Patents

Literature

35results about How to "Uniform reflow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-cycle composite bioreactor and process thereof

ActiveCN103951059AIncrease concentrationReduce outputTreatment with aerobic and anaerobic processesSludgeControl manner

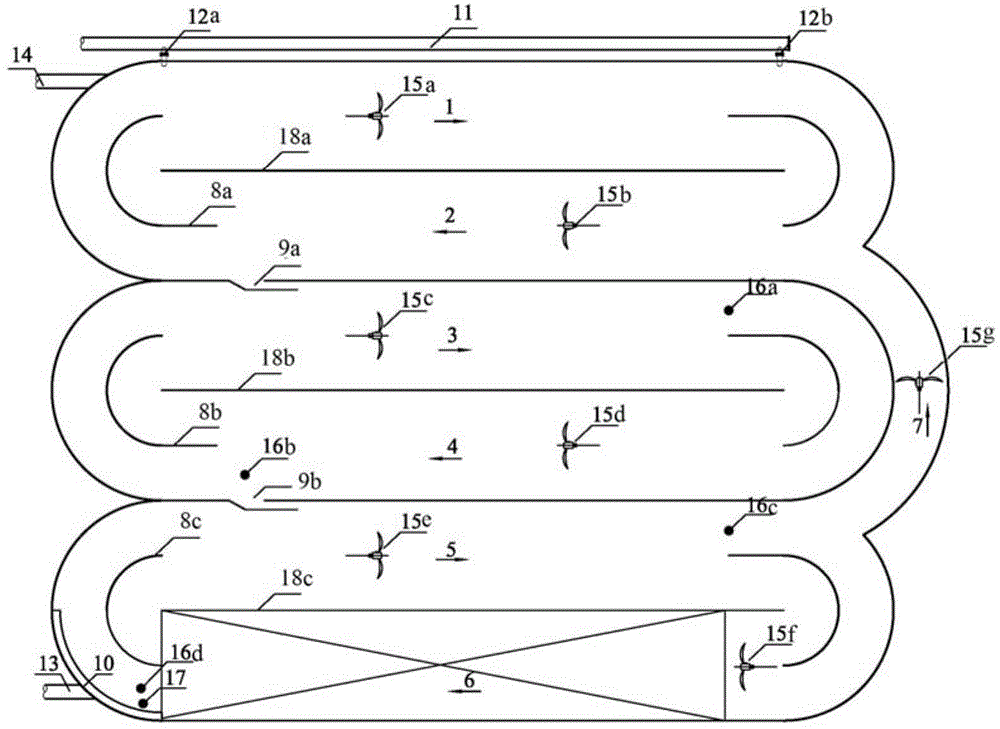

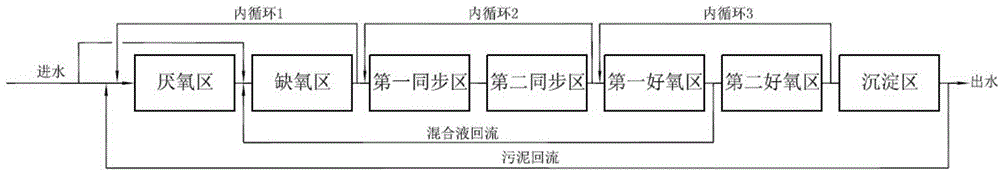

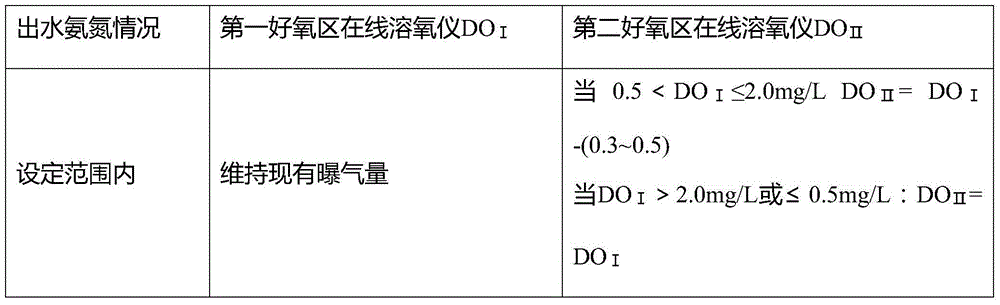

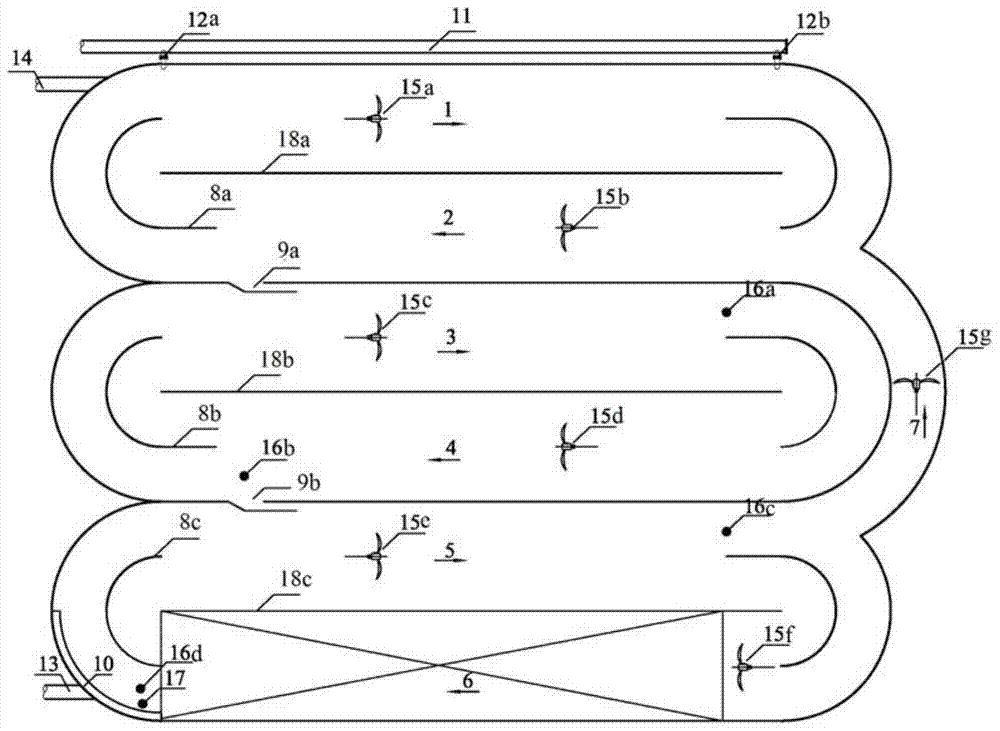

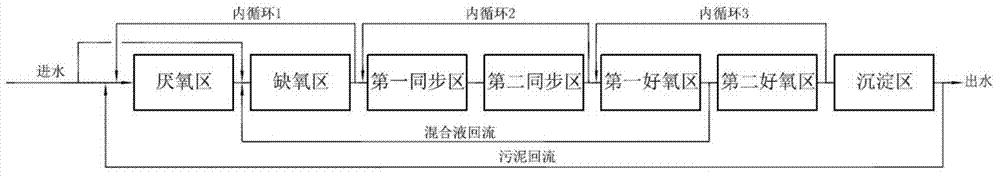

The invention relates to a multi-cycle composite bioreactor and a process thereof. The multi-cycle composite bioreactor comprises an anaerobic zone, an anoxic zone, a first synchronization zone, a second synchronization zone, a first aerobic zone, and a second aerobic zone. The process of the multi-cycle composite bioreactor adopts multi-cycle design and composite sludge film coexistence design, comprises an anoxic / anaerobic cycle, a synchronization zone internal cycle, an aerobic zone internal cycle, an anoxic zone / aerobic zone mixed liquid backflow cycle, and a sludge backflow cycle, facilitates enrichment of denitrification dephosphorization bacteria and realization of synchronous nitrification and denitrification, improves the efficiency of denitrification and dephosphorization, and is low in running energy consumption, and flexible in control mode.

Owner:CHUANGTSING SHARE ENVIRONMENT NANJING CO LTD

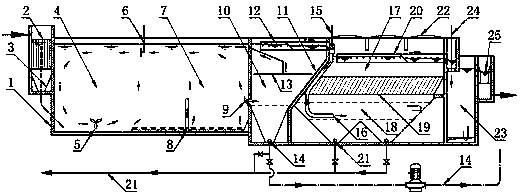

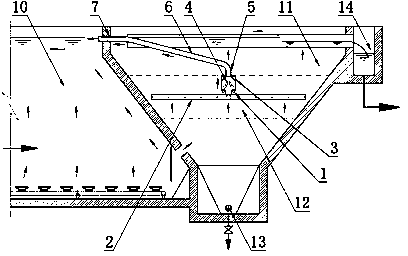

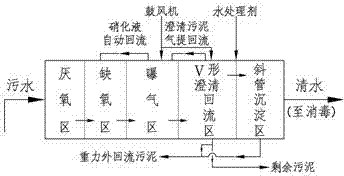

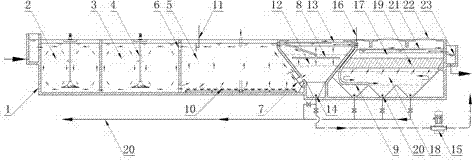

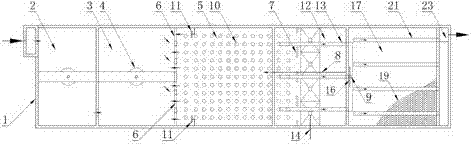

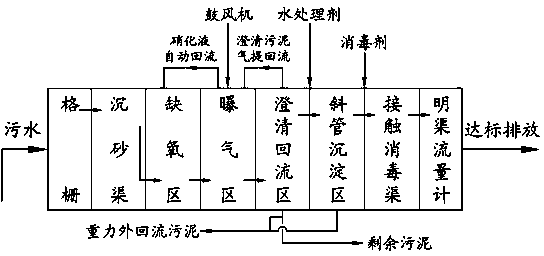

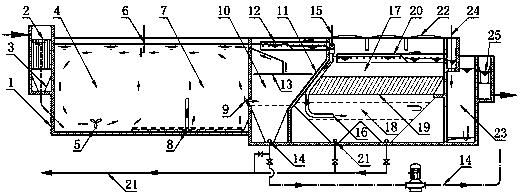

Z-shaped gas stripping reflux two-stage precipitation integrated sewage treatment tank

ActiveCN103395948ALow costPrevents clogging and wearMultistage water/sewage treatmentSludgeWater quality

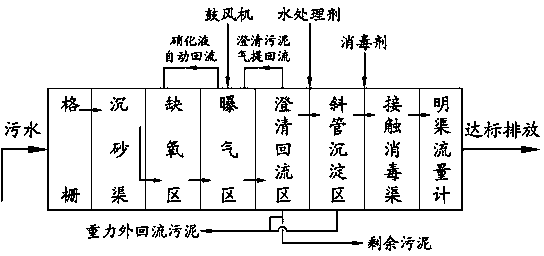

The present invention provides a Z-shaped gas stripping reflux two-stage precipitation integrated sewage treatment tank, wherein the rectangular tank body contains a grid-containing sand settling pretreatment zone, an anoxic zone, an aeration zone, a clarifying reflux zone, an inclined pipe / plate precipitation zone, a contact disinfection ditch, and the like, and conventional water treatment equipment, a horizontal slit-type gas-water separator, a Z-shaped separation wall, a surface type gas stripping micro power reflux device arranged in a horizontal and completely-paving manner, and an L-shaped hydropower hybrid spiral flow generator are arranged inside the tank body. The Z-shaped gas stripping reflux two-stage precipitation integrated sewage treatment tank has a simple and compact structure, and has the following advantages that: denitrogenation, phosphorus removing, two stage precipitation and disinfection treatment are completed in the same tank; and compared with the conventional process adopting a plurality of independent small tanks, the Z-shaped gas stripping reflux two-stage precipitation integrated sewage treatment tank of the present invention has advantages of low investment, small occupation area, less agent consumption, less sludge discharge, low energy consumption, low cost, stable and controllable water quality, easy operation and management, and the like, and is especially suitable for sewage denitrogenation and phosphorus removing integrated treatments with a scale of 10000 tons / day and below.

Owner:WUHAN PURGELON ENVIRONMENTAL ENG TECH

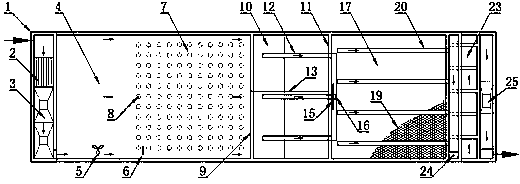

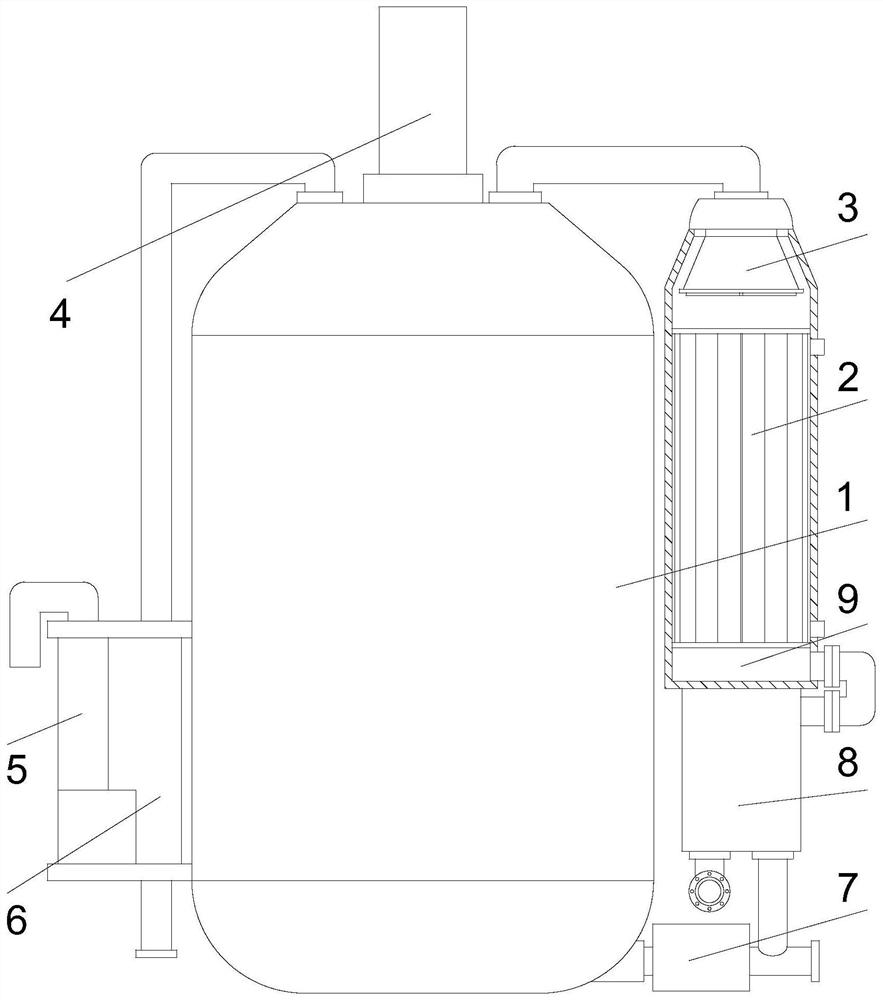

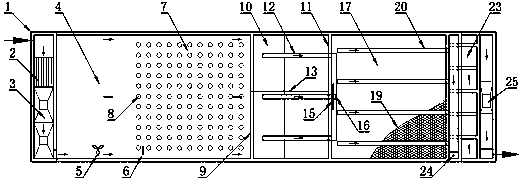

Electrolyte solution charging device

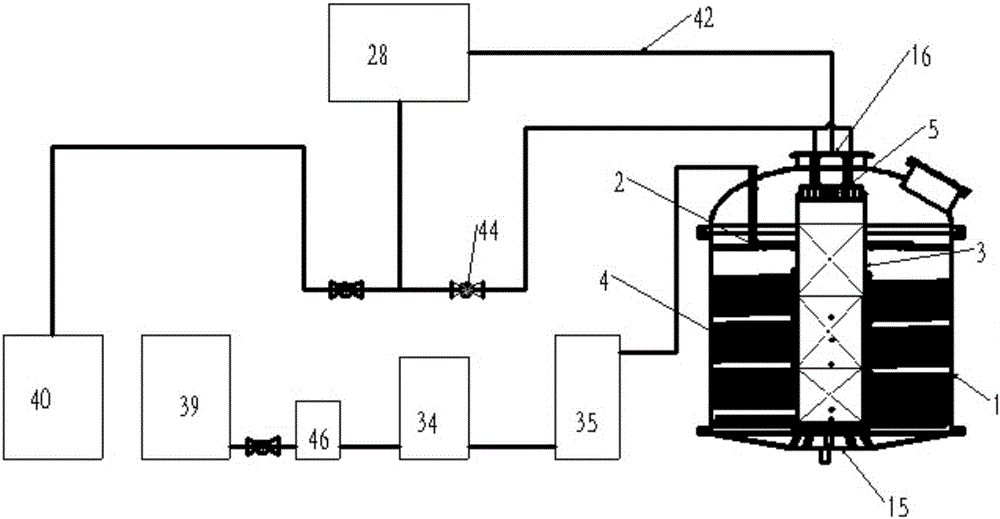

ActiveCN108166022ASolve the problem of deposits on the lower part of the stirring shaftUniform reflowPhotography auxillary processesElectrolysis componentsElectrolysisPhysical chemistry

The invention discloses an electrolyte solution charging device which is used for producing copper foils. The electrolyte solution charging device comprises an electrolyte solution stirring barrel, abuffer storage barrel, an electrolysis slot and a controller, wherein a first pump is used for extracting an electrolyte solution in the electrolyte solution stirring barrel through a pipeline, and feeding the electrolyte solution into the buffer storage barrel through a solution transfer pipeline; the electrolyte solution in the buffer storage barrel is fed into the electrolysis slot through a flow pump; an electrolyte solution sensor is arranged in the electrolysis slot; and the electrolyte solution sensor is mainly used for measuring concentration of copper sulfate in the electrolysis slotin real time. The invention aims to provide the electrolyte solution charging device which can solve the problem about how to automatically charge the electrolyte solution.

Owner:陈治政

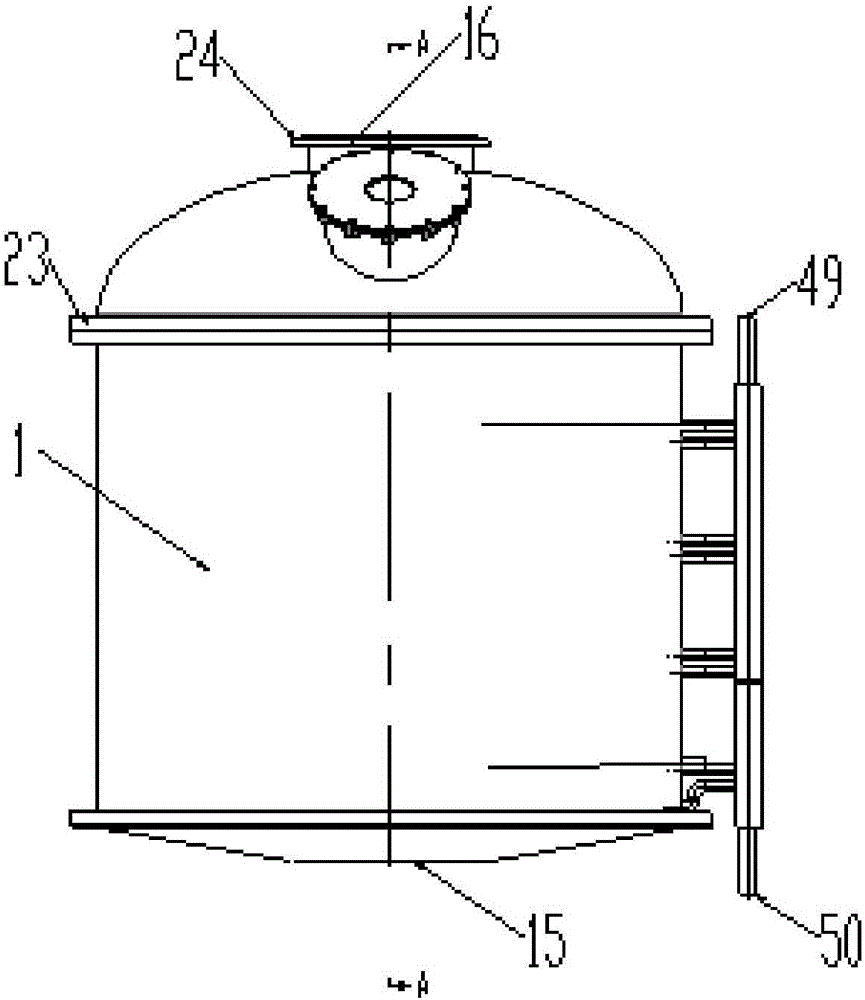

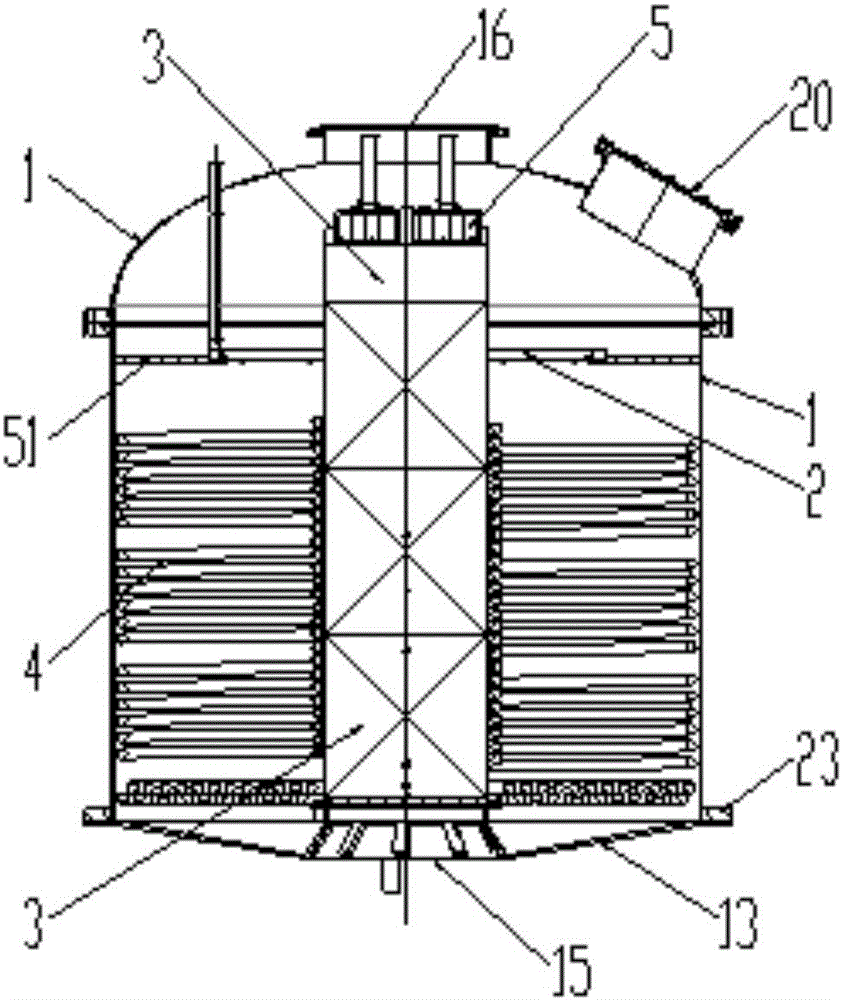

Annular spray evaporation device

InactiveCN106621435ASpeed up evaporationContinuously workingFractional distillationThermal energyVapor liquid

The invention provides an annular spray evaporation device. The annular spray evaporation device at least comprises an evaporation chamber which comprises a shell, an annular spray atomizer, an in-built plug-in filler drum, U-shaped heating rings and a vapor-liquid distribution disc, wherein the upper part of the shell is provided with a volatile phase outlet, and the lower part of the shell is provided with a non-volatile phase outlet; the annular spray atomizer, the U-shaped heating rings and the vapor-liquid distribution disc are arranged inside the shell; the annular spray atomizer is connected with a feed liquid booster pump by passing through a feed liquid inlet pipe, a preheater and a filter; the U-shaped heating rings are connected with a heat medium; and the top end of the in-built plug-in filler drum arranged inside the shell is provided with the vapor-liquid distribution disc which is composed of a reflux liquid conduit, a reflux distributor and a ventilation pipe. The evaporation device provided by the invention can fully and efficiently utilize heat energy, realizes continuous operation, simplifies equipment, saves space and reduces investment.

