Patents

Literature

85 results about "Mud systems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Effective solids control can be attributed to the overall performance of all the components of the mud systems. Conditioning the drilling fluid with the goal of dramatically lowering maintenance cost, avoiding excessive chemical treatment and maintaining mud systems volume will decrease the chance of equipment failure, unnecessary high mud costs, hole and drilling problems.

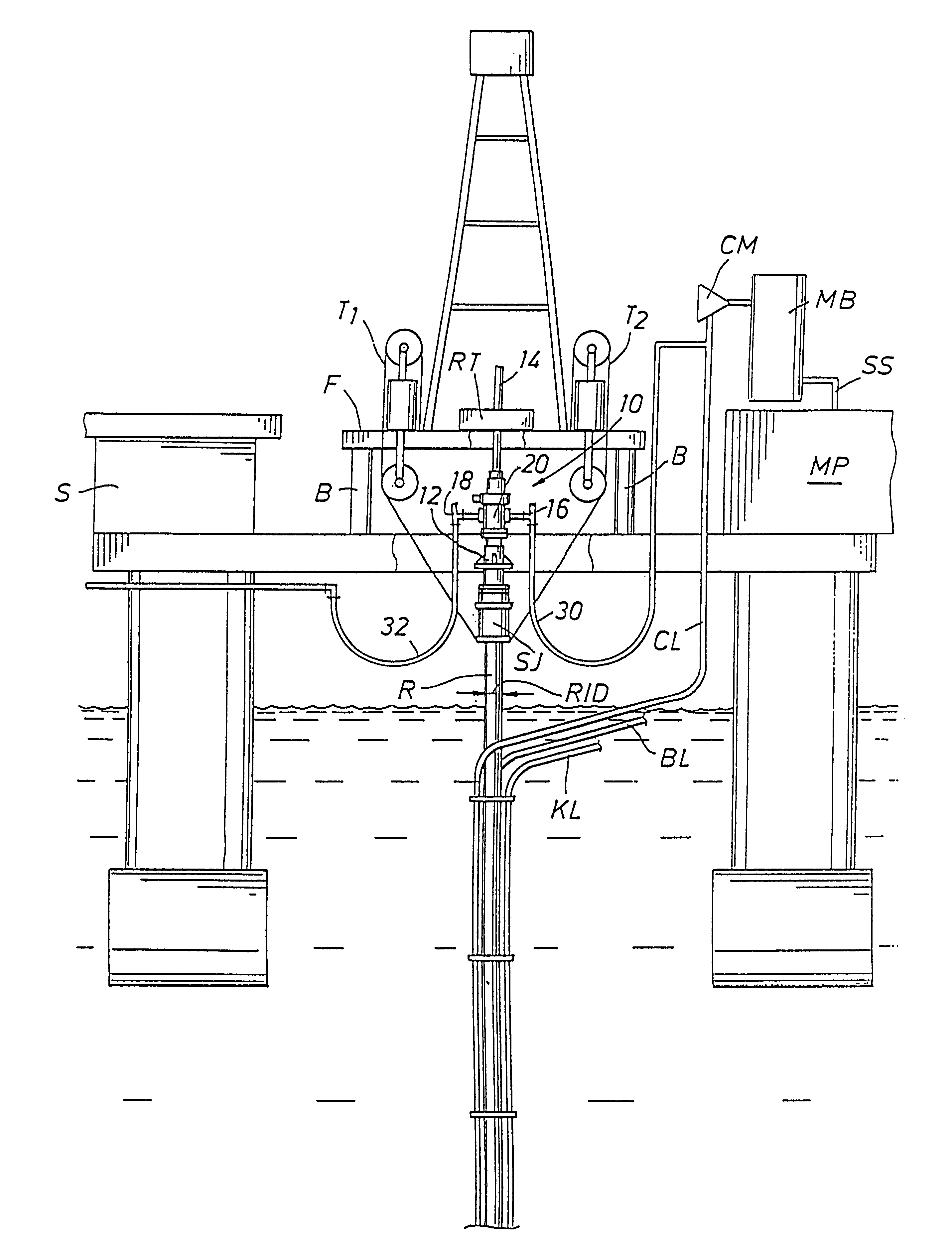

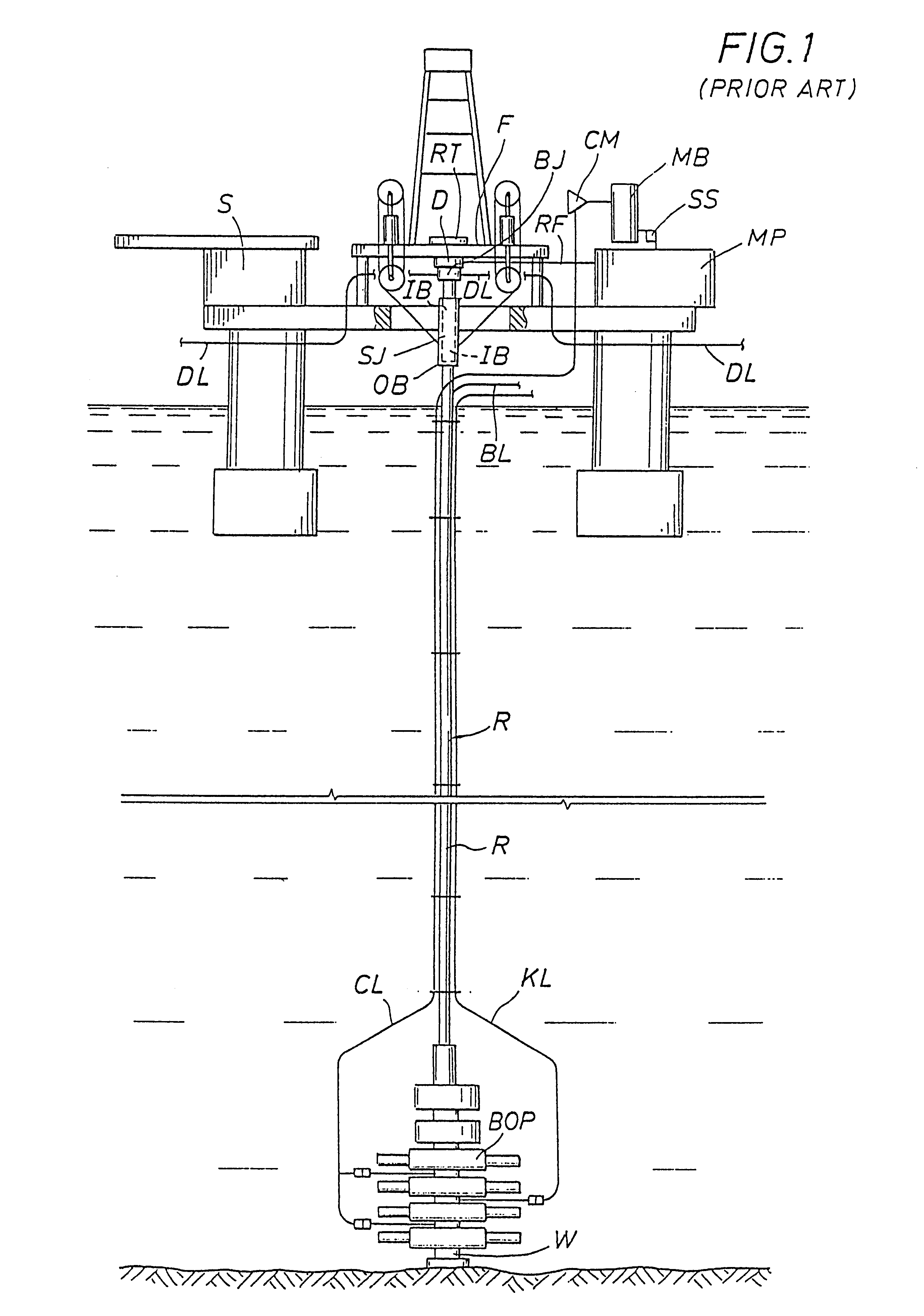

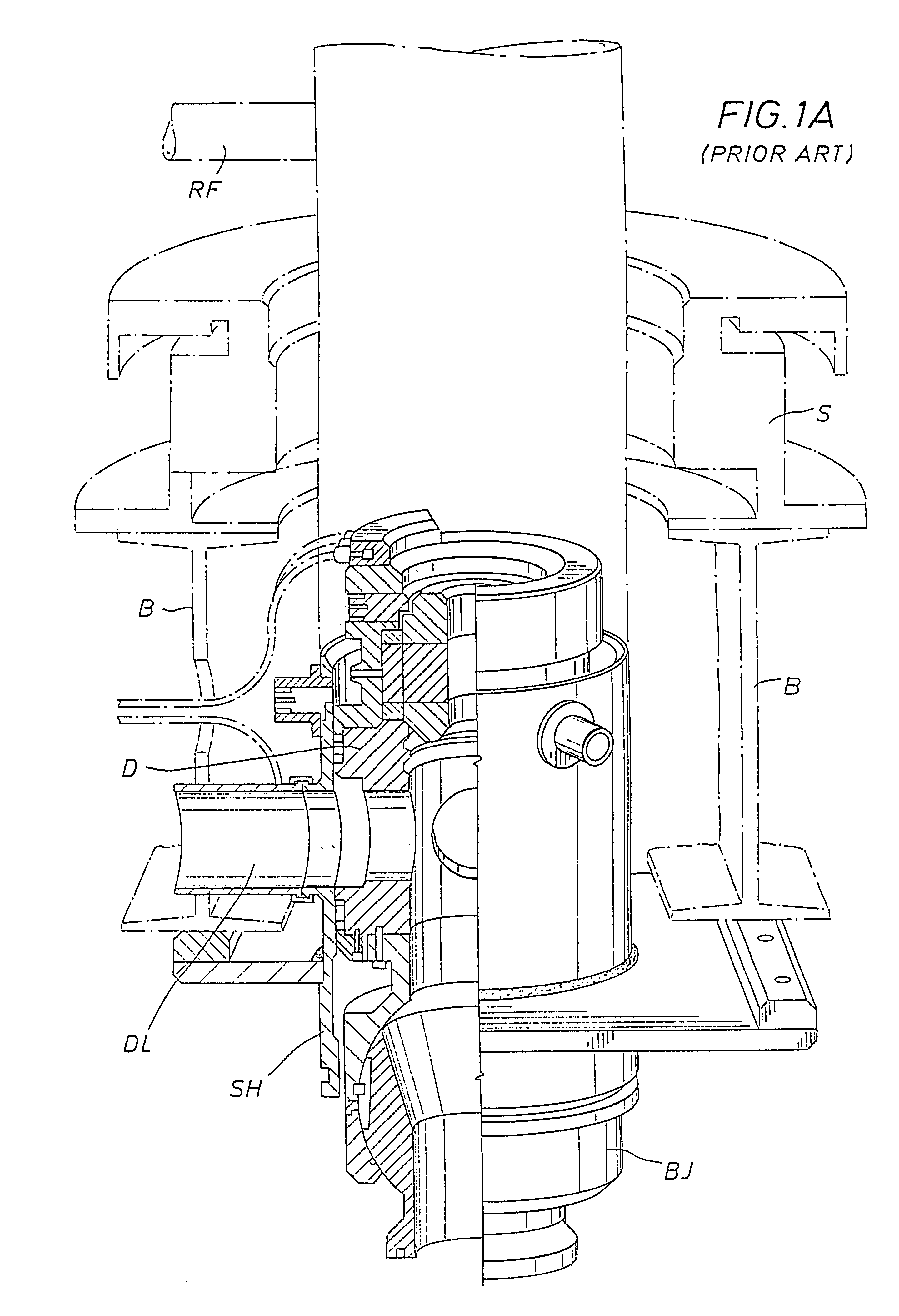

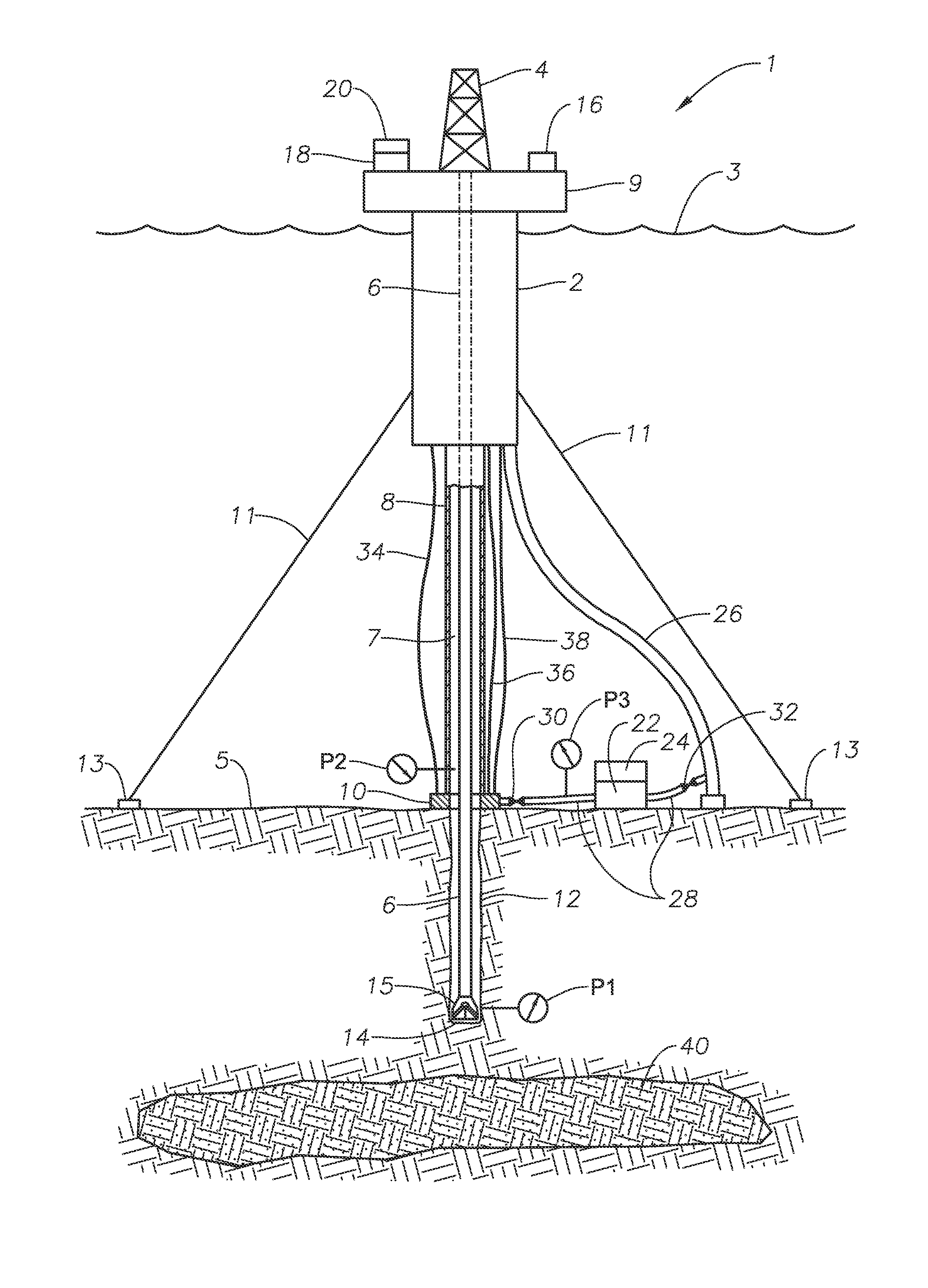

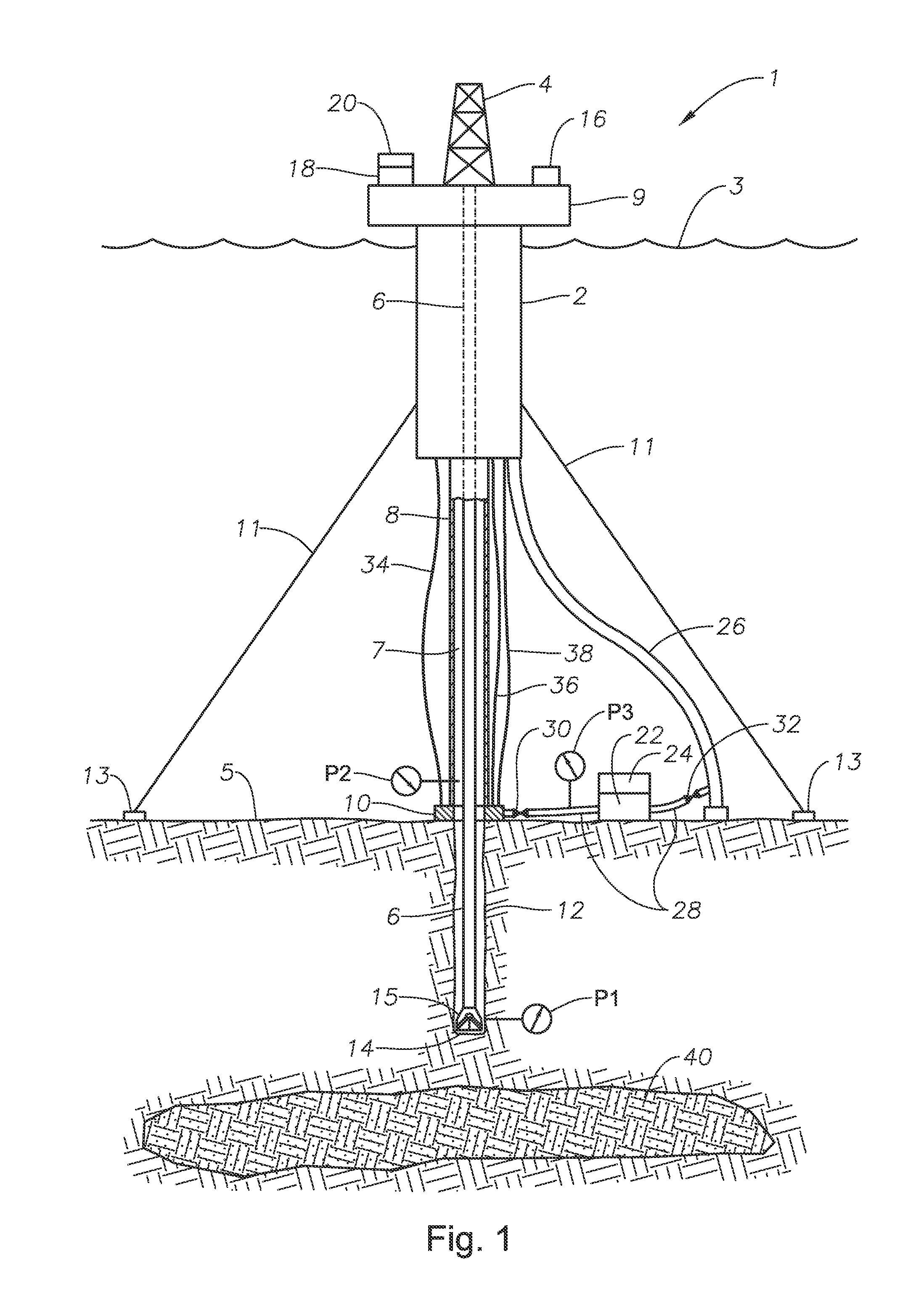

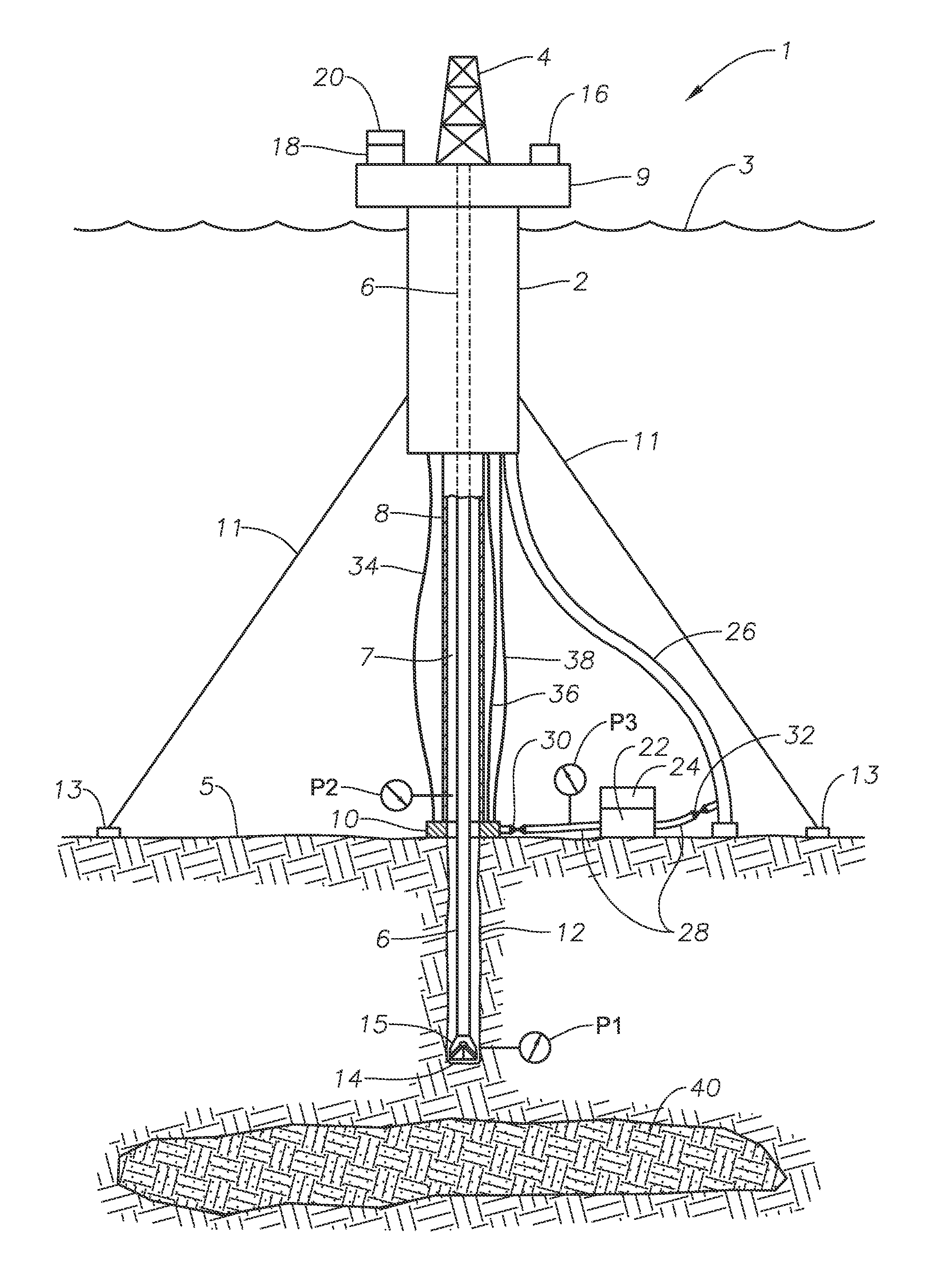

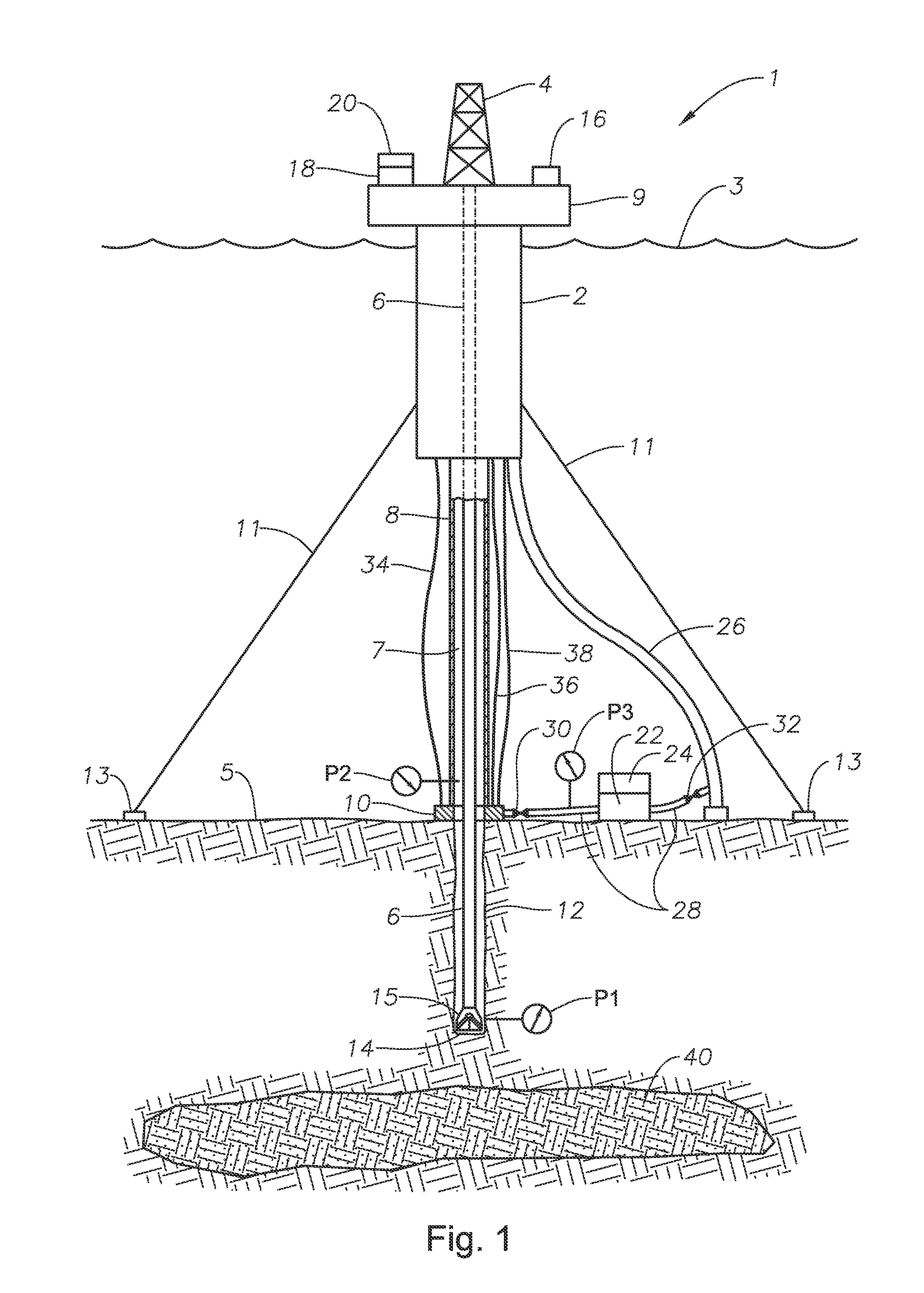

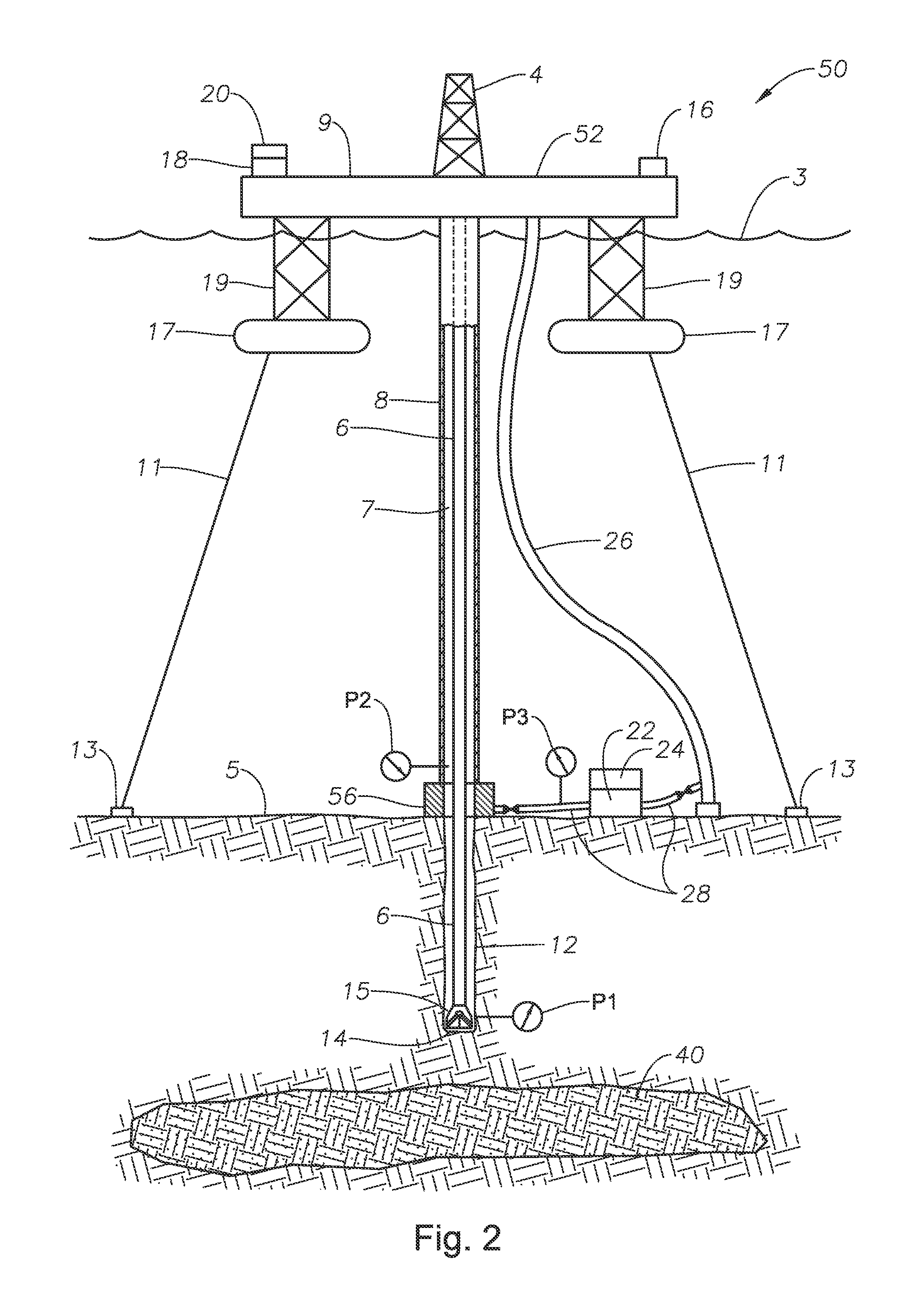

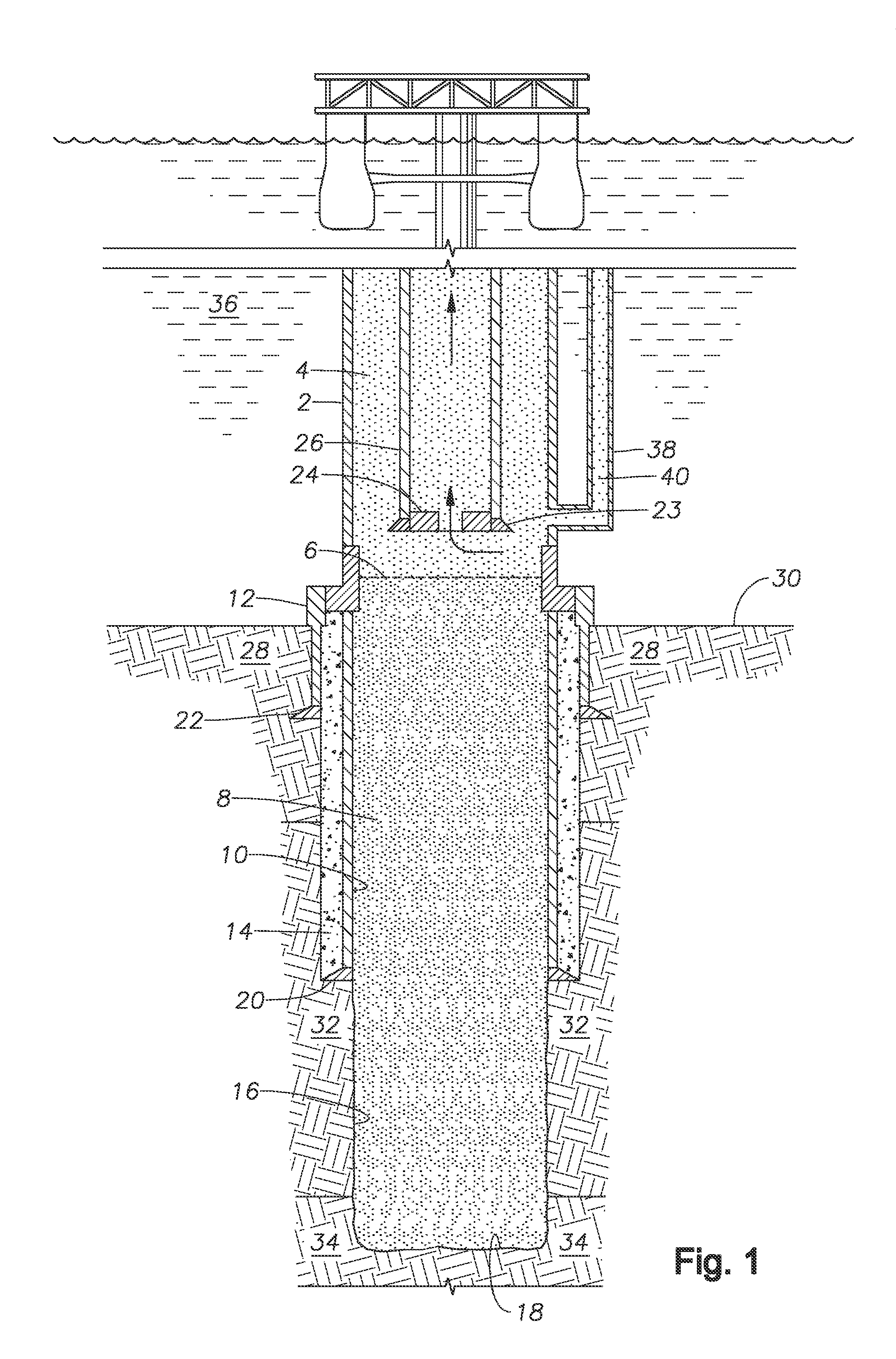

