Patents

Literature

262results about How to "Fast full" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Charging method of power battery of electric vehicle

InactiveCN104393357AFast fullTemperature balanceSecondary cells charging/dischargingBatteriesPower batteryHeating time

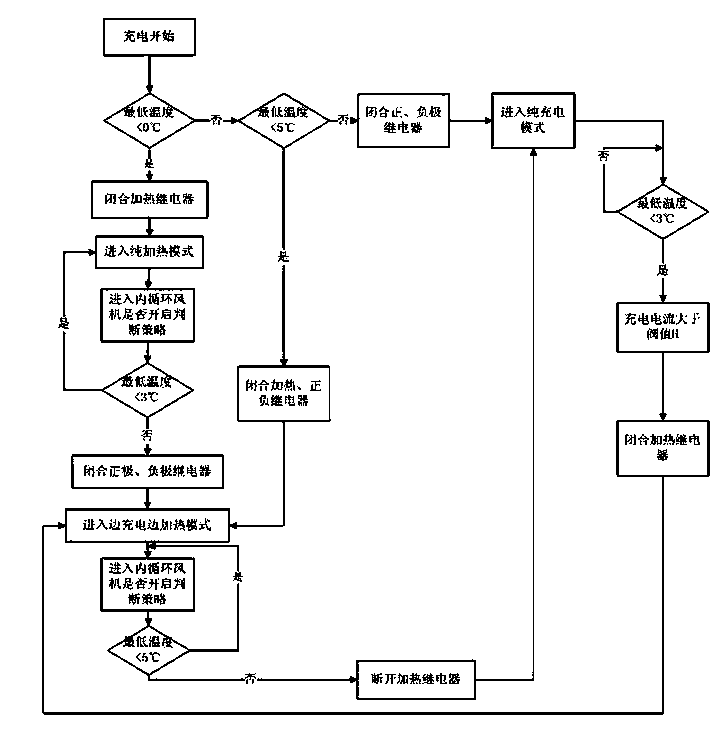

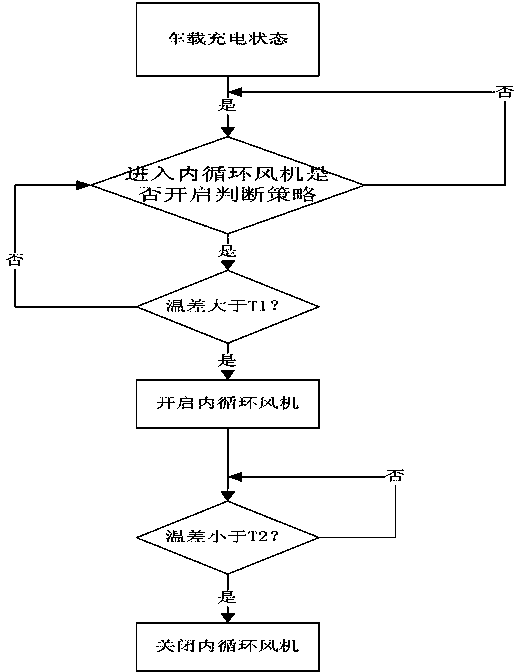

The invention provides a charging method of a power battery of an electric vehicle. The charging method comprises the following steps: S1, detecting the maximal temperature and the minimal temperature of a battery, and judging whether the minimal temperature is lower than a first threshold temperature or not, if so, executing a step S2; if not, continuing to judge whether the minimal temperature is higher than a second threshold temperature or not, if so, executing a step S4, if not, executing a step S3; S2, entering a pure-heating mode; S3, entering a charging and heating mode; and S4, entering a pure-heating mode. According to the charging method of the power battery of the electric vehicle, provided by the invention, the power battery at low temperature is charged, the power battery enters different charging procedures according to the minimal temperature of the battery, namely, the pure-charging mode, the heating and charging mode and the pure-charging mode, so that the low-temperature charging and heating time can be shortened, and the rapid charging of the battery is ensured.

Owner:HUIZHOU EPOWER ELECTRONICS

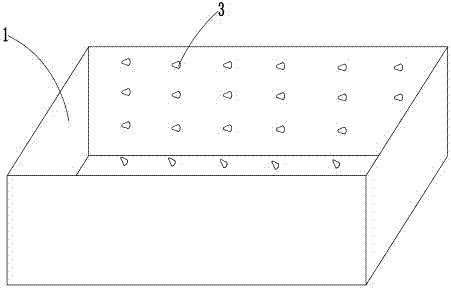

Phellinus igniarius (L.ex Fr.) cultivating seed preparation method

ActiveCN106472104AGrow fastFast fullCalcareous fertilisersMagnesium fertilisersRoom temperaturePhellinus igniarius

The invention discloses a Phellinus igniarius (L.ex Fr.) cultivating seed preparation method. The Phellinus igniarius (L.ex Fr.) cultivating seed preparation method includes firstly, cutting mulberry twigs into small blocks, evenly mixing the small blocks, mulberry wood bits, wheat bran and gypsum, bagging a mixture, sterilizing, inoculating a Phellinus igniarius strain and culturing for 25-35 days so as to obtain an activated Phellinus igniarius strain; secondly, preparing a Phellinus igniarius cultivating culture medium from mulberry wood bits, wheat bran, maize meal, monopotassium phosphate, magnesium sulfate, gypsum and white sugar, bagging, sterilizing and inoculating the activated Phellinus igniarius strain; thirdly, culturing in a dark but ventilative culture room at a room temperature of 22-28 DEG C and at a relative air humidity of 60-75%; finally, taking Phellinus igniarius (L.ex Fr.) out after culturing for 60-80 days. The Phellinus igniarius (L.ex Fr.) cultivating seed preparation method has the advantages that a growth process of the Phellinus igniarius (L.ex Fr.) in a natural world is simulated, artificial cultivating of the Phellinus igniarius (L.ex Fr.) can be achieved truly, the Phellinus igniarius (L.ex Fr.) with hyphae growing fast is capable of spreading culture bags fast and yields a great number of fruiting bodies, every fruiting body is heavy and attractive in shape, proneness to growing of sundry fungi is avoided, bag discharge is fast and simple, and the Phellinus igniarius (L.ex Fr.) is good in commercial quality; the preparation method is simple in fruiting mode and suitable for large-scale production, thereby being worthy of popularization.

