Preparation method of positively charged composite nanofiltration membrane

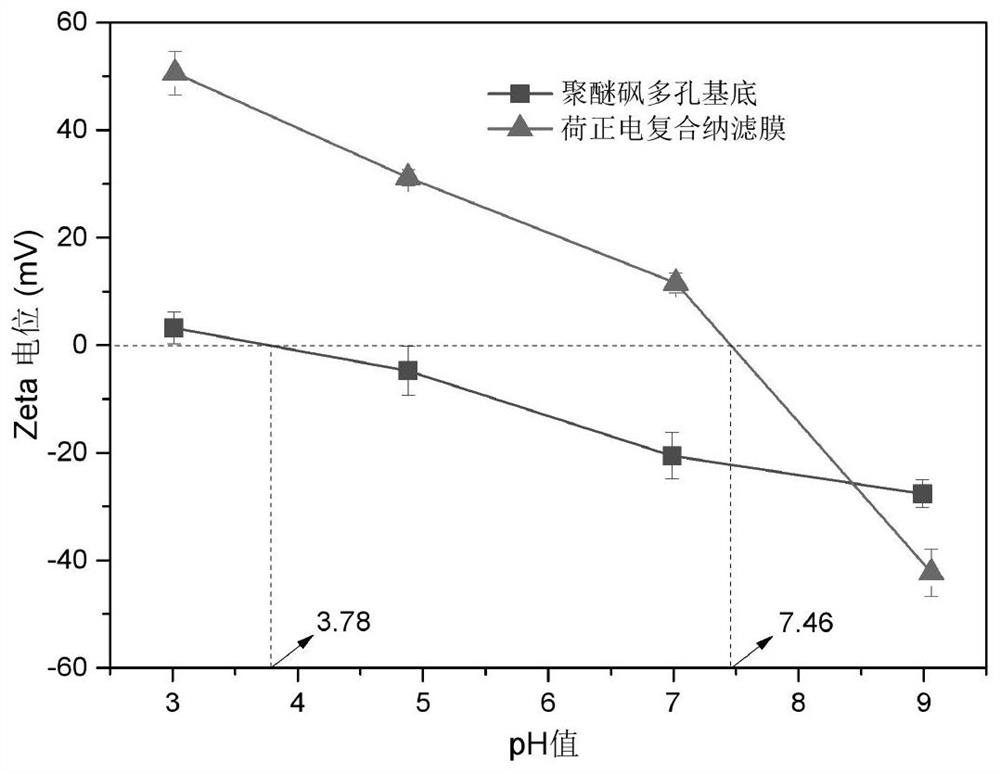

A composite nanofiltration membrane and positively charged technology, which is applied in the field of membrane separation, can solve the problems of low permeability selectivity and poor anti-pollution ability of positively charged nanofiltration membranes, and achieve strong anti-pollution ability and high permeability selectivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of positively charged composite nanofiltration membrane specifically comprises the following steps:

[0036] (1) Preparation of aqueous phase solution

[0037] Adding 0.5% (w / v) of polyethyleneimine with a molecular weight of 600Da and 0.5% (w / v) of O, O'-bis(2-amino) with a molecular weight of 1900Da to water Propyl) polypropylene glycol-block-polyethylene glycol-block-polypropylene glycol copolymer, stirred at a speed of 300r / min for 60min to completely dissolve to obtain an aqueous phase solution;

[0038] (2) Preparation of organic phase solution

[0039] Add trimesoyl chloride with a mass volume percentage of 0.2% (w / v) to n-hexane, stir at a speed of 300 r / min for 60 min until completely dissolved, and obtain an organic phase solution;