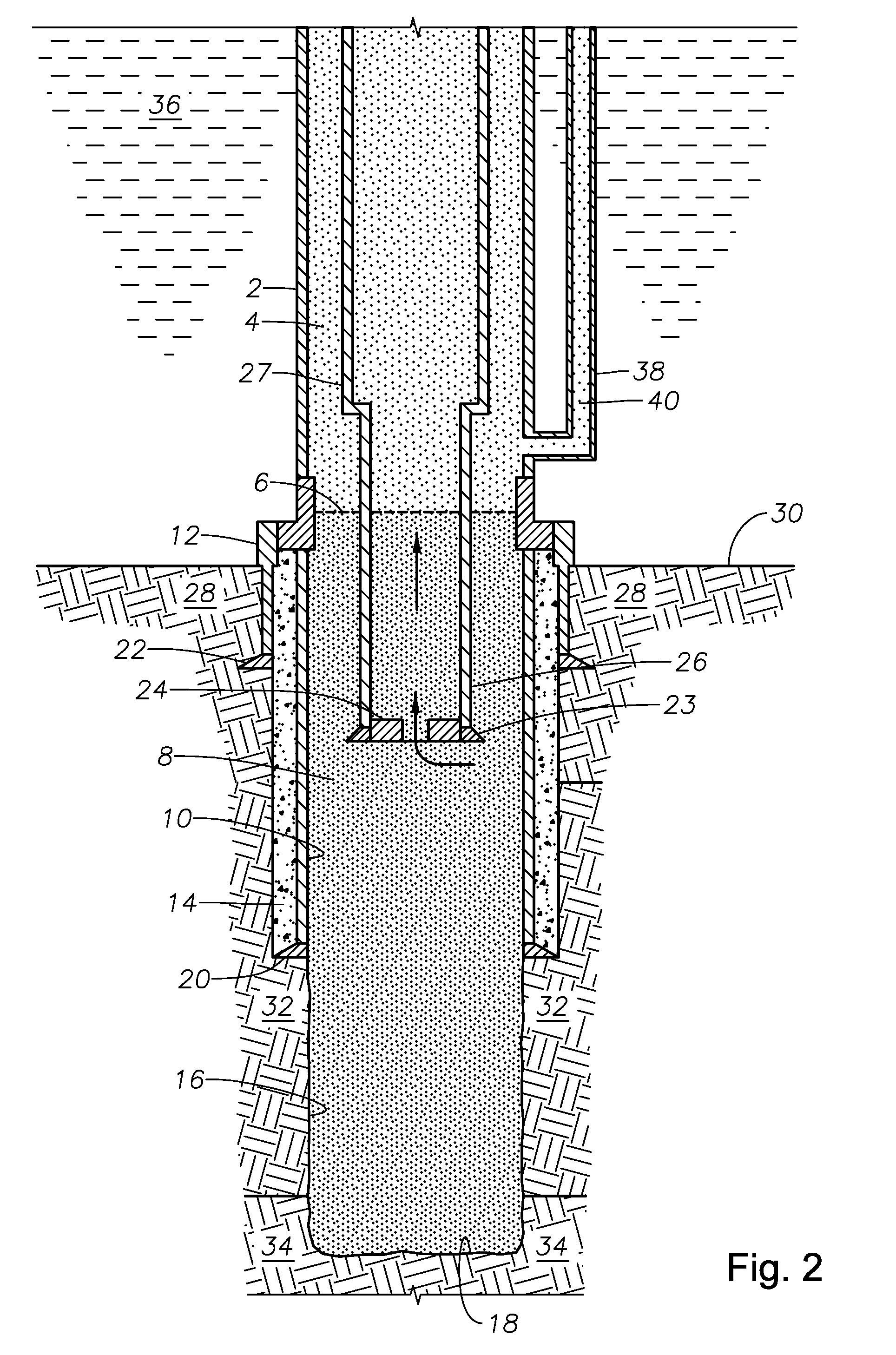

Method and system for return of drilling fluid from a sealed marine riser to a floating drilling rig while drilling

A floating rig or structure for drilling in the floor of an ocean using a rotatable tubular includes a seal housing having a rotatable seal connected above a marine riser fixed to the floor of the ocean. The seal rotating with the rotating tubular allows the riser and seal housing to maintain a predetermined pressure in the system that is desirable in underbalanced drilling, gas-liquid mud systems and pressurized mud handling systems. A flexible conduit or hose is used to compensate for the relative movement of the seal housing and the floating structure since the floating structure moves independent of the seal housing. A method for use of the system is also disclosed.