Owner:付红敏 +1

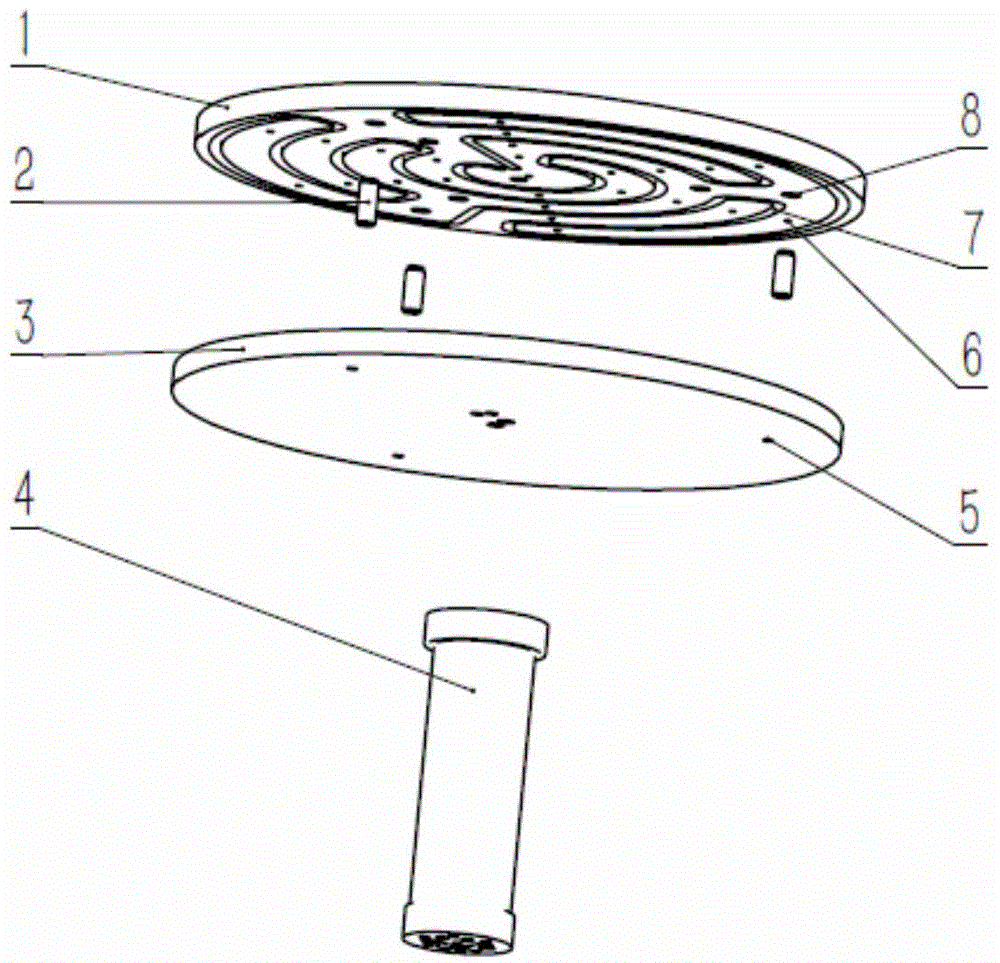

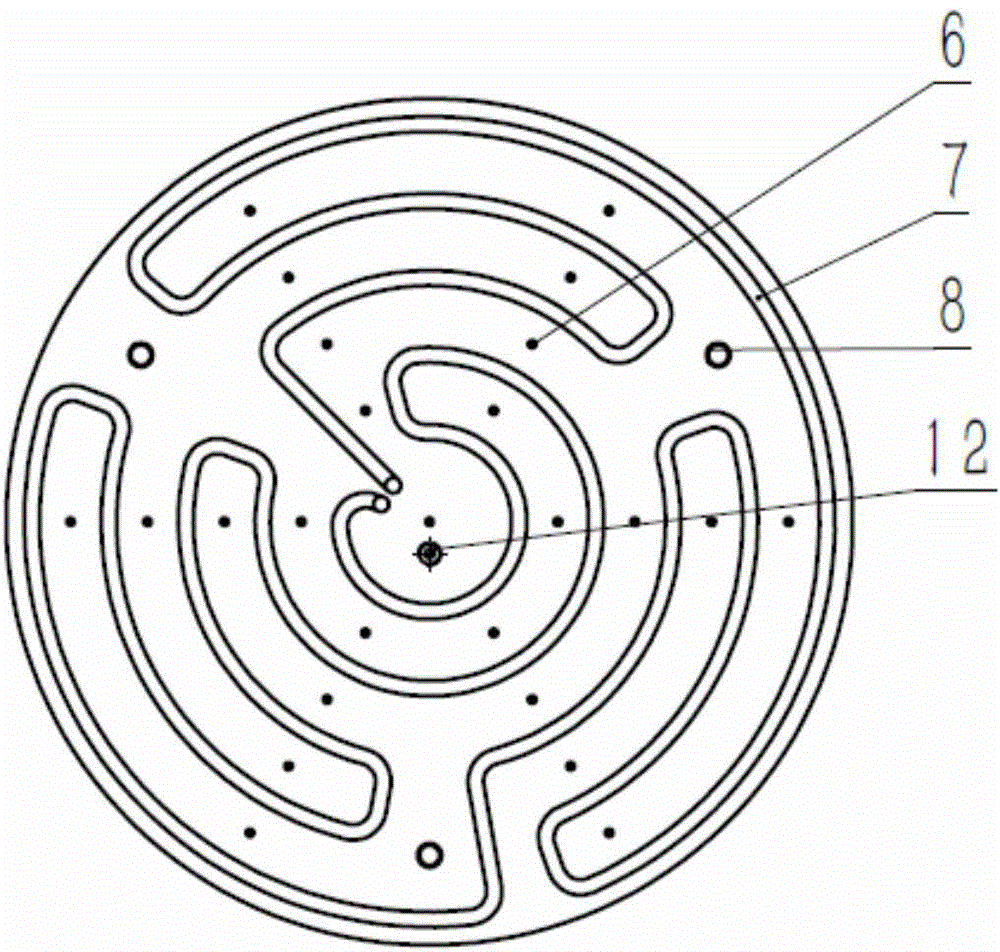

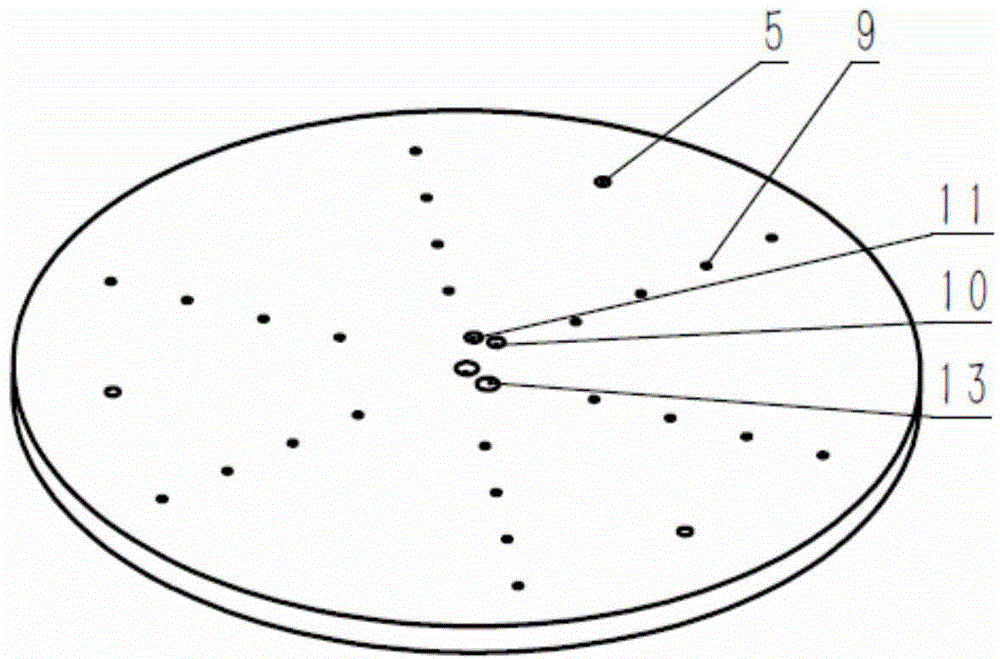

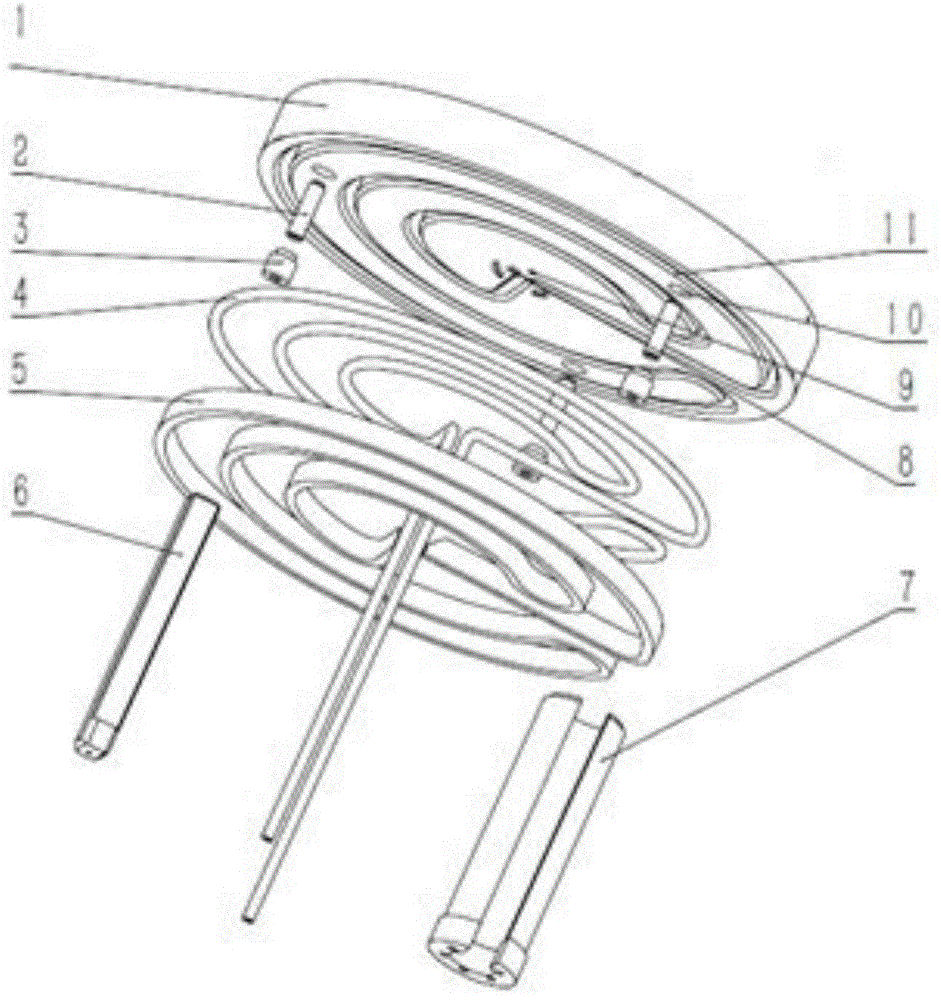

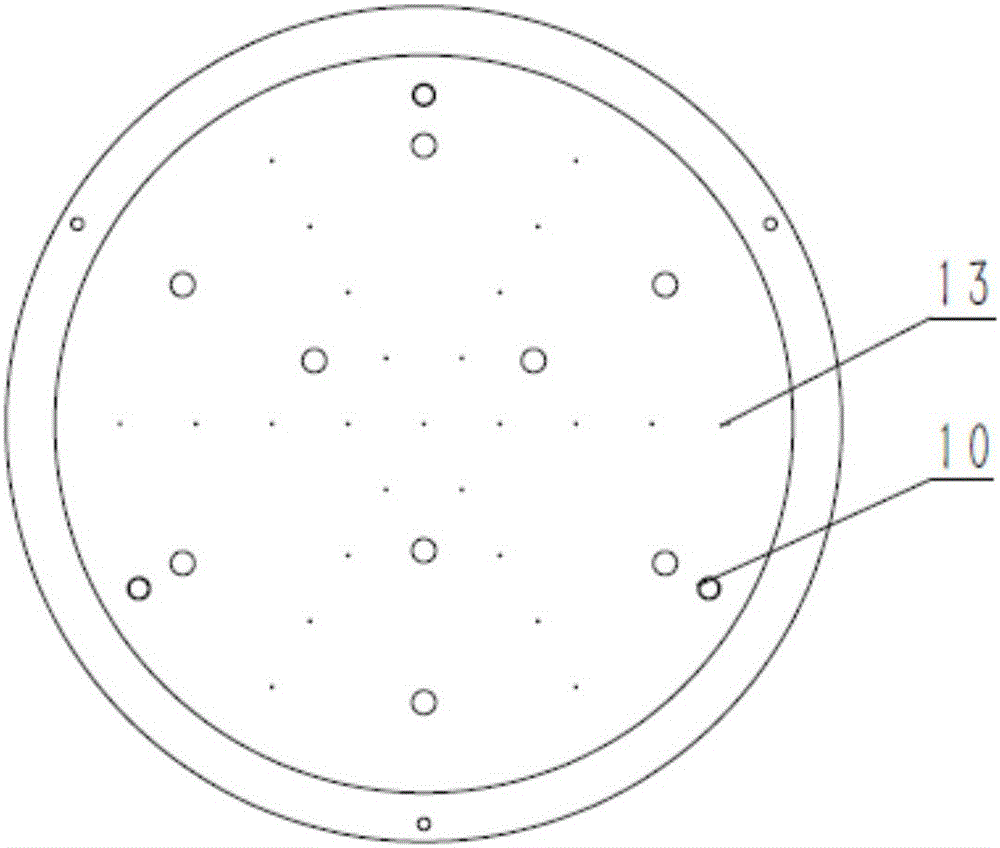

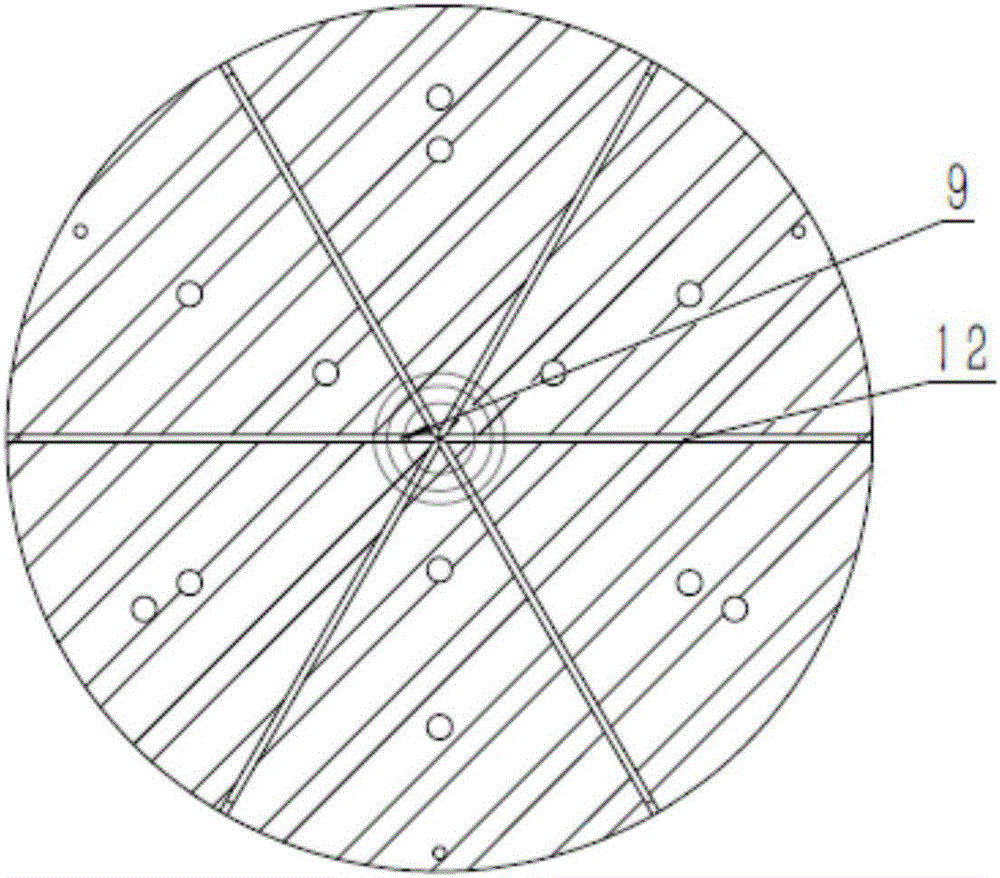

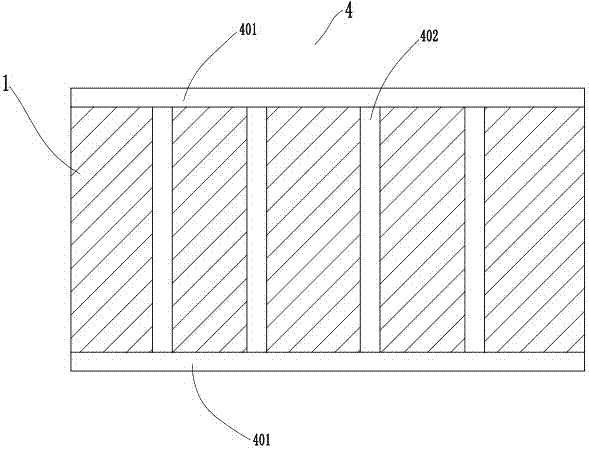

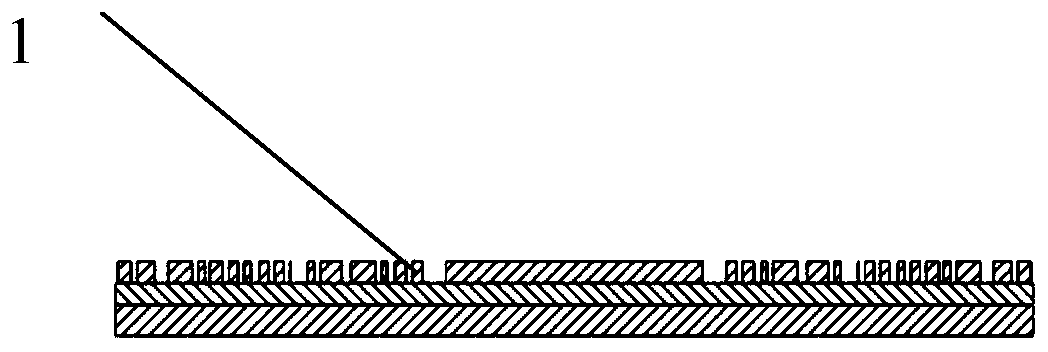

Temperature control disc

ActiveCN104911544AReasonable structureFast fullVacuum evaporation coatingSputtering coatingTemperature controlHeat conducting

The invention provides a temperature control disc. The temperature control disc is mainly used for solving the technical problem of thin film failure due to relatively low heat exchange efficiency and yield of the existing semiconductor coating equipment and not-uniform wafer temperature. The temperature control disc mainly comprises three parts, namely an upper heating disc body, a lower heating disc body and a heating disc base. The parts are connected by virtue of welding. The temperatures of the heating disc and the wafer are controlled by use of a medium and a heat conducting gas; each part has a different structure, so that medium channels and heat conducting gas channels of the heating disc can be formed, and furthermore, the temperature of the heating disc can be controlled; the temperature control disc is cooled and heated by use of a medium; and due to the circulation of the medium, the temperature of the heating disc is controlled; the medium channels are distributed inside the heating disc. The temperature control disc is reasonable in structure; the heat conducting gas inlet structure of the temperature control disc is capable of fully charging the heat conducting gas between the heating disc and the wafer quickly and evenly so that the temperature of the heating disc can be transferred to the wafer quickly and evenly or the temperature of the wafer can be quickly transferred to the heating disc for dissipation. The temperature control disc can be widely applied to the technical field of semiconductor thin-film deposition.

