Stable low-corrosiveness sporicide and its preparation method

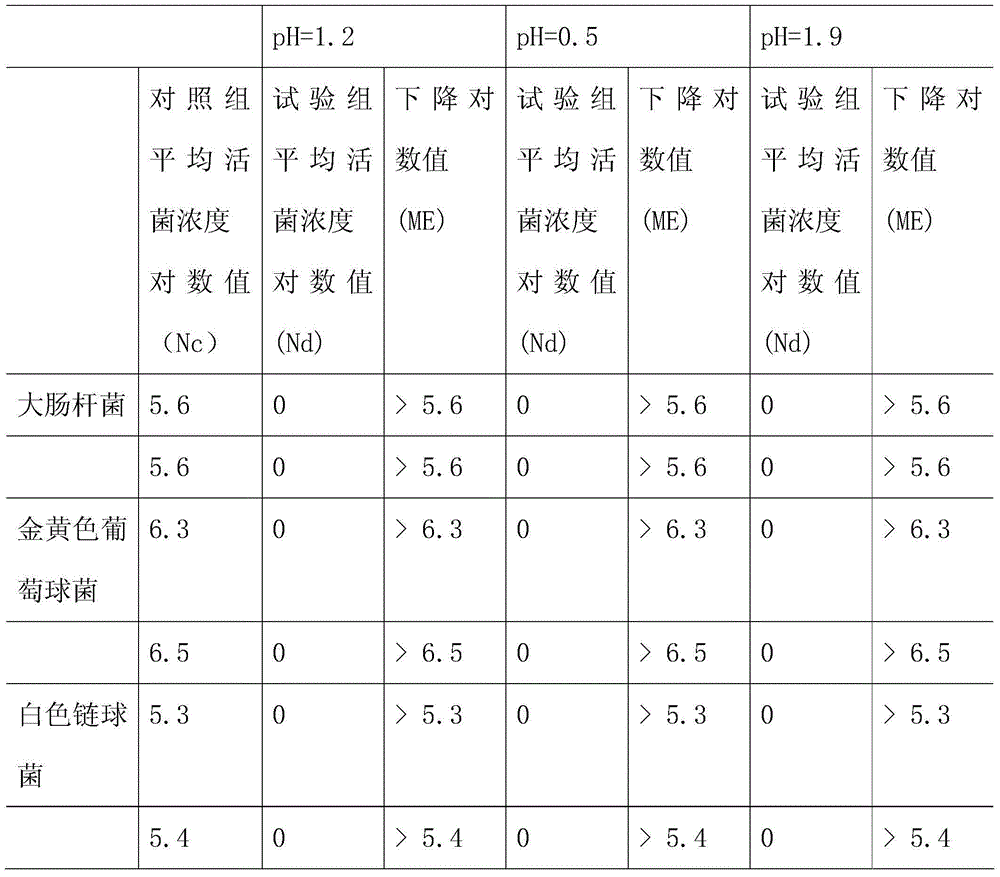

A sporicide and corrosive technology, applied in the field of low corrosive sporicide and its preparation, can solve problems such as toxicity, secondary pollution, residue, etc., and achieve the effects of reducing toxicity, inhibiting decomposition and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0039]1. Weigh 13.3 g of ethylenediamine tetramethylene phosphonic acid and 6.7 g of sodium pyrophosphate and mix them uniformly to prepare a compound stabilizer.

[0040] 2. Pass the preparation water through a cation exchange resin to remove metal ion impurities in the water, and set aside.

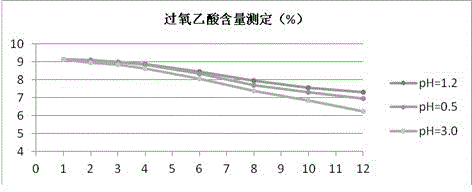

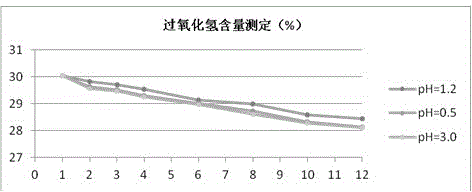

[0041] 3. Prepare according to the following steps: 1) Put 0.5L of hot water at 70-80°C into the liquid mixing tank, add 400g of isooctanoic acid, stir to dissolve, and mix evenly; 2) Put 20g of compound stabilizer into the liquid mixing tank, stir Dissolve and mix evenly; 3) When the temperature of the mixed solution drops to 25°C, put 200g of hydrolyzed polymaleic anhydride into the liquid mixing tank, stir to dissolve, and mix evenly; 4) Put 400g of acetic acid, 50% over 8 kg of hydrogen oxide and 11.5 kg of 26% peracetic acid were stirred and mixed evenly; 5) the pH value was adjusted to 1.3 with hydrochloric acid, and water was added to 20 L, and stirring was continued for 30 minut...

preparation Embodiment 2

[0044] 1. Weigh 266.6 g of hexamethylene diamine tetramethylene phosphonic acid and 133.4 g of potassium pyrophosphate and mix them uniformly to prepare a compound stabilizer.

[0045] 2. Pass the preparation water through a cation exchange resin to remove metal ion impurities in the water, and set aside.

[0046] 3. Prepare according to the following steps: 1) Put 0.5L of hot water at 70-80°C into the liquid mixing tank, add 400g of isooctanoic acid, stir to dissolve, and mix well; 2) Put 400g of compound stabilizer into the liquid mixing tank, stir Dissolve and mix evenly; 3) When the temperature of the mixed solution drops to 25°C, put 10g of maleic acid-polyacrylic acid copolymer into the liquid mixing tank, stir to dissolve, and mix evenly; 4) Put 400g of acetic acid, 50% hydrogen peroxide 16kg, 26% peracetic acid 3kg, stir and mix evenly; 5) adjust the pH value to 1.1 with phosphoric acid, add water to 20L, continue stirring for 30 minutes to obtain the finished sporicid...

preparation Embodiment 3

[0049] 1. Weigh 80g of ethylenediaminetetramethylenephosphonic acid, 80g of 2-hydroxyphosphonoacetic acid and 80g of sodium acid pyrophosphate and mix them uniformly to prepare a compound stabilizer.

[0050] 2. Pass the preparation water through a cation exchange resin to remove metal ion impurities in the water, and set aside.

[0051] 3. Prepare according to the following steps: 1) Put 0.5L of hot water at 70-80°C into the liquid mixing tank, add 400g of isooctanoic acid, stir to dissolve, and mix well; 2) Put 240g of compound stabilizer into the liquid mixing tank, stir Dissolve and mix evenly; 3) When the temperature of the mixed solution drops to 25°C, put 100g of maleic acid-polyacrylic acid copolymer into the liquid mixing tank, stir to dissolve, and mix evenly; 4) Put 400g of acetic acid, 50% hydrogen peroxide 12kg, 26% peracetic acid 7kg, stir and mix evenly; 5) adjust the pH value to 1.2 with sulfuric acid, add water to 20L, continue stirring for 30 minutes to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com