Owner:WEATHERFORD TECH HLDG LLC

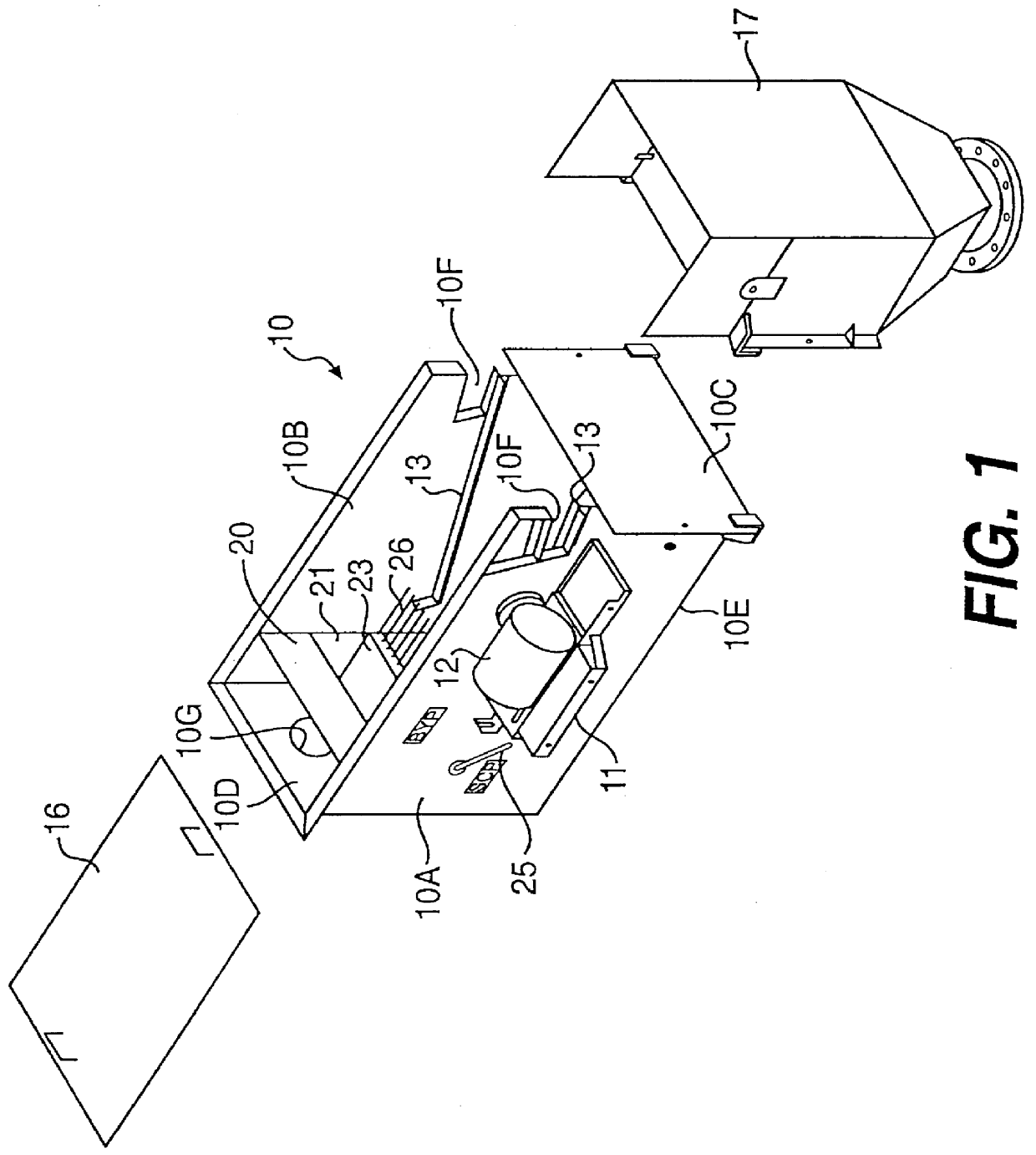

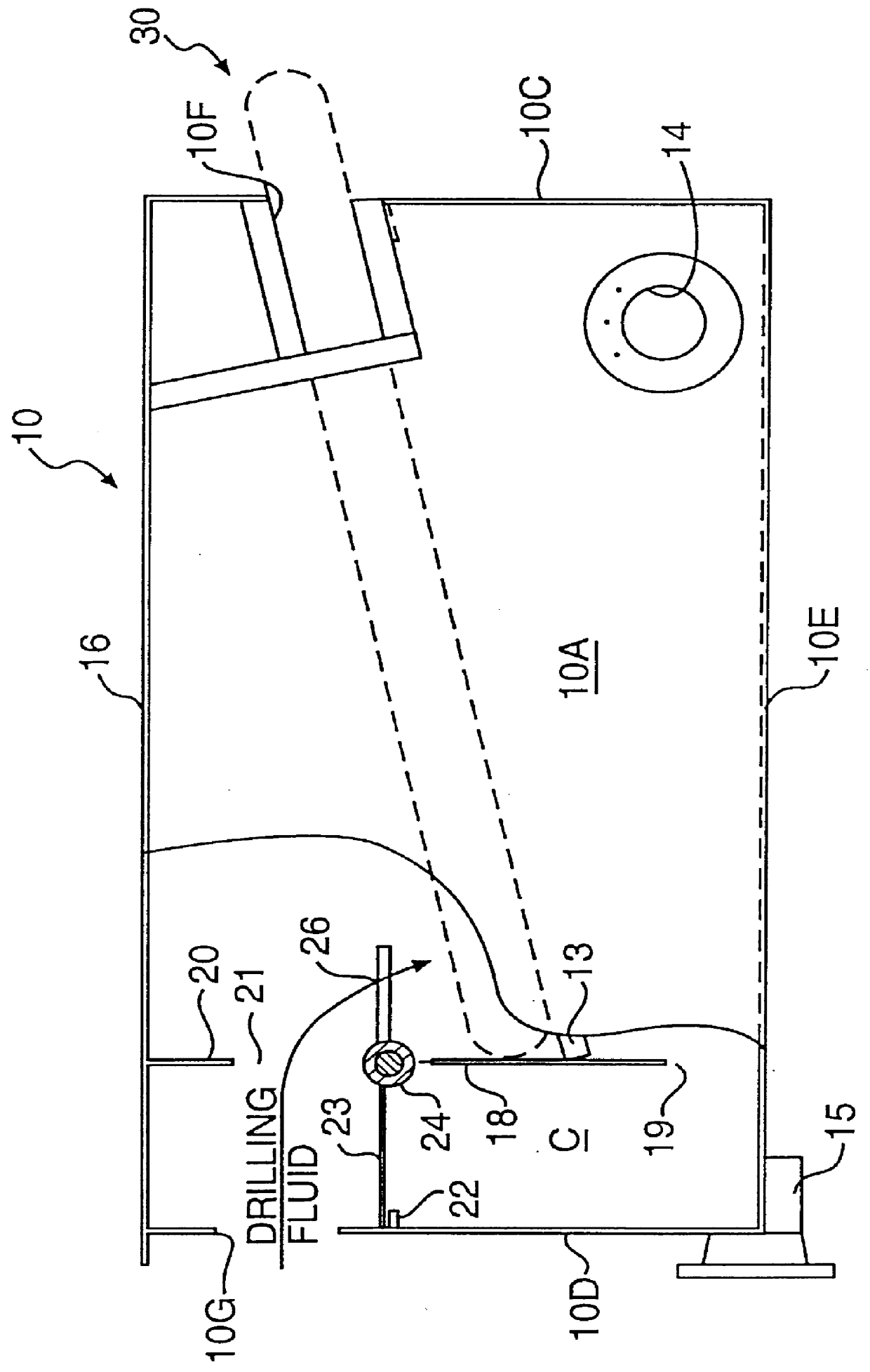

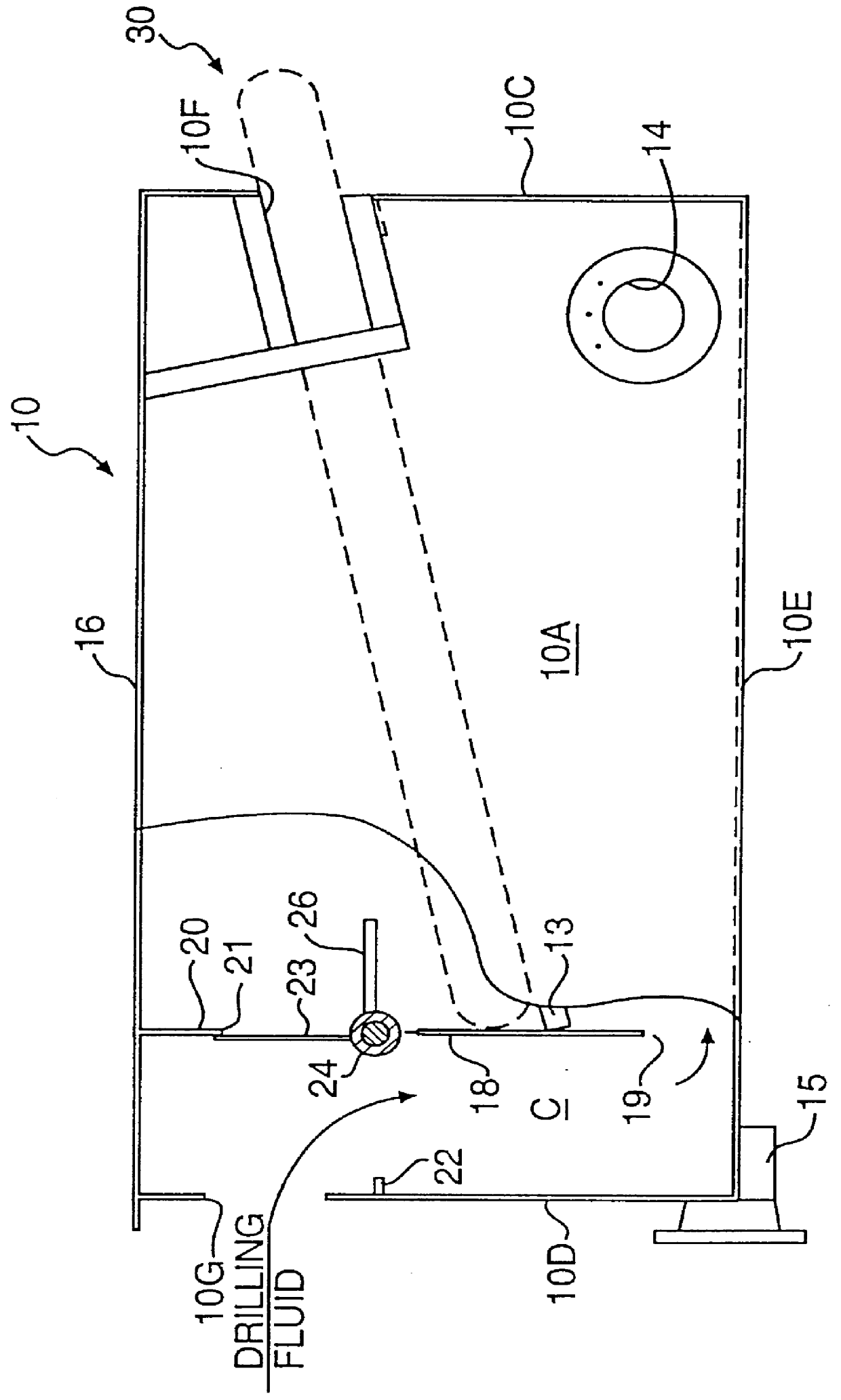

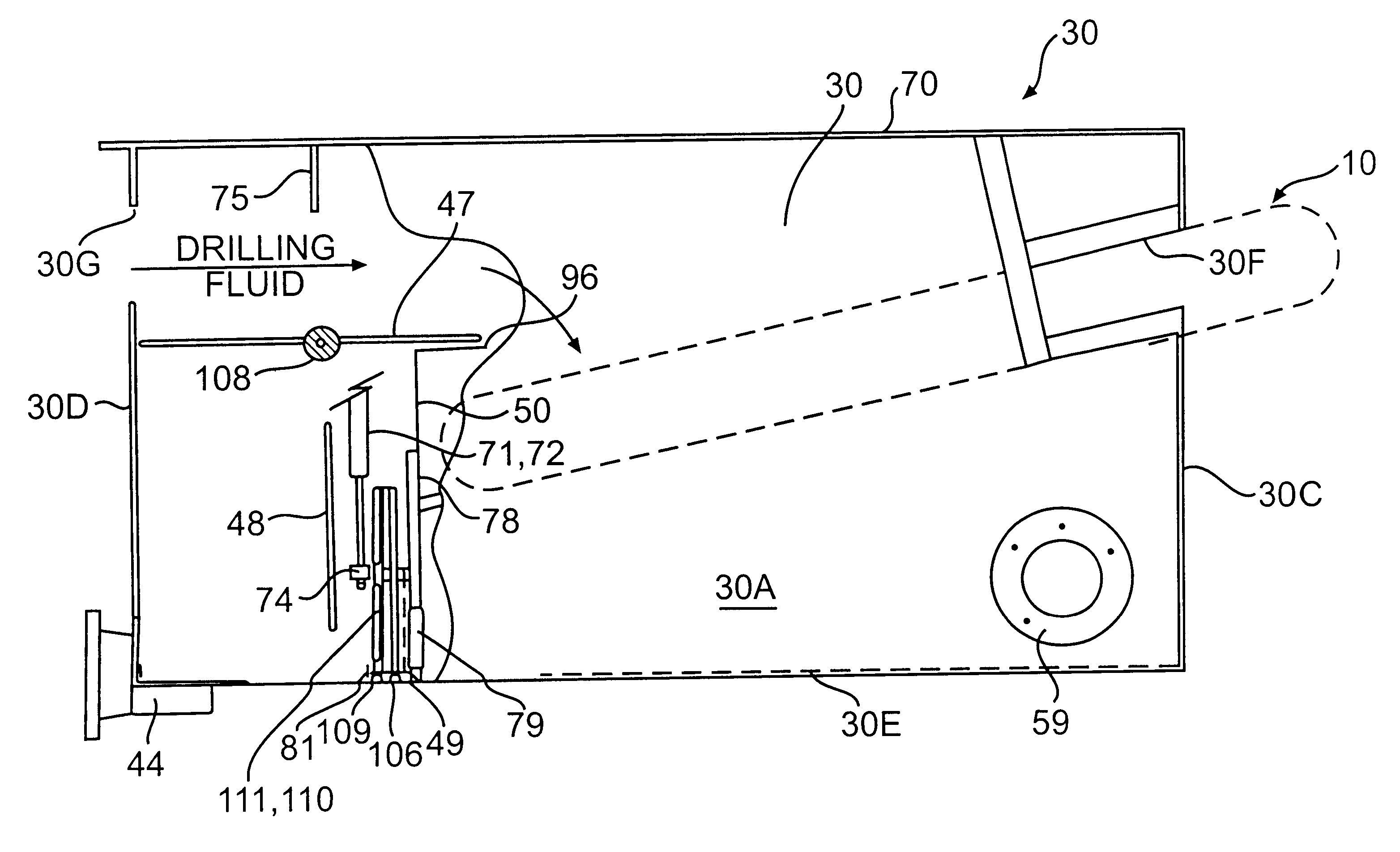

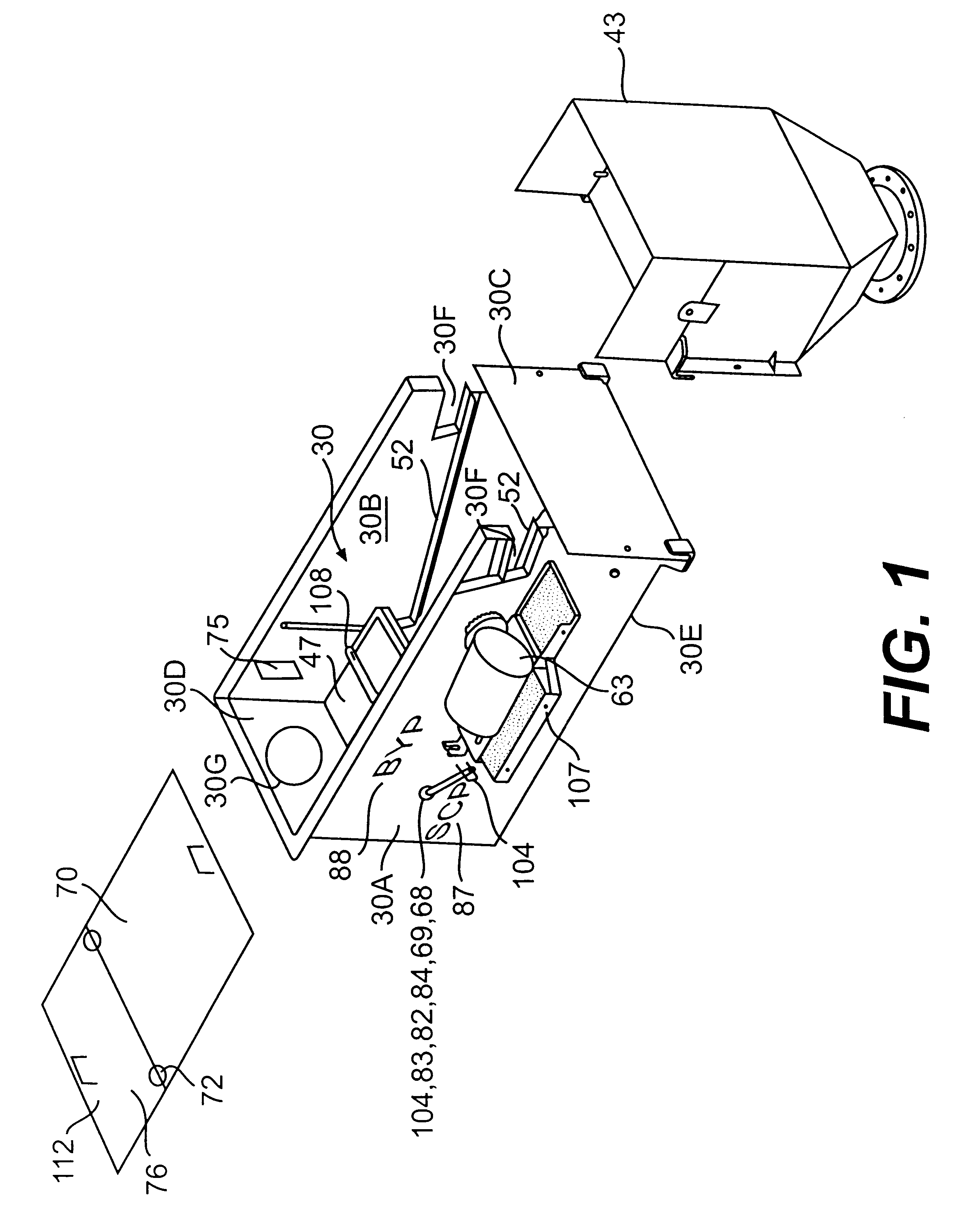

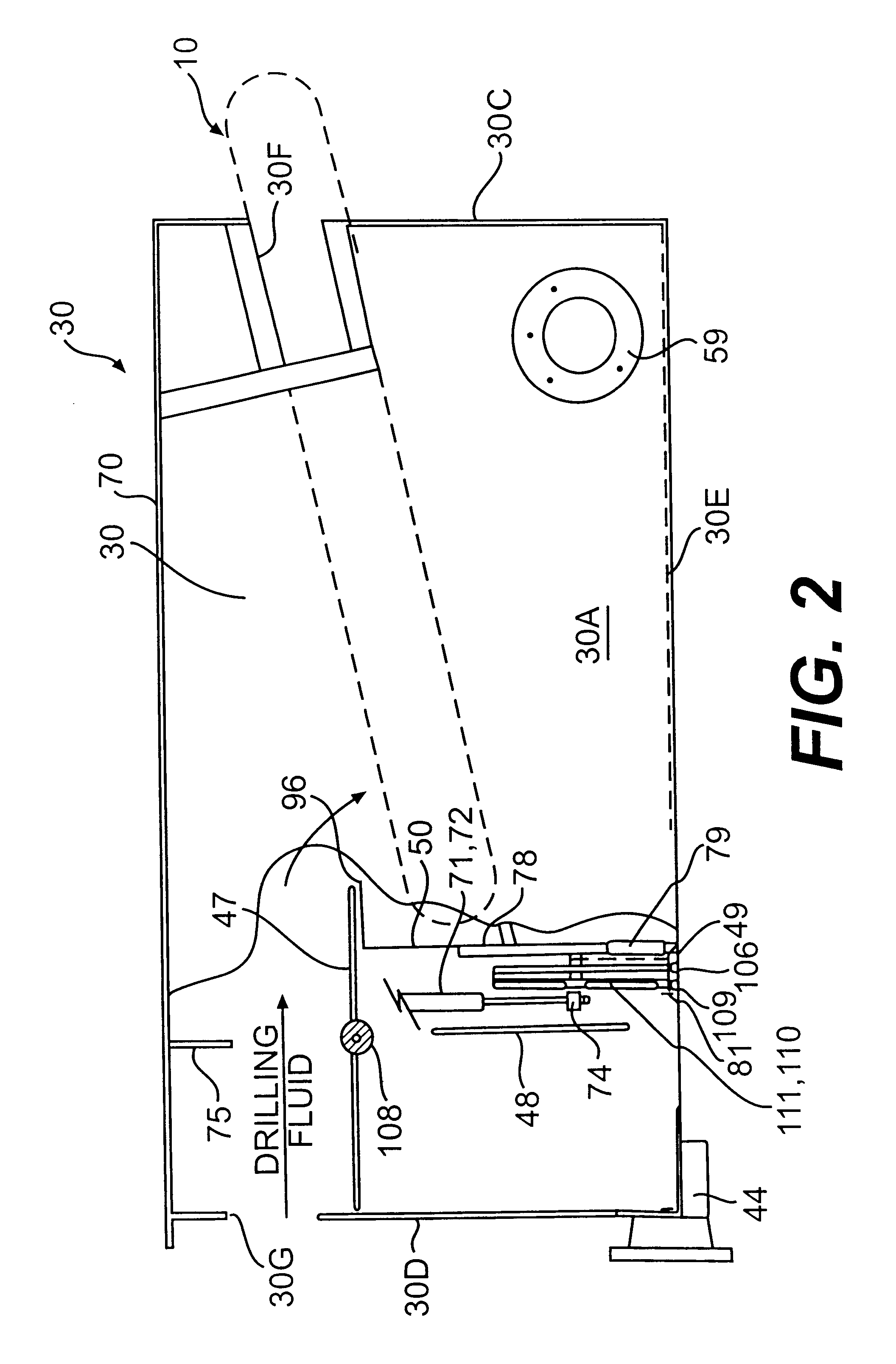

Bypass diverter box for drilling mud separation unit

A bypass diverter box disposed upstream from conventional solids control equipment of a mud system of a drilling rig contains a drilling mud separation unit having a continuous-loop scalper screen that is driven in a continuous loop to separate, convey and discharge large amounts of gumbo, heavy clays and drill solids at the end of the separation unit. The flow divider box is a box-like housing with a verter plate, upper and lower baffle plates and a grate that allows drilling fluid or drilling mud to be selectively directed to the mud separation unit to be separated prior to passing to the conventional downstream solids control equipment or allows the fluid to bypass the separation unit and flow directly to the conventional solids control equipment. The bypass diverter box baffle plates, diverter plate and grate, and selective utilization of the mud separation unit removes large amounts of gumbo, heavy clays and drill solids from the drilling mud and allows high flow rates to be easily processed by shale shakers and other conventional downstream solids control equipment of the mud system and compliments the drilling operations with respect to changes in the lithology, geological formations, or loss of returns in relation to the gallons pumped or folume of drilling fluid or drilling mud entering the bypass diverter box.

Owner:TUBOSCOPE NU TECGNT

High performance water-based mud system

InactiveUS20050187113A1Premature consumptionEffectively stopFluid removalFlushingWater basedPolystyrene

A drilling fluid or mud additive having several components, including leonardite (humic acid); potassium acetate; partially hydrolyzed polyacrylamide (PHPA); polyanionic cellulose polymer (PAC); sulfonated asphalt; sulfoalkylated tannin; polystyrene maleic anhydride copolymer; micronized cellulose fiber; and calcium carbonate. These components are preferably premixed in a dry formulation as a powder or as pellets, and shipped to the site in bags or bulk tanks. This offers substantial advantages over the prior art in that the drilling mud of the present invention may be formed simply by adding the dry mix to a predetermined amount of water, and is thus much easier to make than the prior art wet mix drilling fluids, which typically require precise ratios of several different powders and liquids to be mixed together. Hydration buffers help keep the powder or pellets dry and flowable.

Owner:HAYES JAMES R

Weir box for drilling mud separation unit

InactiveUS6244362B1Settling tanks feed/dischargeLoose filtering material filtersLithologyShale shakers

A weir box disposed upstream from conventional solids control equipment of a mud system of a drilling rig contains a drilling mud separation unit having a continuous-loop scalper screen that is driven in a continuous loop to separate, convey and discharge large amounts of gumbo, heavy clays and drill solids at the end of the separation unit. The flow divider box is a box-like housing with a diverter plate, weir baffle plates and a sliding gate that allows drilling fluid or drilling mud to be selectively directed to the mud separation unit to be separated prior to passing to the conventional downstream solids control equipment or allows the fluid to bypass the separation unit and flow directly to the conventional solids control equipment. The sliding gate is adjustable to selectively control or meter the flow rate and to create a hydrostatic head upstream from the conventional solids control equipment. The weir box baffle plates, sliding gate, and selective utilization of the mud separation unit allows the operator to produce an increased hydrostatic head, which enables high flow rates to be easily processed by shale shakers and other conventional downstream solids control equipment of the mud system and to compliment the drilling operation with respect to changes in the lithology, geological formations, or loss of returns in relation to the gallons pumped or volume of drilling fluid or drilling mud entering the weir box.

