Grouting pile construction method for dry operation drilling and waterless pouring of concrete

A technology of pouring concrete and construction method, which is applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of high risk of under-hole operation, increased labor cost, difficulty, etc., and achieves improved construction quality, fast acceptance speed, The effect of fast infusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

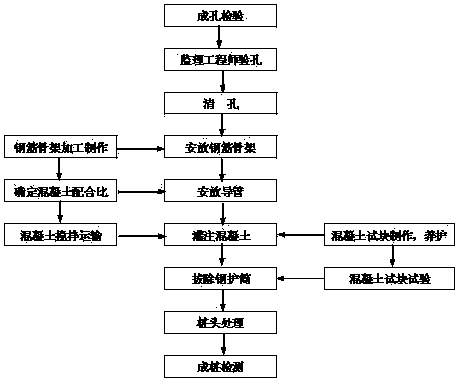

[0034] Example 1 Construction of cast-in-place piles for the Qinglan Aqueduct in the Handan section of the main canal of the middle route of the South-to-North Water Diversion Project, combined with figure 1 The inventive method is described in detail:

[0035] (1) Geological survey and confirmation of pile locations: the conventional method completes the survey work before laying the casing and confirms the pile locations

[0036] The geological overburden that the pile passes through is mainly multi-layer structures such as artificial fill, clay rock, argillaceous siltstone, fine sand, and silt. Mainly clay rock. The thickness of a single layer of clay rock is generally 5m-20m, the thickness of a single layer of argillaceous siltstone is 0.5m-6.1m, and the thickness of a single layer of silt-fine sand (locally medium sand) is 1.1m-7.3m.

[0037] There is no surface water in the site. The site is located in the funnel area of Handan City. The buried depth of groundwater ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com