Owner:PIOTECH CO LTD

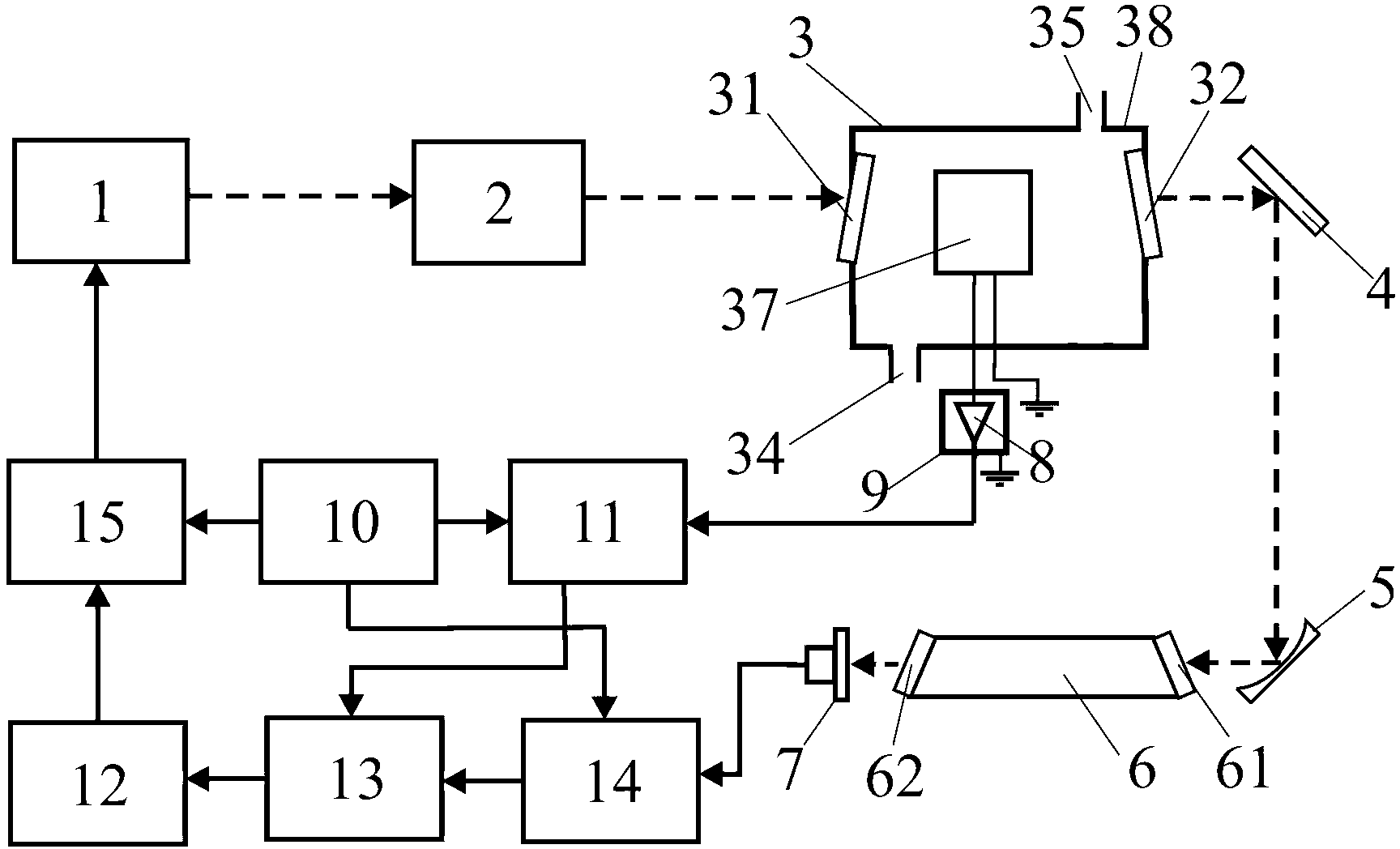

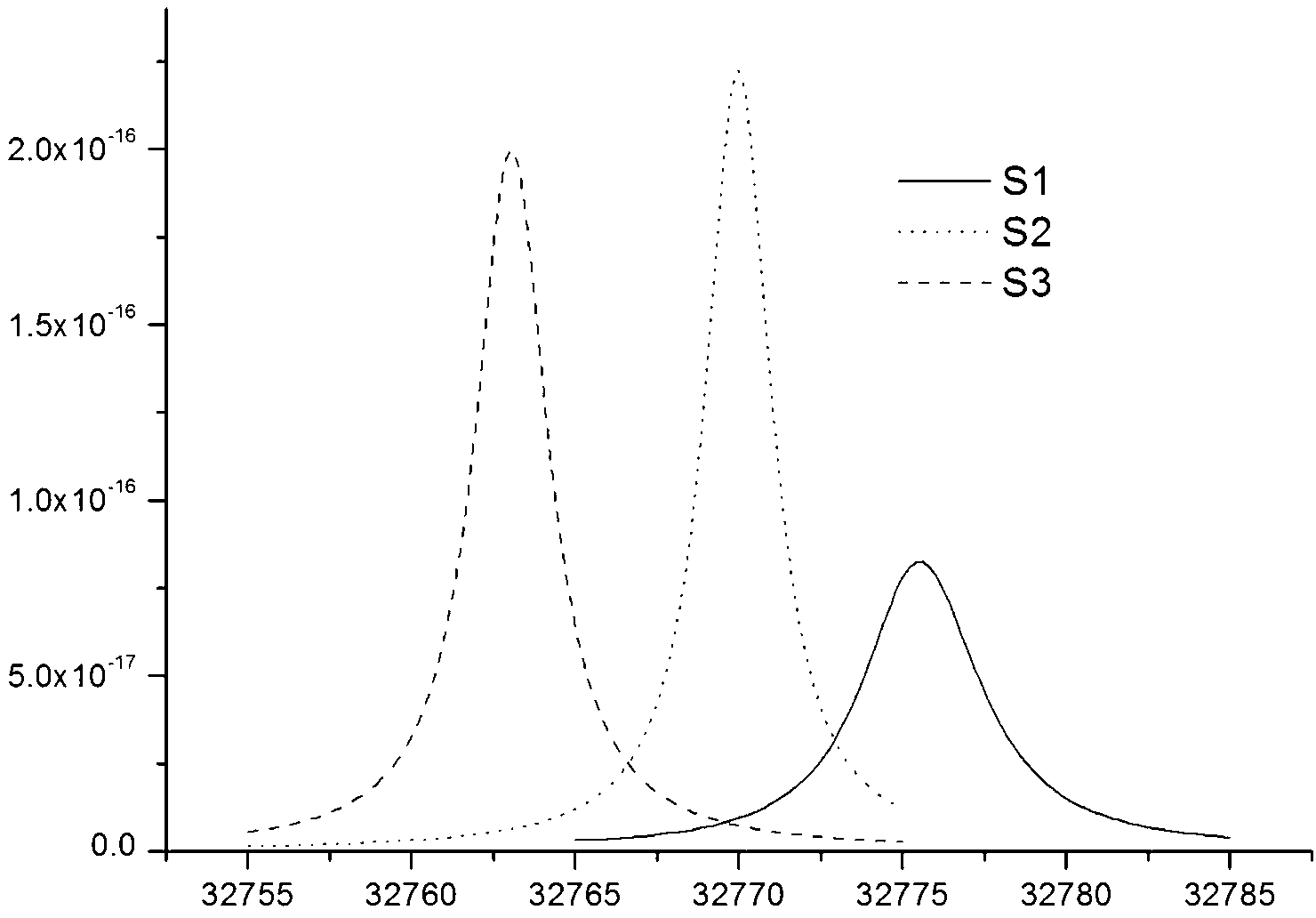

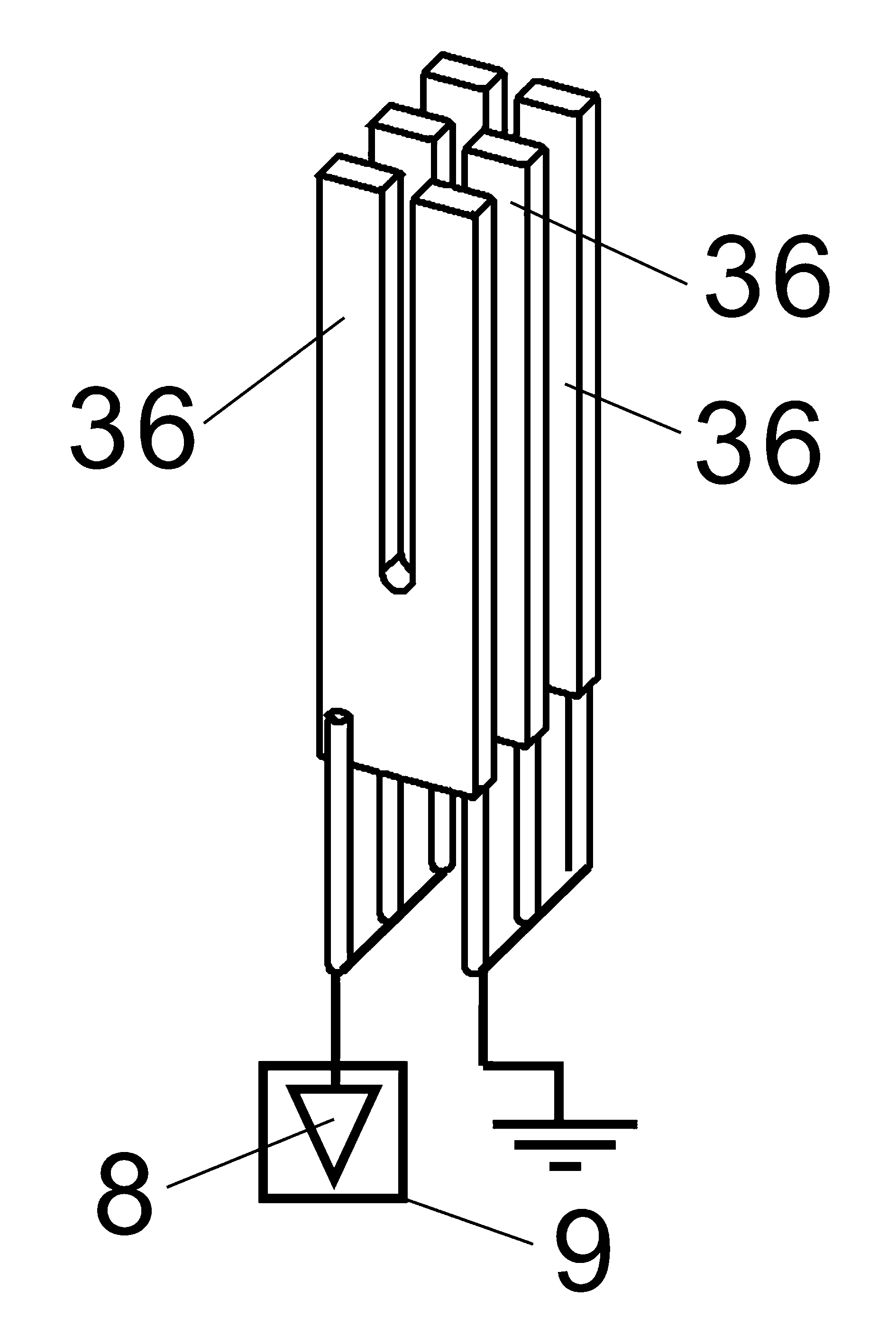

Multi-quartz-crystal-oscillator spectral phonometer and gas detection device employing same

