Patents

Literature

90 results about "Mass-Volume Percentage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

There are two types of percent concentration: percent by mass and percent by volume. Percent by mass (m/m) is the mass of solute divided by the total mass of the solution, multiplied by 100 %.

Preservative for grass carp fillets and use method

InactiveCN101828589AReduce fat oxidationGuaranteed qualityMeat/fish preservation by coatingPolyphenolRefrigerated temperature

The invention discloses a preservative for grass carp fillets and a use method, belonging to the technical field of aquatic product freshness retaining and processing. The preservative is a mixed aqueous solution comprising the following components in concentration by mass-volume percent: 1.3-1.7 percent of chitosan, 0.9-1.1 percent of acetic acid and 0.4-0.6 percent of tea polyphenol. The use method of the preservative comprises the following steps of: soaking grass carp fillets in the preservative for 2-3min, taking out and trickling for 1min and then drying the grass carp fillets at 4 DEG C so as to form a thin freshness retaining film; then putting the grass carp fillets coated with the thin freshness retaining film into a freshness retaining bag and tying the opening of the bag; and storing the grass carp fillets in a refrigerator at 4 DEG C. Compared with an ordinary refrigeration method, the preservative can better keep the freshness, the water and the flavor of the grass carp fillets and prolong the shelf life of the grass carp fillets for 8-10 days; the operation process of coating the film is simple; and the preservative has high cost performance, wherein the cost of per ton of preservatives for the grass carp fillets is lower than 90 yuan.

Owner:CHINA AGRI UNIV

Surface texturing processing method of monocrystalline silicon solar cell

InactiveCN104630900AHigh speedImprove uniformityAfter-treatment detailsFinal product manufactureSodium hydroxideIon

The invention discloses a surface texturing processing method of a monocrystalline silicon solar cell. The processing method comprises the following steps: cleaning oil stains and finger prints on a surface of a monocrystalline silicon wafer by ultrasonic; surface texturing, which comprises putting the ultrasonic cleaned monocrystalline silicon wafer into a texturing tank which contains a sodium hydroxide solution having a mass volume percentage of 2%, performing surface corrosion texturing processing; and adding TS4 as a texturing catalyst into the sodium hydroxide solution to increase a silicon surface corrosion speed and uniformity of surface corrosion; removing an oxide from the surface of the monocrystalline silicon wafer, and cleaning the monocrystalline silicon wafer by using a hydrofluoric acid solution (a concentration of 49%) with a volume percentage of 16%; removing metal ions, and cleaning the monocrystalline silicon wafer by using a hydrochloric acid solution (a concentration of 37%) with a volume percentage of 28%; and drying the final monocrystalline silicon wafer with a pyramid-shaped surface. According to the invention, a surface texturing speed of the monocrystalline silicon wafer is increased; uniformity of surface texturing of the monocrystalline silicon wafer is improved; and then monocrystalline silicon solar cell prepared by the method is higher in photoelectric conversion efficiency of the solar cell and good in stability. The surface texturing processing method is a better choice for application of photovoltaic power generation.

Owner:江苏天宇光伏科技有限公司

Propofol fat emulsion injection and preparation method thereof

ActiveCN102805728AImprove physical stabilityImprove stabilityNervous disorderHydroxy compound active ingredientsO-Phosphoric AcidMass-Volume Percentage

The invention discloses propofol fat emulsion injection and a preparation method thereof. The propofol fat emulsion injection comprises, by weight percent, 1% of propofol, 6-8% of soybean oil, 1.5-2.0% of soybean lecithin, 3-5% of glycerol, 0.1-0.8% of tween-80, 0.05-0.1% of phosphoric acid, appropriate amount of pH regulator and the balance of water for injection, wherein the amount of the pH regulator is enough to regulate pH of the water for injection to 7.5-8.0. The propofol fat emulsion injection improves drug delivery, decreases particle size, and improves uniformity of particle size, and accordingly stability of the injection is improved, pain during injection is lowered, and drug dependency of patients is increased.

Owner:NANJING CHIA TAI TIANQING PHARMA

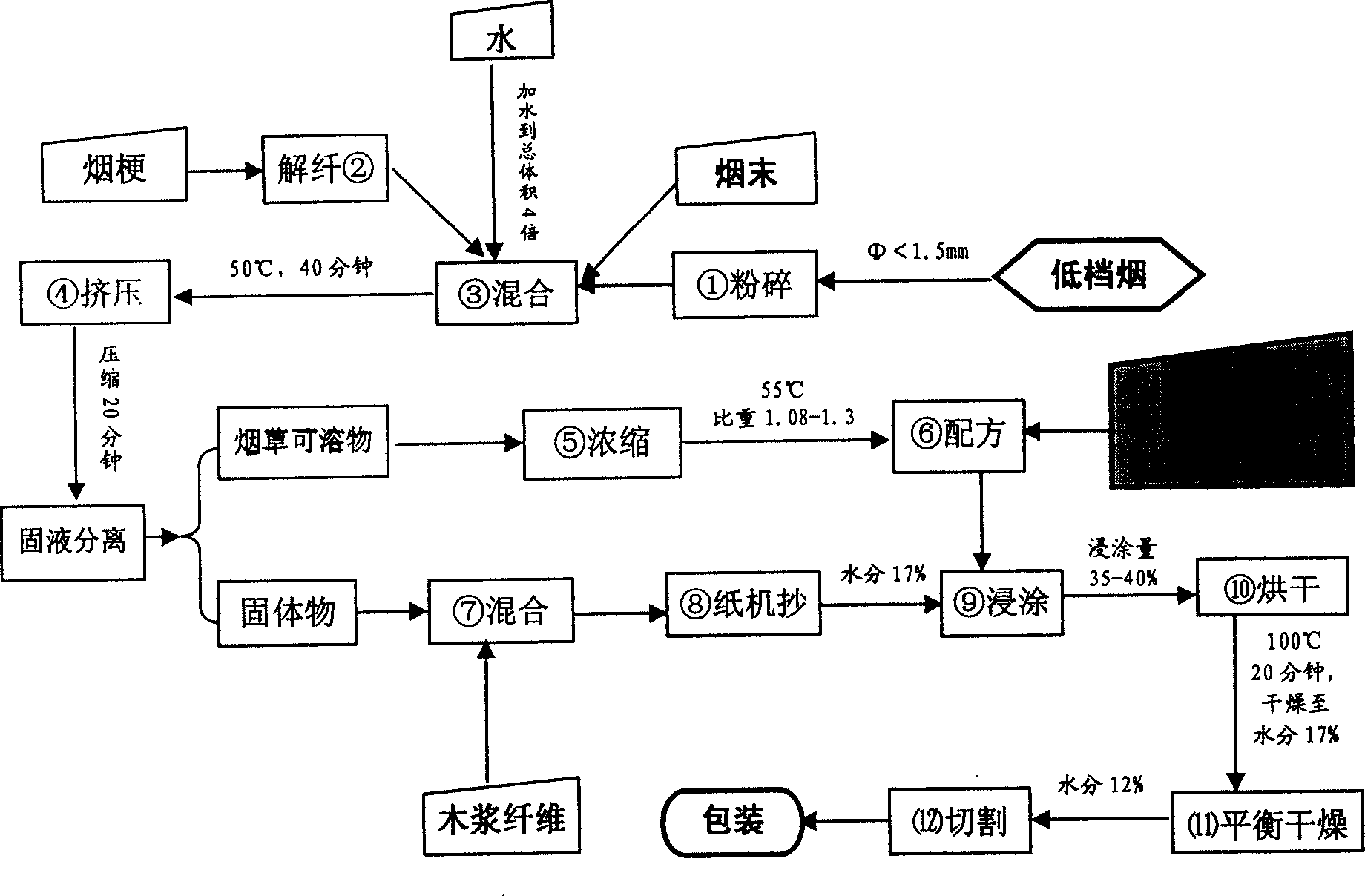

Process for thin tobacco sheets by color papermaking method

A technology for preparing the color tobacco sheets by color paper making method includes such steps as breaking low-grade tobacco leaves, loosening the fibres of tobacco stem, proportionally mixing tobacco dust, broken tobacco leaves and stem fibres, squeezing, concentrating juice, adding essence, combustion promoter and edible pigment, mixing, making paper, drying, cutting and packing.

Owner:CHINA TOBACCO SHANDONG IND

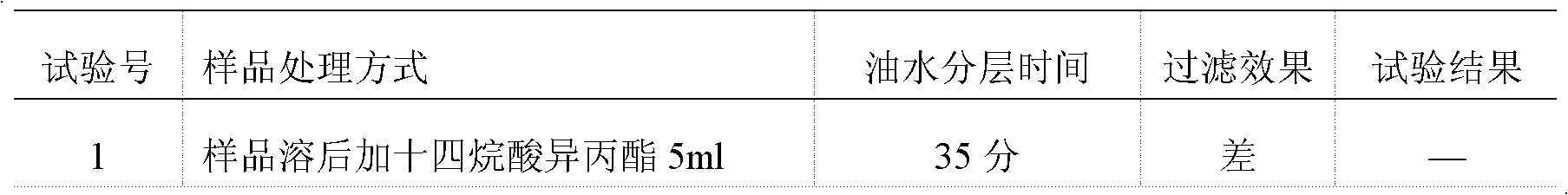

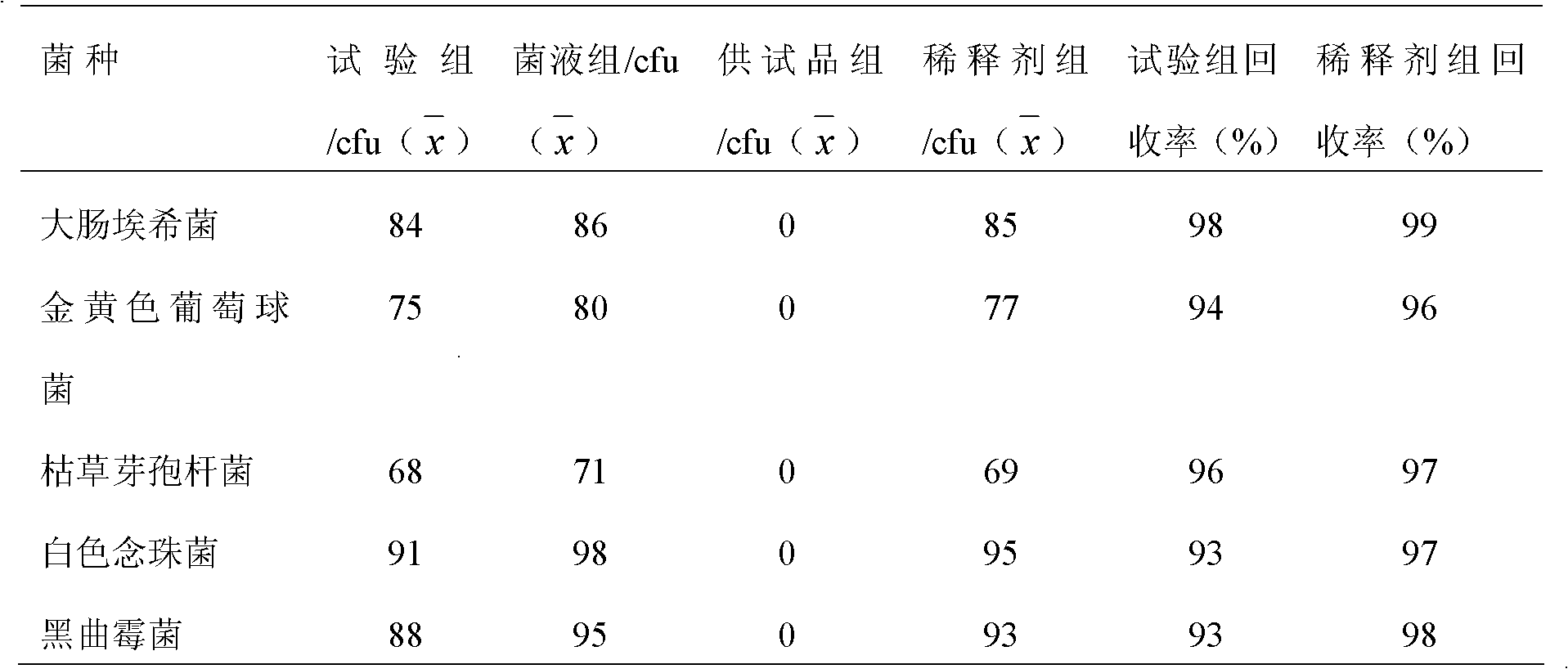

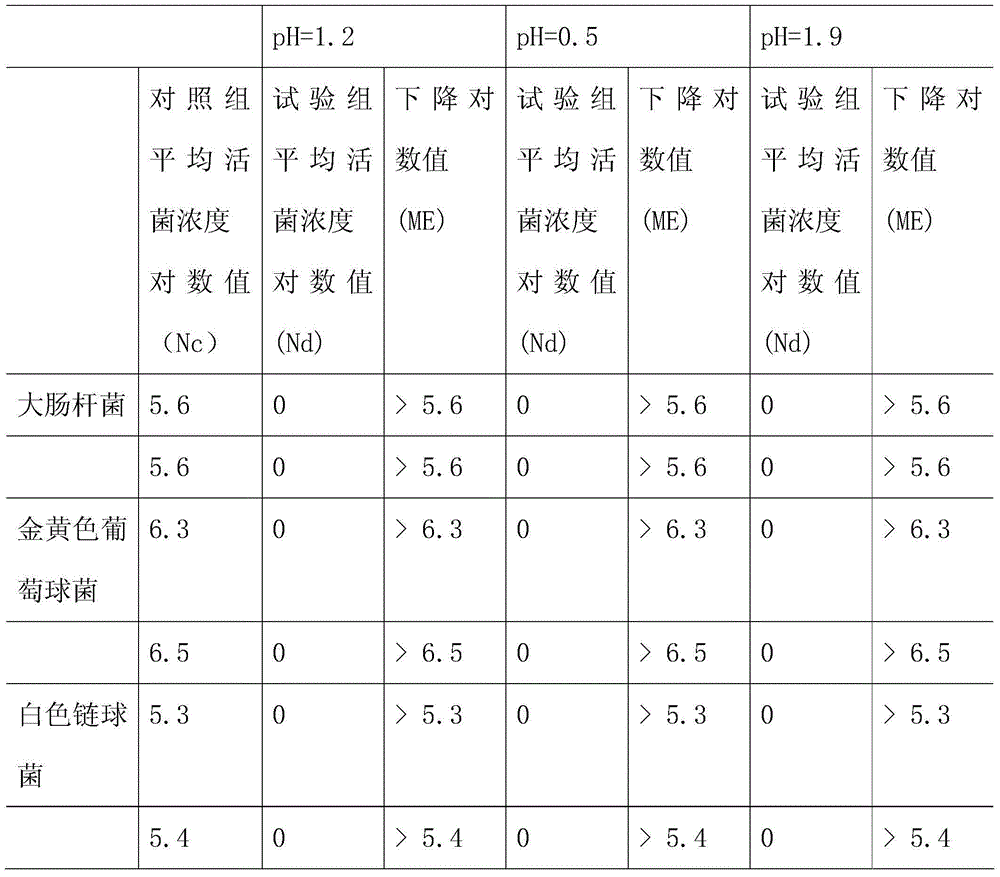

Microbial limit detection method of miconazole nitrate suppository

InactiveCN102586393AGood antibacterial effectPromote stratificationMicrobiological testing/measurementMicroorganism based processesFiltrationStaphyloccocus aureus

The invention discloses a microbial limit detection method of miconazole nitrate suppository. The method comprises dissolving sample with sodium chloride-peptone buffer solution (pH 7.0) containing 10 vol% polysorbate 80 (Tween 80), adding 20ml of isopropyl myristate, and washing with aqueous solution containing 0.1 vol% polysorbate 80 and 0.1 wt% peptone. Membrane filtration method is adopted for bacteria, mildew, yeast, Staphyloccocus aureus and Monilia albican, with recovery rate all above 70%. Culture medium dilution method is adopted to detect Pseudomonas Aeruginosa. The addition of isopropyl myristate can accelerate fat / water layer separation, shorten experiment time, stabilize flow rate, reduce test cost, and achieve strong operability.

