Novel rotary tangential flow efficient vertical flow sedimentation tank

A vertical flow sedimentation tank and tangential flow technology, applied in the field of water treatment, can solve the problems of uneven return sludge and difficult sludge discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

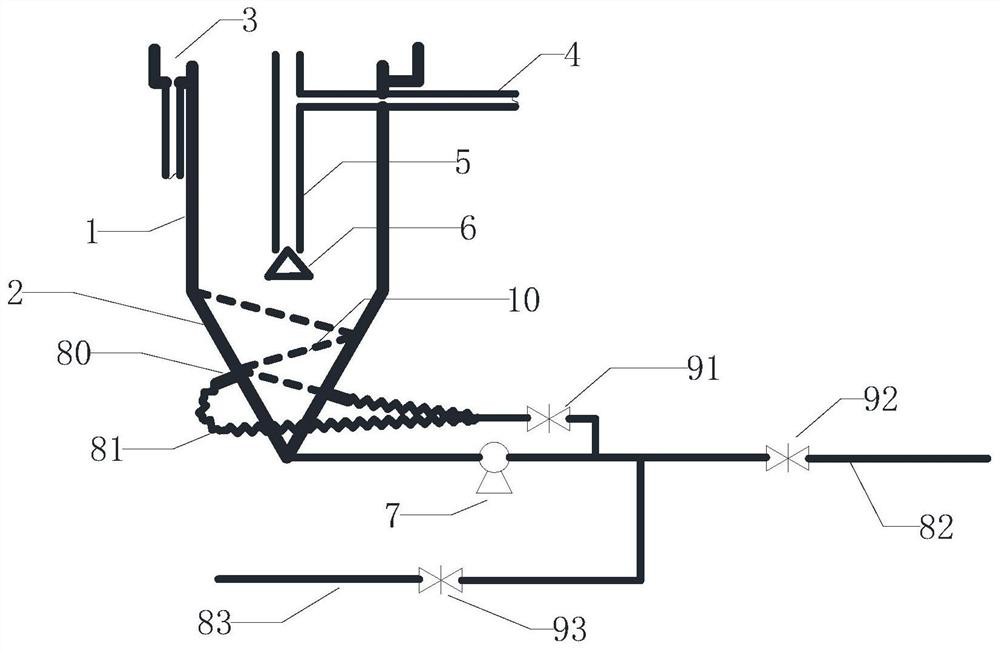

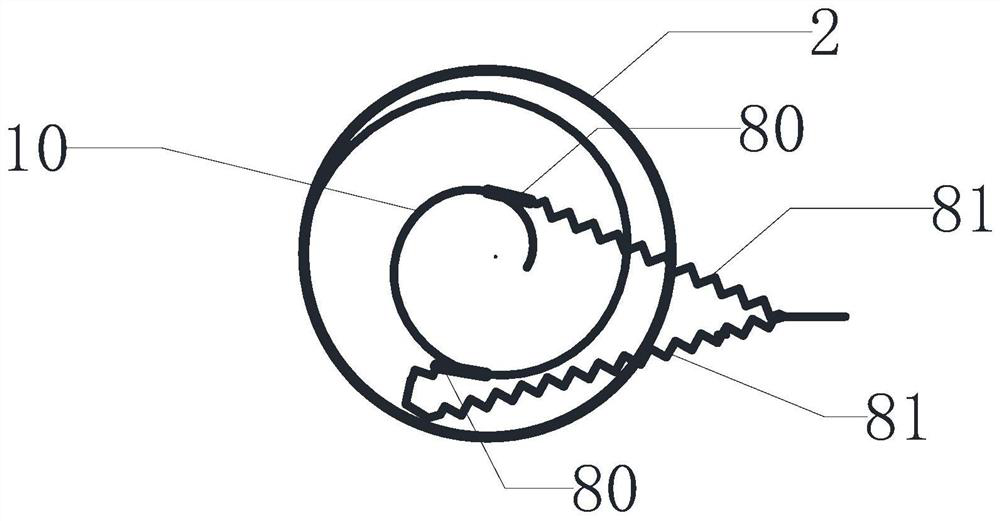

[0021] Such as figure 1 As shown, a novel rotating tangential flow high-efficiency vertical flow sedimentation tank provided by this patent has a cylindrical tank body 1 at the top and a conical sludge bucket 2 at the bottom. The tank body 1 is provided with a water inlet pipe 4 and a central guide. Flow tube 5, reflection cone 6, outlet tank and outlet pipe, and sludge treatment system.

[0022] The mud-water mixture enters the central guide tube 5 from the water inlet pipe 4, and the water outlet from the bottom of the central guide tube 5 contacts the reflective cone 6 and disperses evenly around. Mud bucket 2, so as to realize the separation of mud and water.

[0023] The sludge treatment system includes a sludge discharge pipe 82, a sludge return pipe 83...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com