ActiveCN103175791ALower impedanceLower Q valueColor/spectral properties measurementsLight beamGas chamber

The invention relates to gas sensing technologies and particularly relates to a multi-quartz-crystal-oscillator spectral phonometer and a gas detection device employing the same. The gas detection device is used for solving the technical problems of low sensitivity and cumbersomeness in operation of existing gas detection devices. The multi-quartz-crystal-oscillator spectral phonometer comprises a gas chamber, wherein the gas chamber is located outside a multi-quartz-crystal-oscillator assembly, and the bottom of the gas chamber is provided with a hole; an entrance window and an exit window are respectively formed in a sidewall of the gas chamber along a light path; and the entrance window, the multi-quartz-crystal-oscillator assembly and the exit window are located on the same light path. The gas detection device comprises a light source and a light source driver connected with the light source; and a light beam focusing device and the spectral phonometer are sequentially arranged on an exit light path of the light source. The gas detection device further comprises a first phase-locked amplifier and a signal generator which are sequentially connected with each other. According to the spectral phonometer and the gas detection device, through the ingenious arrangement of the multi-quartz-crystal-oscillator assembly, the technical problems in current gas detection that the detection sensitivity is low and the frequency of quartz crystal oscillators is required for being measured frequently are solved.

Owner:SHANXI UNIV

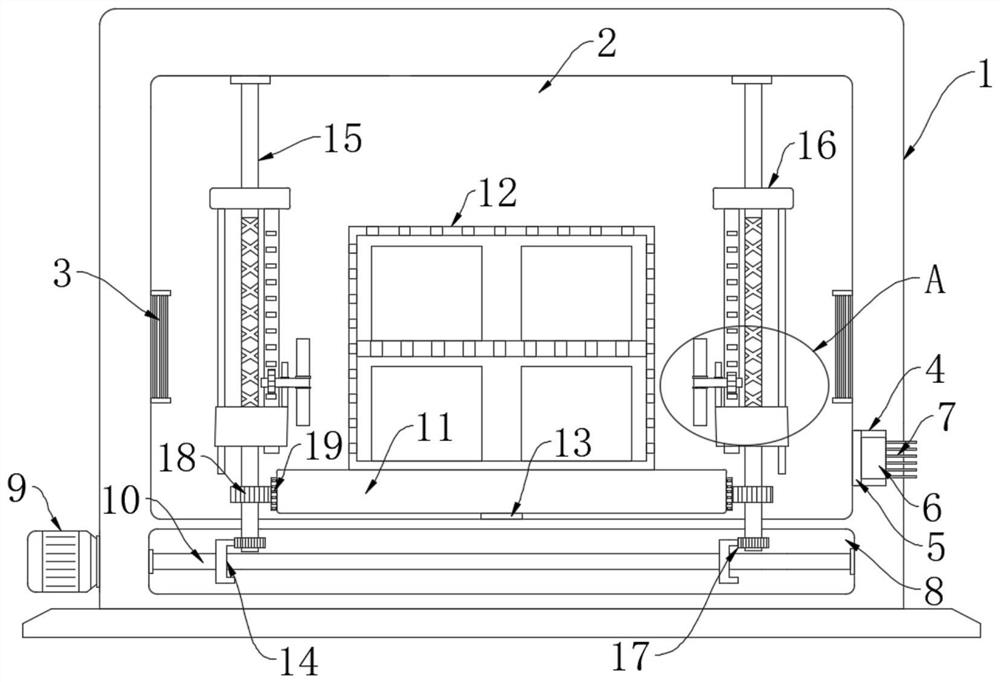

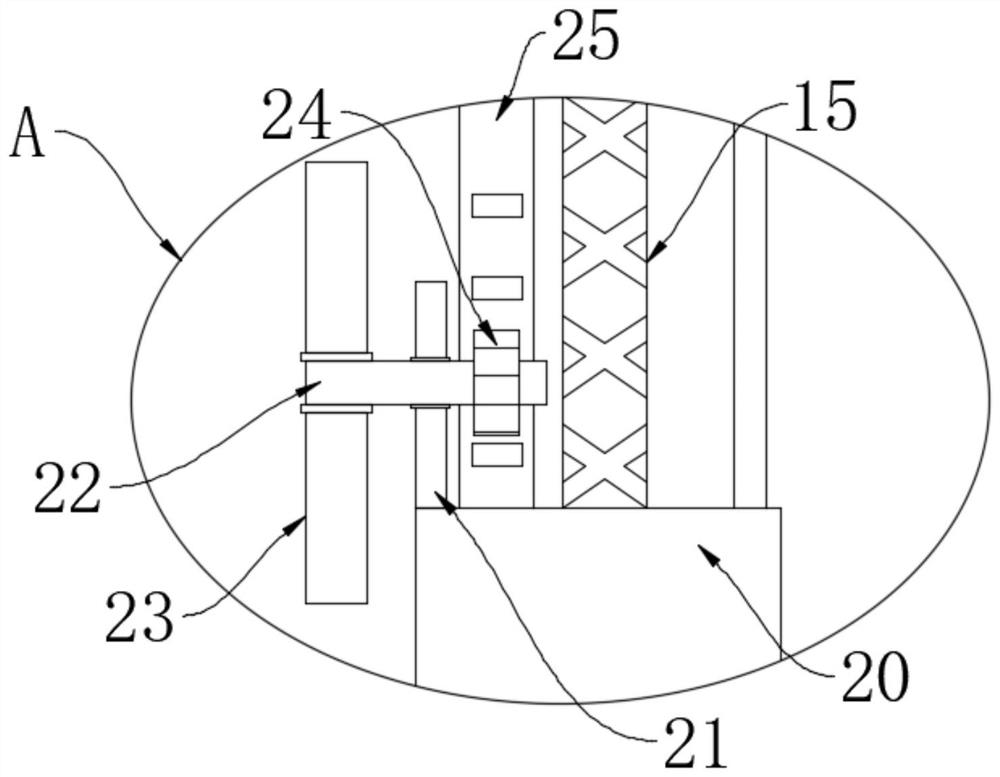

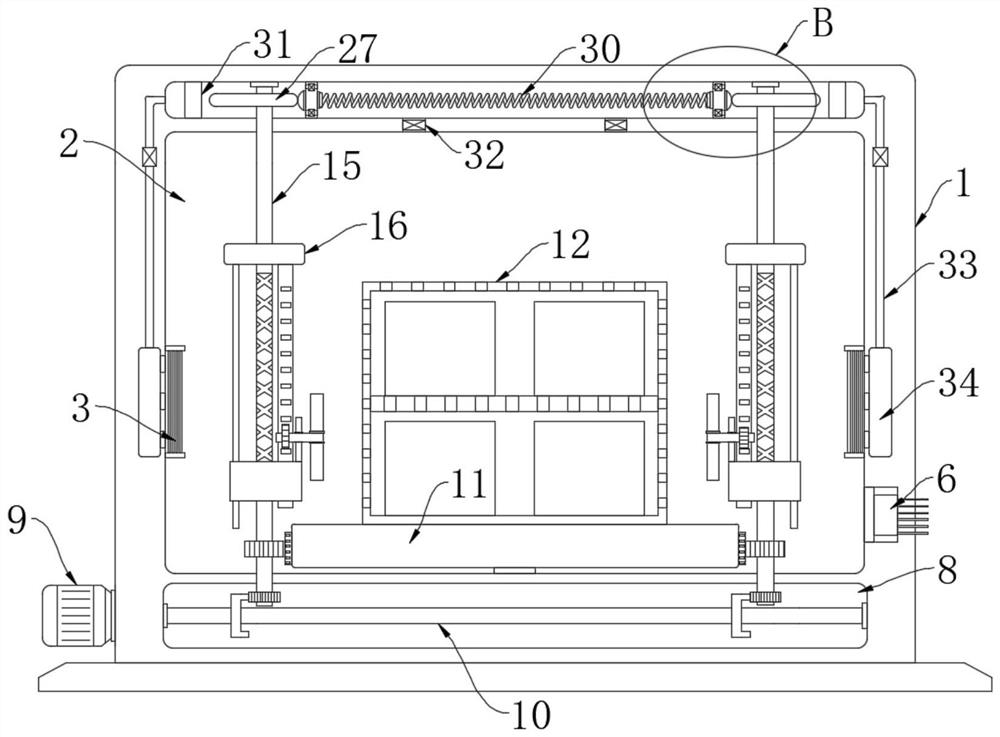

Foamed plastic mold

Owner:龙海市永隆泡沫包装有限公司

Casting method of spheroidal graphite cast iron valve

ActiveCN108531803AStable productionReduce manufacturing costFoundry mouldsFurnace typesElectricitySlag

The invention discloses a casting method of a spheroidal graphite cast iron valve, and relates to the spheroidal graphite cast iron valve. The method comprises the steps of model making, modeling, smelting, pouring, heat treatment and obtaining of a finished product valve casting. Alloy elements are not added, the spheroidal graphite cast iron valve with the supersize can be stably produced, a dedicated slag blocking device is arranged at the front end of a transverse sprue, when molten iron of the transverse sprue is introduced into the front end, the slag blocking effect is achieved, it is ensured that a mold cavity is rapidly and stably filled with the molten iron, oxide inclusions are reduced, a heat preservation top riser is adopted, and is placed on the top of the valve, and castingfeeding, slag discharging and exhausting are facilitated; a chilling block is arranged at the position, on the large and thick section and the portion with the large wall thickness difference, in thecasting, chromite sand is used around an even core and a shaft head in a shaft hole of the casting, the upper portion of an annular belt is paved with chromite sand, it is ensured that the casting canbe subject to directional sequential solidification, and meanwhile, the casting surface quality is ensured, and the method is particularly suitable for making a spheroidal graphite cast iron water and electricity butterfly valve with the supersize and the large section.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