Owner:WILLIAMS J TERRELL

Systems and methods for circulating out a well bore influx in a dual gradient environment

Methods and systems for drilling subsea wells bores with dual-gradient mud systems include drilling the subsea well bore while employing a subsea pumping system, a subsea choke manifold and one or more mud return risers to implement the dual gradient mud system. When a well bore influx is detected, the well bore is shut in, and components determine if pressure control may be used to circulate the influx out of the well bore, the size of the influx, and how much the mud system weight will need to be reduced to match the dual gradient hydrostatic head before the influx reaches the subsea pump take point. The subsea pumping system, subsea choke manifold, and mud risers are isolated while the influx is circulated up one or more fluid passages in the drilling riser package using the surface pump, through the wellhead, and out the surface choke manifold.

Owner:BP CORP NORTH AMERICA INC

Systems and methods for circulating out a well bore influx in a dual gradient environment

Methods and systems for drilling subsea wells bores with dual-gradient mud systems include drilling the subsea well bore while employing a subsea pumping system, a subsea choke manifold and one or more mud return risers to implement the dual gradient mud system. When a well bore influx is detected, the well bore is shut in, and components determine if pressure control may be used to circulate the influx out of the well bore, the size of the influx, and how much the mud system weight will need to be reduced to match the dual gradient hydrostatic head before the influx reaches the subsea pump take point. The subsea pumping system, subsea choke manifold, and mud risers are isolated while the influx is circulated up one or more fluid passages in the drilling riser package using the surface pump, through the wellhead, and out the surface choke manifold.

Owner:BP CORP NORTH AMERICA INC

Petroleum-hydrocarbon-contaminated soil repairing medicament and use method

InactiveCN107008745AWide variety of sourcesLow costContaminated soil reclamationOrganic fertilisersSulfate radicalsBiological activation

The invention relates to a petroleum-hydrocarbon-contaminated soil repairing medicament and a use method and belongs to the technical field of soil environment repairing. The medicament is composed of sodium persulfate (Na2S2O8), zero-valent iron (Fe <0>) and calcium peroxide (CaO2), and the molar ratio of the Na2S2O8 to Fe <0> to CaO2 is 5: 2: 2. The Na2S2O8 is fed into a slurry system, the Fe <0> and the CaO2 are added for interphase activation, two types of free radicals with extremely high oxidability including a sulfate radical anion and a hydroxyl radical (.OH) can be obtained simultaneously for decomposing petroleum hydrocarbon in soil, wherein the formula of the sulfate radical anion can be found in the specification. According to use parameters of the repairing medicament, the feeding amounts of the sodium persulfate, the zero-valent iron and the calcium peroxide are 2 mmol / g, 0.8 mmol / g and 0.8mmol / g of soil correspondingly; the water soil ratio (milliliter: g) is 2.5: 1; a reaction is performed for 4-8 hours after the water and soil are uniformly mixed; and the water can be used repeatedly. Compared with a traditional chemical method, the range of acted organic pollutants is wider; the Fe <0> and the CaO2 are wide in resource, easy to obtain and low in cost; the two types of activating agents including the CaO2 and the Fe <0> are fed, the activating effect is better, and secondary pollution is avoided; and the reaction is mild, and safety is high.

Owner:NANJING AGRICULTURAL UNIVERSITY

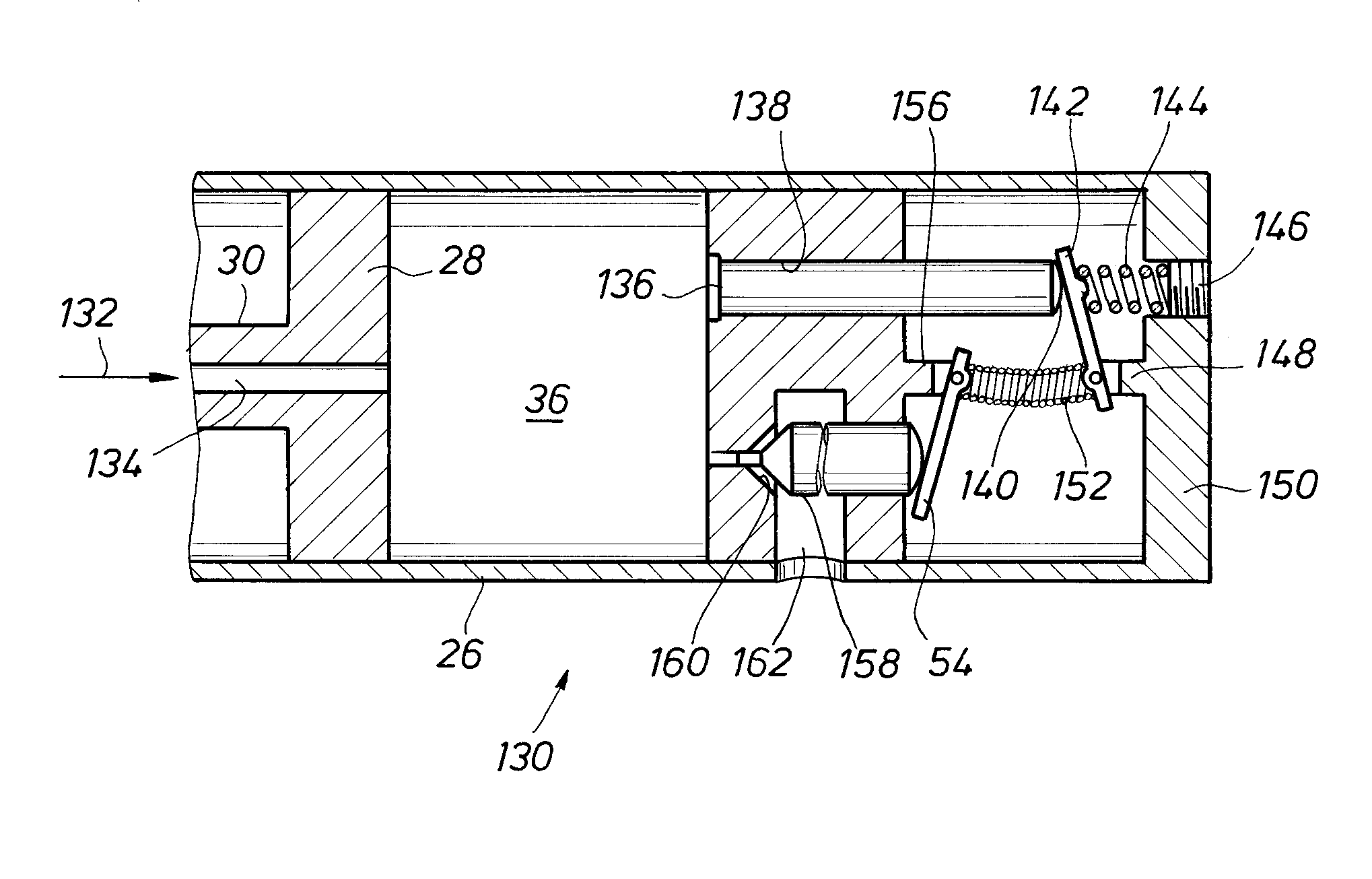

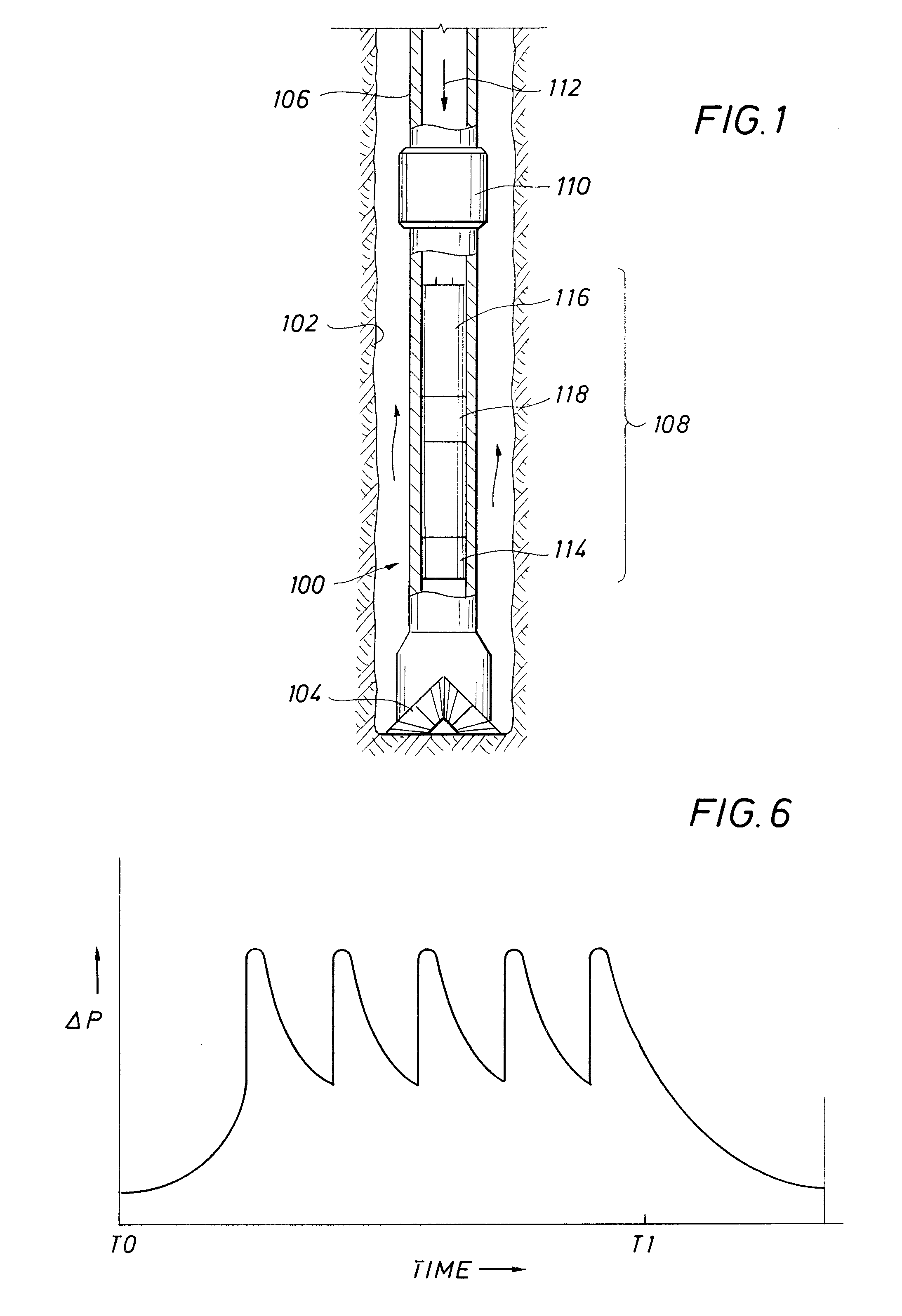

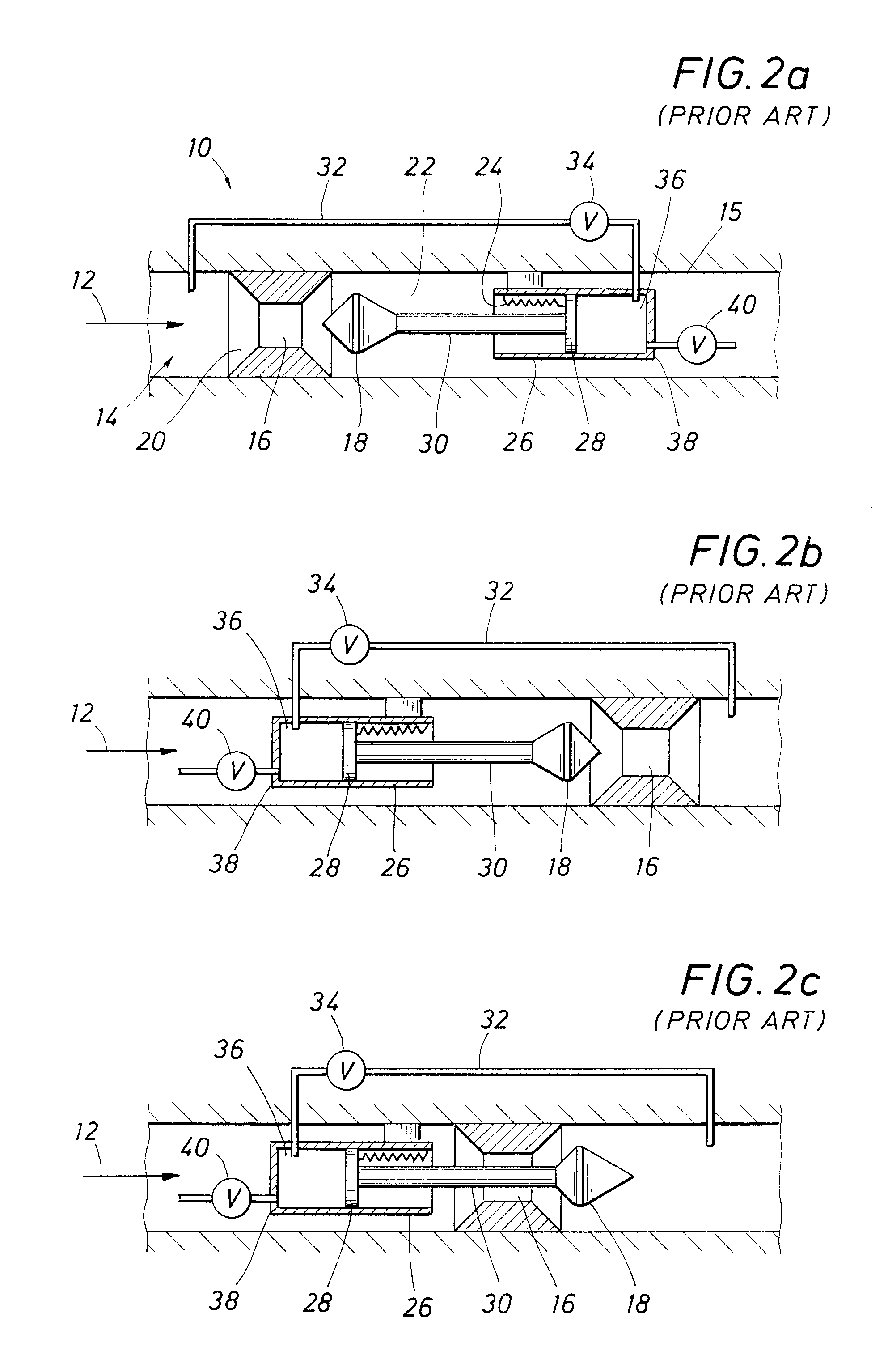

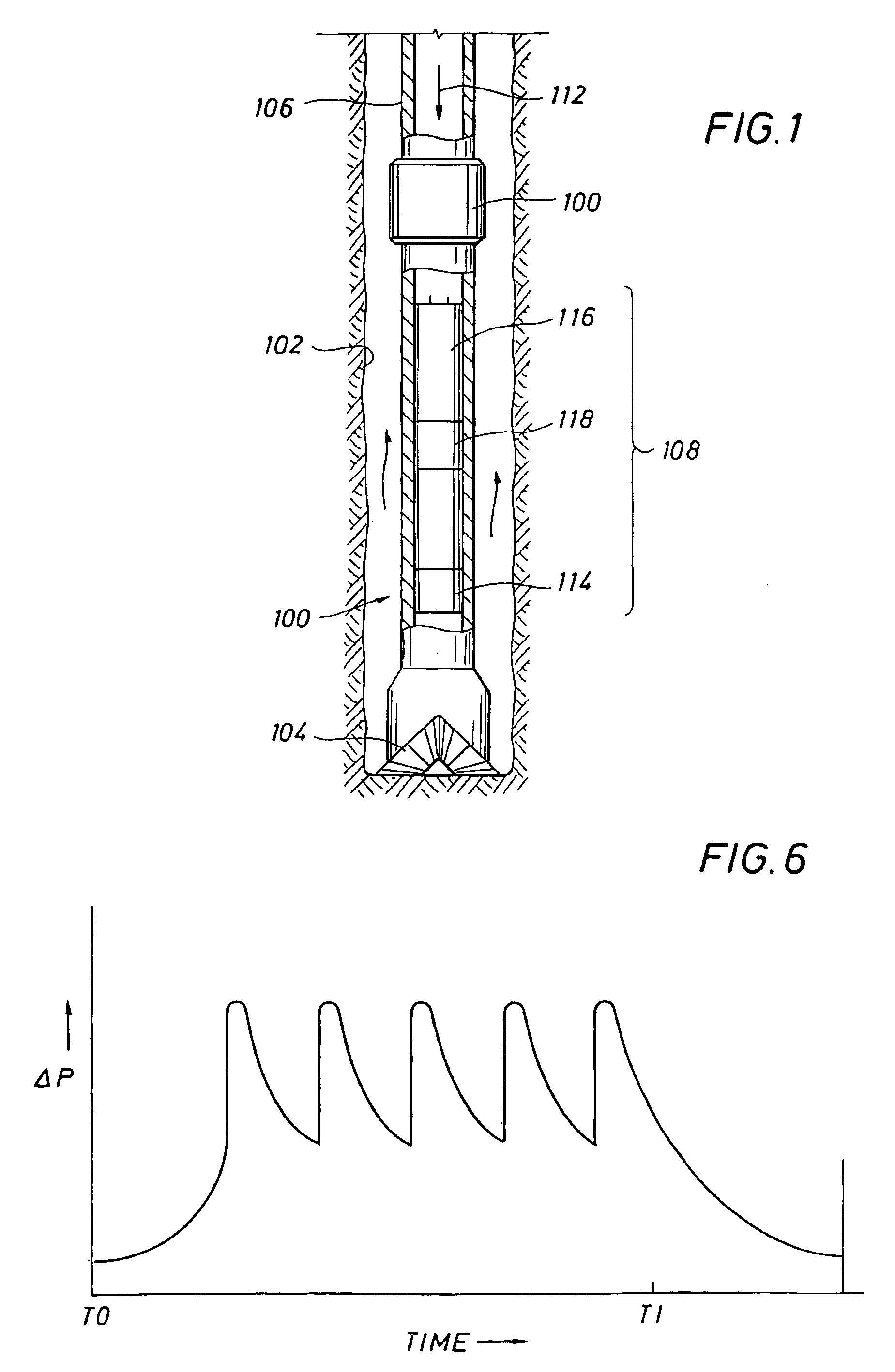

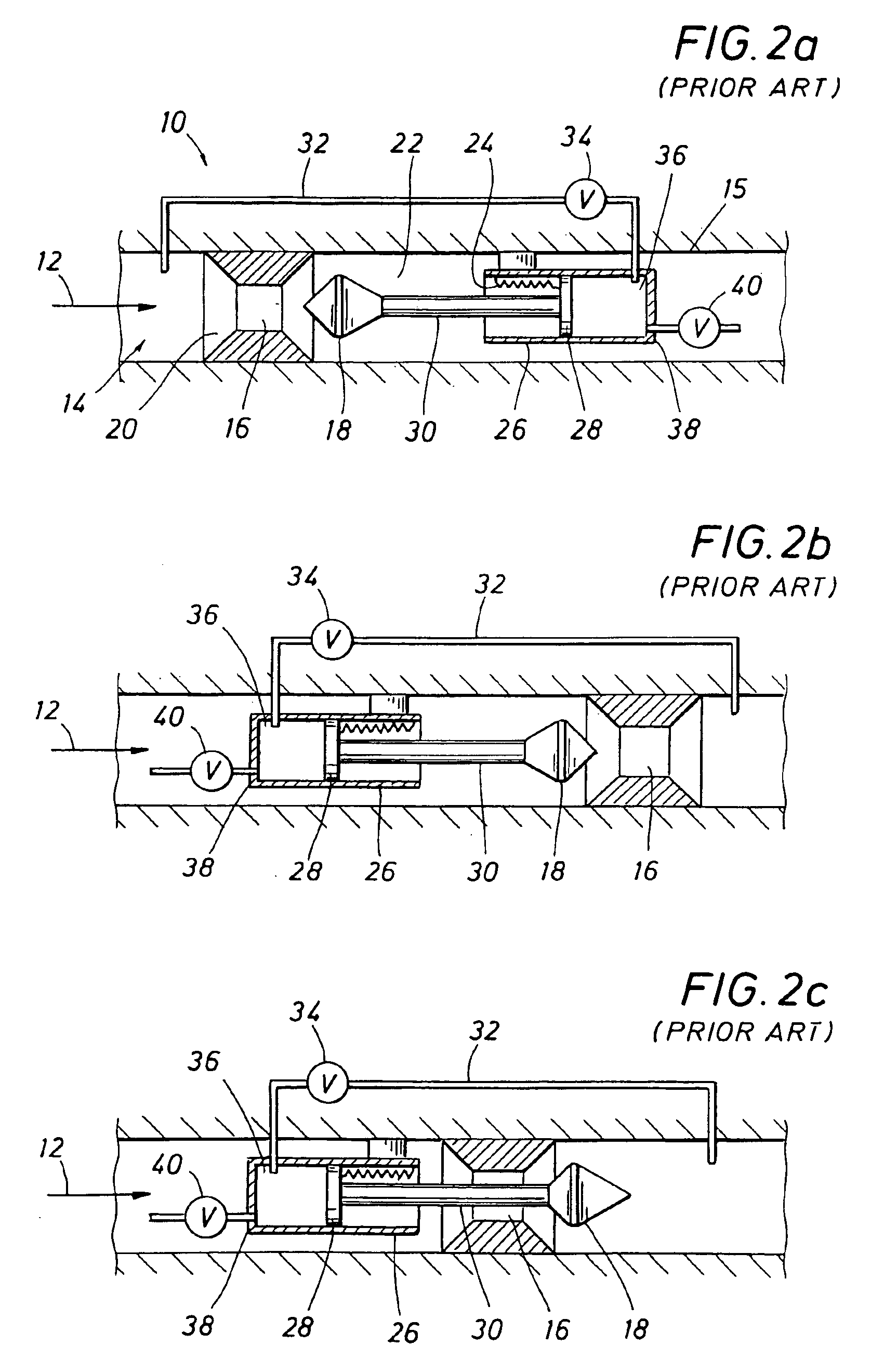

Hydraulic oscillator for use in a transmitter valve

An oscillating valve driven by the pressure in a mud pulser develops a pressure variation in the mud pulse signal that is at a frequency that is different than the frequencies of the mud system. The oscillating valve is coupled to or integral with the pulse drive cylinder, whether the drive means for operation of the pulser is upstream or downstream from the orifice. A bistable valve improves performance of the transmitting element at low flow rates by providing a toggle mechanism which assures positive seating of the bistable valve.

