Patents

Literature

222 results about "Synthetic membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An artificial membrane, or synthetic membrane, is a synthetically created membrane which is usually intended for separation purposes in laboratory or in industry. Synthetic membranes have been successfully used for small and large-scale industrial processes since the middle of twentieth century. A wide variety of synthetic membranes is known. They can be produced from organic materials such as polymers and liquids, as well as inorganic materials. The most of commercially utilized synthetic membranes in separation industry are made of polymeric structures. They can be classified based on their surface chemistry, bulk structure, morphology, and production method. The chemical and physical properties of synthetic membranes and separated particles as well as a choice of driving force define a particular membrane separation process. The most commonly used driving forces of a membrane process in industry are pressure and concentration gradients. The respective membrane process is therefore known as filtration. Synthetic membranes utilized in a separation process can be of different geometry and of respective flow configuration. They can also be categorized based on their application and separation regime. The best known synthetic membrane separation processes include water purification, reverse osmosis, dehydrogenation of natural gas, removal of cell particles by microfiltration and ultrafiltration, removal of microorganisms from dairy products, and Dialysis.

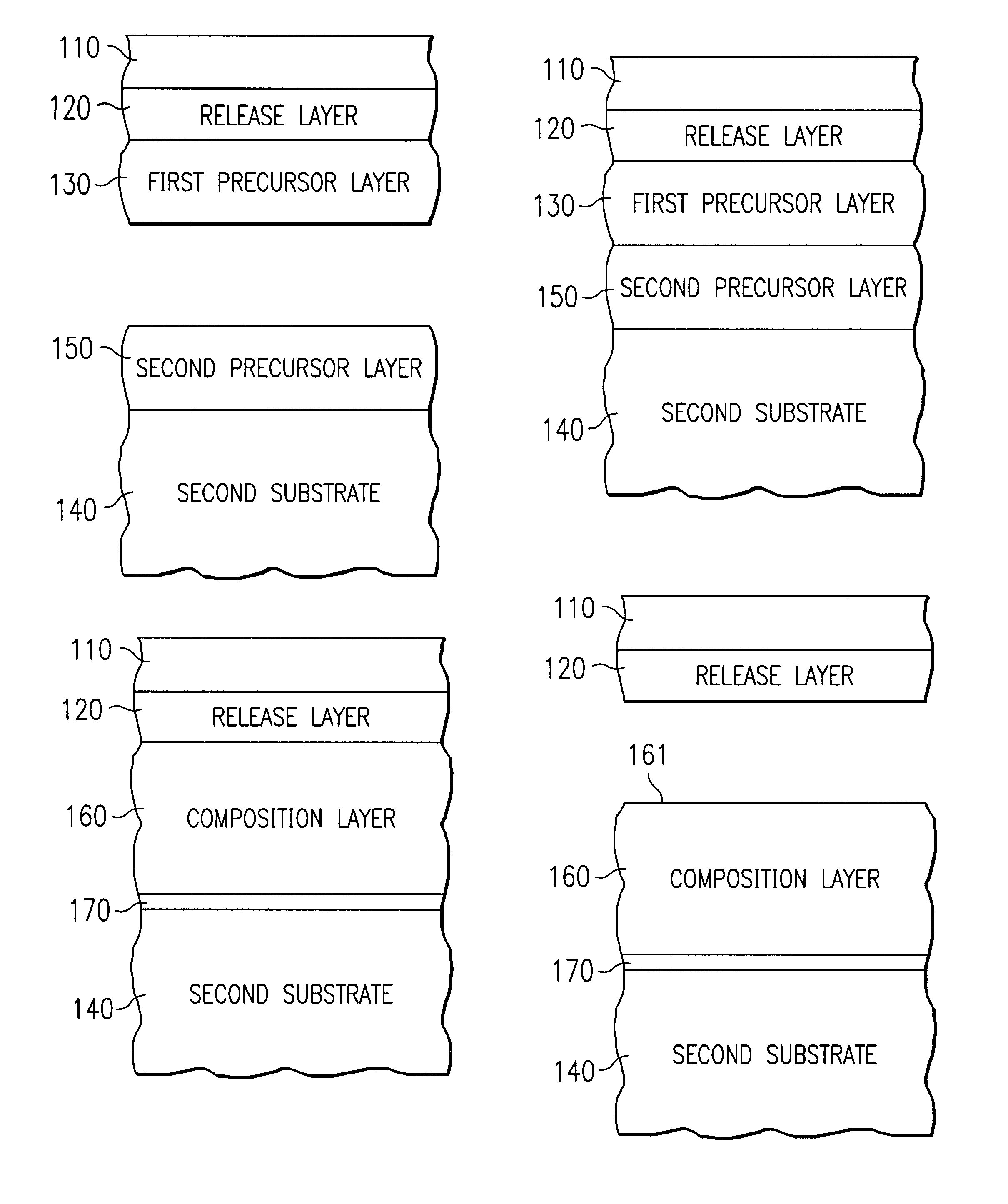

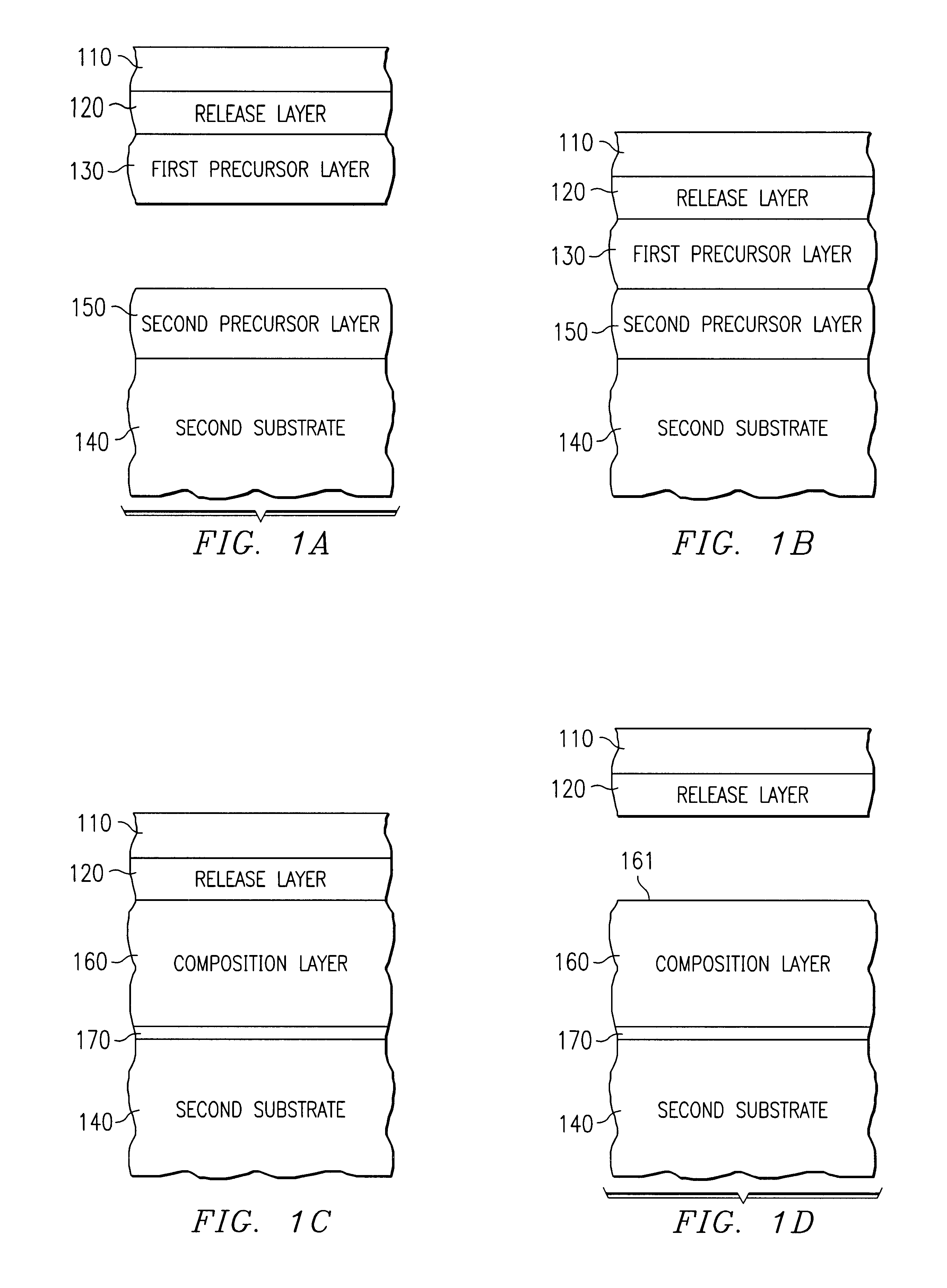

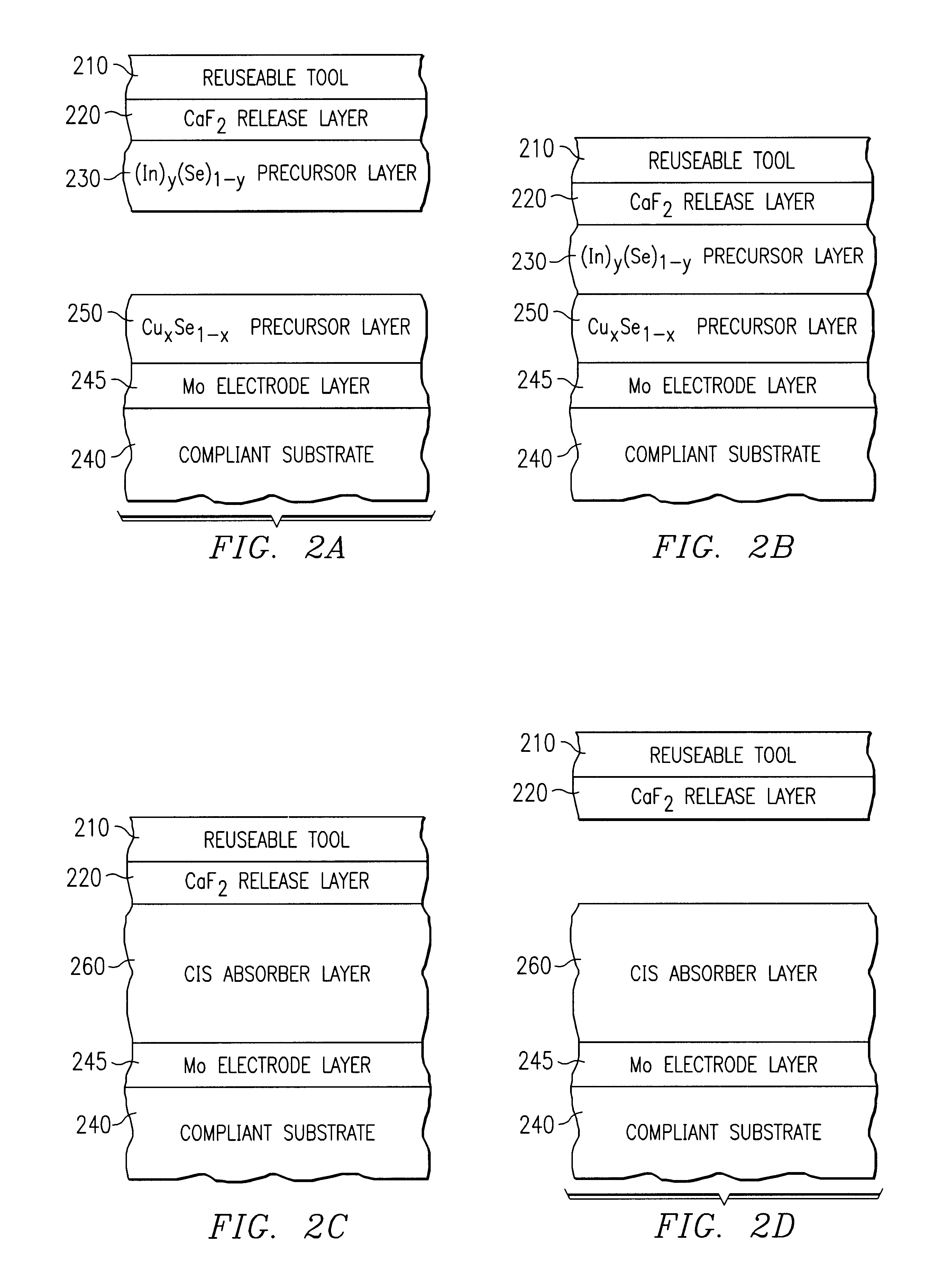

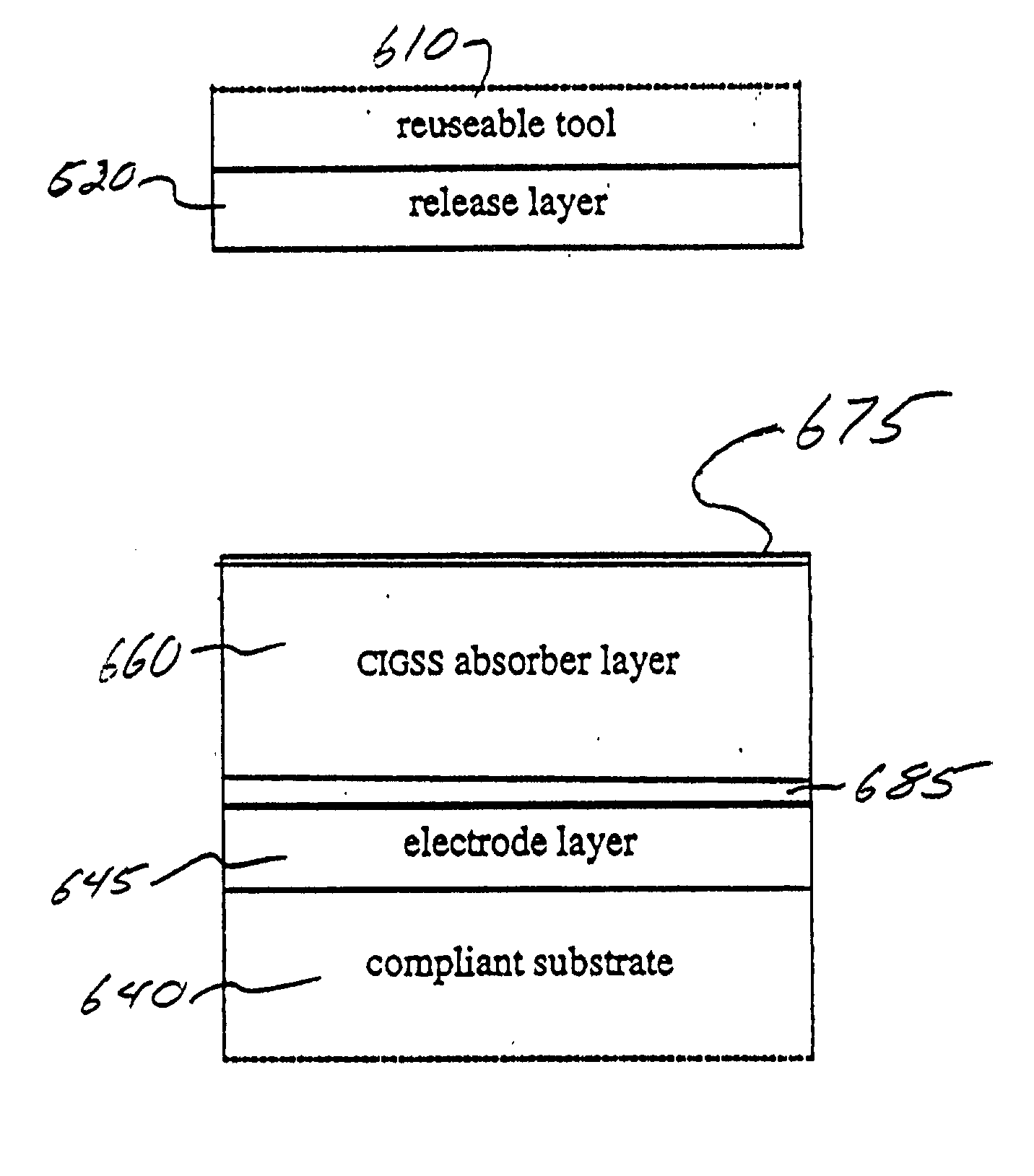

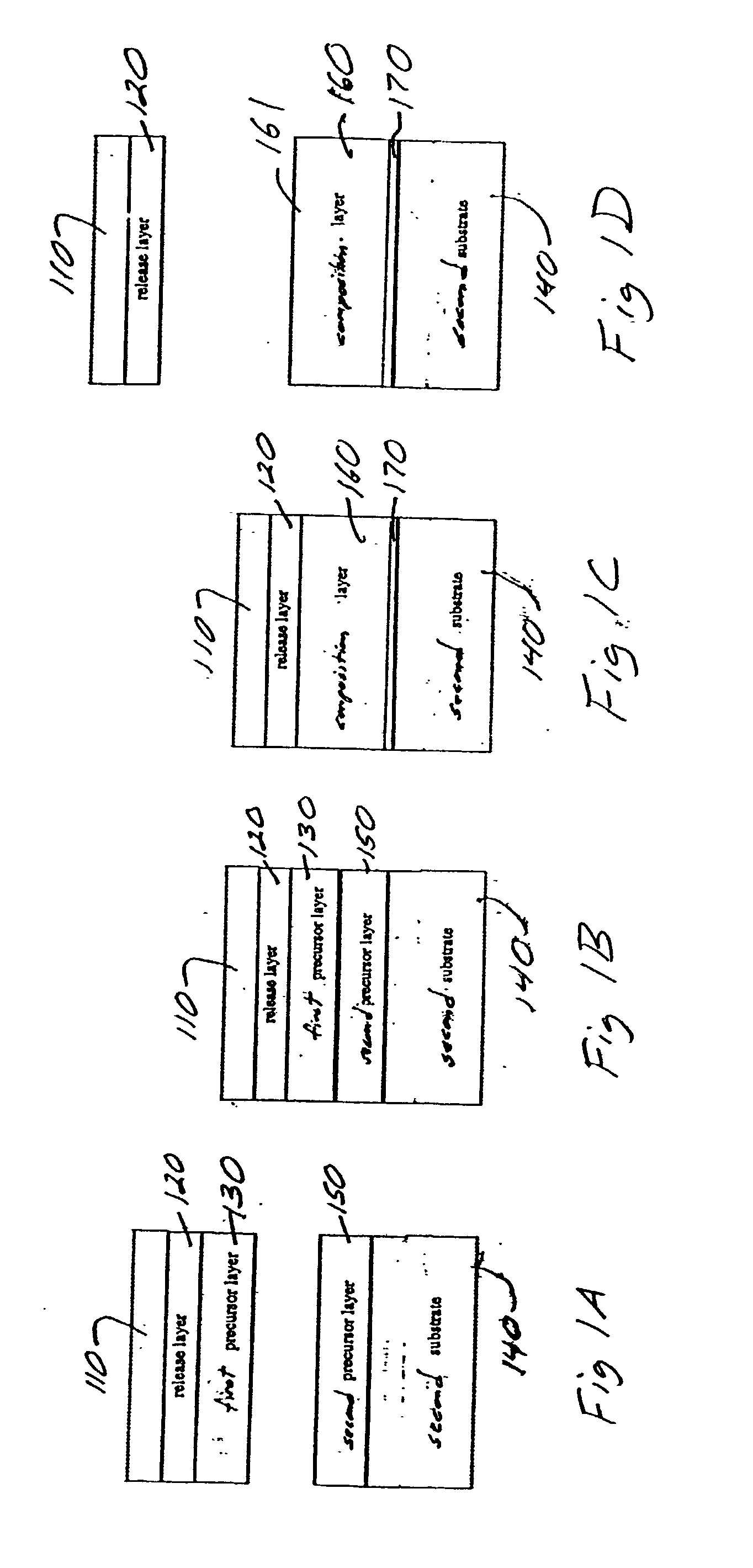

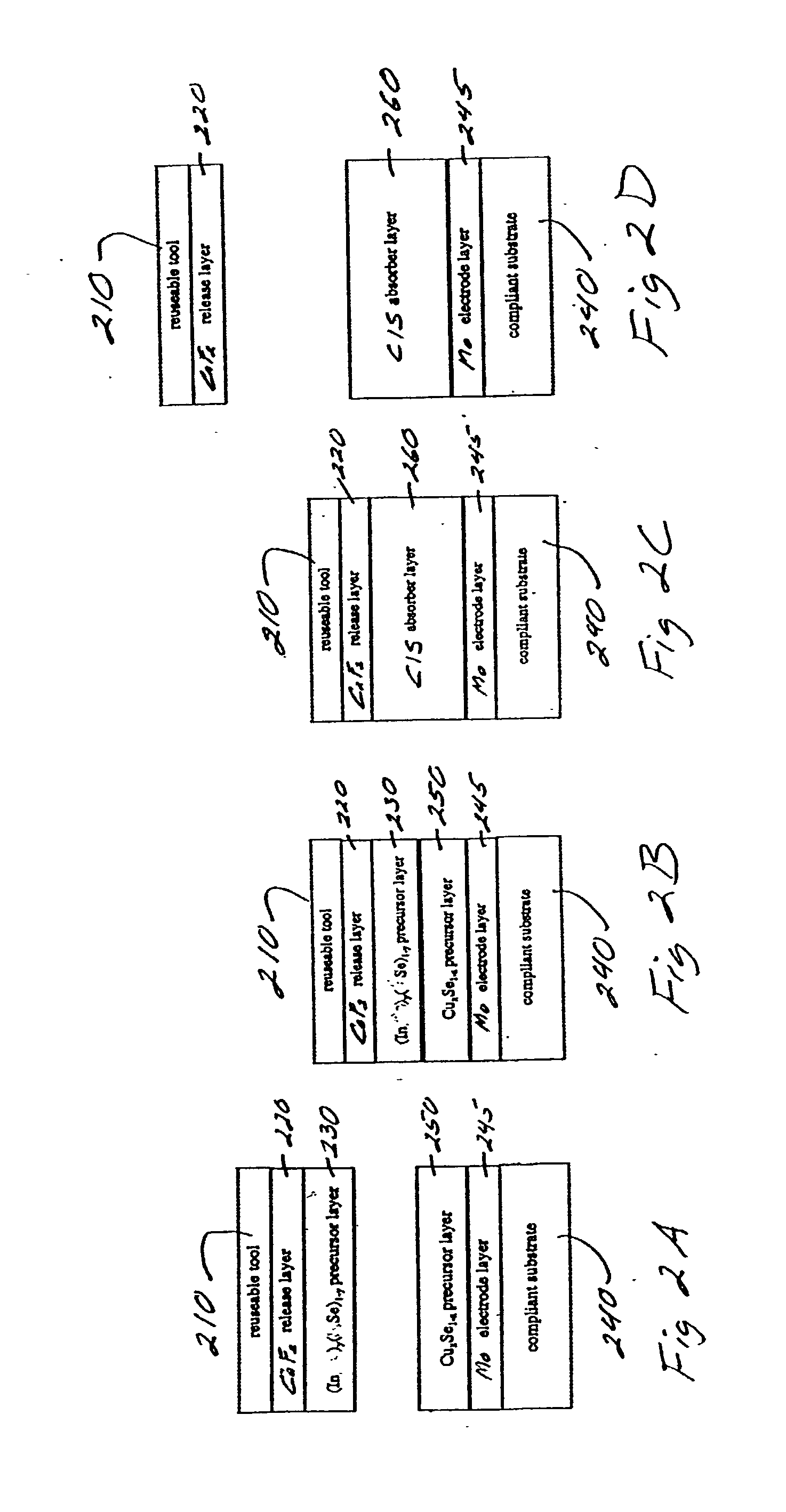

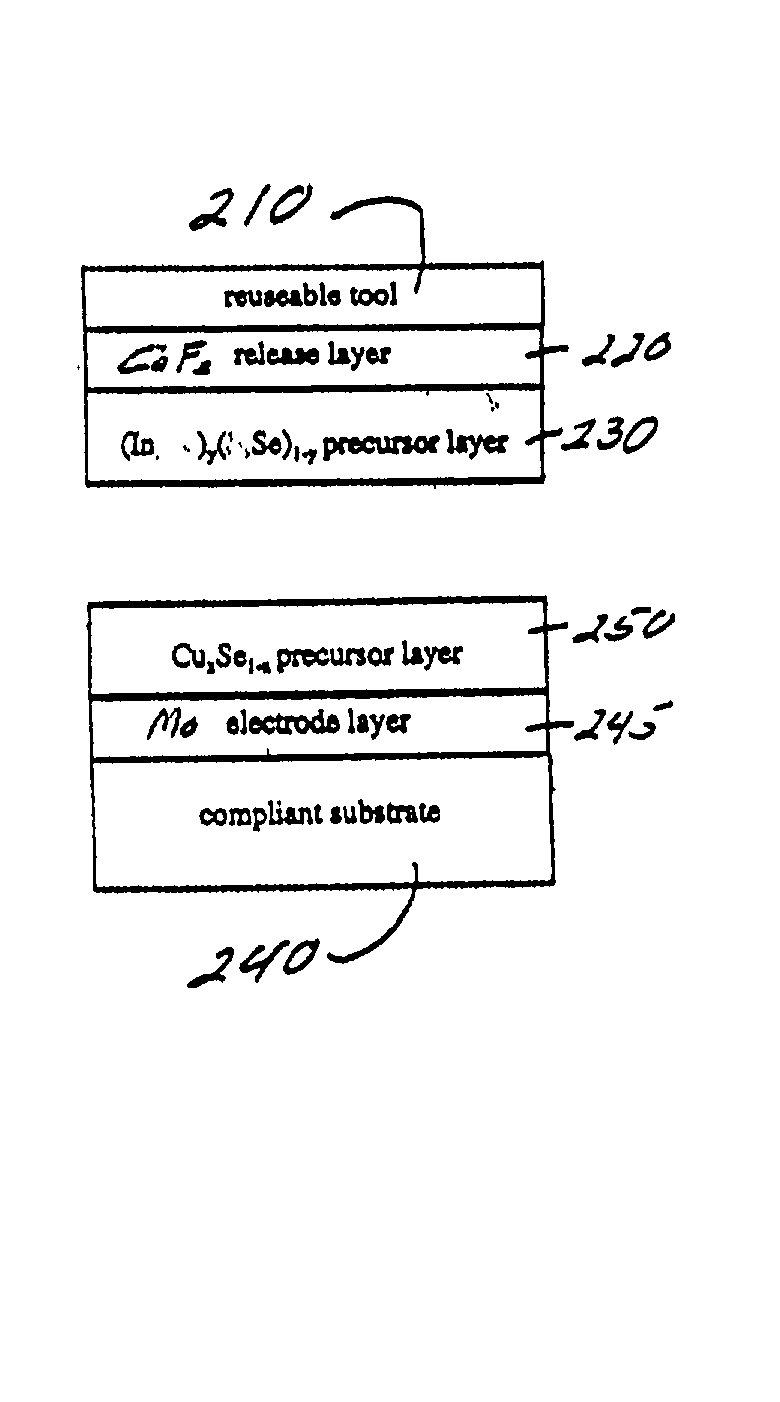

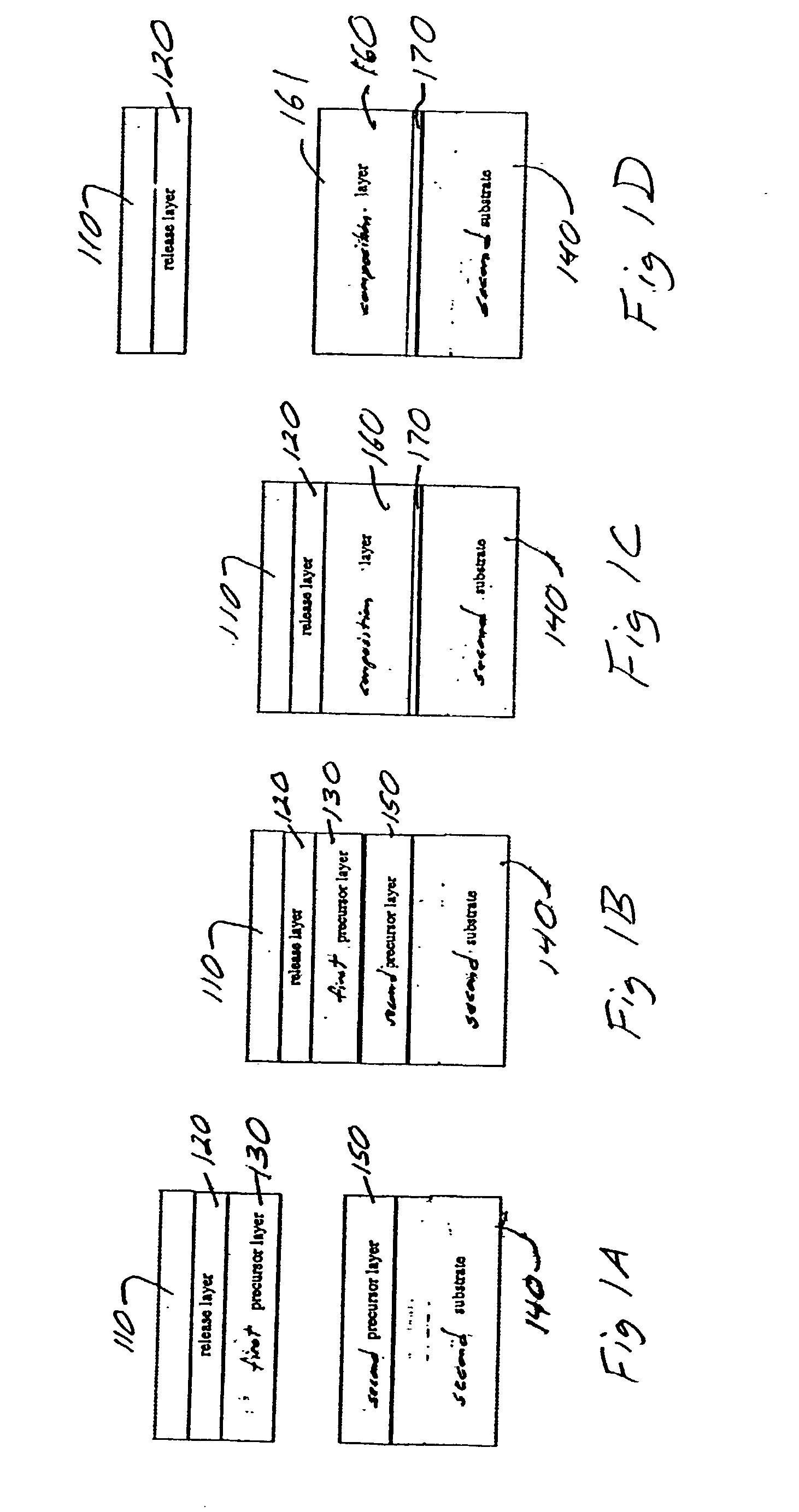

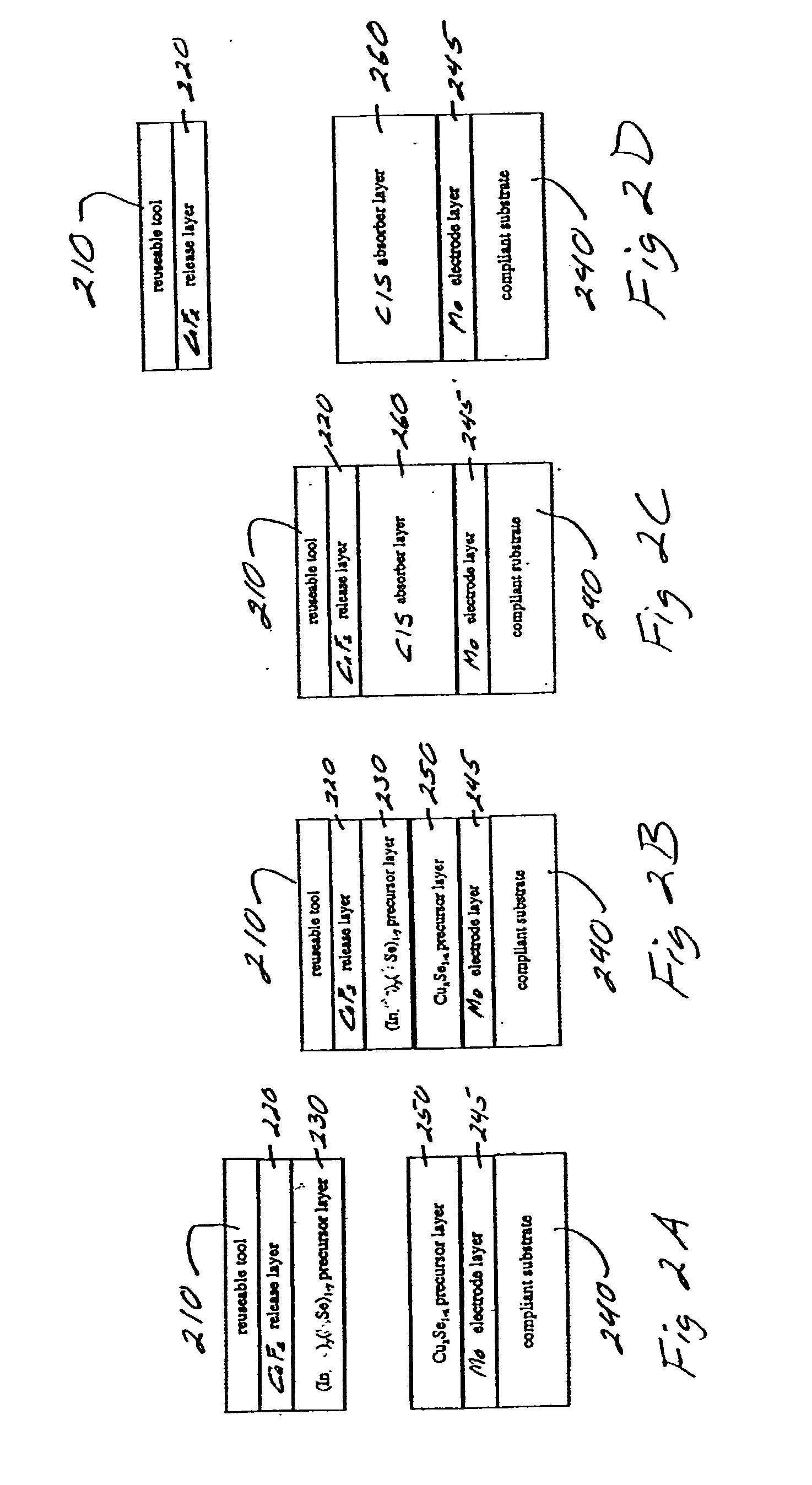

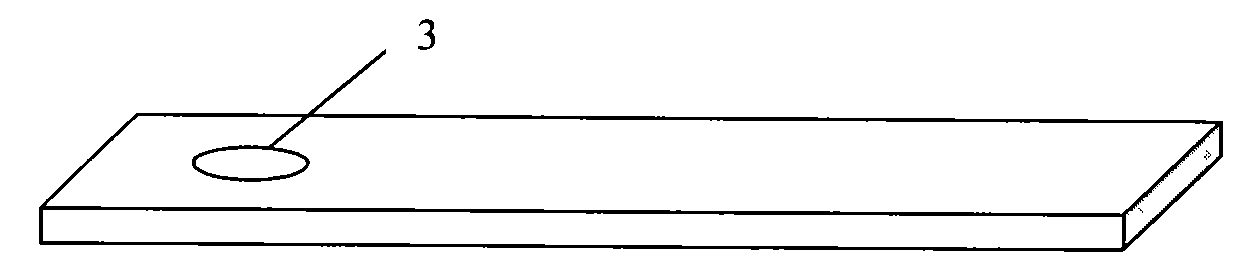

