Multi-cycle composite bioreactor and process thereof

A bioreactor and composite technology, applied in the field of sewage treatment, can solve the problems of insufficient carbon sources, poor simultaneous removal of nitrogen and phosphorus, and high energy consumption, and achieve efficient synchronous nitrification and denitrification, reduce sludge production, and improve operating efficiency. The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

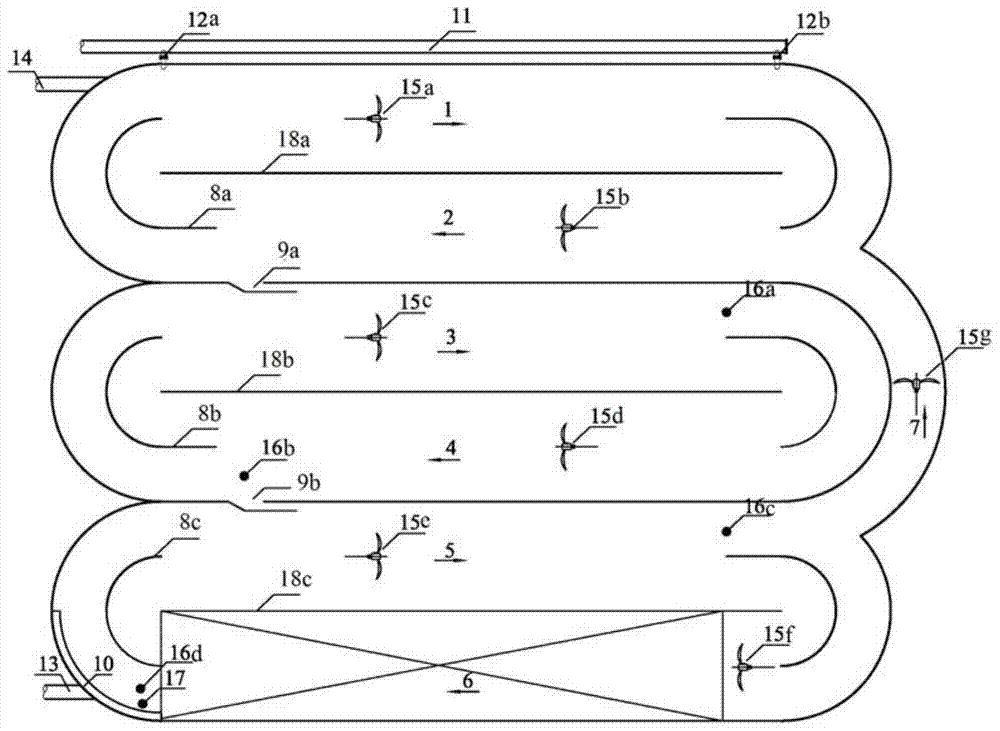

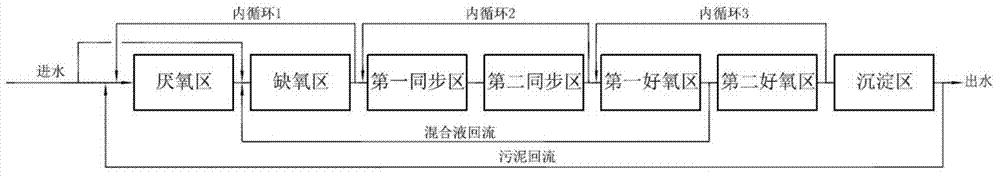

[0043] Such as figure 1As shown, the multi-cycle compound bioreactor used in this embodiment includes anaerobic zone 1, anoxic zone 2, first synchronous zone 3, second synchronous zone 4, first aerobic zone 5 and second aerobic zone Zone 6, wherein the anaerobic zone 1 and the anoxic zone 2, the first synchronous zone 3 and the second synchronous zone 4, the first aerobic zone 5 and the second aerobic zone 6 each form a circulation corridor.

[0044] The multi-cycle composite bioreactor comprises an anaerobic zone 1, anoxic zone 2, a first synchronous zone 3, a second synchronous zone 4, a first aerobic zone 5 and a second aerobic zone 6, wherein

[0045] One or more water inlets are distributed on the main water inlet pipe 11, and each water inlet is equipped with an inlet flow regulating valve, which is connected to the anaerobic zone 1, and the sludge return pipe 14 from the secondary sedimentation tank is connected to In the anaerobic zone 1, a partition wall 18a is set b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com