Owner:山东擎雷环境科技股份有限公司

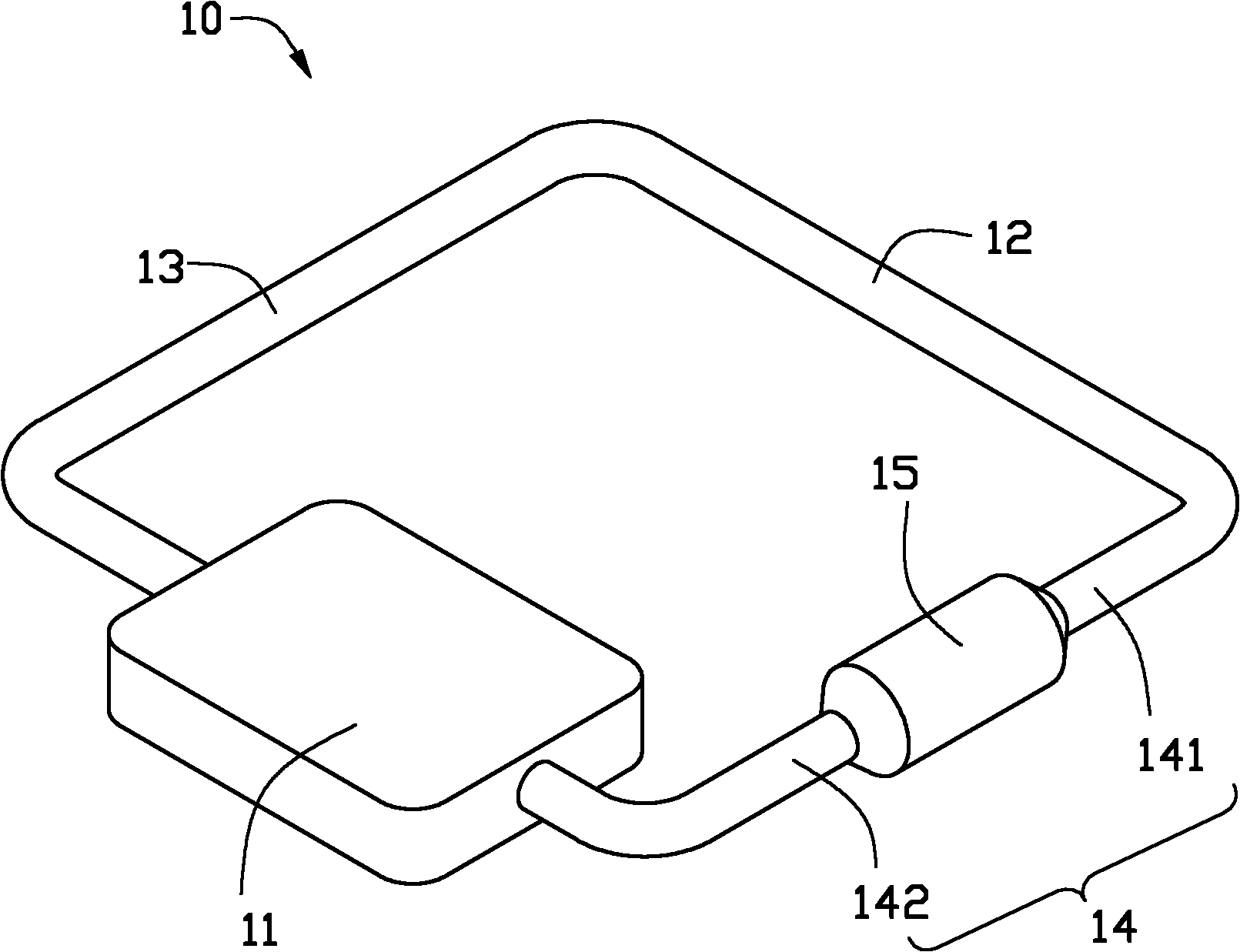

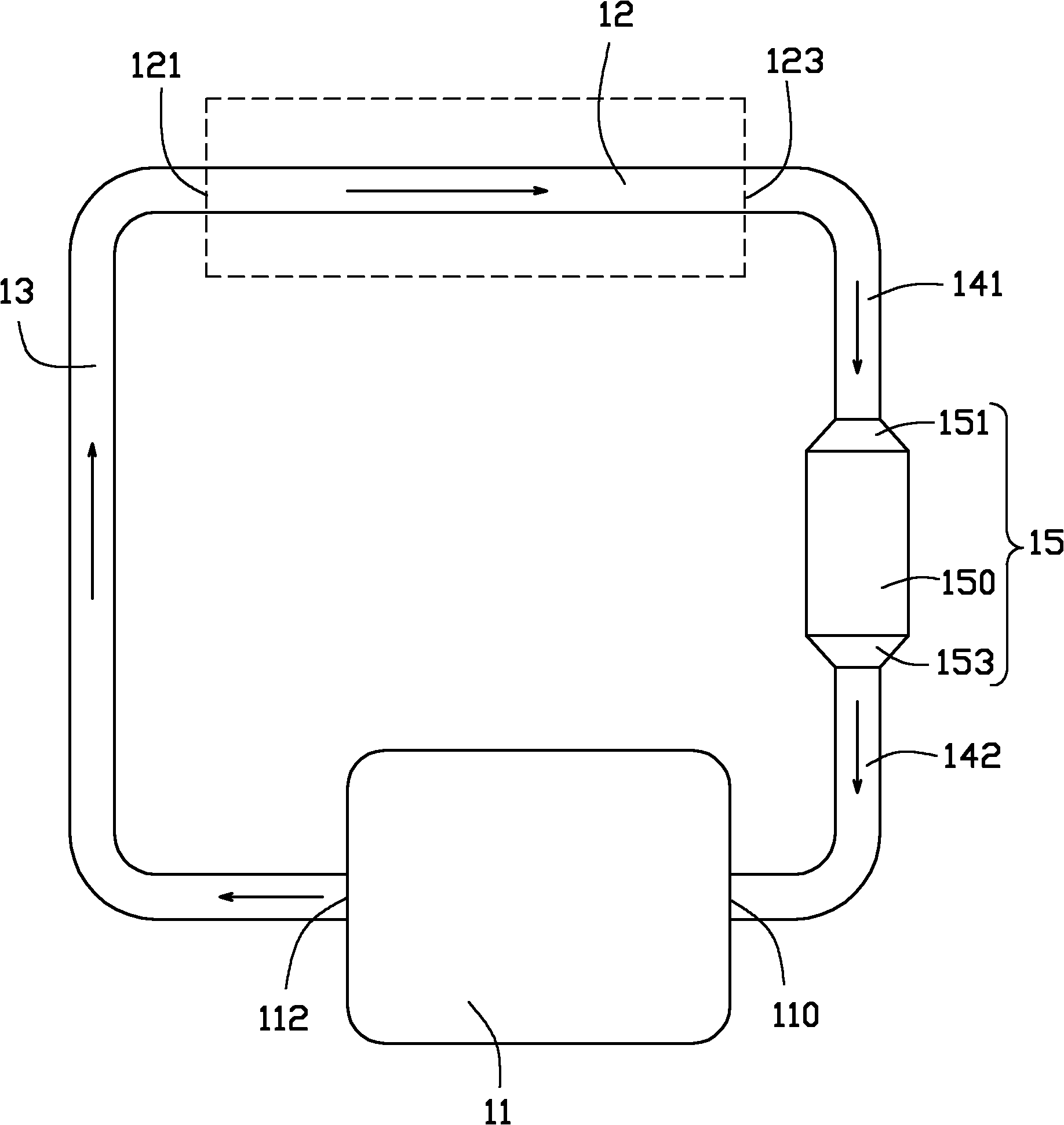

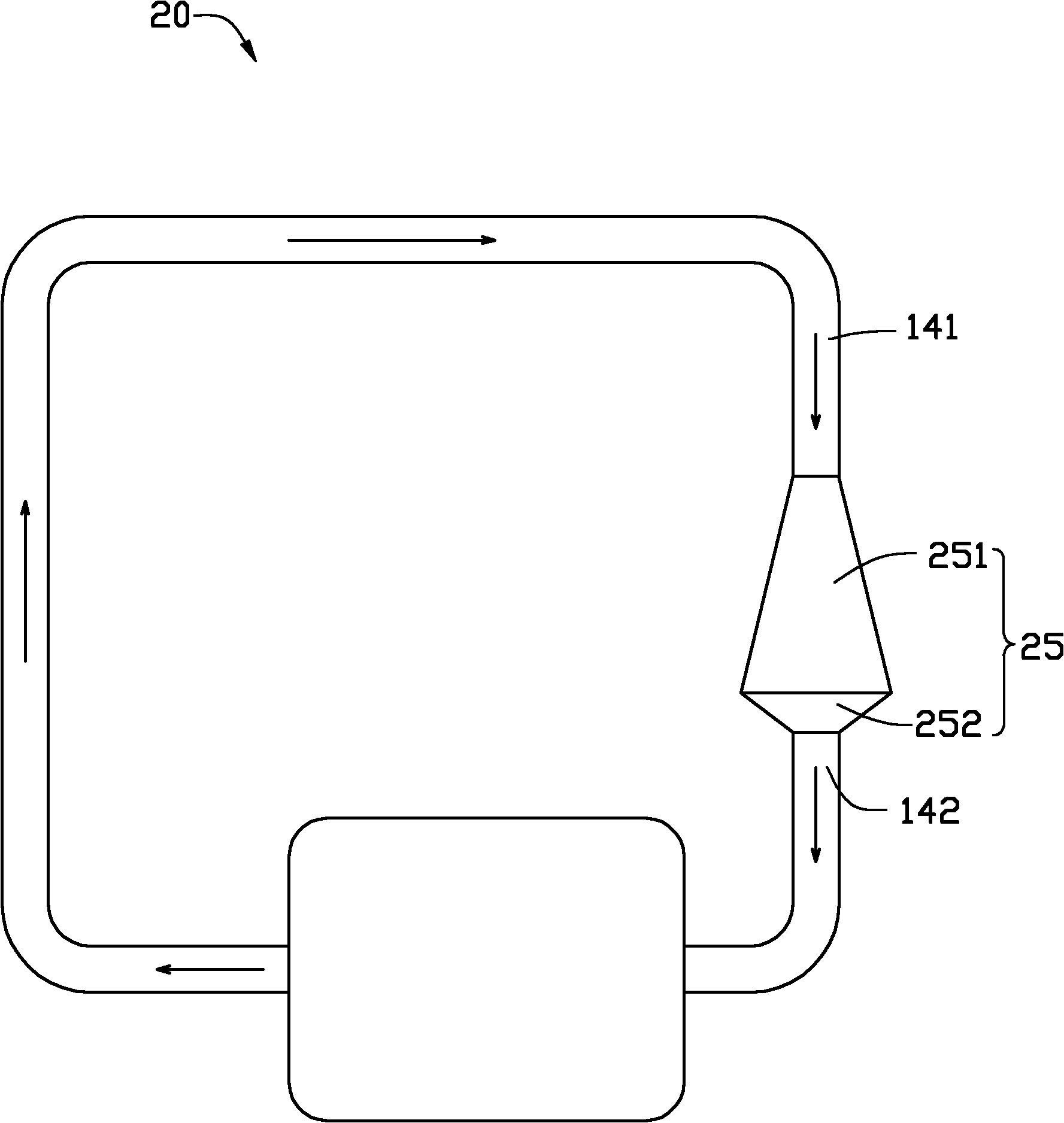

Loop heat pipe

InactiveCN102374803AGuaranteed stabilityBackflow continuousSemiconductor/solid-state device detailsSolid-state devicesMicro-loop heat pipeEvaporation

The invention relates to a loop heat pipe. The loop heat pipe comprises an evaporation part, a condensation part, a vapor pipeline and a liquid pipeline, wherein the vapor pipeline and the liquid pipeline are arranged between the evaporation part and the condensation part; the evaporation part is connected with the condensation part to form a loop; the loop is filled with a working medium; the liquid pipeline is connected with a dripping hopper part; the volume of the dripping hopper part is greater than that of the liquid pipeline in the same length; and the dripping hopper part is used for separating mixed gaseous working medium and liquid working medium which are delivered by the liquid pipeline.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