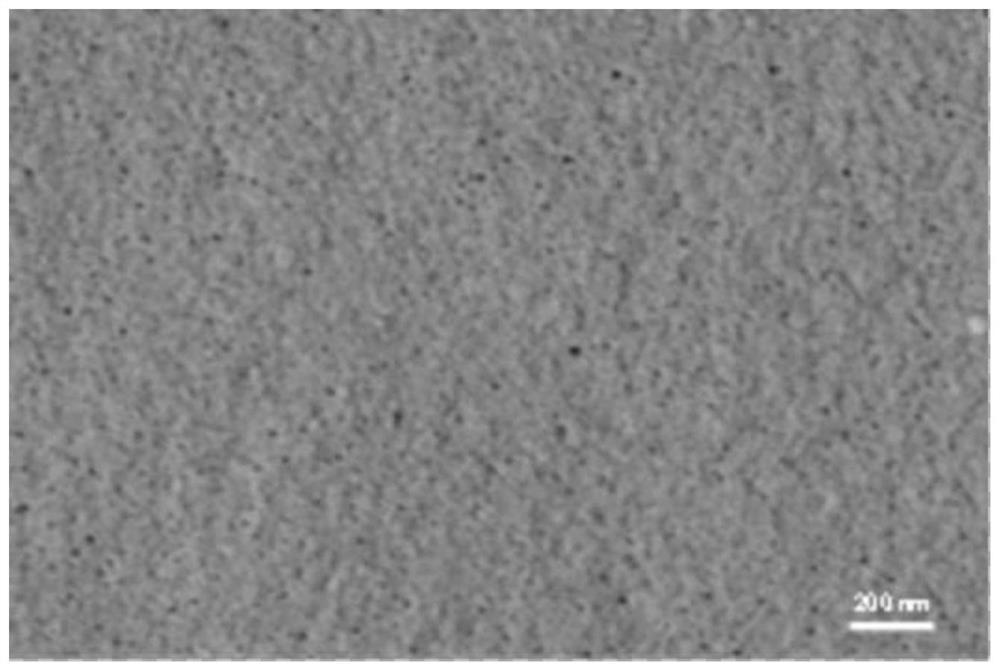

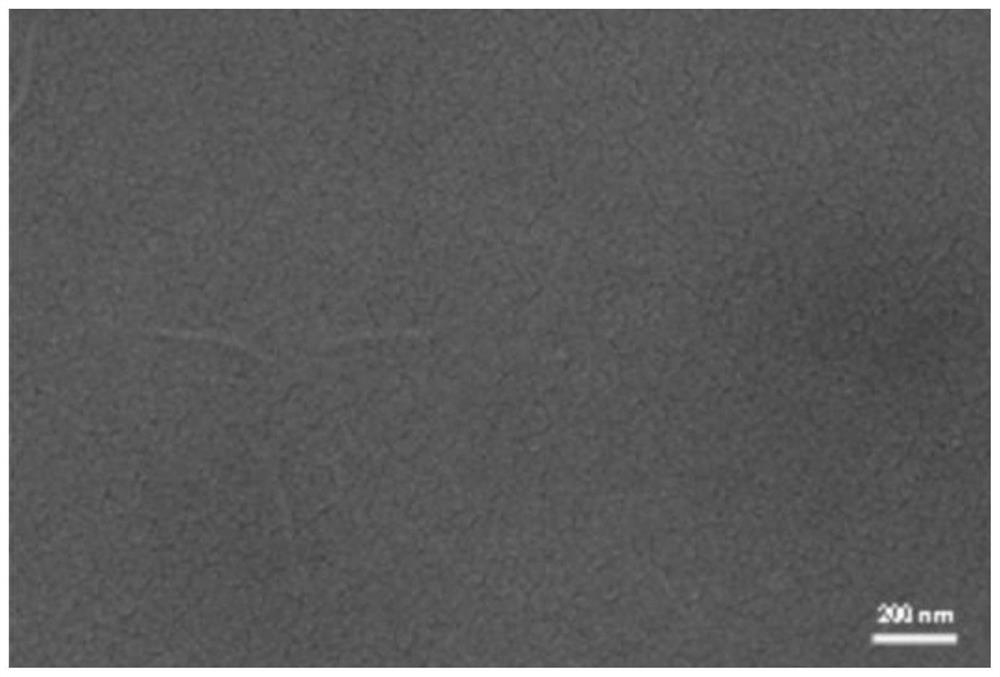

[0040] (3) Preparation of positively charged composite nanofiltration membrane

[0041] First, pour the aqueous phase solution into the surface of the polysulfone porous ultrafiltration membrane and immer...

Embodiment 2

[0045] The preparation method of positively charged composite nanofiltration membrane specifically comprises the following steps:

[0046] (1) Preparation of aqueous phase solution

[0047] Add 1% (w / v) of polyethyleneimine with a molecular weight of 70000Da and 1% (w / v) of O, O'-bis(2-amino) with a molecular weight of 500Da to water Propyl) polypropylene glycol-block-polyethylene glycol-block-polypropylene glycol copolymer, stirred at a speed of 100r / min for 90min to completely dissolve to obtain an aqueous phase solution;

[0048] (2) Preparation of organic phase solution

[0049] Add trimesoyl chloride with a mass volume percentage of 0.05% (w / v) to n-heptane, stir at a speed of 100 r / min for 90 min until completely dissolved, and obtain an organic phase solution;

[0050] (3) Preparation of positively charged composite nanofiltration membrane

[0051]First, pour the aqueous phase solution into the surface of the polysulfone porous ultrafiltration membrane and immerse fo...

Embodiment 3

[0053] The preparation method of positively charged composite nanofiltration membrane specifically comprises the following steps:

[0054] (1) Preparation of aqueous phase solution

[0055] Adding mass volume percent to water is 1.5% (w / v) of polyethyleneimine with a molecular weight of 10000Da and a mass volume percentage of 1.5% (w / v) of a molecular weight of 800Da O, O'-bis(2-amino Propyl) polypropylene glycol-block-polyethylene glycol-block-polypropylene glycol copolymer, stirred at a speed of 300r / min for 60min to completely dissolve to obtain an aqueous phase solution;

[0056] (2) Preparation of organic phase solution

[0057] Add trimesoyl chloride with a mass volume percentage of 0.1% (w / v) to n-octane, stir at a speed of 300r / min for 60min until completely dissolved, and obtain an organic phase solution;

[0058] (3) Preparation of positively charged composite nanofiltration membrane

[0059] First pour the aqueous phase solution into the surface of the polyacrylo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com