Owner:COLLETTE HERMAN D

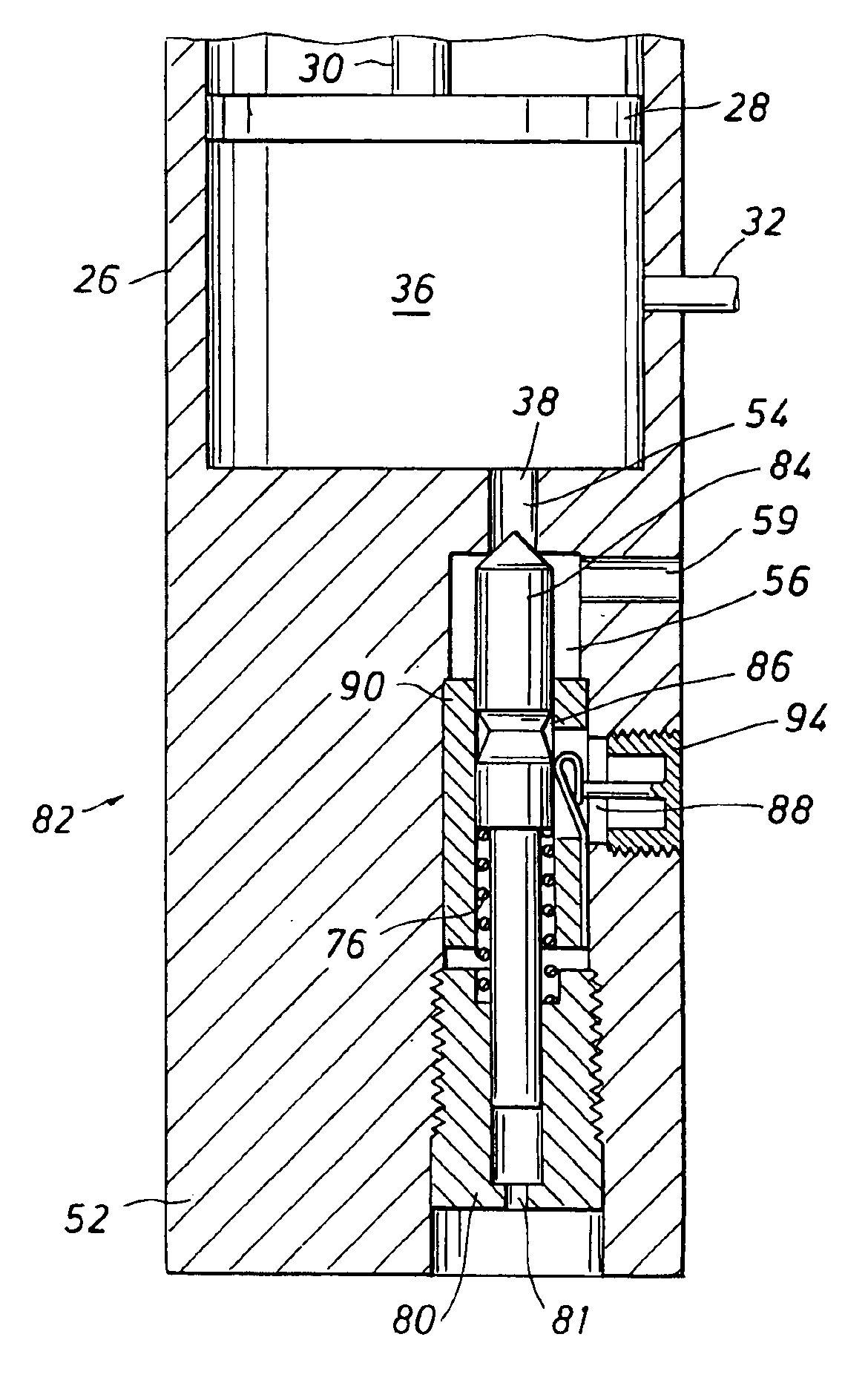

Frequency regulation of an oscillator for use in MWD transmission

InactiveUS6867706B2Move quicklyReduces poppet force and strokeSurveyConstructionsEngineeringFrequency regulation

An oscillating valve driven by the pressure in a mud pulser develops a pressure variation in the mud pulse signal that is at a frequency that is different than the frequencies of the mud system. The oscillating valve is coupled to or integral with the pulse drive cylinder, whether the drive means for operation of the pulser is upstream or downstream from the orifice, or whether or not the drive means and the poppet are on the same side or opposite sides of the orifice. The oscillating valve is a bistable valve which preferably forms one wall of the drive piston of the pulser. Pressure from the drive cylinder behind the drive piston is directed in such a way as to unseat the bistable valve. When the bistable valve unseats, pressure is bled from within the drive cylinder, which also bleeds the pressure that unseated the bistable valve in the first place. When pressure drops, the bistable valve reseats, and the cycle repeats as long as pressure is being ported to the cylinder, thereby creating a tone in the drilling mud.

Owner:COLLETTE HERMAN D

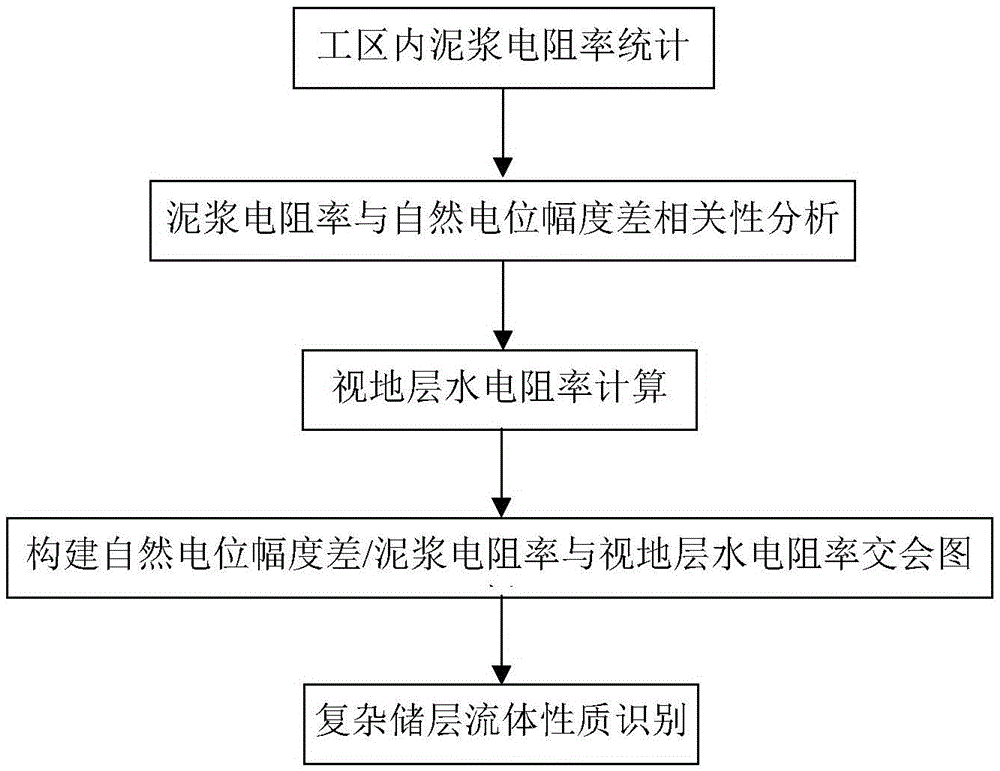

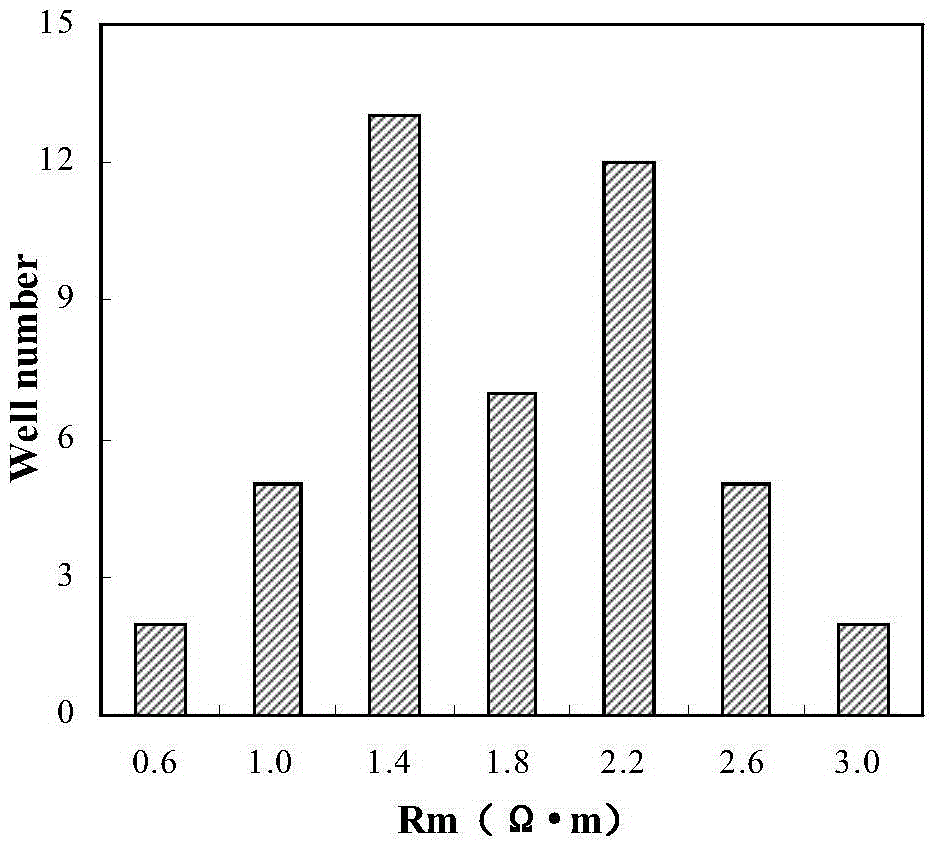

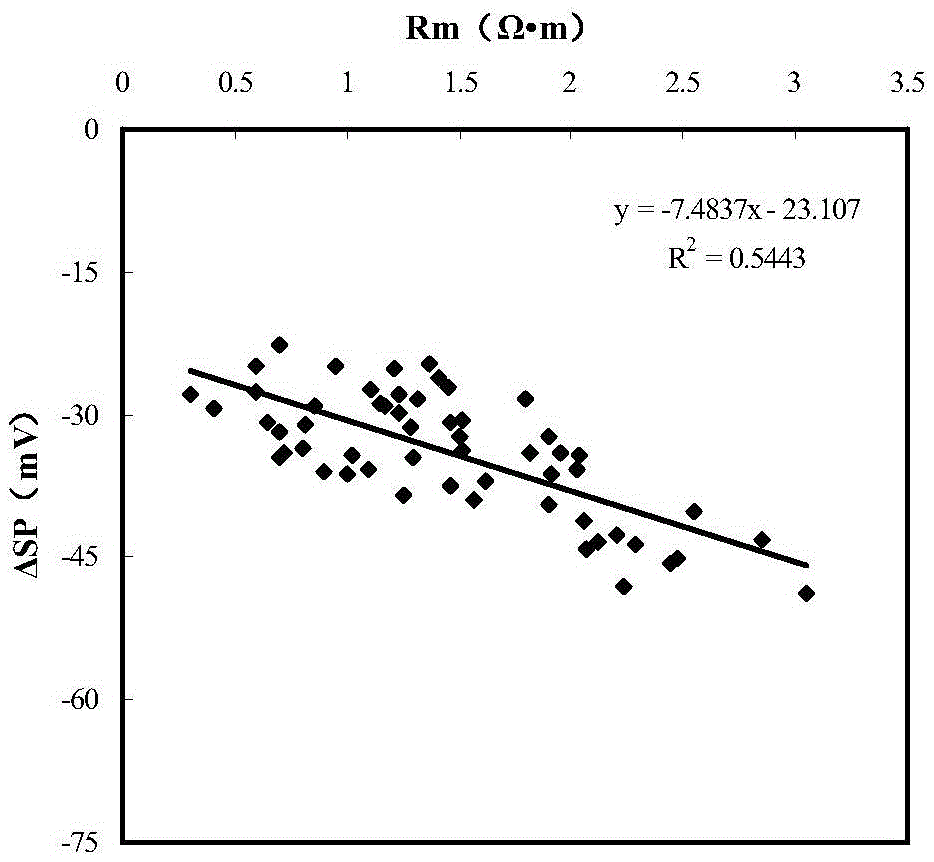

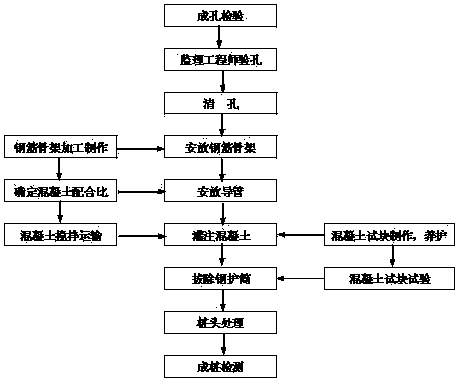

Recognition method of properties of complex reservoir stratum fluid in different mud systems

InactiveCN105545301AAvoiding the problem of identifying fluid properties in well loggingImprove recognition accuracyBorehole/well accessoriesPorosityMud systems

Provided is a recognition method of properties of complex reservoir stratum fluid in different mud systems. Based on the natural potential, resistivity logging data and sonic time difference calculation porosity, the ratio of a natural potential amplitude difference to mud resistivity and an apparent formation water resistivity crossplot are established through combination of mud resistivity and formation water resistivity in an industrial region and rock-electro parameters, the properties of fluid in complex reservoir stratums in different mud systems in the industrial region are recognized through the plot, and technological support of logging will be provided for improving the recognition precision of a low oil-resisting layer and a high water-resisting layer. The natural potential amplitude difference and a mud resistivity parameter are organically combined, a new path is provided for recognizing the low oil-resisting layer and the high water-resisting layer, and the problem that the fluid properties are recognized just through resistivity logging is also avoided.

Owner:XI'AN PETROLEUM UNIVERSITY

Insulating liquid for injecting cement in oil well

The invention relates to an isolating liquid used in oil well cementing, comprising fresh water, suspension agent, thinner agent and aggravation agent. The invention is characterized in that: the suspension agent is made from hydroxy ethyl cellulose, carboxymethyl cellulose, xanthan and na-bentonite; the thinner agent is made from sodium lignosulphonate, sodium dodecyl benzene sulfonate and alkyl phenol polyoxyethylene ether; the aggravation agent is made from barite, fly ash, limestone and slag. When preparing the isolating liquid, the suspension agent is dissolved in water for one hour, thereafter thinner agent is added. Before cementing, the aggravation agent is added into the solution and mixed evenly. The isolating liquid is characterized by low viscosity, good rheological performance, slow critical velocity and being easy to form turbulent flow, so as to effectively substitute and wash mud, prevent forming mixed slurry of cement slurry and mud. Meanwhile, the invention can be compatible with ordinary cement slurry and mud system, thus diluting and improving cement slurry rheological performance.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Clay inhibitor for concrete and preparation method thereof

The invention discloses a mud-repelling agent for concrete. The monomer composition and mass percent content of the polymerization mother liquor are: 50-75% of alkenyl amine ether, 5-15% of (meth)acrylic acid ester, and 0.1-1% of DA %, alkenyl sulfonate 0.5-5%, EA 0.1-1%, vinyl ester 5-15%. The mud inhibitor introduces polymerized monomer lipid monomers, so that after the molecule is adsorbed on the surface of the mud particles, it will reduce the water absorption of the mud particles, so that the water demand of the concrete can be at an appropriate value. At the same time, the polymer monomer of the mud-repelling agent is a molecule with a branched chain structure, and the branched chain can effectively reduce the possibility of mud particles approaching each other to coagulate and gel, so that the mud-containing concrete system has good fluidity.

Owner:JIANGSU MINGHE GRP

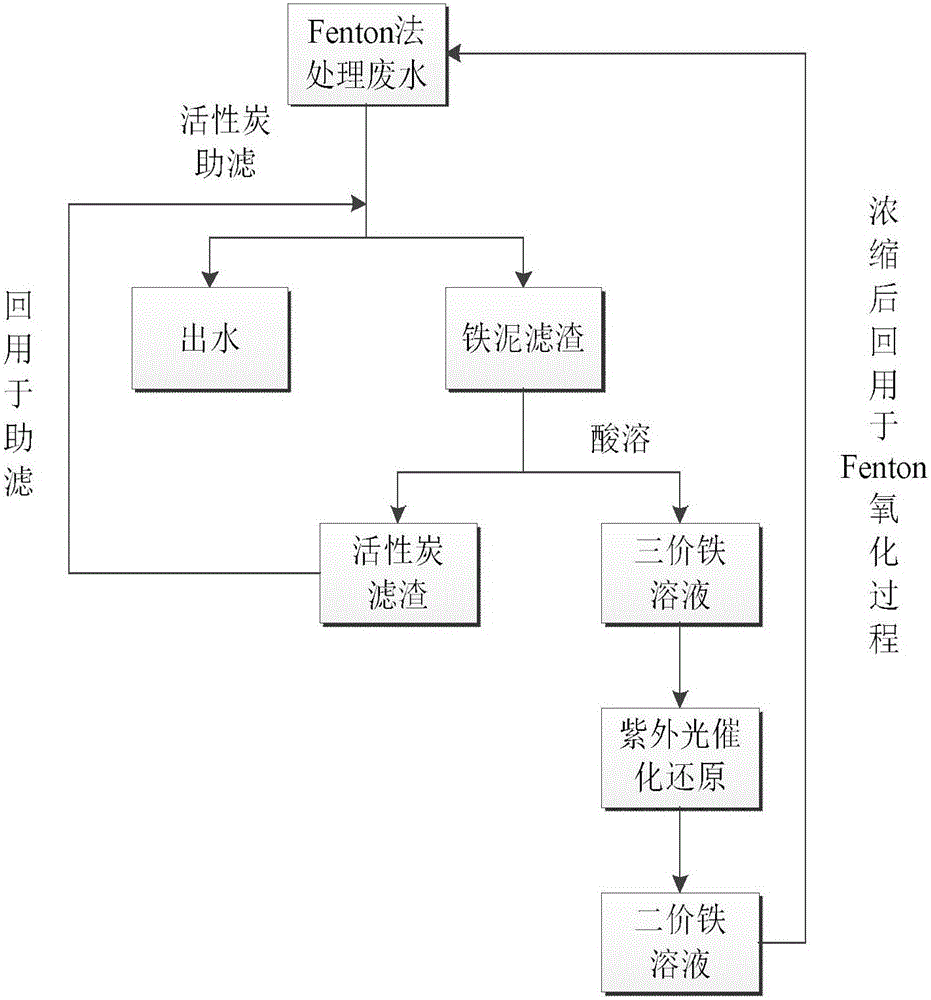

Method for recycling Fenton iron mud

ActiveCN105668759ATake advantage ofSolve secondary pollutionWater treatment compoundsWater/sewage treatment by oxidationActivated carbonMud systems

The invention discloses a method for recycling Fenton iron mud. The method for recycling the Fenton iron mud comprises the following steps: 1, treating wastewater by adopting a Fenton process, after reaction is finished, adding 0.05-1% activated carbon for adsorbing and aiding filtration, stirring and reacting for 0.5-1 h, filtering and separating to obtain water and iron mud filter residue; 2, adding sulphuric acid into the iron mud filter residue, stirring and dissolving for 0.5-2 hours at the temperature of 60-80 DEG C, filtering and separating to obtain a Fe<3+> solution and activated carbon filter residue; and 3, placing a solution containing Fe<3+> into an ultraviolet light reaction tank, wherein the reaction tank contains a supported semiconductor catalyst, reducing Fe<3+> in the solution into Fe<2+> under the ultraviolet light catalytic condition, concentrating a Fe<2+> solution and then reusing the concentrated Fe<2+> solution in a Fenton oxidation wastewater treatment process in the step 1, so that self circulation of an iron mud system is formed. The method for recycling the Fenton iron mud has the advantages that the problem that iron mud secondary pollution is produced by the Fenton oxidation process is solved, recycling of iron resources and activated carbon is realized, and wastewater treatment cost is reduced.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