Synthesis of layers, coatings or films using precursor layer exerted pressure containment

InactiveUS6500733B1Cost effectiveImprove Defect ControlFinal product manufactureVacuum evaporation coatingSynthetic membraneChemistry

Systems and methods are described for synthesis of films, coatings or layers using precursor exerted pressure containment. A method includes exerting a pressure between a first precursor layer that is coupled to a first substrate and a second precursor layer that is coupled to a second substrate; forming a composition layer; and moving the first substrate relative to the second substrate, wherein the composition layer remains coupled to the second substrate.

Owner:HELIOVOLT CORP

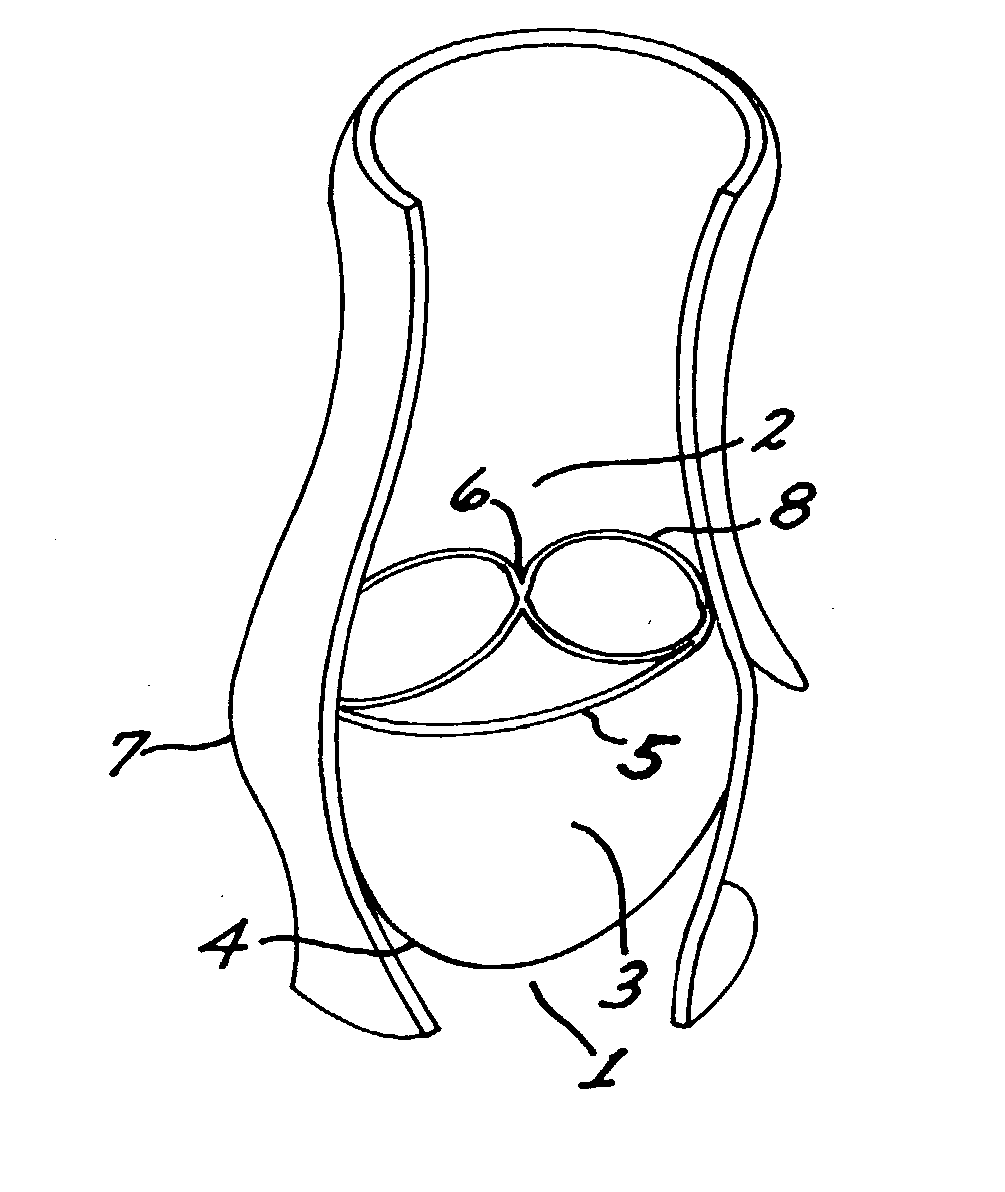

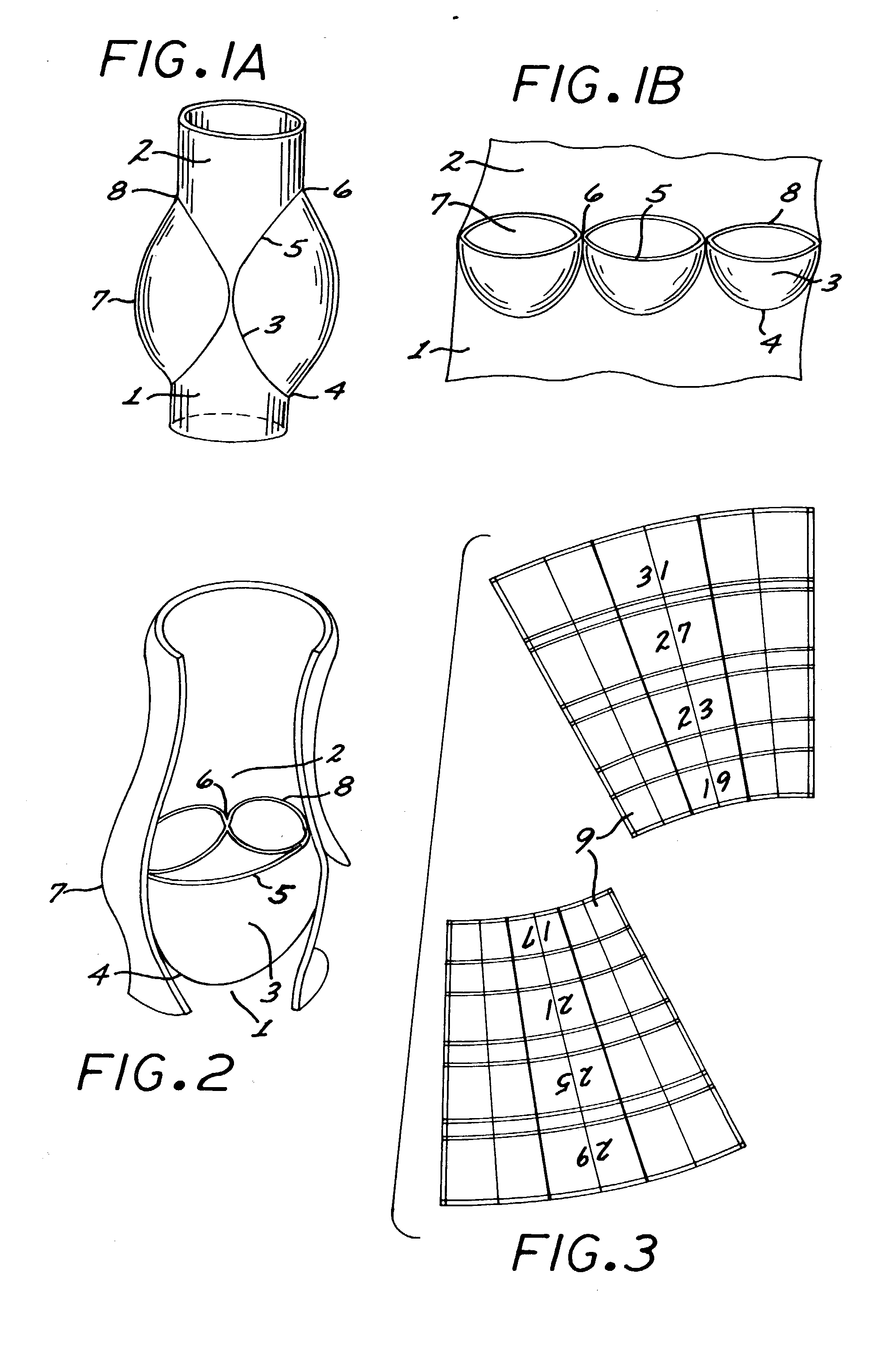

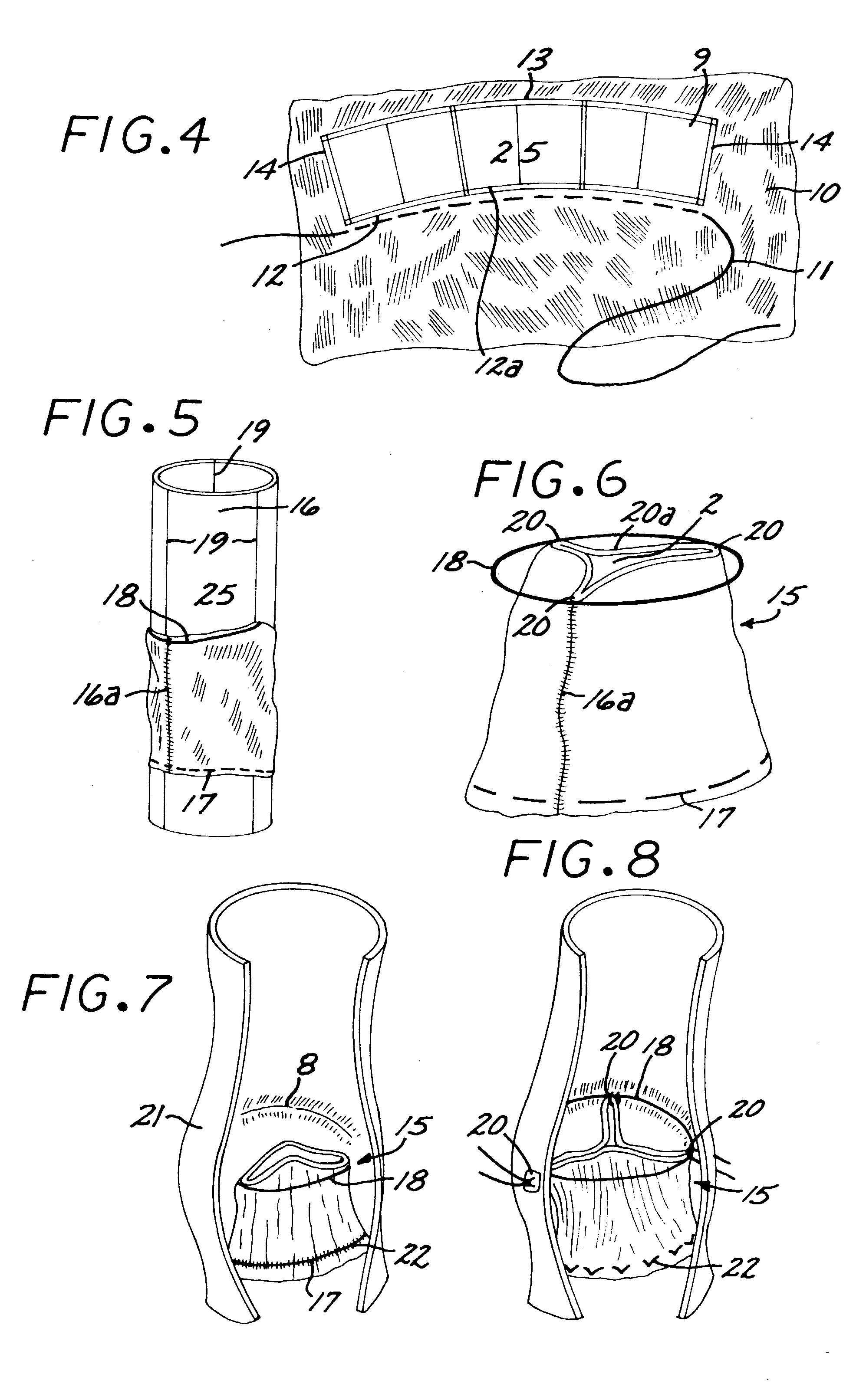

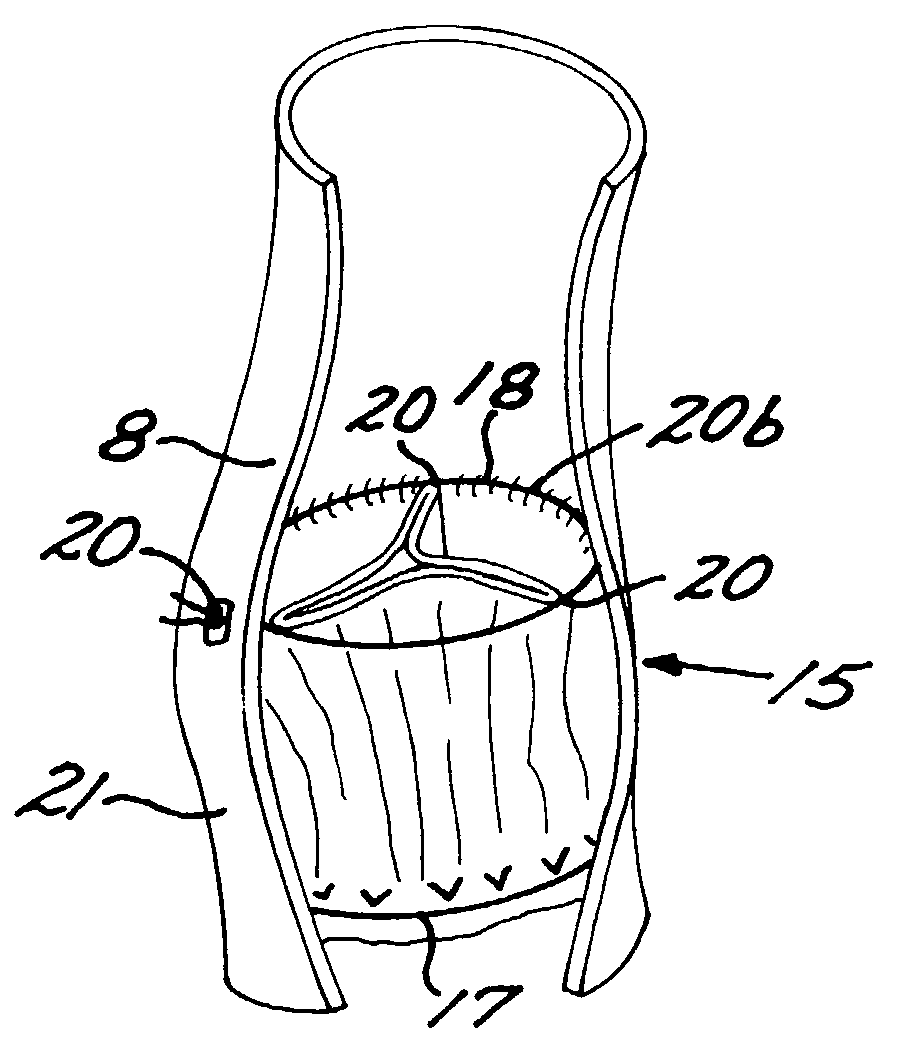

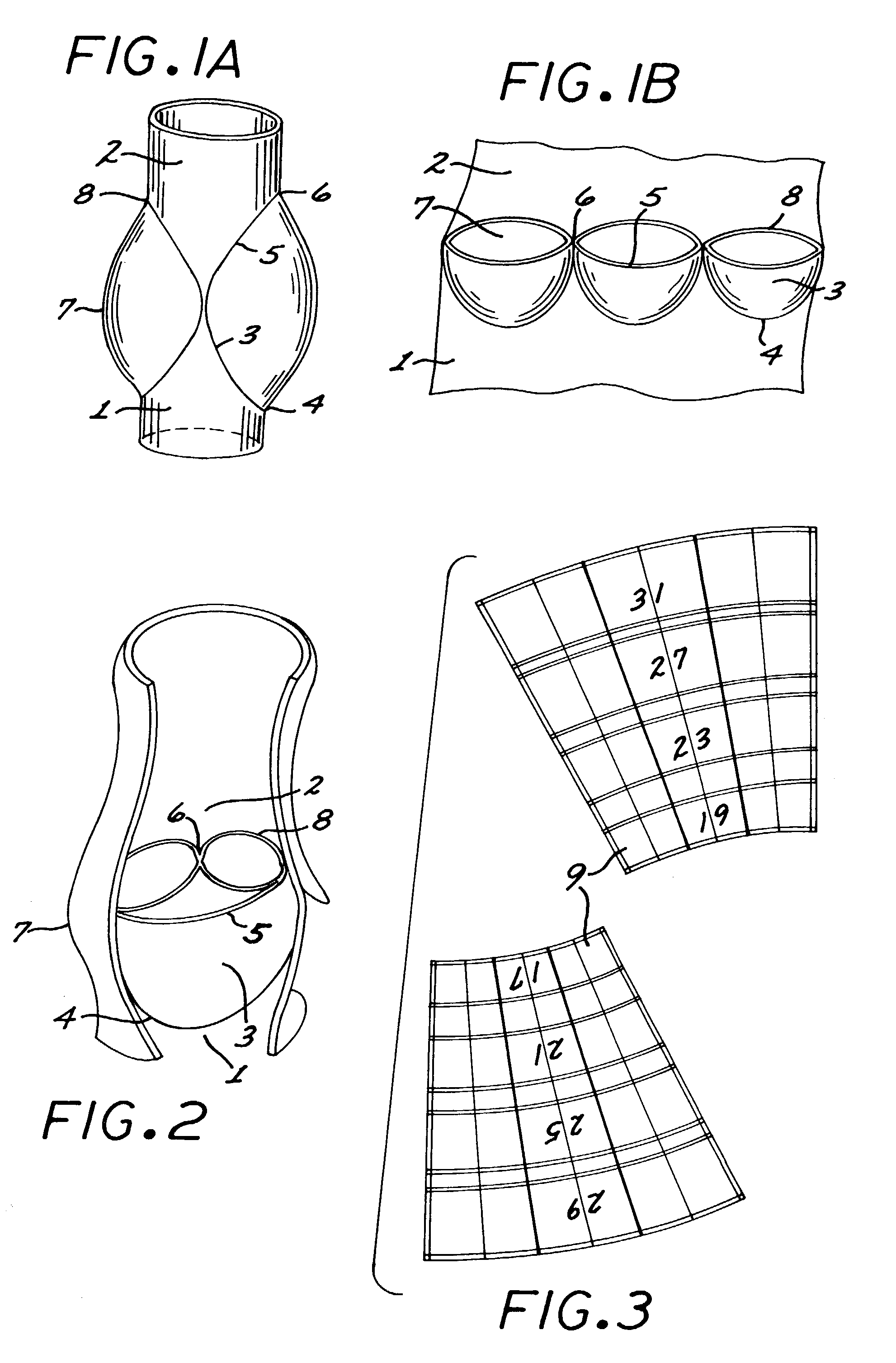

Reed valve for implantation into mammalian blood vessels and heart with optional temporary or permanent support

A multi-leaflet valve adapted to serve as a prosthesis for diseased native valve of a mammal is constructed of biologic membrane or of biocompatible synthetic membrane. The valve has the shape of a truncated cone that has an inflow and an outflow orifice with leaflets forming the outflow orifice and forming a plurality of commissures. A first flexible stent is removably affixed in a substantially circular fashion around the truncated cone in proximity of the inflow orifice, and a second flexible stent is removably affixed at the location of the commissures to form a circle around the truncated cone in proximity of the outflow orifice. The stents maintain the shape of the valve during the surgical implantation procedure. Each stent independently can be left in the valve or can be removed during the implantation procedure based upon the judgement of the cardiac surgeon performing the implantation procedure. A holder designed to maintain the geometry of the valve during implantation to a mammal is also disclosed.

