Monocomponent wear-resistant aqueous polyurethane wood floor coating for container and preparation method thereof

A waterborne polyurethane, one-component technology, applied in polyurea/polyurethane coatings, coatings, fibrous fillers, etc., can solve problems such as environmental pollution, flammability and explosion, and affect the health of construction workers, and achieve the goal of solving environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

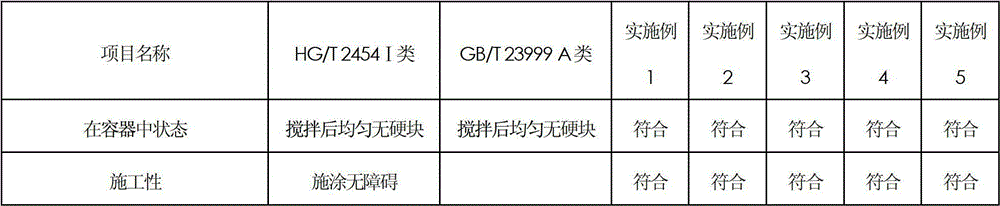

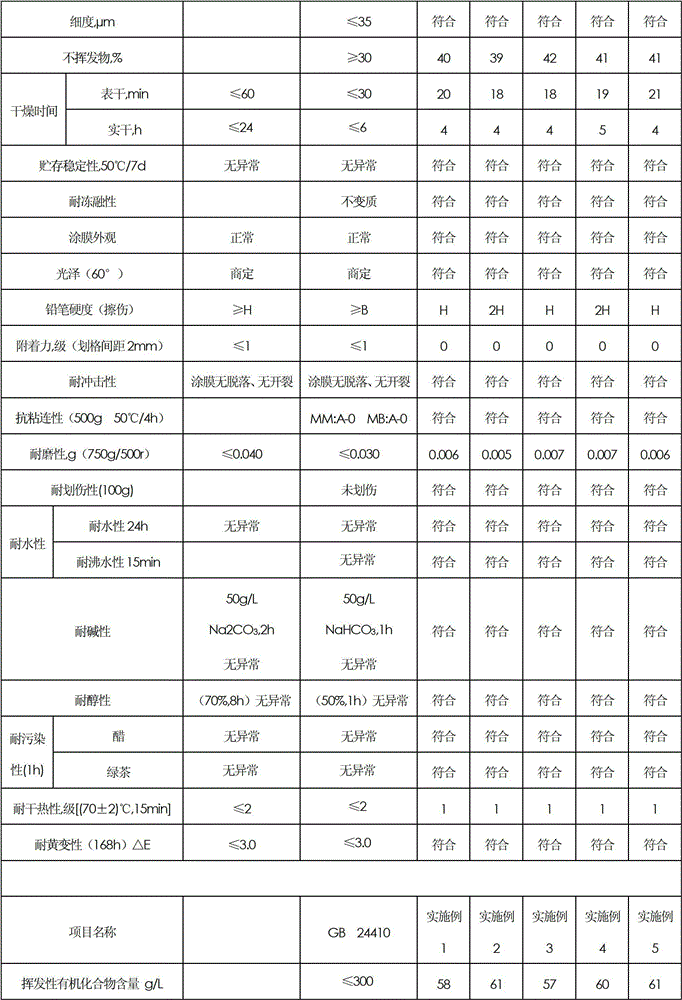

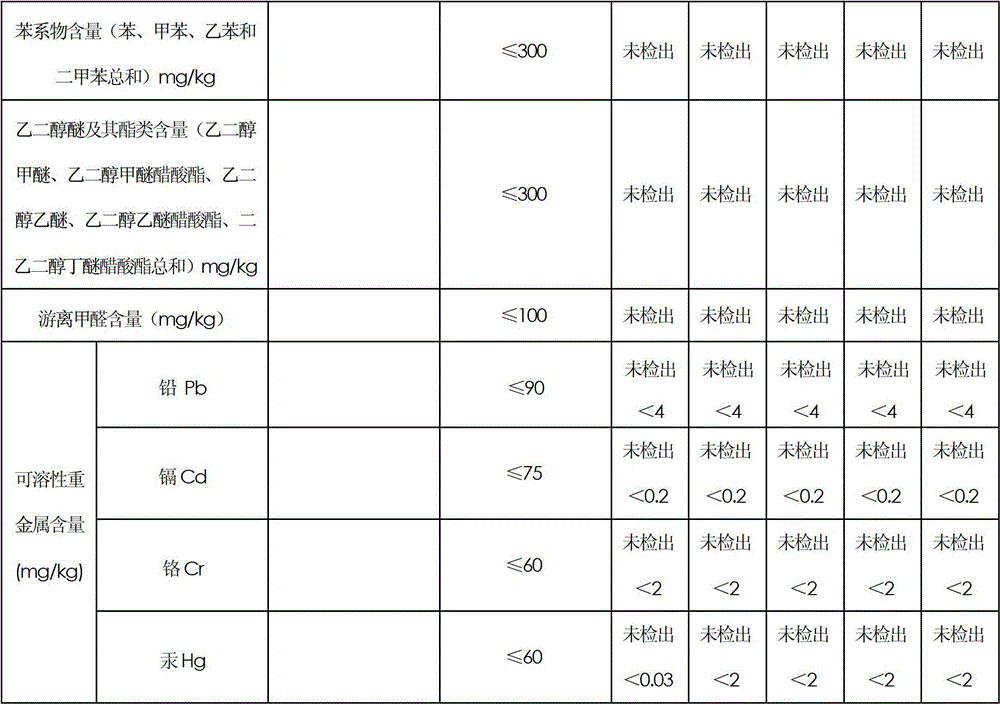

Examples

Embodiment 1

[0037] 1) According to the mass percentage of the constituent components of the nano-alumina slurry (deionized water 91%, NDZ201 titanate coupling agent 0.03%, nano-Al 2 o 3 4%, SN-5040 dispersant 0.1%, diethanolamine 0.3%, each component was weighed and prepared according to the following steps and process conditions: deionized water, NDZ201, nano-Al 2 o 3 , SN-5040, dimethylethanolamine, added to the container, and mechanically stirred (800r / min speed) while adding raw materials; after adding raw materials, first high-speed dispersion (2000r / min speed) for 8min and then ultrasonic Disperse (20KHz frequency) for 8 minutes to prepare nano-alumina slurry for later use.

[0038] 2) Add 6% deionized water, under the condition of stirring at 700r / min, add the composite film-forming aid (Texanol, 2.5% from Eastman Company of the United States, PnP, 2.5% from Dow Chemical) in the formula and stir for 8 minutes; wait for the solution to drop To room temperature, the film-forming a...

Embodiment 2