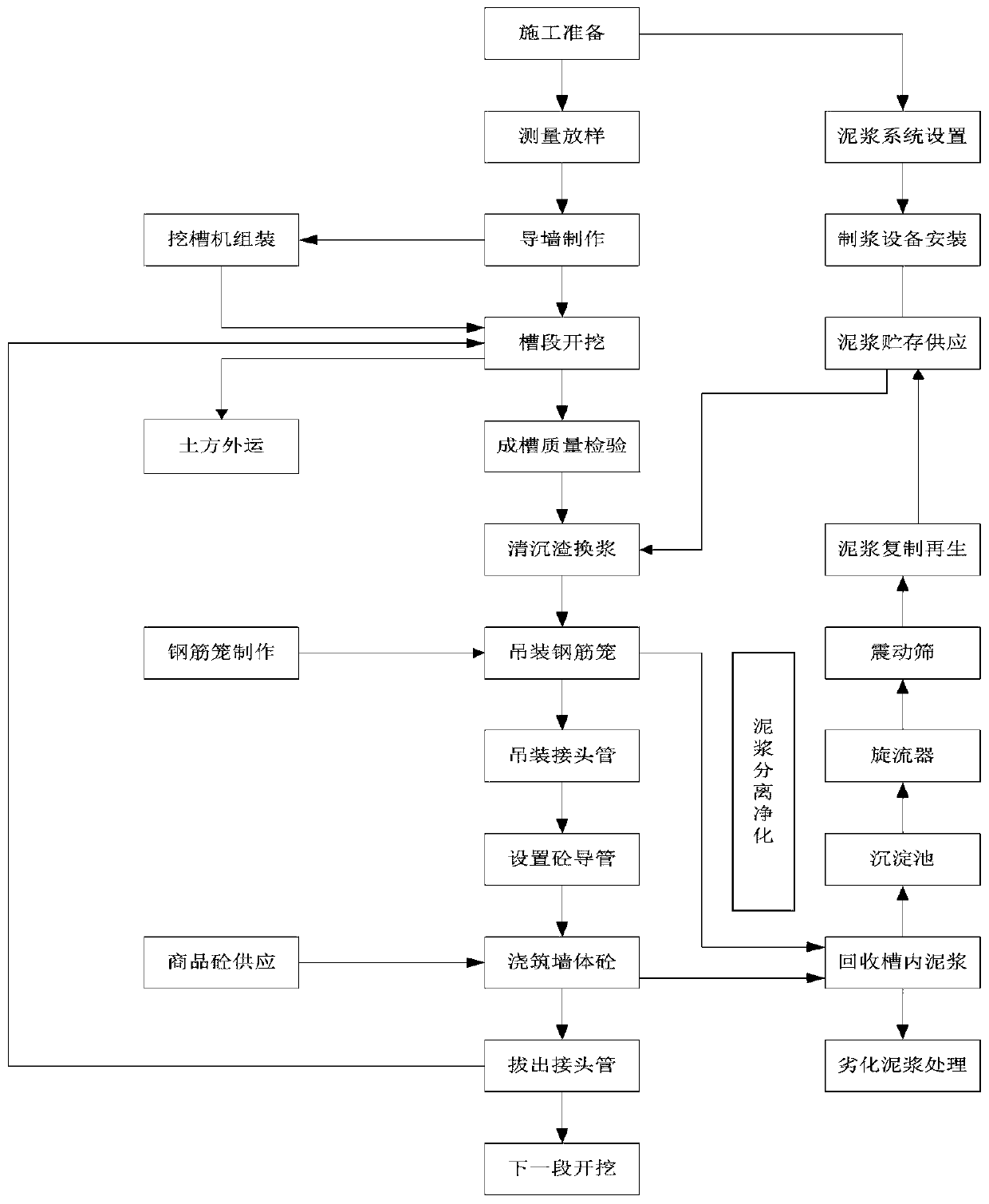

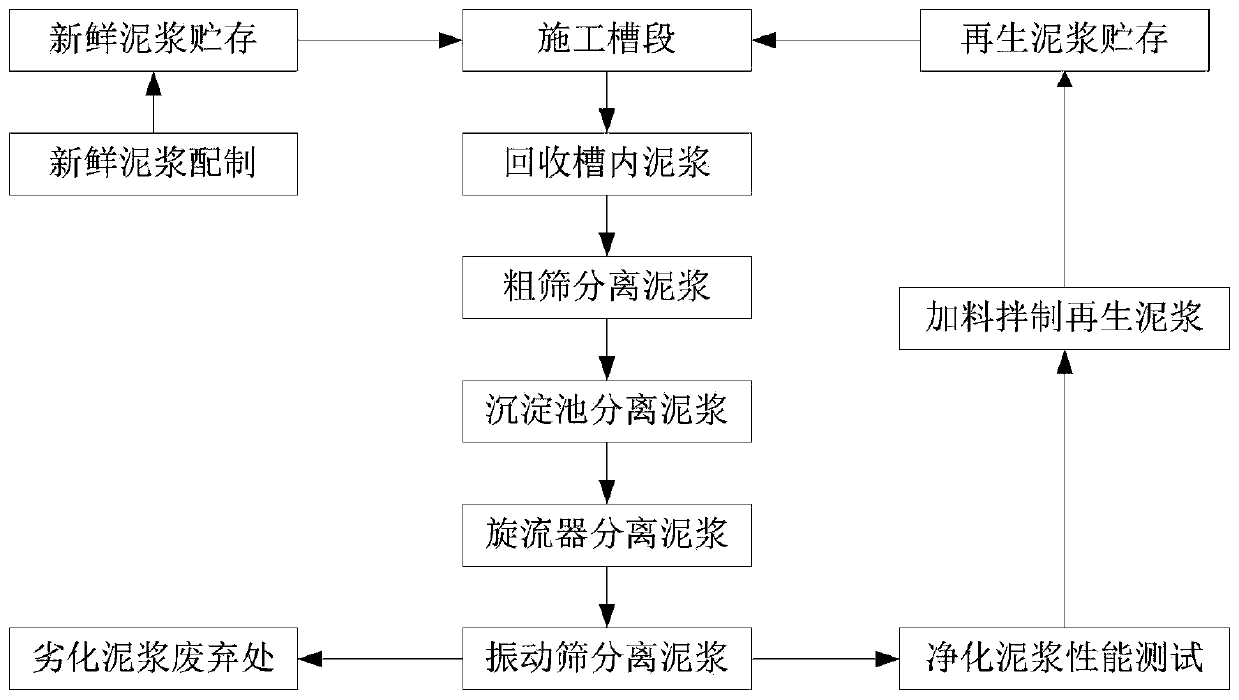

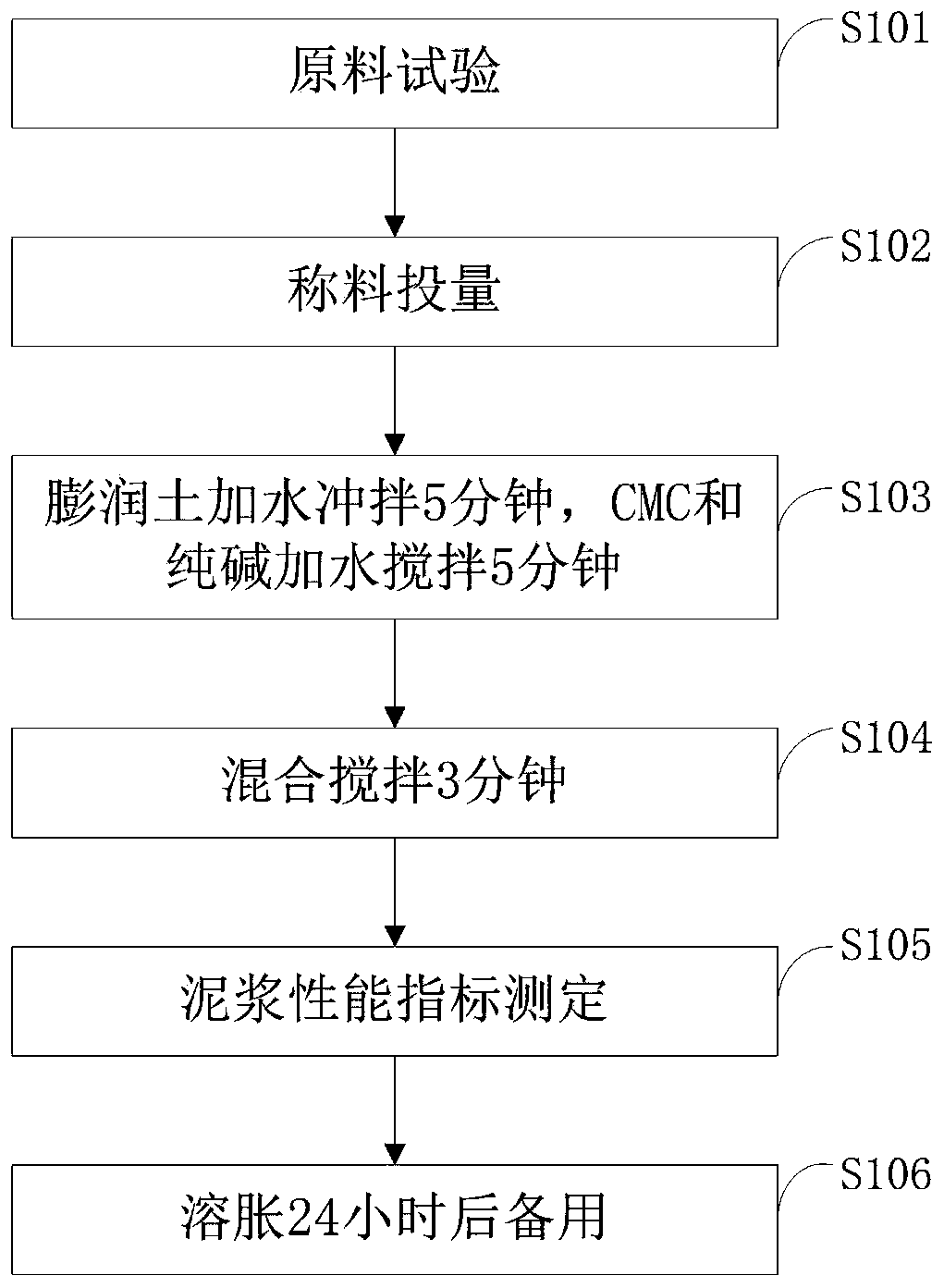

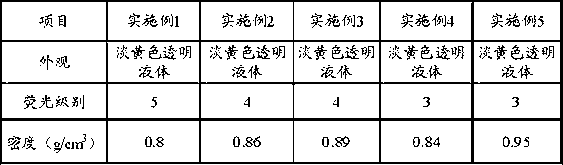

Construction method of underground diaphragm wall of railway transit engineering

InactiveCN109972609AConstruction method safetyApplicable construction methodExcavationsBulkheads/pilesMud systemsSlurry wall

The invention belongs to the technical field of underground engineering construction, and discloses a construction method of an underground diaphragm wall of railway transit engineering. The construction method of the underground diaphragm wall of the railway transit engineering specifically comprises the step: construction preparation, guide wall construction, mud system, channel section excavation, channel section examining, bottom clearing for mud replacing, wall brushing, reinforcement cage manufacturing, reinforcement cage hoisting, concrete pouring, joint treatment, embedded part arrangement and control protection measure, and wastewater and waste mud treatment. The method is safe, economical, applicable, reasonable, high in quality, efficient and advanced in technology; on the basisof sufficient field visit and traffic study, a construction scheme is reasonably compiled, thus is scientific and applicable, and considers factors such as economy of construction in particular, andthus the scheme is scientific, economical, applicable and safe; and based on normalized and standardized construction, the scientific and advanced construction method is selected preferentially, and the engineering quality and the construction period are guaranteed, and comprehensive, reliable and operable safety-ensuring measures are established.

Owner:SOUTHWEST FORESTRY UNIVERSITY

Method for removing hydrochloric ether contained in underground water and soil mud system through chemical reduction

InactiveCN103288200AEasy to operateGood processing effectWater contaminantsContaminated soil reclamationMud systemsEther

The invention relates to a method for removing hydrochloric ether contained in underground water and a soil mud system through chemical reduction, and belongs to the technical field of environmental management. The method mainly removes certain hydrochloric ether contaminants which exist in the underground water and the soil mud system through the reduction action of ZVI (Zero-Valent Iron). The method achieves the purpose of hydrochloric ether treatment by adding the zero-valent iron to the mud system which contains the hydrochloric ether contaminants in a treatment process. The method disclosed by the invention is simple, effective and outstanding in treatment effect. According to the invention, the zero-valent iron is rich in source, low in cost and higher in reducing capacity, and the hydrochloric ether can be fast dechlorinated and degraded and achieves high removal efficiency, for instance, the removal ratio of 1,1,1-trichloroethane can achieve 99.5%. The method disclosed by the invention can be used for simultaneously treating the hydrochloric ether contained in the underground water and the soil mud system and is less influenced by temperature and pH on reaction process and wide in application range.

Owner:EAST CHINA UNIV OF SCI & TECH

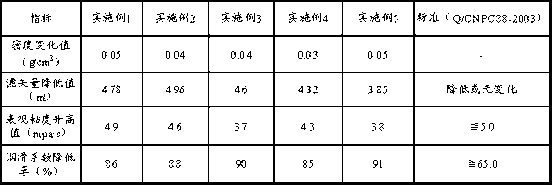

Low fluorescent lubricating agent for drilling fluid and method for preparing low fluorescent lubricating agent

ActiveCN103013464AImprove the lubrication effectReduce the lubrication coefficientDrilling compositionWater basedVegetable oil

The invention discloses a low fluorescent lubricating agent for drilling fluid and a method for preparing the low fluorescent lubricating agent. The low fluorescent lubricating agent is prepared from the following materials by weight percent: 30%-70% of swill-cooked dirty oil, 10%-30% of natural fatty acid, 10%-30% of vegetable oil, 1%-10% of oleic acid, 1%-3% of dodecylbenzene sulfonic acid and 1%-3% of polyvinyl alcohol. The method for preparing the low fluorescent lubricating agent comprises the following steps: accurately weighing the materials in a ratio, then putting the materials into a reactor, heating to 40-60 DEG C and stirring for 1-2hours at constant temperature. The method is simple in polymerization process and is suitable for industrial production; the low fluorescent lubricating agent for the drilling fluid is high in performance cost ratio, small in dosage and excellent in lubricating performance, is suitable for various water-base mud systems; and the low fluorescent lubricating agent is fluorescent-free and pollution-free, does not interfere geological logging work, dose not foam, dose not stick sieves, dose not influence other drilling fluid performances and dose not increase viscosity and water loss.

Owner:河北华运鸿业化工有限公司

High performance water-based mud system

A drilling fluid or mud additive having several components, including leonardite (humic acid); potassium acetate; partially hydrolyzed polyacrylamide (PHPA); polyanionic cellulose polymer (PAC); sulfonated asphalt; sulfoalkylated tannin; polystyrene maleic anhydride copolymer; micronized cellulose fiber; and calcium carbonate. These components are preferably premixed in a dry formulation as a powder or as pellets, and shipped to the site in bags or bulk tanks. This offers substantial advantages over the prior art in that the drilling mud of the present invention may be formed simply by adding the dry mix to a predetermined amount of water, and is thus much easier to make than the prior art wet mix drilling fluids, which typically require precise ratios of several different powders and liquids to be mixed together. Hydration buffers help keep the powder or pellets dry and flowable.

Owner:HAYES JAMES R

Grouting pile construction method for dry operation drilling and waterless pouring of concrete

ActiveCN104110028AReduce temporary land occupationReduce consumptionBulkheads/pilesMud systemsWater resources

The invention relates to a grouting pile construction method for dry operation drilling and waterless pouring of concrete. According to the method, hole drilling and cleaning are carried out in a rotary drilling dry operating method, and the concrete is poured through a waterless method. The operating steps of waterless pouring of the concrete include that when first batch of concrete is poured, the distance between a lower port of a conduit and the hole bottom ranges from 25 cm to 40 cm, and the depth, buried into the concrete, of the conduit is not less than 1 m; in the process of pouring the concrete, the buried depth of the conduit is controlled to be not less than 3 m; when the poured concrete is close to the top of a pile, the height of a funnel is increased so as to ensure that the elevation between the funnel and the top of the pile is not less than 4 m. By the adoption of the method, a mud system is completely omitted, consumption of mud raw materials and water resources is reduced, and the engineering construction cost is obviously lowered; moreover, the cost for transporting excavated muck is far lower than the cost for transporting and processing the mud, so considerable expenses for discharging and processing the mud are saved, the temporarily occupied land of the mud system is omitted, and the effect is obvious especially when construction is carried out on the condition that an urban site is narrow.

Owner:河北省水利工程局集团有限公司

Extending method of horizontal well safe density window

ActiveCN104712287AAvoid expansionImprove pressure bearing capacityDrill bitsFlushingMud systemsWell drilling

The invention relates to an extending method of a horizontal well safe density window particularly. The extending method comprises the steps that 1 1.5% of bentonite powder, 1% of saw dust, 1% of blocking agent and 1% of mica powder are added into 100 squares of drilling fluid gradually in a borehole with a standard of 83 / 8''according to a mass-volume percent; 2 the displacement of a drilling pump is lowered when the drilling pump enters a leakage layer; 3 when the leakage layer opens, the rate of penetration is controlled, solid control is strengthened at the same time, and harmful solids in the drilling fluid are removed; 4 the well deviation in an oil shale section is controlled; 5, the orientation of the borehole is conducted with a roller bit. According to the extending method of the horizontal well safe density window, blocking agents of different granularity are added gradually through a mud system, the leak-proofing formula is improved, the concentration of the blocking agent when added into the well is guaranteed to be at 3%, blocking is strengthened, and the strength of a leaking well wall is improved; the displacement of the drilling pump is lowered, the expansion of a crack is prevented, and the collapse pressure of the balance oil shale section is lowered, so that the safe density window is extended.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Drilling water based plugging agent and using method thereof

InactiveCN107603574ADehydration fastHigh fluid lossDrilling compositionSealing/packingWater basedSolubility

Owner:成都瑞吉星化工有限责任公司

Drilling fluid filtrate reducer and preparation method thereof

The invention relates to drilling fluid filtrate reducer.The drilling fluid filtrate reducer comprises, by weight, 10-32 parts of a natural or modified mixture, 2-15 parts of organic amine, 2-5 parts of additives and 32-80 parts of solvent.The invention further discloses a preparation method of the drilling fluid filtrate reducer.Compared with the prior art, the drilling fluid filtrate reducer can form thermostable emulsion with emulsifier under the condition that a small amount of the organic amine, the natural or modified mixture and the additives are added, temperature resistance reaches 200-230 DEG C, good dispersive capacity is achieved in oil, meanwhile, certain functions of dilution, viscosity reduction, emulsification assisting and the like are achieved, a mud system can have a good rheological property, the addition amount is small, harm to the environment is small, and in addition, the drilling fluid filtrate reducer can resist to high temperature.

Owner:WEIFANG TIANFU CHEM TECH

Lignosulfonate grafts with an acid, ester and non-ionic monomers

InactiveUS20130274150A1Improve propertiesImprove temperature stabilityOrganic detergent compounding agentsOrganic/inorganic per-compounds compounding agentsWater basedMud systems

The present invention generally relates to controlling the viscosity of water-based mud systems. More particularly, the present invention relates to methods and compositions for thinning and deflocculating aqueous based fluids used in well drilling and other well operations in subterranean formations, especially subterranean formations containing oil and / or gas. The invention also relates to a drilling fluid thinner and / or dispersant having improved temperature stability, dispersing properties and “solids contamination” tolerance.