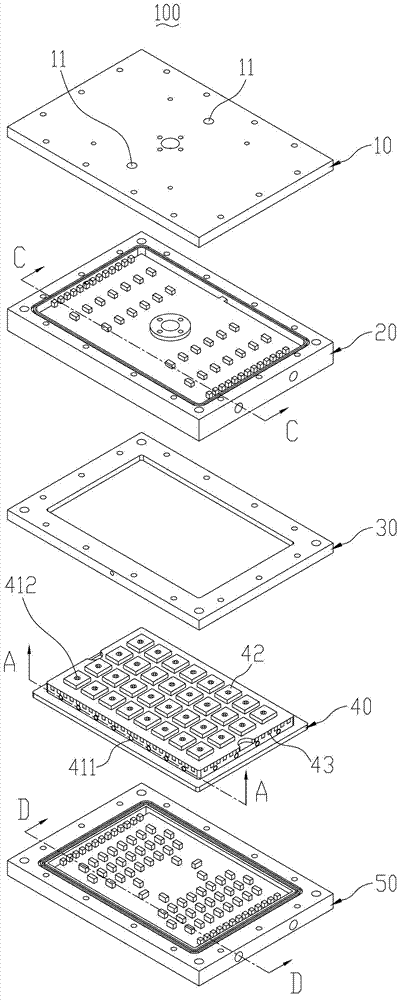

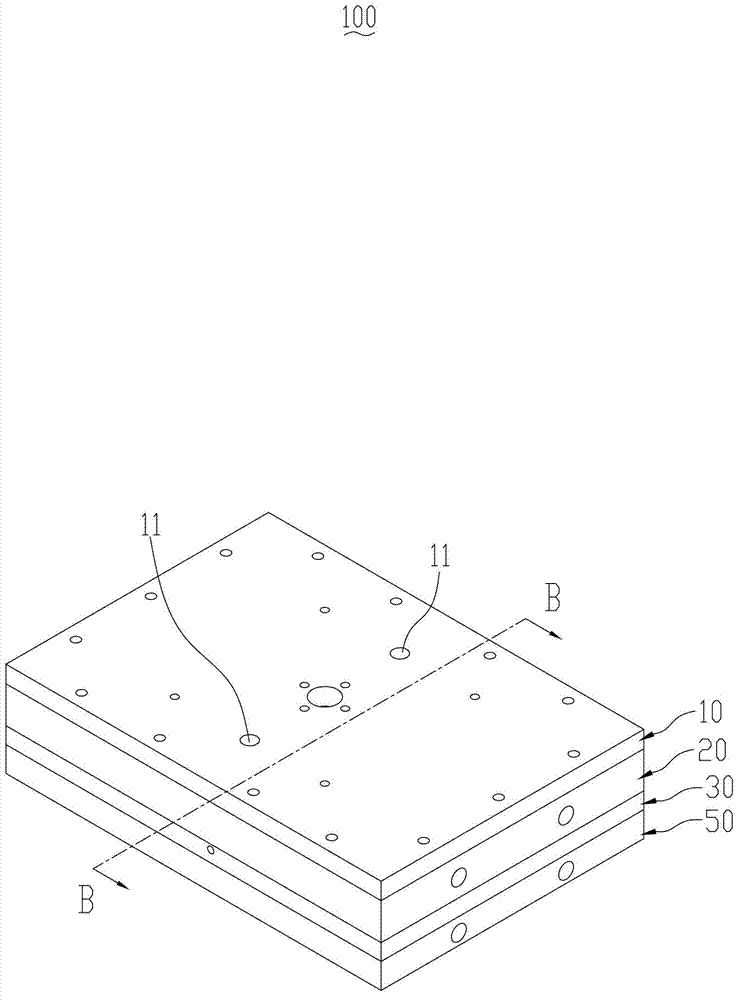

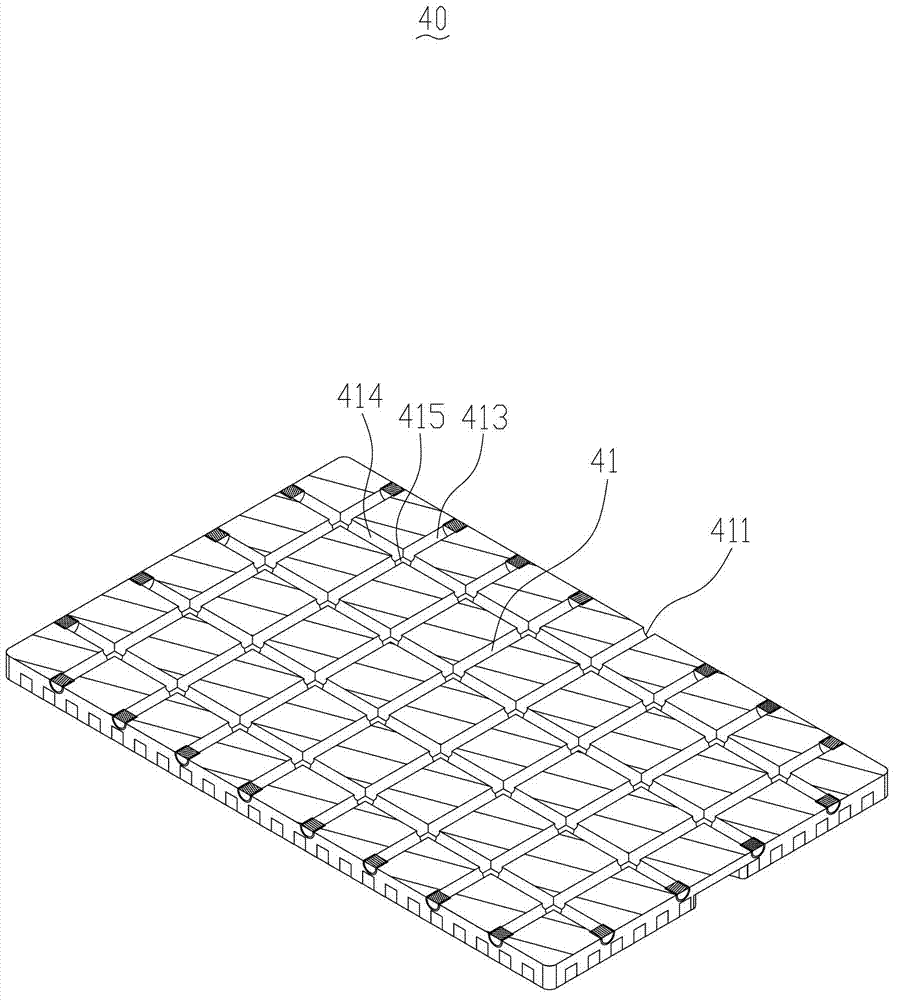

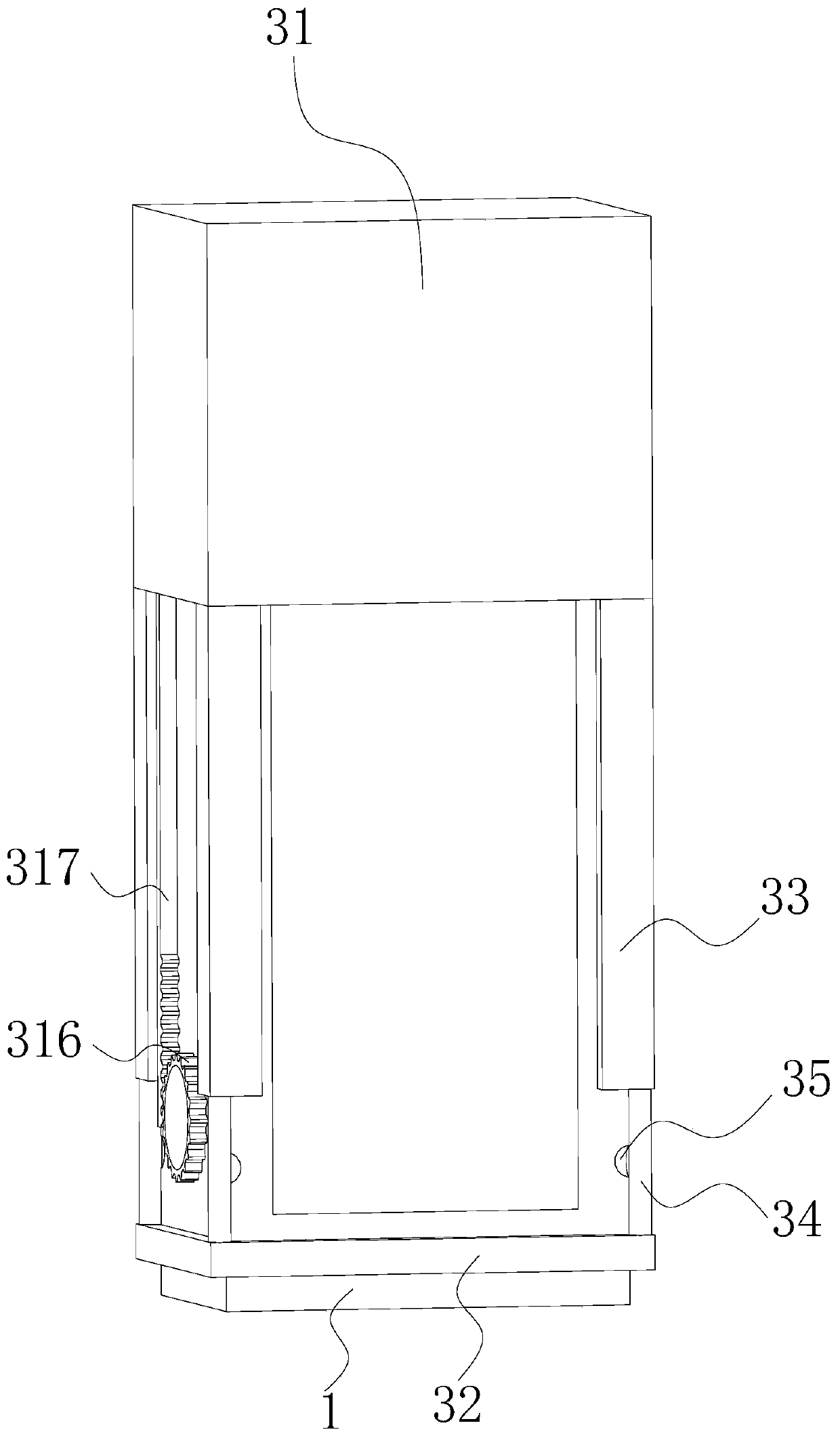

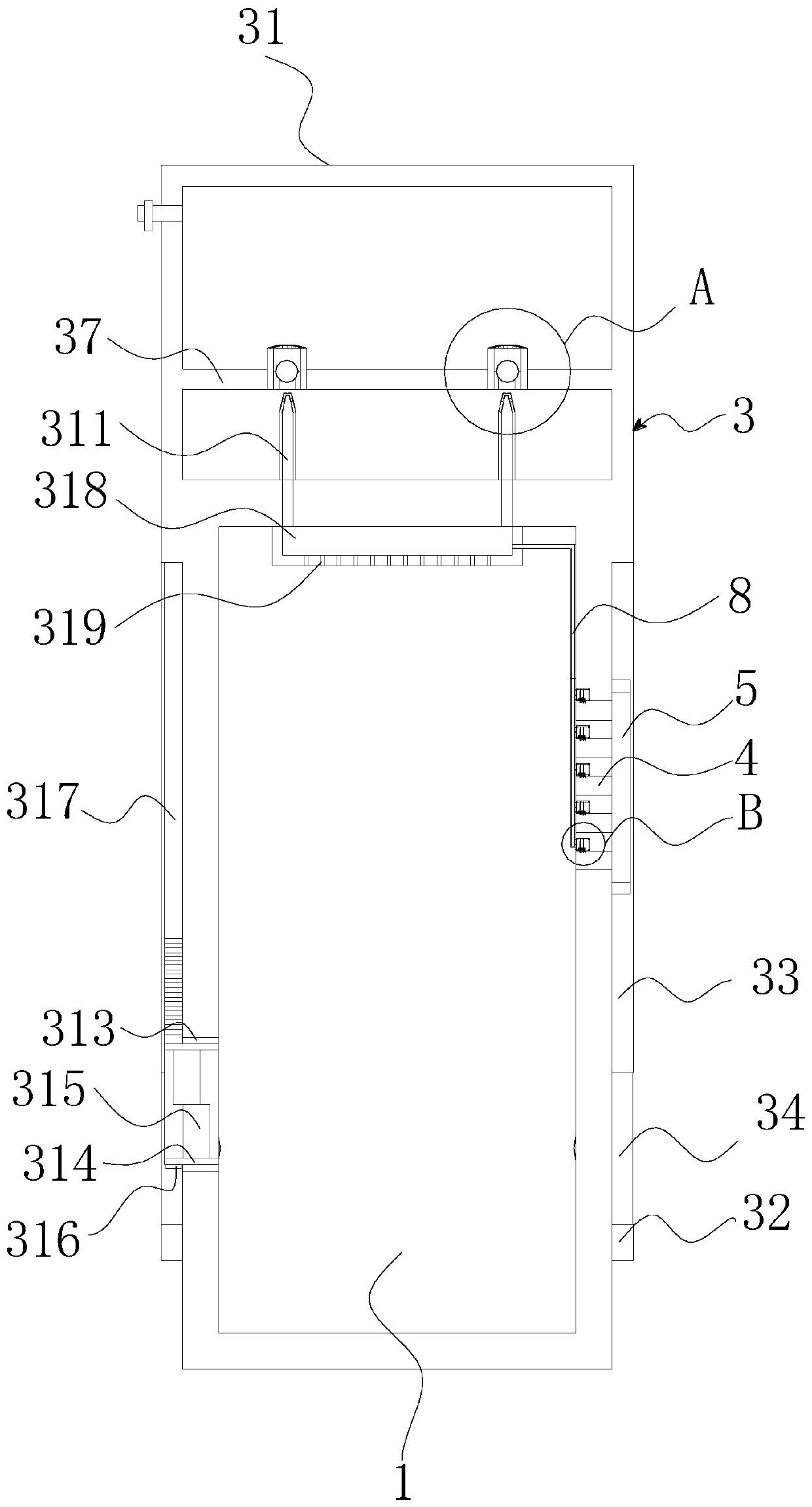

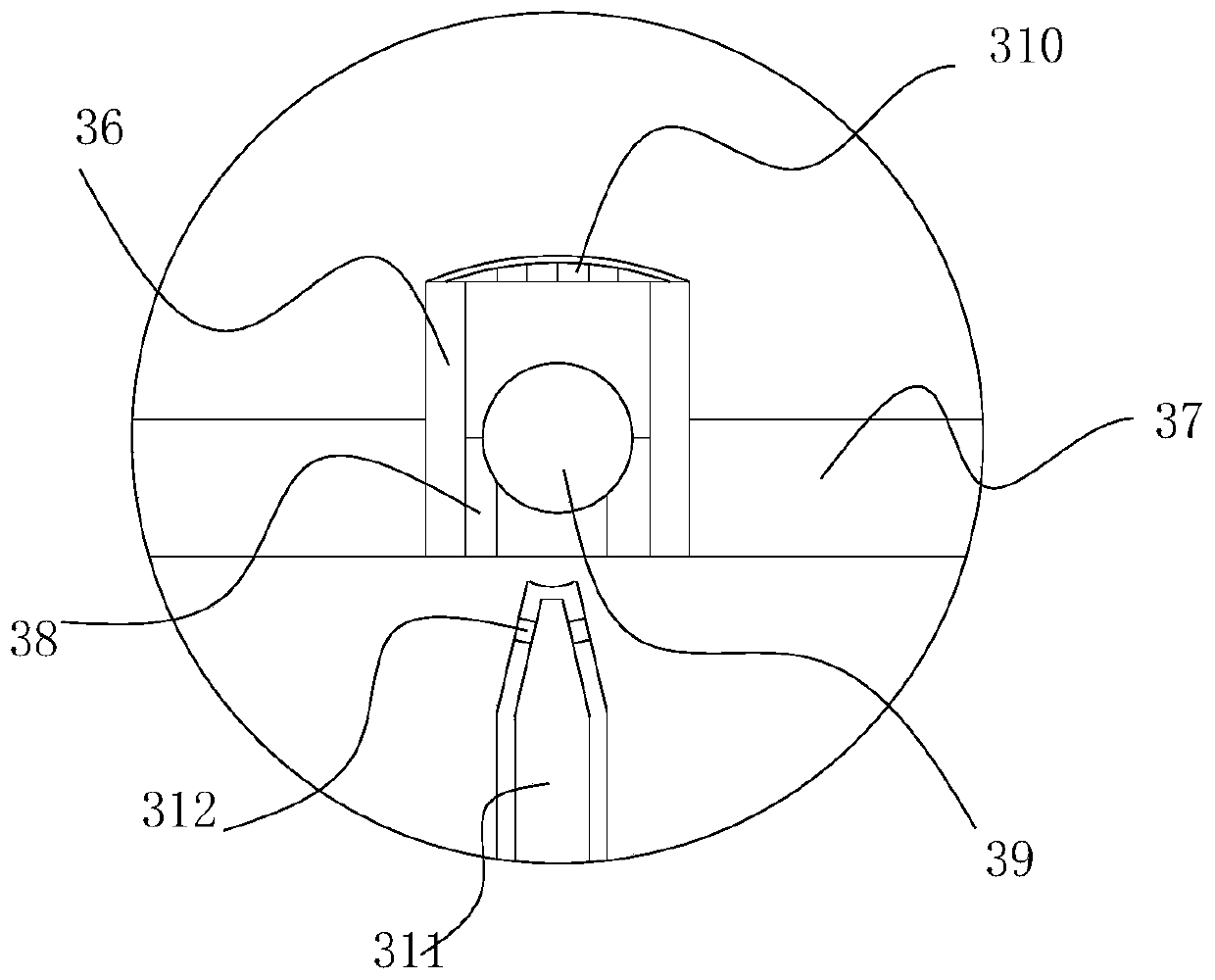

Temperature control system of semiconductor coating device

ActiveCN104988472AReasonable structureFast fullChemical vapor deposition coatingTemperature controlInlet channel

A temperature control system of a semiconductor coating device comprises a heating disc of an integrated structure. The interior of the heating disc is not of an ordinary heating wire structure while a medium pipeline is arranged to control the temperature of the heating disc. According to the heating structure, the medium pipeline is adopted to be arranged inside the heating disc in a casting mode or corresponding grooves are machined in a machining mode, and then the medium pipeline is welded in the heating disc. The medium pipeline structure is arranged according to vortexes, the medium pipeline is arranged evenly as much as possible, and therefore the temperature control can be better achieved. An air inlet channel is arranged in the middle of the heating disc, a heat transferring medium enters the part between the heating disc and a wafer, and a certain air gap is formed between the heating disc and the wafer; due to the fact that the heat conduction effect of the heat transferring medium is good, the heat of the heating disc can be rapidly and evenly conducted to the wafer, or the heat of the wafer is rapidly conducted to the heating disc to be conducted out. By means of the reasonable ventilation structure design, the heat transferring medium can rapidly and evenly flow in the gap, and heat exchange of the heating disc and the wafer is achieved in time.