Owner:THE INT HEART INST OF MONTANA FOUND

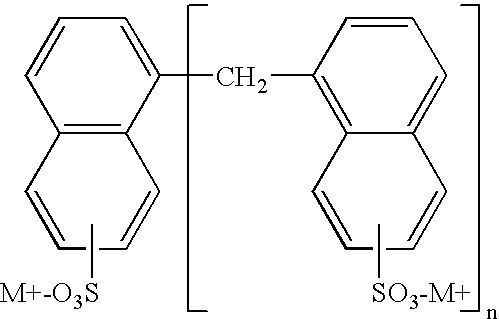

Compositions of suspended non-aggregated carbon nanotubes, methods of making the same, and uses thereof

InactiveUS7365100B2Improved strength and weight and strength to weight ratioMaterial nanotechnologyOther chemical processesCapacitanceElectricity

The invention is directed, in part, to stable compositions of suspended carbon nanotubes, methods of making them, and uses thereof. The invention provides methods of producing high and low concentrations of highly dispersed carbon nanotubes suspended in a liquid. The carbon nanotube suspensions are of use in generating products with improved strength, weight, strength to weight ratio, electrical and thermal versatility, radiation shielding, capacitance, dielectric properties, selective ion flow, catalytic activity and biological applications. The invention provides for industrial processing of materials comprising carbon nanotubes such as, but not limited to, fibers, films, synthetic membranes, coatings, drug delivery systems, and molecular circuitry components.

Owner:VERSILANT NANOTECH +1

Layers, coatings or films synthesized using precursor layer exerted pressure containment

InactiveUS20030052391A1Cost effectiveImprove Defect ControlFinal product manufactureSemiconductor/solid-state device detailsSynthetic membraneChemistry

Systems and methods are described for synthesis of films, coatings or layers using precursor exerted pressure containment. A method includes exerting a pressure between a first precursor layer that is coupled to a first substrate and a second precursor layer that is coupled to a second substrate; forming a composition layer; and moving the first substrate relative to the second substrate, wherein the composition layer remains coupled to the second substrate.

Owner:HELIOVOLT CORP

Synthesis of layers, coatings or films using precursor layer exerted pressure containment

InactiveUS20030054582A1Cost effectiveImprove Defect ControlAdhesive processesFinal product manufactureSynthetic membraneChemistry

Systems and methods are described for synthesis of films, coatings or layers using precursor exerted pressure containment. A method includes exerting a pressure between a first precursor layer that is coupled to a first substrate and a second precursor layer that is coupled to a second substrate; forming a composition layer; and moving the first substrate relative to the second substrate, wherein the composition layer remains coupled to the second substrate.

Owner:HELIOVOLT CORP

Reed valve for implantation into mammalian blood vessels and heart with optional temporary or permanent support

A multi-leaflet valve adapted to serve as a prosthesis for diseased native valve of a mammal is constructed of biologic membrane or of biocompatible synthetic membrane. The valve has the shape of a truncated cone that has an inflow and an outflow orifice with leaflets forming the outflow orifice and forming a plurality of commissures. A first flexible stent is removably affixed in a substantially circular fashion around the truncated cone in proximity of the inflow orifice, and a second flexible stent is removably affixed at the location of the commissures to form a circle around the truncated cone in proximity of the outflow orifice. The stents maintain the shape of the valve during the surgical implantation procedure. Each stent independently can be left in the valve or can be removed during the implantation procedure based upon the judgement of the cardiac surgeon performing the implantation procedure. A holder designed to maintain the geometry of the valve during implantation to a mammal is also disclosed.

Owner:THE INT HEART INST OF MONTANA FOUND

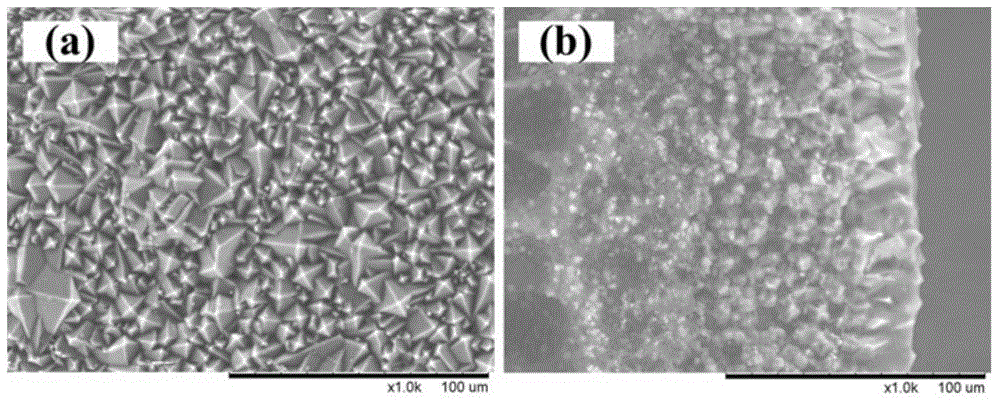

Synthetic method of metal organic skeleton membrane

ActiveCN104959044ASolve the problem of continuous growthSimple methodSemi-permeable membranesSynthesis methodsMetal-organic framework

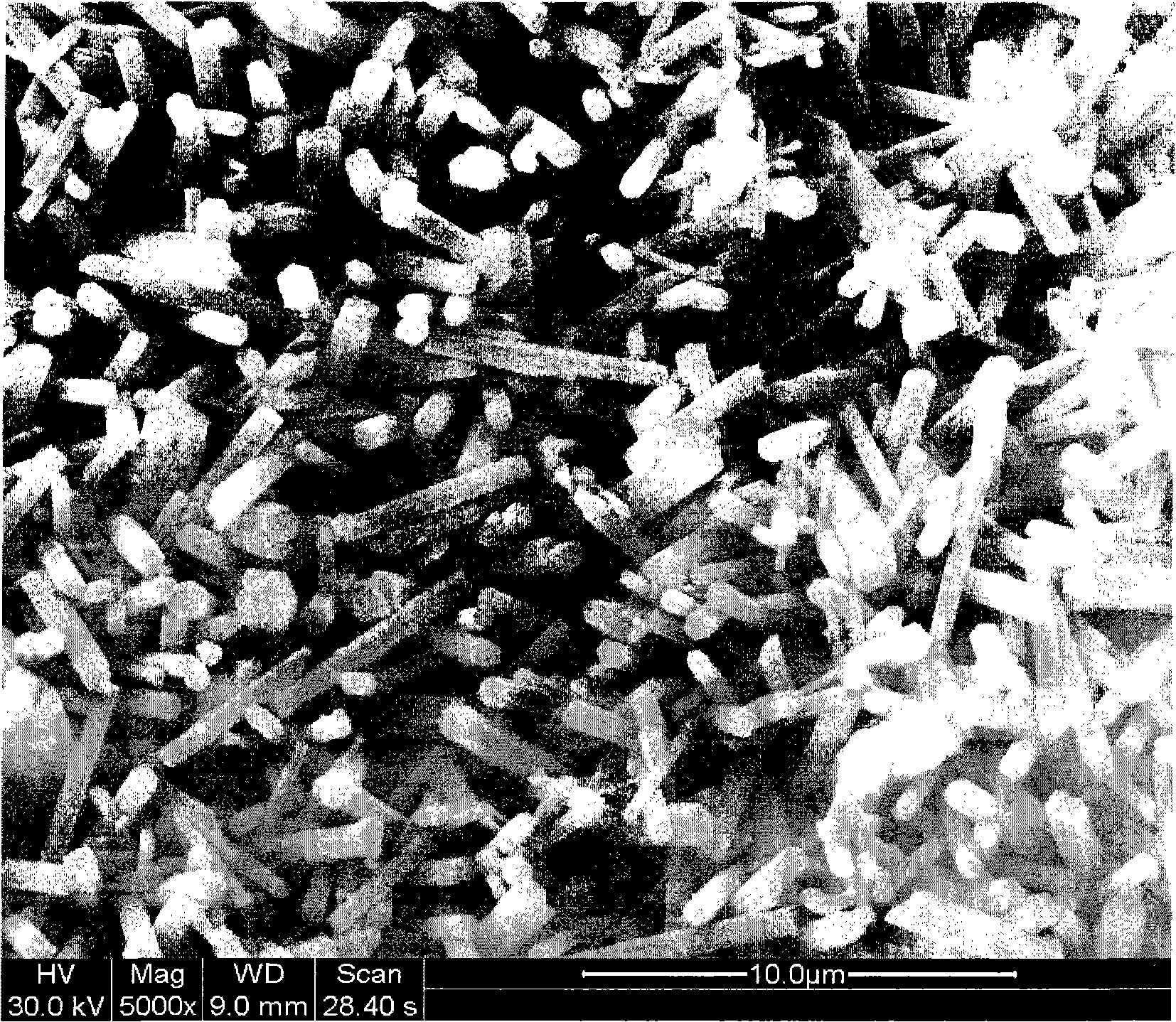

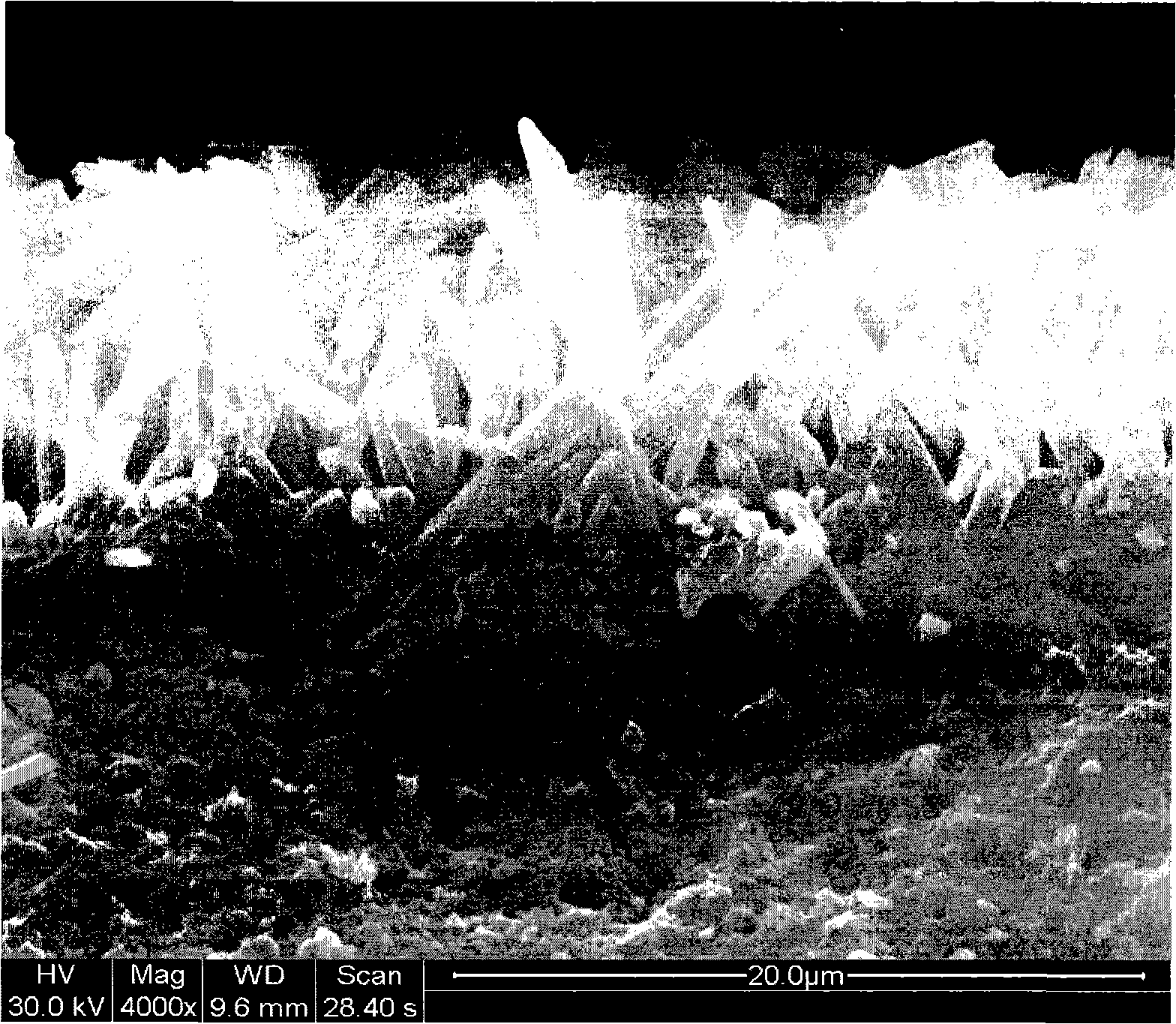

The invention provides a synthetic method of a metal organic skeleton membrane. Firstly, metal salt A is added to a solvent A, so as to be mixed and dispersed, then a stabilizing agent is added to mix and react, so as to obtain metal-sol, a substrate is immersed in the metal-sol for soaking or ultrasonic shaking for 5 to 60 min, and then the substrate is taken out and dried for 2 to 4 h at 60 to 180 DEG C, so as to obtain the substrate containing the metal-sol; then organic ligands, metal salt B and a solvent B are mixed and uniformly stirred, so as to obtain a synthetic solution; subsequently, the substrate containing the metal-sol is immersed in the synthetic solution for solvothermal synthesis, and a synthetic membrane is taken out, flushed and dried after a reaction system is cooled, so as to obtain the metal organic skeleton membrane. According to the synthetic method, the continuous dense metal organic skeleton membrane can be obtained, and metal organic skeleton materials are synthesized in a duct, so as to increase the rigidity and compressive strength of the membrane; the synthetic method is suitable for substrates of various materials and configurations and has the advantage of wide application prospect.

Owner:ZHEJIANG UNIV OF TECH

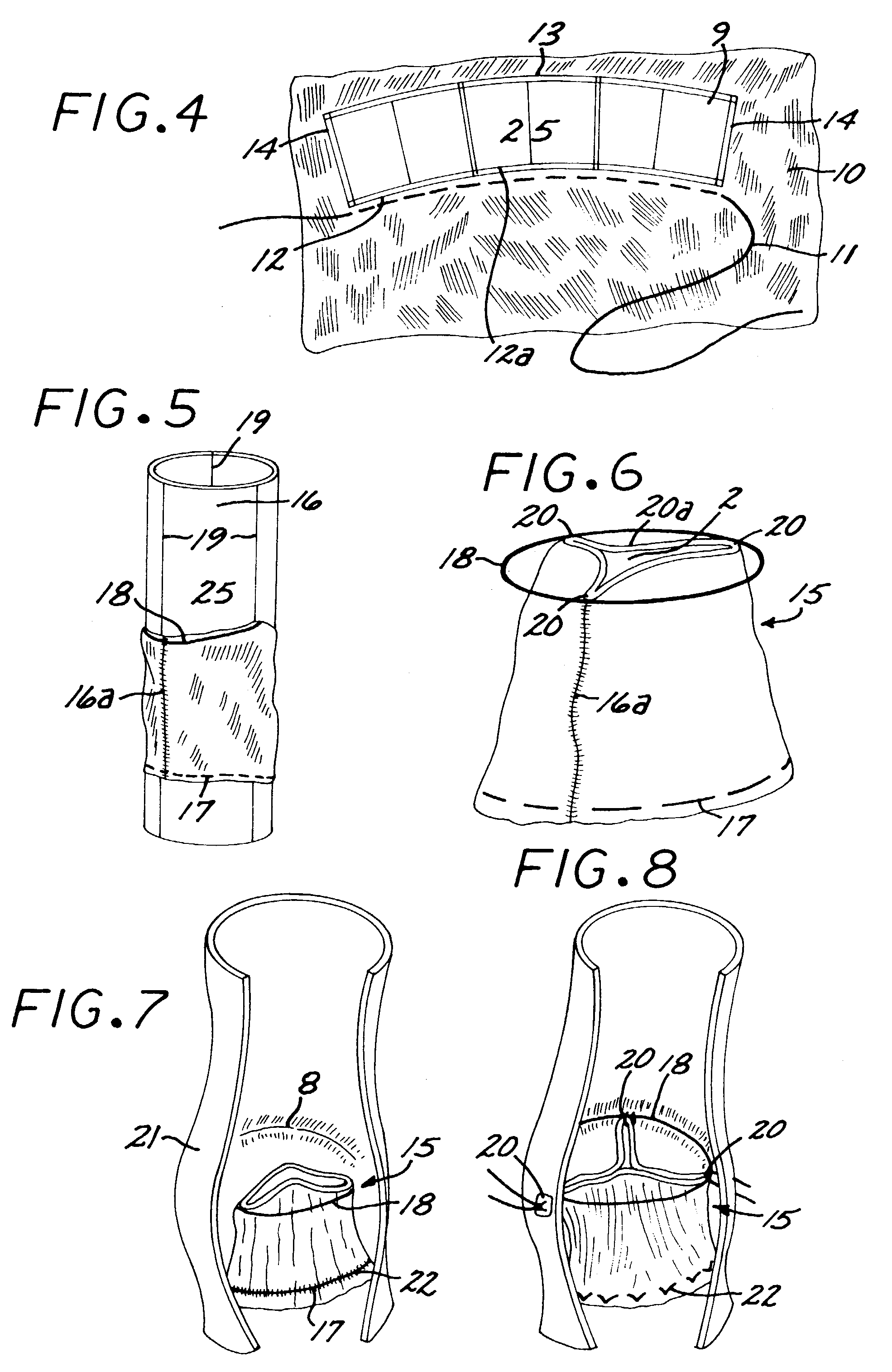

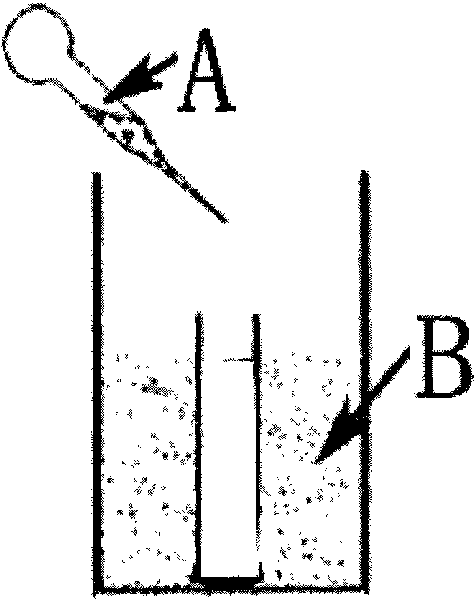

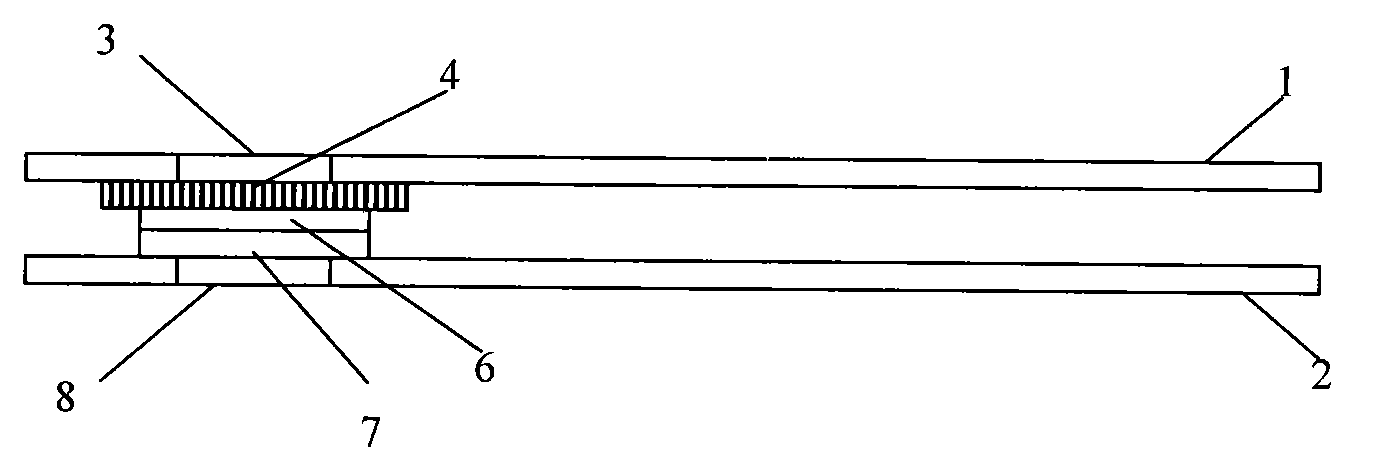

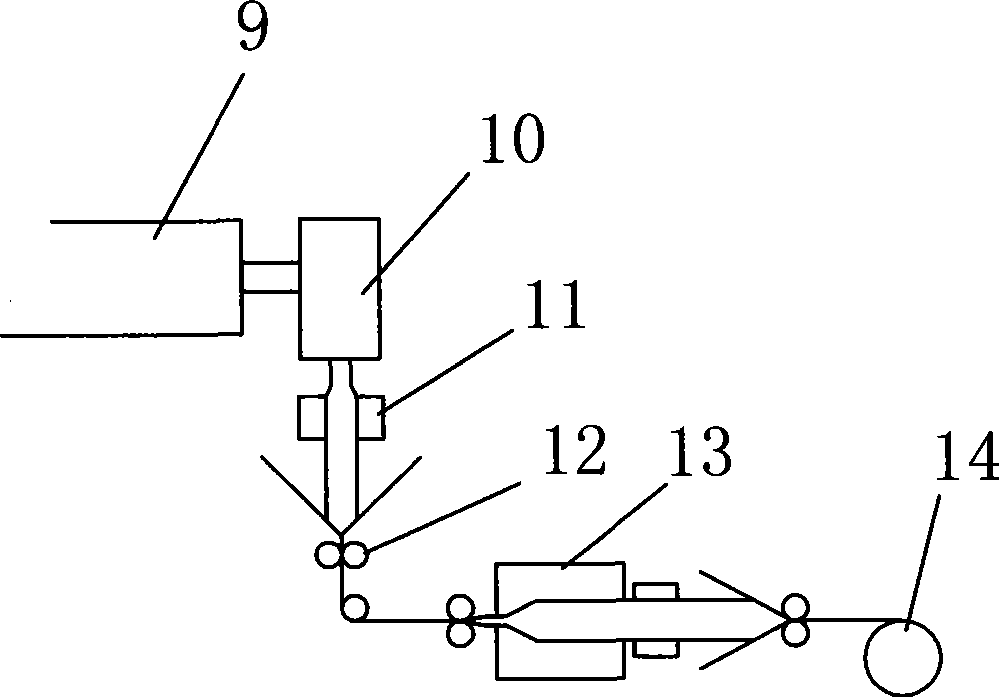

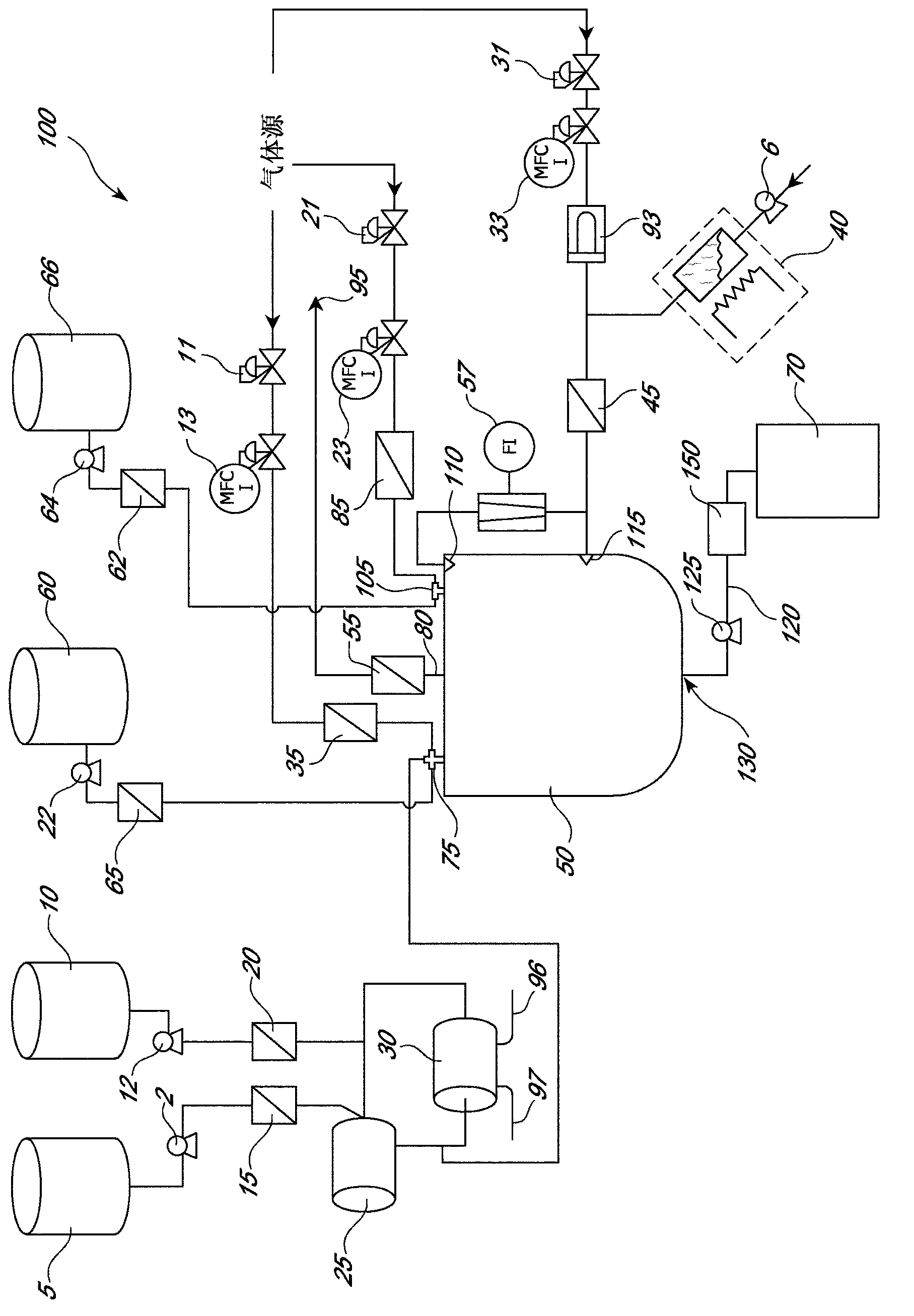

Method for preparing metal organic framework film

InactiveCN101693168AEasy to operateWide applicabilitySemi-permeable membranesDiffusionMetal framework

