T type molecular sieve membrane containing rich erionite, preparation and application in gas separation

A molecular sieve and erionite technology, applied in the field of high-performance T-type molecular sieve membranes, can solve the problems of small permeation flux, high cost, complicated process, etc., and achieve the effect of continuous, evenly distributed and thin film layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

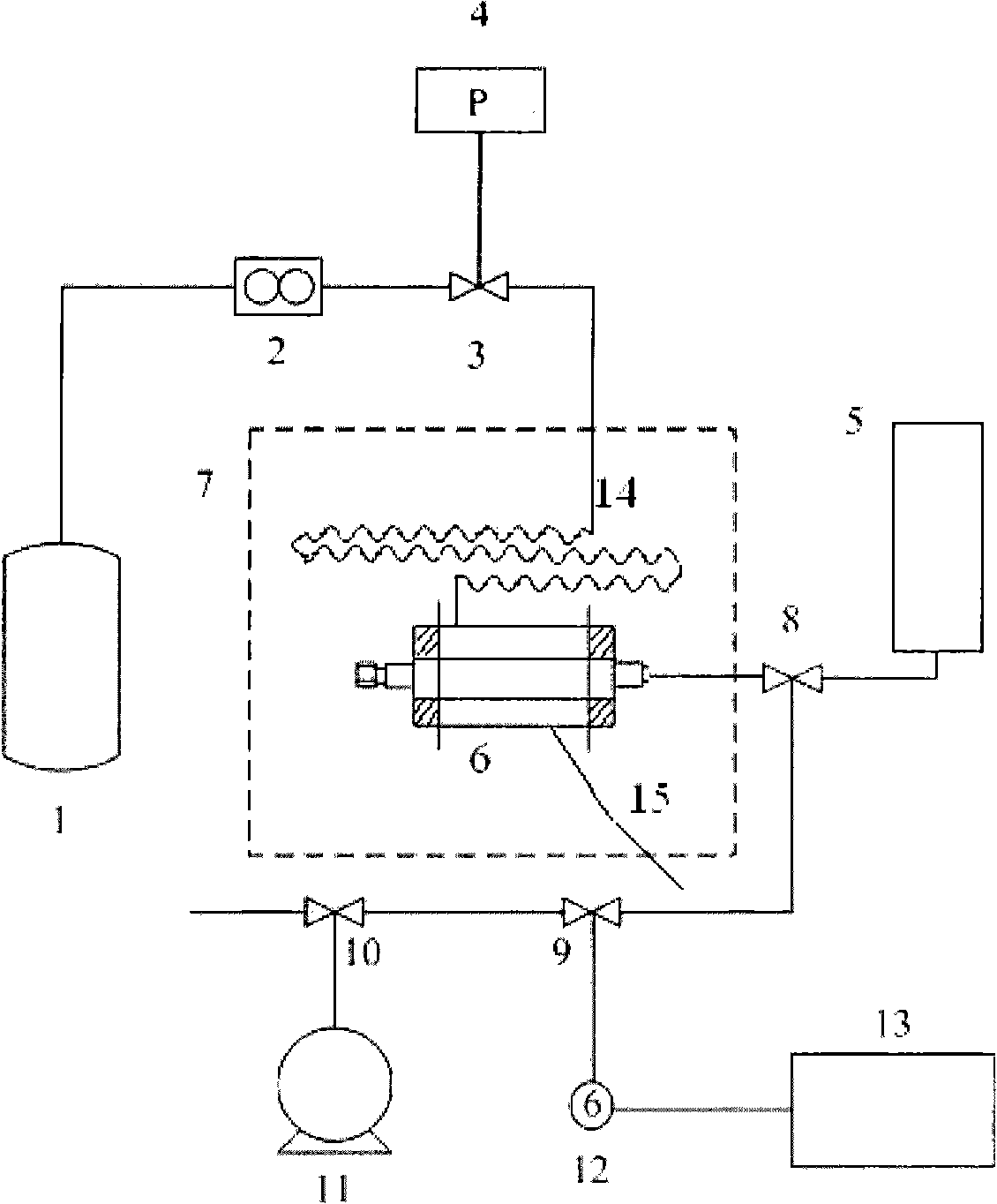

Method used

Image

Examples

Embodiment 1

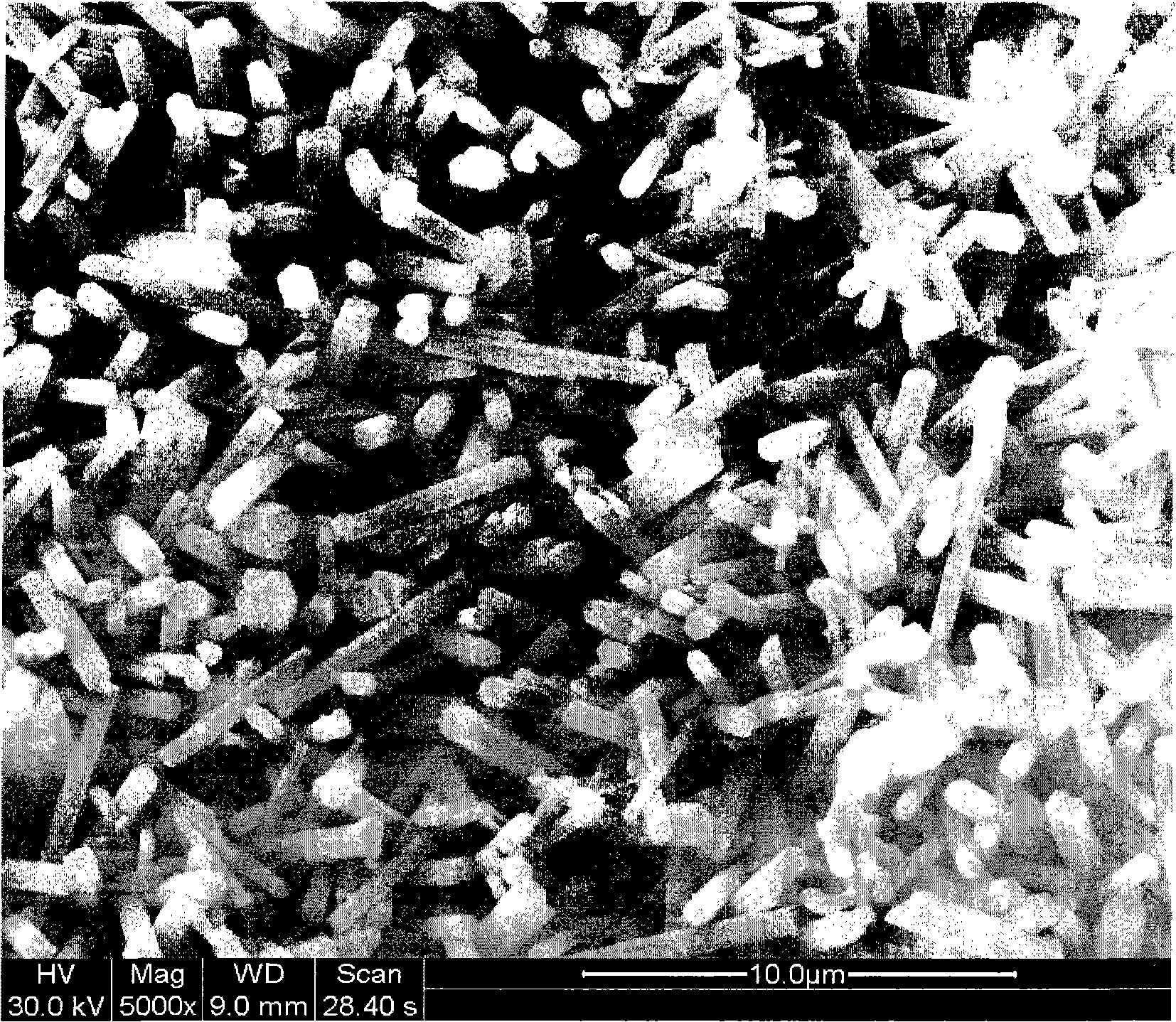

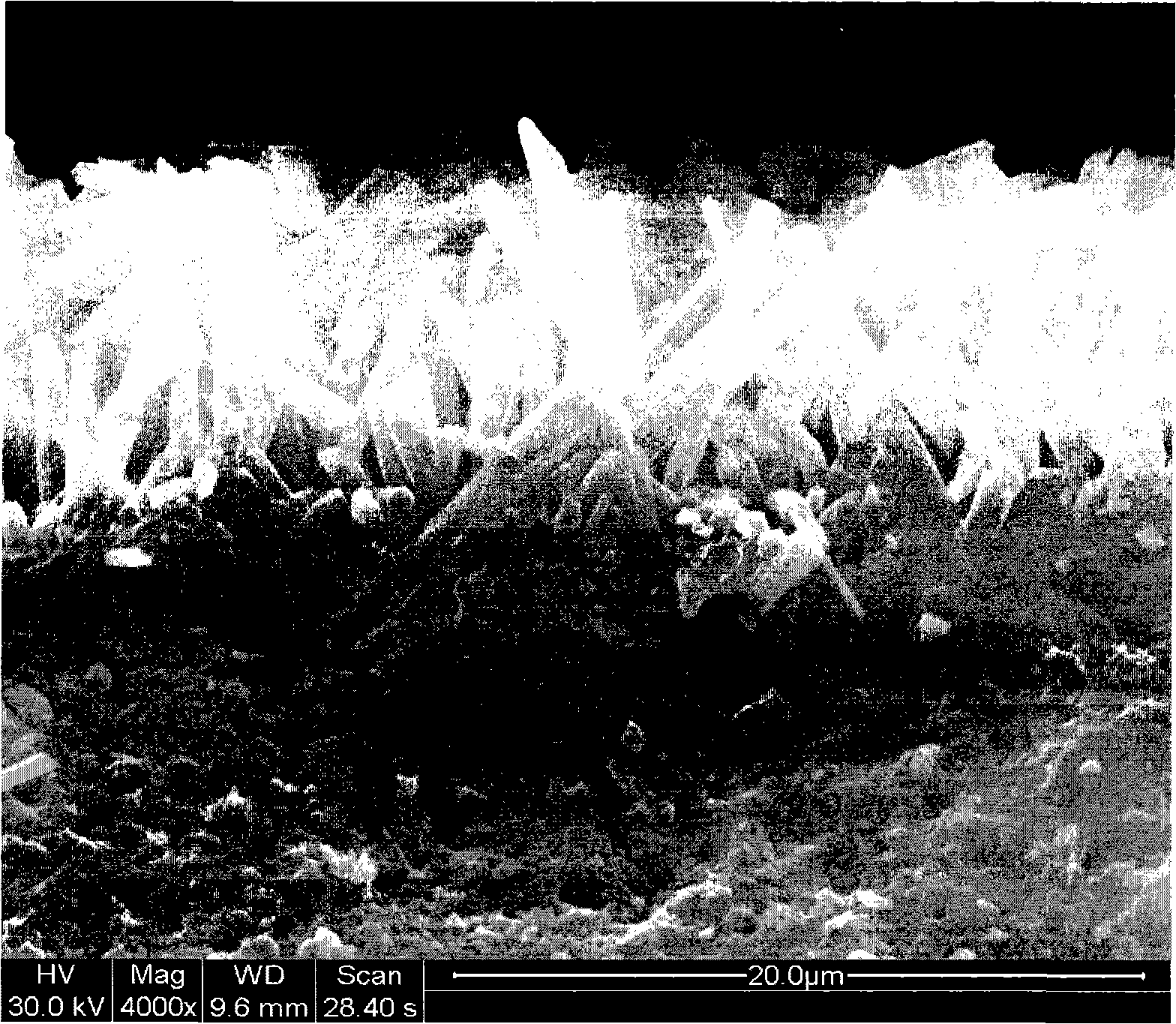

[0050] The porous mullite tube made by Nikkato Co., Ltd. of Japan is used as the support for membrane synthesis, and the mullite composition is 67wt% Al 2 o 3 and 33wt% SiO 2 . After the support is polished with 800-mesh sandpaper and ultrasonically cleaned, a layer of erionite