Owner:SHAANXI INST FOR FOOD & DRUG CONTROL

Carboxymethyl chitosan antibacterial film spray and preparation method thereof

InactiveCN104586753APromote healingNo scarsOrganic active ingredientsAntisepticsSolubilityWound healing

The invention relates to a carboxymethyl chitosan antibacterial film spray and a preparation method thereof. The antibacterial film spray comprises the following components in percentage by mass-volume in final liquid: 0.5-0.4% of carboxymethyl chitosan. 0.5-10% of plasticizer, and the balance of deionized water. The preparation method comprises the following steps: dissolving the carboxymethyl chitosan, adding plasticizer, removing solid residues and performing constant volume process. The carboxymethyl chitosan antibacterial film spray not only has the characteristics of being good in film forming property, biodegradability and biocompatibility, being safe and non-toxic, and the like, but also has various pharmacological action of hemostasis, bacteriostasis, promotion of wound healing without left scars and the like. The defects that the traditional ointment, gel and other preparations are easily lost, bad in breathability, easy to pollute clothes, inconvenient to use, undesirable in effect and the like can be overcome; also, the defects that the carboxymethyl chitosan in the carboxymethyl chitosan film spray is poor in water solubility, and a diluted acid or pH regulator and the like is needed to be added can be overcome.

Owner:CHINA PHARM UNIV

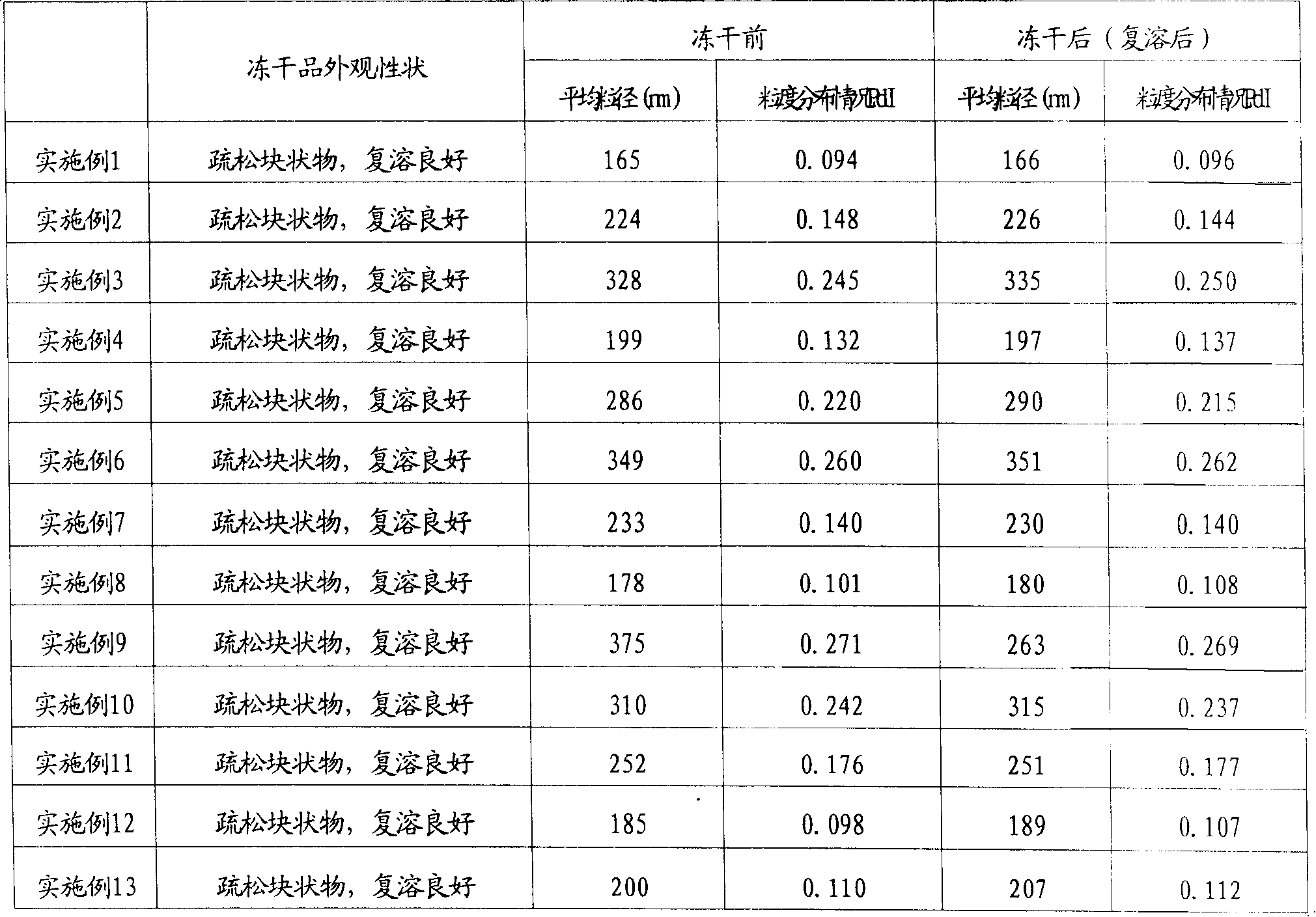

Nimodipine lyophilized emulsion for injection and preparing method thereof

InactiveCN101199522AAvoid stimulationAvoid harmOrganic active ingredientsPowder deliveryFreeze-dryingNimodipine

The invention relates to nimodipine lyophilization dry emulsion for injection. Before freeze-dried or reconstituted, according to percentage concentration per 1000 ml of fat emulsion, the lyophilization dry emulsion contains 0.001 percent to 0.2 percent of nimodipine, 0.5 percent to 30 percent of oiliness solvent, 0.1 percent to 5 percent of emulsifier, 5 percent to 40 percent of the freeze-drying protective agent and 0.1 percent to 10 percent of isotonic regulator. The invention also relates to a preparation method of nimodipine lyophilization dry emulsion. The invention has the advantages that ethanol is avoided to decrease irritation; the product can be mixed with any proportion of water for injection, sodium chloride solution, glucose solution, blank fat emulsion or other aqueous solution without phenomena of precipitation or crystallization; in addition, compared with the fat emulsion, the lyophilization dry emulsion is more helpful to improve the stability of nimodipine and excipient of the nimodipine, thereby lowering the requirements of production, transportation and storage conditions and prolonging the period of validity.

Owner:YAOPHARMA CO LTD +1

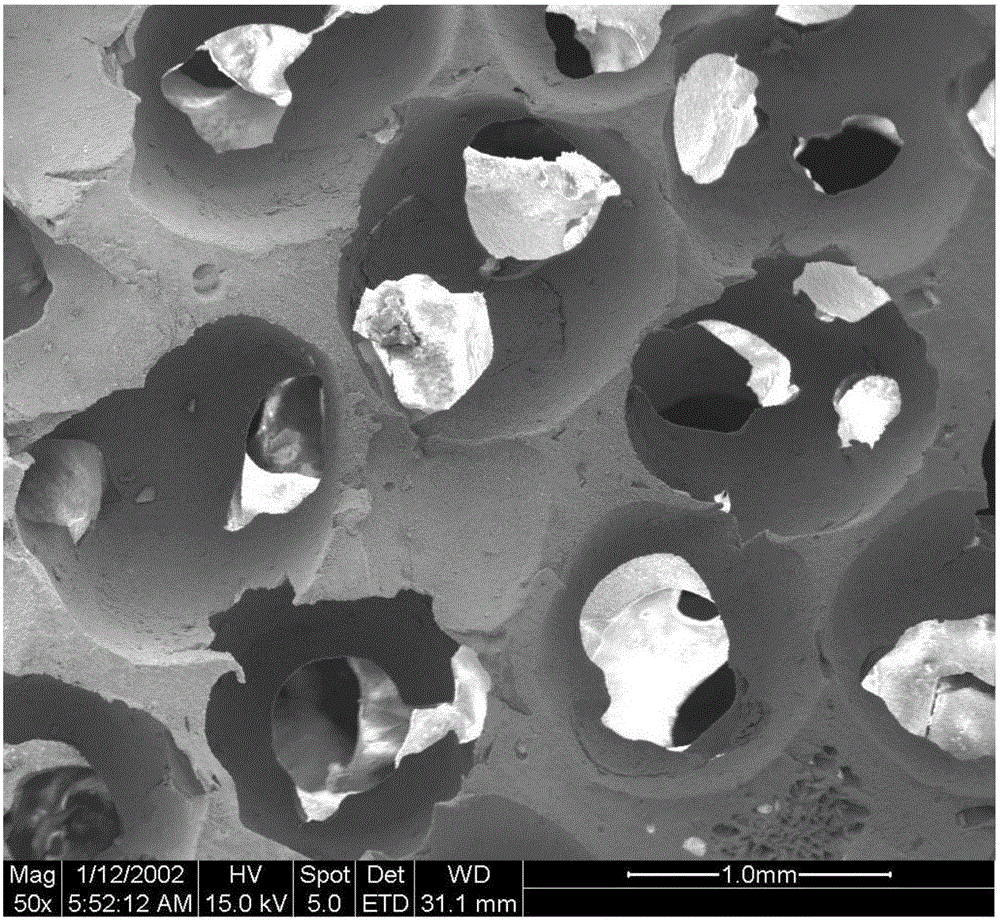

Preparation method of porous structural ceramic material

InactiveCN106512103ASimple processGood sphericityTissue regenerationProsthesisFurnace temperatureMaterials preparation

The invention provides a preparation method of a porous structural ceramic material, and belongs to the technical field of ceramic material preparation methods. The preparation method comprises the following steps: I, preparing a ceramic slurry which contains 10-35% of calcium phosphate in mass-volume percentage; II, preparing sodium alginate particles: preparing a sodium alginate solution which is 1-2% in mass-volume percentage, promoting free dropping of the solution into 1% of a calcium chloride solution in the form of liquid drops by virtue of a needle, and conducting cross-linking, so that the spherical sodium alginate gel particles are prepared; III, repeatedly soaking the spherical sodium alginate gel particles obtained in the step II in pure ethanol for three times, so that cured sodium alginate particles are obtained, wherein each time lasts for 10min; IV, stacking the cured sodium alginate particles obtained in the step III in a die, applying pressure so that the particles get into face-to-face contact, injecting the ceramic slurry into the die so as to obtain a porous material in the form of a gel in the die after the gelatinization of the slurry, and drying the porous material at 40 DEG C so as to obtain an initial blank; and V, calcining the initial blank at furnace temperature of 500 DEG C for 1h, and sintering the initial blank at increased temperature of 1000-1200 DEG C, so that the porous structural ceramic material is prepared.

