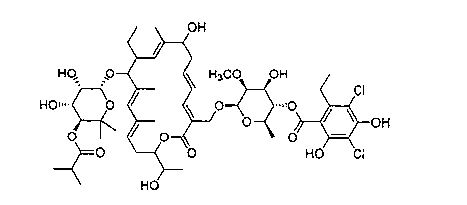

Method for purifying tiacumicin B by high performance liquid chromatography

A high-performance liquid chromatography and taigamycin technology, which is applied in the field of high-performance liquid chromatography to purify taigamycin B, can solve the problems that the separation effect needs to be further improved, the product purity cannot meet the requirements, the separation factor is low, and the like. High recovery rate, good removal effect, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

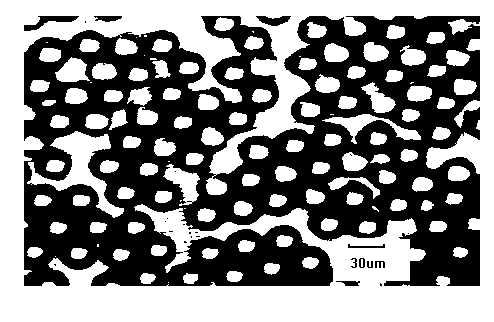

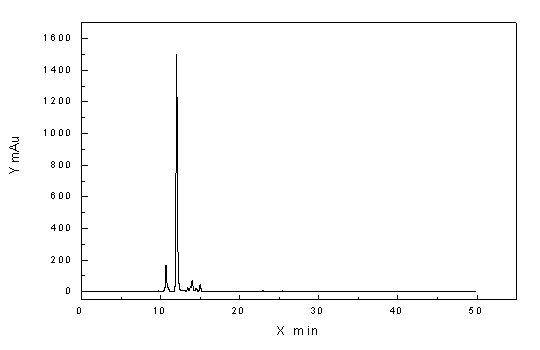

[0026] Purification of tiacumicin B: use a 15×310mm glass column, Uni30BPC resin (pyrrolidone and styrene copolymer particle size 30±1.5um, Suzhou Nano Microorganism Technology Co., Ltd.) as chromatography filler, and the column volume is 55ml , wash 2 CVs (column volumes) with 60% acetonitrile in water, and then equilibrate 2 CVs with 20% acetonitrile. Mobile phase: A: 0.1% formic acid aqueous solution; B: acetonitrile. The crude tiacumicin B (purity 78%) was dissolved in 60% methanol aqueous solution and filtered with a 0.45um filter membrane. The concentration is 8mg / ml, the sample volume is 45.8ml, the sample flow rate is 5ml / min, 1CV of 20% B is pre-washed, and then 8 CVs of 50% B are eluted. Collected in sections, the purity of the collected liquid in the front section is 85.6% (basically no after-impurity), accounting for 20.9% of the sample volume; the purity of the middle section is 90.72%, accounting for 49.85% of the sample volume; Miscellaneous), accounting for 2...

Embodiment 2

[0030] Purification of tiacumicin B: use 15×310mm glass column, Uni30BPC resin (material pyrrolidone and styrene copolymer ball particle size 30±1.5um, Suzhou Nano Microbe Technology Co., Ltd.) as chromatography packing material, the column volume is 55ml, wash 2 CVs with 60% acetonitrile aqueous solution first, then equilibrate 2 CVs with 20% acetonitrile. Mobile phase: A 0.1% formic acid in water; B acetonitrile. The collected front stage tiacumicin B was mixed in 5 batches and then concentrated under reduced pressure to make the concentration of acetonitrile lower than 35%. Samples were loaded directly, the flow rate was 5ml / min, 1CV of 20% B was pre-washed, and then 8 CVs of 45% B were eluted. Collected in sections, the yield with a purity of 98% was 89.82%.

Embodiment 3

[0032] Purification of tiacumicin B: use 15×310mm glass column, Uni30BPC resin (material pyrrolidone and styrene copolymer ball particle size 30±1.5um, Suzhou Nano Microbe Technology Co., Ltd.) as chromatography packing material, the column volume is 55ml, wash 2 CVs with 60% acetonitrile aqueous solution first, then equilibrate 2 CVs with 20% acetonitrile. Mobile phase: A 0.1% aqueous formic acid; B acetonitrile. The collected tiacumicin B in the middle stage was mixed and then concentrated under reduced pressure to keep the concentration of acetonitrile below 35%. Direct sample loading, flow rate 5ml / min, 1 CV of 20% B prewash, and then 8 CVs of 50% B elution. Collected in sections, the yield with a purity of 98% was 36.46%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com