[0041] 1) According to the mass percentage of the components of the nano-alumina slurry (deionized water 97%, NDZ201 titanate coupling agent 0.07%, nano-Al 2 o 3 6%, Orotan 731A dispersant 0.4%, AMP950.7%) were weighed and prepared according to the following steps and process conditions: deionized water, NDZ201, nano-Al 2 o 3 , Orotan 731A, AMP95, added to the container, and mechanically stirred (1000r / min speed) while adding the raw materials; after the raw materials were added, first high-speed dispersion (2500r / min speed) for 12min and then ultrasonic dispersion (50KHz frequency ) for 12 minutes, that is, the nano-alumina slurry is prepared for use.

[0042] 2) Add 18% deionized water, under the condition of stirring at 900r / min, add the composite film-forming aids (PPh, Dow Chemical 1.5%, PnP, Dow Chemical 1.5%) in the formula and stir for 12min; To room temperature, the film-forming aid mixed solution is prepared for subsequent use;

[0043] 3) Add 85% of water-based...

Embodiment 3

[0045] 1) According to the mass percentage of the constituent components of the nano-alumina slurry (deionized water 95%, NDZ201 titanate coupling agent 0.05%, nano-Al 2 o 3 5%, SN-5034 dispersant 0.2%, ammonia water 0.2%) were weighed and prepared according to the following steps and process conditions: deionized water, NDZ201, nano-Al 2 o 3 , SN-5034, and ammonia water are added to the container, and mechanically stirred (900r / min speed) while adding the raw materials; after the raw materials are added, first high-speed dispersion (2200r / min speed) for 10min and then ultrasonic dispersion (30KHz Frequency) for 11 minutes, that is, the nano-alumina slurry is prepared for use.

[0046] 2) Add 10% deionized water, and under the condition of stirring at 800r / min, add the composite film-forming aids in the formula (propylene glycol methyl ether PM, Dow Chemical 1.5%, propylene glycol butyl ether PnB, Dow Chemical 3%) Stir for 10 minutes; when the solution drops to room temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com