Rubber waterstop and foam board fixing device for box culvert continuous placement and using method thereof

A technology of rubber waterstop and fixing device, which is applied in protection devices, construction, water conservancy projects, etc., can solve the problems of reducing amortization costs, labor and time-consuming, and excessive mold removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

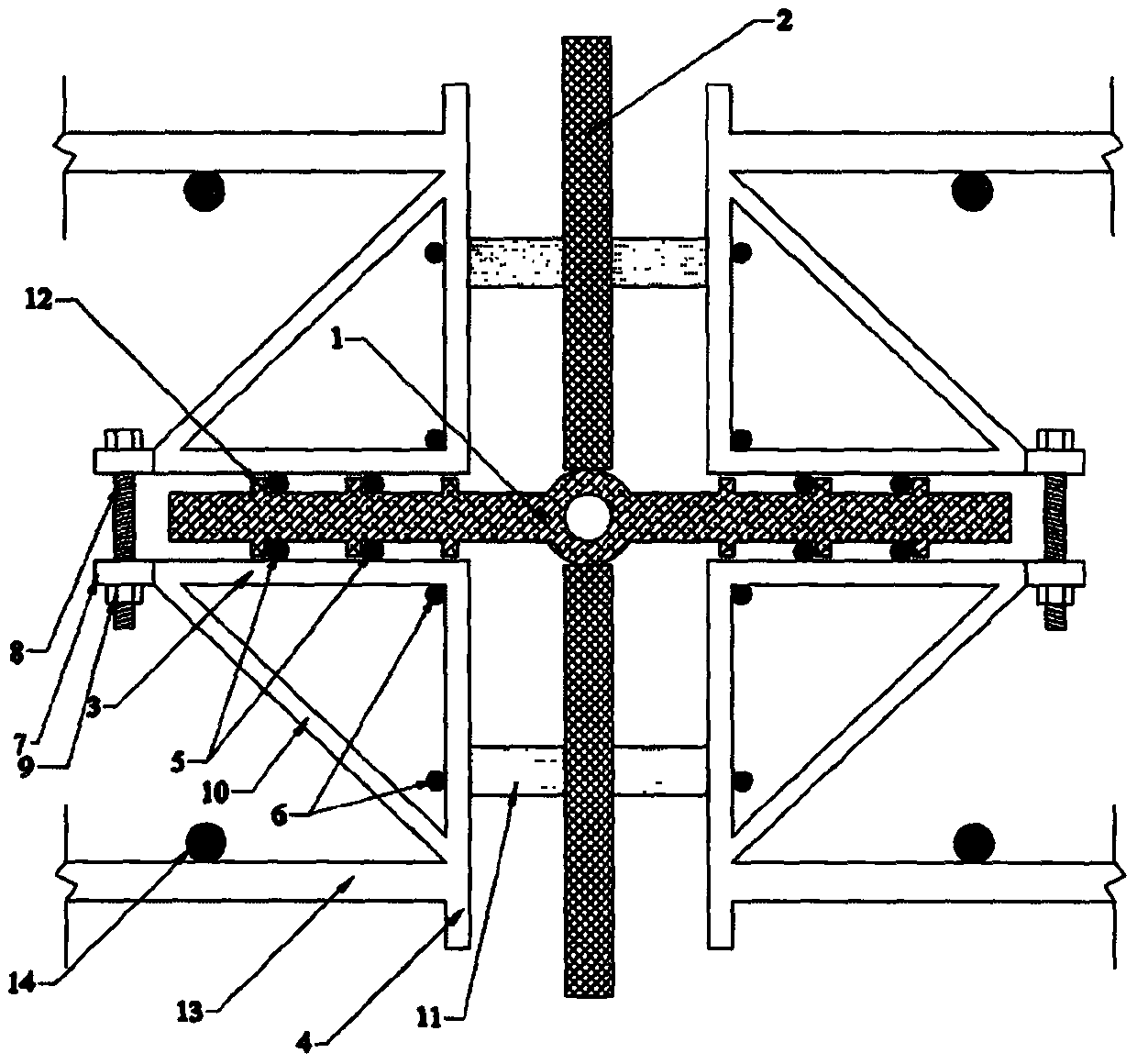

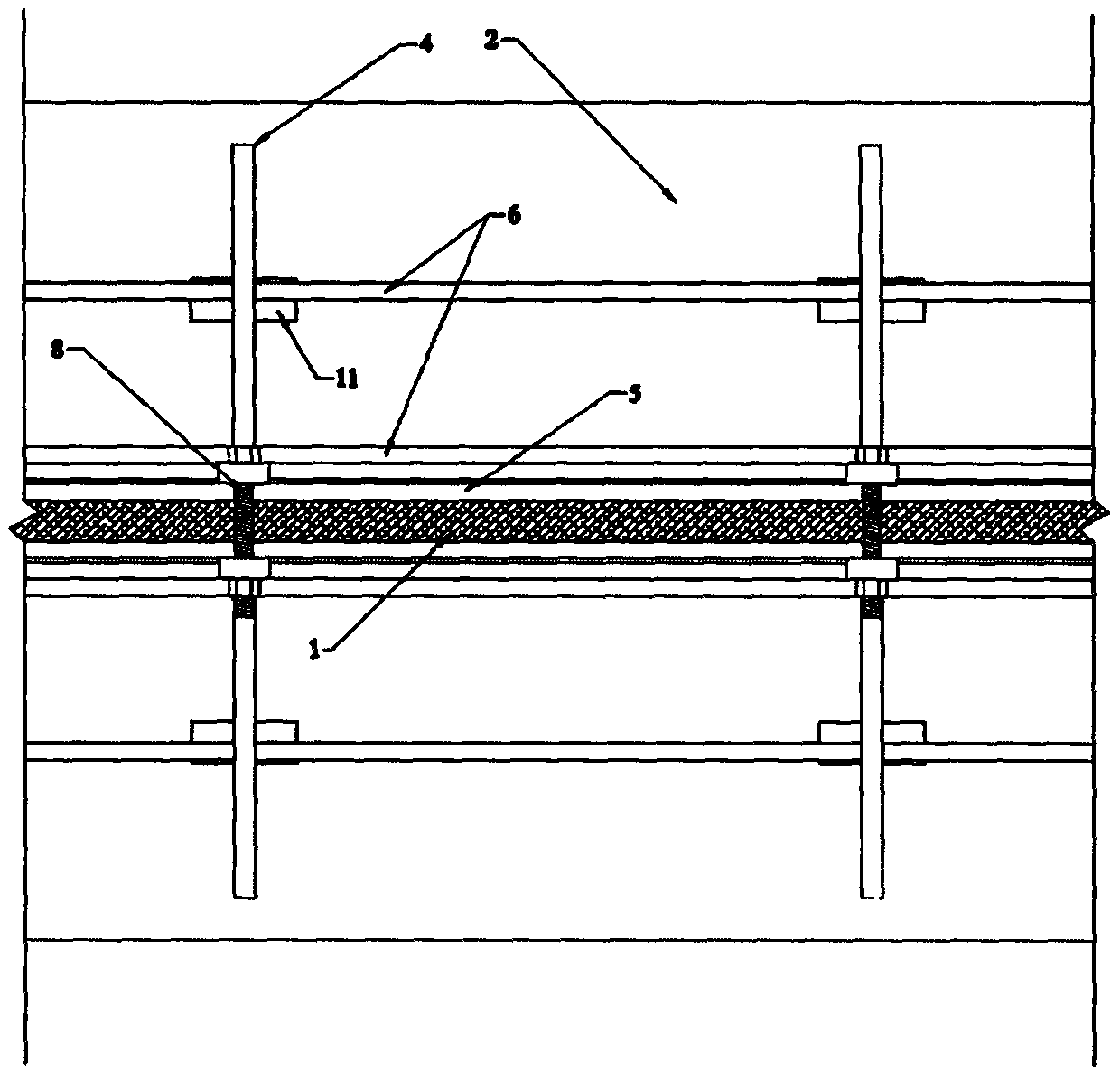

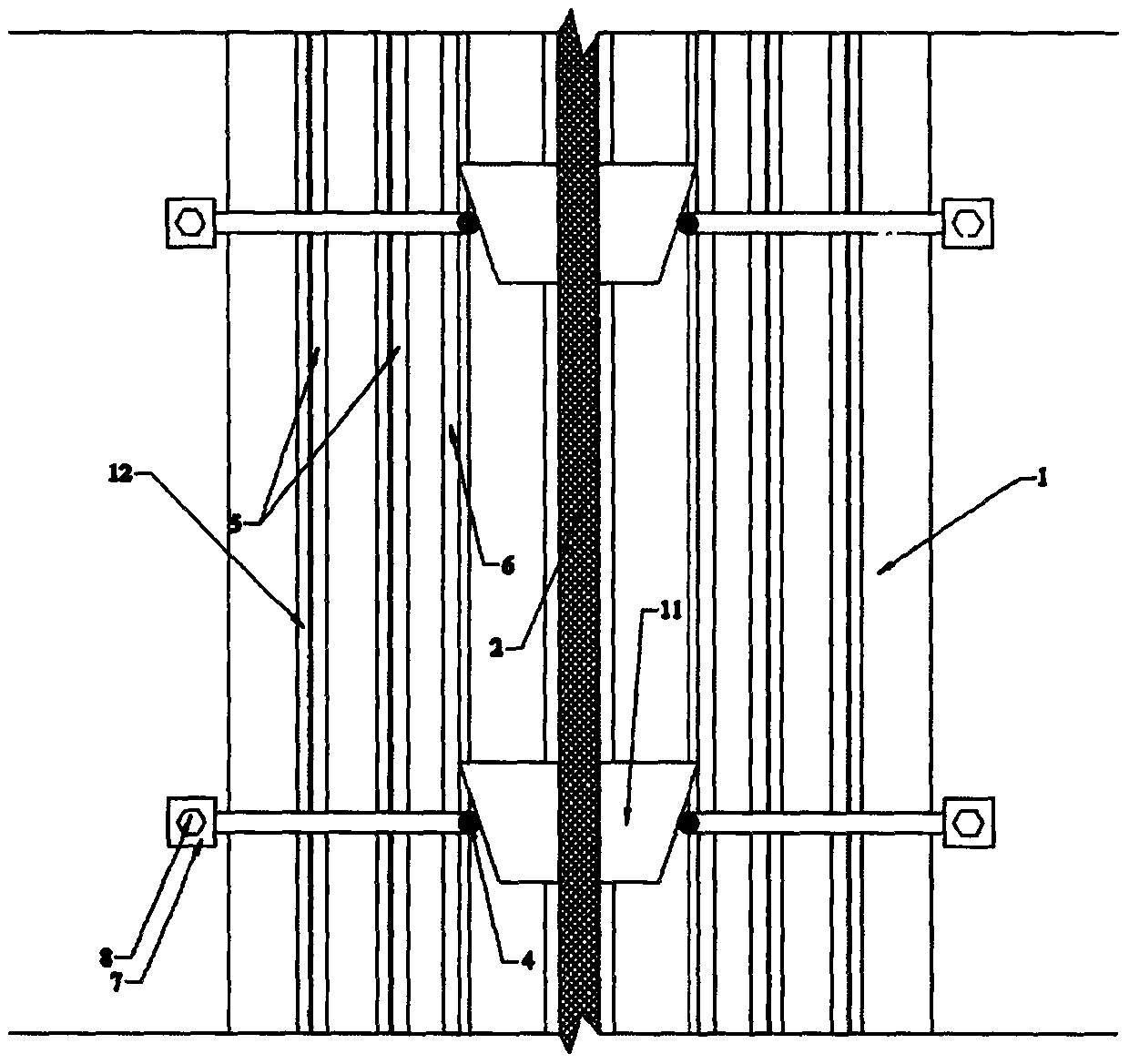

[0026] Example 1: A box culvert adopts a mid-buried rubber waterstop with a width of 350mm and a thickness of 20mm. There are two anti-skid protrusions on the outside, which are 50mm and 90mm from the edge respectively; the wall thickness of the box culvert is 400mm, and the vertical foam board direction box The culvert distributed rib spacing is 150mm, the design protective layer thickness is 40mm, and the expansion joint width is 20mm. The steel bar brackets all use smooth round steel bars with a diameter of 10mm, and the diameter of the screw rod is 10mm.

[0027] Then the relevant dimensions of the reinforcement support can be determined: the length of the fixed rib 3 of the water stop belt is 130mm, the length of the fixed rib 4 of the foam plate is 150mm, the distance between the two rubber waterproof and anti-slip distribution ribs 5 is 30mm and 70mm respectively, and the distance between the welding ends of the two fixed ribs is 30mm and 70mm respectively, and the steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com