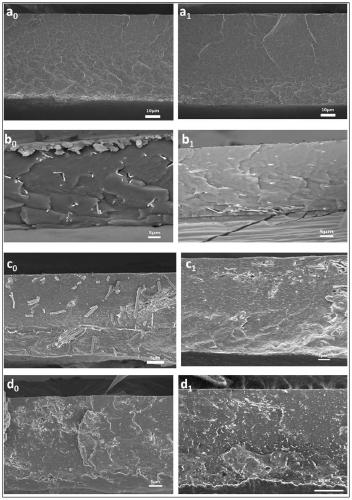

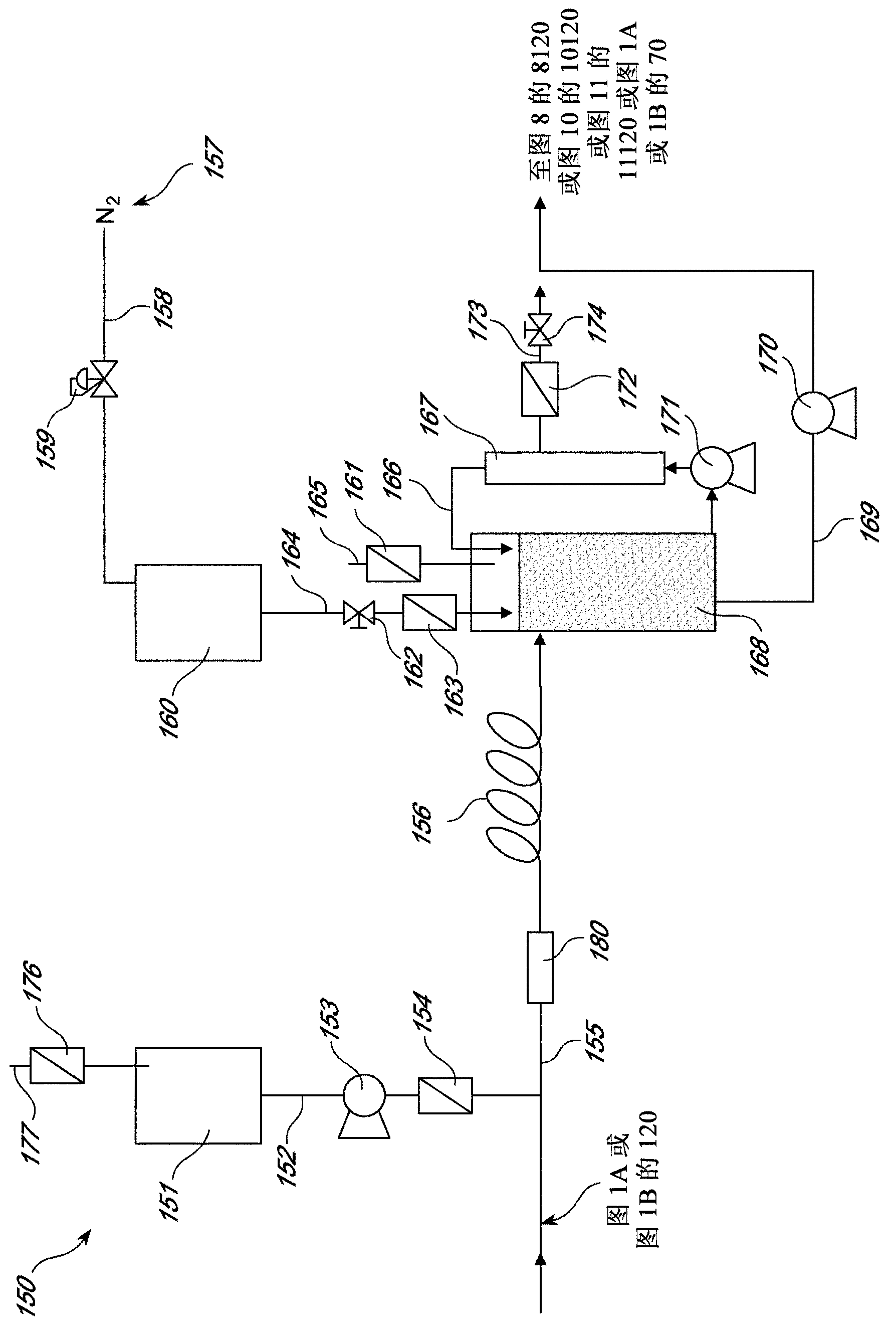

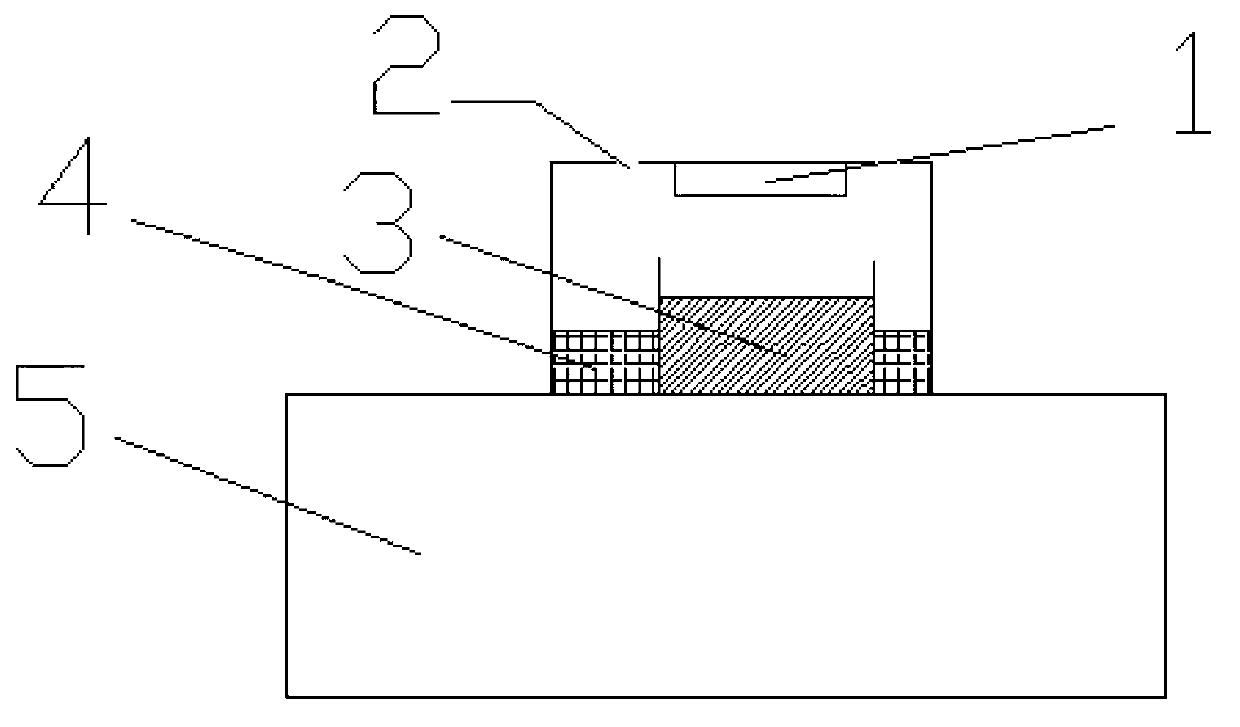

The invention belongs to the technical field of new material, and relates to a method for preparing a novel metal organic framework (MOFs) film and the potential application prospect thereof, in particular to the MOFs film which is continuous, compact, firm and crackles and is prepared on the surface of a porous carrier by a back diffusion method. The invention is characterized in that metal precursor of a synthetic membrane and organic ligand nutrient solution are respectively supplied from the two sides of a carrier tube (as shown); the diffusion of metal precursor nutrient solution is promoted to facilitate metal organic framework compound to crystallize and grow on the surface of the carrier; and finally, the MOFs separating film which is continuous, compact, firm and crackles and hasselective permeability for molecular mixture is obtained. The invention has the effect and advantage of solving the difficulty that the binding force between metal framework organic matter and the carrier is weak, so that the continuous and compact film is hardly formed; furthermore, the invention provides the method which is used for preparing the MOFs film as well as simple in operation and easy in control, thus initiating the precedent of preparing the MOFs film with high performance on the tubular carrier.

Owner:DALIAN UNIV OF TECH

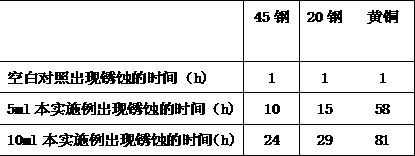

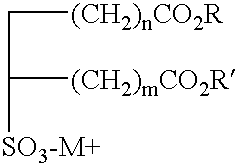

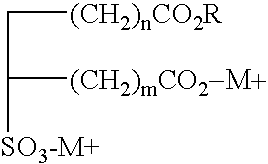

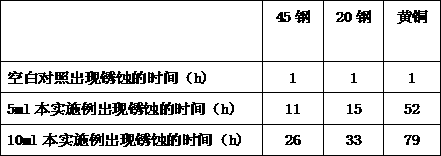

Metal rust-preventive oil comprising butyl acrylate

ActiveCN103214886AGood gas phase anti-rust effectExcellent contact rust resistanceAnti-corrosive paintsMeth-Composite film

The invention discloses metal rust-preventive oil comprising butyl acrylate. The oil is prepared from the raw materials of: No.120 solvent oil, paraffin, methyl diethanolamine, epoxy octyl stearate, magnesium naphthenate, a silane coupling agent KH560, a silane coupling agent A171, microcrystalline wax, aluminum stearate, magnesium lanolin soap, monoethanolamine, barium petroleum sulfonate, sodium lauryl sulfate, trioctyl trimellitate, benzotriazole, 2-aminoethyl heptadecenyl imidazoline, zinc stearate, an antioxidant BHT, an antioxidant 1010, dipropylene glycol, phytic acid, butyl acrylate, modified nano-grade dolomite powder, a composite film-forming material, and ferrocene. The rust-preventive oil provided by the invention has excellent contact rust resistance and good gas-phase rust resistance. The rust-preventive oil provided by the invention provides good gas-phase rust resistance and contact rust resistance for steel and brass.

Owner:SHANTOU HONGSHENG BOLT IND CO LTD

Compositions of suspended non-aggregated carbon nanotubes, methods of making the same, and uses thereof

InactiveUS20080076837A1Improved strength and weight and strength to weight ratioMaterial nanotechnologyOther chemical processesFiberElectricity

The invention is directed, in part, to stable compositions of suspended carbon nanotubes, methods of making them, and uses thereof. The invention provides methods of producing high and low concentrations of highly dispersed carbon nanotubes suspended in a liquid. The carbon nanotube suspensions are of use in generating products with improved strength, weight, strength to weight ratio, electrical and thermal versatility, radiation shielding, capacitance, dielectric properties, selective ion flow, catalytic activity and biological applications. The invention provides for industrial processing of materials comprising carbon nanotubes such as, but not limited to, fibers, films, synthetic membranes, coatings, drug delivery systems, and molecular circuitry components.

Owner:VERSILANT NANOTECH +1

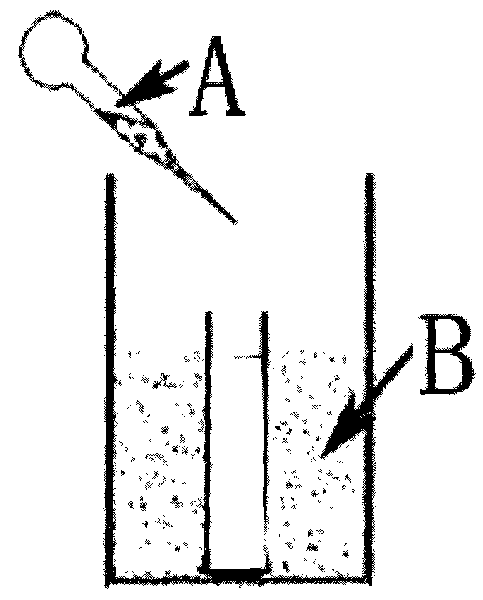

Method of preparing perm-selective porous membrane and method of separating gases using porous membrane prepared thereby

ActiveUS20180272288A1Improve stabilityImprove thermal stabilitySemi-permeable membranesMembranesSeparation factorDiffusion methods

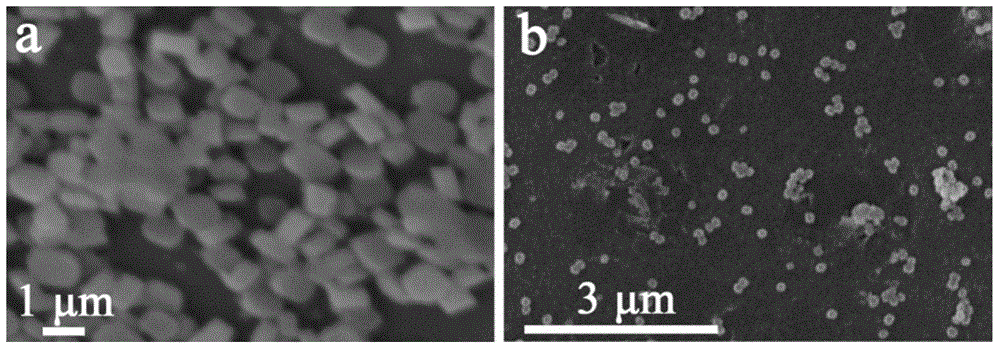

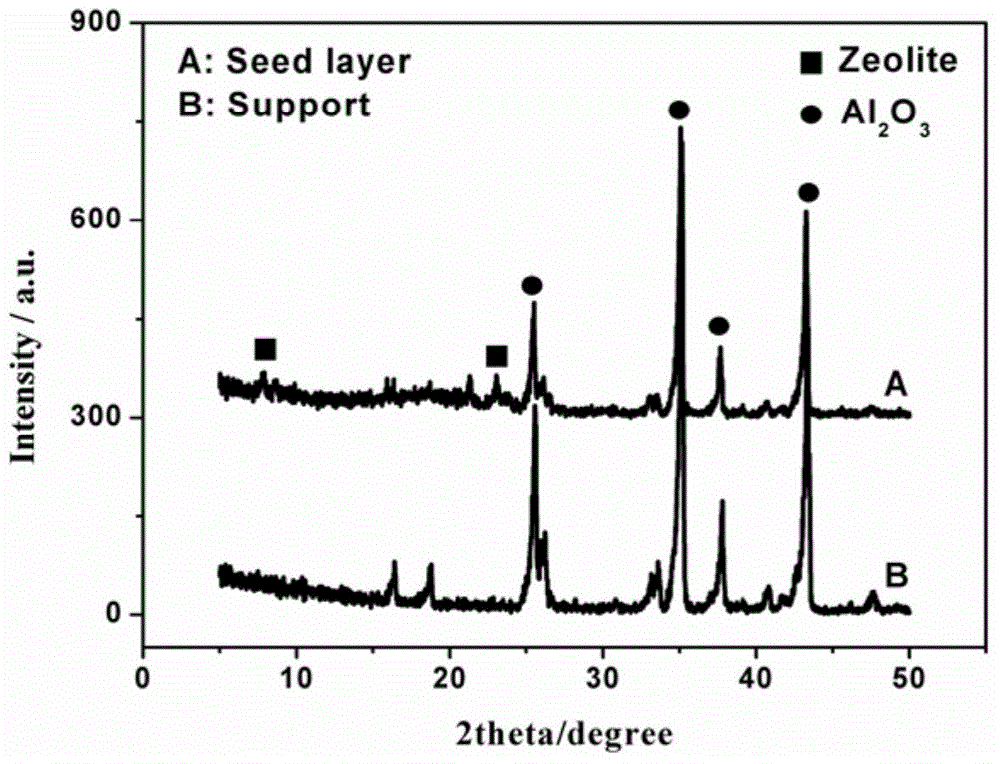

The present invention relates to a method of preparing a perm-selective porous membrane and a method of separating gases using the prepared porous membrane. According to the present invention, a membrane is synthesized using a hierarchically structured alumina porous support by a counter diffusion method. During this synthesis, the diffusion rate of metal ions loaded on the porous support is controlled by controlling the pore size of the porous support, and the position at which the membrane is synthesized is controlled by synthesizing the membrane inside the support. This can increase the physical stability of the membrane and make the membrane thicker so as to ensure higher H2 / CO2 separation factors.

Owner:KOREA UNIV RES & BUSINESS FOUND

Homocysteine dry chemical detection strip and preparation method thereof

InactiveCN101592656ASensitive and goodImprove featuresMaterial analysis by observing effect on chemical indicatorBiological testingReagent stripChemical reaction

The invention provides a homocysteine dry chemical detection strip and a preparation method thereof. The invention aims to provide a detection strip and a preparation method thereof for fast semiquantitatively / quantitatively detecting homocysteine. The strip is composed of an elongated upper support layer, an elongated lower support layer and test layers in the middle and is divided into a hand-held area and a test area. A diffusion layer, a filtration layer, an enzyme reagent layer and a colour development reagent layer are arranged in the test area from top to bottom. Various grid materials of synthetic fibre materials can be used to prepare the diffusion layer, various filterable materials for separating blood can be used to prepare the filtration layer, and various asymmetric synthetic membranes can be used to prepare the enzyme reagent layer and the colour development reagent layer. A loading hole is arranged in the upper support layer, a sample is sent from the loading pole to the diffusion layer, the sample then permeates into the filtration layer, the enzyme reagent layer and the colour development reagent layer, chemical reactions are performed in the enzyme reagent layer and the colour development reagent layer to change the colour, and the change of optical density in reaction process can be tested through a test pole of the lower support layer.

Owner:BEIJING HUAANFO BIOMEDICAL RES CENT +1

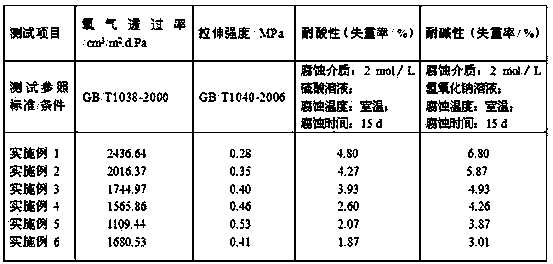

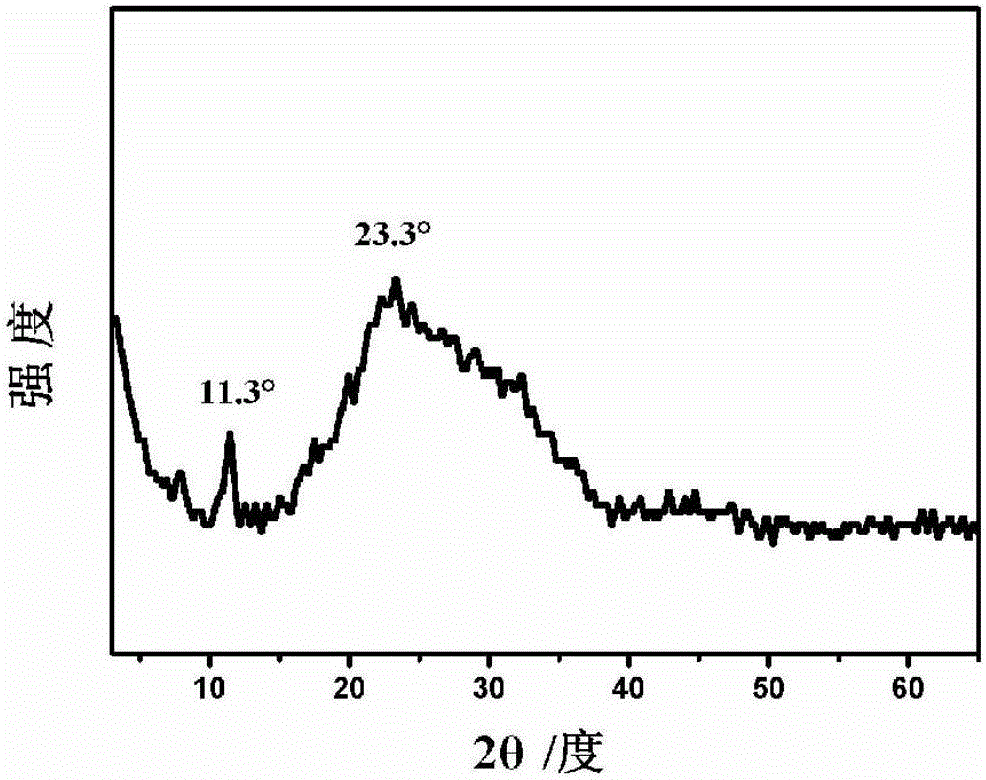

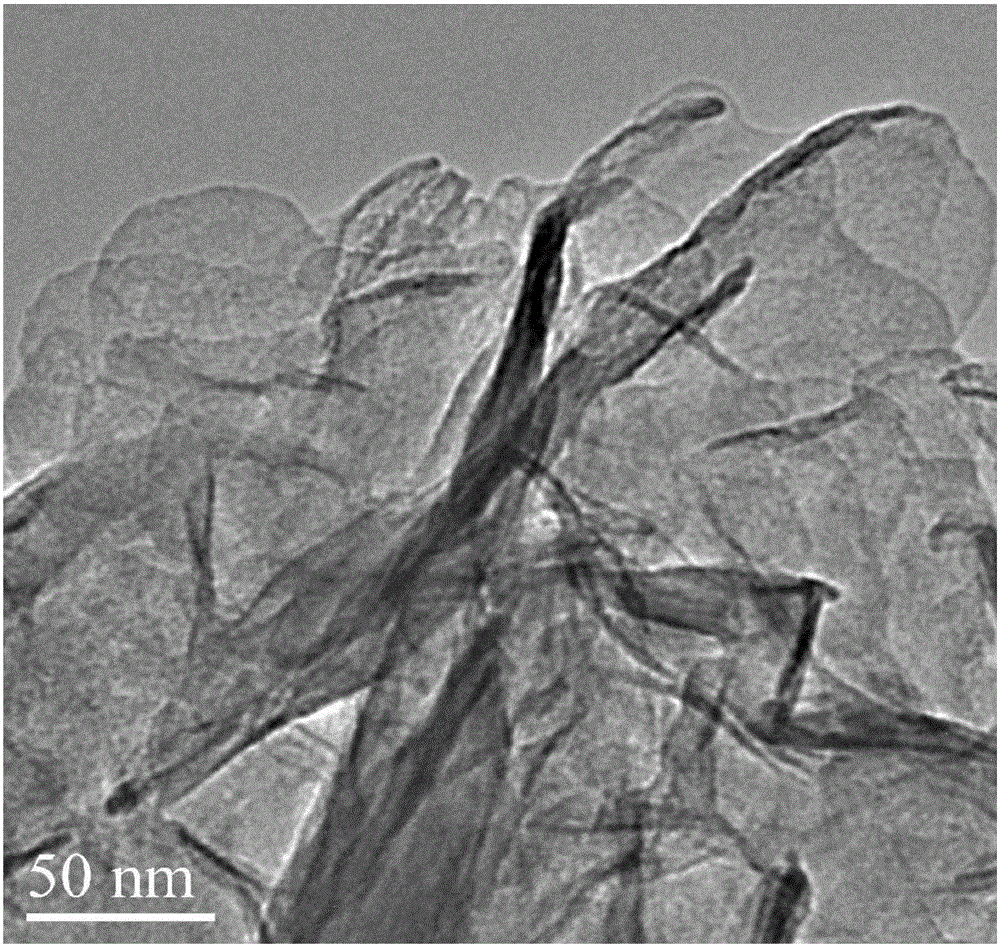

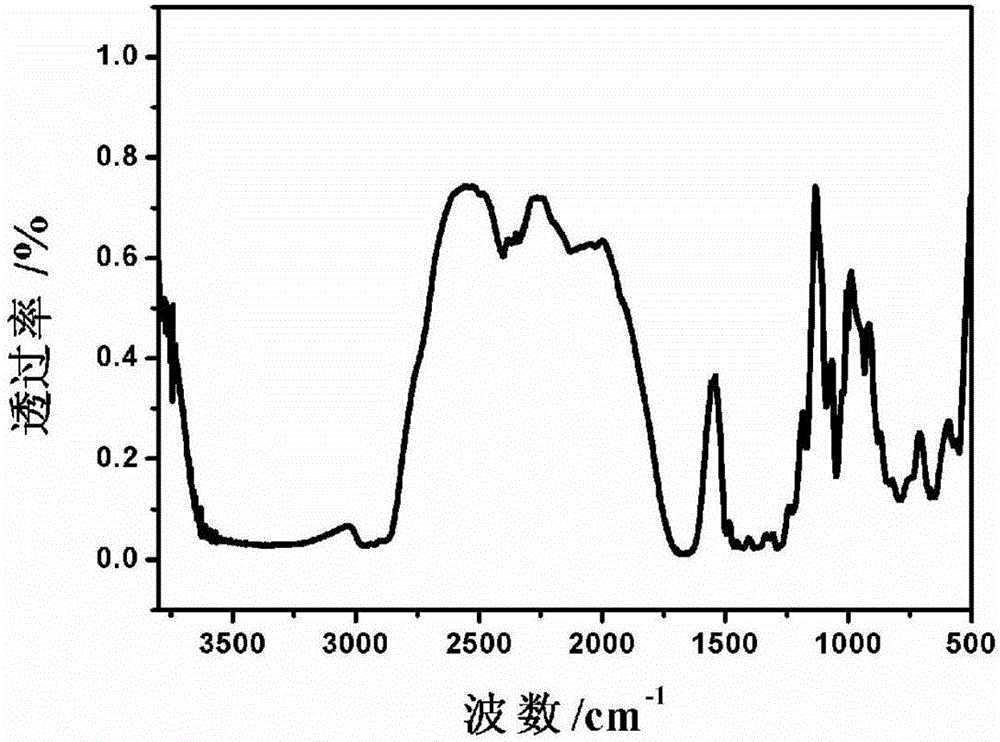

Waterproof and oxygen-insulating sealing film as well as preparation method and application thereof

InactiveCN104212053AImprove barrier propertiesGood acid and alkali resistanceMaterial nanotechnologyFlexible coversComposite filmCarbon nanotube

The invention discloses a waterproof and oxygen-insulating sealing film, a preparation method of the waterproof and oxygen-insulating sealing film, and an application of the waterproof and oxygen-insulating sealing film. The preparation method comprises the following steps: firstly, preparing graphene oxide nanoribbons (GONRs) by adopting a longitudinal multi-walled carbon nanotube oxidization cutting method, performing modification to obtain functional GONRs (K-GONRs), and then compounding the K-GONRs and an ethylene-vinyl acetate copolymer (EVA) on a film coating machine to form a film. According to a composite material thin film prepared by using the method disclosed by the invention, the K-GONRs have excellent compatibility with an EVA matrix, and meanwhile, the K-GONRs achieve good dispersion in the matrix. In addition, most of obtained laminar K-GONRs are distributed in an EVA composite thin film in parallel. By virtue of the multi-layer and parallel-distributed special structure and the close combination between a K-GONRs inserted layer and the EVA matrix, the thin film has excellent blocking performance and good acid and alkali resistance, and further improves the mechanical performance; meanwhile, the thin film is safe and environment-friendly, is particularly suitable for preparing valuable precision instrument sealing films, ice bags for packaging ice and frozen products, and food packaging films, and has wide practical application values.