Owner:SOUTHWEST JIAOTONG UNIV

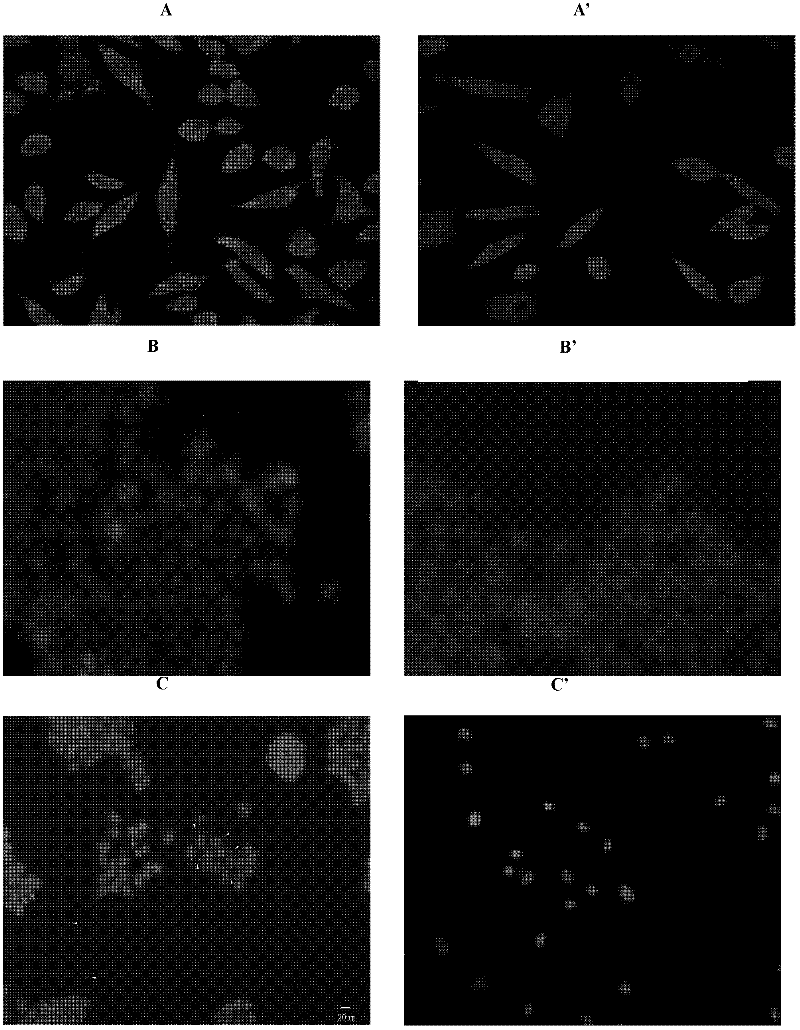

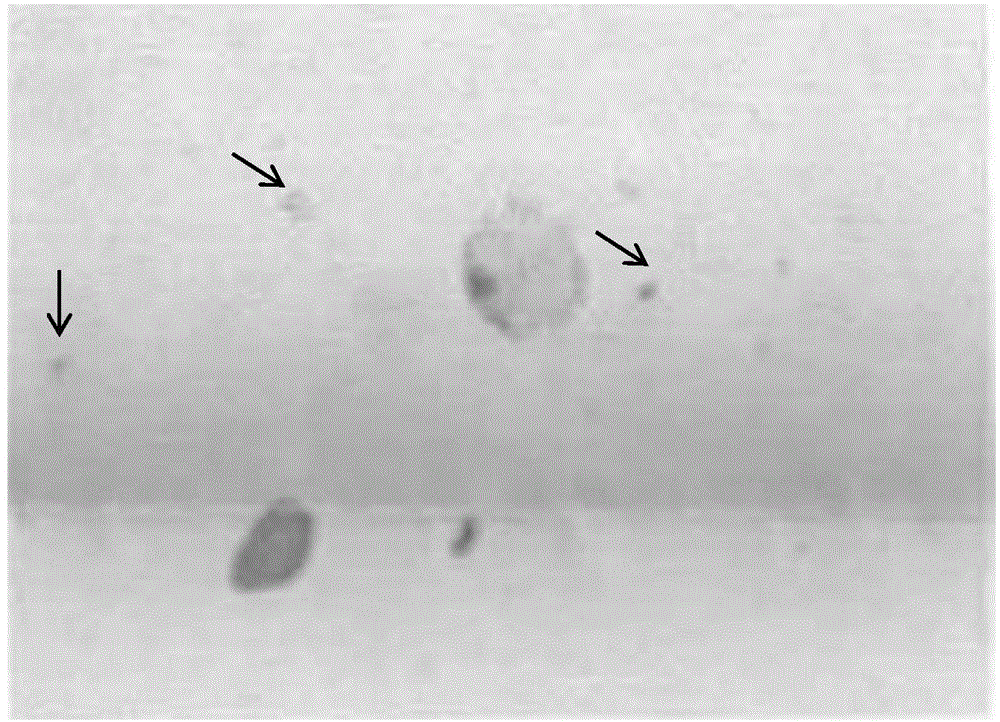

Reagent for eliminating mycoplasma contamination in cell culture and use method thereof

ActiveCN102409019AMetabolic effectsEfficient removalMicrobiological testing/measurementTissue cultureMycoplasma contaminationPleuromutilin

The invention provides a reagent for eliminating mycoplasma contamination in cell culture and a use method thereof. The reagent is prepared by mixing liquid A and liquid B isometrically or mixing liquid A, liquid B and liquid C isometrically, wherein the liquid A is prepared by mixing semisynthetic pleuromutilin derivatives and 0.01MPBS, and the mass-volume percentage concentration of the solute after mixing is 0.5-1.5%; the liquid B is prepared by mixing quinolone derivatives and 0.01MPBS, and the mass-volume percentage concentration of the solute after mixing is 0.5-1.5%; and the liquid C is prepared by mixing tetracycline derivatives and 0.01MPBS, and the mass-volume percentage concentration of the solute after mixing is 0.25-0.75%. The reagent and method provided by the invention havethe following beneficial effects: if contamination is not severe, the effect can be displayed within a week; and after the treatment cycle is finished, black spots do not exist among the treated contaminated cells, the growth cycles of the cells return to normal, the cell morphology is normal, and aggregated growth and netting phenomena are avoided.

Owner:胡晓鹏

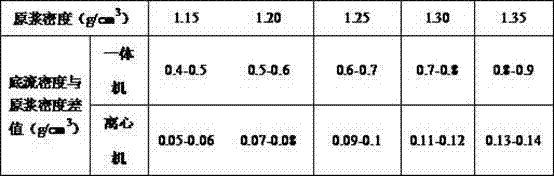

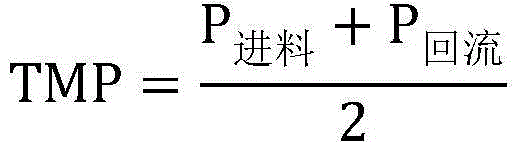

Extending method of horizontal well safe density window

ActiveCN104712287AAvoid expansionImprove pressure bearing capacityDrill bitsFlushingMud systemsWell drilling

The invention relates to an extending method of a horizontal well safe density window particularly. The extending method comprises the steps that 1 1.5% of bentonite powder, 1% of saw dust, 1% of blocking agent and 1% of mica powder are added into 100 squares of drilling fluid gradually in a borehole with a standard of 83 / 8''according to a mass-volume percent; 2 the displacement of a drilling pump is lowered when the drilling pump enters a leakage layer; 3 when the leakage layer opens, the rate of penetration is controlled, solid control is strengthened at the same time, and harmful solids in the drilling fluid are removed; 4 the well deviation in an oil shale section is controlled; 5, the orientation of the borehole is conducted with a roller bit. According to the extending method of the horizontal well safe density window, blocking agents of different granularity are added gradually through a mud system, the leak-proofing formula is improved, the concentration of the blocking agent when added into the well is guaranteed to be at 3%, blocking is strengthened, and the strength of a leaking well wall is improved; the displacement of the drilling pump is lowered, the expansion of a crack is prevented, and the collapse pressure of the balance oil shale section is lowered, so that the safe density window is extended.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Exfoliative cell sap base preserving fluid, method thereof for flaking and kit

ActiveCN104642300ASimple and fast operationEasy to prepareMicrobiological testing/measurementDead animal preservationPotassiumMonopotassium phosphate

The invention discloses an exfoliative cell sap base preserving fluid, a method thereof for flaking and a kit. The exfoliative cell sap preserving fluid comprises the following components by massic volume percentage: 3.8-4.2% of paraformaldehyde, 0.8-1.5% of N-methyl-N-cyclohexyl-2-amino-3,5-bromhexine, 0.8-1.5% of glacial acetic acid, 0.1-0.2% of acetylcysteine, 0.75-0.85% of sodium chloride, 0.01-0.03% of potassium chloride, 0.12-0.15% of disodium hydrogen phosphate, 0.025-0.03% of monopotassium phosphate, and the balance of water; and pH is regulated to 7.2-7.8. The exfoliative cell sap base preserving fluid is small in shrinking to the exfoliative cell, and suitable for storage for a long time; the cell coated by the mucus in the sample is successfully separated, the positive cell stacking and loss are avoided, and the effective cell number is improved; and the preserving fluid can be used for observing whether the occult blood symptom is existent.

Owner:SHANGHAI YU KANG HOSPITAL

Alkaline foam cleanser and preparation method thereof

ActiveCN106479690AReduce adhesionQuick Peel ClearOrganic detergent compounding agentsSurface-active detergent compositionsMass-Volume PercentageBiological membrane

The invention discloses an alkaline foam cleanser and a preparation method thereof. The alkaline foam cleanser is prepared from components in percentage by mass volume as follows: 10%-20% of a degreasing agent, 3%-13% of a foam stabilizer, 1%-5% of a bactericide, 3%-9% of a builder, 10%-20% of a cosolvent, 1%-3% of a pH regulator and the balance of deionized water. The foam cleanser has the pH value ranging from 8.5 to 13.5 and is suitable for removal of organic fouling; the degreasing agent and the foam stabilizer can penetrate into biological membranes to dissolve fat, protein and the like; the bactericide kills bacteria hidden in the biological membranes, so that the adhesive force between the biological membranes and objects is weakened, and stubborn stains in fixed places can be quickly stripped and removed. The cleanser is used for cleansing livestock and poultry farms and equipment and has a sterilization effect, so that the following disinfection operation effect is more remarkable. The cleanser is sprayed by a special foam gun after being diluted in the ratio of (1:50)-(1:200).

Owner:RINGPU TIANJIN BIOLOGICAL PHARMA

Liquid fertilizer containing chitosan and urea

InactiveCN103044148AIncrease growth rateMaintain nutritional balanceFertilizer mixturesDisease damageMass-Volume Percentage

The invention relates to a liquid fertilizer which is urea aqueous solution added with chitosan, wherein the concentration of chitosan is 2-4% by massic volume. The chitosan is water-soluble chitosan such as carboxymethyl chitosan. Bacillus subtilis or Chinese herbal medicine extract liquid prepared from tripterygium wilfordii, calamus and lemongrass is selectively added into the liquid fertilizer provided by the invention. The fertilizer provided by the invention can effectively promote the growth rate of crop and keep the nutrient balance of the crop. The component with an insecticidal effect is added into the fertilizer, thereby effectively reducing the pest and disease damage of the leaf surface when being applied to the leaf surface.

