Preparation of polyvinylamine/polyaniline mixed matrix membranes used for separation of gas containing carbon dioxide

A technology of mixed matrix membrane and polyvinylamine, applied in separation methods, chemical instruments and methods, semi-permeable membrane separation, etc., can solve the problem of low performance of composite membranes, and achieve the effect of good stability and high CO2 permeation selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

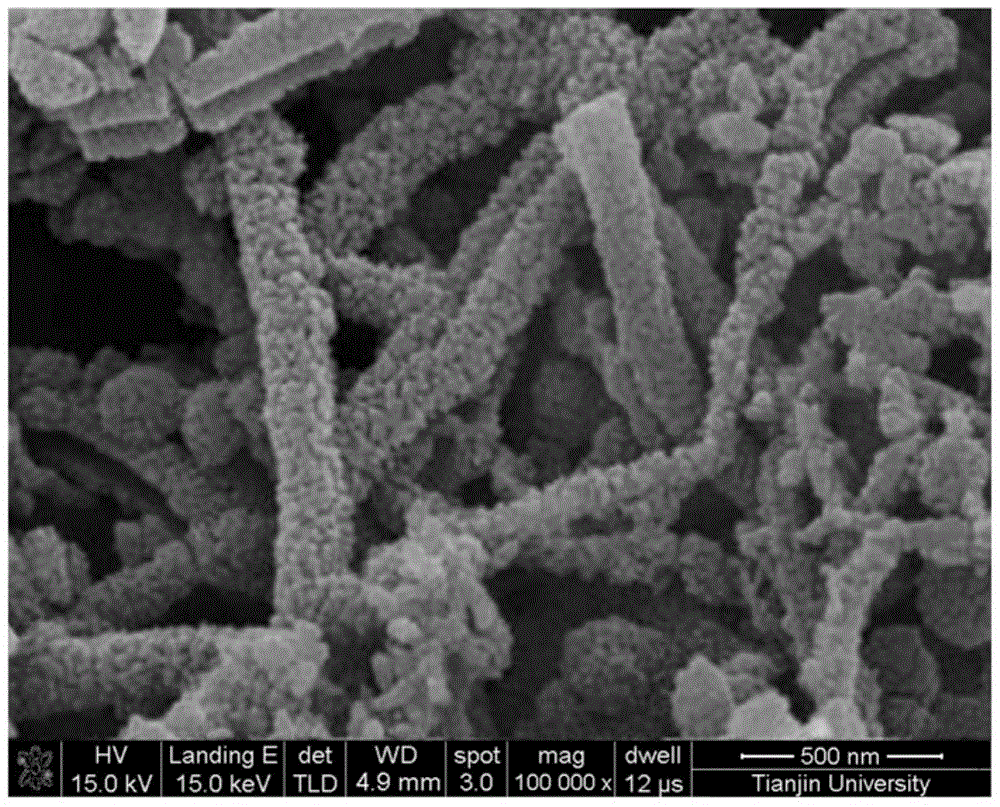

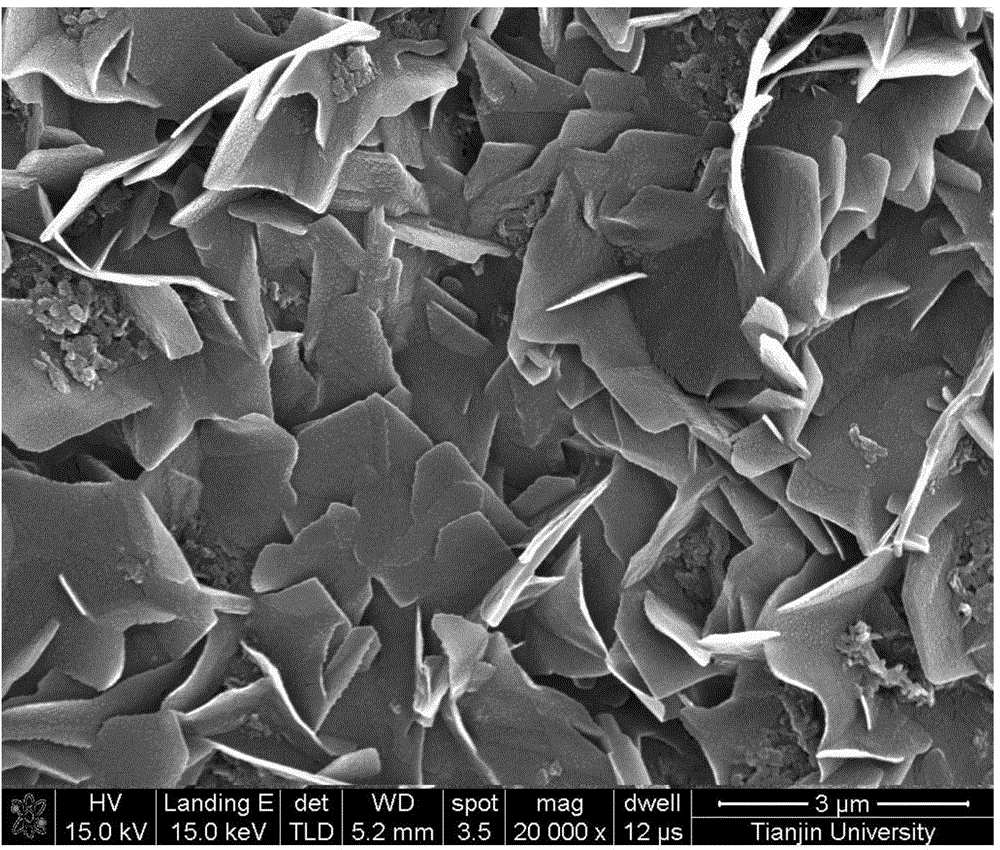

[0021] First, an aqueous hydrochloric acid solution with a pH of 1 was prepared, and cetylammonium bromide and aniline were added to obtain solution A. Then, solution B was prepared by dissolving ammonium persulfate in water. Two solutions were mixed, wherein the concentration of cetyl ammonium bromide was 0.3 mol / L, and the concentrations of aniline and ammonium persulfate were both 0.05 mol / L. The mixed solution was left at 5°C for 36 hours. The samples were centrifuged and washed to obtain polyaniline nanosheets, such as figure 1 shown.