Owner:FUZHOU UNIV

Waterborne anticorrosive coating and preparation method

InactiveCN105176313AReduce surface tensionIncrease wettabilityAnti-corrosive paintsEpoxy resin coatingsMeth-Sodium phosphates

The invention discloses a waterborne anticorrosive coating. The waterborne anticorrosive coating comprises the following components: waterborne epoxy resin emulsion, a pigment filler, a film forming assistant, a leveling agent, a defoaming agent, a thickening agent, a dispersing agent, water and a curing agent, wherein the pigment filler is mixture of iron oxide red and zinc phosphate which are mixed according to a mass ratio of 1:1; the film forming assistant is glycol; the leveling agent is polyacrylic acid or hydroxymethyl cellulose; the defoaming agent is tributyl phosphate; the thickening agent is hydroxymethyl cellulose; the dispersing agent is sodium hexametaphosphate; the curing agent is one of diethylenetriamine, m-phenylenediamine, modified phenolic amine and diamino diphenyl sulfone (DDS). The invention further discloses a preparation method of the waterborne anticorrosive coating, the coating has good anticorrosive performance, the preparation method is simple and feasible and the cost is low.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

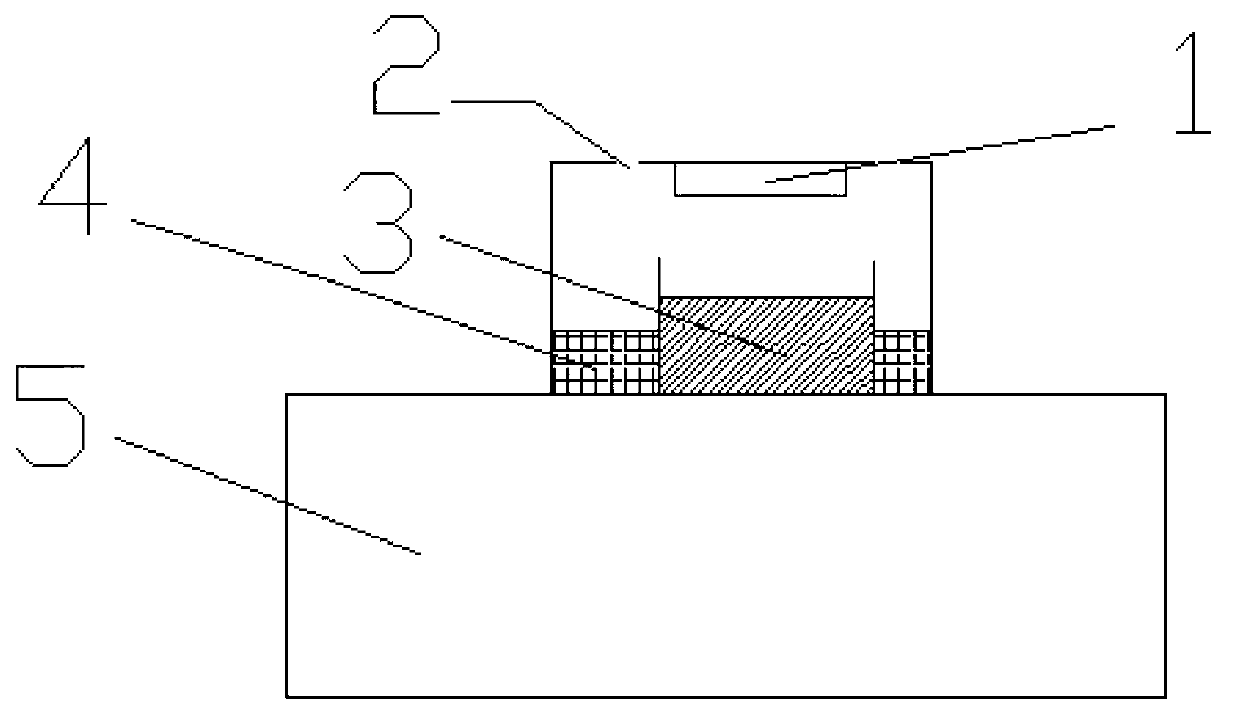

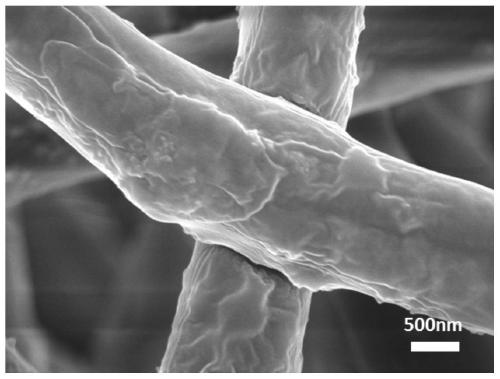

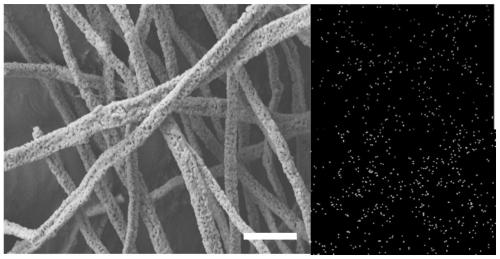

Polymer-based composite solid electrolyte film and preparation method thereof

ActiveCN111403804AShorten the transmission pathFast transferSolid electrolytesSecondary cellsSolid state electrolyteFiber

The invention relates to a polymer-based composite solid electrolyte film adopting magnetic composite fibers as filler and a preparation method of the polymer-based composite solid electrolyte film. The polymer-based composite solid electrolyte film comprises the magnetic composite fibers and a polymer matrix in which lithium salt is dissolved, the volume ratio of the magnetic composite fibers is0.5%-2%, the volume ratio of the polymer is 99.5%-98%, and the magnetic composite fibers are arranged in the polymer matrix in a vertical orientation mode. The preparation method comprises the following steps: 1) preparing precursor sol into magnetic composite fibers by an electrostatic spinning method and a calcining process; and 2) compounding the polymer matrix in which the lithium salt is dissolved and the magnetic composite fibers again to form a film, and introducing a magnetic field to carry out orientation regulation and control. According to the process, the distribution and orientation of the filler in the composite film can be controlled, so that the mechanical and electrical properties of the composite film can be improved by regulating and controlling the distribution structure of the filler, and finally, the room-temperature ionic conductivity of the solid electrolyte film is improved.

Owner:WUHAN UNIV OF TECH

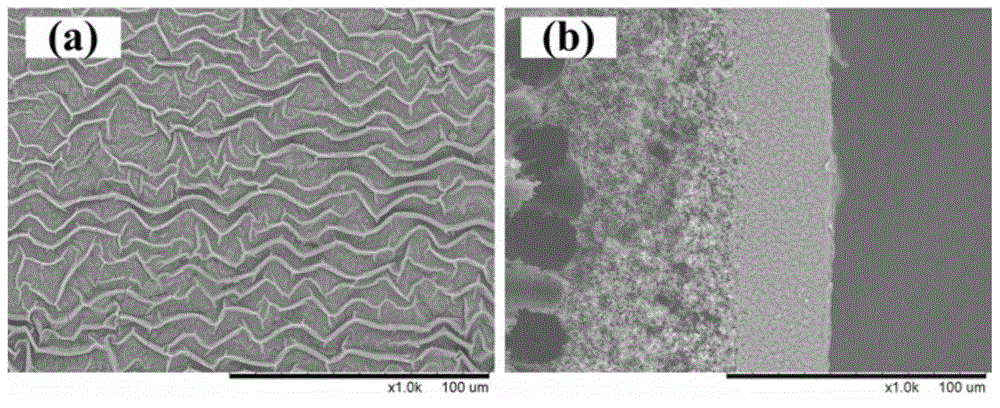

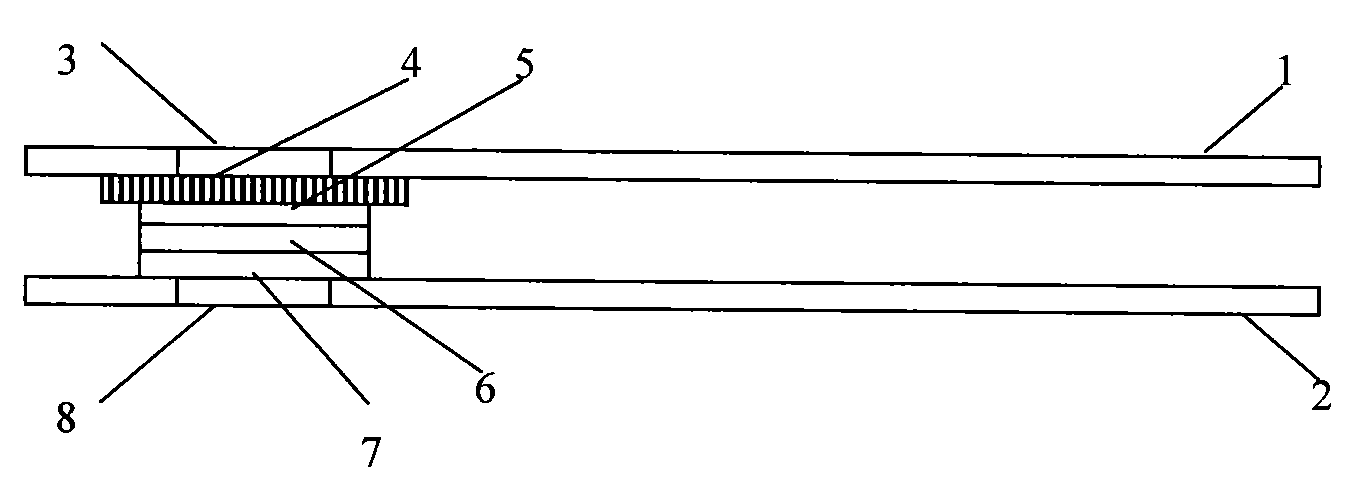

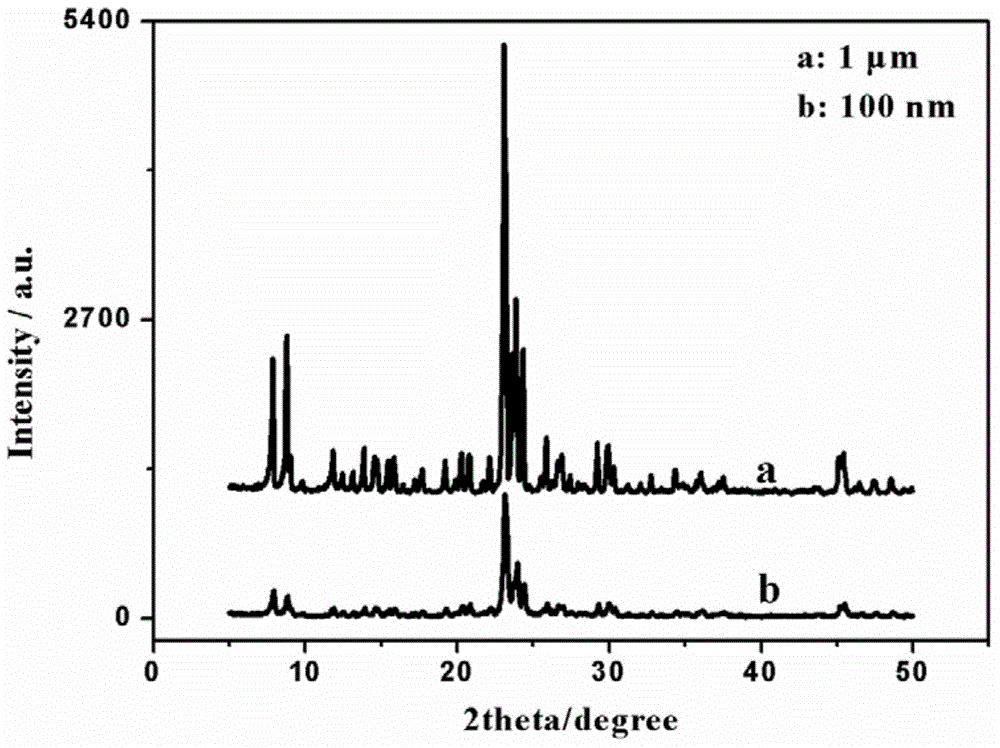

Method for preparing high-performance B-ZSM-5 molecular sieve membrane in dilute synthesis solution

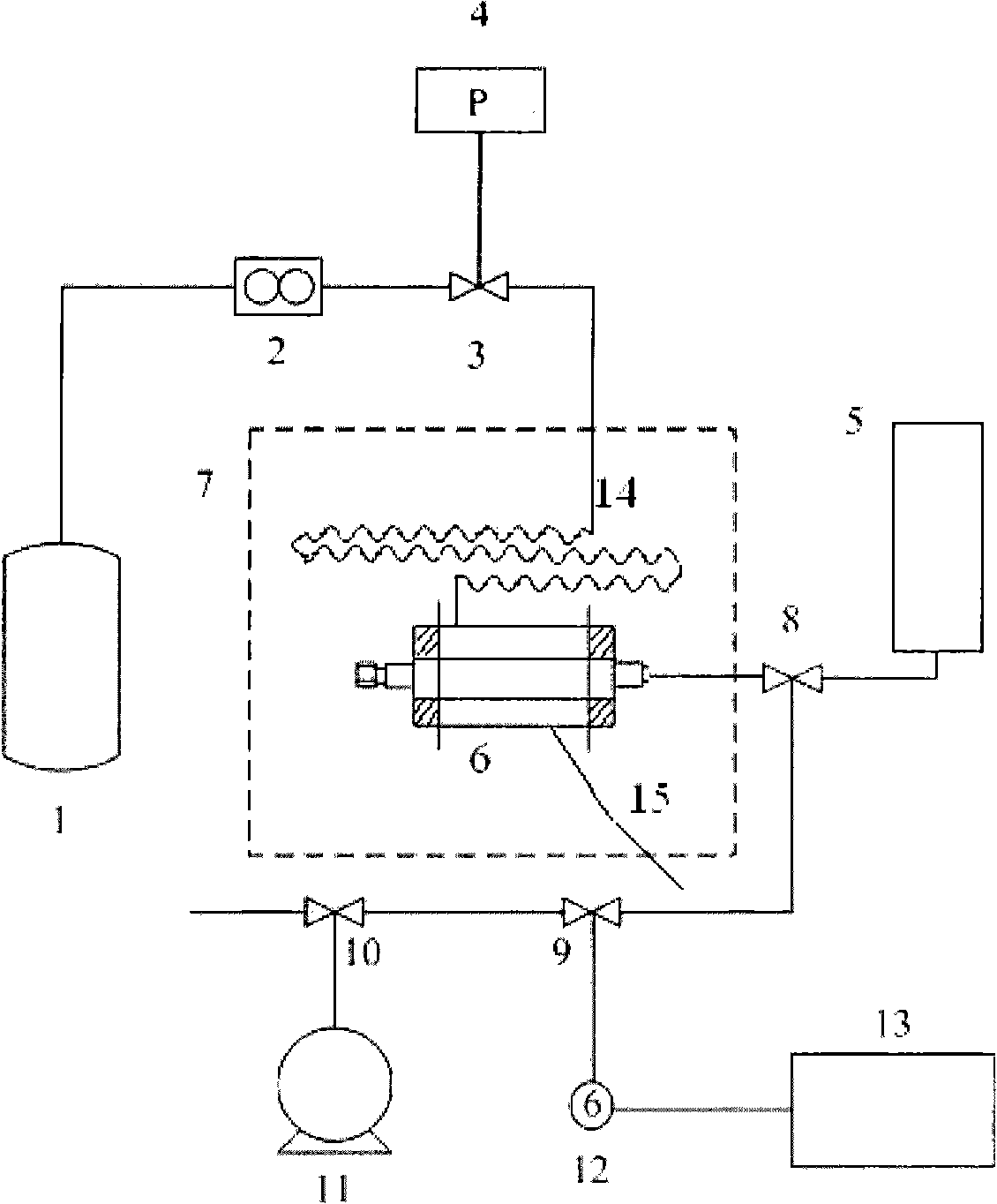

The invention provides a method for preparing a high-performance B-ZSM-5 molecular sieve membrane in a dilute synthesis solution. According to the method, B-ZSM-5 zeolite molecular sieves of different sizes are adopted as seed crystals and a thin and dense seed crystal layer is formed directly on the surface of a macroporous carrier tube. After that, the seed crystals and the seed crystal layer are subjected to hydro-thermal synthesis in a dilute synthesis solution, wherein the ratio of H2O to SiO2 is 200-1200. Finally, a high-performance B-ZSM-5 molecular sieve membrane is formed on the surface of a macroporous carrier. According to the method, boron is led into a zeolite framework in the isomorphism manner, so that the separation performance of the B-ZSM-5 molecular sieve membrane is greatly improved. The pervaporation performance of the prepared B-ZSM-5 molecular sieve membrane is tested in an ethanol / water system, wherein the weight ratio of ethanol to water is 5 to 95. The result of the test shows that, at 60 DEG C, the permeation flux and the separating factor of the B-ZSM-5 molecular sieve membrane are respectively 2.60 kg / m<2>*h, and 54.98. Due to the adoption of the dilute synthesis solution, the application amounts of a silicon source and a template agent for synthesizing the membrane are reduced. Therefore, the method is suitable for the recovery of fuel ethanol during the fermentation-based ethanol production process.

Owner:DALIAN UNIV OF TECH

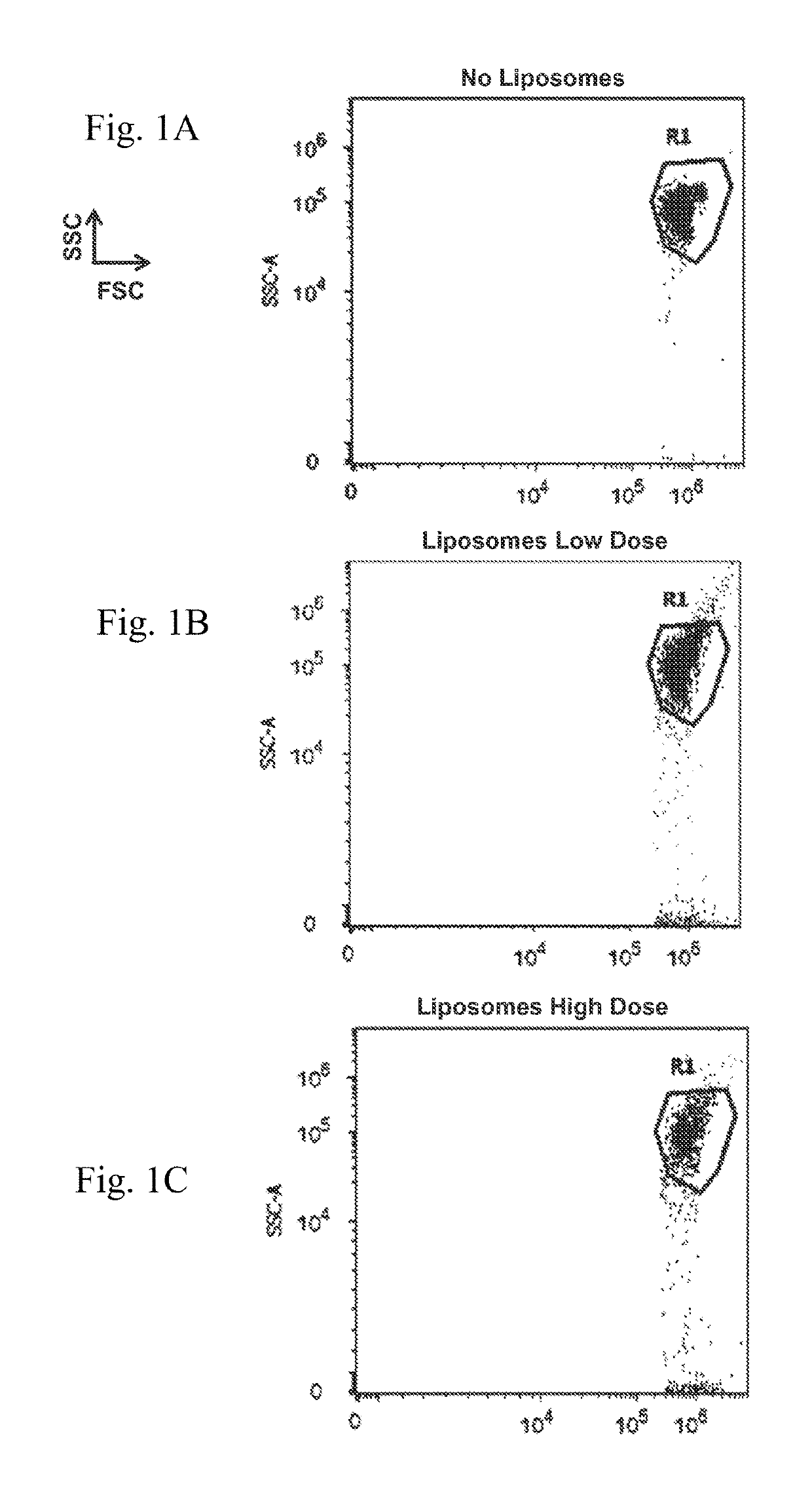

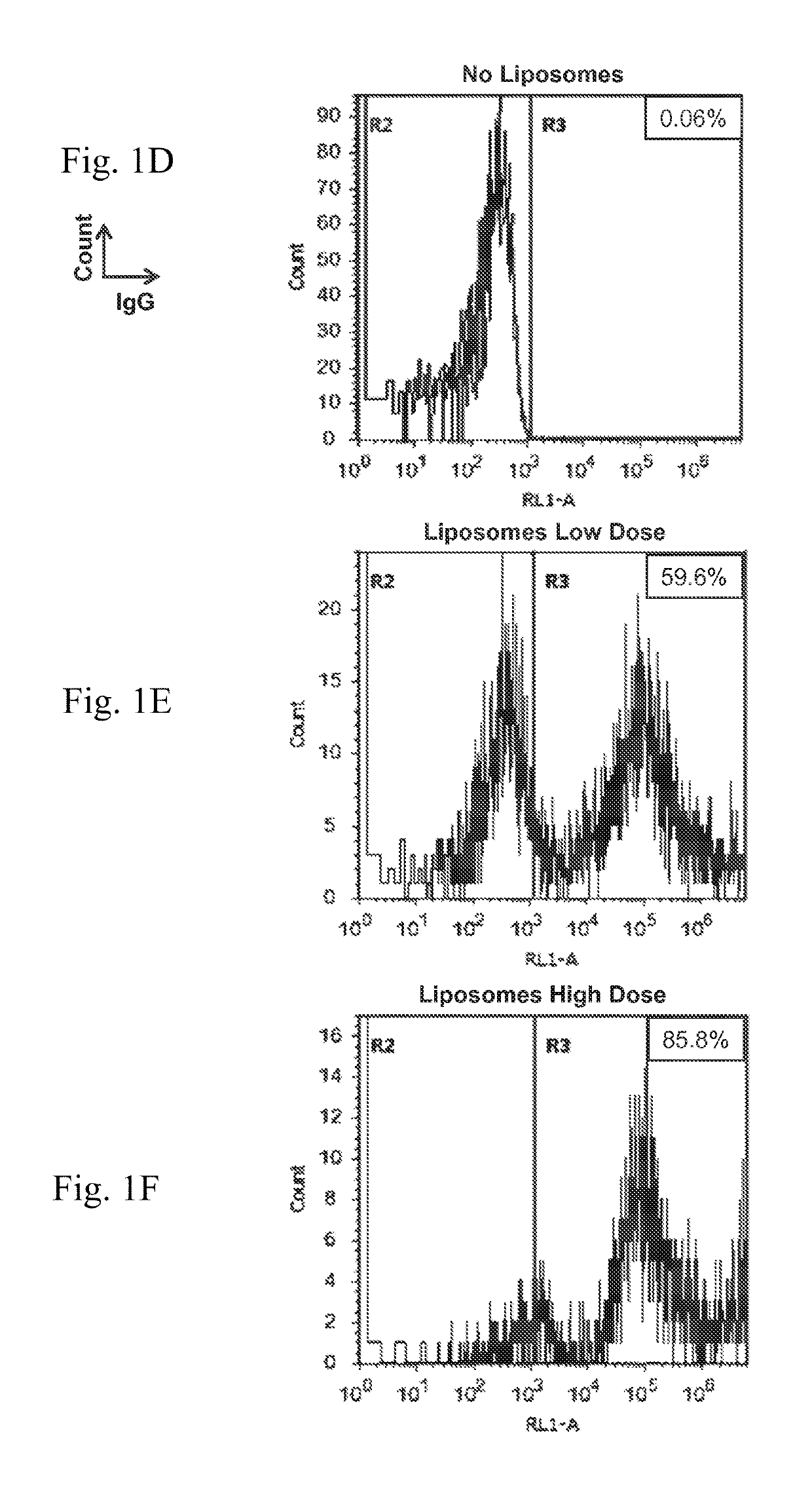

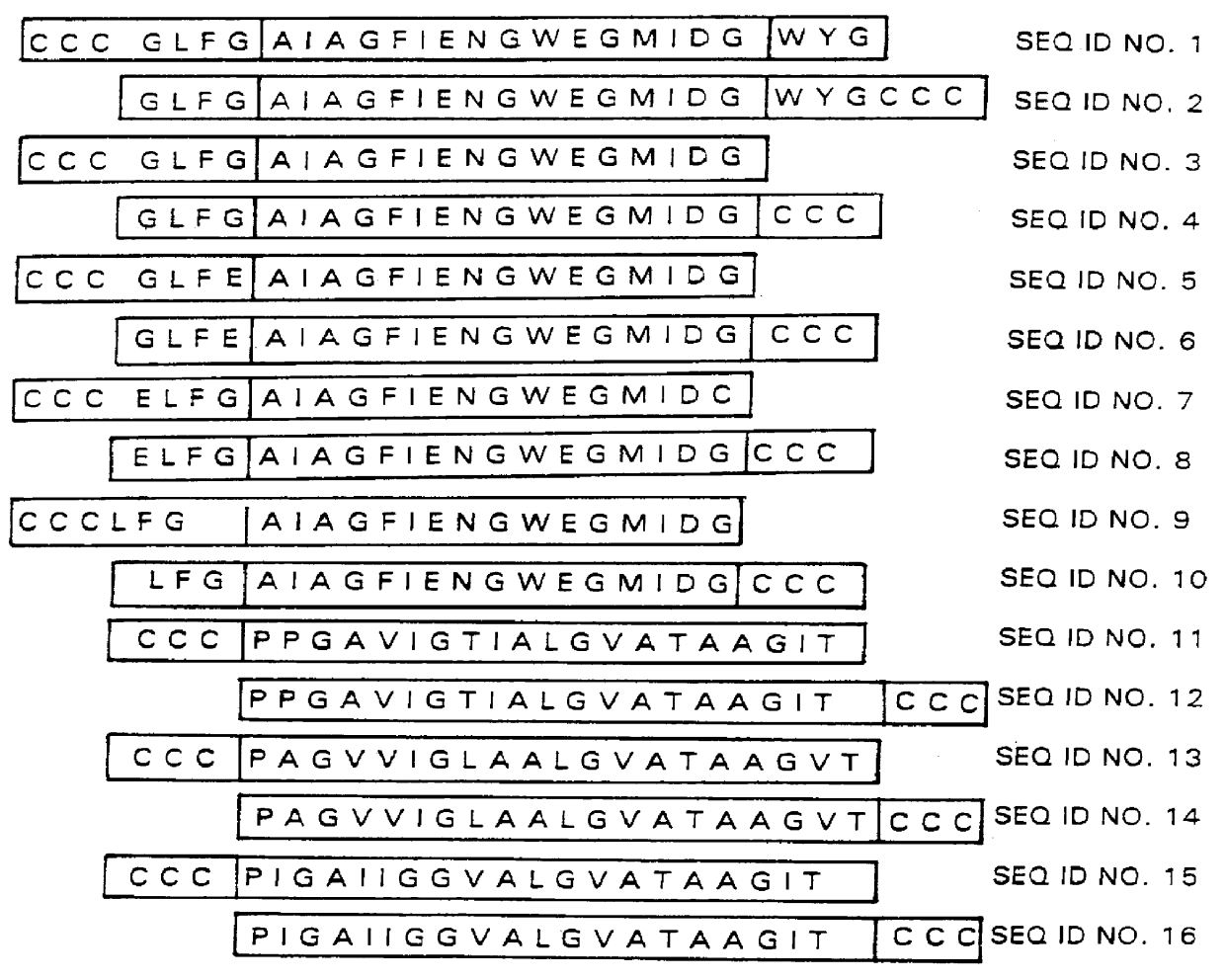

Synthetic membrane-receiver complexes

Compositions comprising synthetic membrane-receiver complexes, methods of generating synthetic membrane-receiver complexes, and methods of treating or preventing diseases, disorders or conditions therewith.

