Pressure sensitive adhesive composition for transferring flexible substrate

A flexible substrate and composition technology, applied in adhesives, applications, adhesive products, etc., can solve problems such as insurmountability, metal powder precipitation, and specific gravity, and achieve the effect of small defects and prevention of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0096] Hereinafter, a method of transferring a flexible substrate using an adhesive composition according to an embodiment of the present invention will be described in detail with reference to the accompanying drawings.

[0097] First, a method of transferring a flexible substrate according to a first embodiment of the present invention will be described in detail.

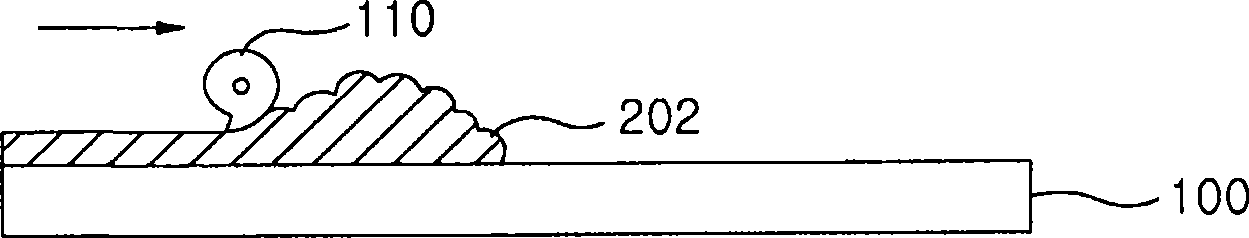

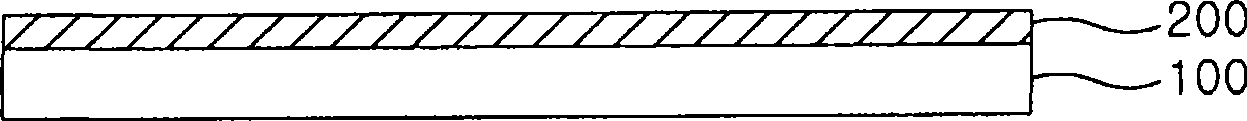

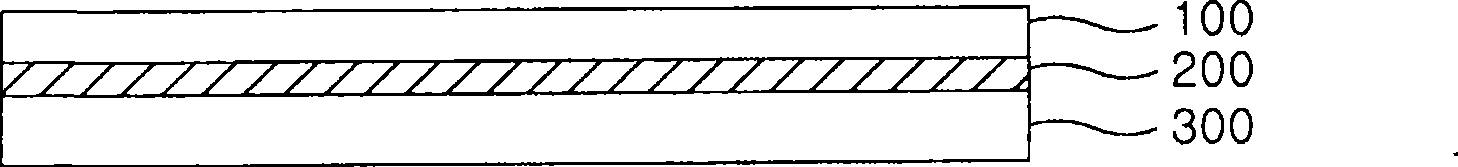

[0098] Figure 1~4 is a sectional view showing a method of transferring a flexible substrate according to a first embodiment of the present invention.

[0099] refer to figure 1 , place a predetermined amount of adhesive composition 202 on the flexible substrate 100 , and then use the coating machine 110 to coat the adhesive composition 202 on the flexible substrate 100 at a constant speed. A coater generally known in the related art such as a wire bar coater, roll coater, reverse coater, gravure coater, or air knife coater can be used as the coater 110 .

[0100] In addition, such as polyester, polytetrafluor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com