Method for testing particle size distribution of superfine nickel powder

A technology of particle size distribution and nickel powder, which is applied in the field of testing the particle size distribution of ultrafine nickel powder, can solve the problems of poor hydrophilicity, environmental pollution, high cost, etc., and achieve the effects of low price, guaranteed accuracy, and easy purchase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

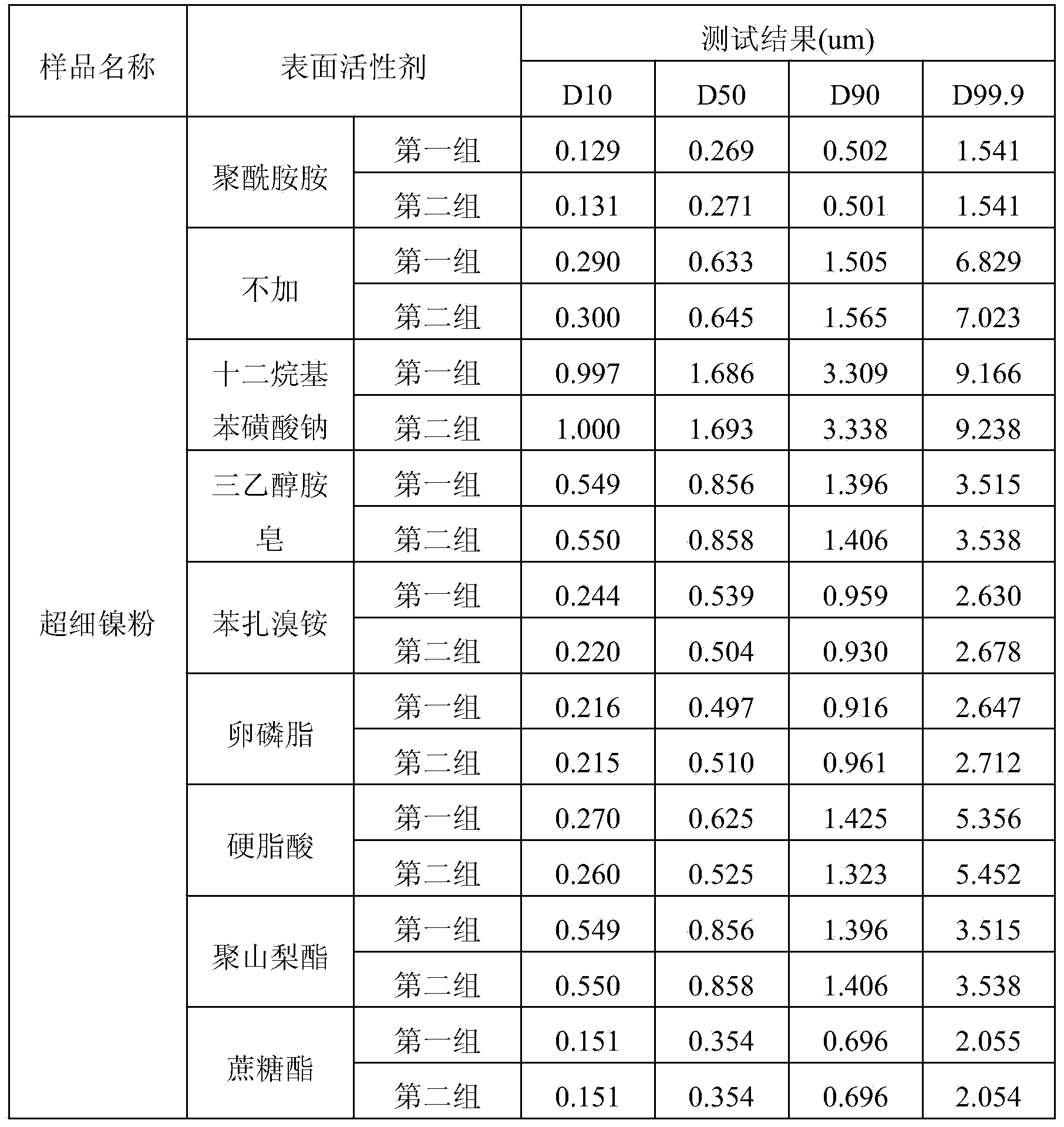

[0019] An ultra-fine nickel powder prepared by PVD method. The specific surface area of the nickel powder is 3.38㎡ / g detected by the specific surface area measuring instrument. The average particle size is 200nm through theoretical calculation. The sample is sent to the authoritative testing institution-Ningbo University for testing The particle size distribution is detected, and the real particle size distribution is obtained as follows:

[0020] D10: 0.125-0.145um, D50: 0.250-0.280um,

[0021] D90: 0.450-0.600um, D99.9: 1.400-1.700um.

[0022] Adopt the inventive method to carry out particle size distribution test to this superfine nickel powder, operation steps are as follows:

[0023] (1) Turn on the LA-950V2 laser particle size distribution detector and stabilize it for 2 hours;

[0024] (2) Use the reverse osmosis device to prepare pure water to obtain reverse osmosis water with a pH of 7±0.2 and a conductivity of 3-4μS / m;

[0025] (3) Take a 500ml beaker, add 100ml...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com