Owner:FLAGSHIP VENTURES MANAGEMENT INC +1

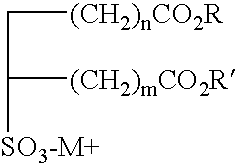

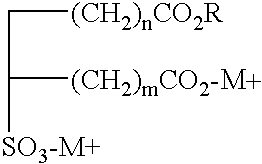

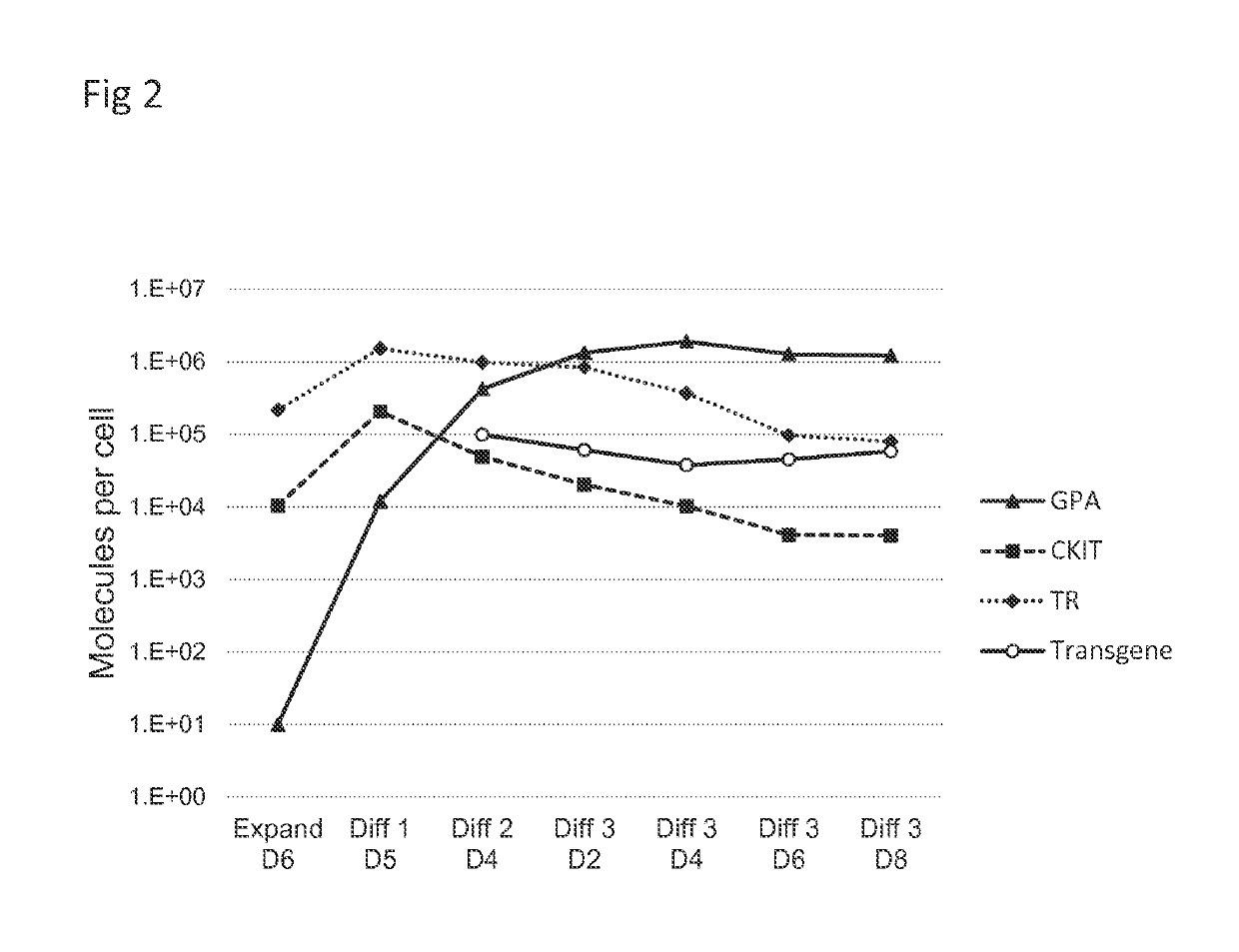

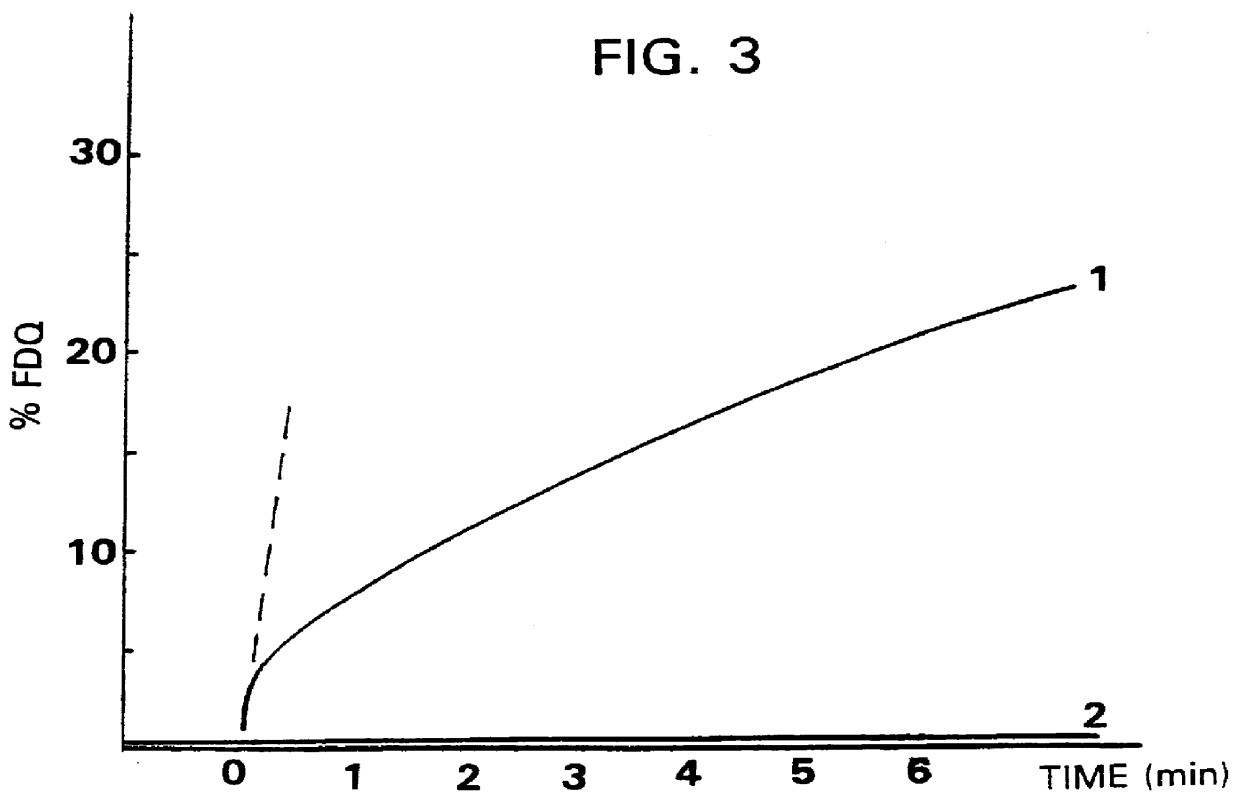

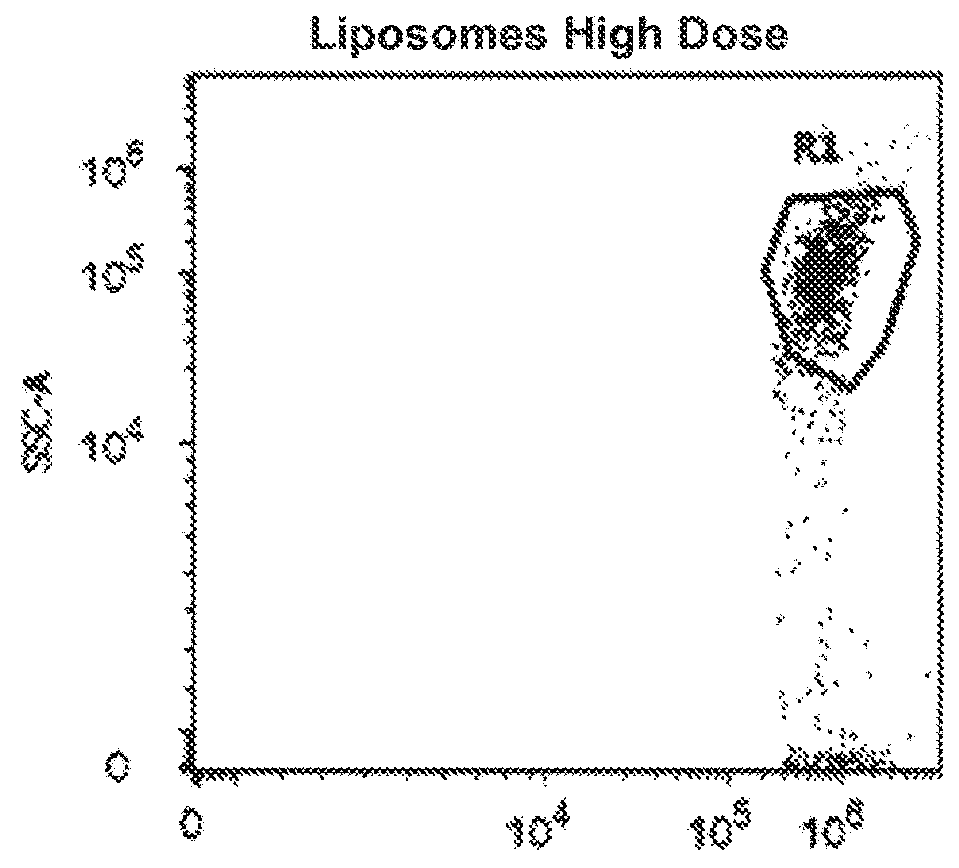

Synthetic membrane vesicles containing functionally active fusion peptides as drug delivery systems

PCT No. PCT / EP92 / 00089 Sec. 371 Date Nov. 2, 1992 Sec. 102(e) Date Nov. 2, 1992 PCT Filed Jan. 17, 1992 PCT Pub. No. WO92 / 13525 PCT Pub. Date Aug. 20, 1992The phospholipid bilayer contains at least one pharmaceutically active drug and comprises cell-specific markers on the membrane which have at least 90% biological activity when measured according to Luescher & Glueck, Antiviral Research 14, 39-50. In the membrane, the cholesterol content is preferably less than 2% by weight, the detergent content preferably less than 1 ppb. The vesicle diameter preferably is about 80 nm. the phospholipid in the membrane may comprise 70 to 95% by weight of phosphatidylcholine and preferably 10 to 20% by weight of phosphatidylethanolamine; preferably 6-8% by weight of a crosslinker, preferably of a sulfosuccinimidyl derivate, and at least one cell-specific fusion peptide are linked to the membrane. The vesicles are used for the preparation of pharmaceuticals against AIDS and carcinomas.

Owner:NIKA HEALTH PRODUCT LTD

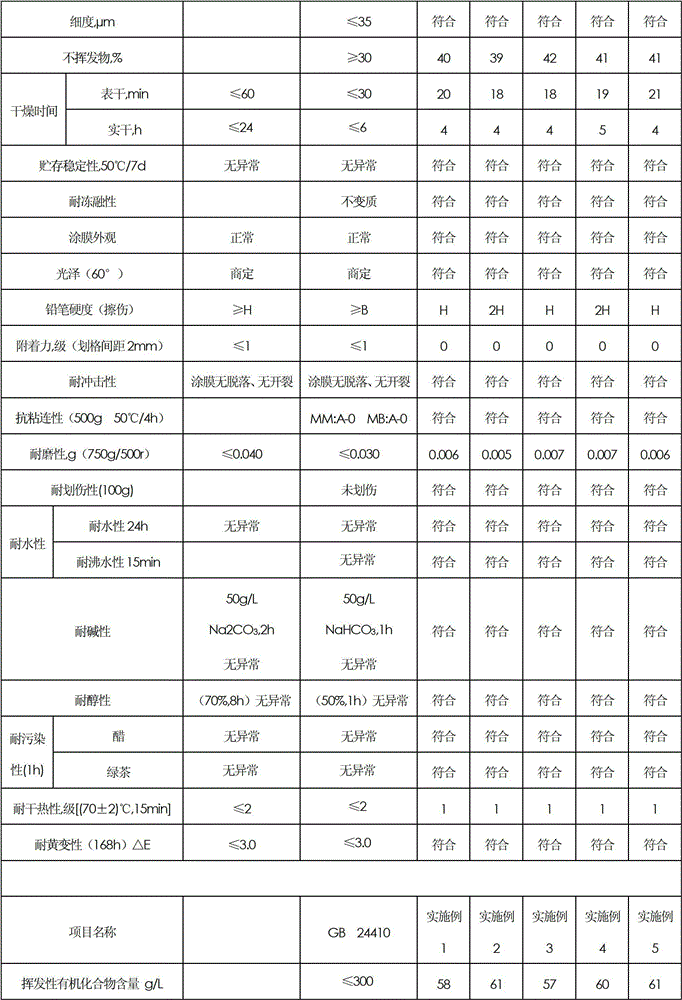

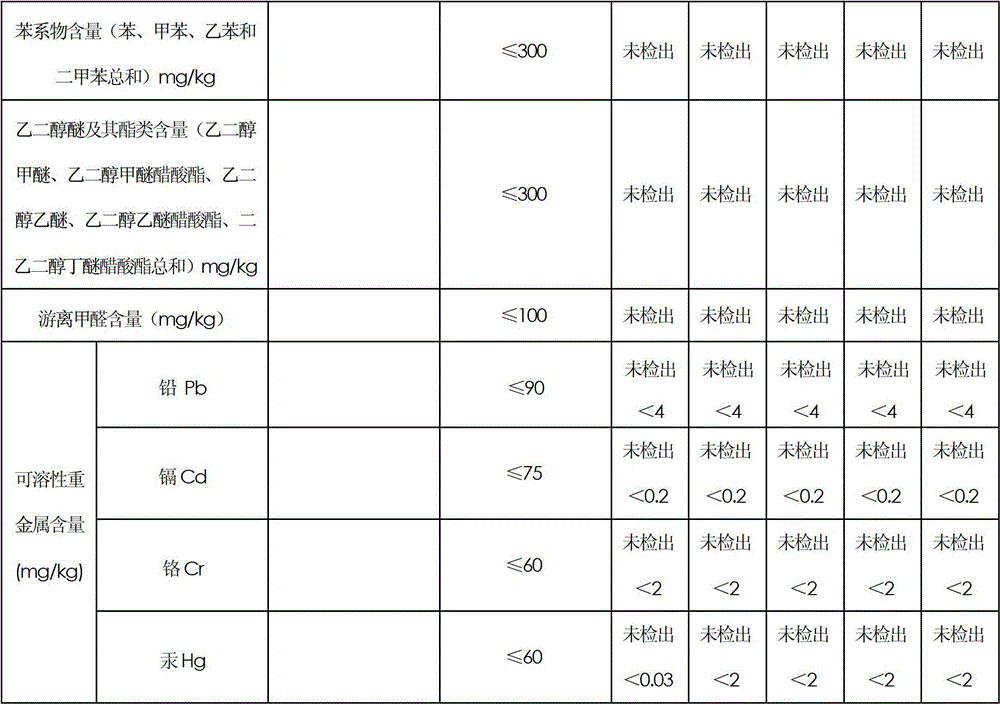

Monocomponent wear-resistant aqueous polyurethane wood floor coating for container and preparation method thereof

ActiveCN102746777AAdhesiveChemical resistantPigmenting treatmentPolyurea/polyurethane coatingsPolymer scienceCoating system

The invention discloses monocomponent wear-resistant aqueous polyurethane wood floor coating for containers and a preparation method thereof. The coating is composed of deionized water, aqueous fatty group polyurethane resin, nanometer alumina slurry, wetting dispersant A, wetting dispersant B, a pH regulator, a composite film-forming auxiliary agent, an antifoaming agent and a thickening agent. According to the invention, the nanometer alumina is effectively dispersed in the aqueous coating system through the preparation of the nanometer alumina slurry, enabling the coating to have excellent combination properties such as wear resistance, high hardness, high gloss and good adhesion, and both the quality and performance of the coating reach and go far beyond the GB / T 23999-2009 type A standard. With simple and convenient application, safety storage and stable performance, the product obtained through the invention contains no harmful substances such as benzene series, glycol ether and ester thereof, free formaldehyde and soluble heavy metals, and has excellent environmental protection performance which is significantly better than solvent coating, and reach and go far beyond the GB 24410-2009 standard,.

Owner:GUANGZHOU JOINTAS CHEM

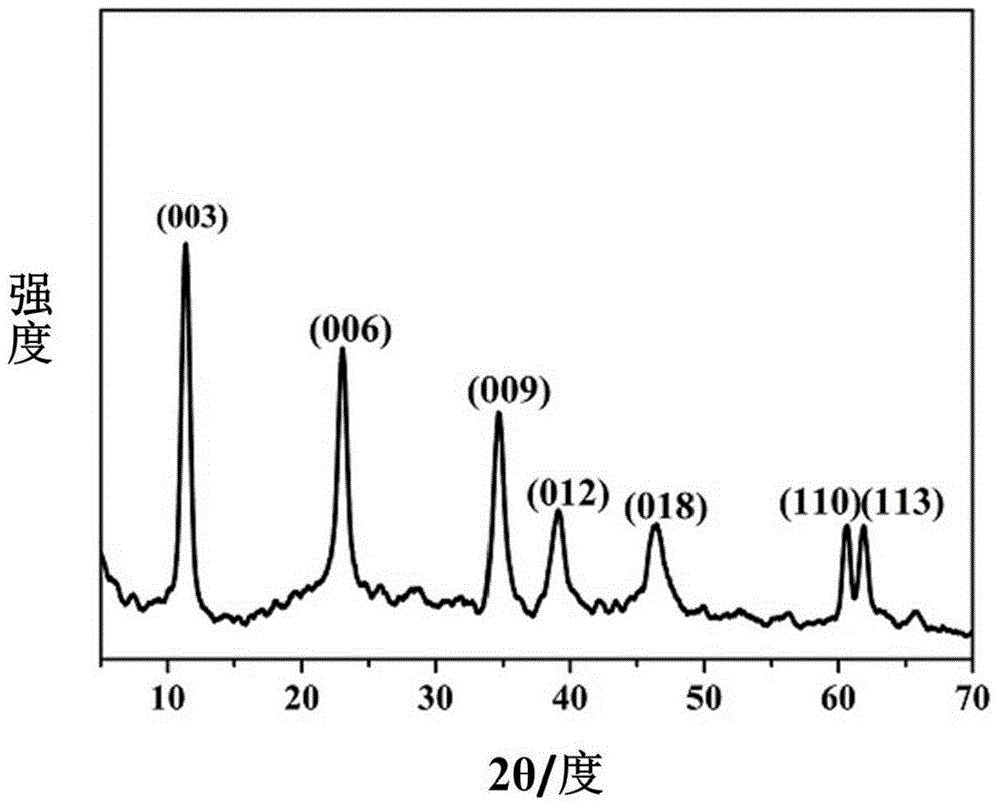

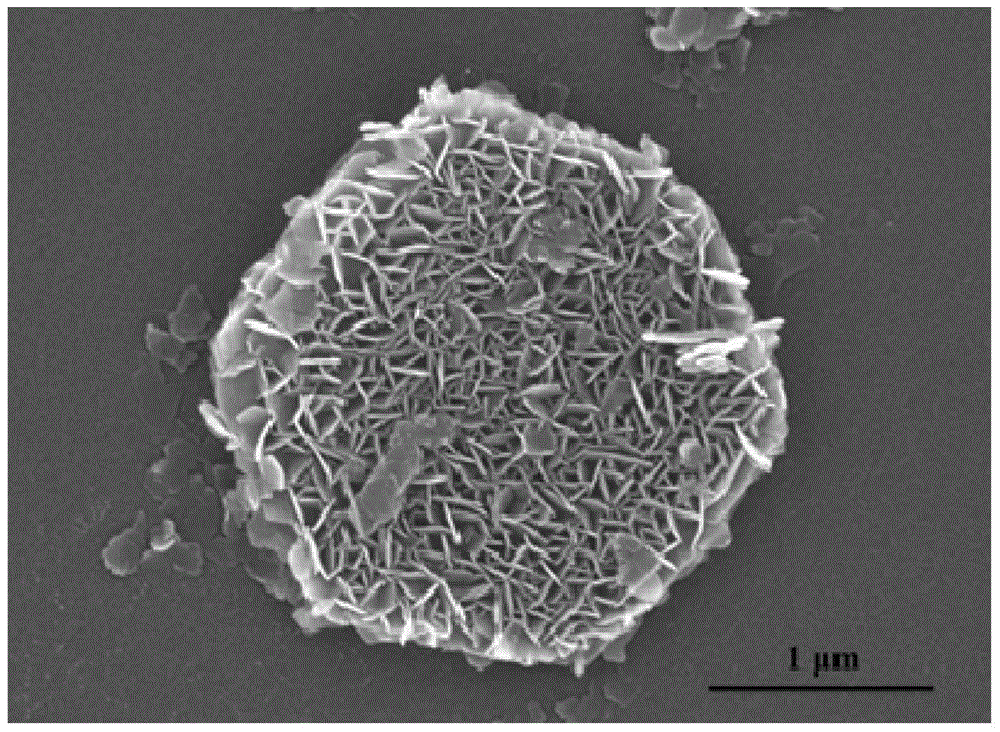

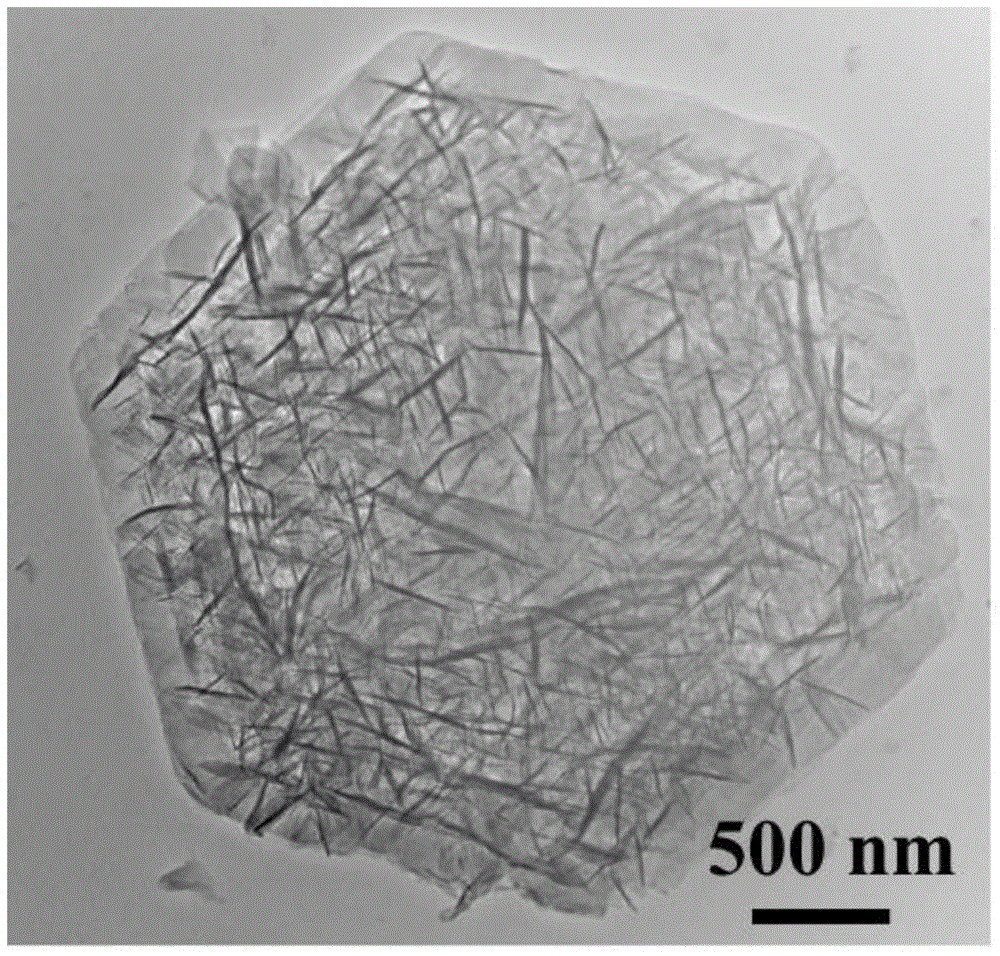

Preparation method of ultrathin modified hydrotalcite and application thereof to rubber gas barrier thin film material

ActiveCN106674572AExtended Diffusion PathImprove interface compatibilityConjugated diene hydrocarbon coatingsHydrotalciteComposite filmHeat stability

The invention discloses a preparation method of ultrathin modified hydrotalcite and an application thereof to a rubber gas barrier thin film material. Firstly, coprecipitation is used for preparing ultrathin hydrotalcite with a high length diameter ratio, surface modification is carried out, spin coating method technology is used, the ultrathin modified hydrotalcite and rubber are compounded in order to form a film, and finally the gas barrier thin film material is prepared by compounding the ultrathin modified hydrotalcite and the rubber. The ultrathin hydrotalcite with a nanometer sheet shaped structure has high length diameter ratio, and can be used as a filler for substantially prolonging diffusion path of oxygen molecules in a thin film material; surface modification of hydrotalcite can improve interfacial compatibility between hydrotalcite and rubber, and reduce free volume, so that the composite thin film materials has excellent gas barrier performance, good heat stability and mechanical performance. The method has wide source, low cost, and simple preparation, and accords with environmental protection requirements; and the method has wide application prospects in the fields of automobile industry, outdoor packaging and aerospace industry.