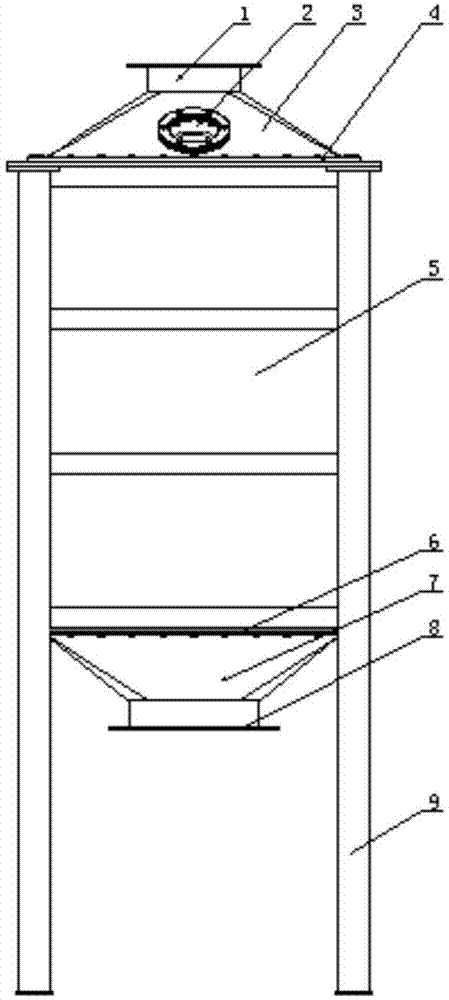

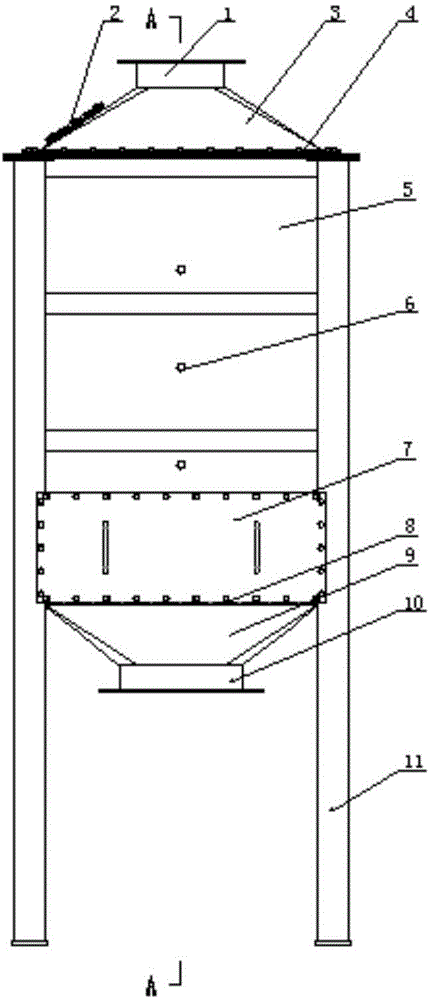

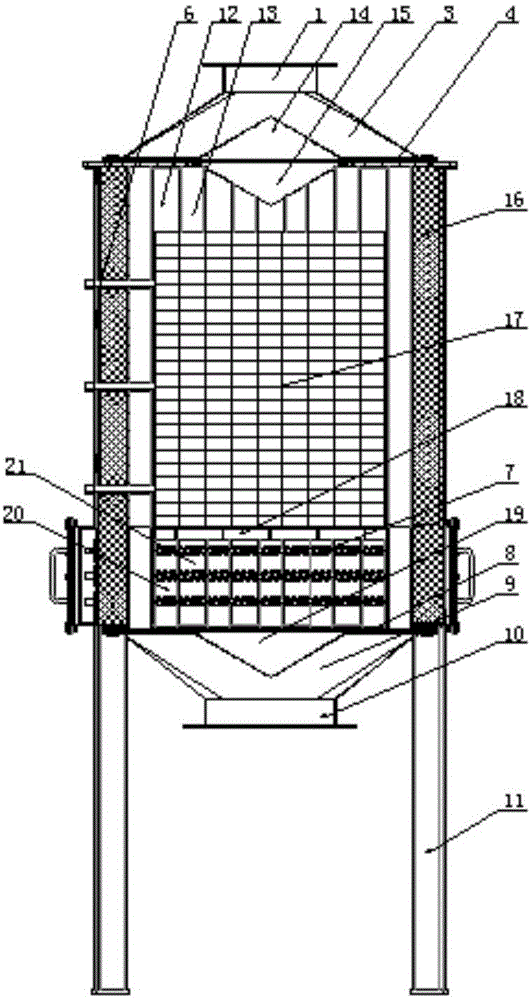

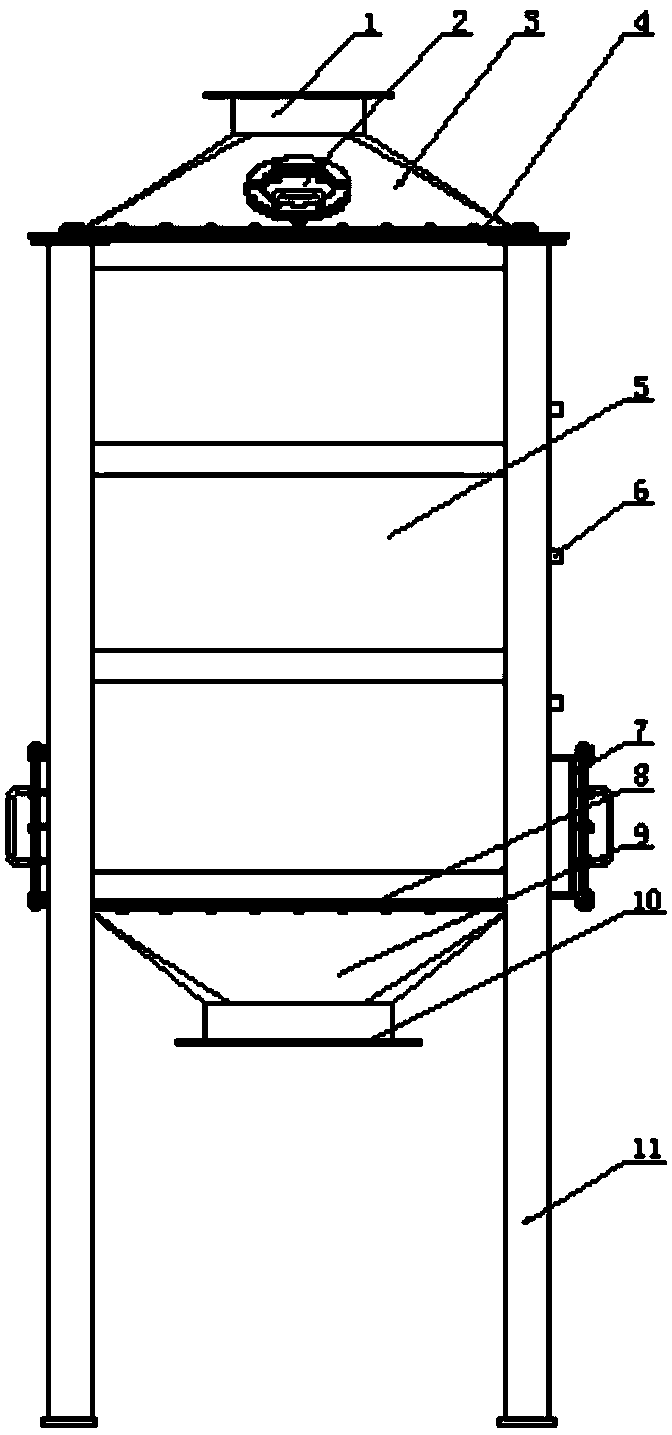

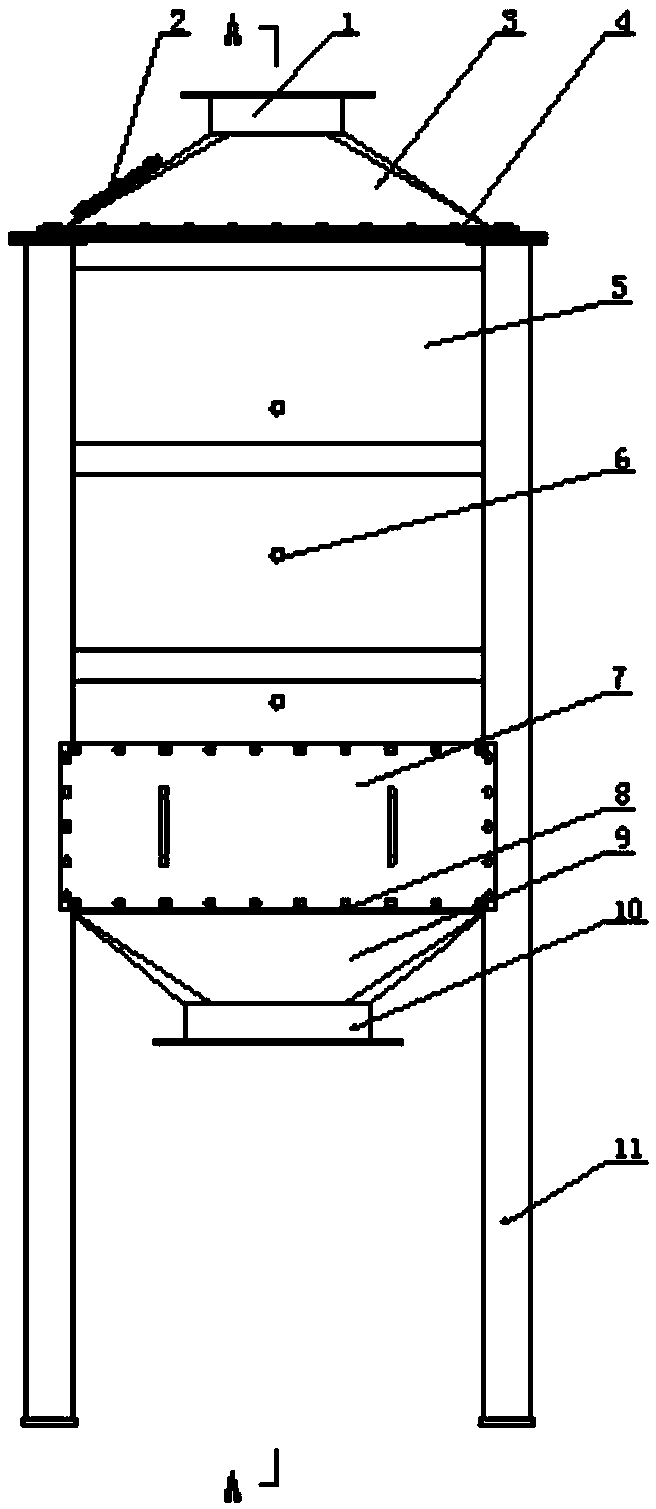

Energy-saving type catalytic bed system with controllable temperature

InactiveCN103486601AUniform air intakeUniform adsorptionIncinerator apparatusDesorptionHeat exchanger

The invention relates to an energy-saving type catalytic bed system with the controllable temperature. The energy-saving type catalytic system comprises a gas inlet heater, a catalytic bed and a heat exchanger. A gas inlet channel and a gas outlet channel are alternately formed between a furnace body inner surrounding plate and a furnace body outer surrounding plate. The inlet of the gas inlet channel is formed in an upper end plate, and the outlet of the gas inlet channel is formed between a lower end plate and the furnace body inner surrounding plate. The inlet of the gas outlet channel is formed between the upper end plate and the furnace body inner surrounding plate, and the outlet of the gas outlet channel is formed in the lower end plate. The heater is arranged in a furnace body corresponding to the outlet of the gas inlet channel. A gas outlet flow guide cover is arranged on the lower face of the middle of the lower end plate corresponding to the outlet of a gas outlet cover. A catalytic tail gas inlet, a catalytic tail gas outlet, a catalytic gas inlet, a catalytic gas outlet, a desorption gas supply inlet and a desorption gas supply outlet are formed in the heat exchanger. By the adoption of the energy-saving type catalytic bed system, heat efficiency of the catalytic bed is effectively improved, the heat loss is reduced, the heat recovery utilization rate, combustion efficiency and the purification rate are improved, heat exchange is increased, heat energy is more reasonably utilized, and the energy saving and emission reduction requirements are met.

Owner:赛智环保科技(天津)有限公司

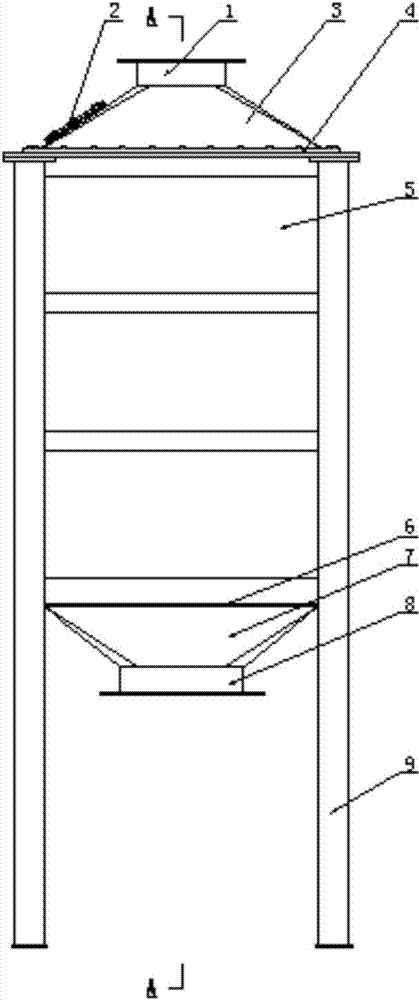

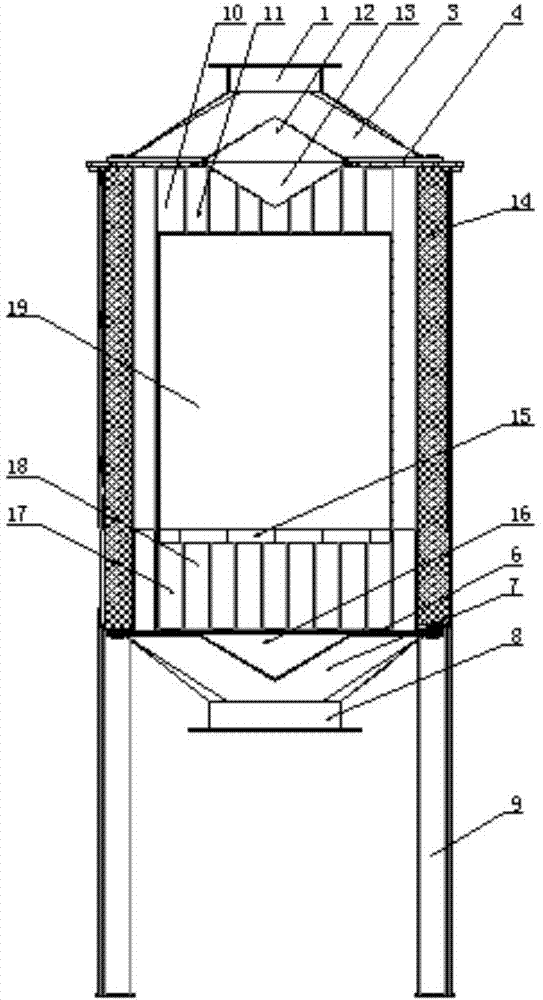

Novel rotary tangential flow efficient vertical flow sedimentation tank

PendingCN111714936ADiverge comprehensivelyUniform reflowSedimentation settling tanksSludgeMechanical engineering

The invention discloses a novel rotary tangential flow efficient vertical flow sedimentation tank which comprises a cylindrical tank body positioned at the upper part and a conical sludge hopper positioned at the lower part, wherein a water inlet pipe, a central guide cylinder, a reflecting cone and a water collecting tank are arranged in the tank body; the efficient vertical flow sedimentation tank further comprises a sludge treatment system; the sludge treatment system comprises a sludge discharge pipe, a sludge return pipe, a flushing hose and a sludge pump; the sludge pump is arranged at an outlet of the conical sludge hopper; the sludge pump is used for introducing a sludge-water mixture sucked from the conical sludge hopper into the sludge discharge pipe, the sludge return pipe and / or the flushing hose; the sludge hopper is provided with a flushing pipe orifice for connecting the flushing hose; a flow guide groove is formed in the inner wall of the sludge hopper, the flow guide groove spirally ascends to the joint of the tank body and the sludge hopper from the bottom of the sludge hopper, the flushing pipe orifice is formed in the position of the flow guide groove, and the outflow direction of the flushing pipe orifice is the tangential direction of the flow guide groove.