Owner:PIOTECH CO LTD

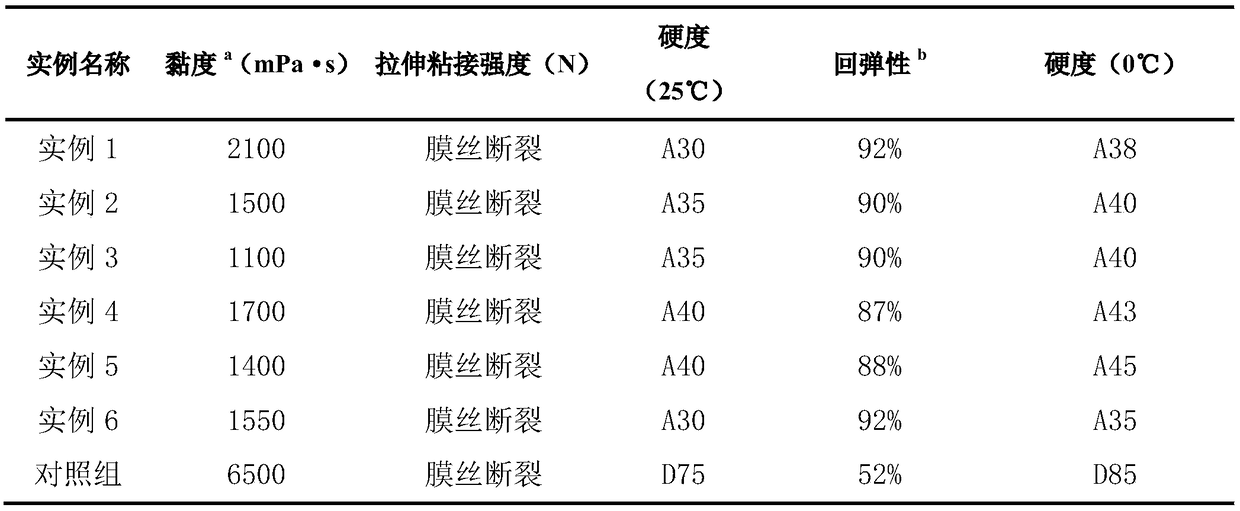

Low-hardness and high-elasticity water treatment membrane component epoxy pouring sealant preparation method and application

The invention discloses a low-hardness and high-elasticity water treatment membrane component epoxy pouring sealant preparation method and application. An epoxy pouring sealant comprises a component Aand a component B, the component A comprises, by weight, 30-70 parts of epoxy resin, 5-20 parts of activated thinners, 10-20 parts of toughening agents, 5-30 parts of fillers and 0.1-3 parts of coupling agents, the component B comprises, by weight, 20-50 parts of polyether amine, 40-70 parts of alicyclic amine and 2-15 parts of curing accelerators, and the weight ration of the component A to thecomponent B is (100:10)-(100:50). By the aid of a 'trinity' toughening modified mode of the flexible toughening agents, the activated toughening thinners and flexible curing agents, the epoxy pouringsealant is characterized of low hardness, high elasticity and stable hardness within wide temperature range, the epoxy pouring sealant has excellent adhesive performance and is low in initial viscosity, high in mold filling speed, simple and convenient to operate and applicable to the fields such as package of water treatment membrane components and flexible package of electronic devices, and theblocking efficiency of the membrane components can be greatly improved.