Owner:AKZO NOBEL CHEM INT BV

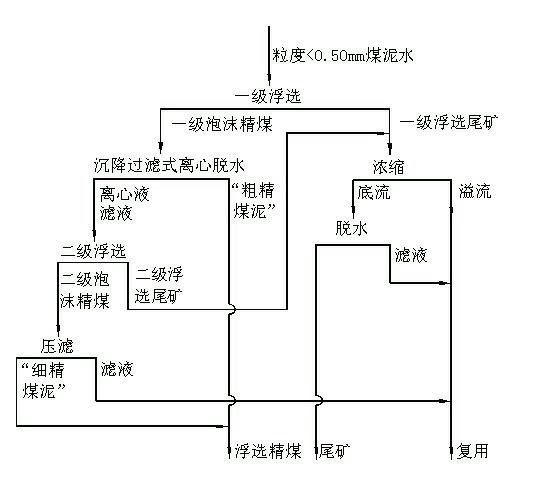

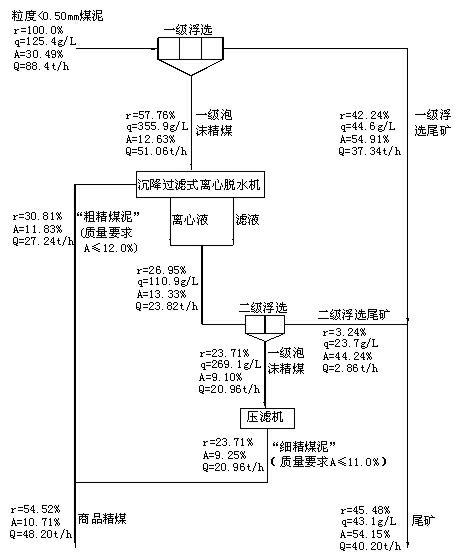

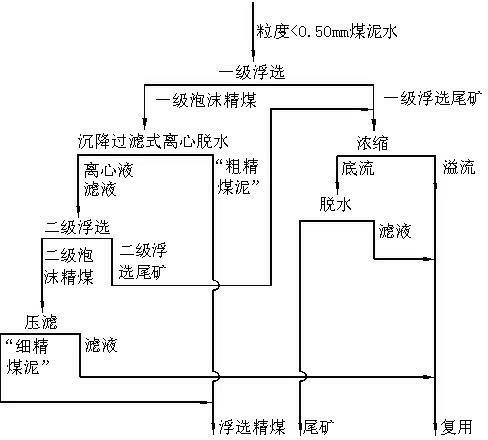

Two-stage flotation process of coal slime with particle size less than 0.5mm

InactiveCN102274786AEliminate the ills of the vicious circleLow ashWet separationMud systemsFiltration

A two-stage flotation process for coal slime with a particle size of less than 0.5mm, the steps are: the coal slime with a particle size of less than 0.5mm enters the first-stage flotation, and its tailings enter the tailings treatment process; the foamed clean coal of the first-stage flotation is passed through After dehydration by the sedimentation filter centrifuge, the coarse fine coal slime with a particle size greater than 0.045mm is recovered; the centrate and filtrate after dehydration by the sedimentation filter centrifuge enter the secondary flotation, and the tailings of the secondary flotation are collected through the pipeline. into the tailings of the first-stage flotation for treatment together; the foamed clean coal of the second-stage flotation is dehydrated by a filter press with thorough solid-liquid separation, and the fine coal slime with a particle size of less than 0.045mm is recovered, and the filtrate is reused ; The fine fine coal slime and the coarse fine coal slime are used as flotation clean coal to enter the commercial clean coal. The invention reduces the ash and moisture of the flotation clean coal, improves the yield, and especially overcomes the disadvantage of the vicious cycle of high ash fine mud in the foam product in the system.

Owner:唐山国华科技国际工程有限公司

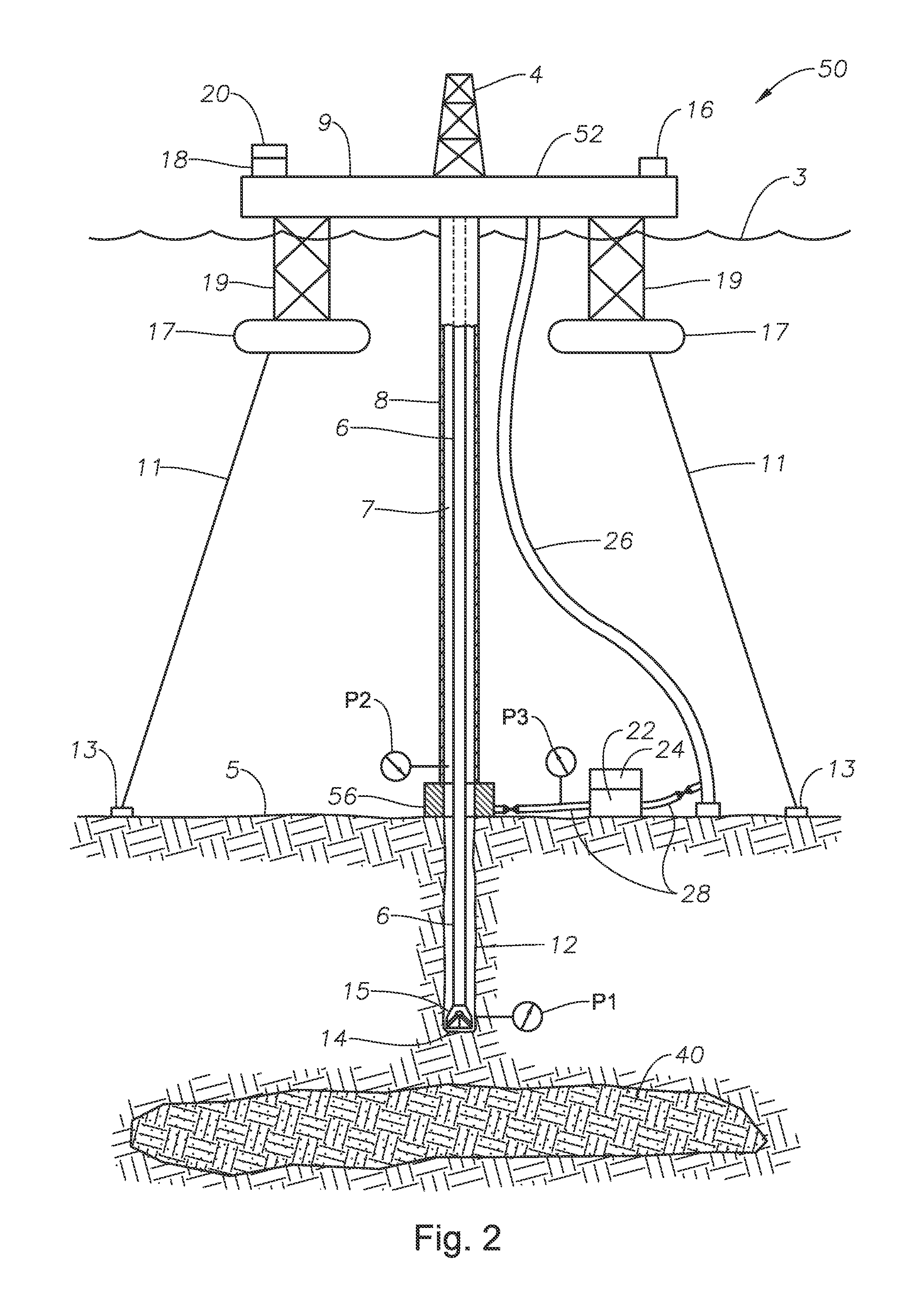

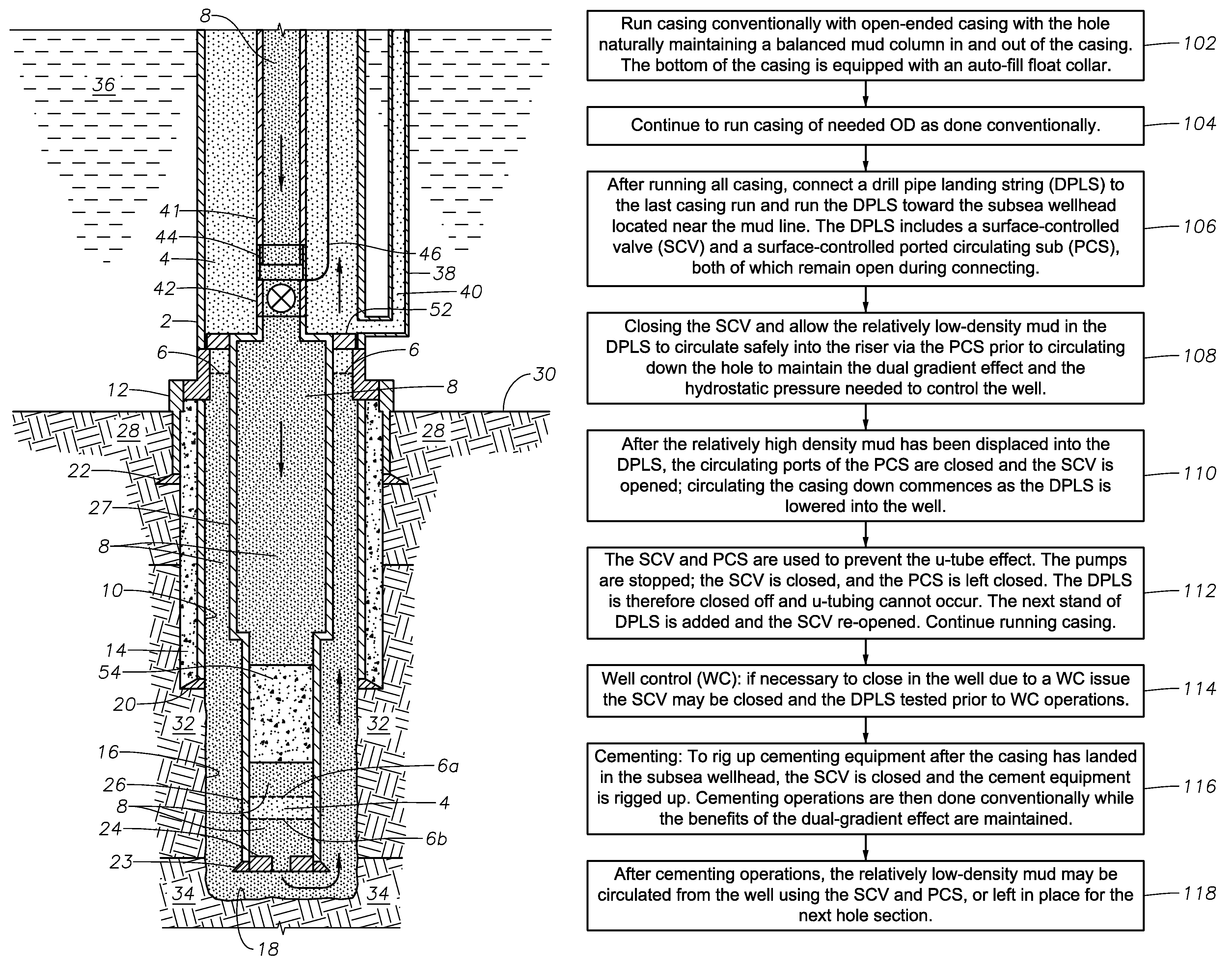

Systems and methods for running casing into wells drilled with dual-gradient mud systems

Systems and methods for running and cementing casing into wells drilled with dual-gradient mud systems include running casing through a subsea wellhead connected to a marine riser, the casing having an auto-fill float collar, and connecting a landing string to the last casing run. The landing string includes a surface-controlled valve (SCV) and a surface-controlled ported circulating sub (PCS). The SCV and PCS are manipulated as needed when running casing, washing it down while preventing u-tubing on connections and prior to cementing to displace mixed density mud from the landing string and replace it with heavy-density mud prior to circulating below the mudline thus maintaining the dual gradient effect.

Owner:BP CORP NORTH AMERICA INC

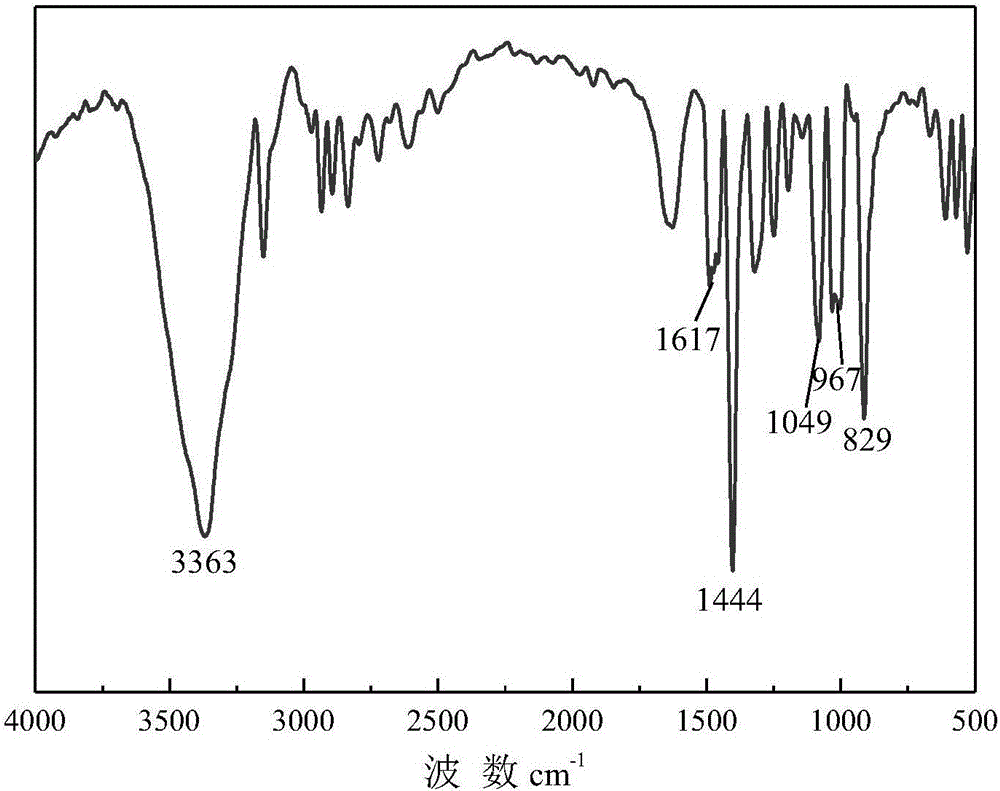

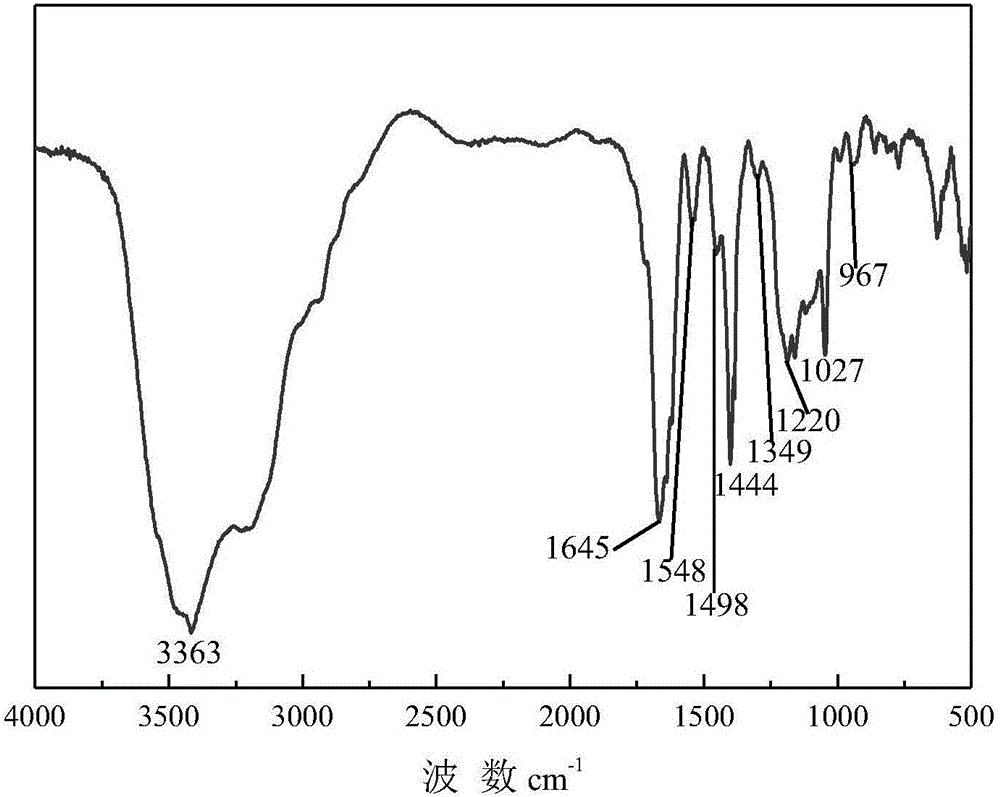

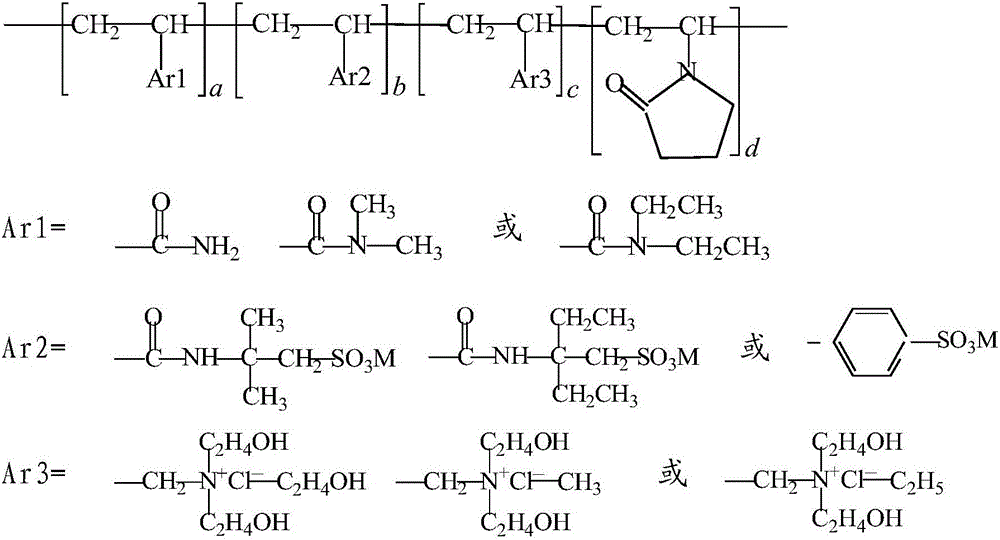

Temperature-resistant and salt-tolerant polymeric filtrate loss reducer for water-based drilling fluid and method for preparing temperature-resistant and salt-tolerant polymeric filtrate loss reducer

InactiveCN106046251AImprove temperature resistanceStrong resistance to salt and calciumDrilling compositionWater basedMud systems

The invention relates to a temperature-resistant and salt-tolerant polymeric filtrate loss reducer for water-based drilling fluid and a method for preparing the temperature-resistant and salt-tolerant polymeric filtrate loss reducer. The method includes copolymerizing monomers of alkenyl amide, alkenyl propanesulfonic acid, alkenyl ammonium chloride and vinyl pyrrolidone by the aid of free radical solution polymerization processes according to certain proportions to obtain the temperature-resistant and salt-tolerant polymeric filtrate loss reducer. The relative molecular mass of copolymers is 100-300 thousands. The temperature-resistant and salt-tolerant polymeric filtrate loss reducer and the method have the advantages that the temperature-resistant and salt-tolerant polymeric filtrate loss reducer is high in temperature resistance (the temperature-resistant and salt-tolerant polymeric filtrate loss reducer can resist temperatures of 220 DEG C) and is still excellent in filtrate loss reducing performance in high-salinity environments, and basic mud systems are good in rheological property after the temperature-resistant and salt-tolerant polymeric filtrate loss reducer is added into the basic mud systems; high-temperature thickening can be prevented, accordingly, requirements of current deep drilling operation can be met, the method is simple and is high in yield, and conditions are mild.