Owner:BEIJING ENFI ENVIRONMENTAL PROTECTION CO LTD

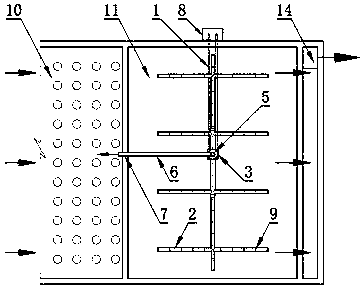

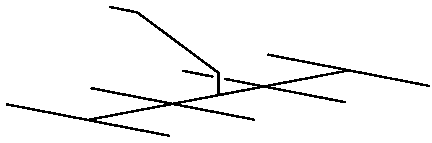

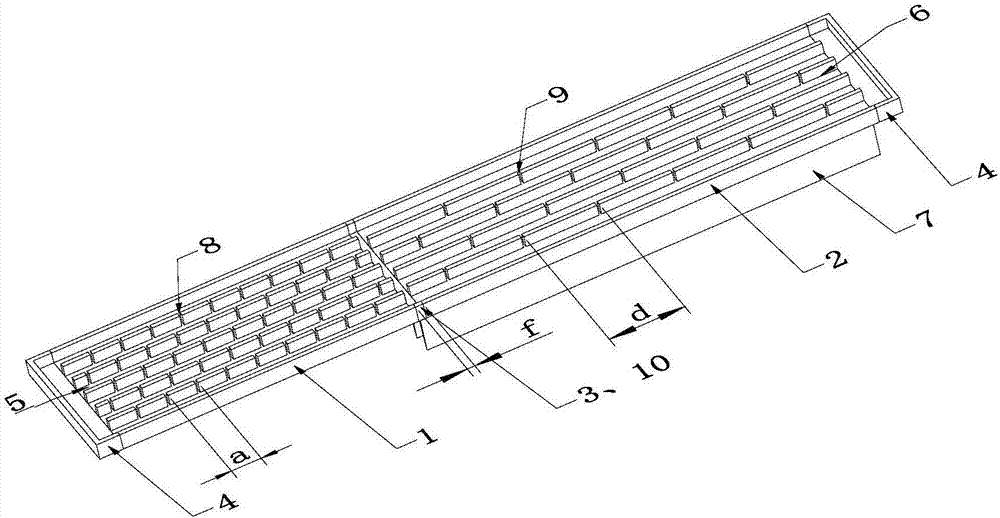

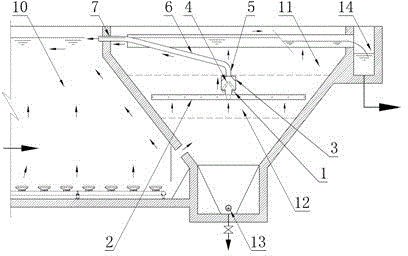

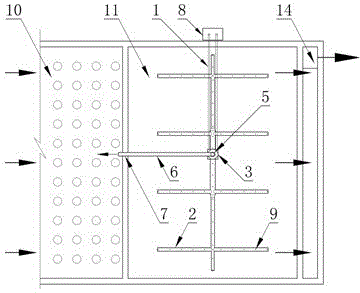

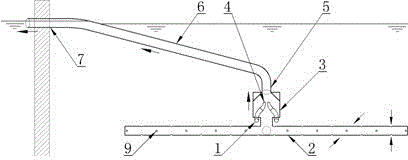

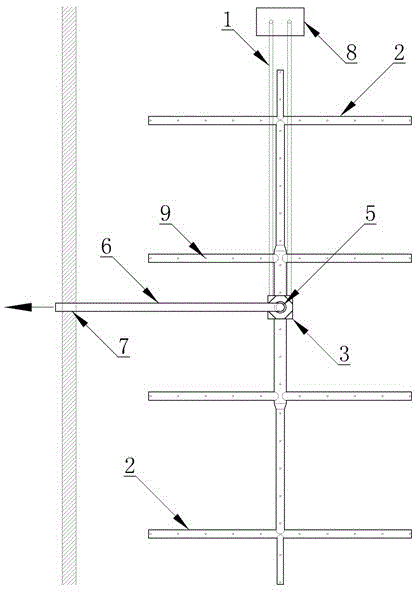

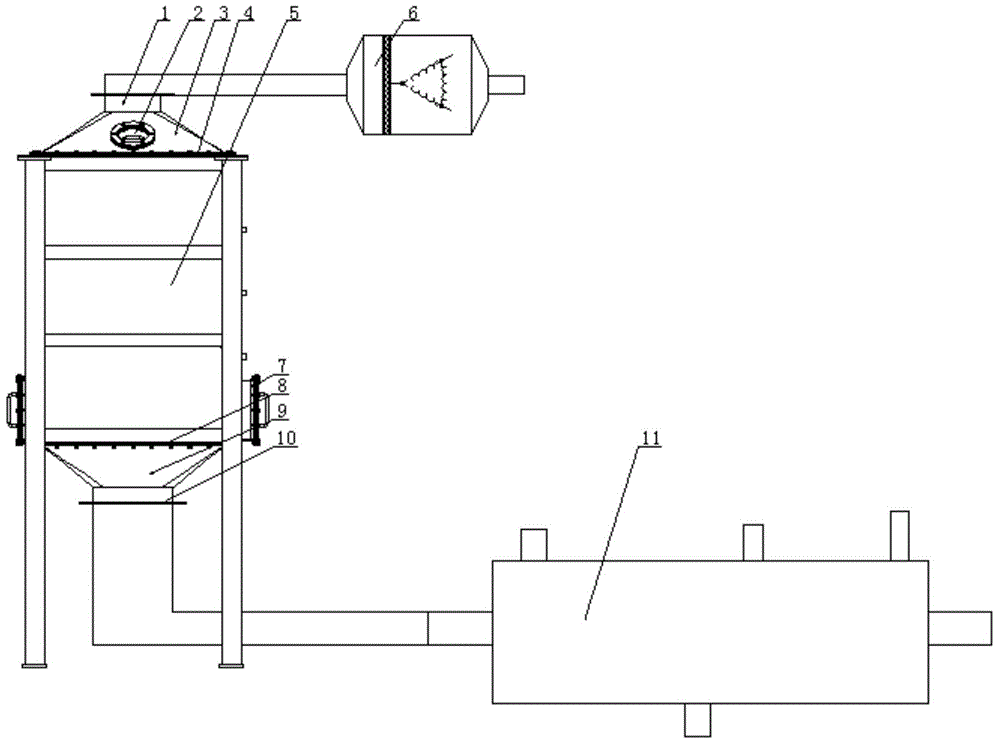

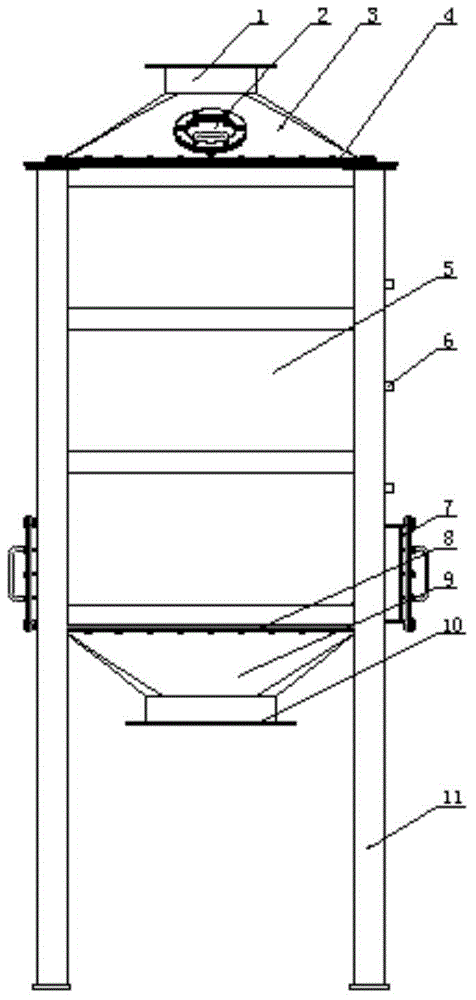

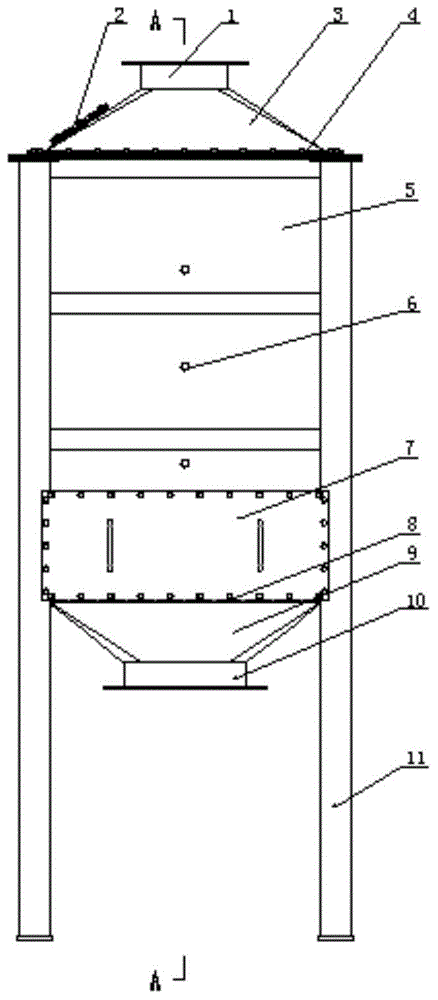

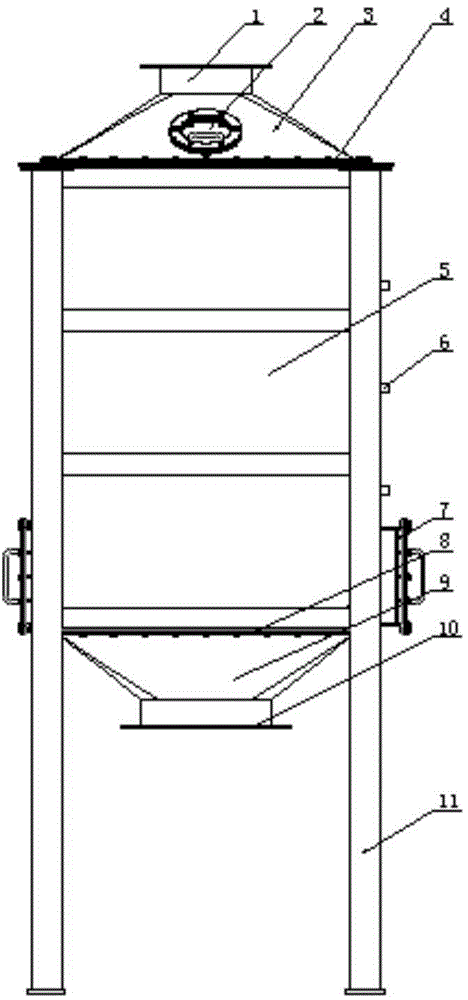

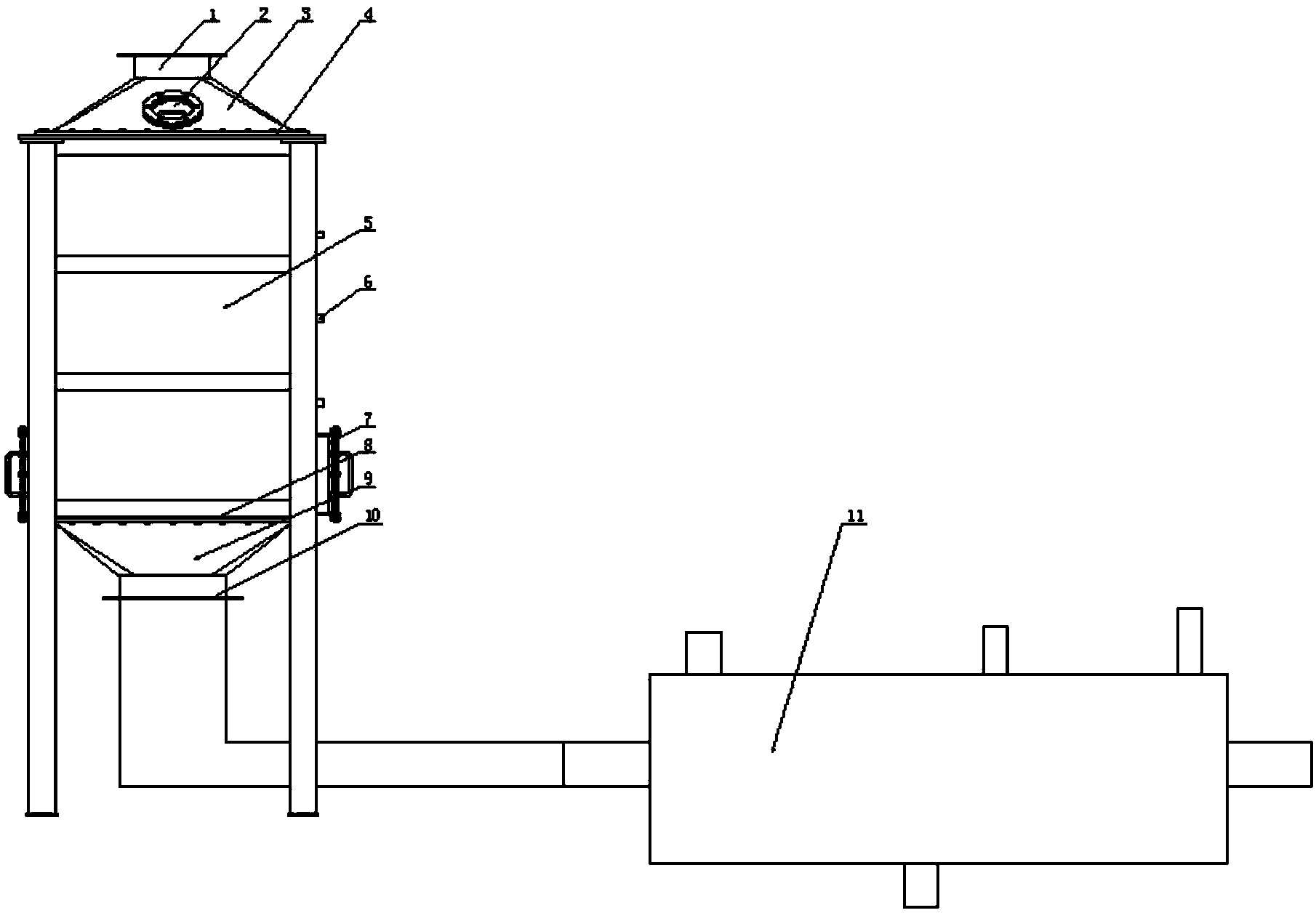

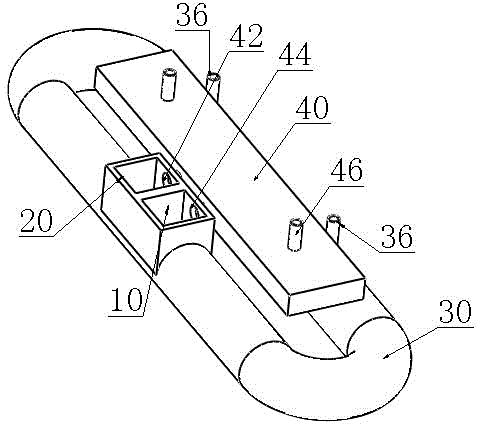

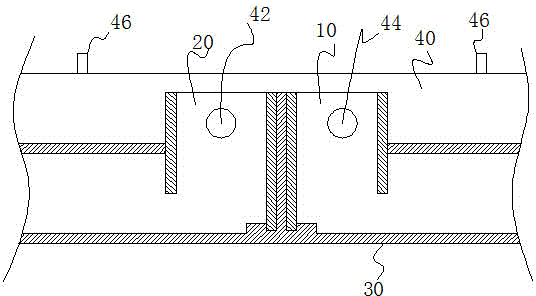

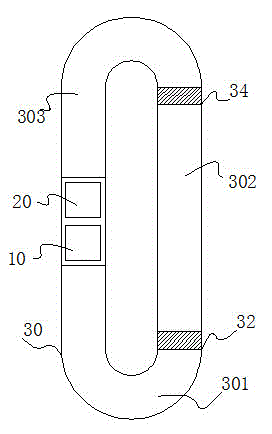

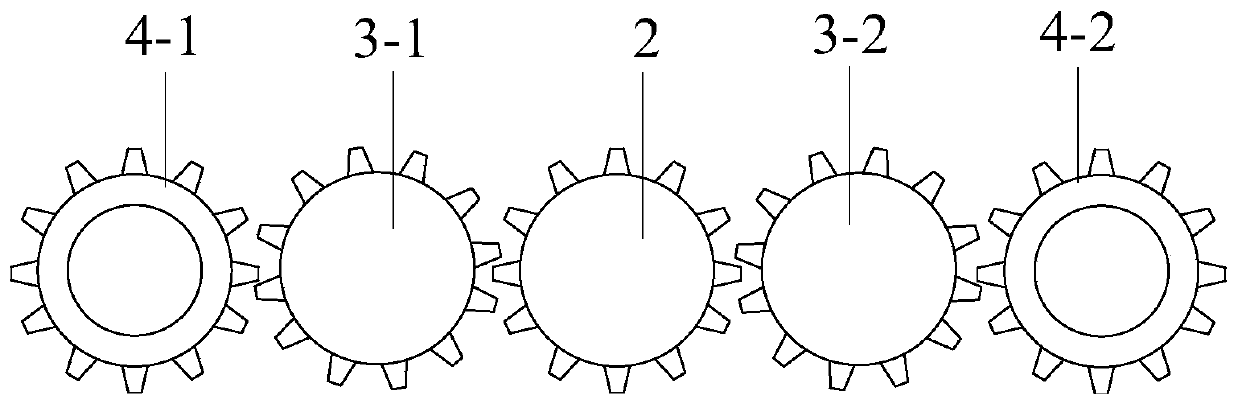

Horizontal suspension sludge air-lift backflow method

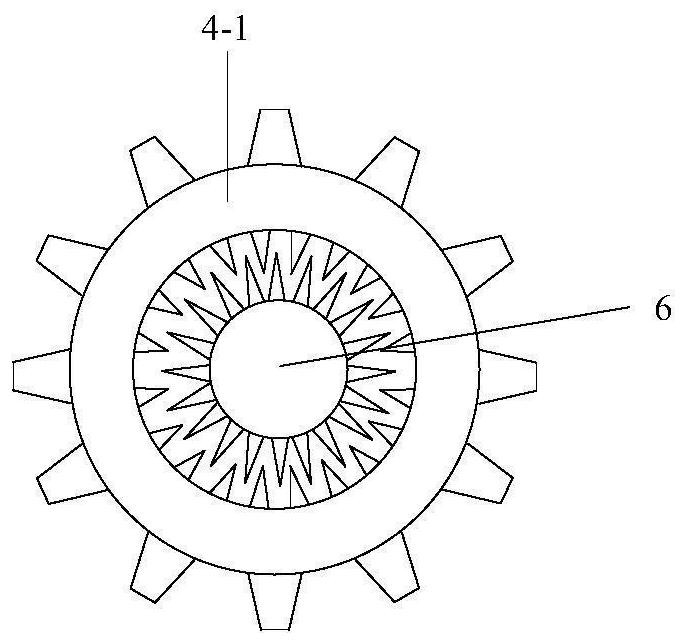

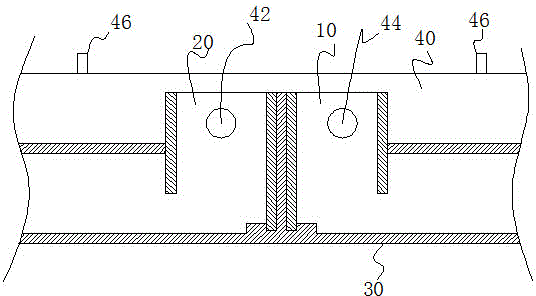

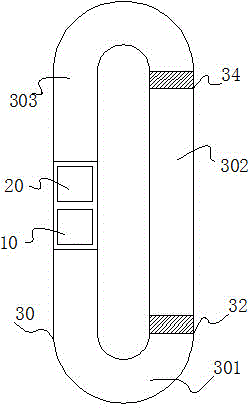

ActiveCN103435148AEnsure consistencyNo hardening depositsBiological water/sewage treatmentAir volumeEngineering

The invention provides a horizontal suspension sludge air-lift backflow method. The method mainly comprises the following steps: sludge is sucked completely and in equilibrium and lifted to a biochemical reaction tank for recycling by arranging a horizontal plane-type air-lift micro-power backflow device in a suspension thick activated sludge layer and utilizing sludge suction pipes of the backflow device, which are horizontally arranged in the vertical and horizontal directions, and a compressed air control device outside the tank adjusts the air volume to control the quantity of backflow. Compared with the conventional sludge backflow method, the horizontal suspension sludge air-lift backflow method provided in the invention has a high backflow efficiency, there is no dead area or dead angle of sludge return in the large-area suspension sludge layer, and the backflow is in equilibrium; and besides, the activated sludge floc structure is not damaged, the control of backflow quantity is flexible, rapid and visual, no moving part or electrical equipment is used under water, and the backflow reliability is extremely high. Furthermore, an aeration blower of a sewage treatment plant is adopted for air supply, the corrected energy consumption for air-lift backflow is extremely low, and the energy-saving effect is obvious.

Owner:CENT & SOUTHERN CHINA MUNICIPAL ENG DESIGN & RES INST

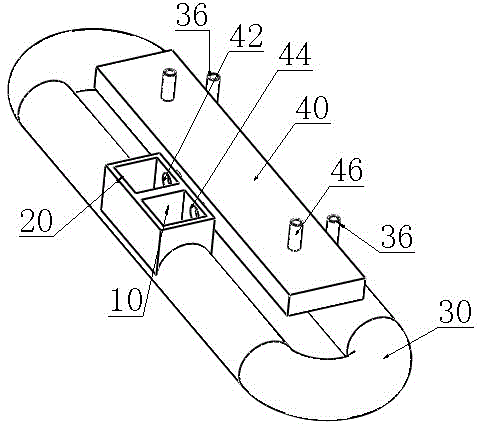

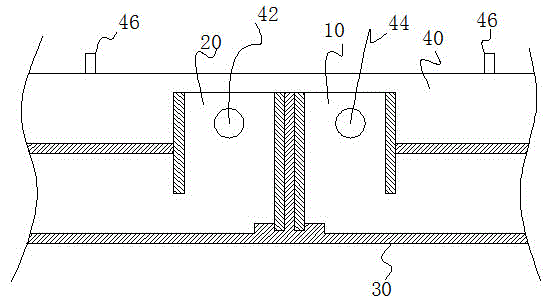

V-type air lift backflow two-stage sedimentation integrated sewage treatment tank

ActiveCN103395947BLow costImprove processing efficiencyMultistage water/sewage treatmentSludgeWater quality

The present invention provides a V-shaped gas stripping reflux two-stage precipitation integrated sewage treatment tank, wherein the rectangular tank body contains an anaerobic zone, an anoxic zone, an aeration zone, a V-shaped clarifying reflux zone and an inclined pipe / plate precipitation zone, wherein the water surface on the upper portion of a vertical separation wall arranged between the anoxic zone and the aeration zone is provided with a reflux hole, is matchedly provided with an umbrella-shaped stirrer and an auxiliary flow maker, and is further provided with an inclined hole-type gas-water separator, a surface type gas stripping micro power reflux device, an L-shaped hydropower hybrid spiral flow generator and other equipment so as to achieve gas stripping reflux of a nitrification liquid and sludge, and achieve a two-stage precipitation treatment on a mixed solution after a biochemical reaction. The V-shaped gas stripping reflux two-stage precipitation integrated sewage treatment tank has a simple and compact structure, and has the following advantages that: denitrogenation, phosphorus removing and precipitation separation are completed in the same tank; and compared with the conventional biochemical reaction tank, the secondary precipitation tank, the coagulation reaction tank and the inclined pipe precipitation tank, the V-shaped gas stripping reflux two-stage precipitation integrated sewage treatment tank of the present invention has advantages of low investment, small occupation area, less agent consumption, less sludge discharge, low energy consumption, low cost, stable and controllable water quality, easy operation and management, and the like.

Owner:WUHAN PURGELON ENVIRONMENTAL ENG TECH

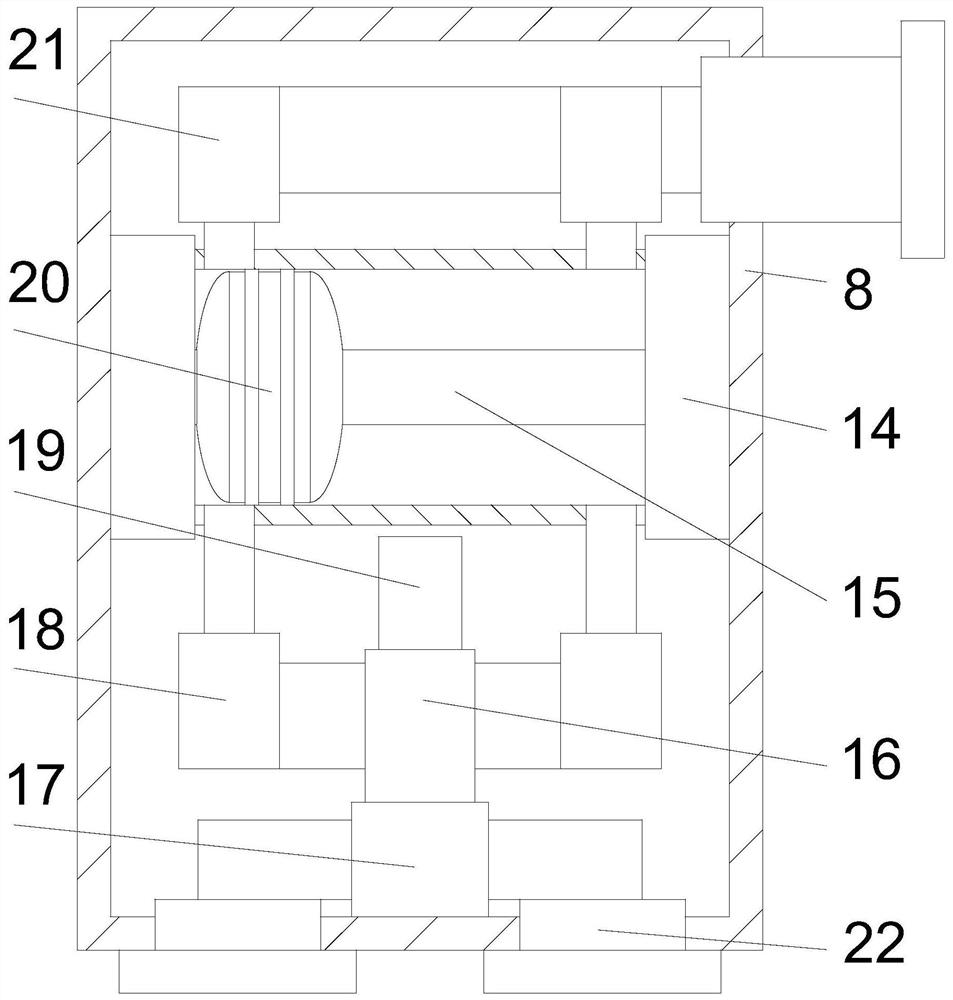

Reaction kettle with reflux ratio control and temperature and density interlock control

PendingCN112295532AReasonable designPrecise control of reflux ratioProcess control/regulationDistillation regulation/controlPhysicsMaterial Separation

The invention discloses a reaction kettle with reflux ratio control and temperature and density interlock control. The reaction kettle mainly comprises an outer frame, a cooling pipe, a stirrer, a pumping device, a shell and an electromagnetic valve, the stirrer is fixedly arranged in the middle of the top end of the outer frame in a penetrating way, a stirring rod is fixedly arranged at the bottom end of the stirrer and in the outer frame, a vacuum pipe penetrates through the left portion of the top end of the outer frame, a filter is fixedly installed at the bottom end of the vacuum pipe, and a vacuum pump is fixedly mounted at the left side of the filter. The reaction kettle is reasonable in structural design, capable of accurately controlling the reflux ratio, convenient and fast to use, high in practicability, capable of achieving temperature and density interlocking control, capable of enabling material separation to be more stable, capable of achieving uniform flow dividing andhedging cooling and good in condensation effect.