Owner:浙江航通舟新材料科技股份有限公司

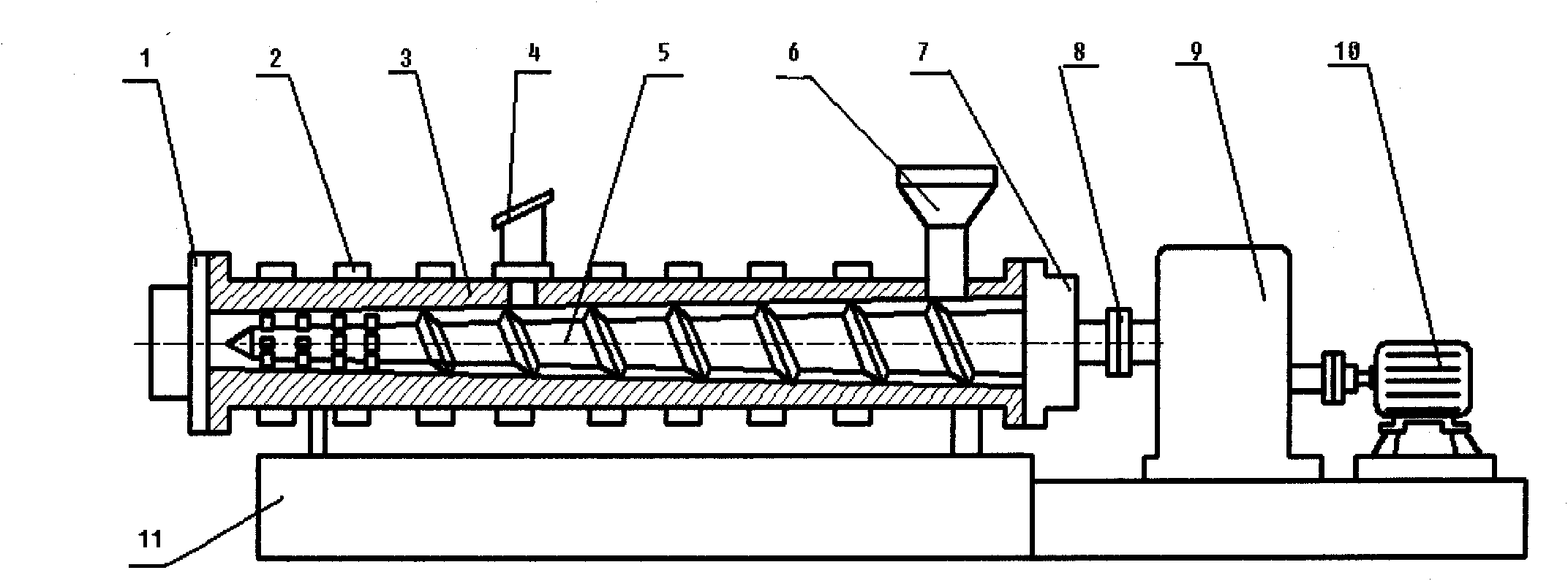

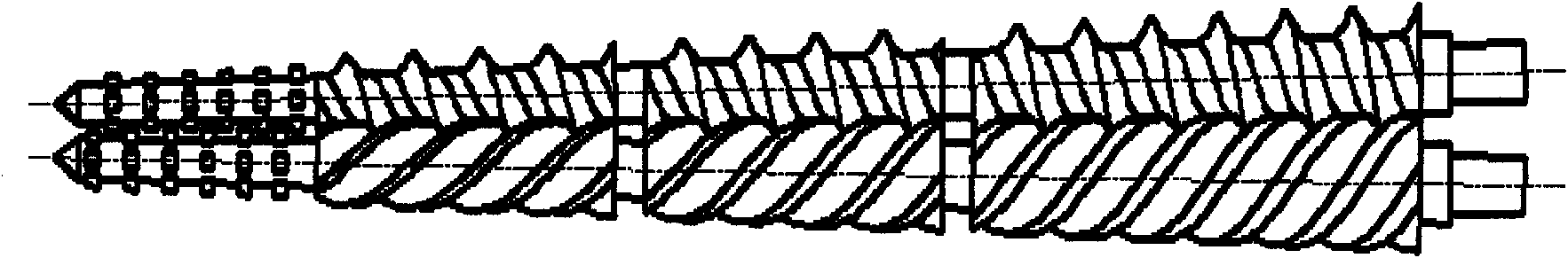

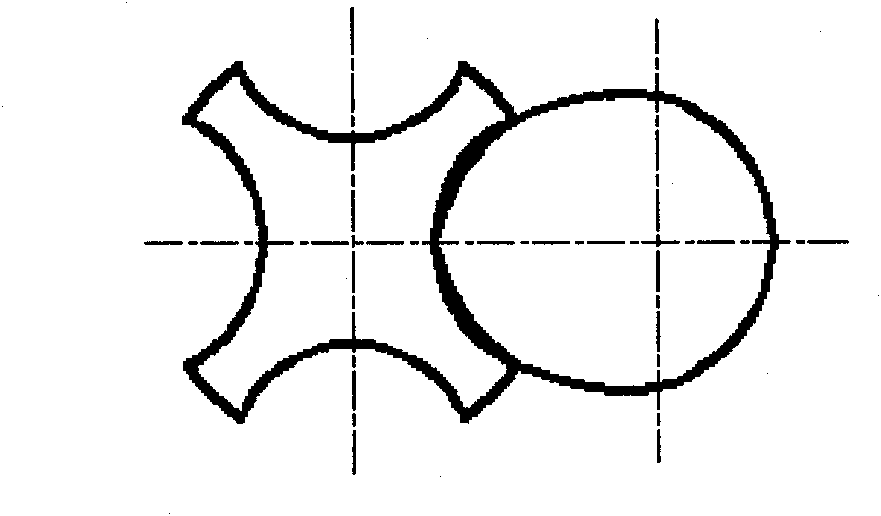

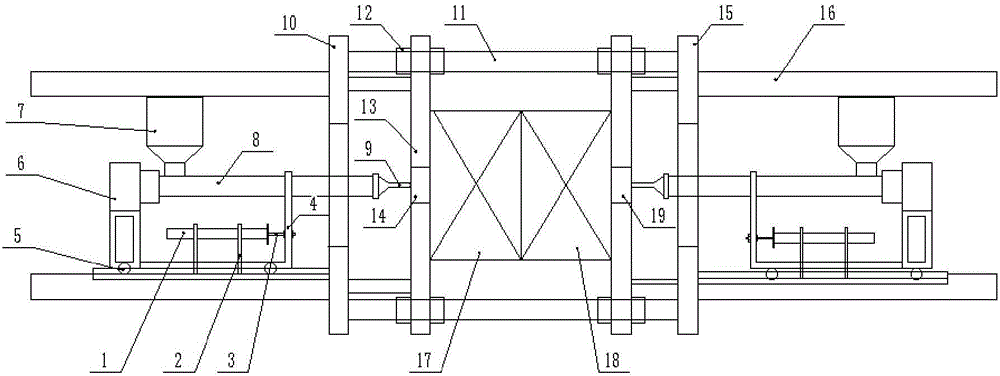

Differential-speed conical twin-screw extruder

The invention discloses a differential-speed conical twin-screw extruder mainly consisting of a machine head, a heating and cooling device, a machine barrel, an air outlet, two screws, a feeder, a driving device and a motor. The two screws are conical screws, have different numbers of screw flights and are divided into a female rotor and a male rotor, and the ratio of revolutions of the female rotor to the male rotor is in inverse proportion to the ratio of the numbers of the screw flights of the female rotor to the male rotor; the screws are at least provided with a thread meshing region during combination, the number of the screw flights of the female rotor is integral multiple of that of the male rotor in the thread meshing region, and the ratio of the rotation speeds of the female rotor to the male rotor is in inverse proportion to the ratio of the numbers of the screw flights of the female rotor to the male rotor, thus differential-speed rotation can be realized, and the female rotor and the male rotor are not influenced during motion. According to material processing requirements, thread sections with different leads and section molded lines or other forms can be arranged on different sections, such as a feeding section, a fusing section, an exhaust section and a measuring section of each screw, and the screws can be meshed and can not be meshed in different sections during mounting, besides at least one thread meshing region rotated in differential speeds is ensured, thus a function of reinforcing mixing or other functions can be realized. The extruder disclosed by the invention has excellent mixing, plasticizing and conveying capabilities and is suitable for machine-shaping of various granular materials, powder materials, even block materials, such as plastics, rubber, foods, explosives and the like.

Owner:BEIJING UNIV OF CHEM TECH

Electric appliance fireproofing and fire-fighting equipment for switching room

InactiveCN106983973AFor the purpose of surroundingSink quicklyFire rescueBoring toolsFireproofingEngineering

The invention relates to fire fighting apparatuses, in particular to electric appliance fireproofing and fire-fighting equipment for a switching room. According to the technical aims, an alarm can be given out at the first time and can be processed through the electric appliance fireproofing and fire-fighting equipment for the switching room. In order to achieve the above technical aims, the electric appliance fireproofing and fire-fighting equipment for the switching room is provided and comprises a fireproofing box, fixing plates, first sliding rails, first sliding blocks, an alarming lamp, a connecting block, a separating plate, a first connecting plate, a second sliding rail, a second sliding block, a first spring and the like; the fixing plates are arranged on the inner walls of the front, back, left and right sides of the interior of the fireproofing box in a bolt connecting manner, the first sliding rails are installed in the fixing plates in a bolt connecting manner, and the first sliding blocks are connected into the first sliding rails in a sliding manner. By means of the electric appliance fireproofing and fire-fighting equipment, the effects of giving out the alarm at the first time and processing the alarm can be achieved; and the manner that the alarm lamp is triggered by burning out a fusing wire when an electric appliance catches a fire is adopted, and therefore a user can rapidly finds the fire.

Owner:南昌安润科技有限公司

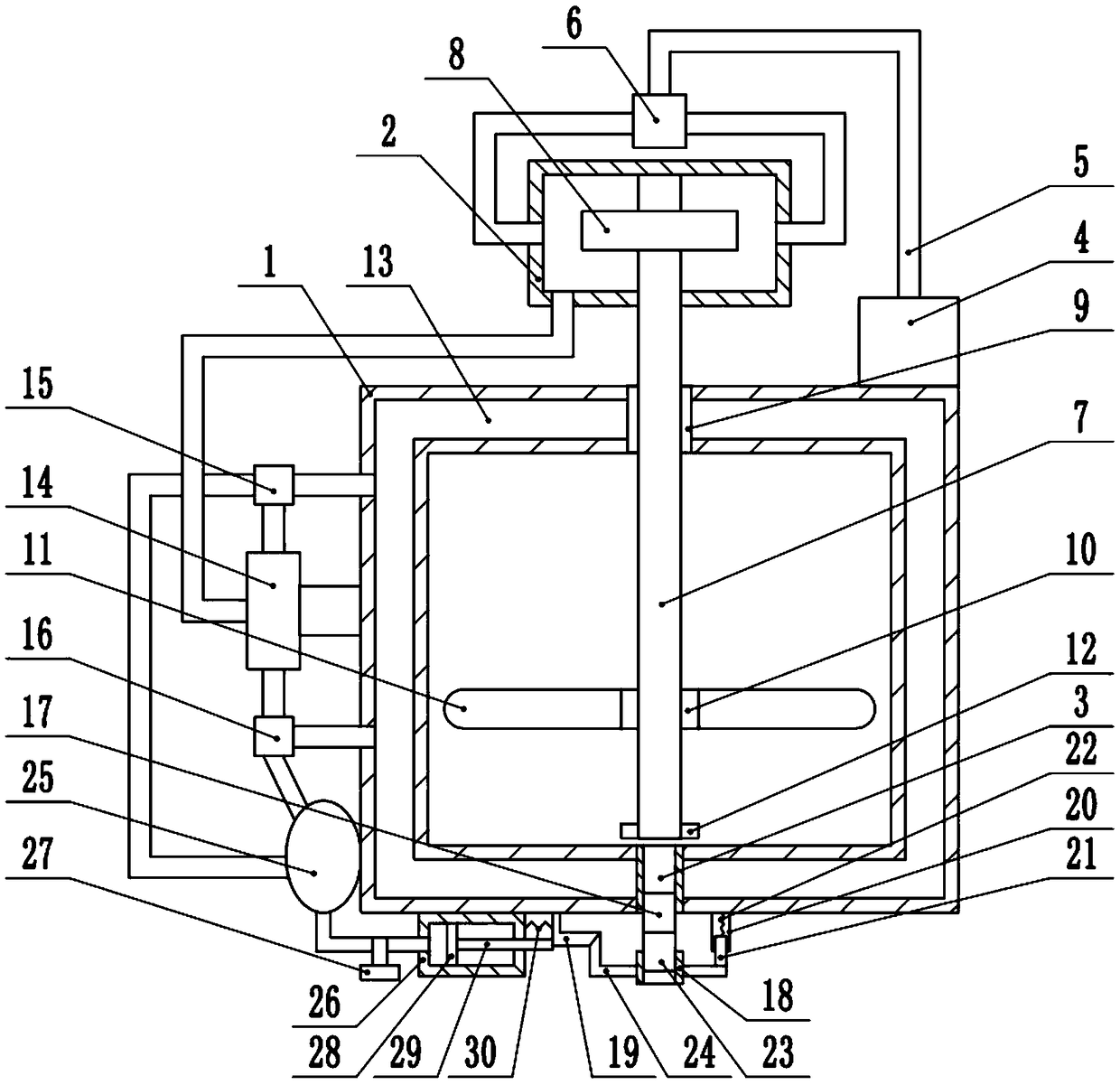

Vacuum welding furnace and welding technology

ActiveCN107931768AReduce the temperaturePrevent oxidationHeating appliancesMetal working apparatusEngineeringOxygen

The invention provides a vacuum welding furnace and a welding technology, and belongs to the technical field of vacuum welding. The vacuum welding furnace is characterized in that one end, close to the feeding end, of a welding platform (20) is used as a heating area; one side, close to the discharging end, of the welding platform (20) is used as a cooling area; a negative pressure pumping module(9) is arranged at the upper side of one end, close to the cooling area, of the heating area, and the negative pressure pumping module (9) is mounted on a furnace cover (4) by lifting; the bottom partof the negative pressure pumping module (9) and the heating area encircles a closed negative pressure chamber; a protecting gas inlet pipe is arranged on a welding chamber (18) or the furnace cover (4). According to the vacuum welding furnace, material sheets can be heated through the heating area, so that the material sheets can be quickly welded in the negative pressure chamber; protecting gasis charged, so that the material sheets are prevented from reacting with oxygen during being heated; the material sheets can be cooled and prevented from being oxidized through the cooling area. According to the welding technology, the welding time is decreased; the welding is accelerated; with the adoption of the cooling area, the material sheet can be completely cooled and is prevented from deformation caused by excessively quick cooling.