Owner:QINGDAO JINGLING OCEAN TECH

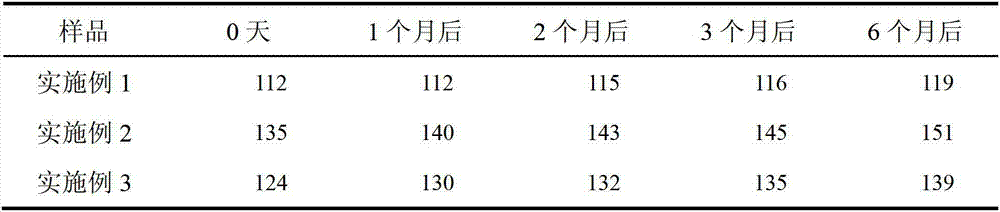

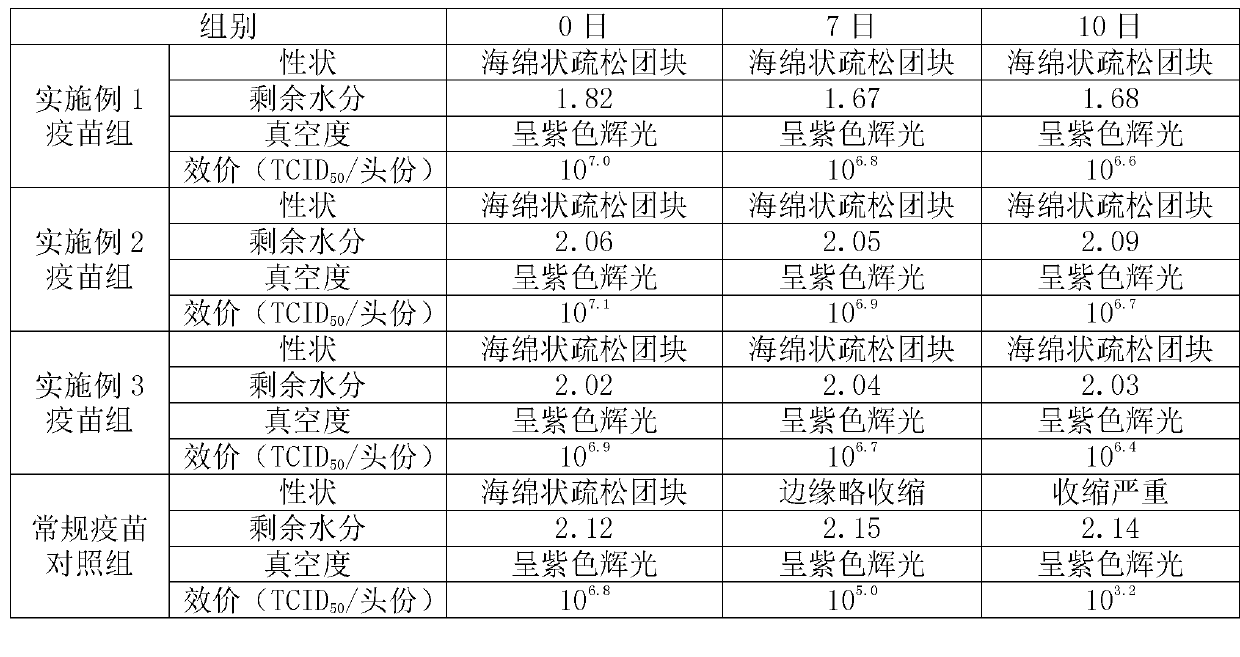

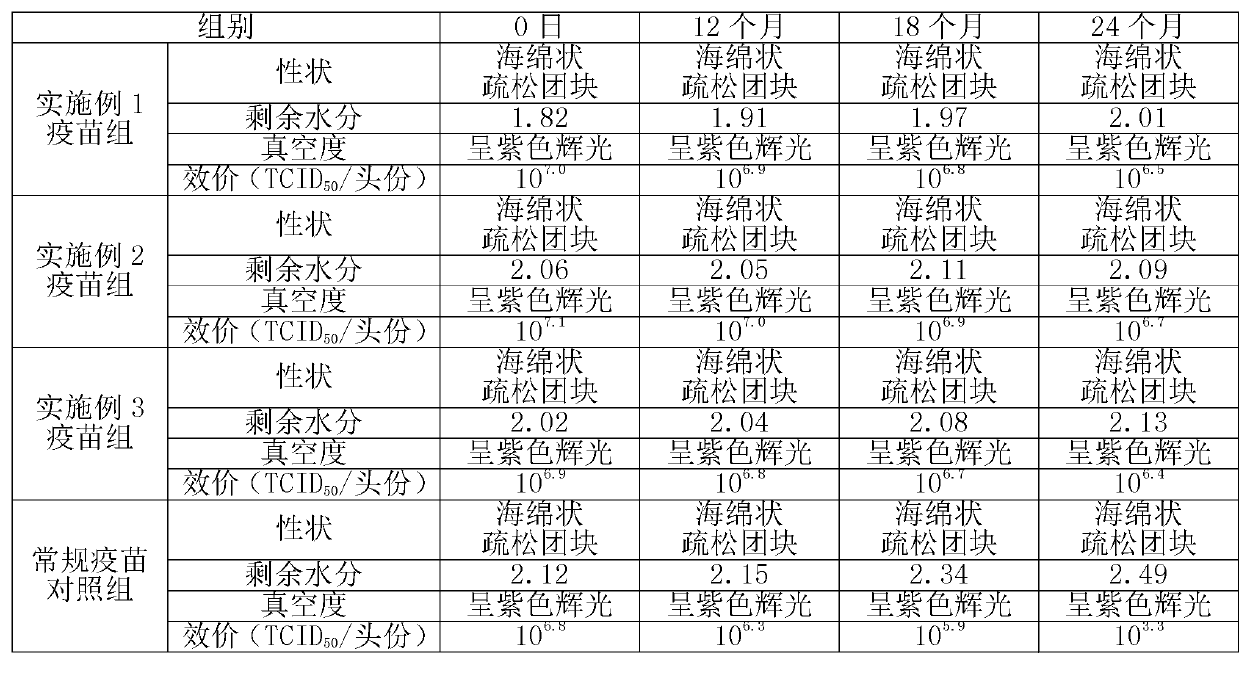

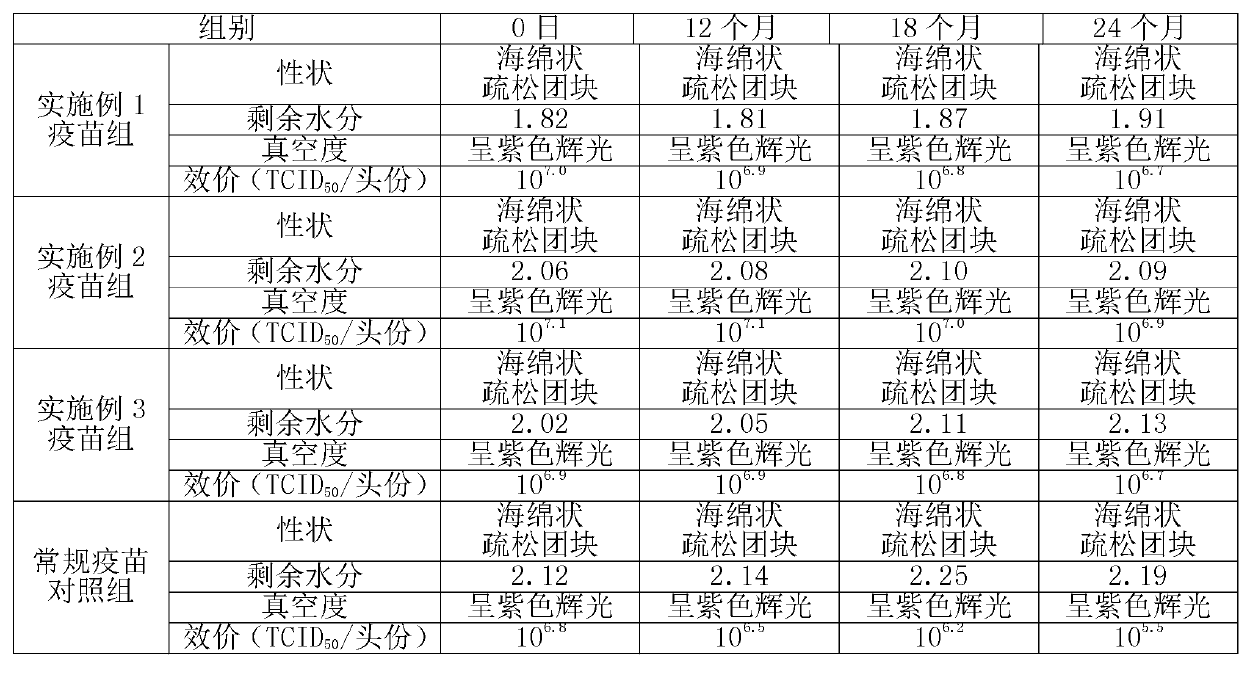

Freeze-drying protective agent for vaccines

The invention relates to a freeze-drying protective agent which is composed of the following components in percentage by mass or volume: 2.4-4% of NZ-amine, 0.3-0.5% of monopotassium salt of glutamic acid, 20-25% of sucrose, 1.5-2.5% of hydrolyzed lactoprotein, 4-6% of hydrolyzed gelatin and the balance of water. The freeze-drying protective agent provided by the invention is low in raw material cost and simple to operate, and can implement large-scale production. After the vaccines are stored at 2-8 DEG C for 24 months, the titers of the vaccines are respectively greater than or equal to 105.7TCID50 / dose (Chinese Standard), thereby effectively prolonging the storage life of the vaccines.

Owner:YEBIO BIOENG OF QINGDAO

Nucleic acid releasing agent and nucleic acid on-site releasing method

InactiveCN109306350ASolve the lossSolve pollutionMicrobiological testing/measurementDNA preparationPotassiumBovine serum albumin

The invention provides a nucleic acid releasing agent, and belongs to the technical field of nucleic acid extraction. The nucleic acid releasing agent is a liquid preparation. In the nucleic acid releasing agent, volume percentage content of a nonionic surfactant is 0.2-2%, mass volume percentage content of trehalose is 0.01-2%, mass volume concentration of protease K is 0.1-5 mg / ml, concentrationof potassium chloride is 50-200 mmol / L, the concentration of guanidinium isothiocyanate is 20-100 mmol / L, the concentration of bovine serum albumin is 0.5-10 mmol / L, the concentration of ethylene diamine tetraacetic acid is 1-10 mmol / L, and the concentration of Tris-HCl is 0.2-5 mmol / L. The nucleic acid releasing agent further comprises the balance of water. The nucleic acid releasing agent is capable of eliminating a recovering step of nucleic acid, and avoiding nucleic acid losing or polluting. The nucleic acid releasing agent can be applied for realizing on-site releasing and detecting ofthe nucleic acid.

Owner:宁波奇天基因科技有限公司

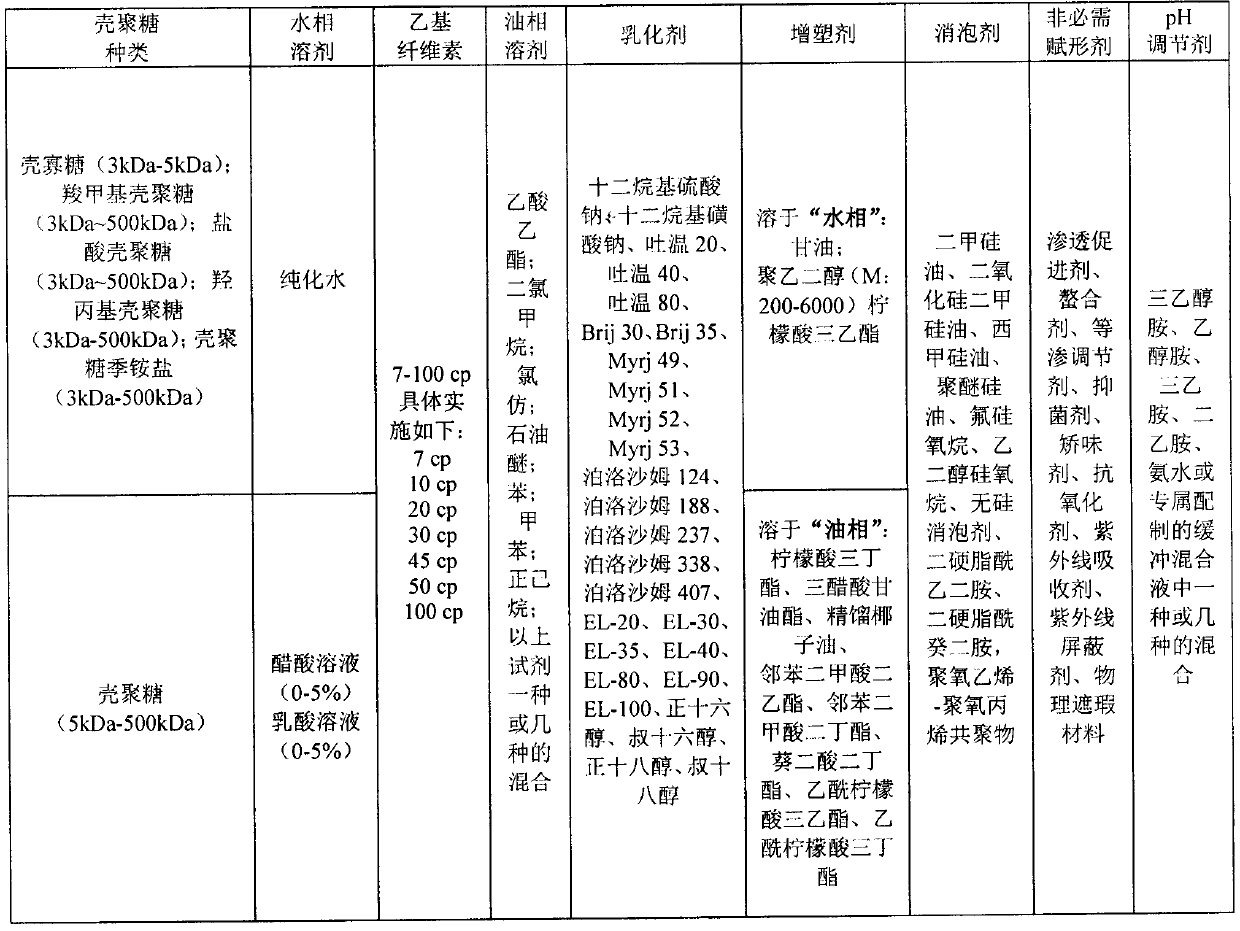

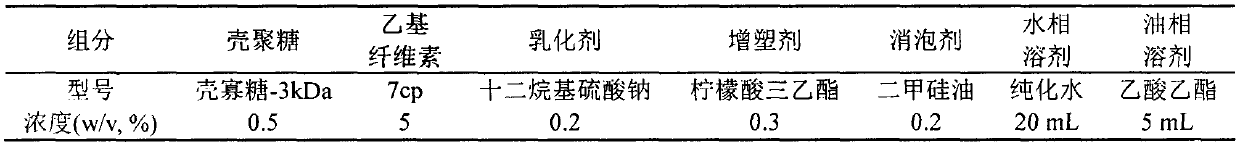

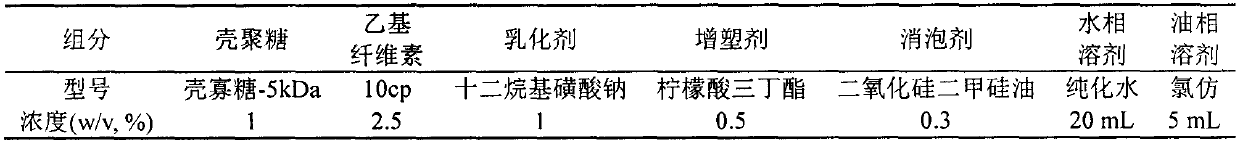

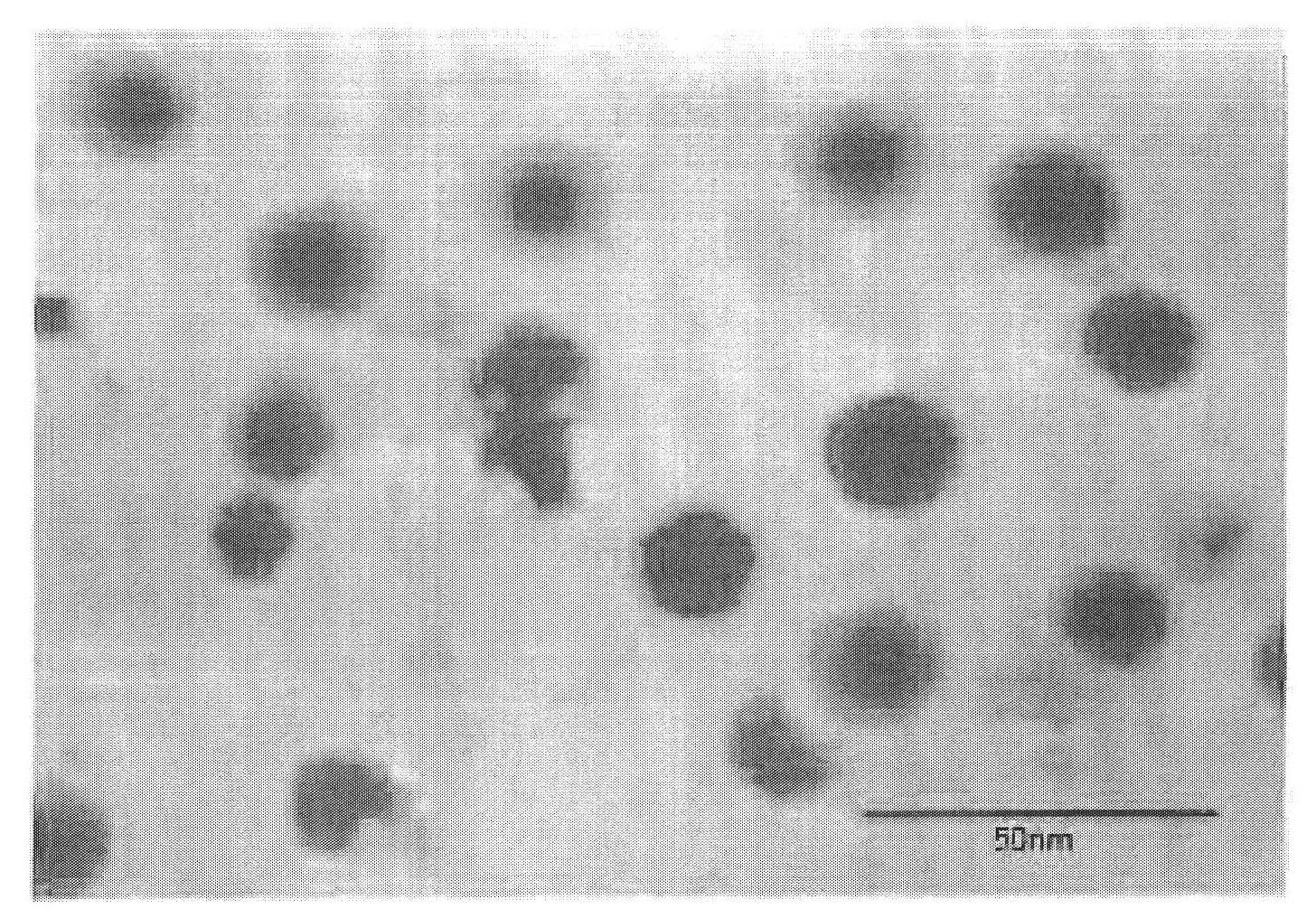

Pharmacologically-active chitosan/ethyl cellulose long-acting spraying agent

InactiveCN107638570ASynergize to play an advantageous rolePromote healingAntibacterial agentsOrganic active ingredientsExcipientAqueous dispersion