Owner:BEIJING UNIV OF CHEM TECH

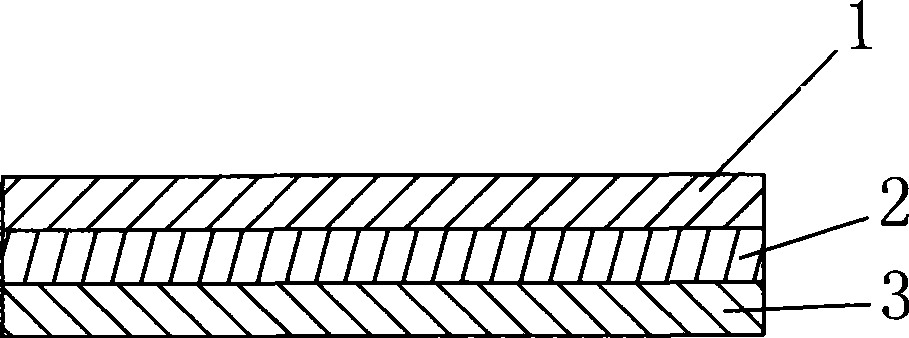

High-density polyethylene (HDPE) geomembrane and processing process thereof

InactiveCN103572738AReduce lossImprove anti-seepage performanceSynthetic resin layered productsLaminationGeomembraneHigh density

The invention relates to a high-density polyethylene (HDPE) geomembrane and a processing process thereof. The processing process comprises a first step of enabling high-density polyethylene resin with the weight ratio being 95-98% to serve as a geomembrane main ingredient, adding about 1%-6% of carbon black, anti-ageing agents, antioxidants, ultraviolet absorbents and stabilizing agents, performing mixing, and injecting the mixture between a non-woven fabric and the geomembrane; a second step of drying a geomembrane high-density polyethylene resin anti-seepage layer which is compounded well; a third step of enabling the geomembrane having undergone treatment of the second step to be subjected to pressed film treatment forming. The non-woven fabric and the geomembrane are produced and adhere to each other to form the HDPE geomembrane by one-time thermal compounding, the loss of the non-woven fabric and the geomembrane is greatly reduced while the production process is simplified, and the anti-seepage capability, chemical stability, ageing resistance and puncture resistance and the like of the anti-seepage geomembrane are improved.

Owner:仪征市双友土工合成材料有限公司

Preparation of multi-stage structured hydrotalcite and application of multi-stage structured hydrotalcite in gasbarrier packaging material

InactiveCN104788704AInhibited DiffusionEnhanced chemical adsorption capacityPolyether coatingsHyaluronic acid coatingsRecovery methodPolymer science

The invention discloses preparation of multi-stage structured hydrotalcite and application of the multi-stage structured hydrotalcite in a gasbarrier packaging material. According to the invention, the multi-stage structured hydrotalcite is prepared through a roasting recovery method by virtue of the memory effect of hydrotalcite; then, the multi-stage structured hydrotalcite and a polymer are compounded to obtain a film by adopting an alternatively rotary coating technology, wherein the multi-stage structured hydrotalcite is capable of inhibiting the diffusion of oxygen molecules longitudinally and transversely and effectively prolonging a diffusion path of the oxygen molecules; furthermore, the surface oxygen vacancy of the multi-stage structured hydrotalcite has strong chemical adsorption effect on oxygen; therefore, the multi-stage structured hydrotalcite is the gasbarrier packaging material having excellent oxygen barrier property, thermal stability, mechanical stability and storage stability. The multi-stage structured hydrotalcite disclosed by the invention is wide in raw material source and low in cost and can satisfy environmental protection and sustainable development requirements; and therefore, the gasbarrier packaging material prepared based on the special structured hydrotalcite material has potential application value in the fields, such as packaging of foods, medicines and electronic devices.

Owner:BEIJING UNIV OF CHEM TECH

Synthetic membrane-receiver complexes

Owner:FLAGSHIP VENTURES MANAGEMENT INC +1

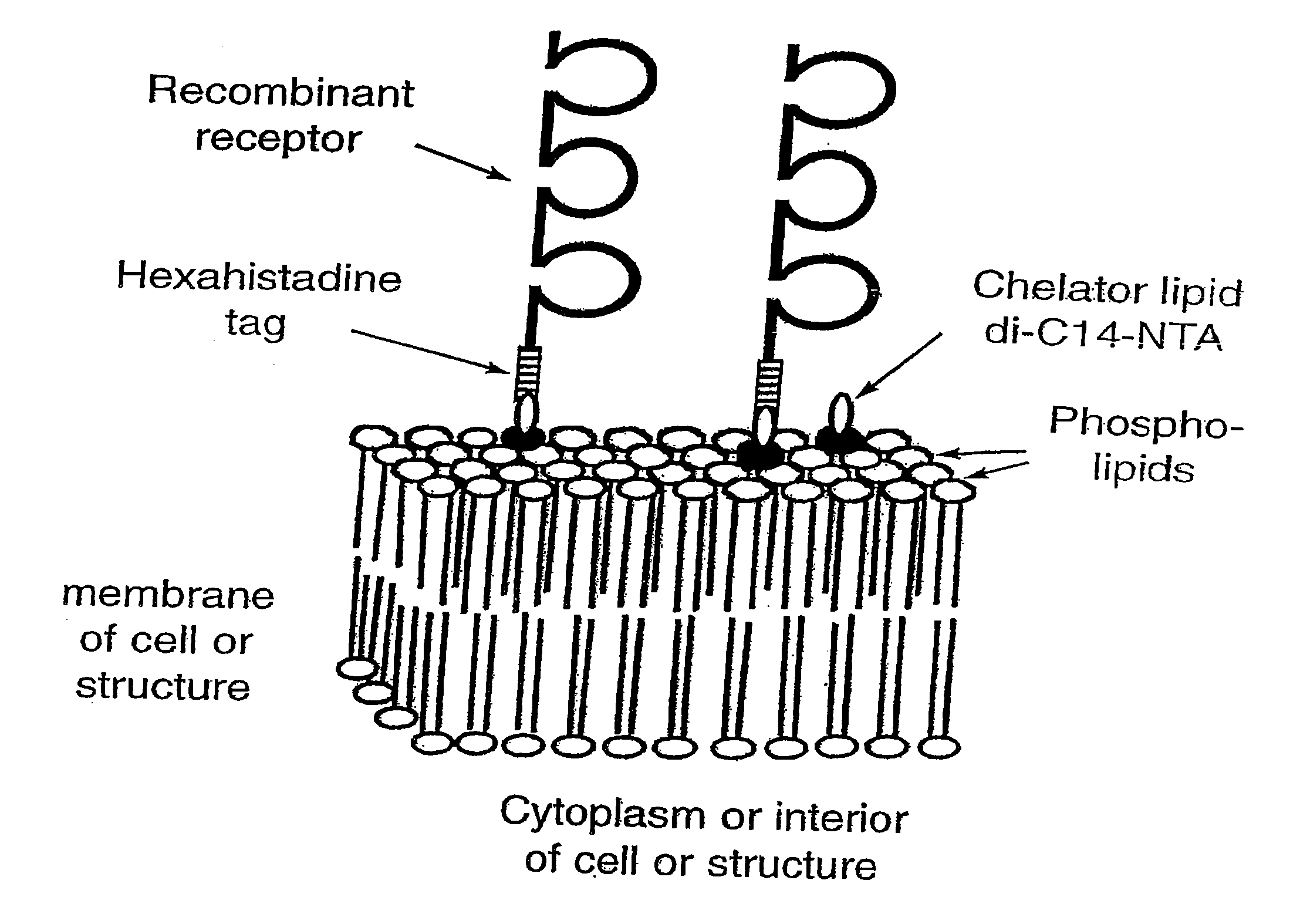

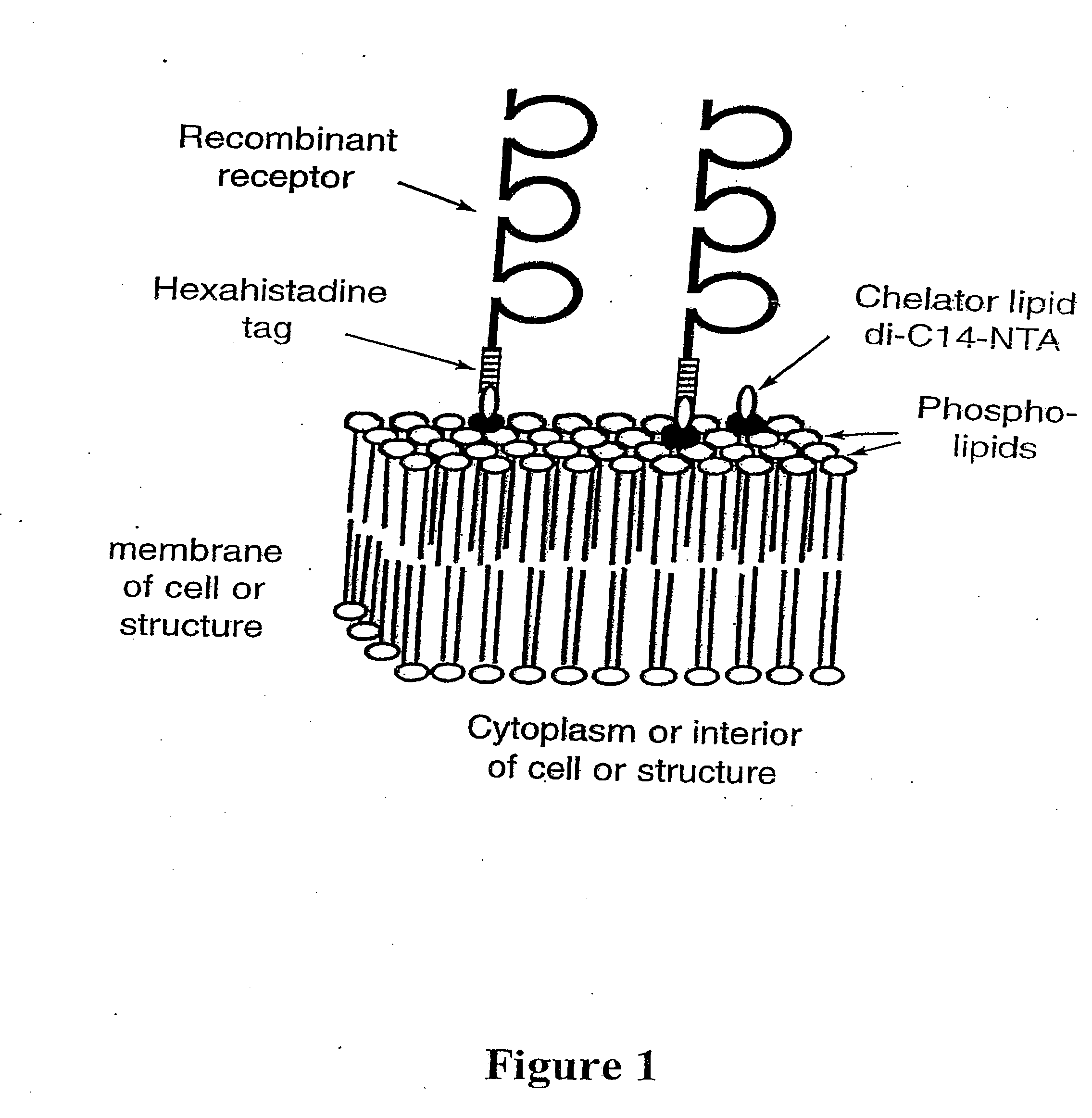

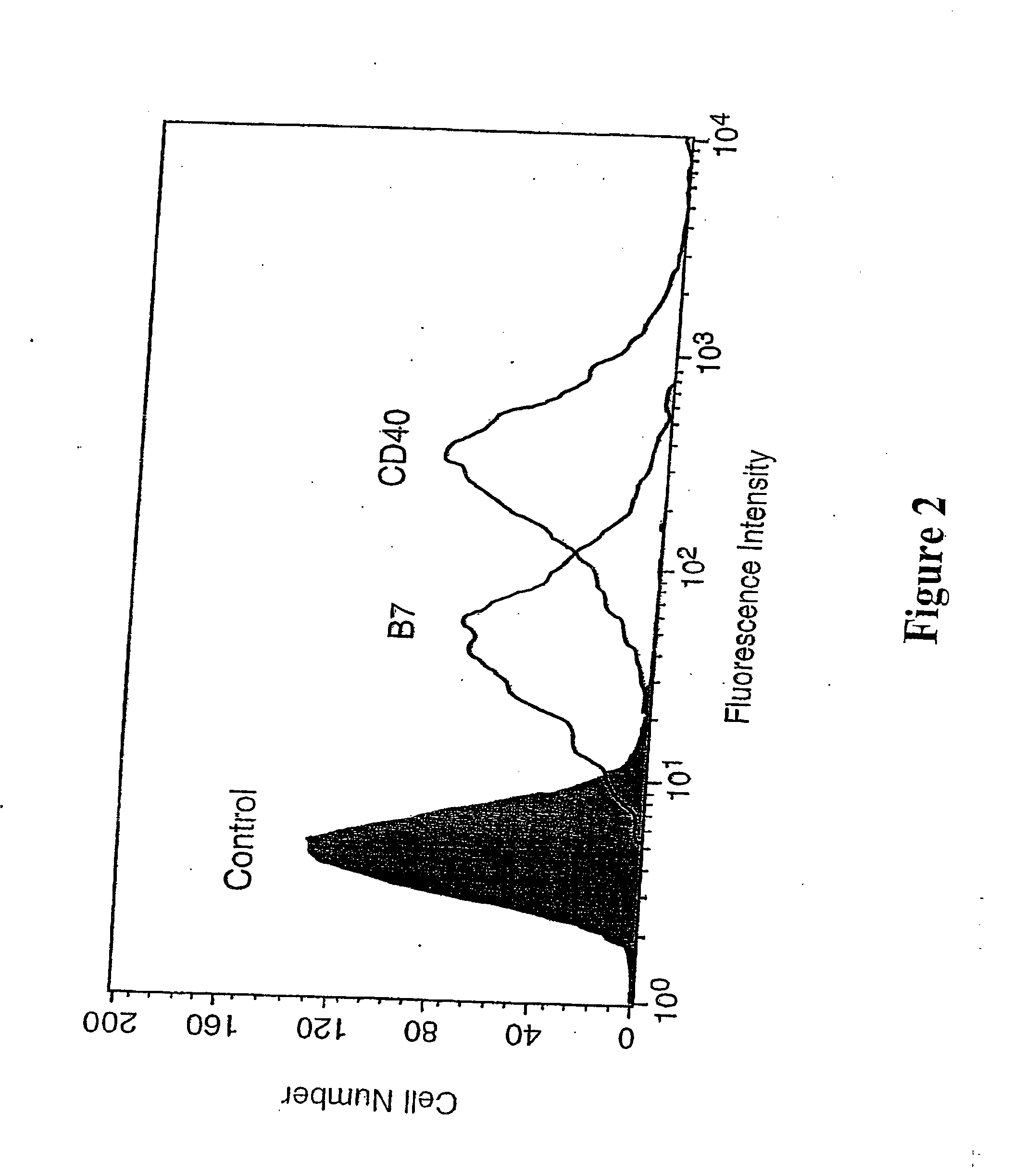

Model membrane systems

The present invention relates generally to modifying biological and / or synthetic membranes or liposomes, or combinations thereof, for the purpose of altering immunity, or for the targeting of drugs and other agents to a specific cell type or tissue when administered in vivo to achieve a therapeutic effect. Modification of the membranes is achieved by incorporation and / or attachment of metal chelating groups, thereby allowing engraftment of one or more targeting molecules possessing a metal affinity tag, and a targeting of the engrafted membranes to specific cell types or tissues in vivo. The invention, thus, provides a means of modifying the properties of biological and / or synthetic membranes and liposomes for the purpose of altering or enhancing immunity when used as vaccines, or for the targeting of encapsulated / incorporated drugs or other agents to a specific cell type or tissue when administered in vivo, to achieve a therapeutic effect or response, or for modifying a physiological response or biological function.

Owner:AUSTRALIEN NAT UNIV

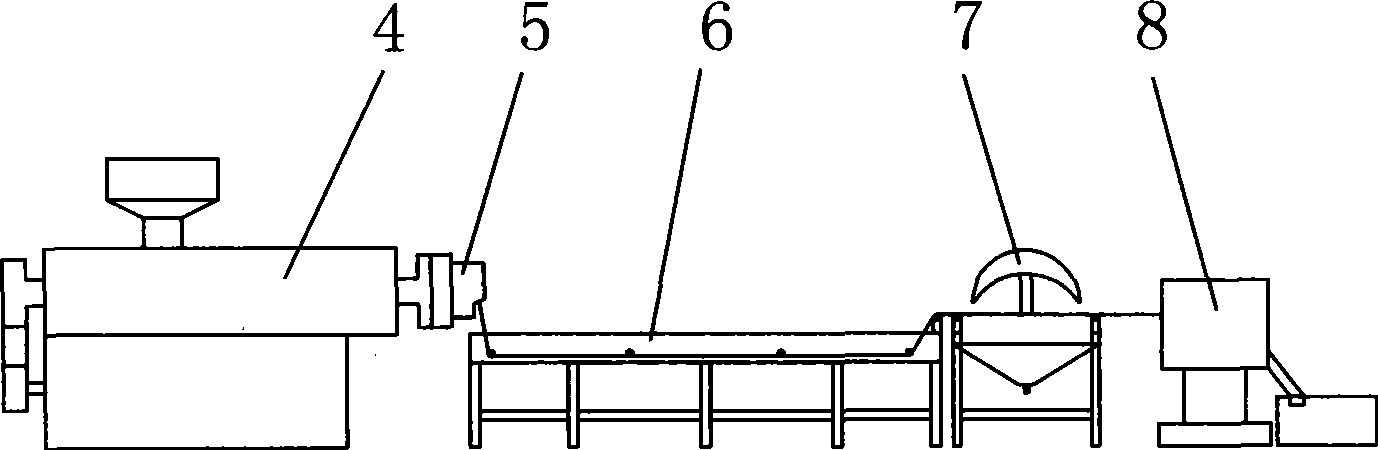

Film for producing composite paper-like film and paper-like film and method for producing the same

InactiveCN101451004AWide variety of sourcesLow costSynthetic resin layered productsLaminationPolymer chemistryExtrusion Granulation

The invention relates to a film for manufacturing a composite paper-imitated film, the composite paper-imitated film and a method for producing the same. The film comprises the following compositions by weight portion: 100 portions of resin, 50 to 200 portions of filler and 0.1 to 5 portions of additive which. The composite paper-imitated film is provided with an upper film and a lower film; an adhesive layer is arranged between the upper film and the lower film; and the orientation of a macromolecular chain inside the upper film and the orientation of a macromolecular chain inside the lower film are in vertical arrangement. The method for producing the paper-imitated film comprises the following steps: the mixing and stirring of raw materials; extrusion and pelletization; the manufacture and stretching of a billet; and compounding and film forming. The film has low cost and environmental protection; and the composite paper-imitated film has high strength and good using effect.

