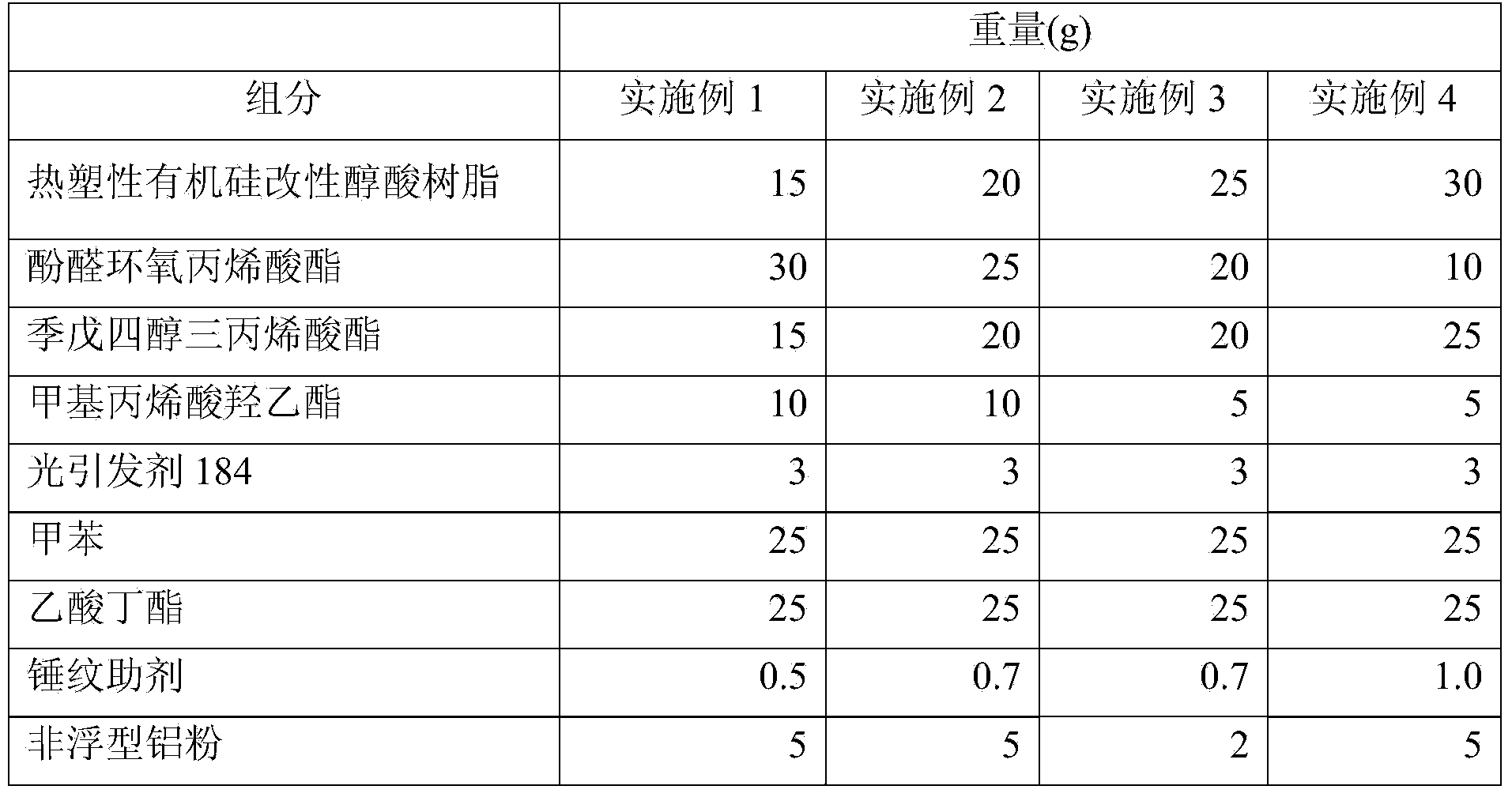

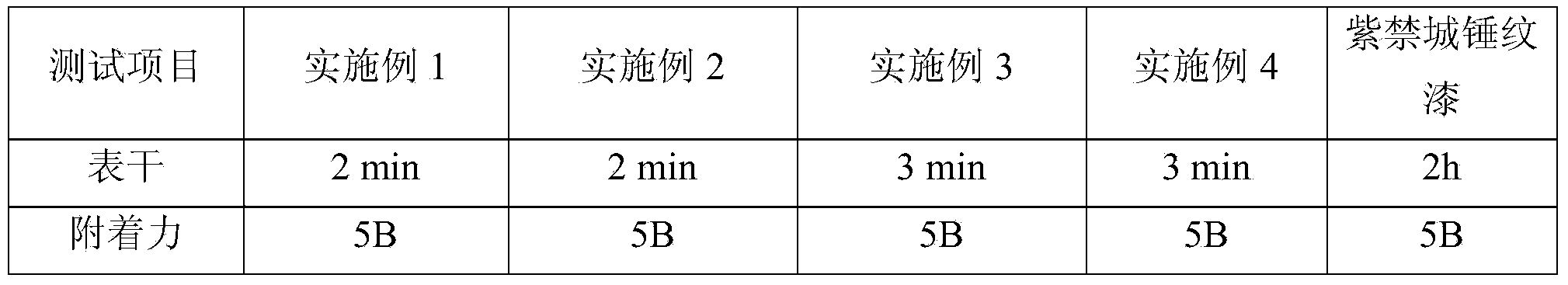

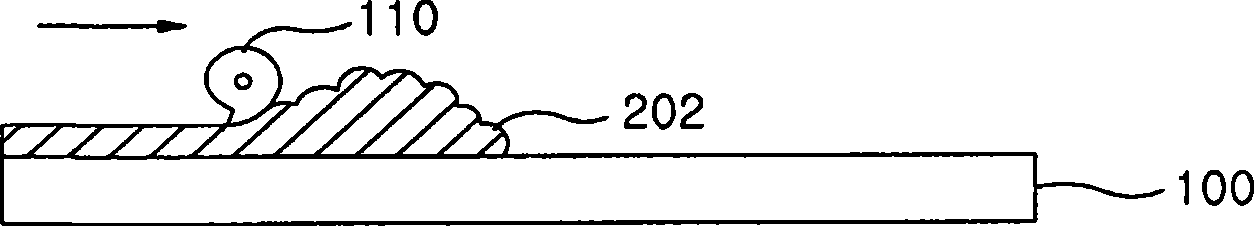

Photocuring hammer paint

The invention discloses photocuring hammer paint. The photocuring hammer paint comprises components in percentage by weight as follows: 15-25% of thermoplastic organic silicone modified alkyd resin, 5-25% of phenolic epoxy acrylic resin, 15-30% of UV (ultraviolet) curing monomers, 1-5% of a photoinitiator, 35-45% of a solvent, 0.5-1% of a hammer additive and 2-4% of non-floating type aluminium powder. According to the photocuring hammer paint, the UV curing components are introduced into the hammer paint, so that the film formation and curing time is shortened, and the construction efficiency is improved; and the UV curing components are introduced, through a photocuring chemical crosslinking reaction, the crosslinking density of a paint film is increased, the heat resistance and the abrasion resistance of the paint film are improved, and the phenolic epoxy acrylic resin in the paint has the excellent chemical resistance, so that the hammer paint has the better chemical resistance, corrosion resistance and temperature variation resistance and can satisfy the requirements of hammer decoration on surfaces of instruments in current aviation and navigation fields for resistance.

Owner:ZHEJIANG UVCHEM SPECIAL COATINGS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com