The invention belongs to the two technical fields such as medical preparations and medical devices, relates to new uses of a water dispersion technology in external application preparations, and discloses a pharmacologically-active chitosan / ethyl cellulose long-acting spraying agent and a preparation method thereof, wherein the components of the pharmacologically-active chitosan / ethyl cellulose long-acting spraying agent in the final solution comprise, by mass volume percentage, 0-5% of chitosan and derivative thereof, 0-10% of ethyl cellulose, 0.1-10% of an emulsifier, 0.1-10% of a plasticizer, 0.1-2% of a defoamer, 0-5% of an acid, a proper amount of a pH value adjusting agent, 0-10% of other non-essential excipients, and the balance of purified water. According to the present invention,the pharmacologically-active true film can be formed after the pharmacologically-active chitosan / ethyl cellulose long-acting spraying agent is sprayed onto the skin so as to achieve the beneficial effects of long acting, water resistance, friction resistance, wound healing promotion, scar formation reduction and spot concealing.

Owner:CHINA PHARM UNIV

A tea milk and method for preparing same

InactiveCN1883286APure tasteGreat tasteMilk preparationPhenolic content in teaMass-Volume Percentage

The invention discloses a tea milk made from tea polyphenol and pure milk, and the preparing process comprises making aqueous solution of tea polyphenol with a mass volume percentage of 4-6%, mixing the aqueous solution of tea polyphenol with fresh milk by a volumetric ratio of 1:9-10, sterilizing and disinfecting, packaging and sealing.

Owner:INST OF BASIC MEDICINE OF SAMS

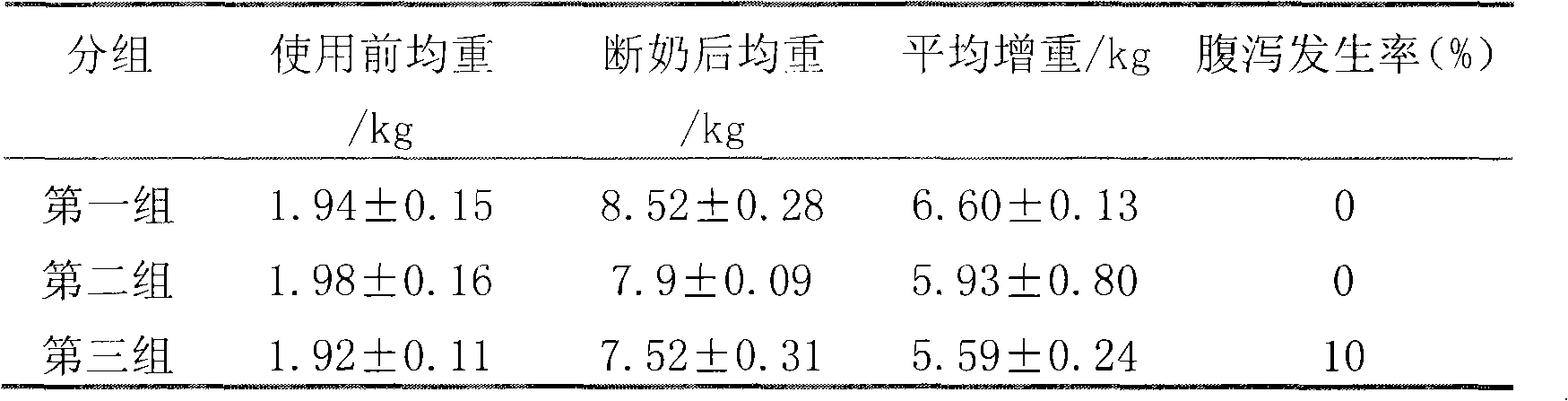

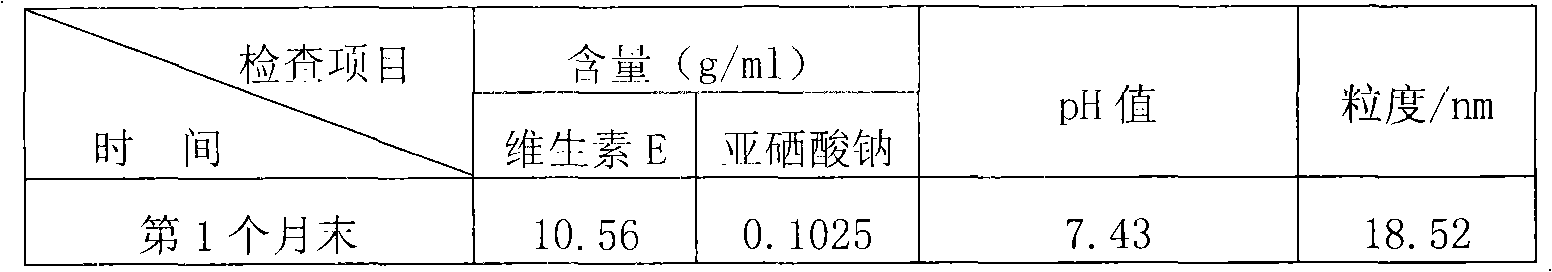

Compound sodium selenite-vitamin E oral nano-emulsion preparation for livestock and preparation method thereof

InactiveCN101982176ASimple production processEasy to operateAntibacterial agentsOrganic active ingredientsSolventRaw material

The invention relates to a compound sodium selenite-vitamin E oral nano-emulsion preparation for livestock and a preparation method thereof. The compound sodium selenite-vitamin E oral nano-emulsion preparation for livestock is prepared from the following raw materials by mass volume percent: 5 to 10% of vitamin E, 15 to 35% of emulsifier, 7.5 to 17.5% of auxiliary emulsifier, 0.1% of sodium selenite, 0.1% of antioxidant and preservative and the balance solvent. The sodium selenite-vitamin E nano-emulsion of the invention is clear and bright emulsion which consists of self-emulsified nano-particles and is a self-emulsified clear and transparent thermodynamically stable system; and the production process is simple and facilitates mass production.

Owner:QILU ANIMAL HEALTH PROD

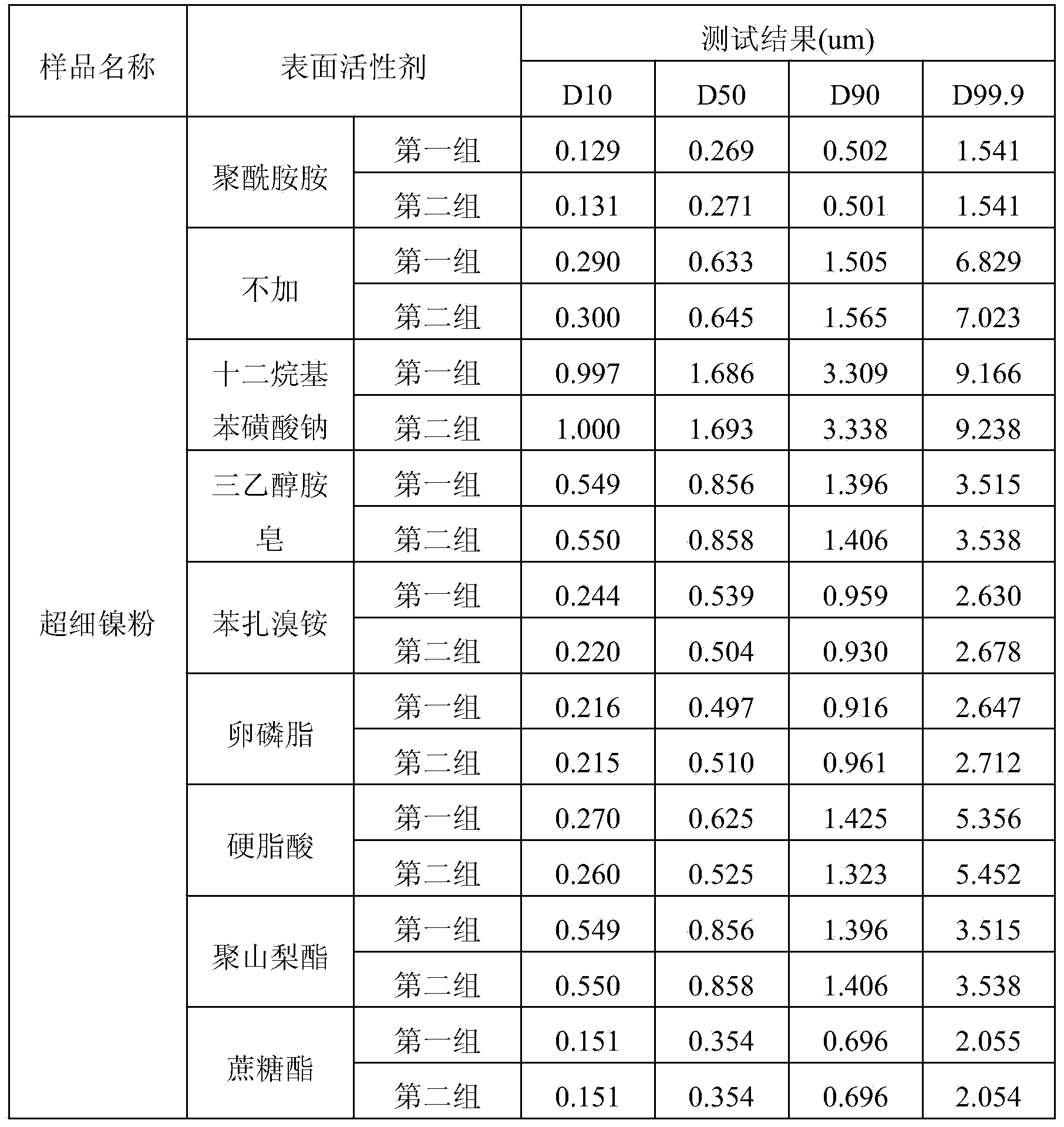

Method for testing particle size distribution of superfine nickel powder

The invention provides a method for testing particle size distribution of superfine nickel powder. The method comprises the operation steps as follows: preparing a polyamidoamine solution with the mass-to-volume percent of 0.5-20% with reverse osmosis water; enabling a laser particle size distribution detector to be located in a stable detection state; preparing a superfine nickel powder solution with the mass-to-volume percent of 0.01-1% with the reverse osmosis water, adding the polyamidoamine solution, wherein the adding amount of the polyamidoamine solution to the amount of reverse osmosis water in the superfine nickel power solution is (0.5-2 ml):150 ml; then dispersing the mixture with an ultrasonic stirrer for 15-20 min; detecting the liquid obtained in the last step by the laser particle size distribution detector to obtain the particle size distribution condition of the superfine nickel power. According to the method, the polyamidoamine is selected as a surfactant, so that the superfine nickel powder is good in hydrophilic property, and the actual particle size distribution condition of the superfine nickel power can be reflected more truly.