Owner:DALIAN PLASTICS RES INST CO LTD

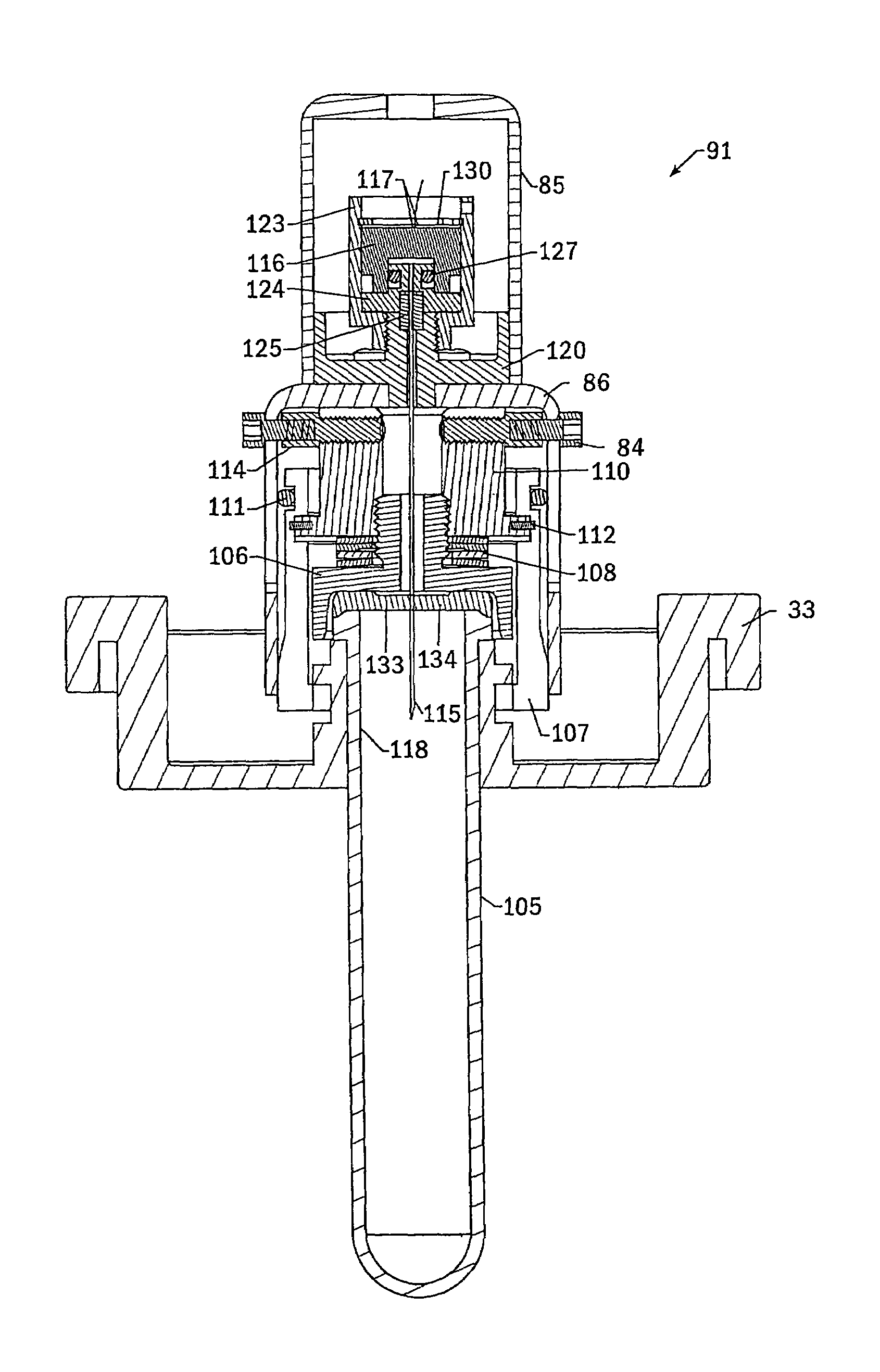

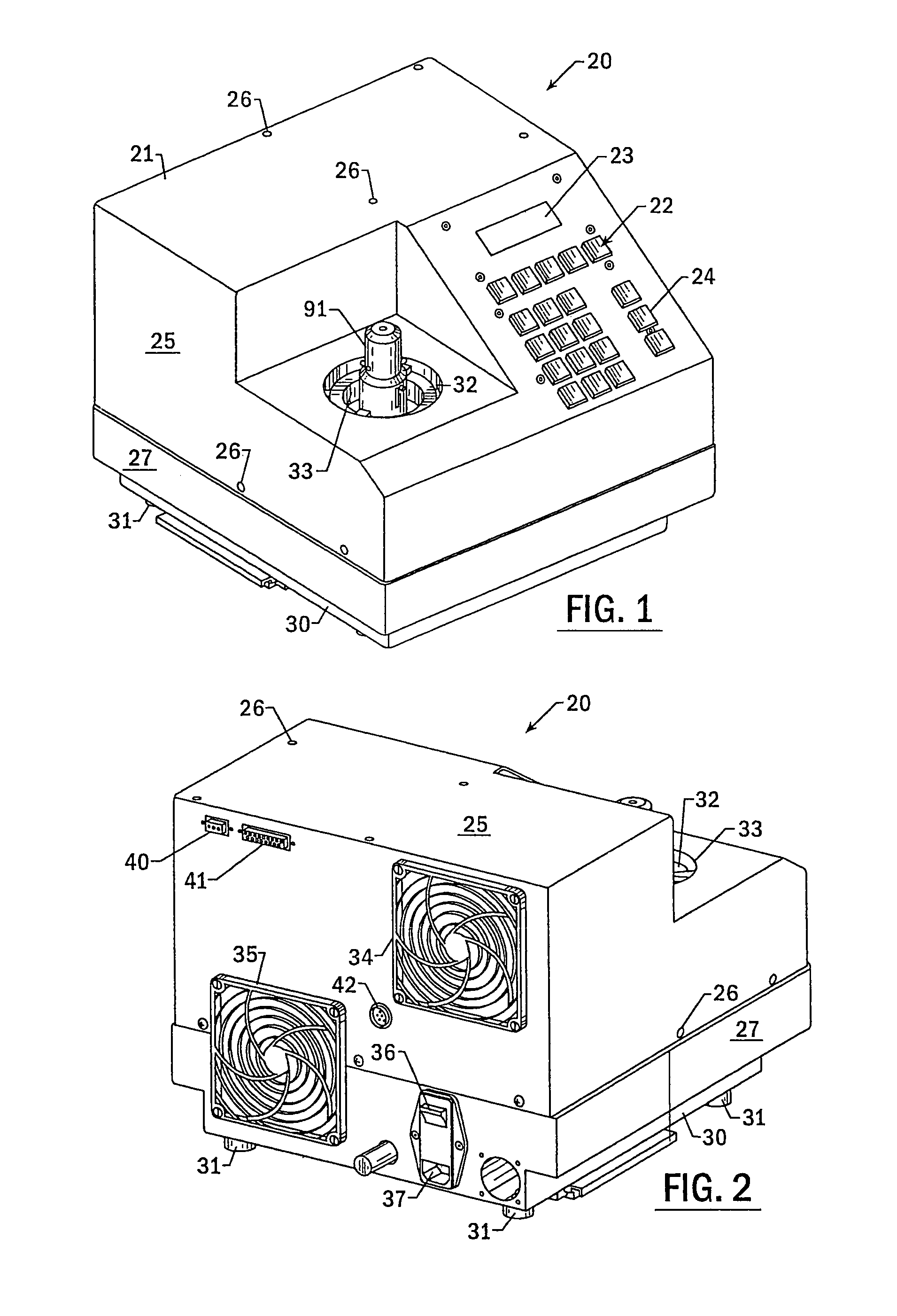

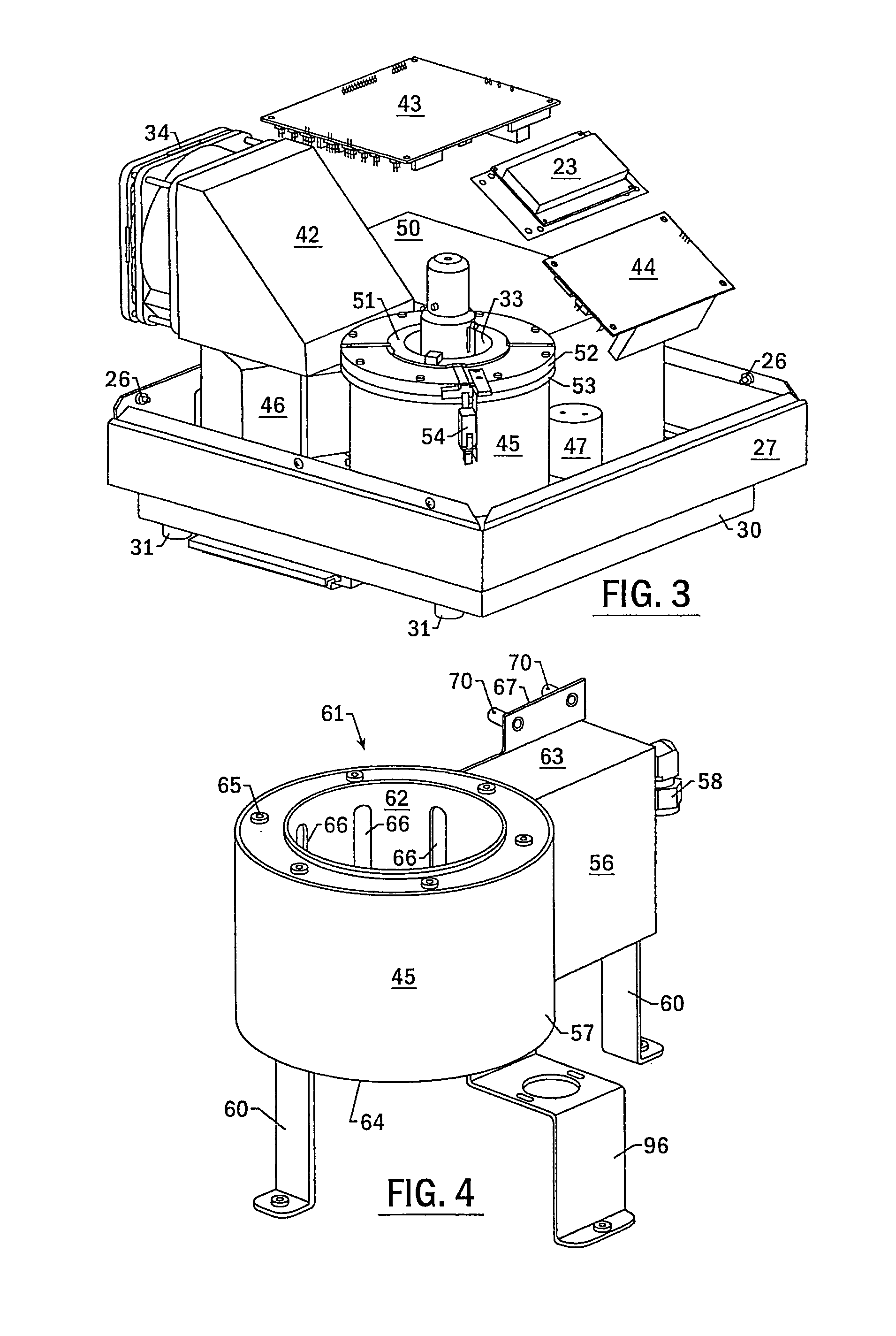

Pressure measurement in microwave-assisted chemical synthesis

InactiveUS7208709B2Handle small samplesEasy to moveMeasurement of fluid loss/gain rateFluid pressure measurement using elastically-deformable gaugesChemical synthesisTransducer

A pressure-measuring vessel system for microwave assisted chemical processes is disclosed. The vessel system includes a pressure resistant vessel that is otherwise transparent to microwave radiation, a pressure-resistant closure for the mouth of the vessel, with portions of the closure including a pressure resistant synthetic membrane, a pressure transducer external to the vessel, and a tube extending from the transducer, through the membrane and into the vessel for permitting the pressure inside the vessel to be applied against the transducer while the closure and membrane otherwise maintain the pressure resistant characteristics of the vessel.

Owner:CEM CORP

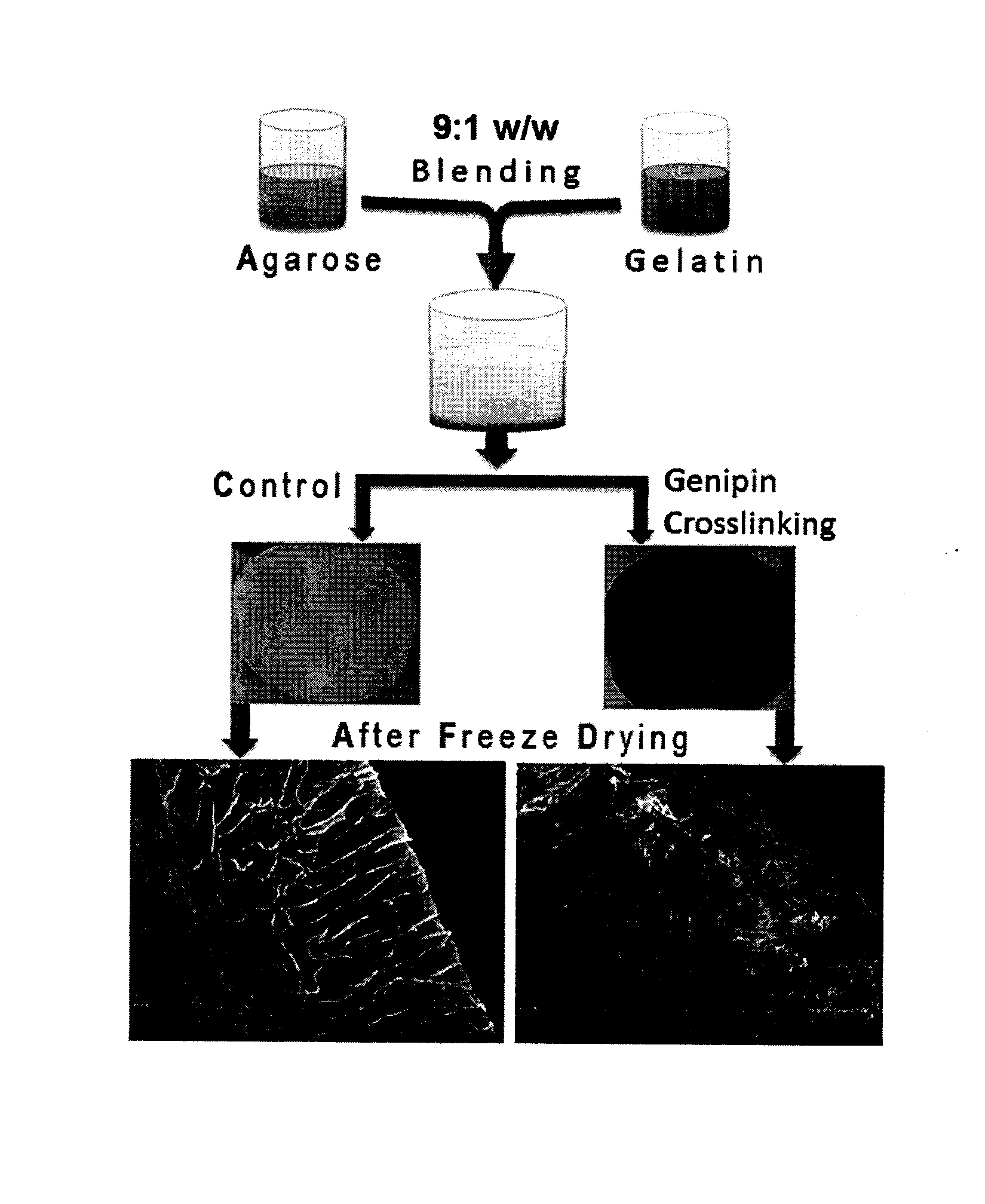

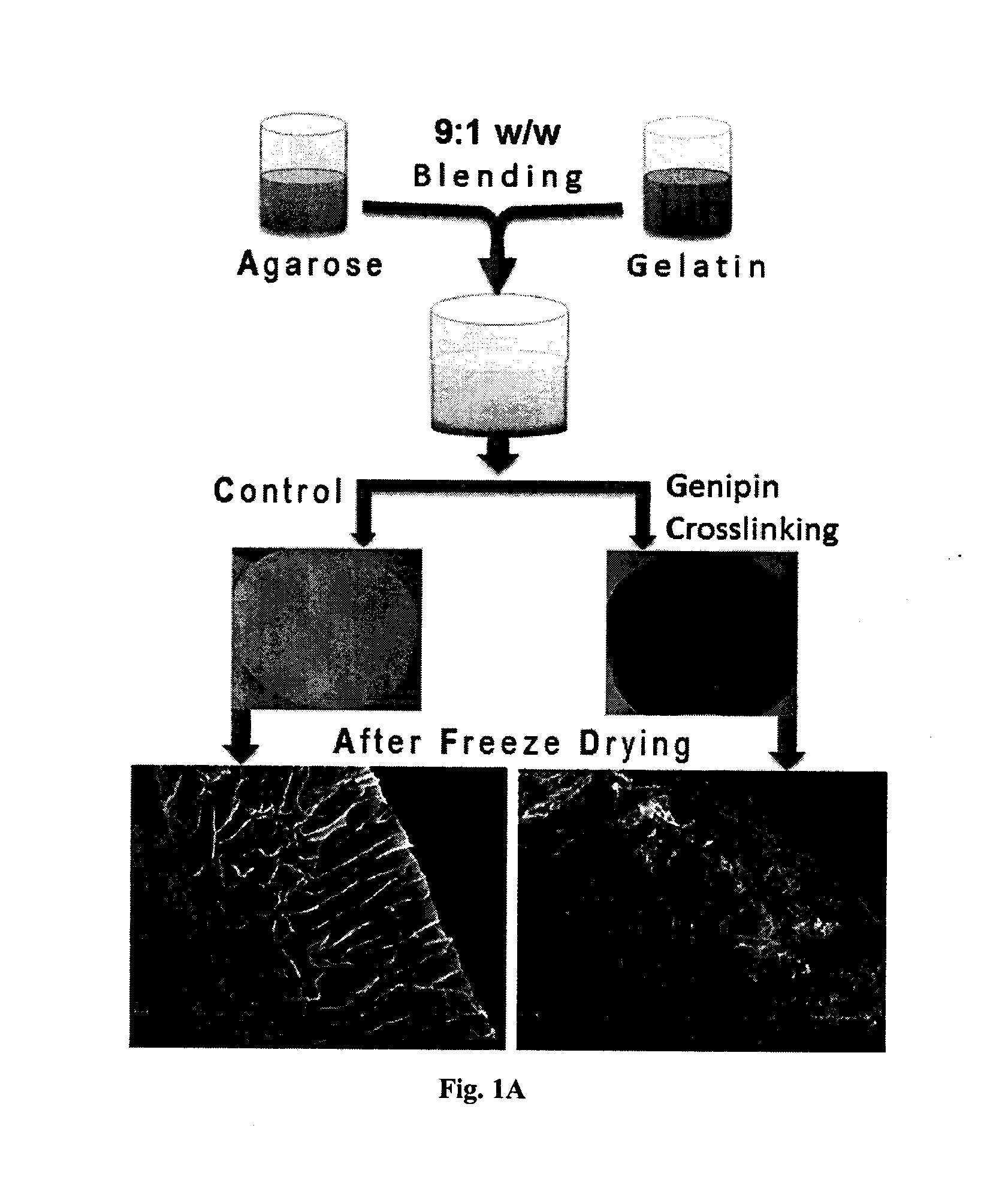

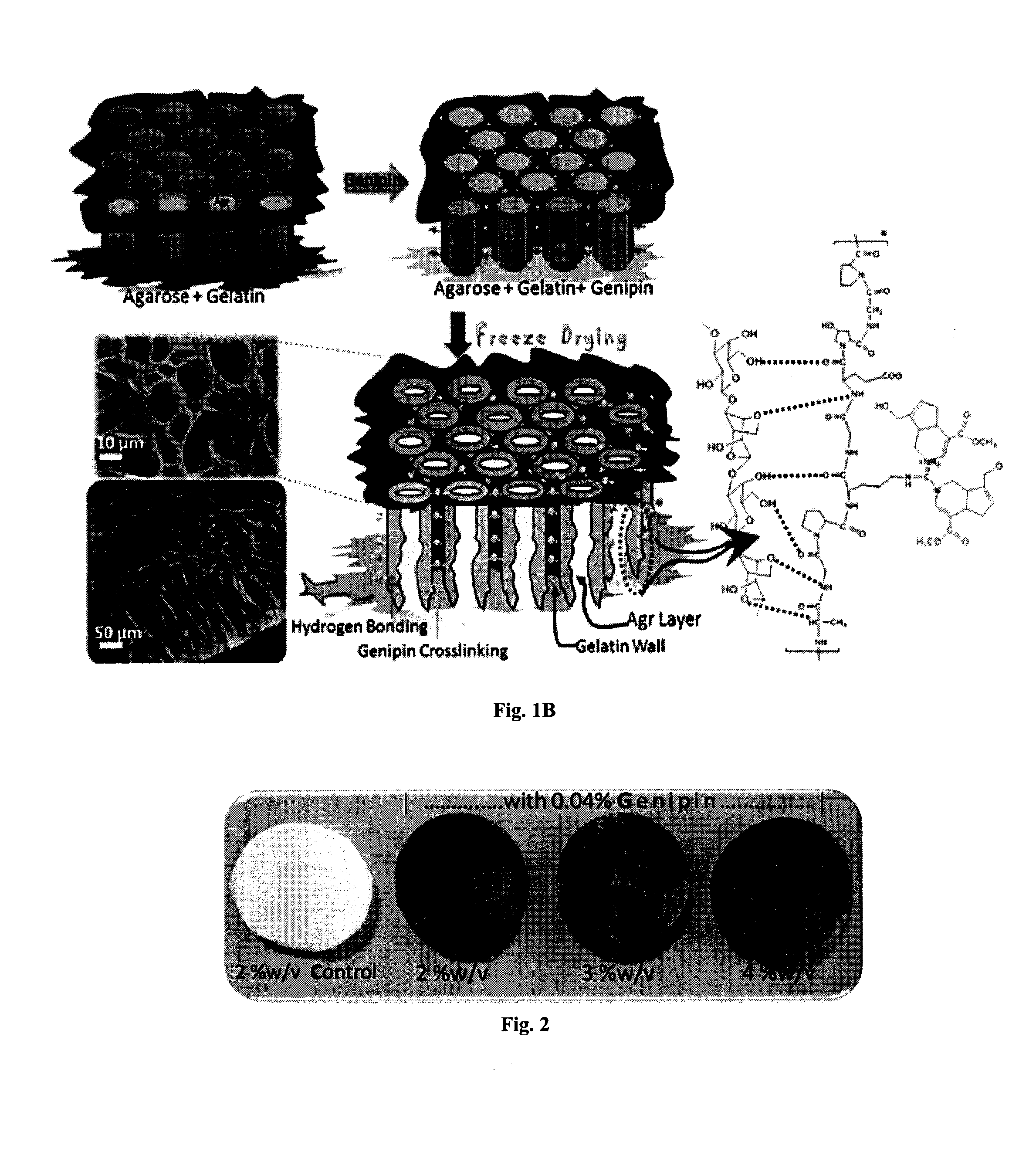

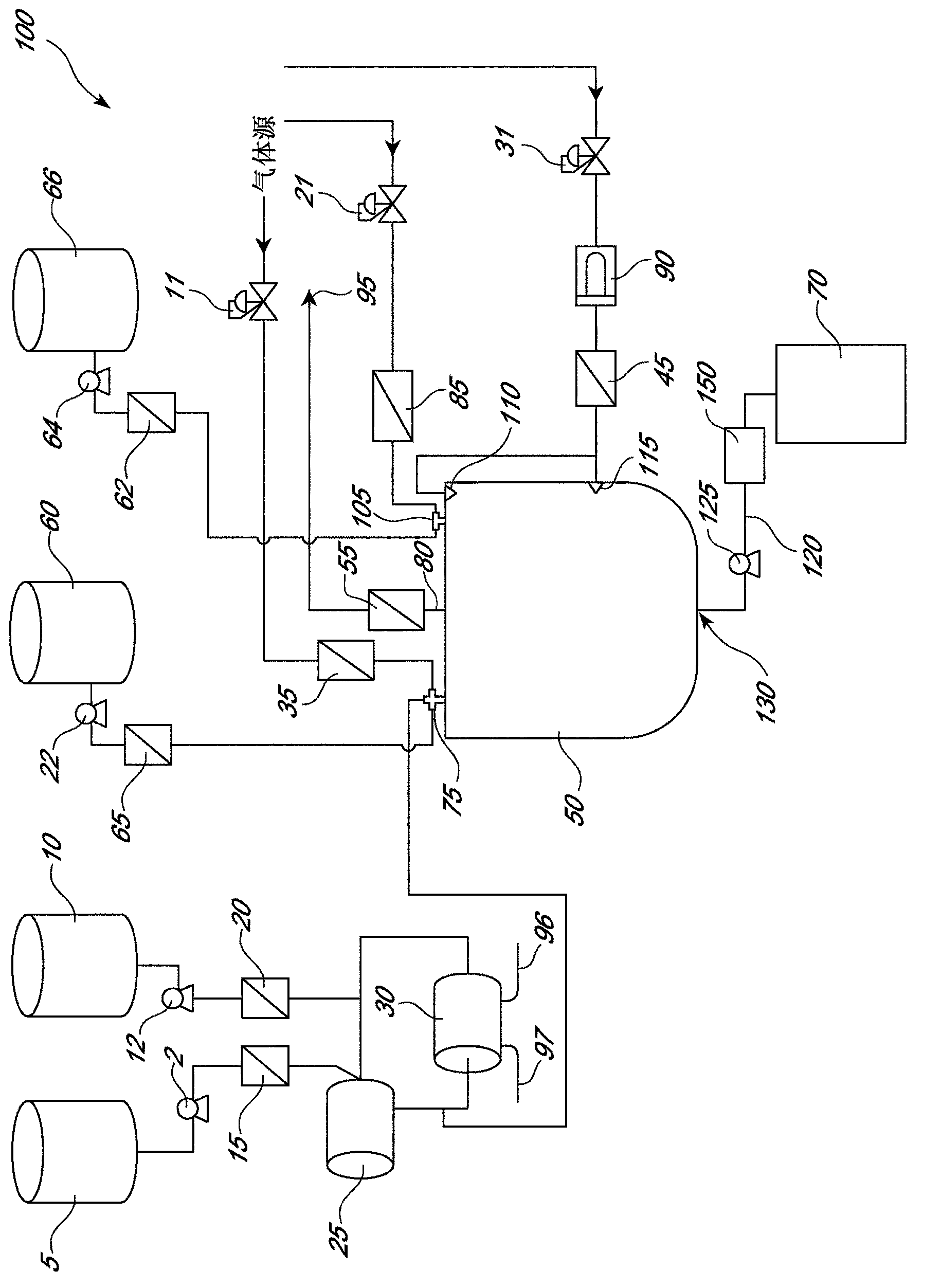

Seaweed Polysaccharide Based Superhydrophilic Foam Membrane for Energy-Efficient Oil-Water Separation

ActiveUS20160243505A1Controlled hydrophilicity and stabilityEasy disposalMembranesSemi-permeable membranesCross-linkGenipin

The present invention relates to a superhydrophilic biodegradable cross linked foam membrane and a process for preparation of said foam membrane from a seaweed polysaccharides by blending with amino biopolymers / amino acids / proteins / amino compounds followed by crosslinking with a naturally occurring cross linker, genipin. The foam membrane can be used as a substitute for synthetic membrane for varied applications including membrane separation for oil-water emulsions, oil-water mixtures and other aqueous-organic mixtures under ambient conditions. These foam membranes can be recycled and reused more than three times without considerable decrease in flux rate and stability. The separation methodology of the mixtures using the foam membrane of the present invention is gravity-driven and therefore, simple and energy-efficient.

Owner:COUNCIL OF SCI & IND RES

Method for formulating large diameter synthetic membrane vesicles

The present invention generally relates to the field of pharmaceutical sciences. More specifically, the present invention includes apparatus and devices for the preparation of pharmaceutical formulations containing large diameter synthetic membrane vesicles, such as multivesicular liposomes, methods for preparing such formulations, and the use of specific formulations for therapeutic treatment of subjects in need thereof. Formation and use of the pharmaceutical formulations containing large diameter synthetic membrane vesicles produced by using the apparatus and devices for therapeutic treatment of subjects in need thereof is also contemplated.

Owner:PACIRA PHARMA INC

T type molecular sieve membrane containing rich erionite, preparation and application in gas separation

InactiveCN101259384ASemi-permeable membranesDispersed particle separationSeparation factorMolecular sieve

The invention provides a T type molecular sieve membrane rich in erionite and a preparation method as well as the application in air separating thereof. The invention is characterized in that an erionite crystal is adopted as a seed crystal to synthesize the T type molecular sieve membrane which is rich in erionite and has excellent shape-selective separation effect; by adopting the method of high-temperature and closed type hydro-thermal synthesis reaction, the synthesizing time of the membrane is shortened, what is more, the stability of the T type molecular sieve membrane under the high temperature is enhanced, thus, the service life of the membrane can be greatly prolonged and the requirements of separating CO2 with blast furnace gas under high temperature can be satisfied. The T type molecular sieve membrane with high performance can be synthesized in larger sol synthesizing and matching range; the sol matching range of the test is that SiO2 / AL2O3 is equal to 10 to 160; OH<-> / SiO2 is equal to 0.55 to 0.85; Na<+> / (Na<+>+K<+>) is equal to 0.6 to 0.8; H2O / (Na<+>+K<+>) is equal to 15 to 160; tubular supporting bodies of various materials (mullite, Alpha-Al2O3 and stainless steel) are adopted so as to adapt to various industrial application occasions. Simultaneously, an air method and an air separating device are provided. The flux and the separation factor of a CO2 / CH4 (50 / 50mol percent) system under an optimizing condition for synthesizing the membrane at the temperature of 200 DGC C respectively reach as high as 1038GPU (10<-6>cm<3>.cm<-2>.s<-1>.cmHg<-1>) and 535.

Owner:JIANGXI NORMAL UNIV

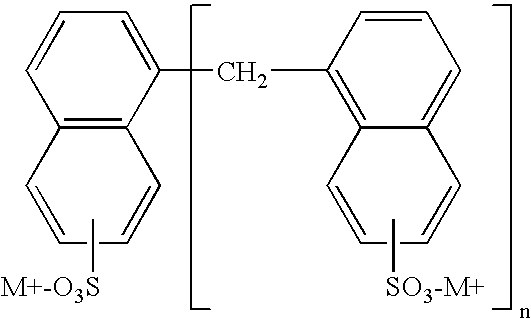

Metal rust-preventive oil comprising coconut oil fatty acid diethanolamide

InactiveCN103215594AGood gas phase anti-rust effectExcellent contact rust resistanceMethacrylateMicrocrystalline wax

The invention discloses metal rust-preventive oil comprising coconut oil fatty acid diethanolamide. The oil is prepared from the raw materials of: No.120 solvent oil, a silane coupling agent KH540, a silane coupling agent KH 602, microcrystalline wax, isobutyl methacrylate, modified nano-grade shale powder, an antioxidant 1010, a composite film-forming material, polyethylene glycol, isobutyl alcohol, an antioxidant 1076, coconut oil fatty acid diethanolamide, barium petroleum sulfonate, petroleum sulfonate, benzotriazole, 2-aminoethyl heptadecenyl imidazoline, magnesium naphthenate, nonylphenol polyoxyethylene ether, Span 80, an antioxidant T501, and phenylethanolamine A. The rust-preventive oil provided by the invention has excellent contact rust resistance and good gas-phase rust resistance. The rust-preventive oil provided by the invention provides good gas-phase rust resistance and contact rust resistance for steel and brass.

Owner:ANHUI FANCHANG COUNTY WANNAN VALVE CASTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com