Multiple spray-head combined type air-injection electrostatic spinning machine

An electrospinning machine and combined technology are applied in the field of multi-nozzle combined air-jet electrospinning machines, which can solve the problems of difficult control of Taylor cone shape, uneven fiber diameter, unstable solution concentration, etc. Simple equipment and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

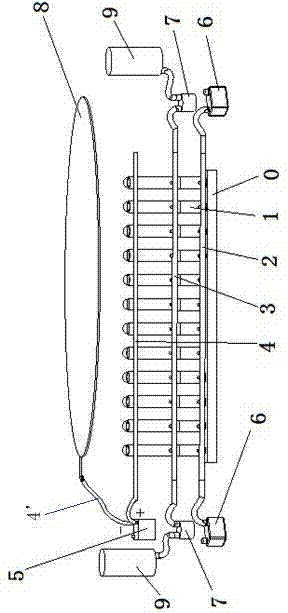

[0024] Example 1: Refer to attached figure 1 And attached Figure 5 , a multi-nozzle combined air-jet electrospinning machine, comprising a base 0, a spinning unit 1, an air pipe 2, an infusion pipe 3, a wire 4, a high-voltage electrostatic generator 5, a cross-flow air pump 6, a metering pump 7, and a receiving electrode Plate 8 and reservoir 9.

[0025] The spinning unit 1 is formed by connecting a spinneret 11 with an air chamber 15 through an intermediate connecting body 14 , and the intermediate connecting body 14 is equipped with a vertically upward air spraying pipe 12 communicating with the air chamber 15 . There is a liquid inlet 13 below the spinneret 11 , the liquid inlet 13 is lower than the upper end surface of the jet pipe 12 , and an air inlet 16 is arranged below the air chamber 15 . A protective ring 10 is installed above the spinneret 11, which can prevent the solution from overflowing during spinning. The inner diameter of spinneret 11 and air chamber 1...

Embodiment 2

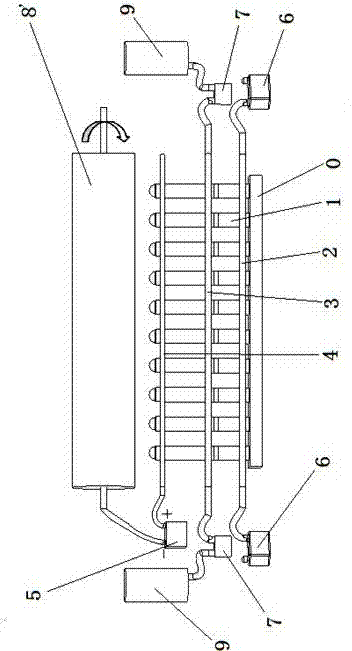

[0029] Example 2: Refer to attached figure 2 And attached Figure 5, a multi-nozzle combined air-jet electrospinning machine, comprising a base 0, a spinning unit 1, an air pipe 2, an infusion pipe 3, a wire 4, a high-voltage electrostatic generator 5, a cross-flow air pump 6, a metering pump 7, and a receiving drum 8' and reservoir tank 9.

[0030] The spinning unit 1 is formed by connecting a spinneret 11 with an air chamber 15 through an intermediate connecting body 14 , and the intermediate connecting body 14 is equipped with a vertically upward air spraying pipe 12 communicating with the air chamber 15 . There is a liquid inlet 13 below the spinneret 11 , the liquid inlet 13 is lower than the upper end surface of the jet pipe 12 , and an air inlet 16 is arranged below the air chamber 15 . A protective ring 10 is installed above the spinneret 11, which can prevent the solution from overflowing during spinning. The inner diameter of spinneret 11 and air chamber 15 is ...

Embodiment 3

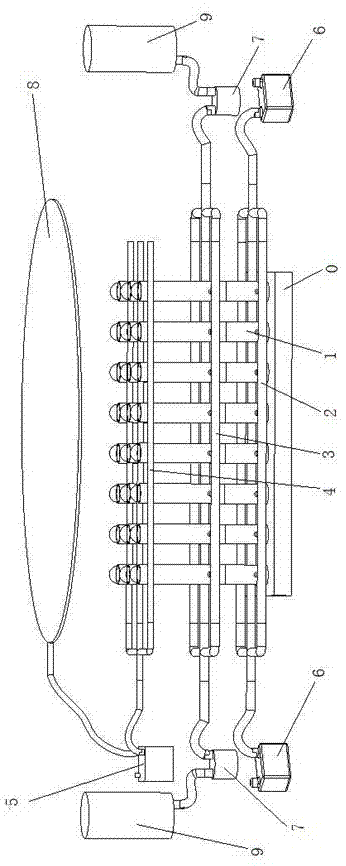

[0034] Embodiment 3: Refer to attached image 3 And attached Figure 5 , a multi-nozzle combined air-jet electrospinning machine, comprising a base 0, a spinning unit 1, an air pipe 2, an infusion pipe 3, a wire 4, a high-voltage electrostatic generator 5, a cross-flow air pump 6, a metering pump 7, and a receiving plate 8 and liquid storage tank 9.

[0035] The spinning unit 1 is formed by connecting a spinneret 11 with an air chamber 15 through an intermediate connecting body 14 , and the intermediate connecting body 14 is equipped with a vertically upward air spraying pipe 12 communicating with the air chamber 15 . There is a liquid inlet 13 below the spinneret 11 , the liquid inlet 13 is lower than the upper end of the jet pipe 12 , and an air inlet 16 is arranged below the air chamber 15 . A protective ring 10 is installed above the spinneret 11, which can prevent the solution from overflowing during spinning. The inner diameter of spinneret 11 and air chamber 15 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com