Owner:JIANGSU BOQIAN NEW MATERIALS

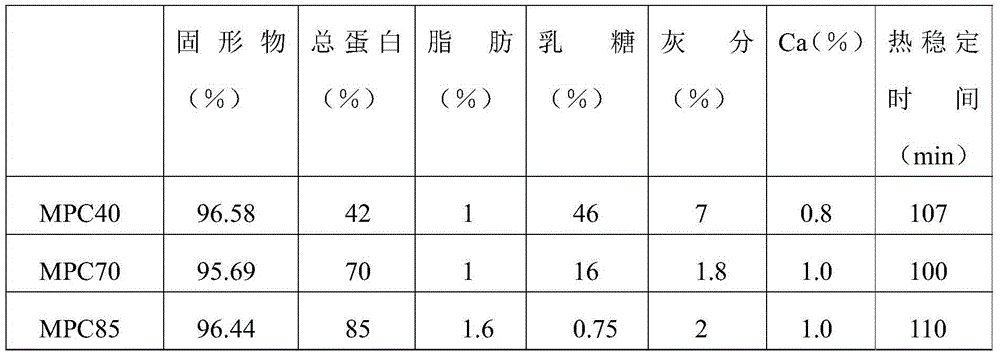

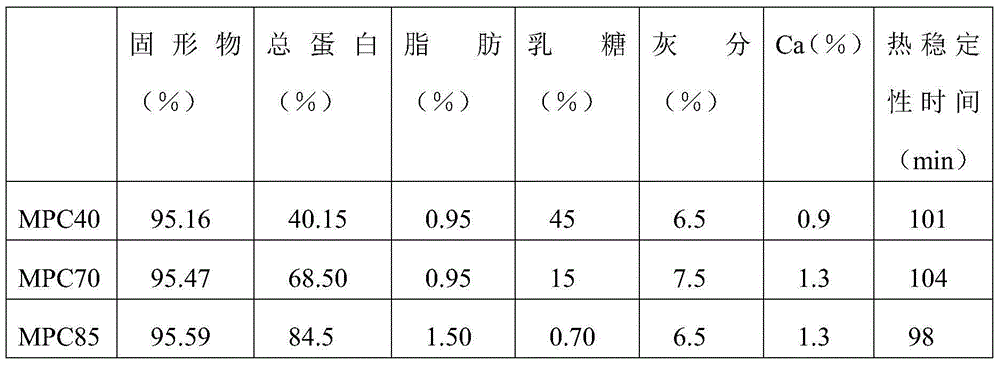

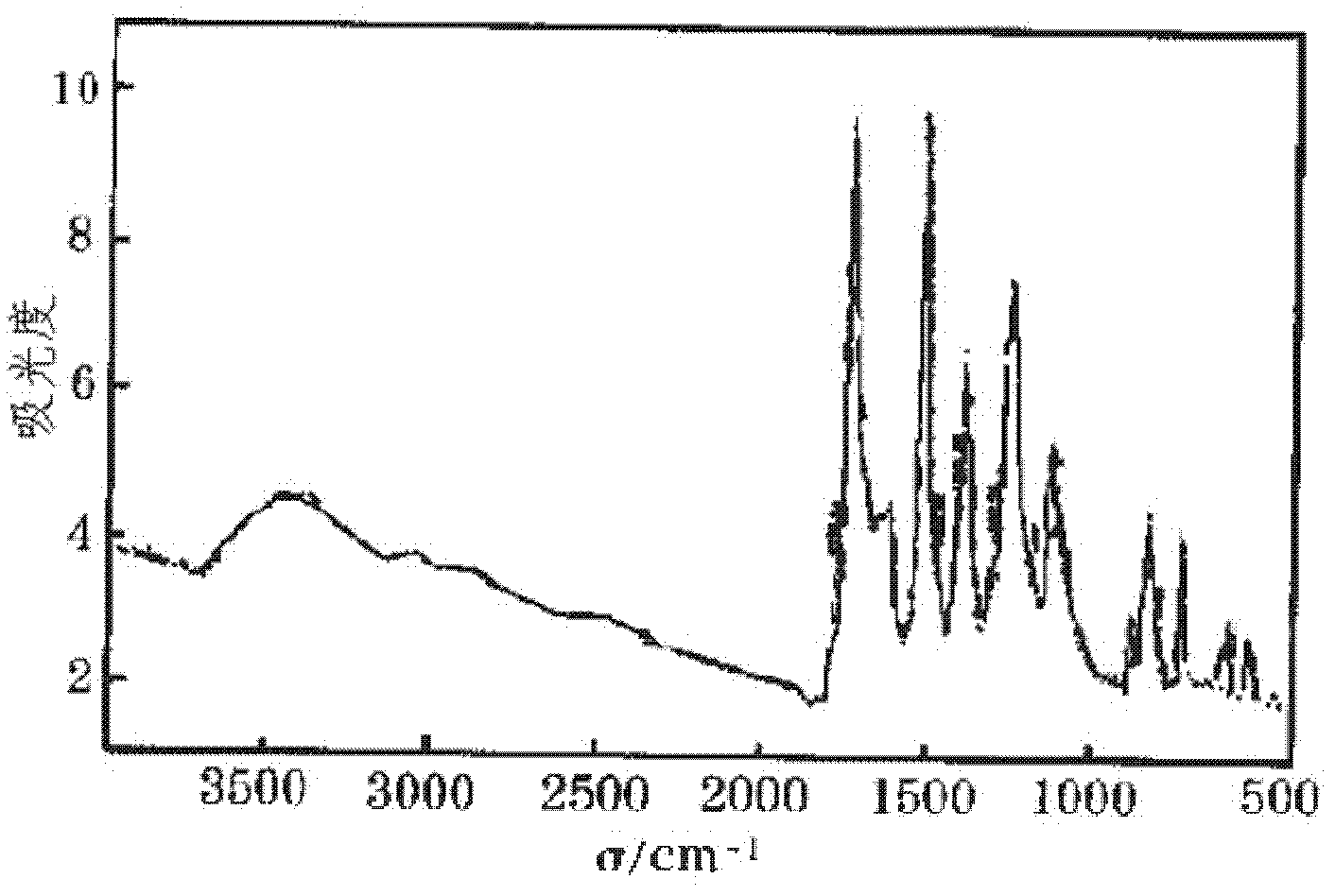

Lactoprotein concentrate with high thermal stability and preparation method thereof

ActiveCN104904989AImprove thermal stabilityImprove powder propertiesProtein composition from milkAnimal proteins working-upMass-Volume PercentageAlbuminous degeneration

The invention discloses a lactoprotein concentrate with high thermal stability and a preparation method thereof The method comprises the following steps of: 1, degreasing raw milk, adding emulsified salt, wherein the mass volume percentage of the emulsified salt is 0.1-0.5%, the emulsified salt is selected from two or three of sodium citrate, sodium pyrophosphate and trisodium phosphate, and the mass ratio of the sodium citrate to the sodium pyrophosphate is 2:3-3:2, the mass ratio of the sodium citrate to the trisodium phosphate is 3:7-7:3, and the mass ratio of the sodium pyrophosphate to the trisodium phosphate is 3:2-4:1, stirring for 5-10min at the speed of 50-100r / m and the temperature of 50-55 DEG C, regulating the pH value to be 5.0-6.5, and sterilizing; evaporating to concentrate or filter washing to concentrate after ultra-filtering at the temperature of 10-40 DEG C, and spray drying. According to the preparation method of the lactoprotein concentrate, the albuminous degeneration is well prevented, and the production efficiency is improved. The prepared lactoprotein concentrate has good thermal stability at high temperatures.

Owner:BRIGHT DAIRY & FOOD CO LTD

Blood serum sample treatment preparation used for protein suspending chip detection

InactiveCN101504410AReduce non-specific adsorptionImproved ability to detect serum samplesMaterial analysisPolyvinyl alcoholPolyvinylpyrrolidone

The invention discloses a serum sample treating preparation used in a method for detecting a liquid phase protein by a suspension chip. The preparation comprises basic buffer solution, polyvinyl alcohol and polyvinylpyrrolidone, wherein the pH value of the basic buffer solution is between 5.5 and 9.0; the mass percentage of the polyvinyl alcohol in volume is between 0.05 and 1.5 percent; and the mass percentage of the polyvinylpyrrolidone in volume is between 0.05 and 2 percent. Because the serum sample treating preparation contains macromolecule surfactants of the polyvinyl alcohol and the polyvinylpyrrolidone, the preparation has the advantages of effectively lowering certain non-specific adsorption of the antibody, lowering background value and improving detection sensitivity.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

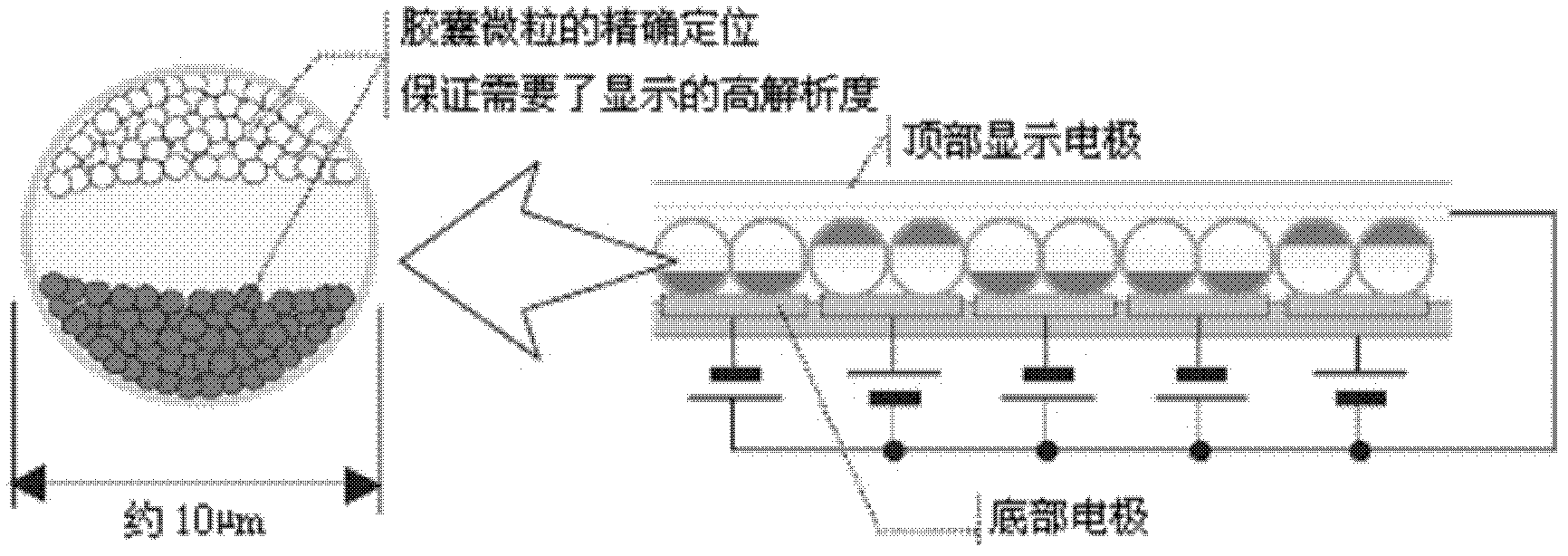

Electronic ink, electronic paper and display method of electronic paper

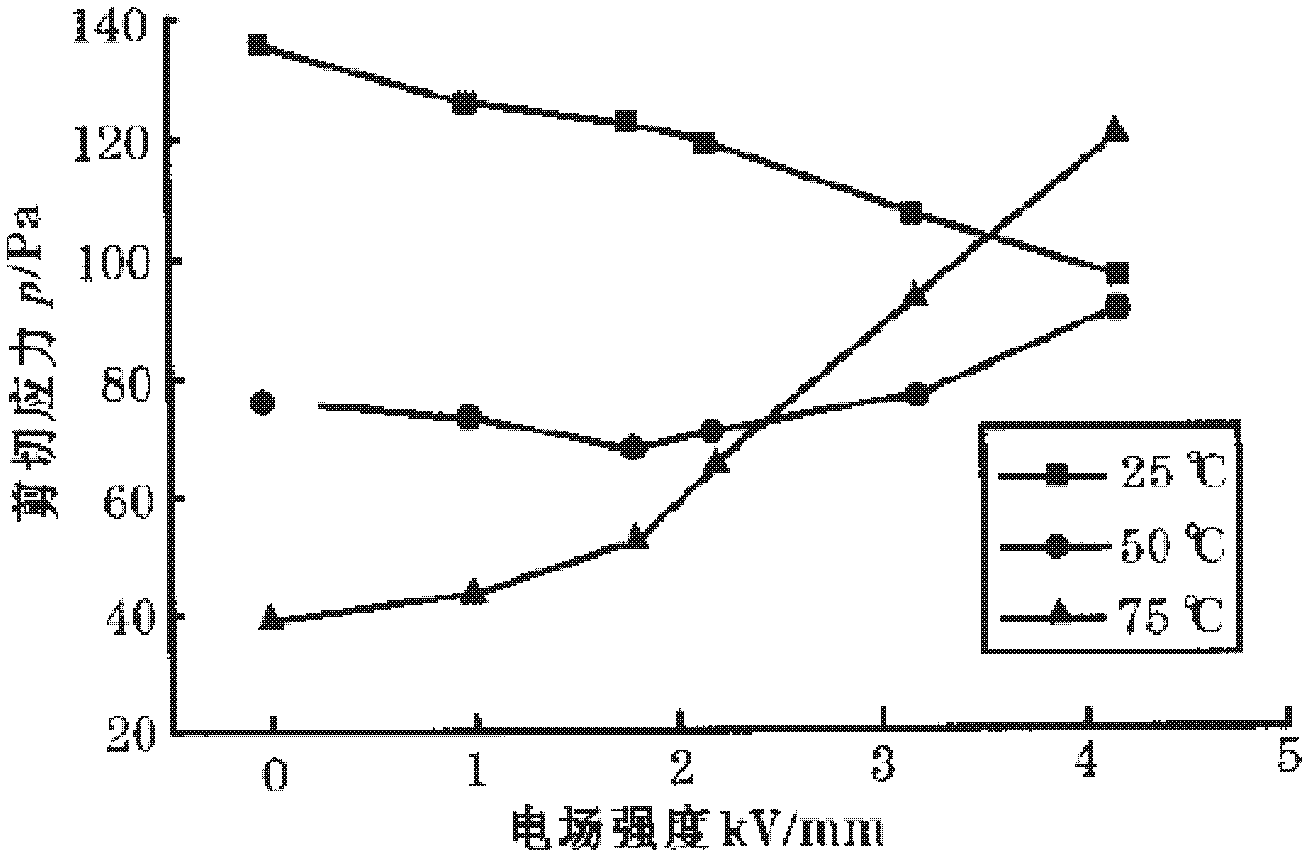

InactiveCN102654709AFast dynamic image switchingStill images hold up wellStatic indicating devicesOrganic dyesElectrical field strengthElectrophoresis

The invention discloses an electronic ink. The electronic ink comprises an electrophoretic disclosing solution, wherein the electrophoretic disclosing solution is electrorheological fluid which essentially consists of basal fluid, solid particles and an additive, wherein the volume percent of the solid particles in the mass of the electrorheological fluid is 5%-50%, and negative electrorheological fluid is preferably selected as the electrophoretic disclosing solution. The invention also discloses electronic paper containing the electronic ink. The invention further discloses a display method of the electronic paper. The viscosity of the electrophoretic disclosing solution is changed by changing the strength of an electric field applied to the electrophoretic disclosing solution, so that the viscosity of the electrophoretic disclosing solution can be reduced when dynamic images are switched and increased when static images are maintained so as to realize faster dynamic image switching and better static image maintaining with the electronic ink.

Owner:BOE TECH GRP CO LTD

Chemical oxidation treatment solution of aluminum and aluminum alloy

InactiveCN103374717AReduce the impactReasonable formulaMetallic material coating processesAluminateSodium molybdate

The invention discloses a chemical oxidation treatment solution of aluminum and aluminum alloy. The solution with pH value between 4.0 and 6.0 is prepared from the following components in mass volume percent: 0.1-2% of sodium molybdate, 0.05-2% of phosphate, 0.01-0.3% of manganese compound, 0.05-0.5% of fluoride, 0.1-2% of aluminate and 0.05-0.5% of citrate. The solution disclosed by the invention is reasonable in formulation, the components are free from heavy metals such as chromium and lead, the influence on the environment is small. The solution can be produced without a special device at normal temperature, and can be used at mild treatment condition and simple process; and the application range is wide.