molecular sieve powder is coated. The loading density of the seed crystal is 0.5~2mg / cm 2 , the pre-coated seeded support was dried in an oven at 70°C for 3 h for use.

[0051] Silica sol, potassium hydroxide, sodium hydroxide and aluminum hydroxide were mixed in a molar ratio of 1SiO 2 : 0.01Al 2 o 3 : 0.25Na 2 O: 0.08K 2 O: 55H 2 O mixed and stirred vigorously for 1 h to form a stable sol. After the sol was aged for 24 hours, it was poured into a stainless steel reaction kettle, and the support body pre-coated with the seed crystal was vertically placed in the reaction kettle, and the liquid level of the sol was guaranteed to be higher than the support body. Put the closed stainless steel r...

Embodiment 2

[0059] Synthesis ratio and preparation steps are the same as in Example 1. The difference is that the crystallization time is extended to 40h. The synthesized membrane is repeatedly washed with deionized water to wash off the amorphous substance on the surface and inner wall of the membrane and the alkali solution adsorbed in the support. Afterwards, the membrane was degassed in a vacuum oven at 200°C for 24 hours to ensure complete removal of water and other adsorbates.

Embodiment 3

[0061] Synthesis ratio and preparation steps are the same as in Example 1. The difference is that the reaction temperature was lowered to 110°C and the synthesis time was extended to 50h. The synthesized membrane is repeatedly washed with deionized water to wash off the amorphous substance on the surface and inner wall of the membrane and the alkali solution adsorbed in the support. Afterwards, the membrane was degassed in a vacuum oven at 200°C for 24 hours to ensure complete removal of water and other adsorbates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com