Owner:苏州市浒墅关化工添加剂有限公司

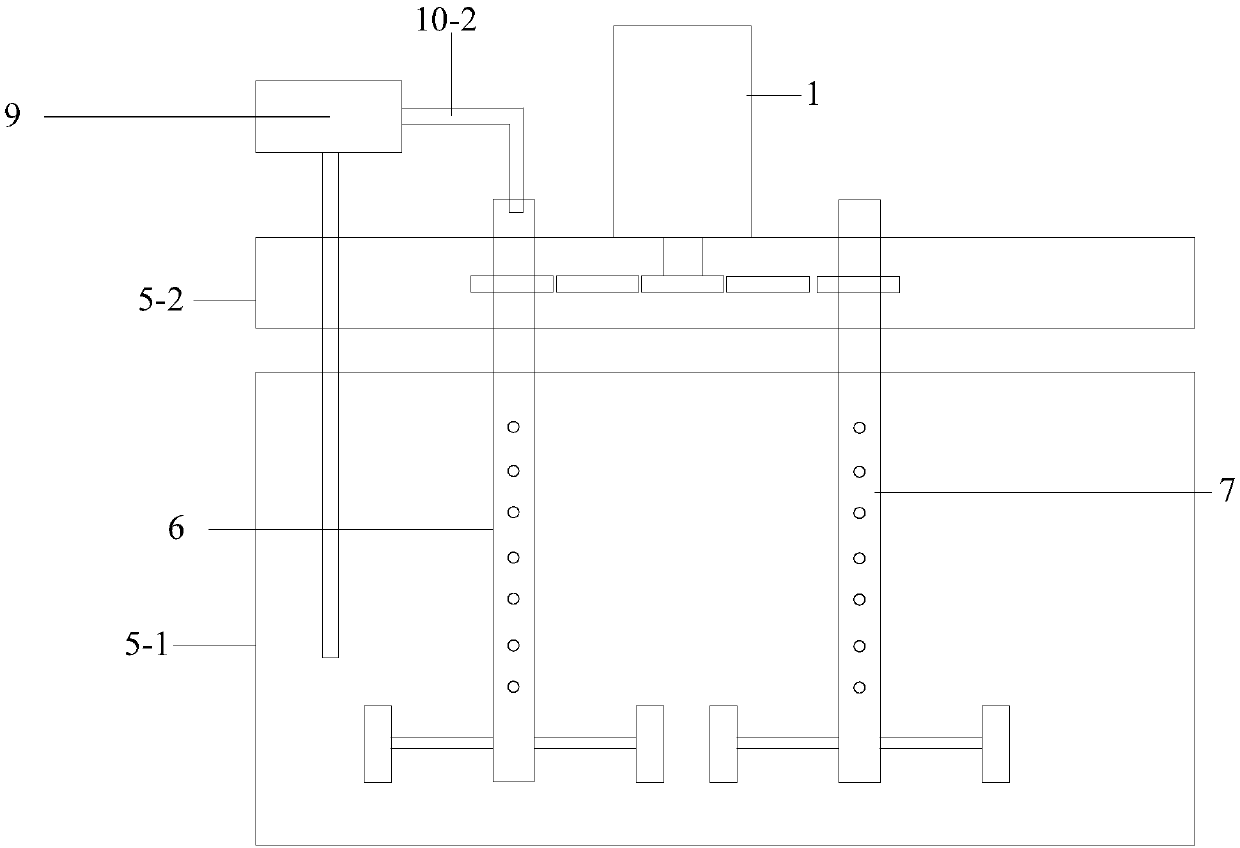

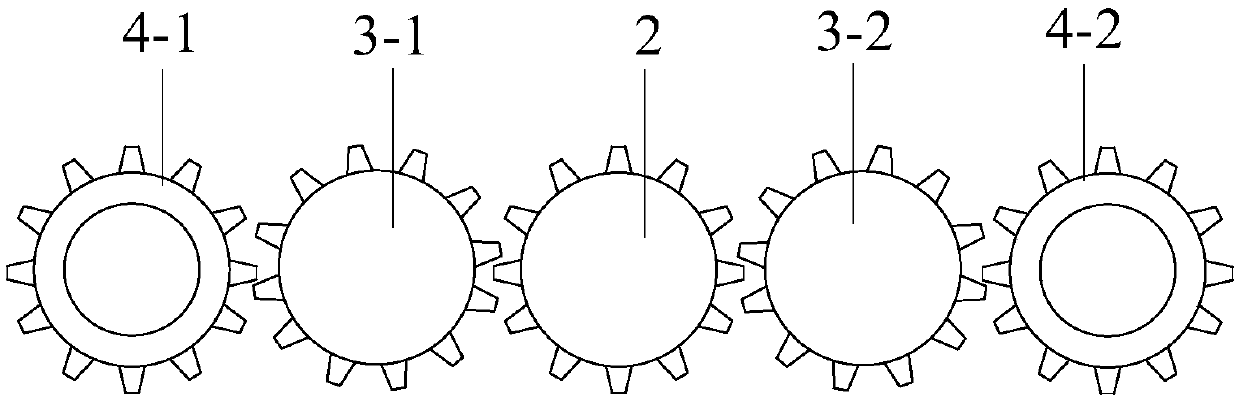

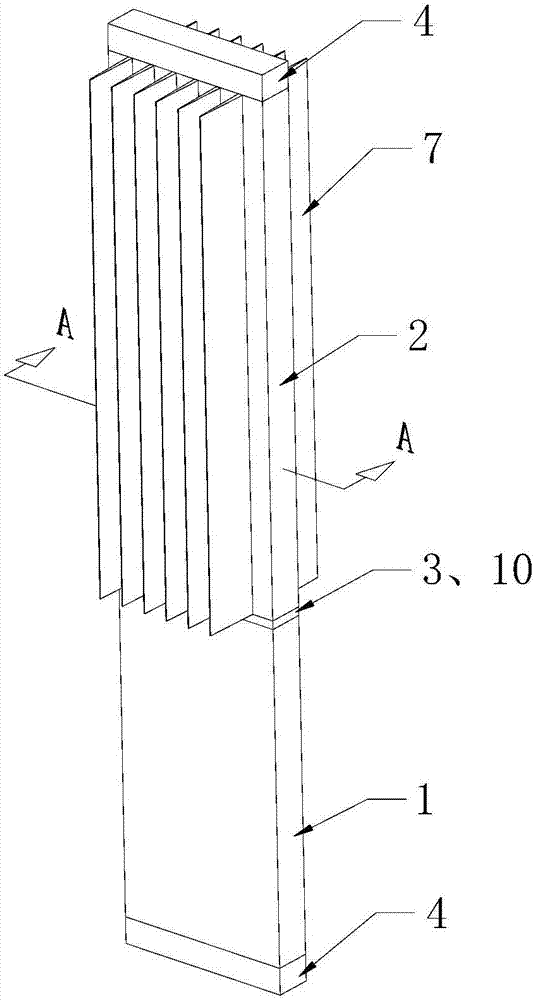

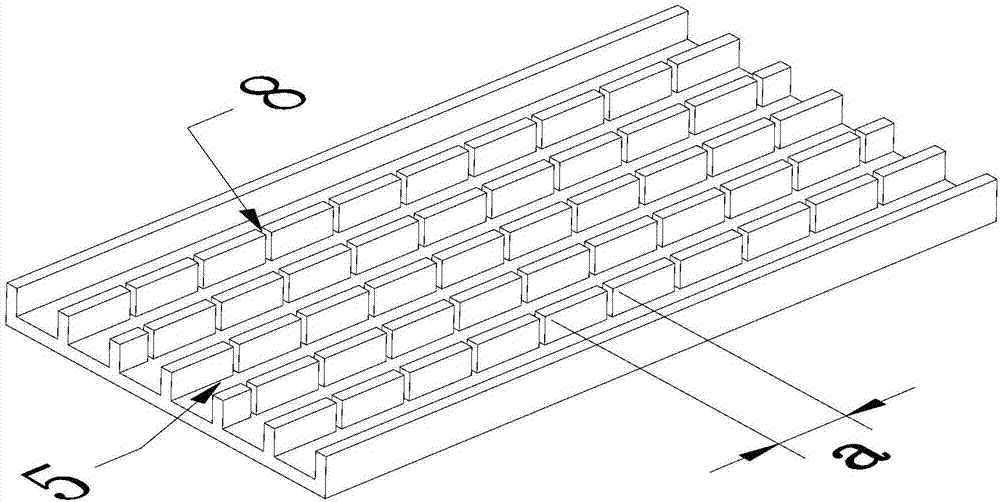

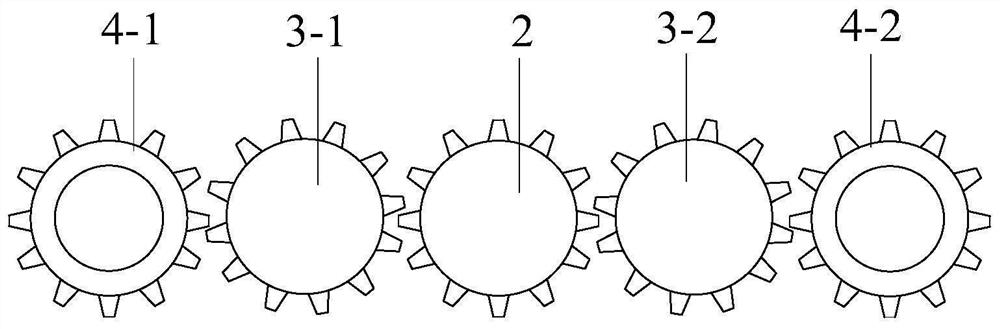

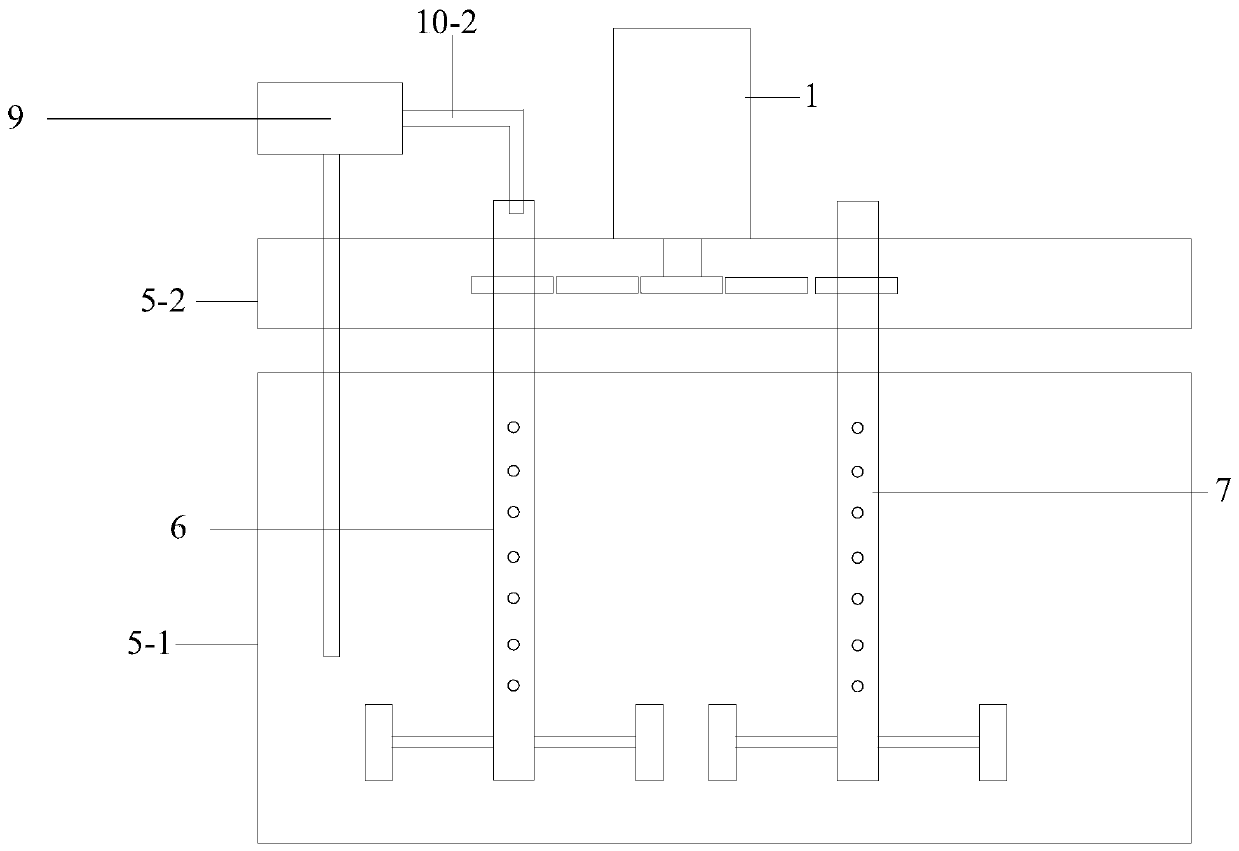

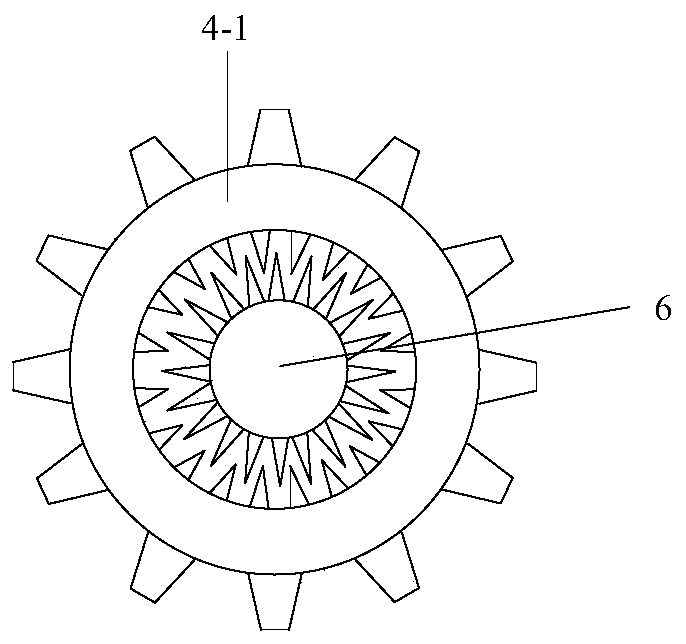

Reducing series-parallel connection channel plate type pulsating heat pipe

PendingCN106931815AAids in coolingPromote development and progressIndirect heat exchangersHeat flowEngineering

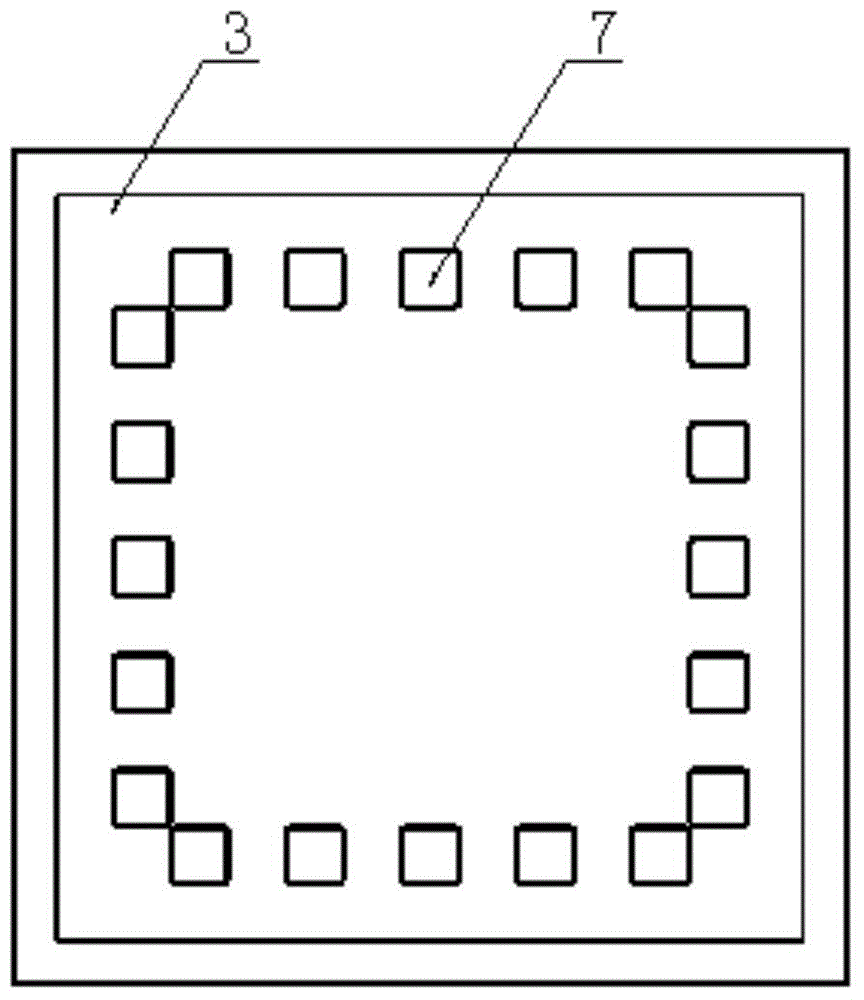

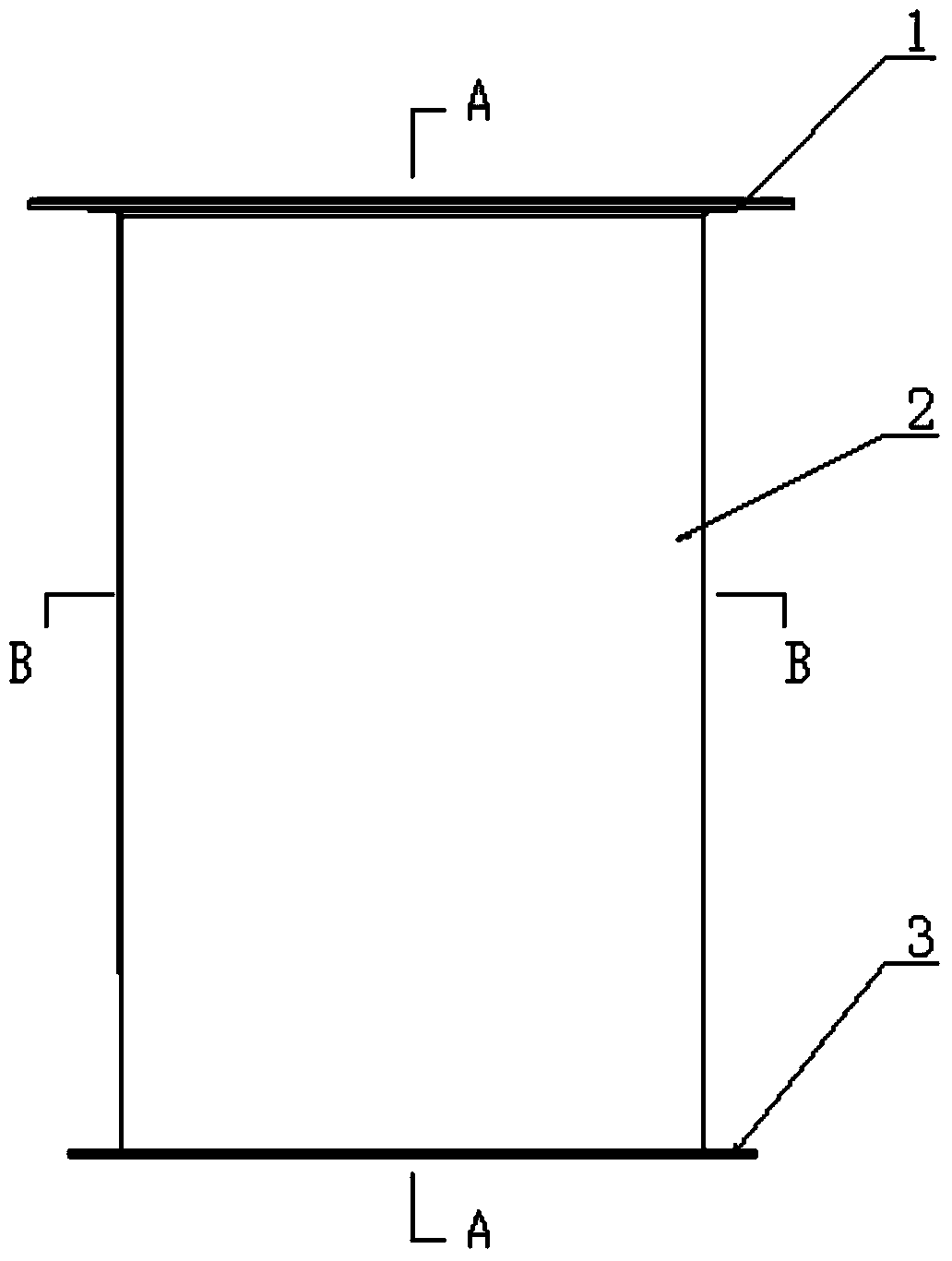

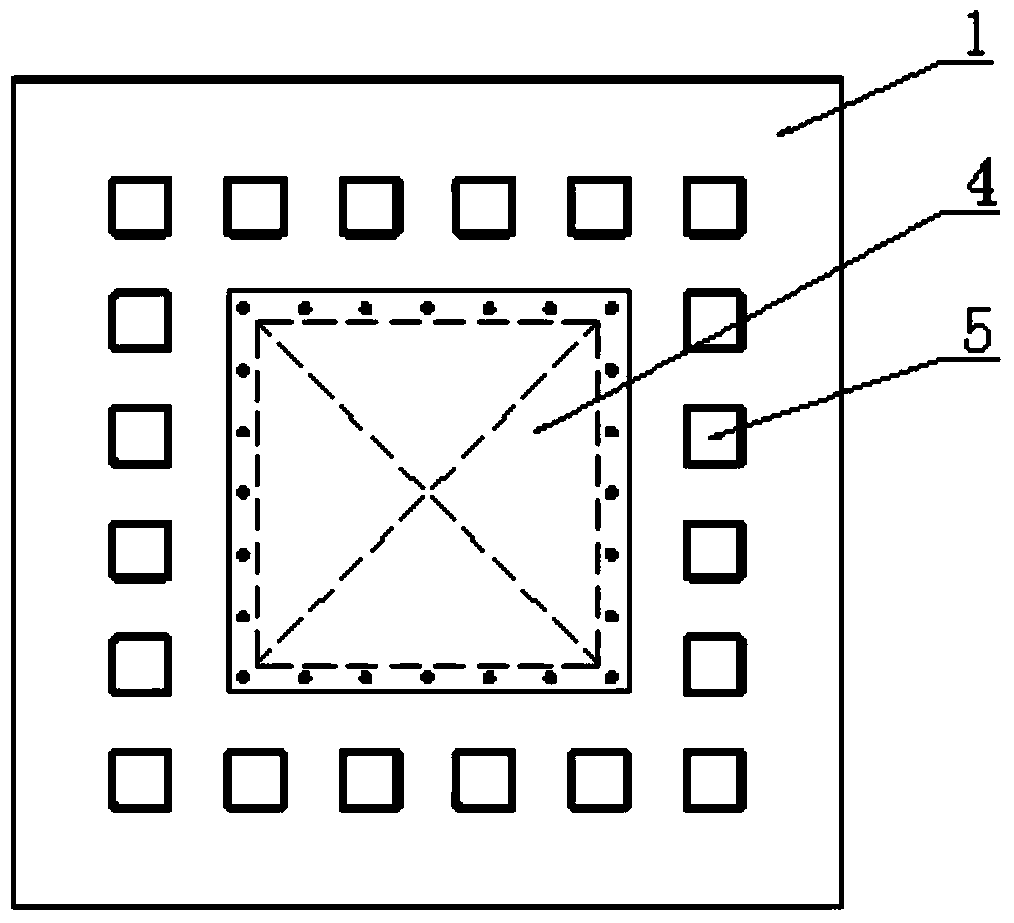

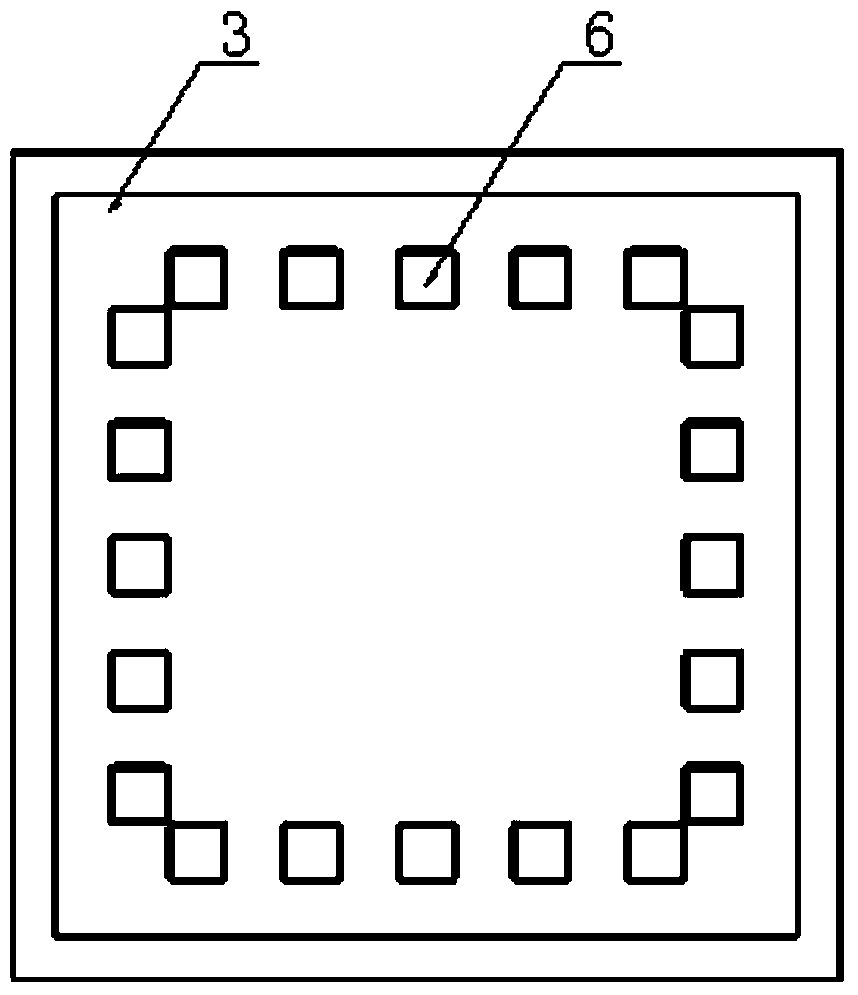

The invention discloses a reducing series-parallel connection channel plate type pulsating heat pipe which comprises a hot end 1, a cold end 2, an intermediate 3 and an end socket 4. The reducing series-parallel connection channel plate type pulsating heat pipe is characterized in that the hot end 1 is a rectangular flat plate with equal-diameter hot end channels 5 evenly distributed inside, the cold end 2 is a rectangular flat plate with equal-diameter cold end channels 6 evenly distributed inside, the equivalent diameter of the cold end channels 6 is 1-10 times that of the hot end channels 5, one end of the hot end 1 is connected with one end of the cold end 2, or the hot end 1 and the cold end 2 are connected through the intermediate 3, and the intermediate 3 is provided with a mixing cavity 10. The reducing series-parallel connection channel plate type pulsating heat pipe is obviously innovated and changed from the structure and the heat transfer mechanism, has actual effects and accords with the physical theory. The cooling principles and requirements of high-heat-flux elements are comprehensively met. The reducing series-parallel connection channel plate type pulsating heat pipe is applied to the high-heat-flux elements to be beneficial to cooling of the elements, and has the positive promoting effect on promoting development of electronic, microelectronic and optoelectronic components and relevant fields.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Multi-cycle composite bioreactor and process thereof

ActiveCN103951059BStable concentrationPromote enrichmentTreatment with aerobic and anaerobic processesSludgeBioreactor

The invention relates to a multi-cycle composite bioreactor and a process thereof. The multi-cycle composite bioreactor comprises an anaerobic zone, an anoxic zone, a first synchronization zone, a second synchronization zone, a first aerobic zone, and a second aerobic zone. The process of the multi-cycle composite bioreactor adopts multi-cycle design and composite sludge film coexistence design, comprises an anoxic / anaerobic cycle, a synchronization zone internal cycle, an aerobic zone internal cycle, an anoxic zone / aerobic zone mixed liquid backflow cycle, and a sludge backflow cycle, facilitates enrichment of denitrification dephosphorization bacteria and realization of synchronous nitrification and denitrification, improves the efficiency of denitrification and dephosphorization, and is low in running energy consumption, and flexible in control mode.