Owner:TIANCHANG JINGFA ALUMINUM IND

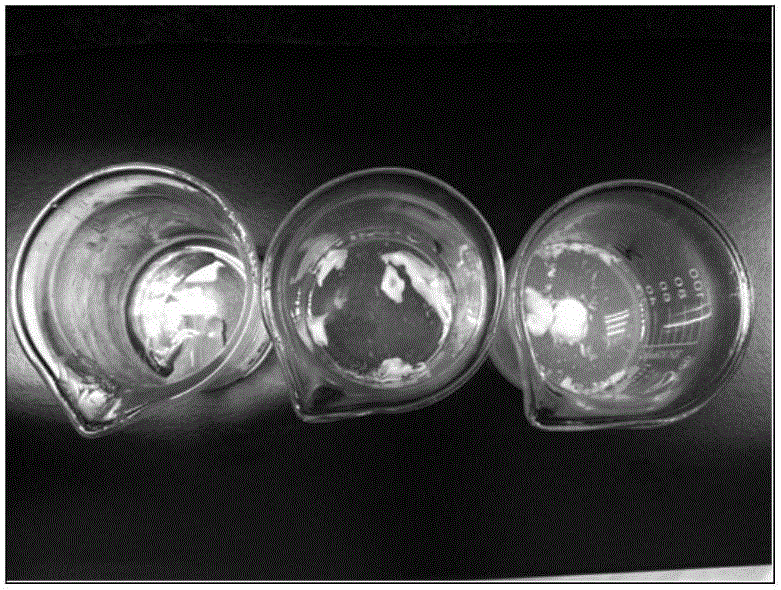

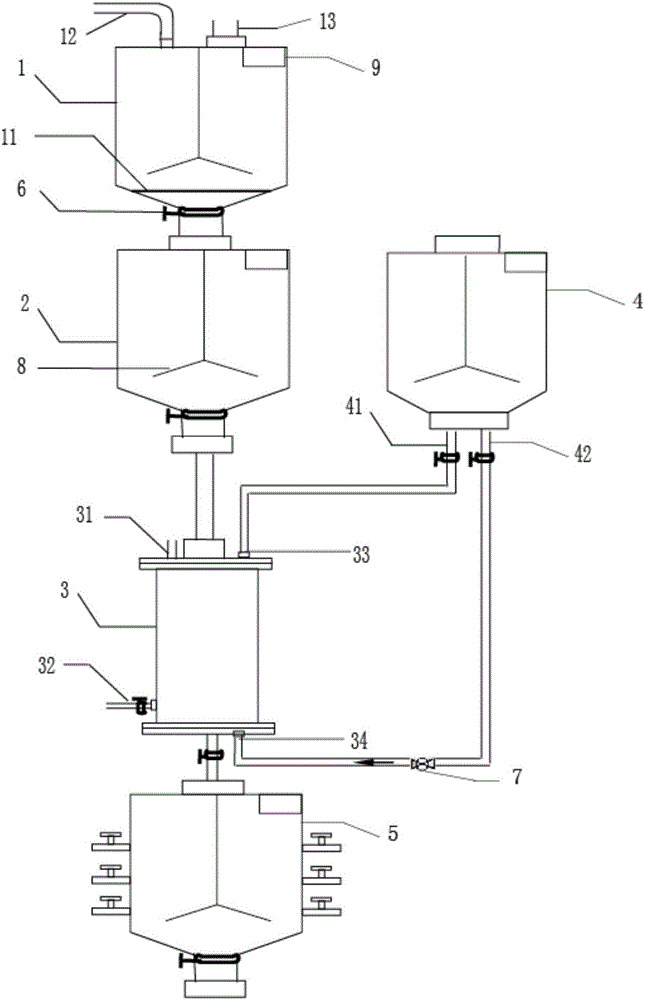

Preparation method of high-titer heparin sodium crude product and production apparatus therefor

The invention belongs to the technical field of biology and particularly relates to a preparation method of a high-titer heparin sodium crude product and a production apparatus therefor. The invention provides a reagent composition for preparing the heparin sodium crude product. The reagent composition includes: a low-salt washing reagent A: a NaCl water solution being 2-5% in mass volume percentage; a medium-salt washing reagent B: a NaCl water solution being 3-6% in mass volume percentage; a high-salt washing reagent C: a NaCl water solution being 4-7% in mass volume percentage; an elution reagent D: a NaCl water solution being 8-20% in mass volume percentage; and a precipitation reagent E: a heparin sodium ethanol water solution in 20-40 degrees. In the invention, gradient washing is carried out with the washing reagents in different salinity. The heparin sodium crude product prepared through the method of low-salinity elution and low-ethanol-degree precipitation is low in impurity content and has complete heparin sodium molecular structure. The bioactivity of the heparin sodium crude product is approximate to or reaches injection grade of heparin sodium.

Owner:重庆伊诺生化制品有限公司

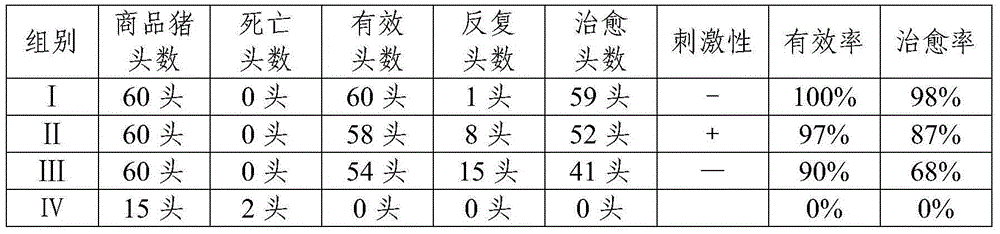

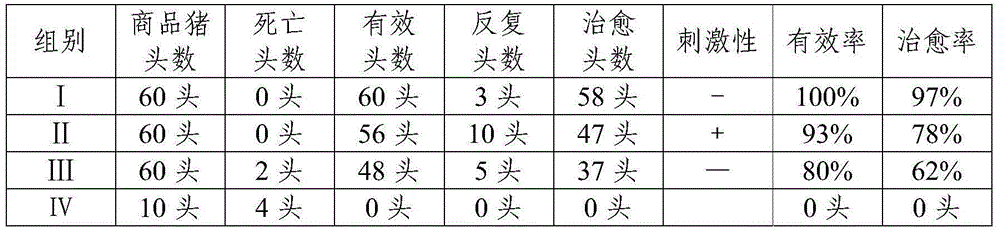

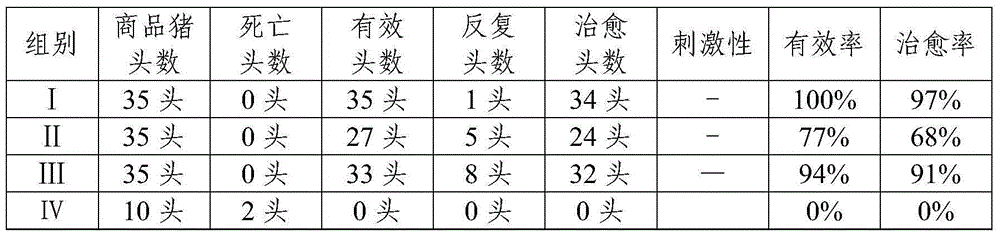

Painless doxycycline injection and preparation method thereof

InactiveCN105125484AImprove bioavailabilityReduced bioavailabilityAntibacterial agentsTetracycline active ingredientsSide effectHalf-life

The invention relates to the fields of a common veterinary tetracycline antibiotic for domestic animal and a preparation of the antibiotic, and specifically provides a painless doxycycline injection and a preparation method thereof; the painless doxycycline injection consists of the following components in mass-volume percentage: 2.5-30.0% of doxycycline, 0.1-5.0% of a painless agent, 0.5-10.0% of a complexing agent, 0.01-5.00% of an antioxidant, proper amount of a pH value regulating agent, 25-95% of an organic solvent and the balance of injection water. The painless doxycycline injection disclosed by the invention can be used for overcoming the shortcomings of intramuscular injection which causes pain in injected parts and results in swelling due to relatively high irritation to local tissues; meanwhile, the doxycycline injection, after being injected to bodies, can reduce the toxic and side effects of drugs, prolong half-life in vivo of the drugs and improve the bioavailability of the drugs; and in addition, the doxycycline injection, by relieving pain in the injected parts and reducing a stress reaction of injection administration, can facilitate operation during using.

Owner:HUNAN TAIGU BIOLOGICAL VETERINARY DRUG CO LTD

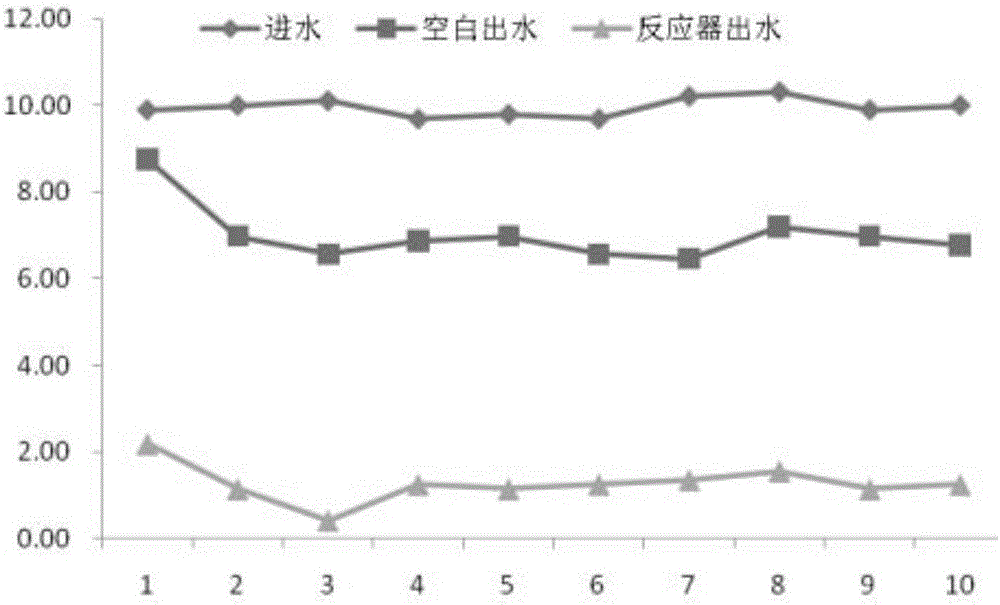

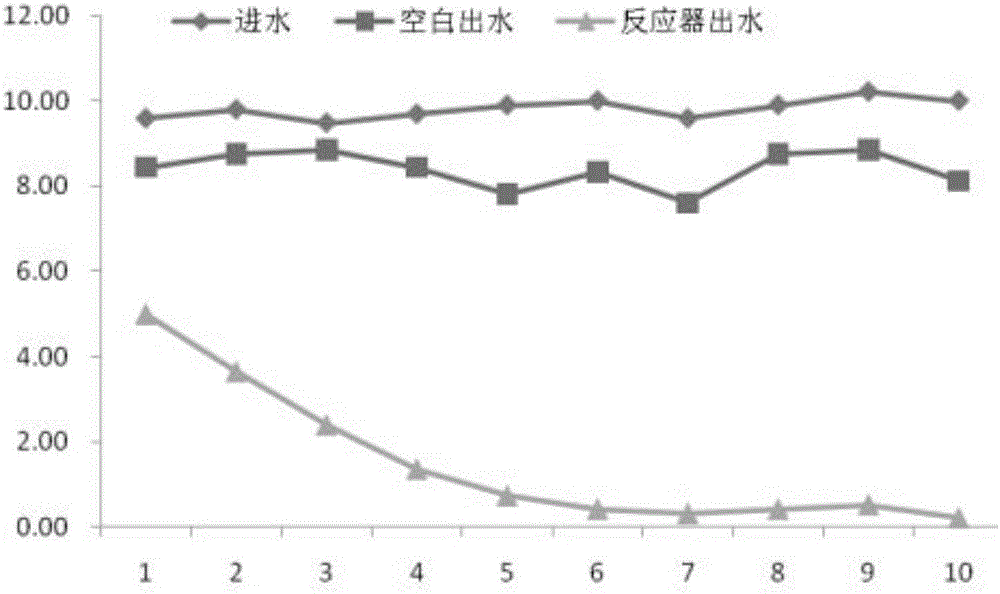

Low-concentration ferric ion underground water nitrate nitrogen eliminating immobilization carrier and preparation method thereof

ActiveCN107523560AImprove the status quo of agingLow investment costWater contaminantsOn/in organic carrierNitrogen removalMass-Volume Percentage

The invention discloses a preparation method of a low-concentration ferric ion underground water nitrate nitrogen eliminating immobilization carrier. The preparation method comprises the following steps of, firstly, adding enrichment mediums into underground water for thermostatic anaerobic cultivation and collecting sediments; secondly, adding culturing solution in the sediments for thermostatic cultivation, and collecting fungi sediments; thirdly, mixing sodium alginate of a mass-volume percentage of 2%-3% with the fungi sediments at a volume ratio of 1:1, and then adding the mixture into calcium chloride solution of a mass-volume percentage of 2%-3% to form the low-concentration ferric ion underground water nitrate nitrogen eliminating immobilization carrier. The invention also discloses the low-concentration ferric ion underground water nitrate nitrogen eliminating immobilization carrier prepared through the preparation method. Based on the low-concentration ferric ion underground water nitrate nitrogen eliminating immobilization carrier, the invention also discloses a low-concentration ferric ion underground water nitrate nitrogen eliminating method. Further, the invention also discloses a reactor for achieving low-concentration ferric ion underground water nitrate nitrogen elimination. The low-concentration ferric ion underground water nitrate nitrogen eliminating immobilization carrier can achieve efficient biological nitrogen removal under the condition of low density of ferric ions in underground water through self-circulation of ferric ions.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

