Internal filled waterproof wire bundle and fabrication method thereof

A production method and technology of waterproof wire, which are applied in the direction of manufacturing wire harnesses, conductors, and insulating conductors/cables, etc., can solve the problems that the wire harness cannot be completely filled, reduce the service life of the wire harness, lose the waterproof function, etc., and achieve high production efficiency. The effect of extended service life and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

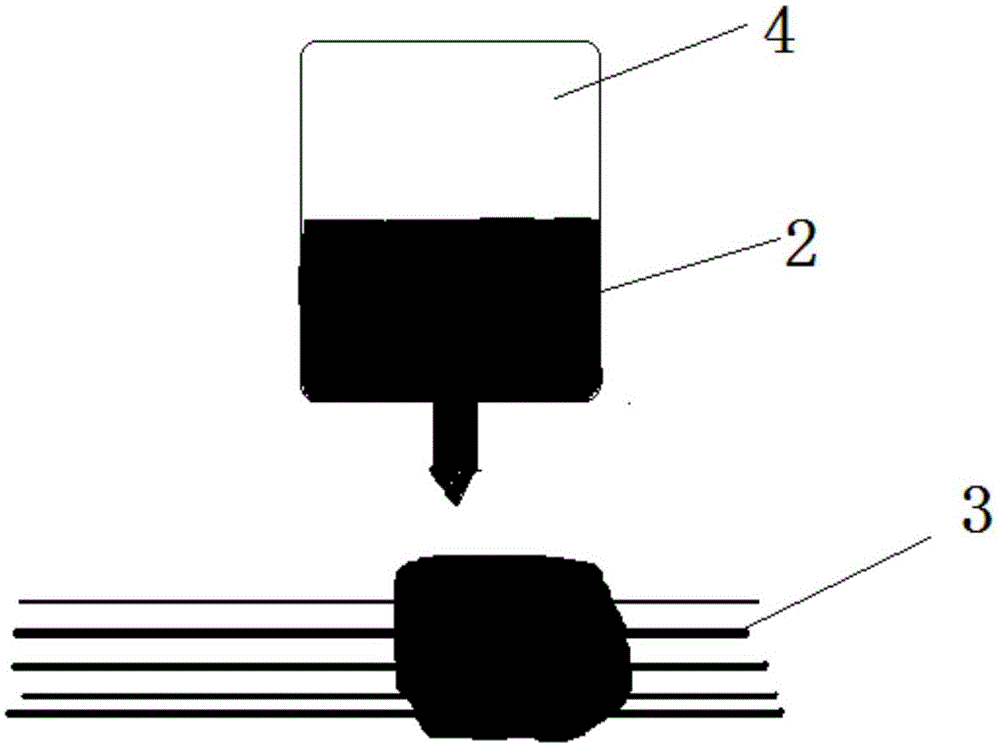

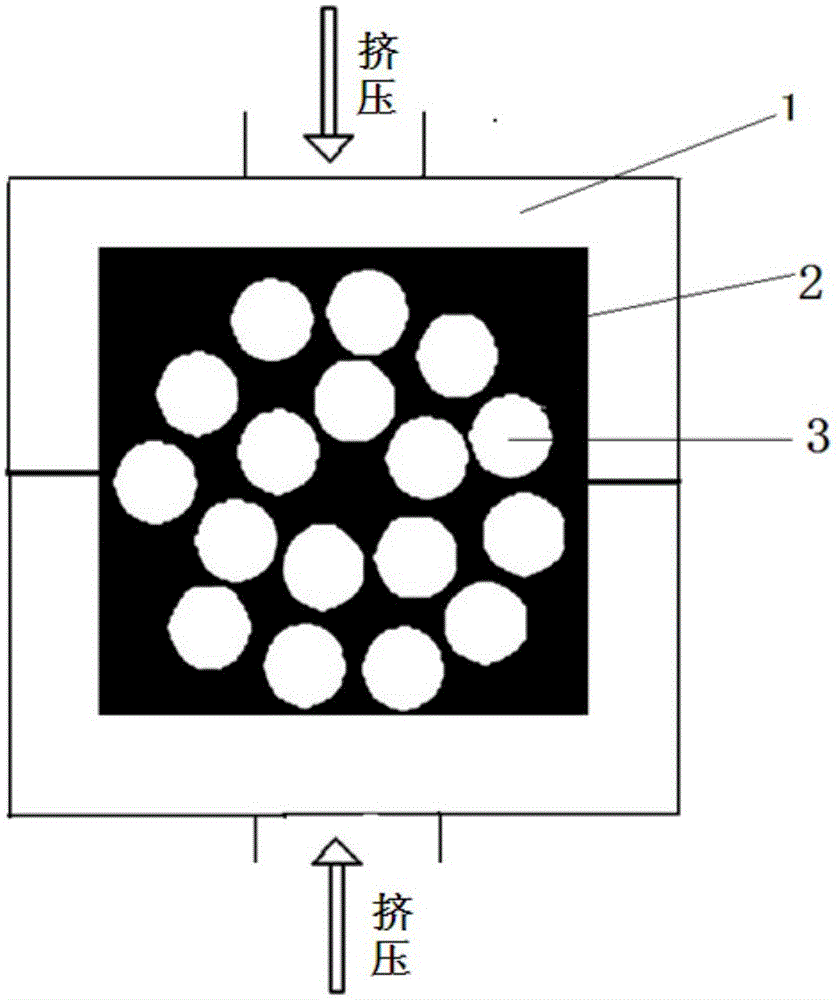

[0034] Such as figure 1 , put any waterproof filling material that is solid at room temperature including hot melt adhesive and thermoplastic resin into the melt machine 4 to heat and melt, and the molten filler 2 is coated on the surface of the wire harness 3; as image 3 , put the wire harness 3 coated with the molten filler 2 into the mold 1 for extrusion, squeeze the melted filler 2 into the gap between the wire bundles, cool and solidify, open the mold 1, and take out the wire harness 3, that is have to Figure 5 Inner waterproofing harness shown left.

Embodiment 2

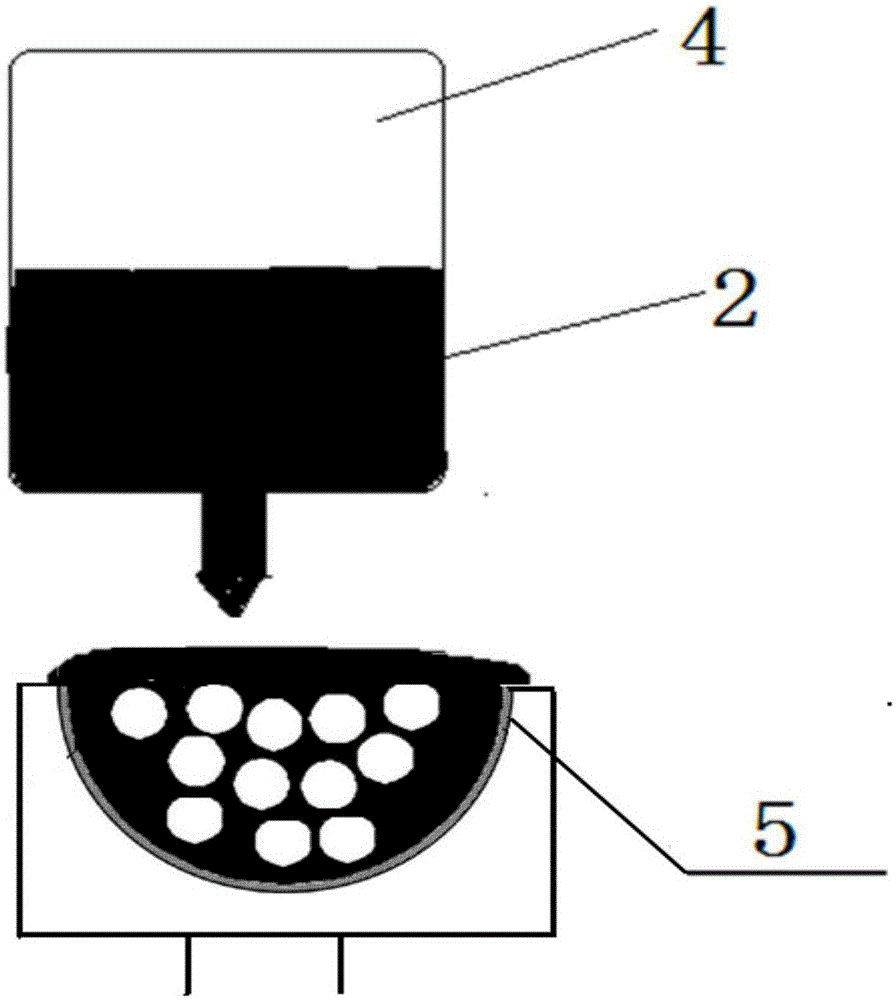

[0036] Such as figure 1 , put any waterproof filling material that is solid at room temperature including hot melt adhesive and thermoplastic resin into the melt machine 4 to heat and melt, and the molten filler 2 is coated on the surface of the wire harness 3; as Figure 4 , the wire harness 3 coated with the molten filler 2 is put into the mold 1 with the plastic film 5 on the surface and extruded, the molten filler 2 is squeezed into the gap between the wire bundles, after cooling and solidifying, the mold 1 is opened , take out harness 3, that is, Figure 5 The inner-filled waterproofing harness shown on the right.

Embodiment 3

[0038] Such as figure 1 , put any waterproof filling material that is solid at room temperature including hot melt adhesive and thermoplastic resin into the melt machine 4 to heat and melt, and the molten filler 2 is coated on the surface of the wire harness 3; as Figure 4 , put the wire harness 3 coated with the molten filler 2 into the mold 1 with aluminum foil 5 on the surface for extrusion, squeeze the melted filler 2 into the gap between the wire bundles, cool and solidify, and open the mold 1, Take out the wiring harness 3 and get Image 6 Inner fill waterproofing harness shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com