Owner:CHUANGTSING SHARE ENVIRONMENT NANJING CO LTD

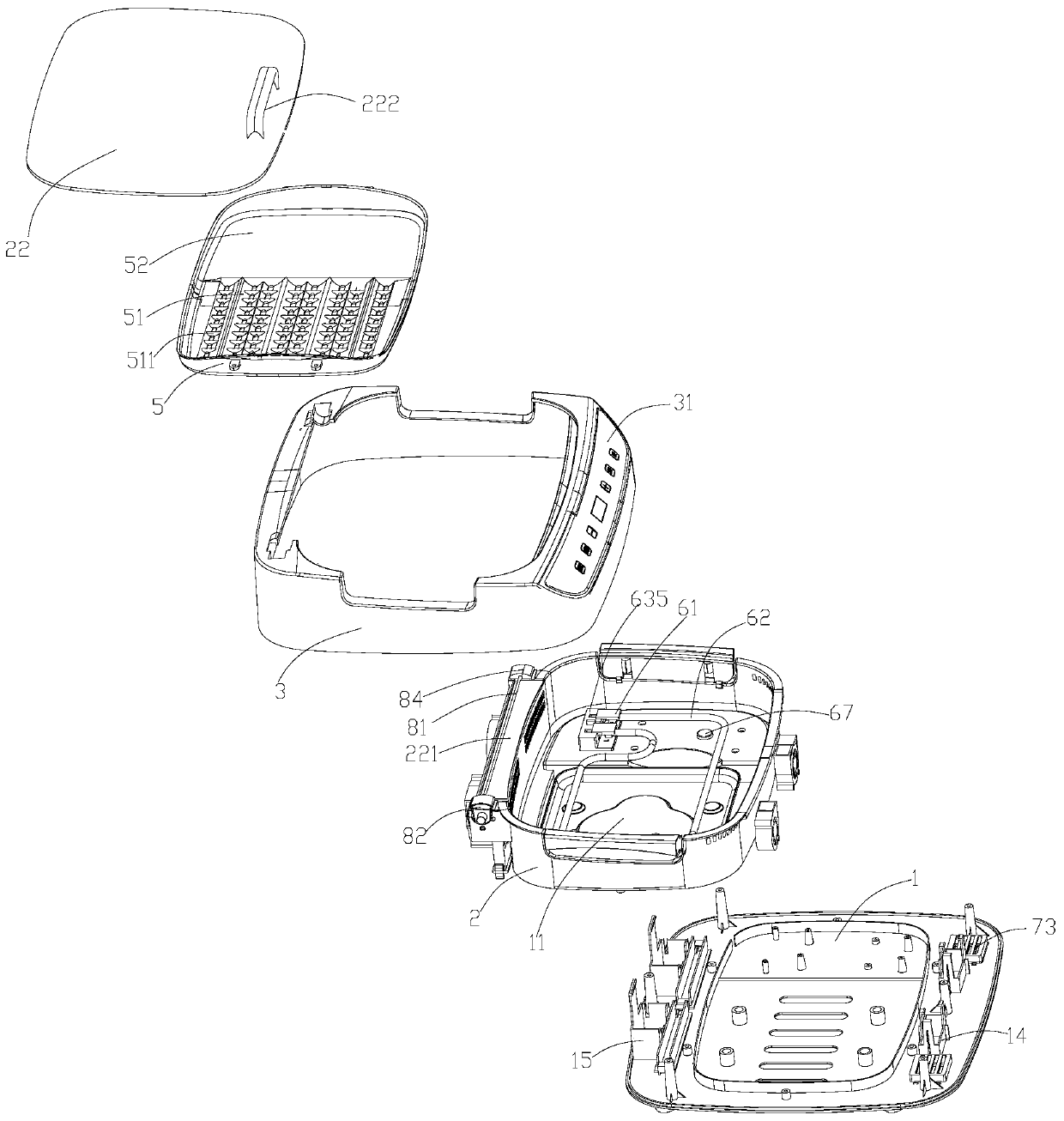

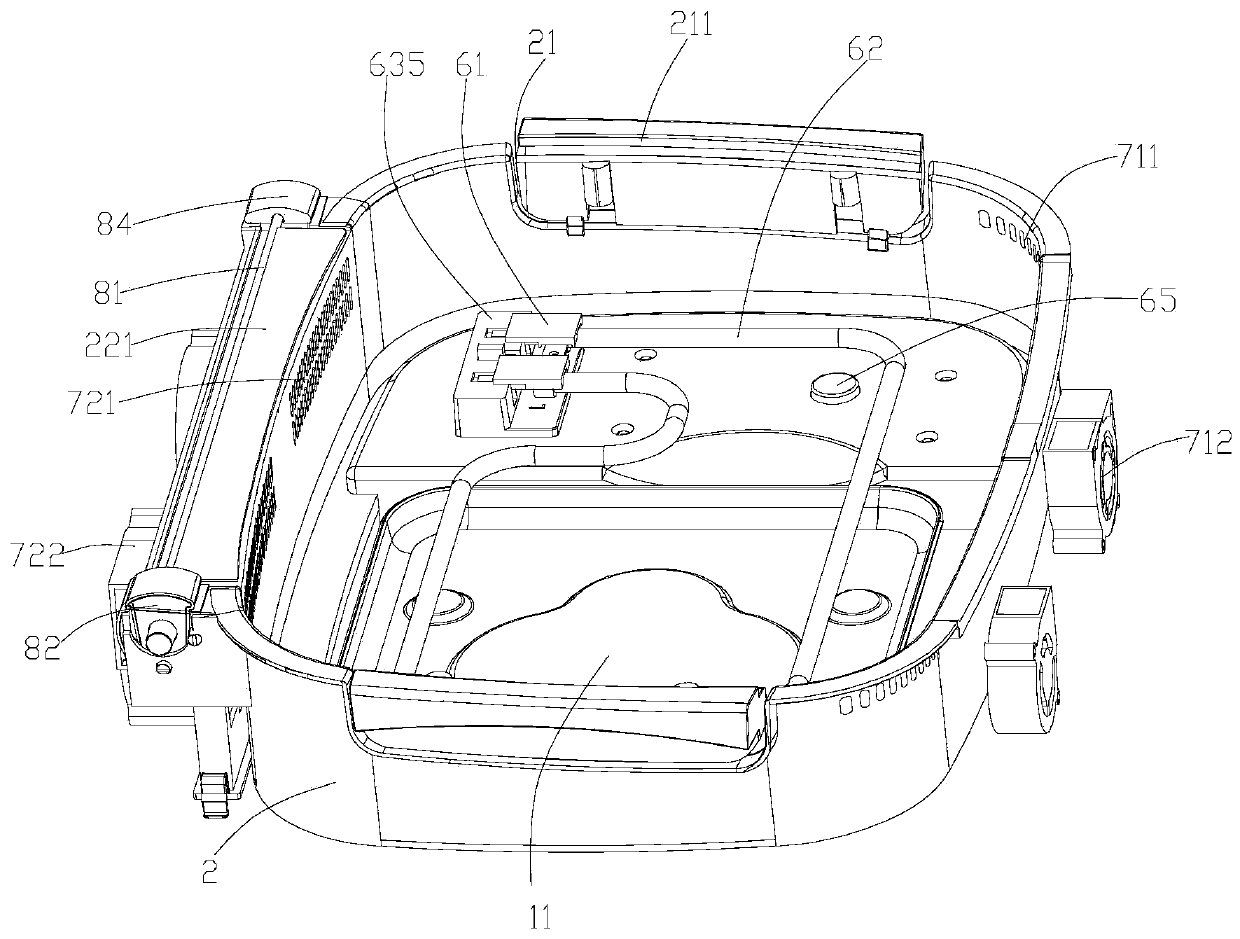

Electrical baking tray with fume suction function

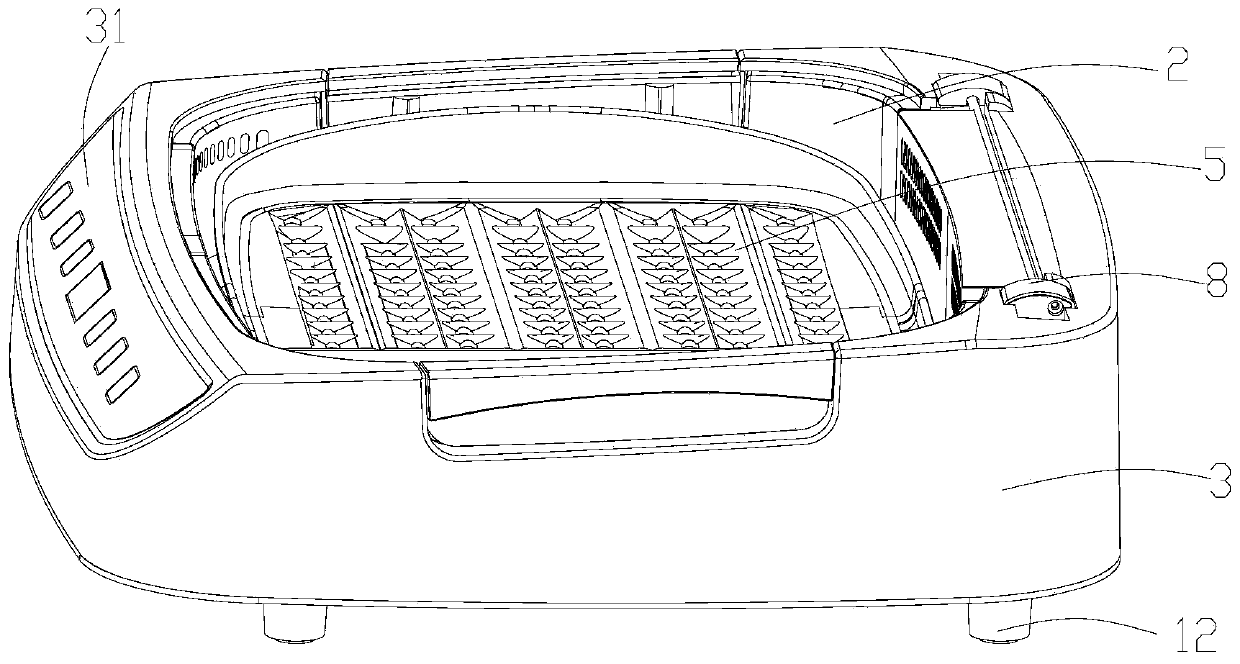

PendingCN109691902AAvoid secondary pollutionNo secondary pollutionRoasters/grillsFresh airEngineering

The invention discloses an electrical baking tray with a fume suction function. The electrical baking tray comprises a base, a casing arranged on the base, a cooking tray arranged on the casing, a heating device arranged below the cooking tray and providing a heat source for the cooking tray, an outer cover arranged on the casing and forming a gap with the outer wall of the casing to form an air circulation channel, a cooking fume filtering device arranged in the air circulation channel and used for filtering and purifying cooking fume on the cooking tray, a first recirculating air device usedfor introducing outside fresh air and air purified by the cooking fume filtering device into the casing and conveying the air above the cooking tray as well as a second recirculating air device usedfor sucking the cooking fume above the cooking tray in the casing and conveying the cooking fume into the air circulation channel. The n electrical baking tray has high fume suction efficiency and cantruly adsorb and purify the fume, can effectively remove strong odor in the fume and cannot pollute surrounding air.

Owner:陶红

Horizontal suspension sludge air-lift backflow method

ActiveCN103435148BIncrease concentrationFlexible and fast controlBiological water/sewage treatmentAir volumeStreamflow

The invention provides a horizontal suspension sludge air-lift backflow method. The method mainly comprises the following steps: sludge is sucked completely and in equilibrium and lifted to a biochemical reaction tank for recycling by arranging a horizontal plane-type air-lift micro-power backflow device in a suspension thick activated sludge layer and utilizing sludge suction pipes of the backflow device, which are horizontally arranged in the vertical and horizontal directions, and a compressed air control device outside the tank adjusts the air volume to control the quantity of backflow. Compared with the conventional sludge backflow method, the horizontal suspension sludge air-lift backflow method provided in the invention has a high backflow efficiency, there is no dead area or dead angle of sludge return in the large-area suspension sludge layer, and the backflow is in equilibrium; and besides, the activated sludge floc structure is not damaged, the control of backflow quantity is flexible, rapid and visual, no moving part or electrical equipment is used under water, and the backflow reliability is extremely high. Furthermore, an aeration blower of a sewage treatment plant is adopted for air supply, the corrected energy consumption for air-lift backflow is extremely low, and the energy-saving effect is obvious.

Owner:CENT & SOUTHERN CHINA MUNICIPAL ENG DESIGN & RES INST CO LTD

Energy-saving catalytic bed system

Owner:赛智环保科技(天津)有限公司

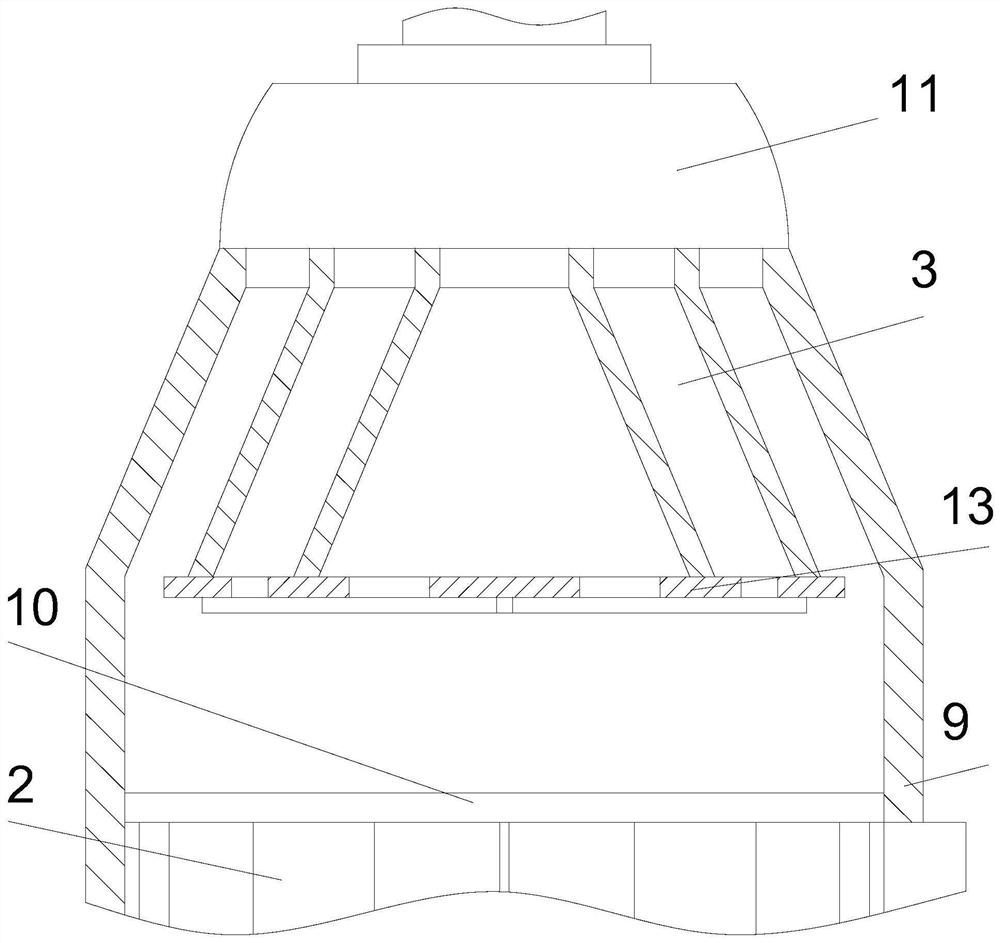

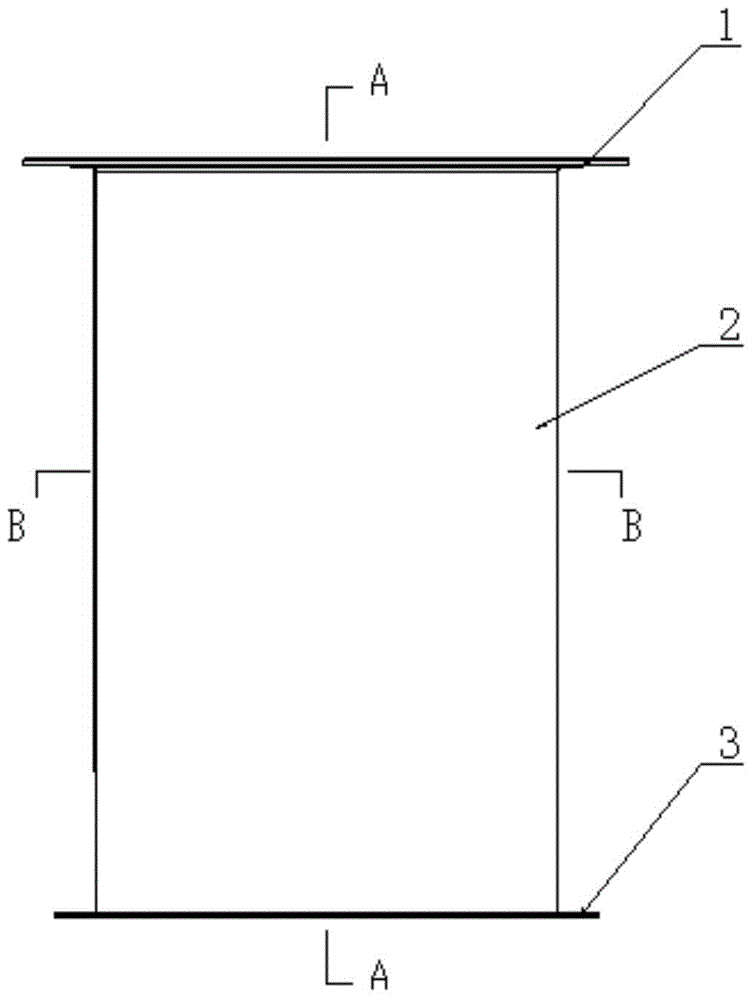

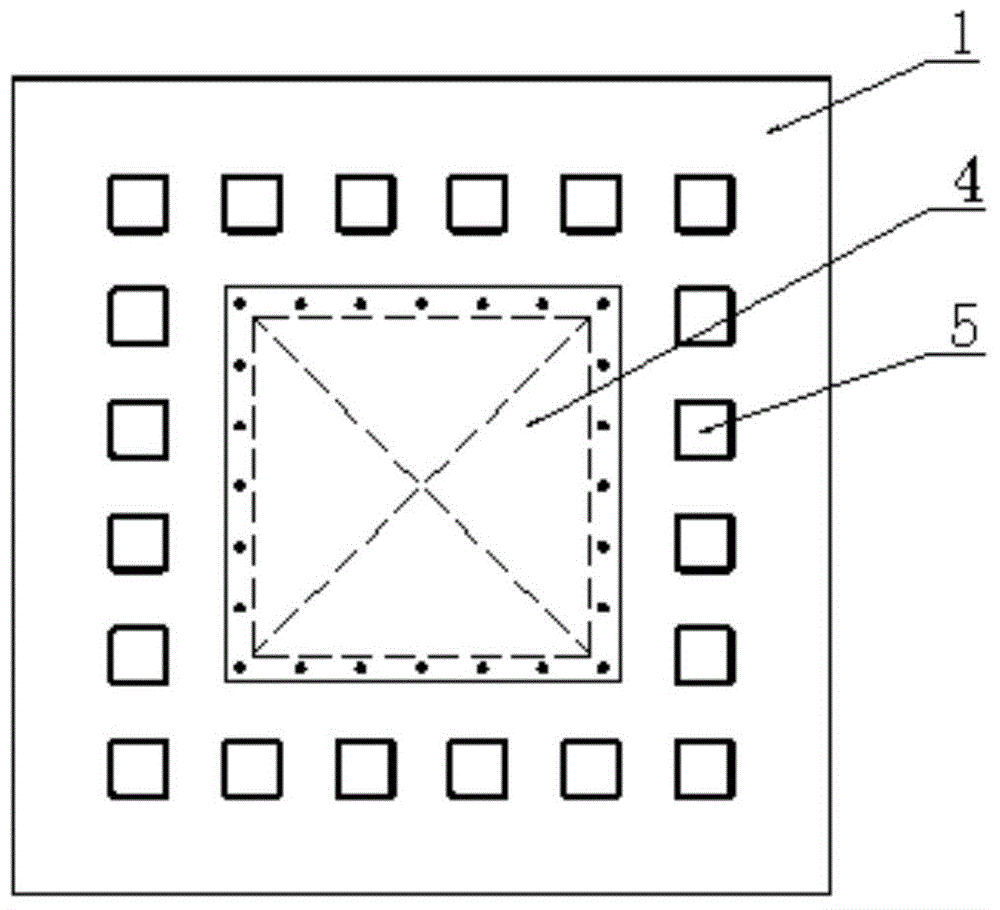

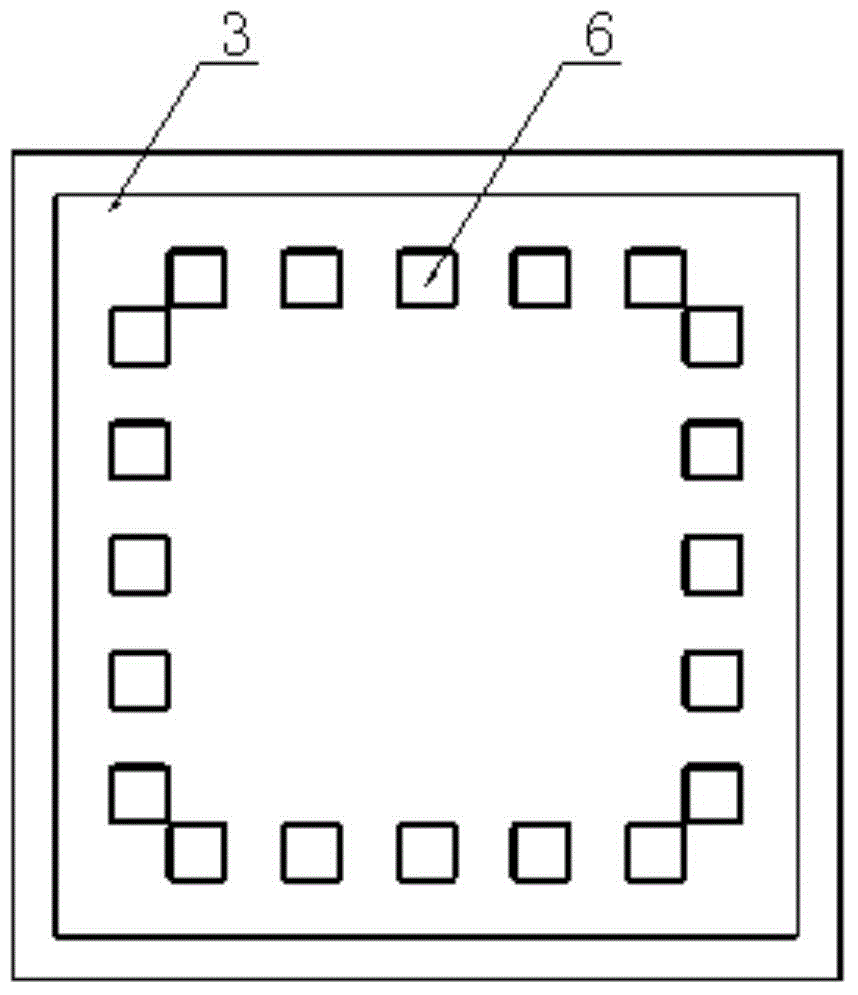

Catalytic bed furnace core structure with guide shield

The invention relates to a catalytic bed furnace core structure with a guide shield. The structure comprises an upper end plate, a lower end plate and a furnace core outer peripheral plate; the upper end plate and the lower end plate are respectively fixedly mounted on the upper end and the lower end of the furnace core outer peripheral plate; a furnace core inner peripheral plate is arranged in the furnace core outer peripheral plate; gas inlet paths and gas outlet paths are alternatively arranged between the furnace core inner peripheral plate and the furnace core outer peripheral plate; the inlet of each gas inlet path is arranged on the upper end plate; the outlet of each gas inlet path is arranged between the lower end plate and the furnace core inner peripheral plate; the inlet of each gas outlet path is arranged between the upper end plate and the furnace core inner peripheral plate; the outlet of each gas outlet path is arranged on the lower end plate; a guide shield with an inversed rectangular pyramid structure is arranged at the lower face of the middle of the upper end plate. The catalytic bed furnace core structure is simple in arrangement and scientific and reasonable in design, the heat efficiency of the furnace core structure can be effectively improved, the heat loss is reduced, the heat recovery utilization rate can be improved, the temperature in the furnace core structure is more uniform during burning, and the burning efficiency and the purifying rate are improved.

