Denitration ammonia spraying flow adjusting device based on cascade PID (proportion integration differentiation) and feedforward and working method of device

A working method and ammonia flow technology, applied in separation methods, chemical instruments and methods, and controllers with specific characteristics, etc., can solve problems such as easy oscillation and divergence of the concentration at the chimney inlet, shaking of the ammonia injection regulating valve, and difficulty in stable control, etc. , to achieve the effect of maintaining stable NOx concentration at the chimney inlet, reducing control overshoot, and overcoming control problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0035] Example.

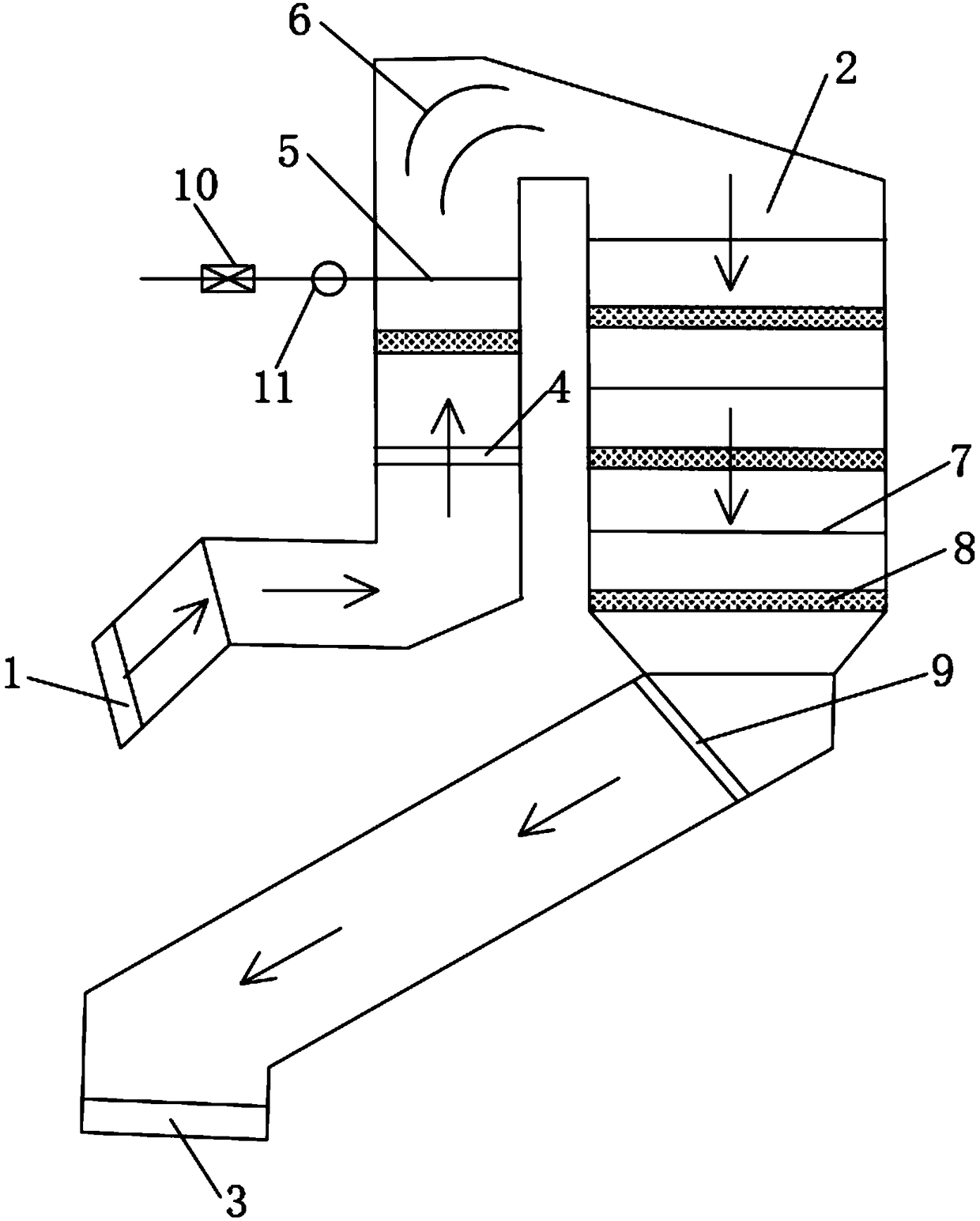

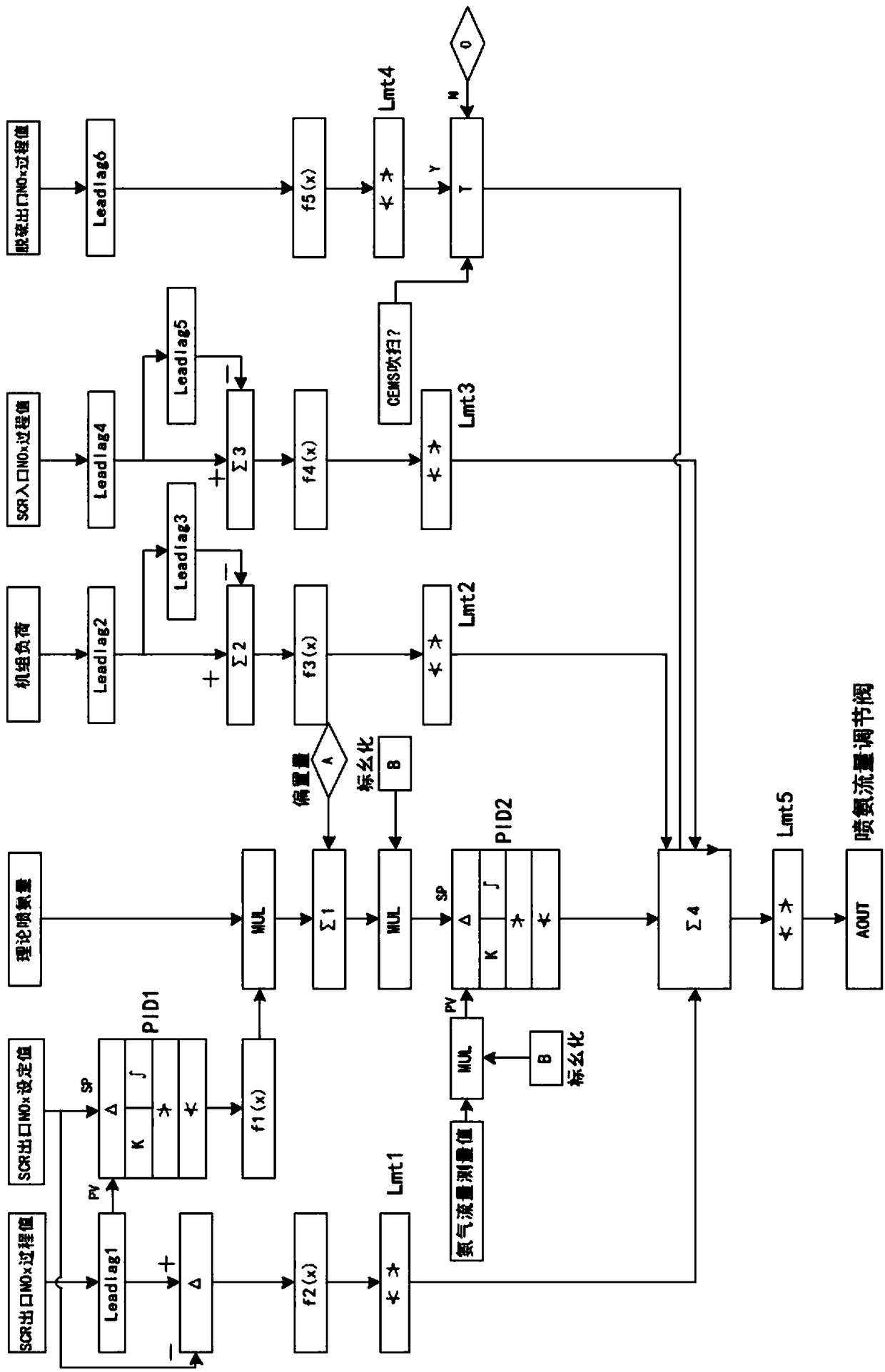

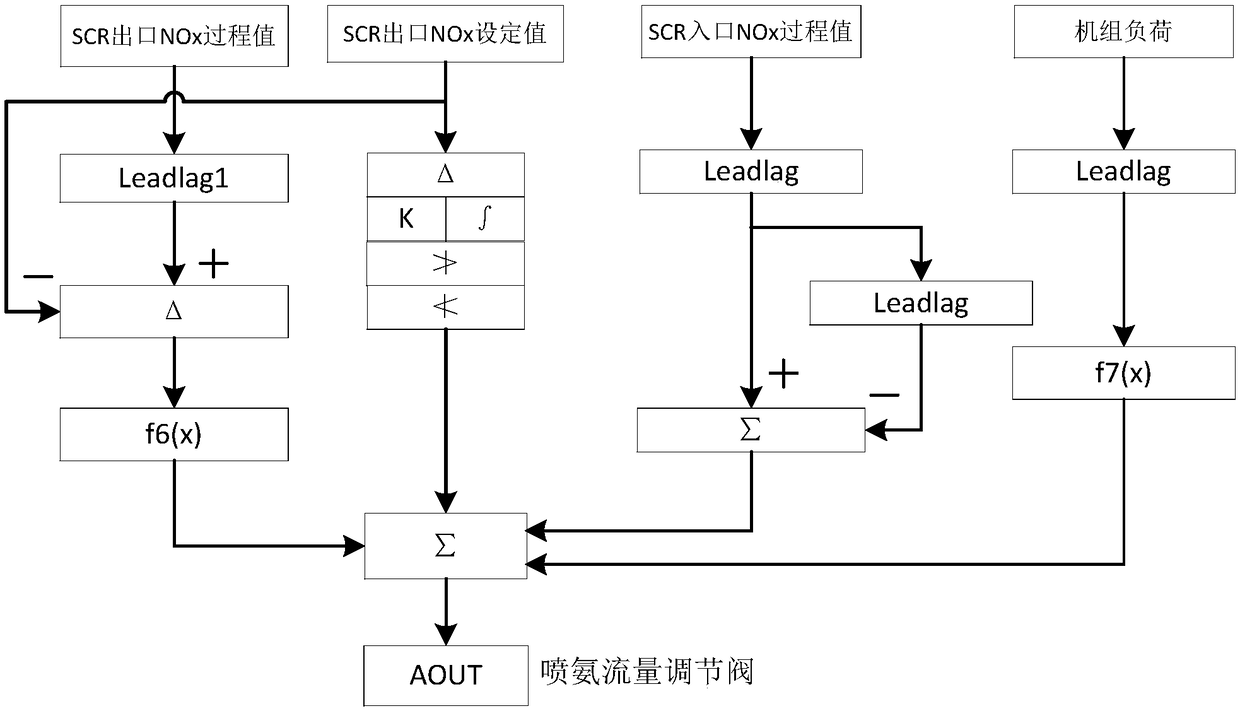

[0036] see figure 1 , the device in this embodiment based on cascade PID plus feed-forward adjustment of denitrification and ammonia injection flow includes SCR reactor 2, electric control valve 10 and flow meter 11, etc., SCR reactor 2 is arranged between boiler economizer 1 and air Between preheaters 3; SCR reactor 2 includes SCR reactor inlet 4, No. 1 ammonia injection grid 5, deflector 6, No. 2 ammonia injection grid 7, catalyst layer 8 and SCR reactor outlet 9; SCR The reactor inlet 4 is arranged adjacent to the boiler economizer 1, and the SCR reactor outlet 9 is arranged adjacent to the air preheater 3; No. 1 ammonia injection grid 5, deflector 6, No. 2 ammonia injection grid 7 and Catalys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com