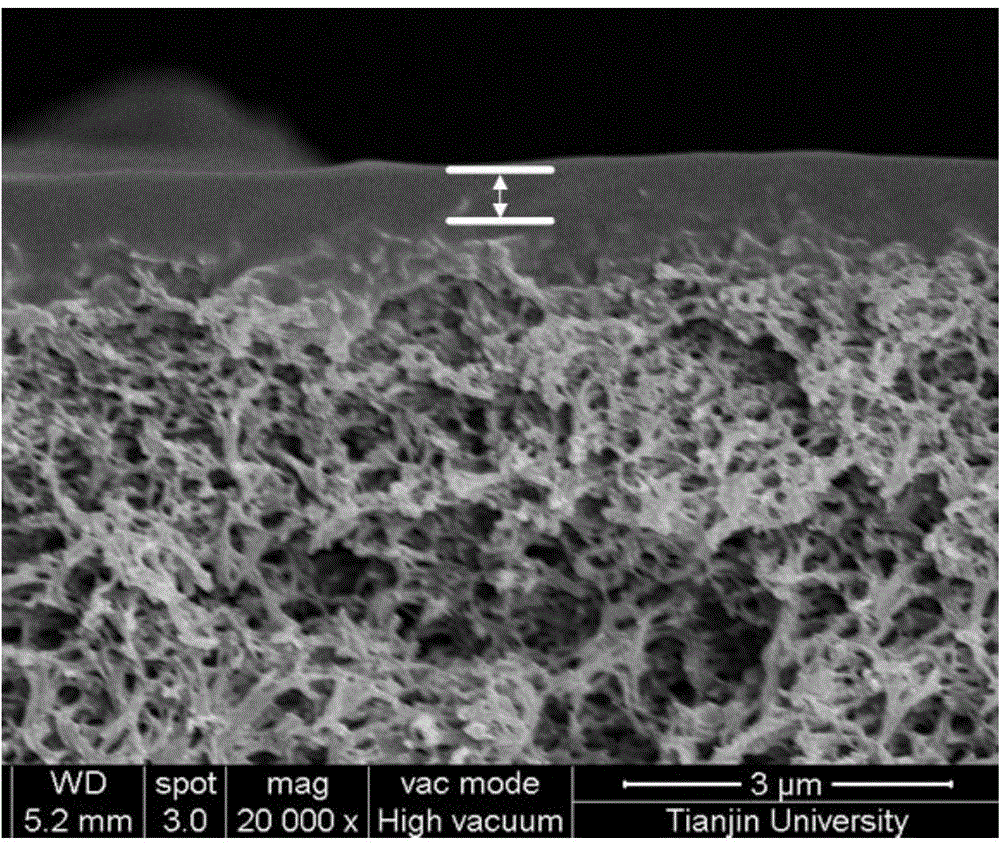

[0022] Polyvinylamine, polyaniline nanosheets and water are mixed, and ultrasonically stirred at room temperature to obtain a coating liquid. Among them, the mass fraction of polyvinylamine is 2%, and the mass ratio of polyvinylamine to polyaniline nanosheets is 9:1. The coating liquid prepared above was coated on a polysulfone base film with a wet coating thickness of 300 μm, and then placed in an environment with a temperature of 30°...

Embodiment 2

[0025] First, an aqueous sulfuric acid solution with a pH of 1.5 was prepared, and solution A was obtained by adding cetylammonium bromide and aniline. Then, solution B was prepared by dissolving ammonium persulfate in water. Two solutions were mixed, wherein the concentration of cetyl ammonium bromide was 0.1 mol / L, the concentration of aniline was 0.2 mol / L, and the concentration of ammonium persulfate was 0.05 mol / L. The mixed solution was left at -10°C for 24 hours. The samples were centrifuged and washed to obtain polyaniline nanosheets.

[0026] A coating liquid is prepared by mixing polyvinylamine, polyaniline nanosheets and water. Among them, the mass fraction of polyvinylamine is 4%, and the mass ratio of polyvinylamine to polyaniline nanosheets is 20:1. The coating liquid prepared above was coated on a polysulfone base film with a wet coating thickness of 50 μm, and then placed in an environment with a temperature of 20° C. and a relative humidity of 30% to dry fo...

Embodiment 3

[0029] First, an aqueous hydrochloric acid solution with a pH of 2 was prepared, and solution A was obtained by adding cetylammonium bromide and aniline. Then, solution B was prepared by dissolving ammonium persulfate in water. Two solutions were mixed, wherein the concentration of cetyl ammonium bromide was 1.0 mol / L, and the concentrations of aniline and ammonium persulfate were both 0.5 mol / L. The mixed solution was left at -10°C for 10 hours. The samples were centrifuged and washed to obtain polyaniline nanosheets.

[0030] A coating liquid is prepared by mixing polyvinylamine, polyaniline nanosheets and water. Among them, the mass fraction of polyvinylamine is 1%, and the mass ratio of polyvinylamine to polyaniline nanosheets is 10:1. The coating liquid prepared above was coated on a polyethersulfone base film with a wet coating thickness of 200 μm, and then placed in an environment with a temperature of 40° C. and a relative humidity of 40% to dry for 20 hours to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com