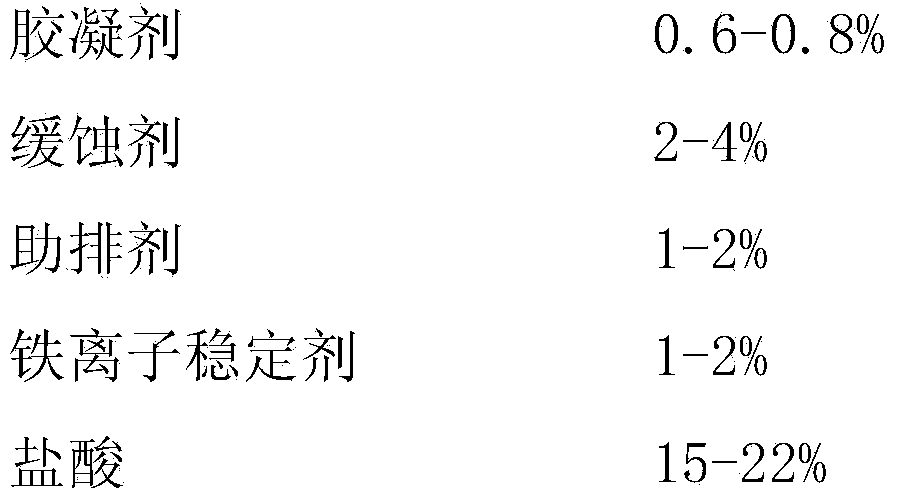

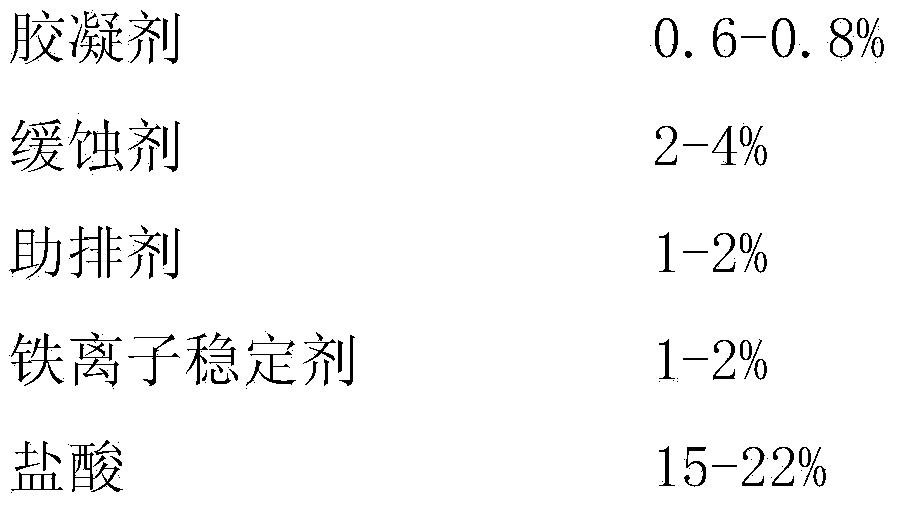

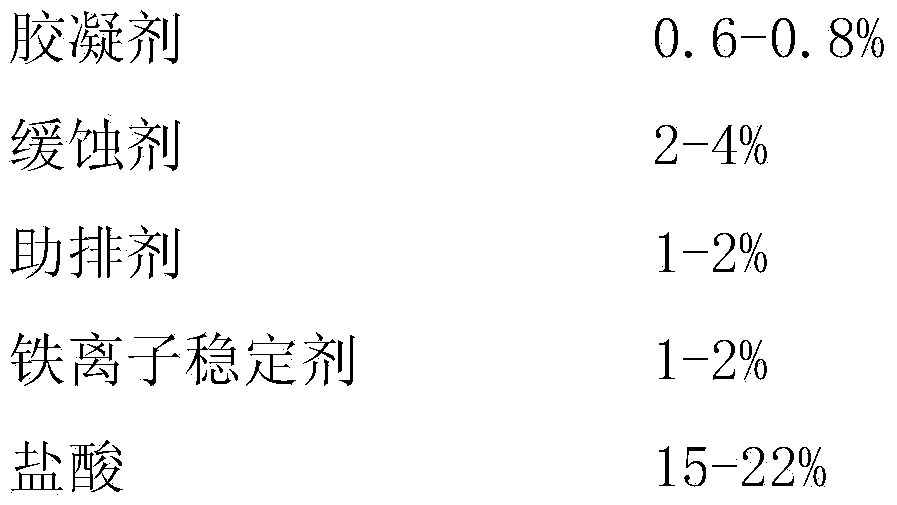

Gelled-acid acid liquor applicable to high-temperature carbonatite acidification

InactiveCN103923633AEasy to prepareGood resistance reduction effectDrilling compositionFiltrationMass-Volume Percentage

The invention discloses gelled-acid acid liquor applicable to high-temperature carbonatite acidification. The gelled-acid acid liquor comprises 0.6%-0.8% by mass volume of gelling agent, 2%-4% by volume of corrosion inhibitor, 1%-2% by volume of discharge aiding agent, 1%-2% by volume of iron ion stabilizer, 15%-22% by volume of hydrochloric acid and the balance of water. The gelled-acid acid liquor disclosed by the invention can be applied to high-temperature carbonatite acidification construction, is high temperature-resistant and salt-resistant, has good retardance, de-filtration, perforating and resistance reducing performances, and can effectively relieve secondary damage to achieve a deep acidification process. The gelled-acid acid liquor system is stable in performance, simple to prepare, convenient to construct and capable of being effectively applied to high-temperature carbonatite acidification modification construction.

Owner:CNPC BOHAI DRILLING ENG

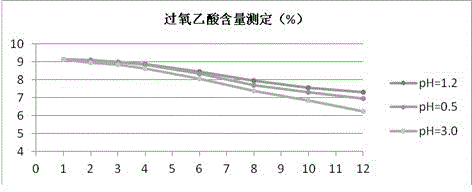

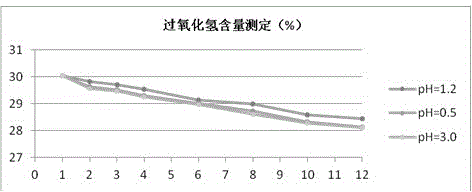

Stable low-corrosiveness sporicide and its preparation method

InactiveCN104304315AAvoid decompositionComponent mass fraction is easy to controlBiocideFungicidesOxygenImpurity

The invention discloses a stable low-corrosiveness sporicide and its preparation method. The sporicide comprises, by mass / volume (g / 100 ml), 4-15% of peroxyacetic acid, 20-40% of hydrogen peroxide, 1-3% of acetic acid, 1-3% of isooctanoic acid, 0.1-2% of a compound stabilizer, 0.05-1% of a corrosion inhibitor, an inorganic acid used to adjust the pH value to 1.1-1..3, and the balance of water without metal ion impurities. The sporicide is diluted 100 times when the sporicide is used. The main effective components of the sporicide are peroxyacetic acid and hydrogen peroxide, and the adjustment of the formula of the stabilizer and the corrosion inhibitor and the optimization of the pH value make the sporicide quickly kill bacteria and fungal spores and have a good killing effect on vegetative forms of common bacteria and fungi, and ensure good stability and low corrosiveness. The sporicide has the characteristics of good stability, low corrosiveness, wide antibacterial spectrum and simple production technology.

Owner:魏巍 +1

Process for producing 2-keto-D-gluconic acid by high-concentration fermentation

ActiveCN102747113AImprove qualityLess impuritiesMicroorganism based processesFermentationOptimal growthSolvent

The invention discloses a process for producing 2-keto-D-gluconic acid by high-concentration fermentation. A microorganism for converting glucose into the 2-keto-D-gluconic acid or salt of the 2-keto-D-gluconic acid is cultured in a fermentation container, as a carbon source in a fermentation culture medium, the glucose is subjected to fermentation culture, and the pH (Potential Of Hydrogen) value before sterilization is 5.5-7.0; and the fermentation culture medium consists of the following substances by massvolume: 10-32% of glucose, 0.1-1% of maize pulp, 1-5% of calcium hydroxide, 0.02-0.08% of de-foaming agent and a solvent as water. The pH value is adjusted by calcium hydroxide in the beginning of fermentation so that the cost is lower, the pH value of a fermentation solution is more accurately adjusted and controlled by liquid ammonia or ammonia water in the mid- to late-period of fermentation so that the fermentation solution is kept in the environment for optimal growth and acid production of the microorganism, and a nitrogen source is supplied at the same time, so that the acid production rate and the acid production concentration of bacteria are increased, the fermentation conversion rate and the yield are increased, the fermentation cycle is shortened, the quality of the fermentation liquid is high, the amount of the impurity is small, the extracting and purifying processes are convenient, and the emission of calcium sulfate waste residues is reduced at the same time; and the formed byproduct is ammonium sulfate which can be used as a fertilizer.

Owner:郑州拓洋生物工程有限公司

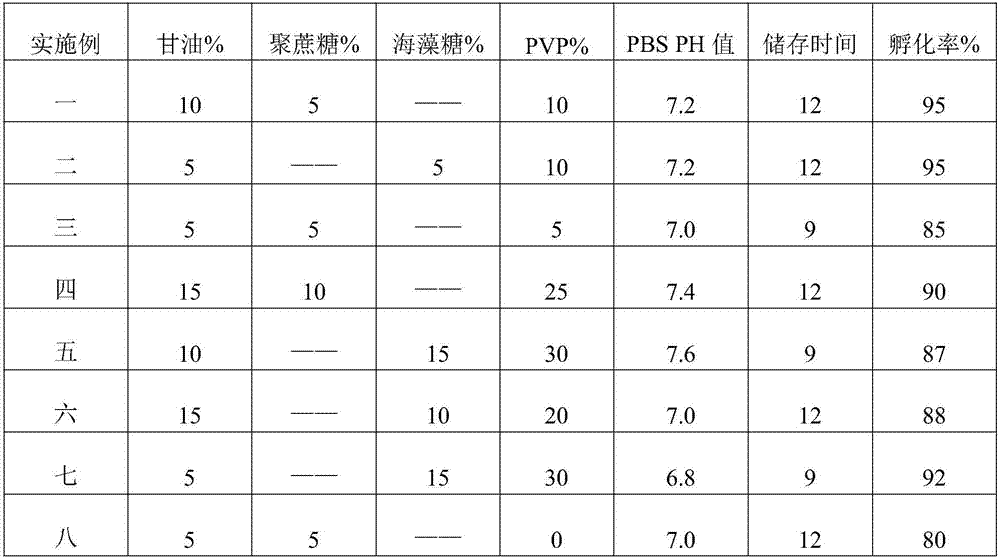

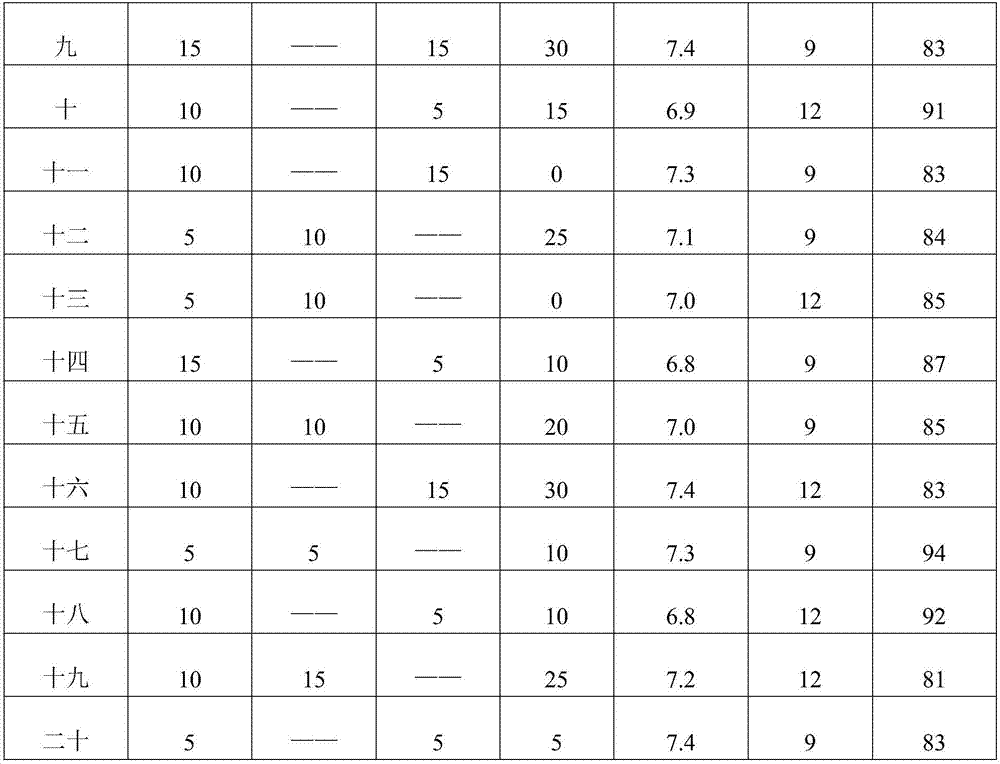

Protective solution for earthworm egg cocoon storage

The invention relates to the technical field of earthworm egg cocoon storage, in particular to a protective solution for earthworm egg cocoon storage. The protective solution is prepared through the following steps: A, a phosphate buffer with PH being 6.8-7.6 is prepared; B, 5%-15% of glycerin, 5%-15% of polysucrose and 0-30% of PVP (polyvinylpyrrolidone) are added to the phosphate buffer in the step A, the phosphate buffer is taken as a standard for the adding amounts of the three components, glycerin is added by volume, and polysucrose and PVP are added by massic volume. Therefore, earthworm egg cocoons are soaked in the protective solution which is prepared from the phosphate buffer by adding glycerin, polysucrose and PVP in specific concentration to the phosphate buffer and uniformly mixing the components, or the protective solution is sprayed to the surfaces of the earthworm egg cocoons, and the earthworm egg cocoons can be dehydrated slowly and stored in a low-temperature environment for a long time. When placed in an environment with proper conditions, the earthworm egg cocoons can hatch rapidly and the hatching rate is high. The protective solution is applicable to fields of earthworm egg cocoon storage and transportation, bio-fertilizer, soil improvement and the like.

Owner:YANTAI YULONG BIOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com