Owner:赛智环保科技(天津)有限公司

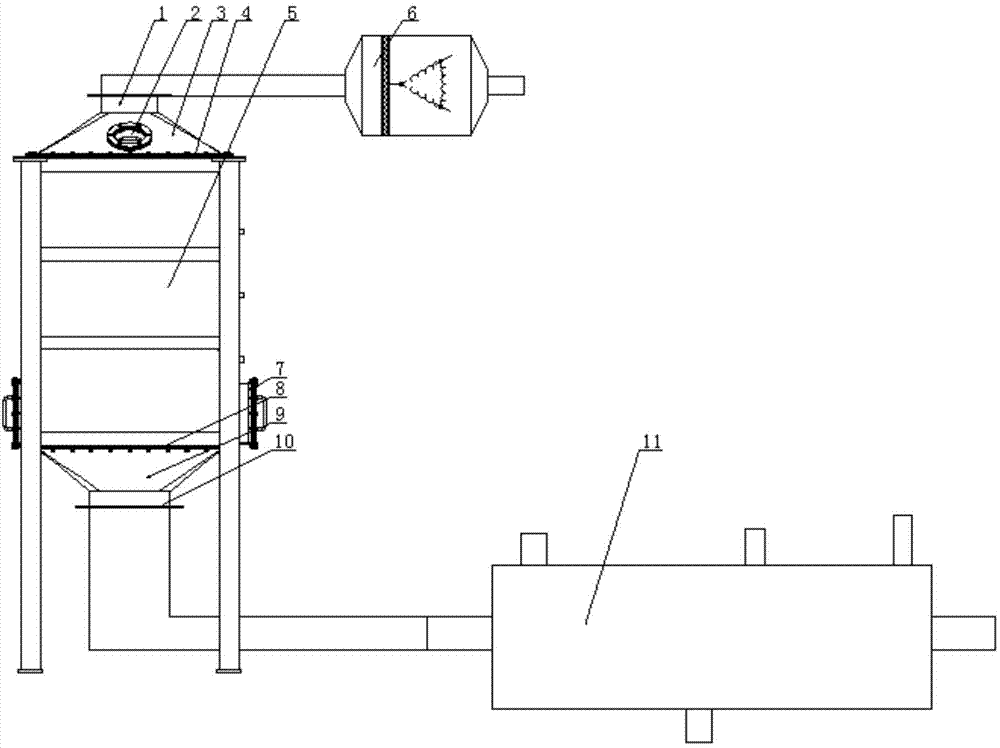

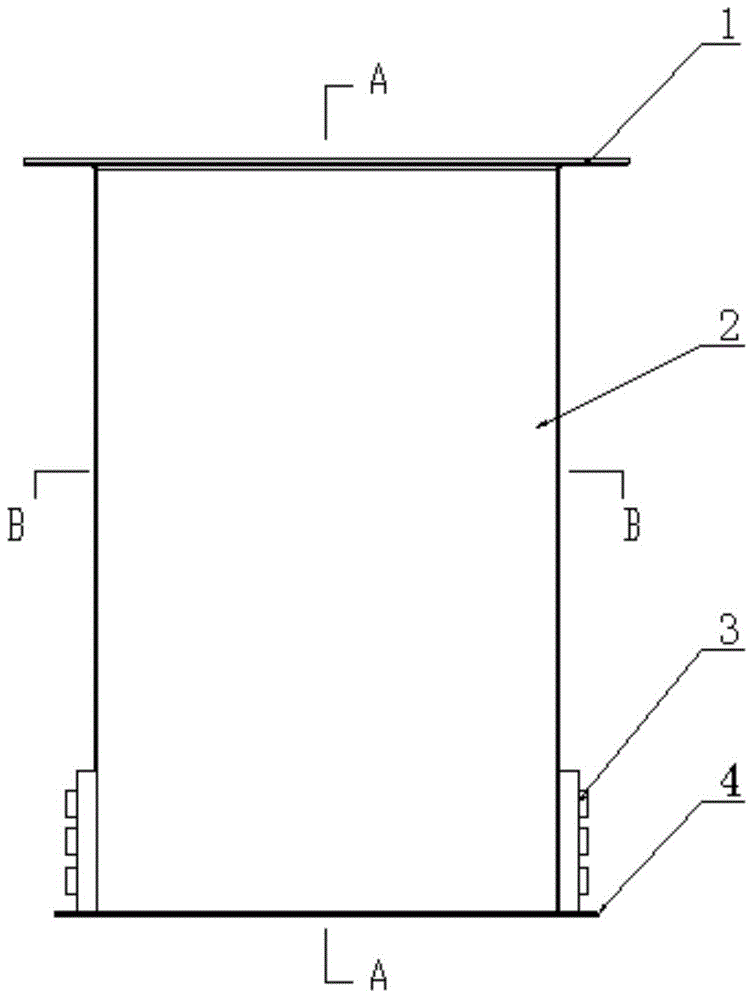

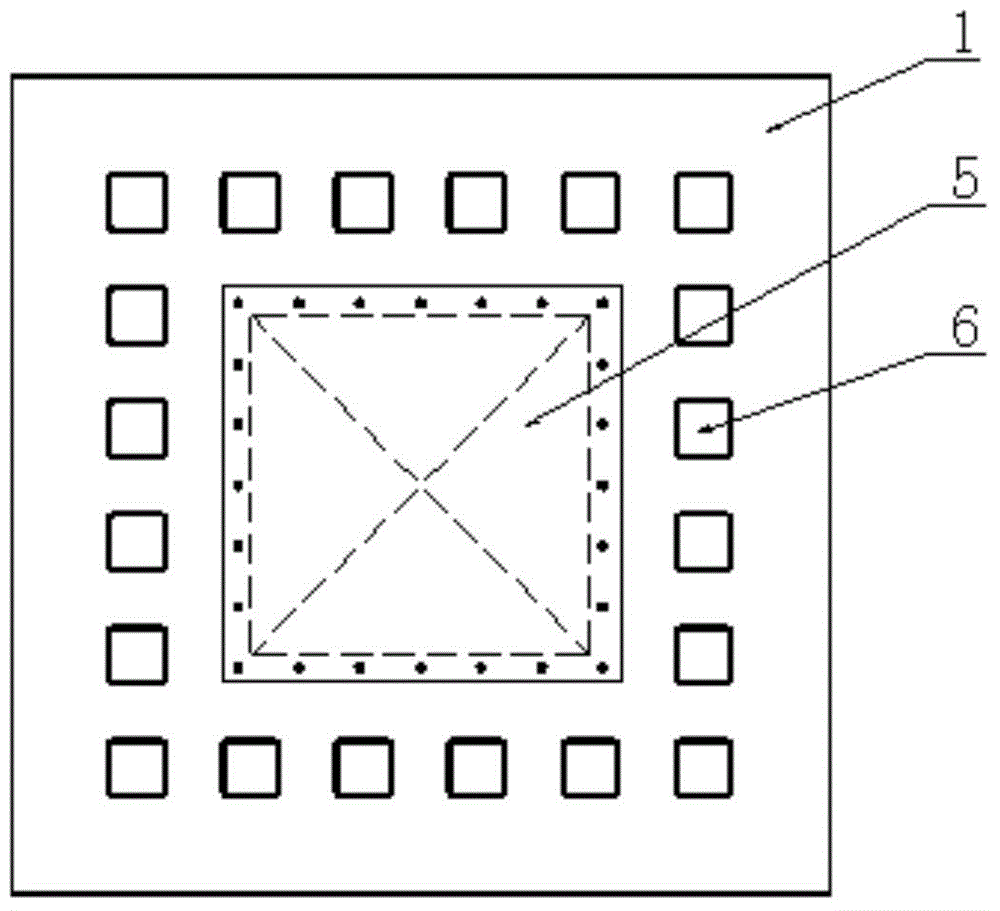

Special catalytic bed for industrial volatile organic pollutants in pm2.5

InactiveCN103486600BUniform air intakeUniform reflowCombustion using catalytic materialIncinerator apparatusParticulatesInsulation layer

The invention relates to a catalyzing bed special for industrial volatilizable organic pollutants in PM2.5 (particulate matter 2.5). The catalyzing bed is characterized in that heat insulation layers are fixedly and uniformly mounted on the outer wall of a furnace body exterior plate, a furnace body interior plate is arranged in the furnace body exterior plate, air incoming ways and air outgoing ways are alternatively arranged between the furnace body interior plate and the furnace body exterior plate, an inlet of each air incoming way is arranged on an upper end plate while an outlet of the same is arranged between a lower end plate and the furnace body interior plate, an inlet of each air outgoing way is arranged between the upper end plate and the furnace body interior plate while an outlet of the same is arranged on a lower end plate, an incoming air guide cover is arranged above the middle portion of the upper end plate corresponding to an air incoming cover inlet, a combustion gas guide cover is arranged above the lower portion of the upper end plate, and an outgoing air guide cover is arranged below the middle portion of the lower end plate corresponding to an air outgoing cover outlet. Heat efficiency of the catalyzing combustion bed is effectively improved, heat loss is reduced, temperature in the catalyzing combustion bed is more uniform during combustion, and combustion efficiency and purifying rate are improved.