Owner:SOUTHWEST PETROLEUM UNIV

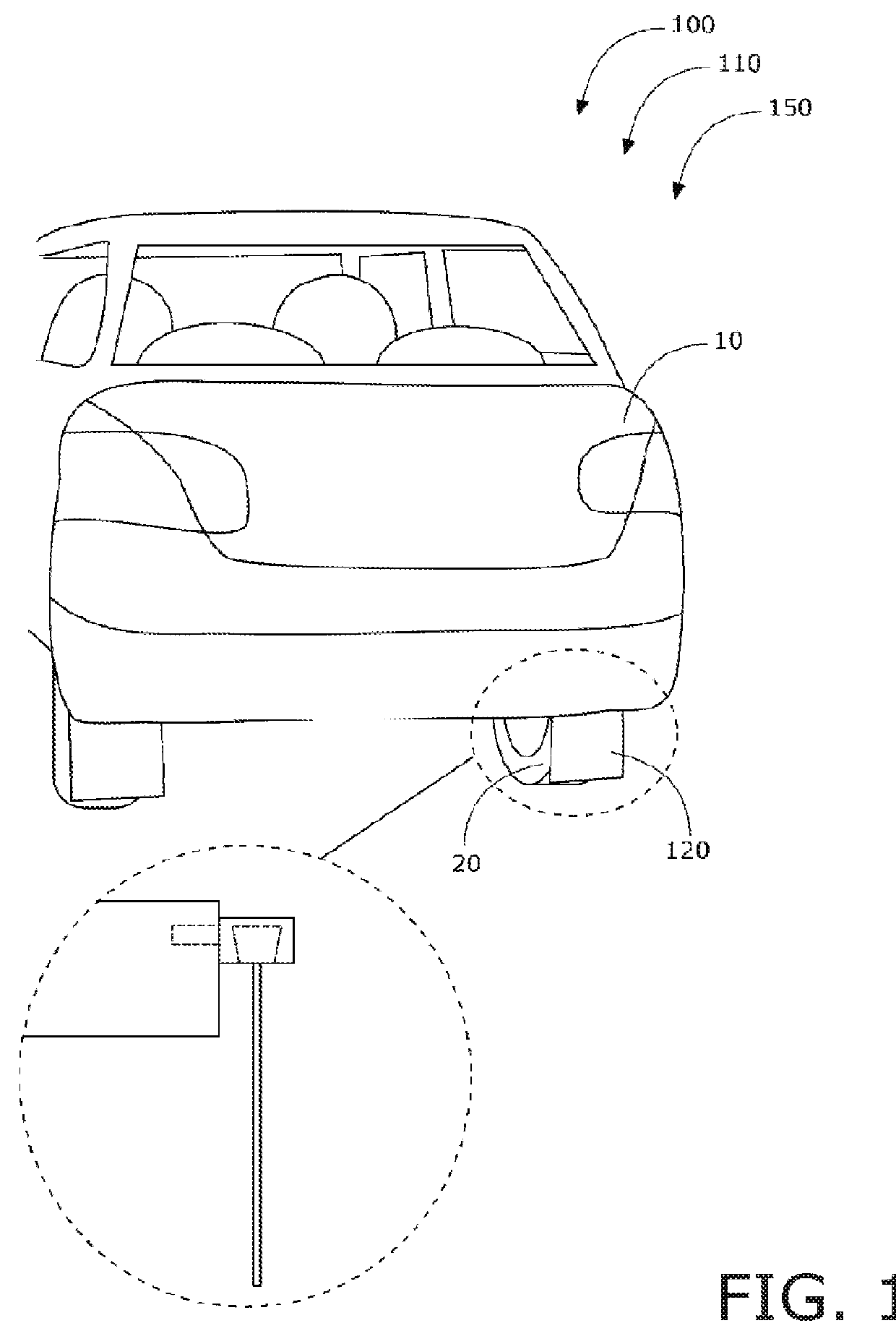

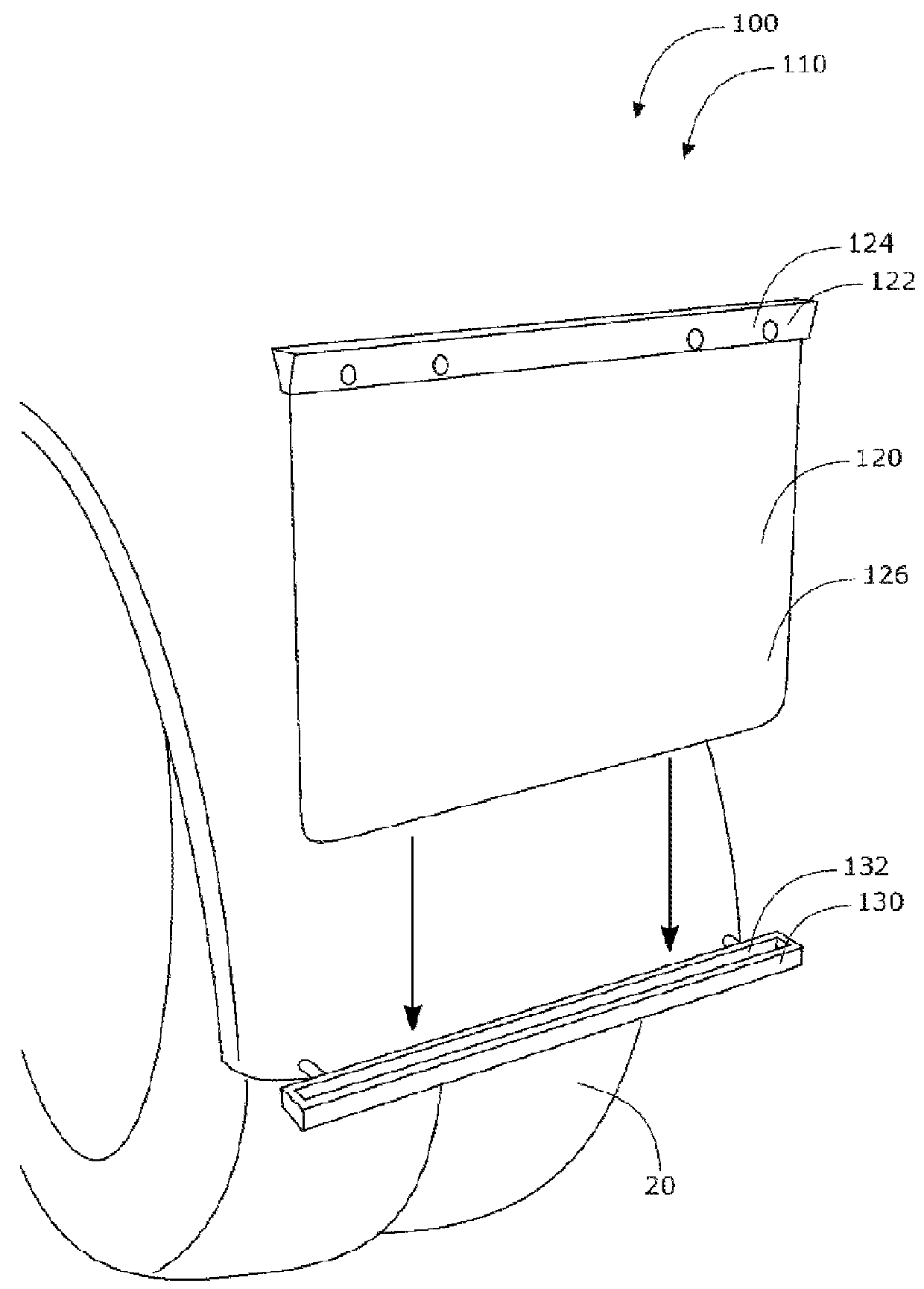

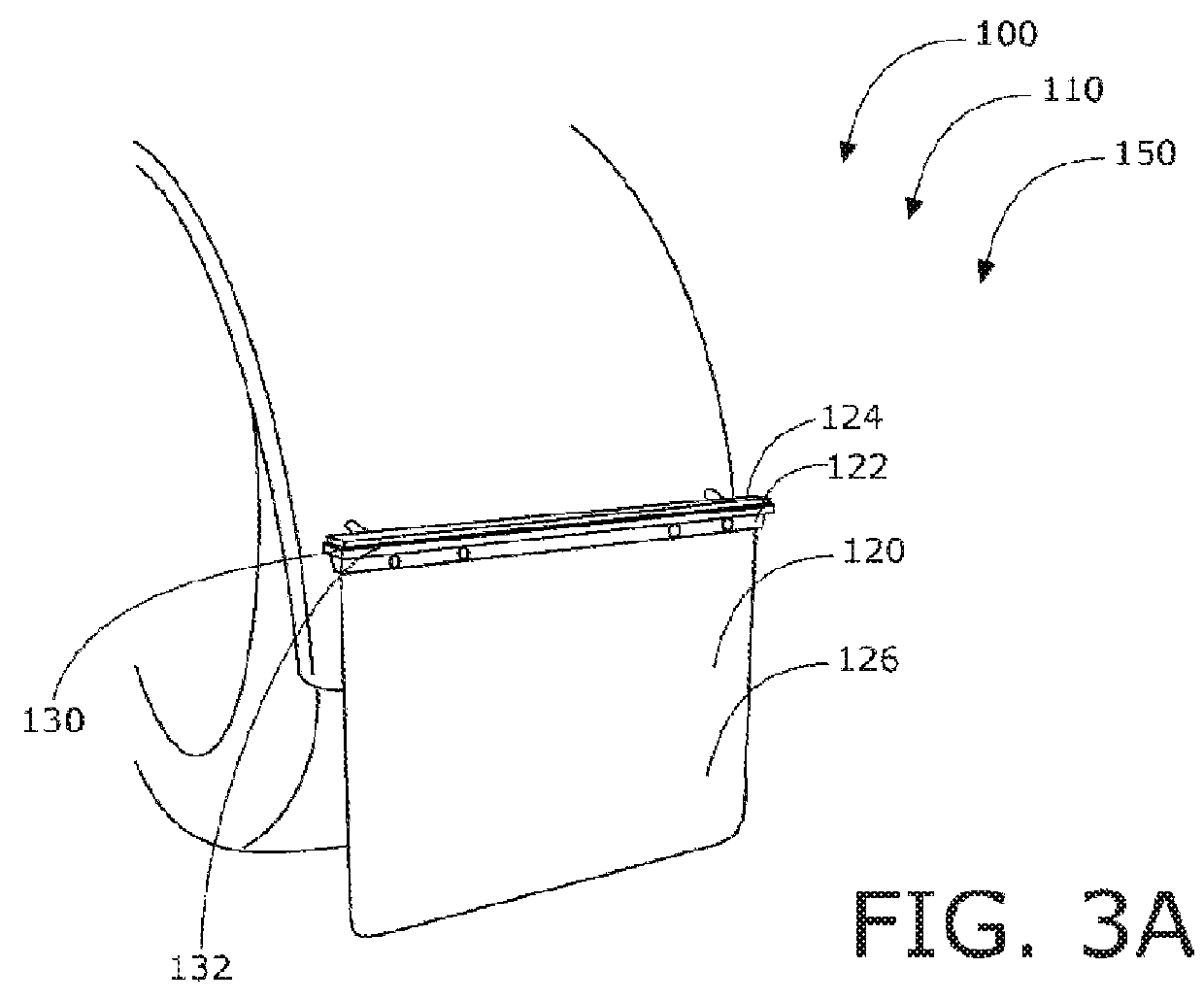

Mud flap systems

InactiveUS9963174B1The process is convenient and fastIncreasing the thicknessSuperstructure subunitsMud systemsEngineering

A mud flap system provides a quick and convenient way to install and reinstall mud flaps. It includes a mud flap with a wedged top that slides into a lockable mud flap mount. It pulls away from the mount if hit with enough force before the mount bends or breaks. This eliminates the need for tools and complicated instructions to replace damaged mud flaps.

Owner:COOPER WILLIAM M

Argillaceous sandstone geological pipe jacking construction process

ActiveCN110864162AGive full play to the effect of drag reductionIncrease the number of openingsPipe laying and repairMud systemsSlurry

The invention discloses an argillaceous sandstone geological pipe jacking construction process. The process comprises the following steps of adopting a thixotropic slurry system to inject thixotropicslurry circumferentially into a concrete pipe, specifically, the concrete pipe comprises a plurality of pipe joints, slurry sleeves are arranged on the pipe joints at the head, slurry sleeves are arranged on the pipe joints in the middle at intervals, grouting holes are distributed in the slurry sleeves in the circumferential direction, and the thixotropic slurry system comprises a grouting pump and a grouting pipeline; mixing grouting materials with water and then stirring to obtain the required slurry during mixing the slurry, and using the slurry after standing for 24 hours; and grouting with the grouting pump, using a pressure gauge and a flow gauge to control the grouting pressure to be 1.1-1.2 times the water depth in the grouting process, and simultaneously controlling the groutingquantity, wherein the grouting pipeline comprises a main pipe and a plurality of branch pipes connected with the main pipe, and the branch pipes convey the slurry fed by the pressure in the main pipeto each grouting hole. Besides the slurry sleeves at the head of a tool for pressure feeding of slurry, the slurry sleeves are additionally arranged on the middle pipe joints, so that a slurry supporting ring belt around the pipe is formed through the slurry sleeves.

Owner:国网浙江省电力有限公司宁波市镇海区供电公司 +1

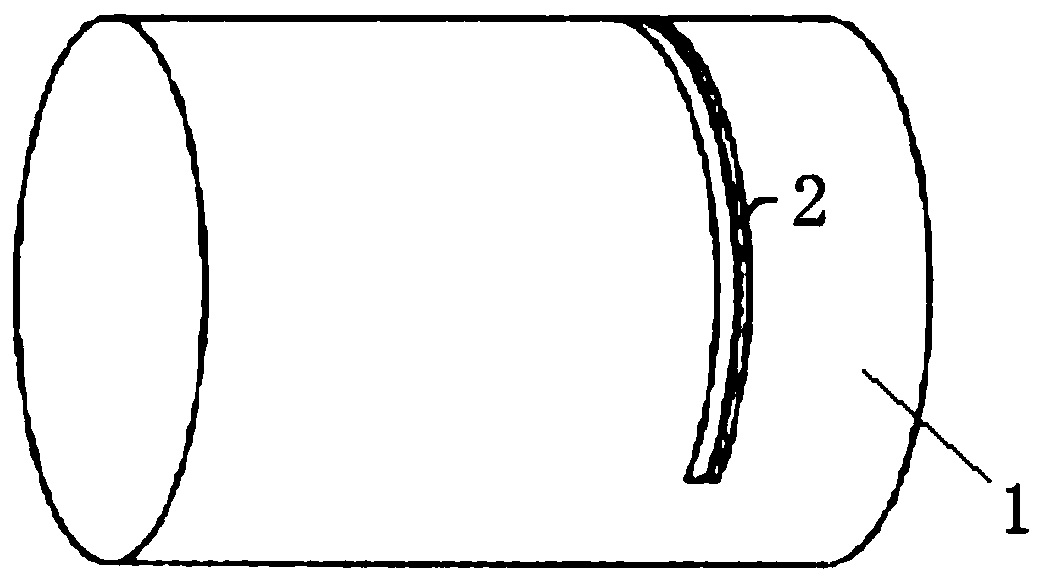

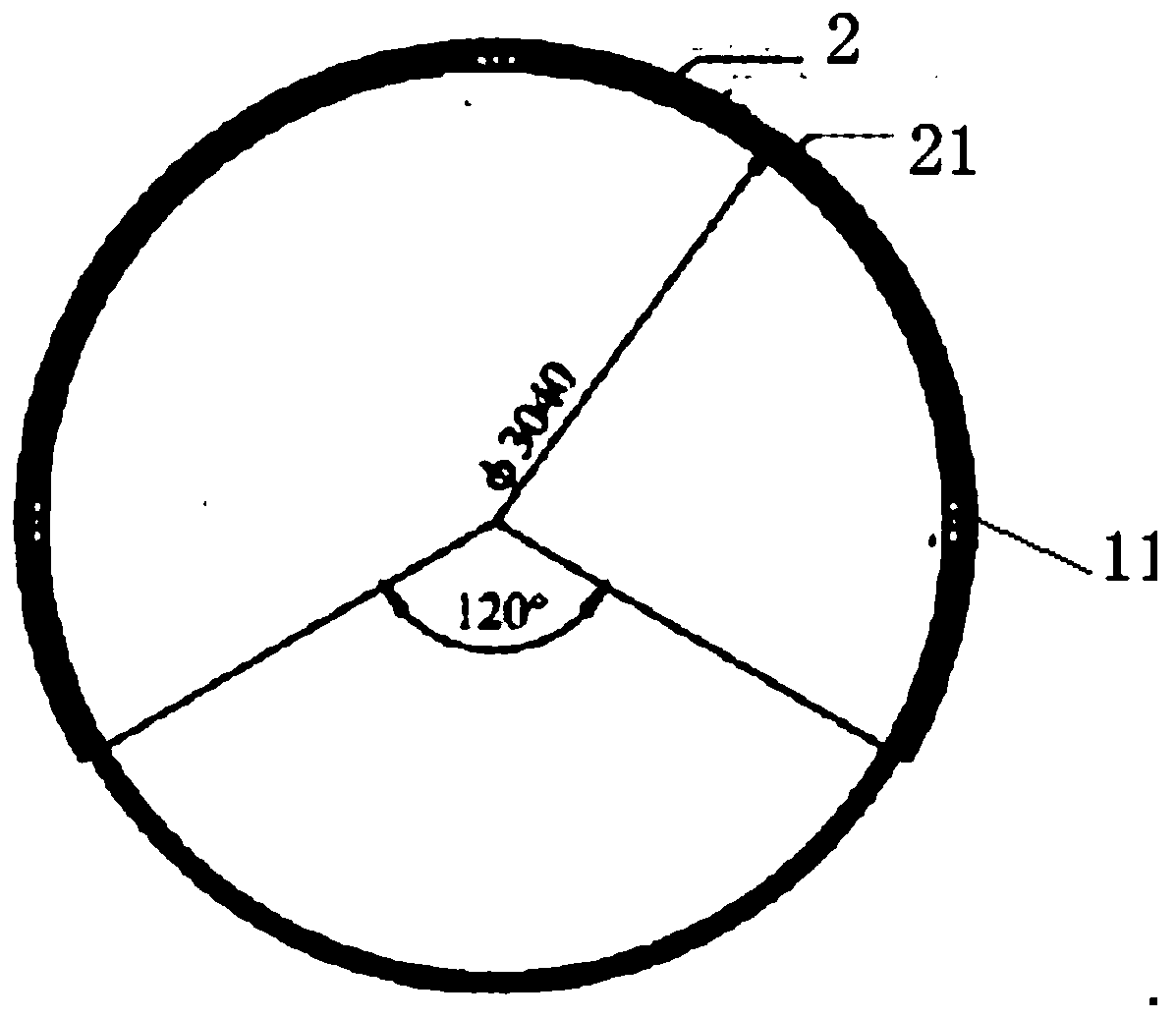

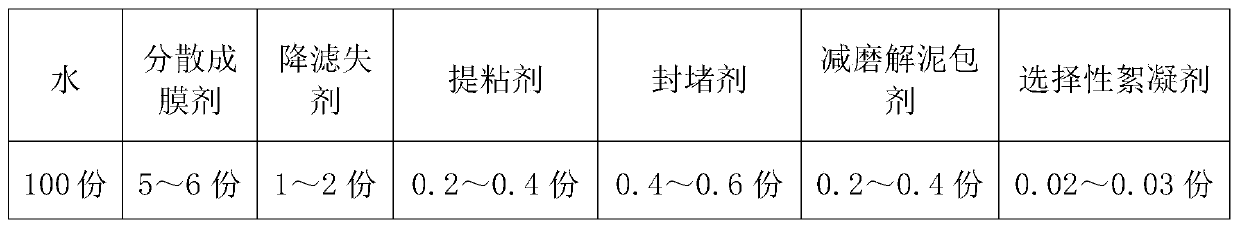

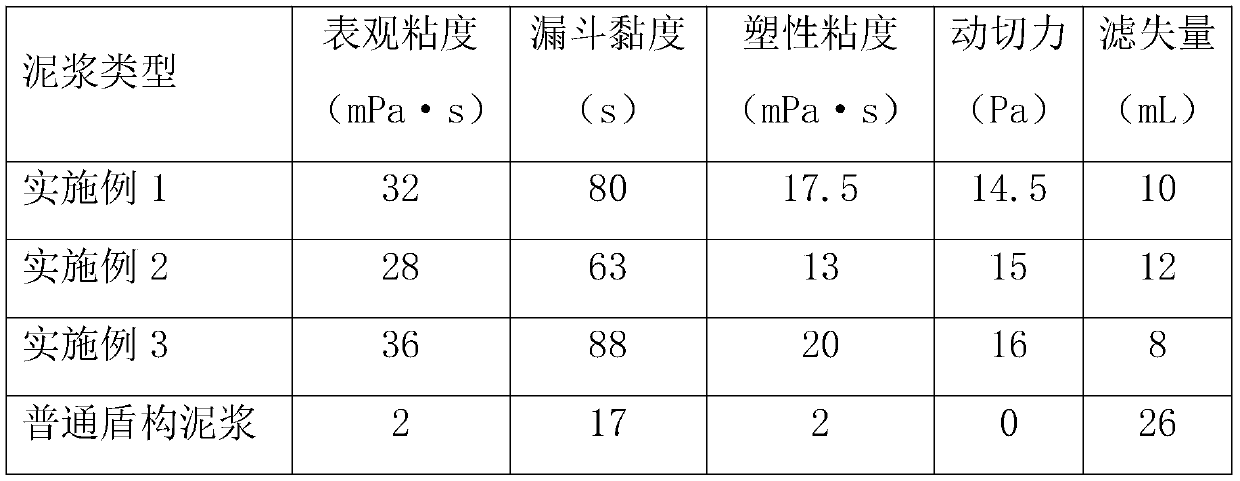

Shield mud system applicable to extra-large-diameter tunnel and preparation method

InactiveCN109762534AImprove recycling ratesQuality improvementDrilling compositionMud systemsFiltration

The invention provides a shield mud system applicable to an extra-large-diameter tunnel. The shield mud system is prepared from the following raw materials in parts by mass: 100 parts of water, 5 to 6parts of a dispersion film-forming agent, 1 to 2 parts of a filtration-reducing agent, 0.2 to 0.4 part of a viscosity improving agent, 0.4 to 0.6 part of a plugging agent, 0.2 to 0.4 part of an anti-wear and mud ball splitting agent and 0.02 to 0.03 part of a selective flocculating agent. The shield mud system provided by the invention has the beneficial effects that the shield mud system has unique 'lubrication and anti-wear performance' and has the effects of protecting a shield bit tool and improving the footage drilling efficiency; a dense mud film can be formed, the filtration loss amount is reduced and the soil pressure is balanced, so that the stability of a well wall is enhanced, the sticking coefficient can be reduced and a mud ball of the shield bit tool is prevented; and the shield mud system has good rheological performance, filtration-reducing performance and lubricating performance and can meet the requirements of shield mud drilling, and has the advantages of environment protection and low cost.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Inhibitive water-based drilling fluid system and method for drilling sands and other water-sensitive formations

ActiveUS7439210B2Enhanced shale stabilizing propertiesImprove performanceFlushingDrilling compositionMud systemsWater based

Owner:HALLIBURTON ENERGY SERVICES INC

Inhibitive water-based drilling fluid system and method for drilling sands and other water-sensitive formations

ActiveUS20050239663A1Improve performanceReduce hydrationFlushingDrilling compositionMud systemsWater based

An inhibitive water-based polymer mud system and method for using the system in drilling and in stabilizing wellbores is disclosed for use in water sensitive formations as an alternative to oil-based muds. The system comprises a non-ionic low molecular weight polyacrylamide in combination with a non-ionic high molecular weight polyacrylamide, preferably long chain alcohol and poly anionic cellulose.

Owner:HALLIBURTON ENERGY SERVICES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com