Catalytic combustion bed core structure with heater

A catalytic combustion bed and heater technology, applied in the direction of combustion using catalytic materials, incinerators, combustion methods, etc., can solve the problem of reducing the combustion efficiency of industrial volatile organic pollutants, the uneven temperature of the furnace core structure, and the impact of catalytic combustion purification rate and other issues, to achieve the effect of uniform reflow, fast heating speed and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

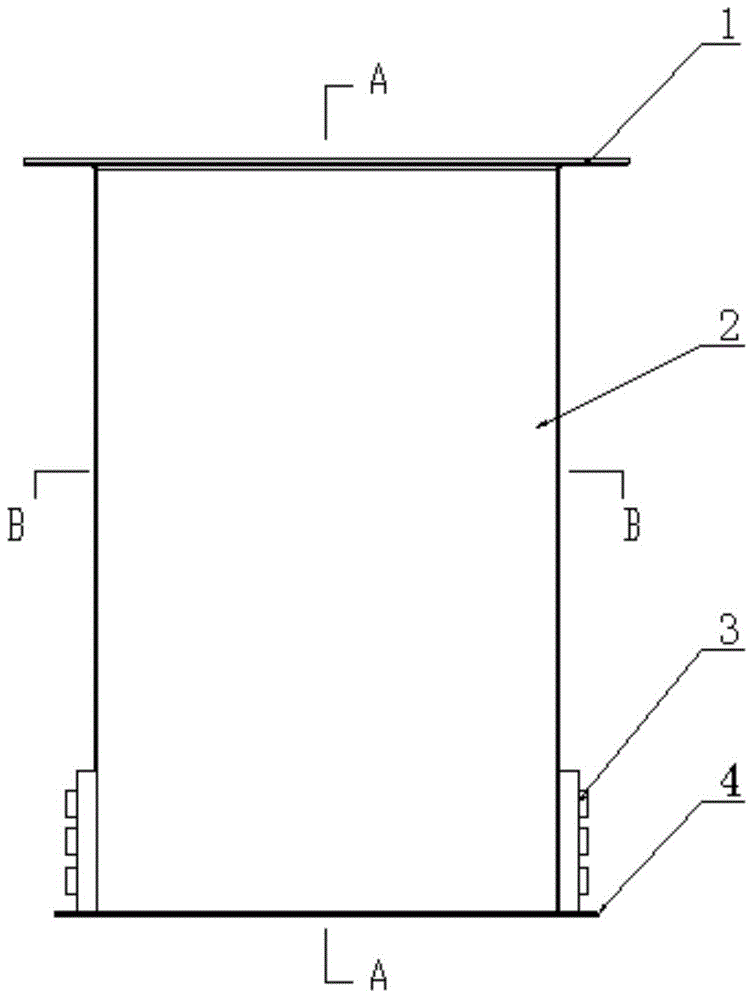

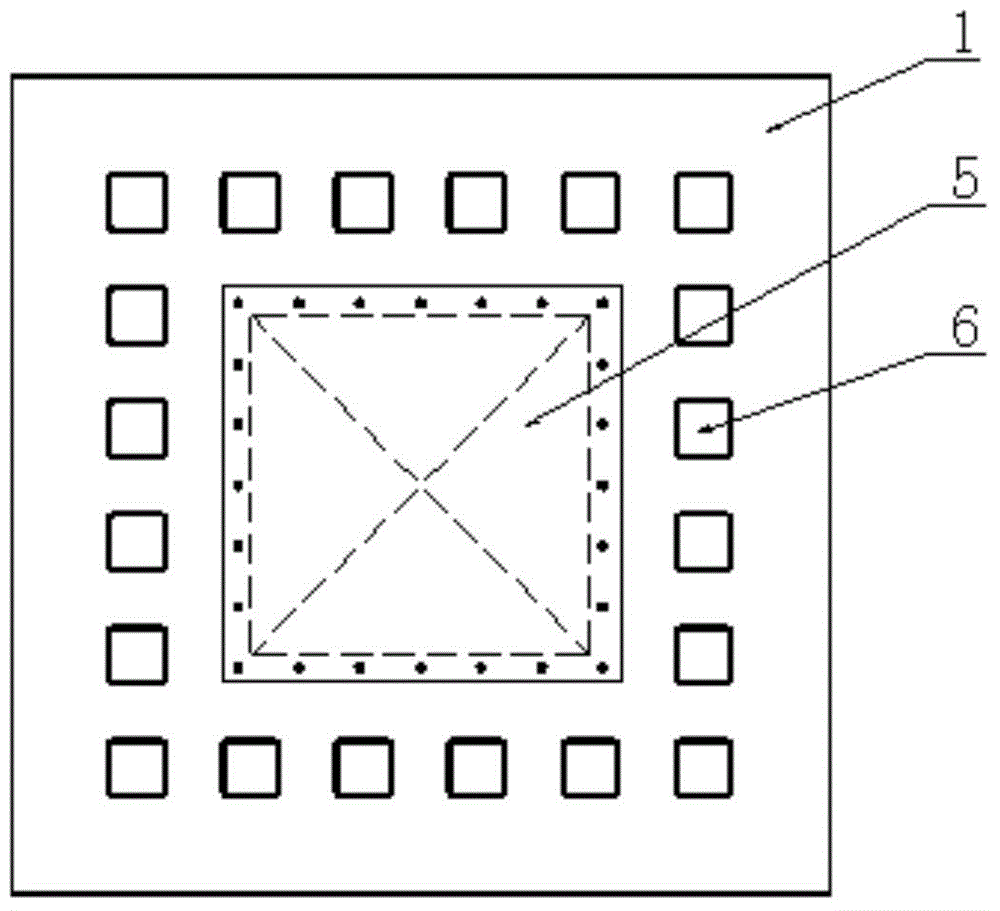

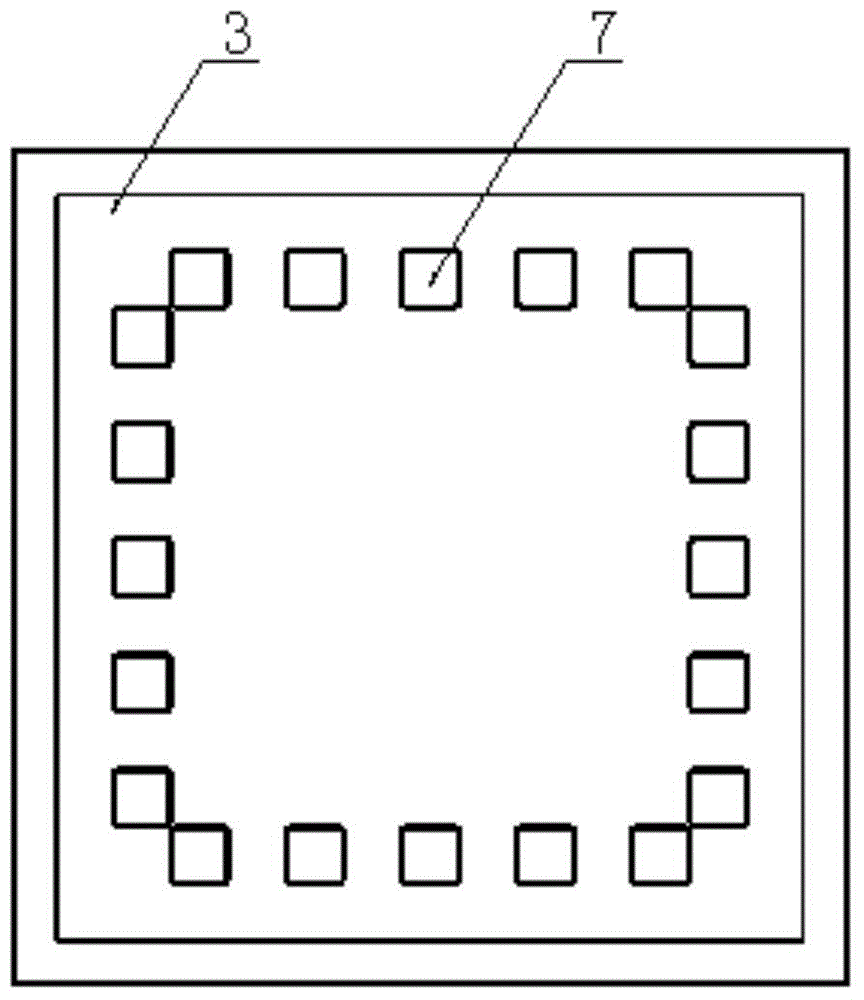

[0033] A catalytic combustion bed furnace core structure with a heater, comprising a furnace core peripheral plate 2, an upper end plate 1 fixed at its upper end and a lower end plate 4 fixed at its lower end, and a furnace core inner The coaming plate 10, the air inlet channel 9 and the air outlet channel 12 are arranged alternately between the inner coaming plate of the furnace core and the peripheral plate of the furnace core, the inlet 6 of the air inlet channel is arranged on the upper end plate, and the outlet 11 of the air inlet channel is arranged on the lower end plate Between the inner wall of the furnace core, the inlet 8 of the air outlet is arranged between the upper end plate and the inner wall of the furnace core, the outlet 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com