Owner:赛智环保科技(天津)有限公司

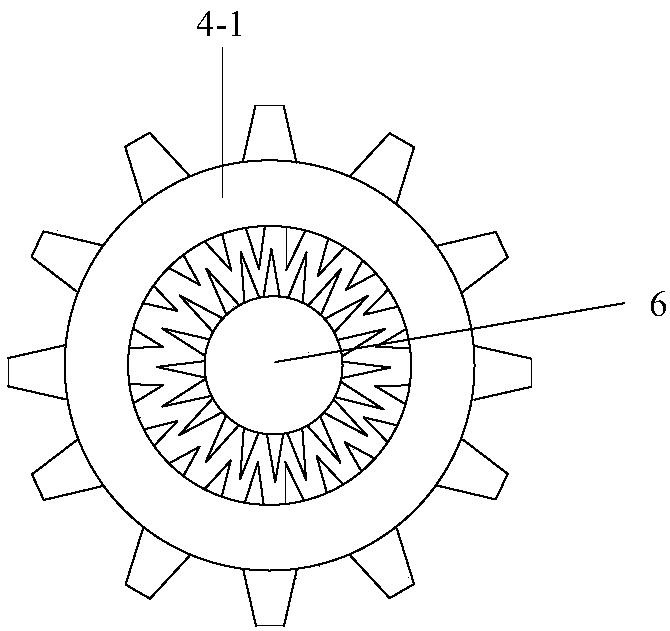

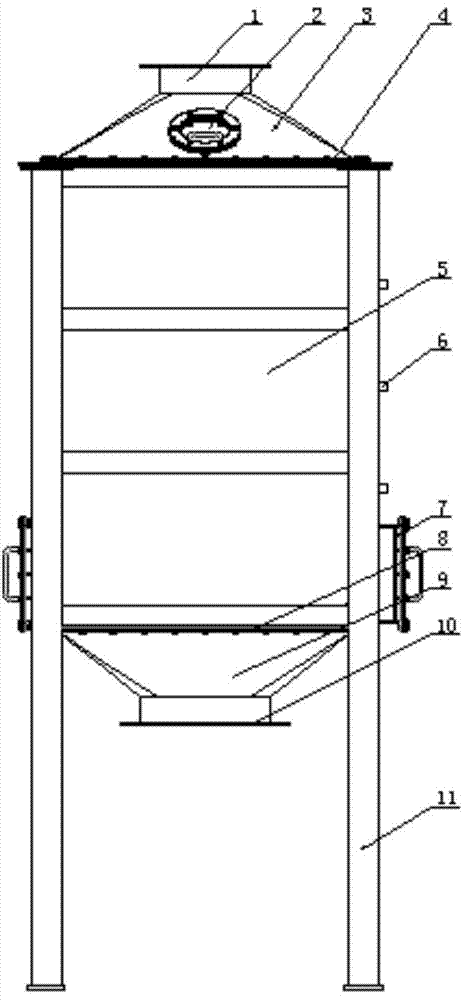

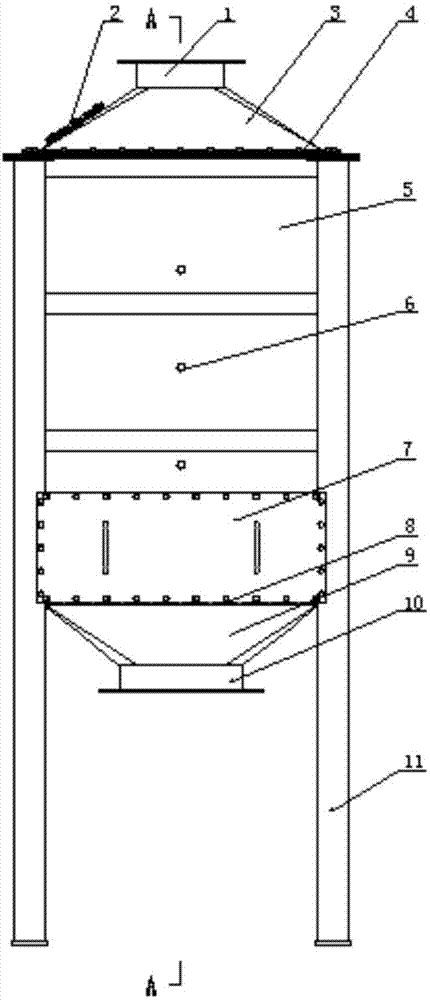

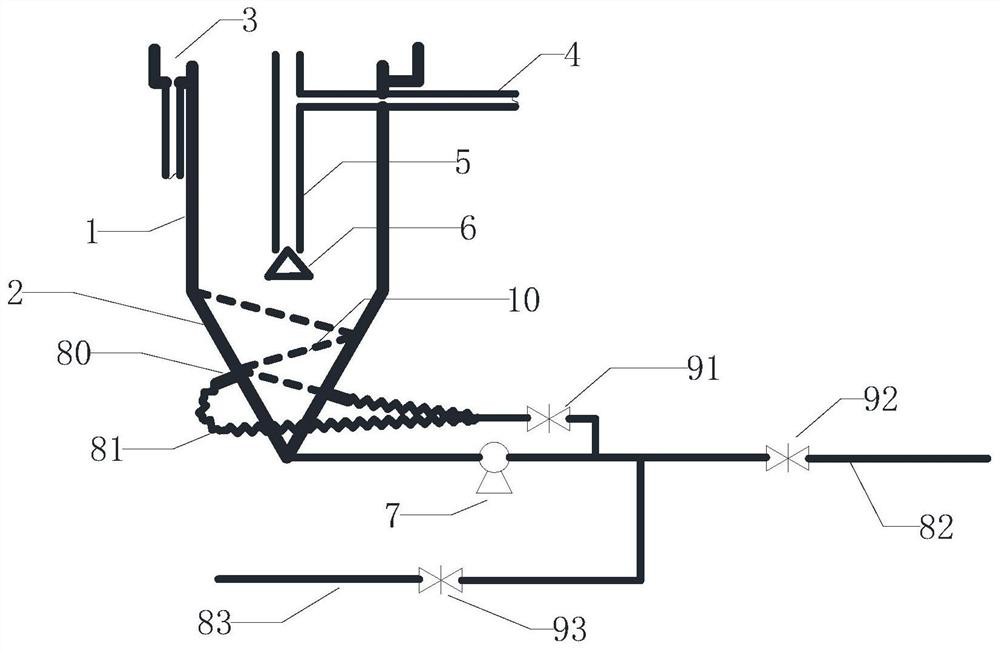

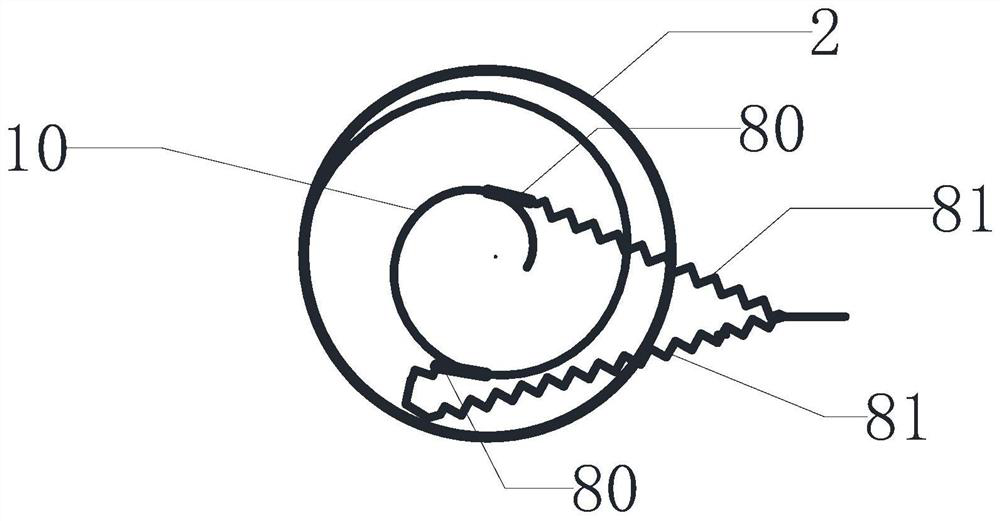

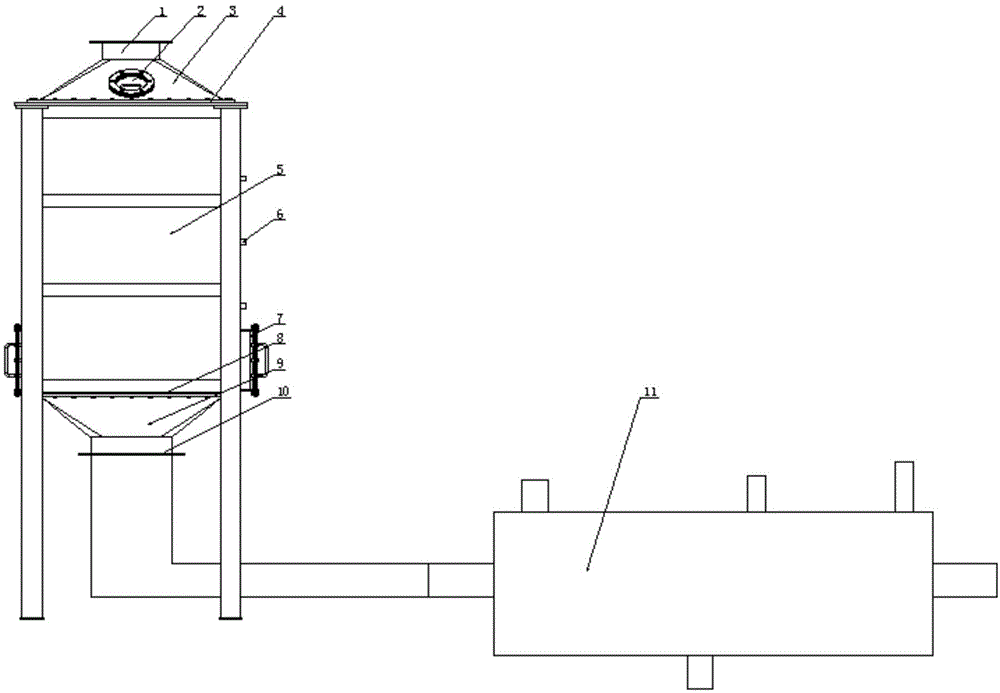

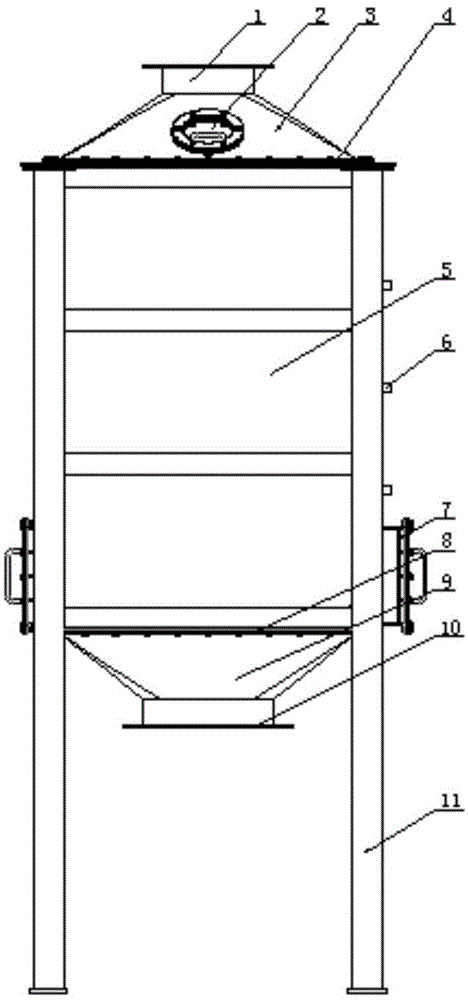

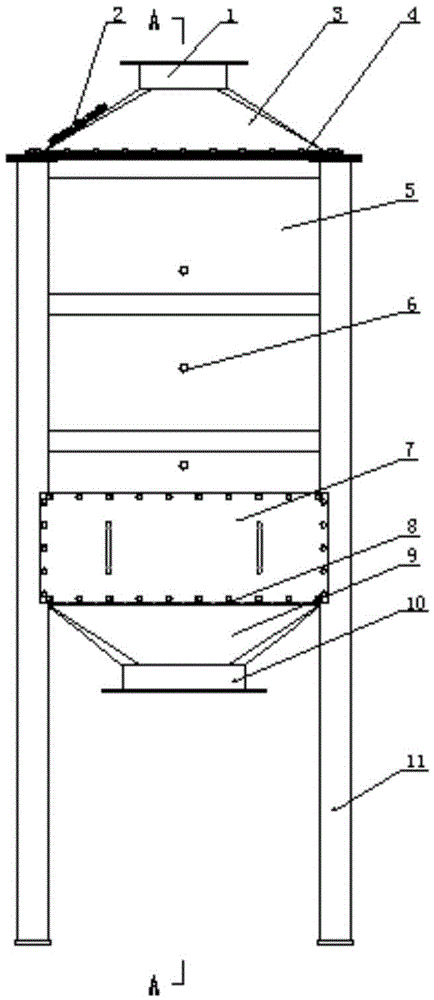

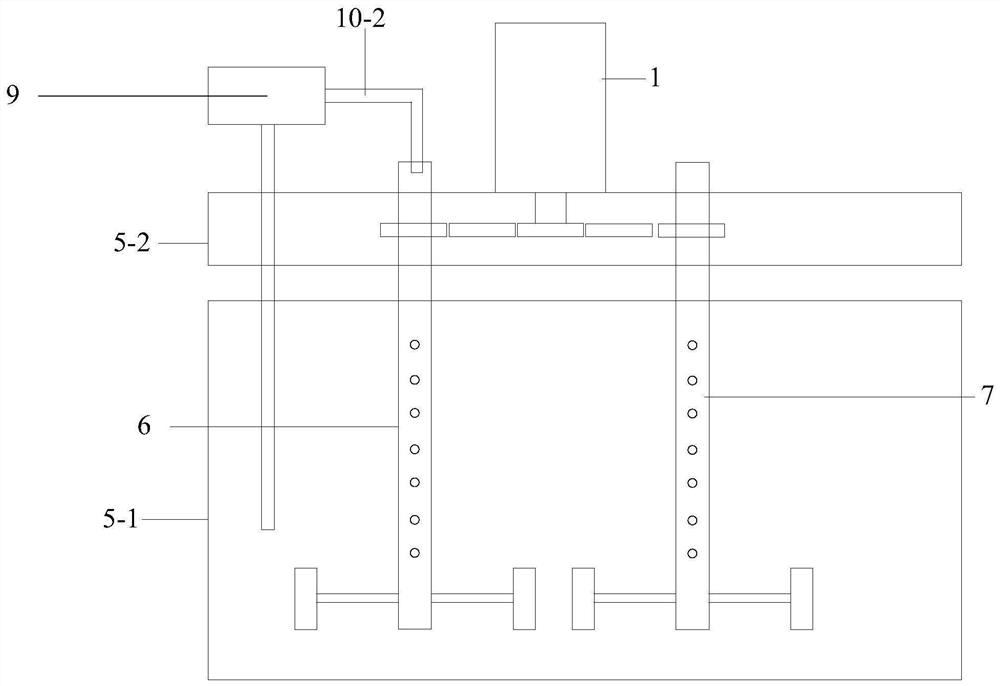

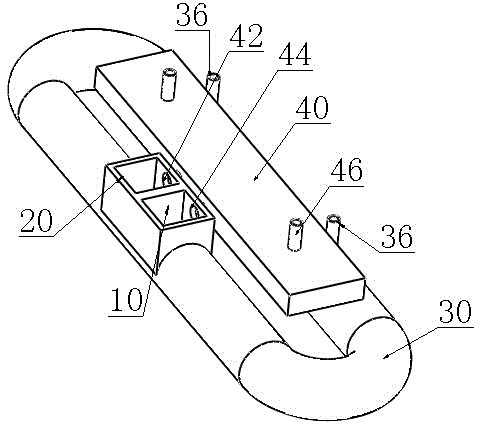

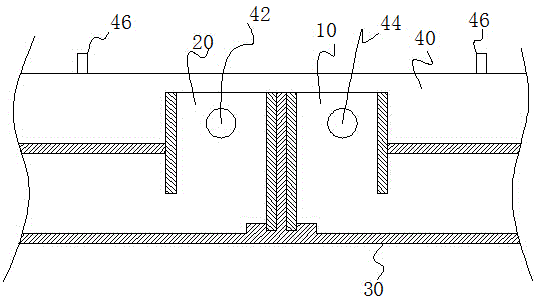

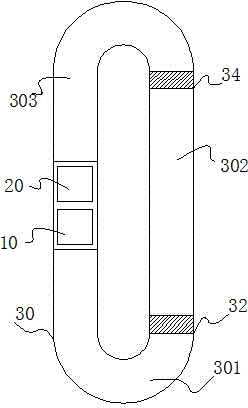

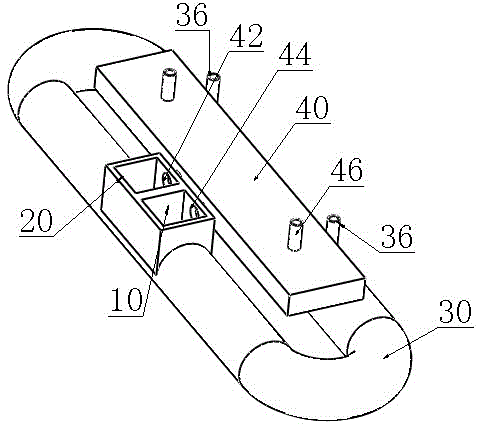

Electrolyte mixing tank and working method thereof

ActiveCN108187532BSolve the problem of deposits on the lower part of the stirring shaftUniform reflowRotary stirring mixersTransportation and packagingElectrolytic agentEngineering

The invention discloses an electrolyte stirring tank and a working method thereof; the main technical points are: the first stirring shaft is a hollow stirring shaft with openings at both top and bottom ends, and the first stirring shaft (6) includes: a first vertical part , the first horizontal part, the second vertical part, stirring blades are all set on the first vertical part and the second vertical part, and the first vertical part and the second vertical part of the first stirring shaft are all provided with stirring blades , and the area of the stirring blade of the second vertical portion is wider than the stirring area of the stirring blade of the first vertical portion; The problem with the bottom of the axis.

Owner:丁建利

Active sludge surface type gas stripping micro power reflux apparatus

ActiveCN103395875BIncrease concentrationFlexible and fast controlBiological water/sewage treatmentRefluxSludge

Owner:WUHAN PURGELON ENVIRONMENTAL ENG TECH

Energy-saving type catalytic bed system with controllable temperature

InactiveCN103486601BUniform air intakeUniform adsorptionIncinerator apparatusDesorptionHeat exchanger

The invention relates to an energy-saving type catalytic bed system with the controllable temperature. The energy-saving type catalytic system comprises a gas inlet heater, a catalytic bed and a heat exchanger. A gas inlet channel and a gas outlet channel are alternately formed between a furnace body inner surrounding plate and a furnace body outer surrounding plate. The inlet of the gas inlet channel is formed in an upper end plate, and the outlet of the gas inlet channel is formed between a lower end plate and the furnace body inner surrounding plate. The inlet of the gas outlet channel is formed between the upper end plate and the furnace body inner surrounding plate, and the outlet of the gas outlet channel is formed in the lower end plate. The heater is arranged in a furnace body corresponding to the outlet of the gas inlet channel. A gas outlet flow guide cover is arranged on the lower face of the middle of the lower end plate corresponding to the outlet of a gas outlet cover. A catalytic tail gas inlet, a catalytic tail gas outlet, a catalytic gas inlet, a catalytic gas outlet, a desorption gas supply inlet and a desorption gas supply outlet are formed in the heat exchanger. By the adoption of the energy-saving type catalytic bed system, heat efficiency of the catalytic bed is effectively improved, the heat loss is reduced, the heat recovery utilization rate, combustion efficiency and the purification rate are improved, heat exchange is increased, heat energy is more reasonably utilized, and the energy saving and emission reduction requirements are met.

Owner:赛智环保科技(天津)有限公司

Special catalytic combustion bed for industrial volatile organic pollutants in PM2.5

InactiveCN103471113BUniform air intakeUniform reflowCombustion using catalytic materialIncinerator apparatusParticulatesProcess engineering

The invention relates to a catalytic combustion bed special for industrial volatilizable organic pollutants in PM 2.5 (particulate matter). A furnace inner enclosing plate is arranged in a furnace body outer enclosing plate; gas inlet paths and gas outlet paths are alternatively arranged between the furnace body inner enclosing plate and the furnace body outer enclosing plate; the inlet of each gas inlet path is arranged on an upper end plate; the outlet of each gas inlet path is arranged between a lower end plate and the furnace body inner enclosing plate; the inlet of each gas outlet path is arranged between the upper end plate and the furnace body inner enclosing plate; the outlet of each gas outlet path is arranged on the lower end plate; a gas inlet flow guiding shield is arranged on the middle, corresponding to the inlet of the gas inlet shield, of the upper end plate; a combustion gas flow guiding layer is arranged under the middle of the upper end plate; a heater is arranged in a furnace body corresponding to the outlets of the gas inlet paths; a catalyst layer is mounted on a catalyst support; a thermalcouple is mounted on the side wall of the furnace body. According to the catalytic combustion bed for the industrial volatilizable organic pollutants in PM 2.5, the heat efficiency of the catalytic combustion can be effectively improved, the heat loss can be reduced, the temperature in the catalytic combustion bed is more uniform during burning, and the burning efficiency and the purifying rate are improved.

Owner:赛智环保科技(天津)有限公司

Energy-saving catalytic bed system

The invention relates to an energy-saving catalytic bed system which comprises an air inlet cover, a furnace body, an air outlet cover and a heat exchanger; air inlet channels and air outlet channels are alternatively arranged between the inner coaming of the furnace body and the outer coaming of the furnace body; the inlet of each air inlet channel is arranged on an upper end plate, and the outlet of each air inlet channel is arranged between a lower end plate and the inner coaming of the furnace body; the inlet of each air outlet channel is arranged between the upper end plate and the inner coaming of the furnace body, and the outlet of each air outlet channel is arranged on the lower end plate; a heater is arranged in the furnace body which corresponds to the outlets of the air inlet channels; an air outlet deflection cover is arranged below the middle part of the lower end plate which corresponds to the outlet of the air outlet cover; the heat exchanger is provided with a catalytic exhaust inlet, a catalytic exhaust outlet, a catalytic gas inlet, a catalytic gas outlet, a desorption gas supply inlet and a desorption gas supply outlet. According to the energy-saving catalytic bed system, the heat efficiency of a catalytic bed is effectively improved, the heat loss is reduced, the heat recovery and utilization rate is improved, the burning efficiency and purification rate are improved, heat exchange is increased, the heat energy is utilized more reasonably, and the energy saving and emission reduction requirements are met.

Owner:赛智环保科技(天津)有限公司

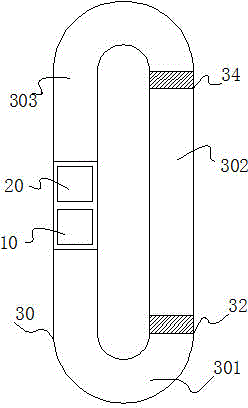

Method for generating biogas by using device for promoting uniform distribution of strain of multi-region circular fermentation system

InactiveCN104673654ASpeed up the flowEffectively bring inGas production bioreactorsWaste based fuelSlurryAtmosphere

The invention discloses a method for generating biogas by using a device for promoting uniform distribution of a strain of a multi-region circular fermentation system. The method comprises the following steps: pouring a fermentation raw material into a feed pipe; pushing a biogas slurry to flow to adjacent fermentation zones when biogas is generated in the fermentation zones formed between side walls of feed / discharge pipes and gas baffle plates or the fermentation zones formed between adjacent gas baffle plates in a circular fermentation pipeline, and pushing the biogas slurry into the feed pipe, the discharge pipe and a bacterium distributing device; when the fermentation zones are full of biogas, flowing the biogas continuously generated by fermentation to the adjacent fermentation zones which are not full of biogas until all the fermentation zones are communicated with one another; and when the biogas slurry liquid level in the circular fermentation pipeline reaches the lowest position of the side wall of the feed pipe or the discharge pipe, overflowing the biogas continuously generated by fermentation out of the fermentation system and discharging the biogas to the atmosphere.

Owner:张玲玲

Ultrahigh-efficiency fermentation system capable of driving strains to be evenly distributed through multiarea biogas slurry turbulence

InactiveCN104694376ASpeed up the flowEffectively bring inGas production bioreactorsBiological material testing proceduresEngineeringSlurry

The invention discloses an ultrahigh-efficiency fermentation system capable of driving strains to be evenly distributed through multiarea biogas slurry turbulence. The ultrahigh-efficiency fermentation system comprises a feed pipe, a discharge pipe, a fermentation pipeline and a water pressure chamber, wherein the feed pipe and the discharge pipe are respectively vertically inserted into two sides of a partition, the side walls of the feed pipe and the discharge pipe extend to the position below the biogas slurry level of a circular fermentation pipeline; a feed pipe drain pipe is connected between the water pressure chamber and the feed pipe, and a discharge pipe drain pipe is connected between the water pressure chamber and the discharge pipe, at least a gas barrier plate is arranged in the circular fermentation pipe, a fermentation area is formed between the adjacent gas barrier plates, an independent gas guide pipe is arranged at the top of the fermentation area, and a valve body is arranged on the gas guide pipe.

Owner:张玲玲

Method for generating marsh gas in fermentation system driving even distribution of strains by multi-zone marsh liquid turbulence

ActiveCN104673656ASpeed up the flowEffectively bring inGas production bioreactorsWaste based fuelMarshAtmospheric air

The invention discloses a method for generating marsh gas in fermentation system driving even distribution of strains by multi-zone marsh liquid turbulence. The method comprises the following steps that: fermentation raw materials are poured into a feeding pipe, when a fermentation zone formed between a feeding / discharging pipe sidewall and a gas blocking plate or a fermentation zone formed between the adjacent gas blocking plates in a ring-shaped fermentation pipeline generates marsh gas, the marsh liquid is pushed to flow to the adjacent fermentation zone, and is further pushed into the feeding pipe, the discharging pipe and a strain distribution device; when the fermentation is full of the marsh gas, the marsh gas generated by further fermentation flows to the adjacent fermentation zones which is not full, until each fermentation zones is intercommunicated; when the liquid level of the marsh liquid in the ring-shaped fermentation pipeline reaches the lowest position of the sidewall of the feeding pipe or the discharging pipe, the marsh gas generated by further fermentation overflows from the fermentation system and is discharged into the atmosphere.

Owner:重庆博视知识产权服务有限公司

Catalytic combustion bed core structure with heater

InactiveCN103471115BGood for auxiliary heatingFast heatingCombustion using catalytic materialIncinerator apparatusHeat lossesEngineering

The invention relates to a catalytic combustion bed furnace core structure with a heater. The structure comprises a furnace core outer peripheral plate as well as an upper end plate and a lower end plate which are respectively mounted on the upper end and the lower end of the furnace core outer peripheral plate; a furnace core inner peripheral plate is arranged in the furnace core outer peripheral plate; gas inlet paths and gas outlet paths are alternatively arranged between the furnace core inner peripheral plate and the furnace core outer peripheral plate; the inlet of each gas inlet path is arranged on the upper end plate; the outlet of each gas inlet path is arranged between the lower end plate and the furnace core inner peripheral plate; the inlet of each gas outlet path is arranged between the upper end plate and the furnace core inner peripheral plate; the outlet of each gas outlet path is arranged on the lower end plate; a gas guide shield with an inversed rectangular pyramid structure is arranged at the lower face of the middle of the upper end plate; the heater is arranged in the furnace core body corresponding to the outlet of each gas inlet path and is fixedly mounted on the furnace core outer peripheral plate. The catalytic combustion bed furnace structure is simple in arrangement, the heat efficiency of the furnace core body can be effectively improved, the heat loss can be reduced, the heat recovery utilization rate can be improved, the temperature in the furnace core structure can be more even during combustion, and the burning efficiency and the purifying rate are improved.

Owner:赛智环保科技(天津)有限公司

Catalytic bed furnace core structure with guide shield

The invention relates to a catalytic bed furnace core structure with a guide shield. The structure comprises an upper end plate, a lower end plate and a furnace core outer peripheral plate; the upper end plate and the lower end plate are respectively fixedly mounted on the upper end and the lower end of the furnace core outer peripheral plate; a furnace core inner peripheral plate is arranged in the furnace core outer peripheral plate; gas inlet paths and gas outlet paths are alternatively arranged between the furnace core inner peripheral plate and the furnace core outer peripheral plate; the inlet of each gas inlet path is arranged on the upper end plate; the outlet of each gas inlet path is arranged between the lower end plate and the furnace core inner peripheral plate; the inlet of each gas outlet path is arranged between the upper end plate and the furnace core inner peripheral plate; the outlet of each gas outlet path is arranged on the lower end plate; a guide shield with an inversed rectangular pyramid structure is arranged at the lower face of the middle of the upper end plate. The catalytic bed furnace core structure is simple in arrangement and scientific and reasonable in design, the heat efficiency of the furnace core structure can be effectively improved, the heat loss is reduced, the heat recovery utilization rate can be improved, the temperature in the furnace core structure is more uniform during burning, and the burning efficiency and the purifying rate are improved.

Owner:赛智环保科技(天津)有限公司

Unordered turbulence super-effective biogas fermentation system

ActiveCN104673635ASpeed up the flowEffectively bring inGas production bioreactorsWaste based fuelAgricultural engineeringSlurry

The invention discloses an unordered turbulence super-effective biogas fermentation system. The system comprises a feeding pipe, a discharging pipe, a fermentation pipeline and a water pressure chamber, wherein the fermentation pipeline is ring-shaped, the water pressure chamber is placed at the top of the ring-shaped fermentation pipeline, the ring-shaped fermentation pipeline is provided with an opening, center of the opening is provided with a partition plate extending to the bottom of the ring-shaped fermentation pipeline, the feeding pipe and the discharging pipe are respectively inserted at two sides of the partition plate in vertical direction, and sidewalls of the feeding pipe and the discharging pipe extend to a position under the liquid level of the biogas slurry in the ring-shaped fermentation pipeline; a drain pipe of feeding pipe is connected between the water pressure chamber and the feeding pipe, a drain pipe of discharging pipe is connected between the water pressure chamber and the discharging pipe, inside of the ring-shaped fermentation pipeline is at least provided with one gas blocking plate, one fermentation zone is formed between the neighboring gas blocking plates, top of the fermentation zone is provided with an independent gas guide pipe, and the gas guide pipe is provided with a valve body.

Owner:北京航天恒丰科技股份有限公司

Z-shaped gas stripping reflux two-stage precipitation integrated sewage treatment tank

ActiveCN103395948BLow costPrevents clogging and wearMultistage water/sewage treatmentSludgeWater quality

The present invention provides a Z-shaped gas stripping reflux two-stage precipitation integrated sewage treatment tank, wherein the rectangular tank body contains a grid-containing sand settling pretreatment zone, an anoxic zone, an aeration zone, a clarifying reflux zone, an inclined pipe / plate precipitation zone, a contact disinfection ditch, and the like, and conventional water treatment equipment, a horizontal slit-type gas-water separator, a Z-shaped separation wall, a surface type gas stripping micro power reflux device arranged in a horizontal and completely-paving manner, and an L-shaped hydropower hybrid spiral flow generator are arranged inside the tank body. The Z-shaped gas stripping reflux two-stage precipitation integrated sewage treatment tank has a simple and compact structure, and has the following advantages that: denitrogenation, phosphorus removing, two stage precipitation and disinfection treatment are completed in the same tank; and compared with the conventional process adopting a plurality of independent small tanks, the Z-shaped gas stripping reflux two-stage precipitation integrated sewage treatment tank of the present invention has advantages of low investment, small occupation area, less agent consumption, less sludge discharge, low energy consumption, low cost, stable and controllable water quality, easy operation and management, and the like, and is especially suitable for sewage denitrogenation and phosphorus removing integrated treatments with a scale of 10000 tons / day and below.

Owner:WUHAN PURGELON ENVIRONMENTAL ENG TECH

An electrolyte feeding device

ActiveCN108166022BReal-time monitoring of concentrationImplement automatic additionPhotography auxillary processesElectrolysis componentsElectrolysisPhysical chemistry

The invention discloses an electrolyte solution charging device which is used for producing copper foils. The electrolyte solution charging device comprises an electrolyte solution stirring barrel, abuffer storage barrel, an electrolysis slot and a controller, wherein a first pump is used for extracting an electrolyte solution in the electrolyte solution stirring barrel through a pipeline, and feeding the electrolyte solution into the buffer storage barrel through a solution transfer pipeline; the electrolyte solution in the buffer storage barrel is fed into the electrolysis slot through a flow pump; an electrolyte solution sensor is arranged in the electrolysis slot; and the electrolyte solution sensor is mainly used for measuring concentration of copper sulfate in the electrolysis slotin real time. The invention aims to provide the electrolyte solution charging device which can solve the problem about how to automatically charge the electrolyte solution.

Owner:陈治政

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com