Method for synchronous defluorination and denitration by using composite absorbent

An absorbent and defluorination technology, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problem of the inability to achieve integrated and efficient removal of harmful components such as sulfur, nitric acid, dust, and fluorine, and the inability to adapt to various Complicated working conditions, high cost of adsorbent and membrane materials, etc., to achieve strong absorption effect, convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

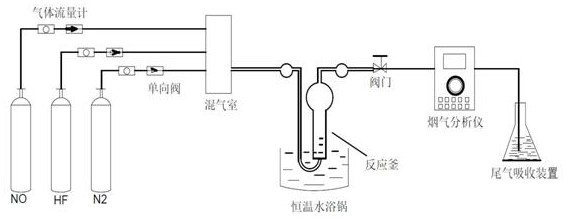

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: the method for simultaneous denitration and defluorination of this composite absorbent is as follows:

[0022] 1. Preparation of hydrophobic ionic liquid membrane: the organic membrane is polyethersulfone membrane, and the hydrophobic ionic liquid is [C 8 F 13 MIM][Tf 2 N] (the ionic liquid [C 8 F 13 MIM][Tf 2 N] is obtained with reference to the following literature methods: Baltus R E , Counce RM , Culbertson B H , et al. Examination of the Potential of IonicLiquids for Gas Separations[J]. Separation Science and Technology, 2005, 40(1):525-541 .), the bulk polyethersulfone membrane was dried and weighed, the mass of the membrane body was 18 g, and the membrane thickness was 200 μm; the dried polyethersulfone membrane was immersed in the hydrophobic ionic liquid [C 8 F 13 MIM][Tf 2 N], let stand for 5h to make the ionic liquid fully fill the pores of the membrane body; gently wipe off the excess ionic liquid on the outer surface of the membrane wit...

Embodiment 2

[0024] Embodiment 2: the method for simultaneous denitration and defluorination of this composite absorbent is as follows:

[0025] 1. Preparation of hydrophobic ionic liquid membrane: the organic membrane body is nylon membrane, and the hydrophobic ionic liquid is [MATMA][BF 4 ] (the ionic liquid [MATMA][BF in the present invention 4 ] Prepared with reference to the following literature methods: Jianbin T , Tang H , SunW , et al. Poly(ionic liquid)s: a new material with enhanced and fast CO 2 absorption[J]. Chemical Communications, 2005(26):3325-3327.), the block nylon membrane was dried and weighed, the mass of the membrane body was 20g, and the thickness of the membrane was 300μm; the dried nylon membrane was immersed in Hydrophobic ionic liquid [MATMA][BF 4], let stand for 9 h to make the ionic liquid fully fill the pores of the support body; gently wipe off the excess ionic liquid on the outer surface of the membrane with blotting paper, and weigh to obtain 50% loading ...

Embodiment 3

[0027] Embodiment 3: the method for simultaneous denitration and defluorination of this composite absorbent is as follows:

[0028] 1. Preparation of hydrophobic ionic liquid membrane: the organic membrane body is a polyvinylidene fluoride membrane, and the hydrophobic ionic liquid is [RMIM][TCM] (the ionic liquid [RMIM][TCM] in the present invention is prepared by referring to the following literature method. Obtained: Tzialla O , Labropoulos A , Panou A , et al. Phase behavior and permeability of Alkyl-Methyl-Imidazolium Tricyanomethanide ionic liquids supported in nanoporousmembranes[J]. Separation and Purification Technology, 2014, 135:22–34.), will The bulk polyvinylidene fluoride film was dried and weighed, the mass of the film body was 16 g, and the film thickness was 400 μm; the dried polyvinylidene fluoride film was immersed in the hydrophobic ionic liquid [RMIM] [TCM], and allowed to stand. 7h, gently wipe off the excess ionic liquid on the outer surface of the membr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com