Polymer-based film waterproofing agent mixed with cement, and preparation method thereof

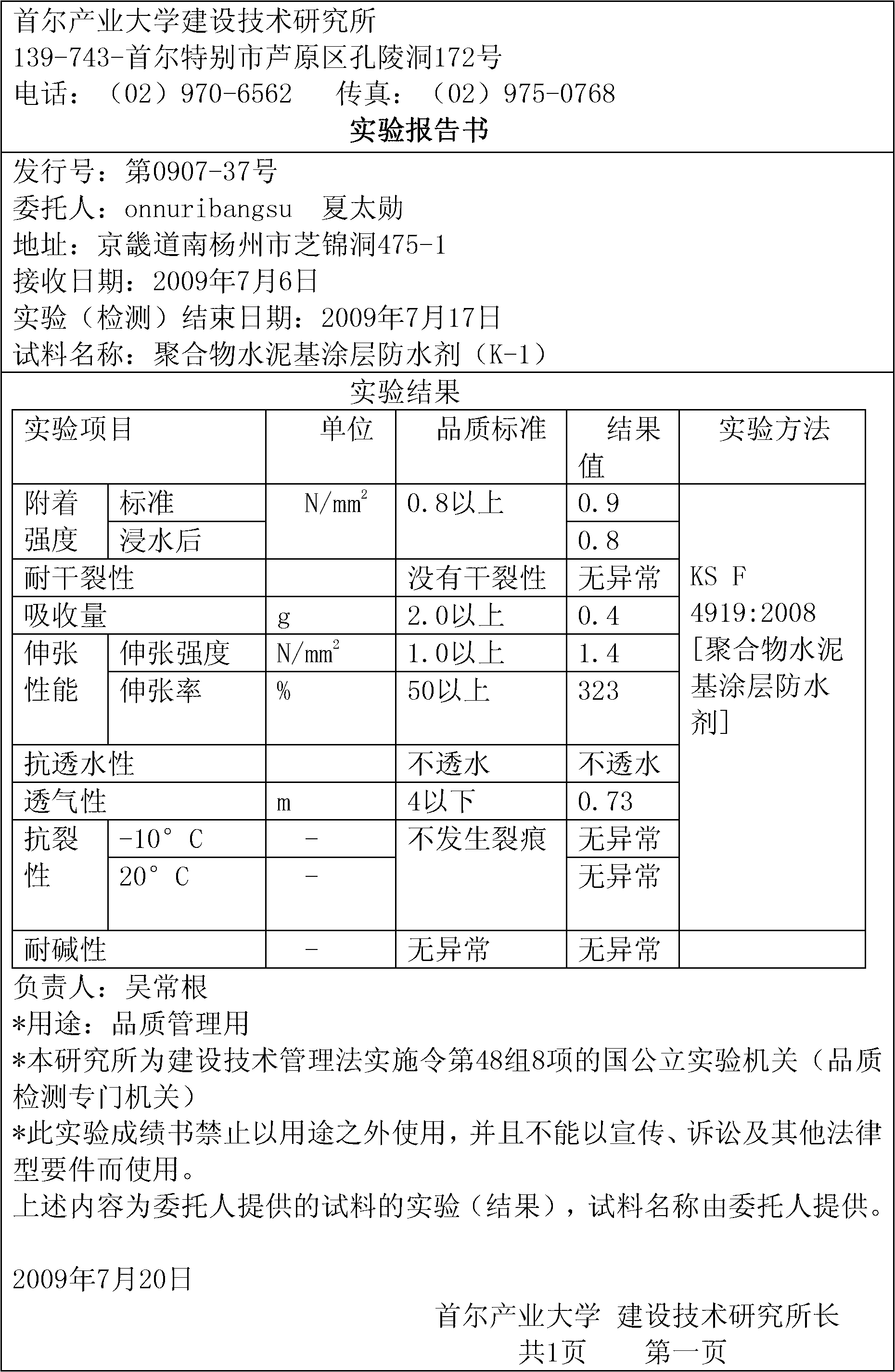

A cement-based, water-repellent technology, used in cement coatings, coatings, ceramic products, etc., can solve the problems of unstable material mix rate, increased cost, unevenness, etc., to achieve excellent tensile strength and elongation, prevent Corrosion and water seepage prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] Embodiments for achieving the object of the present invention are described below.

[0045] First, a commercially available liquid-state acrylic emulsion is prepared.

[0046] In addition, small packages of superfine cement (MS8000) and quicklime that do not react with each other are prepared in advance, and the above-mentioned additives (superplasticizer, defoamer, expansion agent) are also packaged in small packages at the same time, to be prepared.

[0047] Measure the weight of each of the above materials, prepare 70% by weight of acrylic emulsion, 16% by weight of superfine cement, 13.8% by weight of quicklime, 0.06% by weight of superplasticizer, 0.1% by weight of defoamer, and 0.04% by weight of expansion agent. The above-mentioned acrylic emulsion in liquid state is poured into the first drum, and other ultra-fine cement, quicklime, superplasticizer, defoamer and expansion agent in powder state are poured into the second drum, and the lid is closed for storage. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com