Nimodipine lyophilized emulsion for injection and preparing method thereof

A technology of nimodipine and freeze-dried emulsion, which is applied in the field of medicine to achieve the effects of improving stability, reducing toxic and side effects, and avoiding stimulation and injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

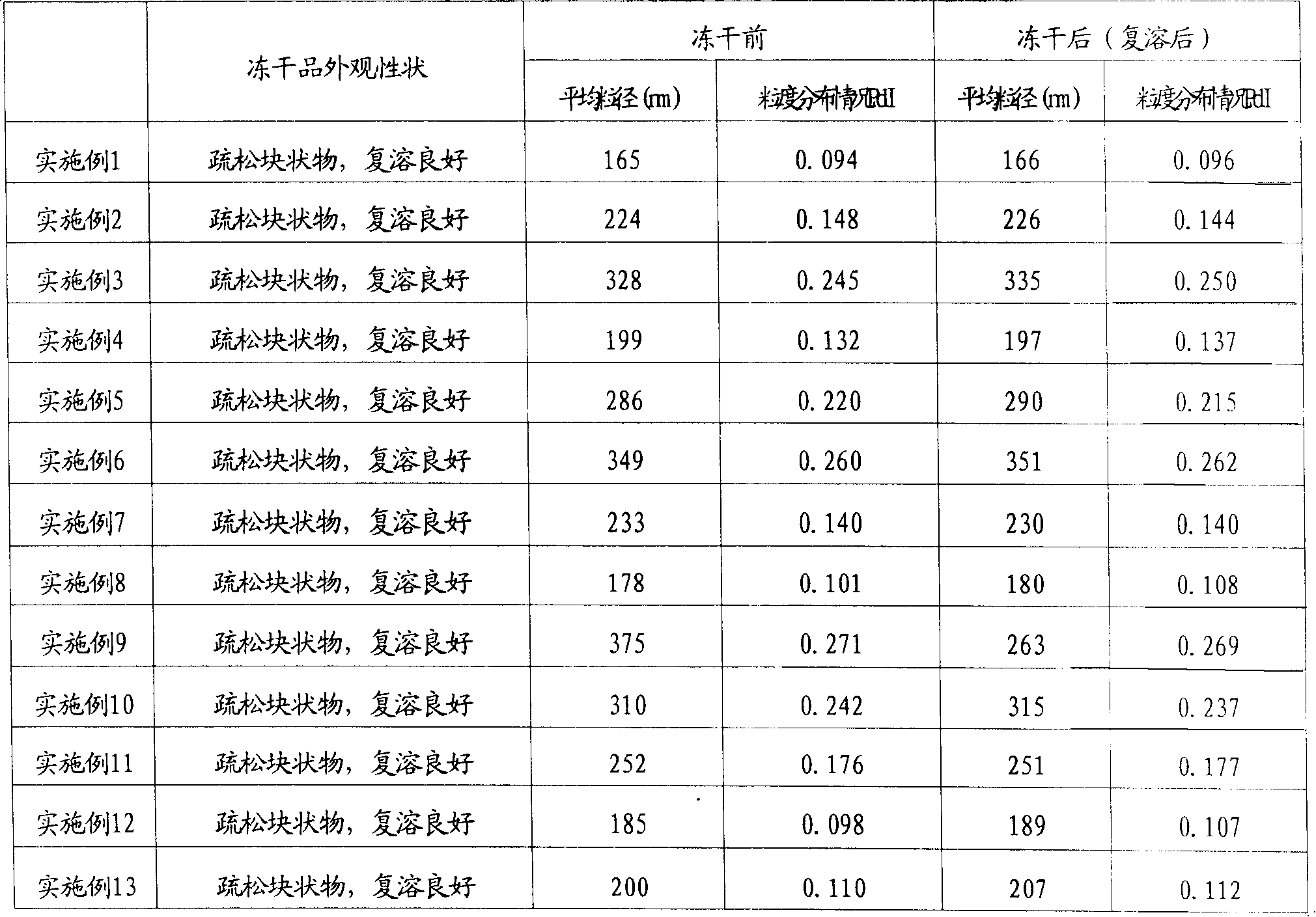

Examples

Embodiment 1

[0033] 1. Dissolve 10 mg of the main drug nimodipine in 5 g of olive oil as the oil phase;

[0034] 2. Disperse 1.0g of soybean lecithin in water, and add 5g of glycerin and 1g of Vc as the water phase;

[0035] 3. Add the oil phase to the water phase under stirring, stir at 20°C at high speed to make it colostrum, and adjust the pH to 8.0 with 0.1mol / L NaOH solution to obtain colostrum;

[0036] 4. The colostrum is homogenized by an APV2000 homogenizer to obtain a uniform emulsion I, and 400g of sucrose is dissolved to obtain a solution II;

[0037] 5. Mix solution I and solution II, dilute the solution to 1000ml, and remove water by freeze-drying to obtain dry nimodipine freeze-dried emulsion. The above processes are all completed under the condition of nitrogen filling.

Embodiment 2

[0039] 1. Dissolve 500mg of the main drug nimodipine in 100g of soybean oil as the oil phase;

[0040] 2. Disperse 20g of egg yolk phospholipids in water, and add 2g of glycerin as the water phase;

[0041] 3. Add the oil phase to the water phase under stirring, stir at 40°C at high speed to make it colostrum, and adjust the pH to 7.5 with 0.1mol / L sodium citrate buffer to obtain colostrum;

[0042] 4. The colostrum is homogenized by an APV2000 homogenizer to obtain a uniform emulsion I, and 100g of glucose is dissolved to obtain a solution II;

[0043] 5. Mix solution I and solution II, dilute the solution to 1000ml, and remove water by freeze-drying to obtain dry nimodipine freeze-dried emulsion. The above processes are all completed under the condition of nitrogen filling.

Embodiment 3

[0045] 1. Dissolve 2.0g of the main drug nimodipine and 25g of egg yolk phospholipid in 300g of soybean oil for injection as the oil phase;

[0046] 2. Disperse 25g of soybean lecithin in water, then add 2.0g of sodium chloride and 1g of sodium oleate as the water phase;

[0047] 3. Add the water phase to the oil phase under stirring, stir at 90°C at high speed to make it colostrum, and adjust the pH to 8.0 with 0.5mol / L citric acid buffer to obtain colostrum;

[0048] 4. The colostrum is homogenized by an APV2000 homogenizer to obtain a uniform emulsion I, and 200g of maltose is dissolved to obtain a solution II;

[0049] 5. Mix solution I and solution II, dilute the solution to 1000ml, and remove water by freeze-drying to obtain dry nimodipine freeze-dried emulsion. The above processes are all completed under the condition of nitrogen filling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com