Preparation method of porous structural ceramic material

A ceramic material and porous structure technology, which is applied in medical science, tissue regeneration, prosthesis, etc., can solve the problems of poor pore connectivity and complicated process of porous scaffolds, and achieve the effect of less impurities, simple process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

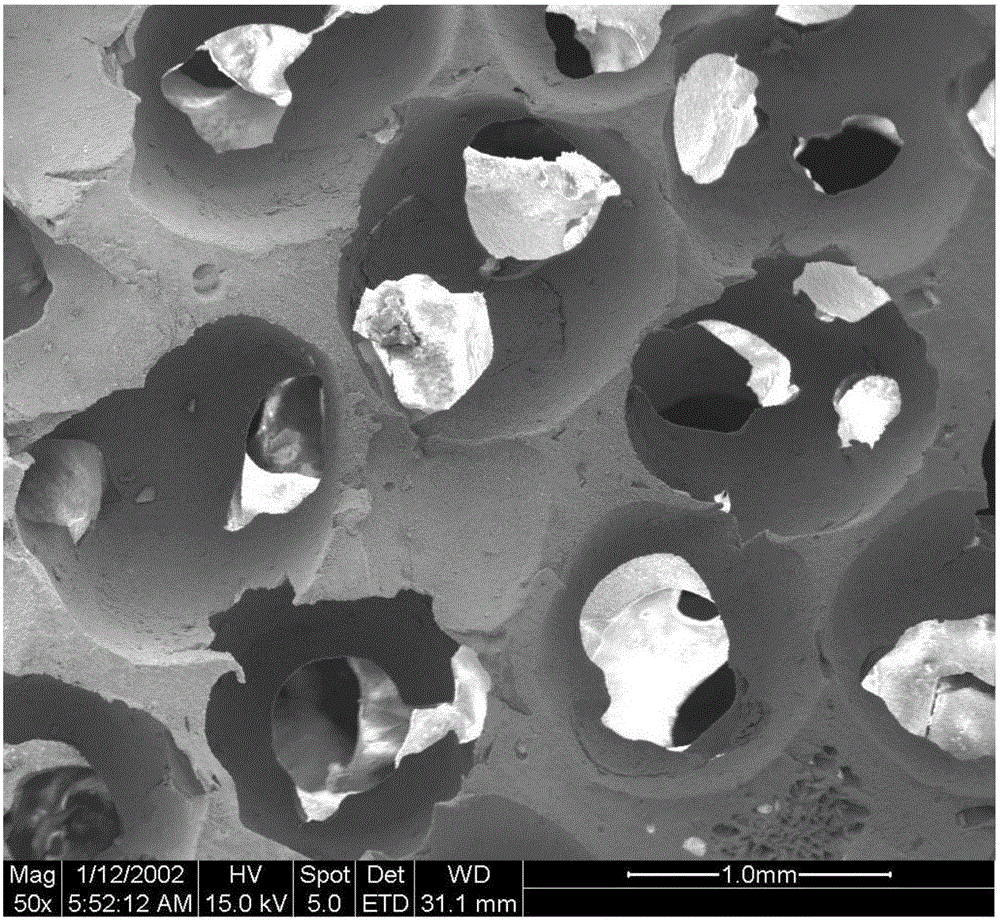

Image

Examples

Embodiment 1

[0016] Step 1. Preparation of ceramic slurry: Take 5g of anhydrous lithium chloride and add it to 100mL dimethylacetamide. After the dissolution is complete, add 0.7g of chitin to form a sol after dissolution, and then add 10g of hydroxyapatite powder to make it evenly mixed , kept heating and stirring during this process, to obtain a ceramic slurry with a mass volume ratio of 10%.

[0017] Step 2: Take 200ml of deionized water and heat it to 65°C, add 2g of sodium alginate, and after it dissolves, form droplets through the needle of a 5ml syringe at room temperature and freely drop them into a calcium chloride solution with a mass-volume ratio of 1% to cross-link to form a spherical shape Sodium alginate gel particles, filter out the gel particles, add deionized water to wash to remove residual calcium chloride.

[0018] Step 3. Soak the spherical sodium alginate gel particles obtained in Step 2 in pure ethanol for ten minutes, then filter out, and repeat the ethanol soaking ...

Embodiment 2

[0022] Step 1. Preparation of ceramic slurry: Take 5g of anhydrous lithium chloride and add it to 100mL dimethylacetamide. After the dissolution is complete, add 0.7g of chitin to form a sol after dissolution, and then add 20g of hydroxyapatite powder to make it evenly mixed , keep heating and stirring during this process, and obtain a ceramic slurry with a mass volume ratio of 20%.

[0023] Step 2: Take 200ml of deionized water and heat it to 65°C, add 2g of sodium alginate, and after dissolving, form a droplet at room temperature through the needle of a 20ml syringe and freely drop it into a calcium chloride solution with a mass-volume ratio of 1% to form spherical alginate Sodium gel particles, filter out the gel particles, add deionized water to wash and remove residual calcium chloride.

[0024] Step 3: Soak the spherical sodium alginate gel particles in pure ethanol for ten minutes, filter out, and repeat the ethanol soaking step three times to obtain solidified sodium a...

Embodiment 3

[0028] Step 1. Preparation of ceramic slurry: Take 100ml of deionized water and heat it to 65°C, add 4g of gelatin, add 2g of carboxymethyl chitosan after dissolving, add 1.2g of sodium citrate after five minutes, and then add 35g of biphasic phosphoric acid Calcium (hydroxyapatite / tricalcium phosphate) powder was mixed uniformly, and heating and stirring were kept during the process to obtain a ceramic slurry with a mass volume ratio of 35%.

[0029] Step 2: Take 200ml of deionized water and heat it to 65°C, add 3g of sodium alginate, after it dissolves, form a droplet at room temperature through the needle of a 20ml syringe and freely drop it into a calcium chloride solution with a mass-volume ratio of 1% to form spherical alginate Sodium gel particles, filter out the gel particles, add deionized water to wash and remove residual calcium chloride.

[0030] Step 3: Soak the spherical sodium alginate gel particles in pure ethanol for ten minutes, then filter out, and repeat th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com