Owner:SHANDONG CAIJU ELECTRONICS TECH CO LTD

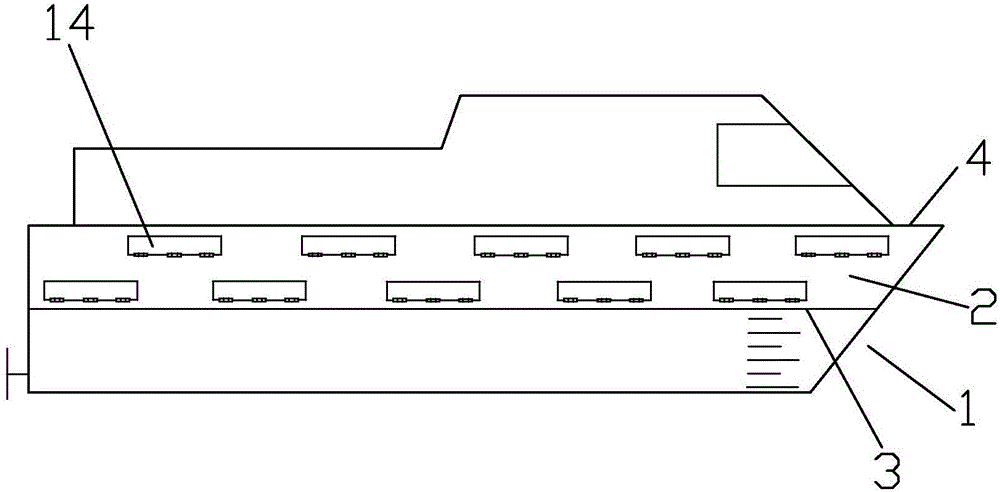

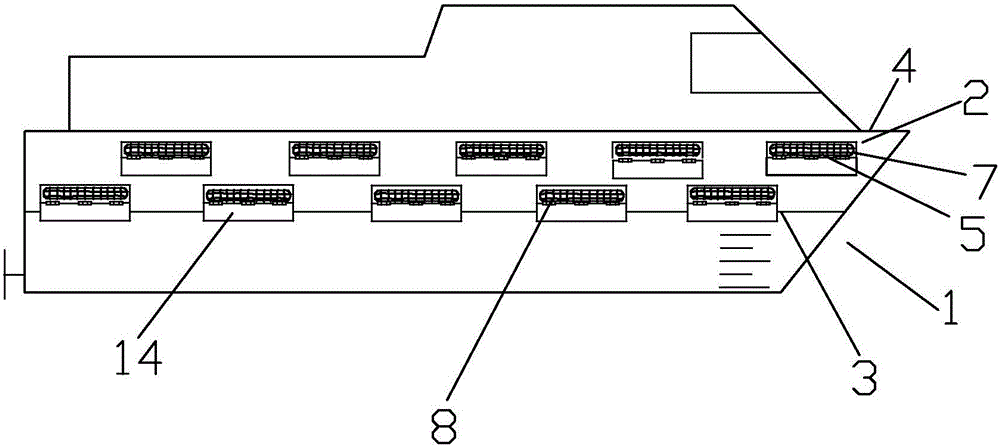

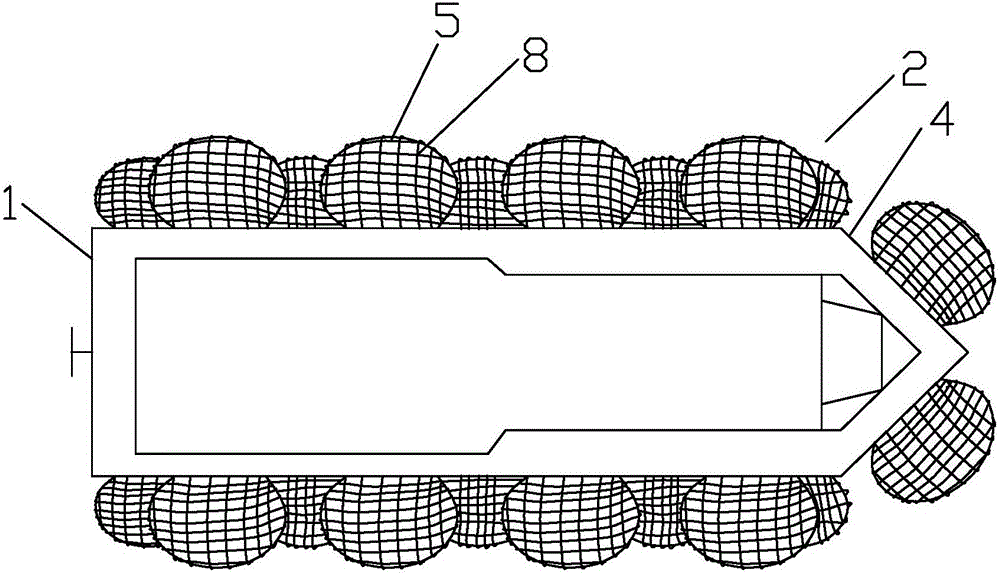

Steamship provided with rollover self-rescuing system

The invention discloses a steamship provided with a rollover self-rescuing system, and belongs to the technical field of steamship manufacturing. The steamship comprises a steamship body and is characterized in that the steamship rollover self-rescuing system is arranged on the steamship body; and the steamship rollover self-rescuing system comprises a plurality of air bags, winches and air bag inflating systems, wherein the air bags are arranged on the two sides of the portion, above the waterline of the steamship body, of a ship board, and the winch are used for fixing and containing the air bags. According to the steamship, the steamship rollover self-rescuing system is additionally arranged on the basis of an existing steamship, the principle that the safety air bags are rapidly inflated is used, once dangerous cases, such as sudden steamship rollover, of the steamship occur, an automatic control system can automatically control electronic valves, the winches and automatic groove opening-closing baffles to move, the air bags are rapidly inflated with air accordingly, the steamship body is supported through buoyancy generated by the air bags on the water surface, the aim of preventing the steamship body from being continuously inclined and sunken or decreasing the sinking speed is achieved accordingly, and valuable time is gained for escaping and rescuing of people.

Owner:毛应吉

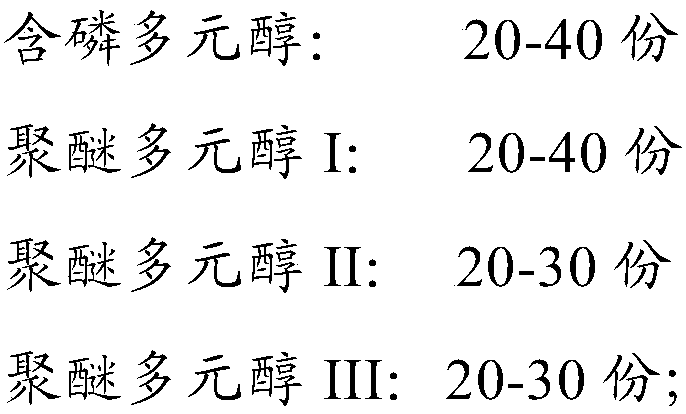

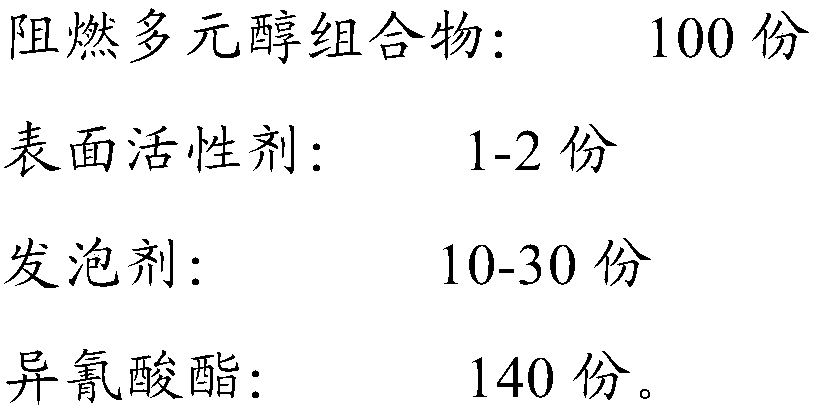

Flame retardant polyol composition and preparation method and application thereof

ActiveCN109096482AAvoid Migration ProblemsGood flame retardant performanceSubstance of very high concernChemical reaction

The invention discloses a flame retardant polyol composition composed of phosphorus-containing polyol and polyether polyol and further discloses a weight fraction ratio of the polyols. The phosphorus-containing polyol is phosphorus-containing flame-retardant polyol prepared by reacting phosphorus-containing small molecules with an epoxy substance, the viscosity of the phosphorus-containing flame-retardant polyol is 1500-3500 mPa s, and the hydroxyl value of the phosphorus-containing flame-retardant polyol is 400-600 mg KOH / g; the molar ratio of a hydroxyl group of the phosphorus-containing small molecules to an epoxy group of the epoxy substance is from 1:0.8 to 1:1. The invention also discloses a preparation method and application of the flame retardant polyol composition in polyurethanerigid foam. A flame retardant element is introduced into a molecular chain of polyurethane through a chemical reaction, high flame retardancy and stability during application are achieved, the development cost is low, there are no by-products, a process is simple, and the flame retardant performance is high.

Owner:HAIER SMART HOME CO LTD +1

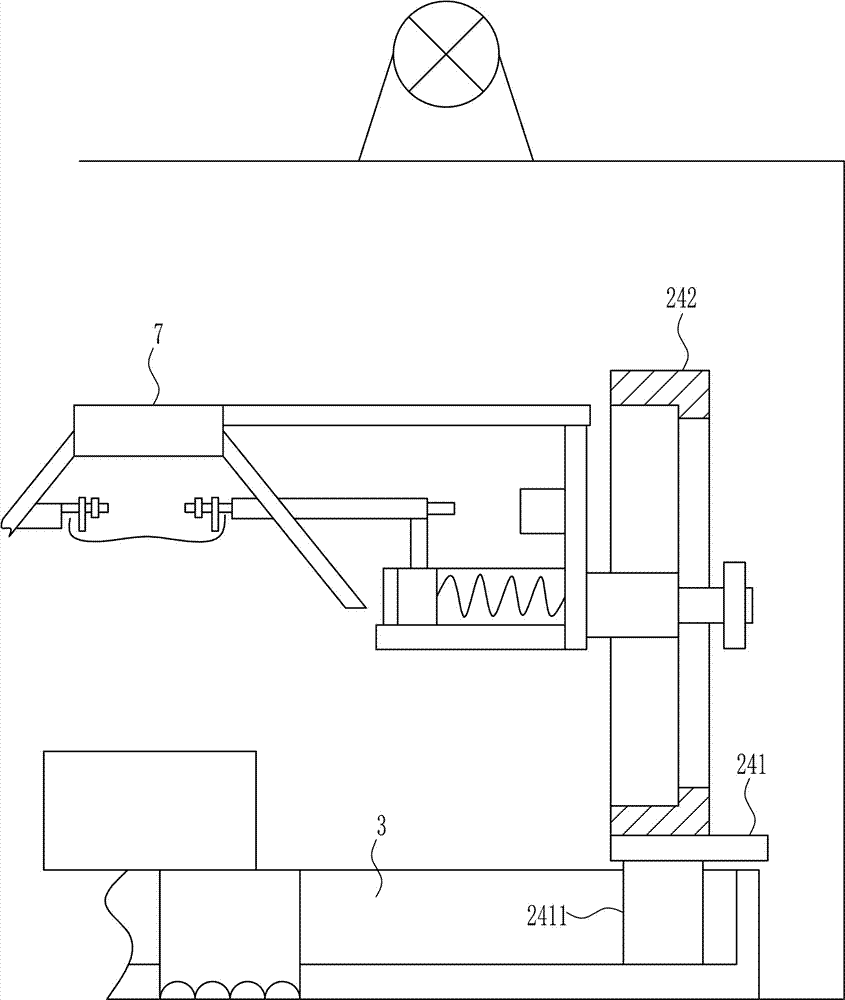

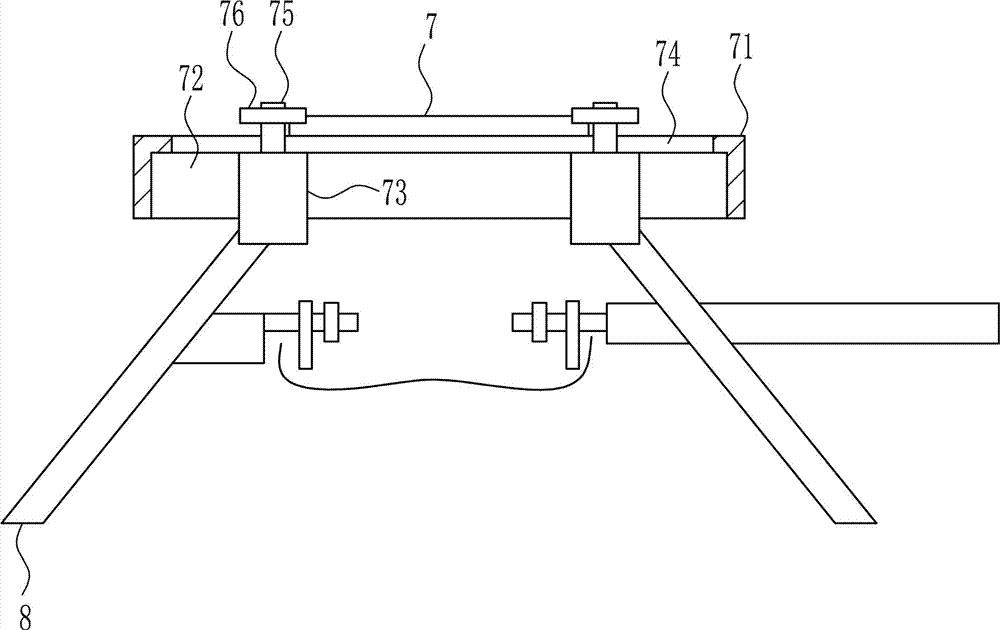

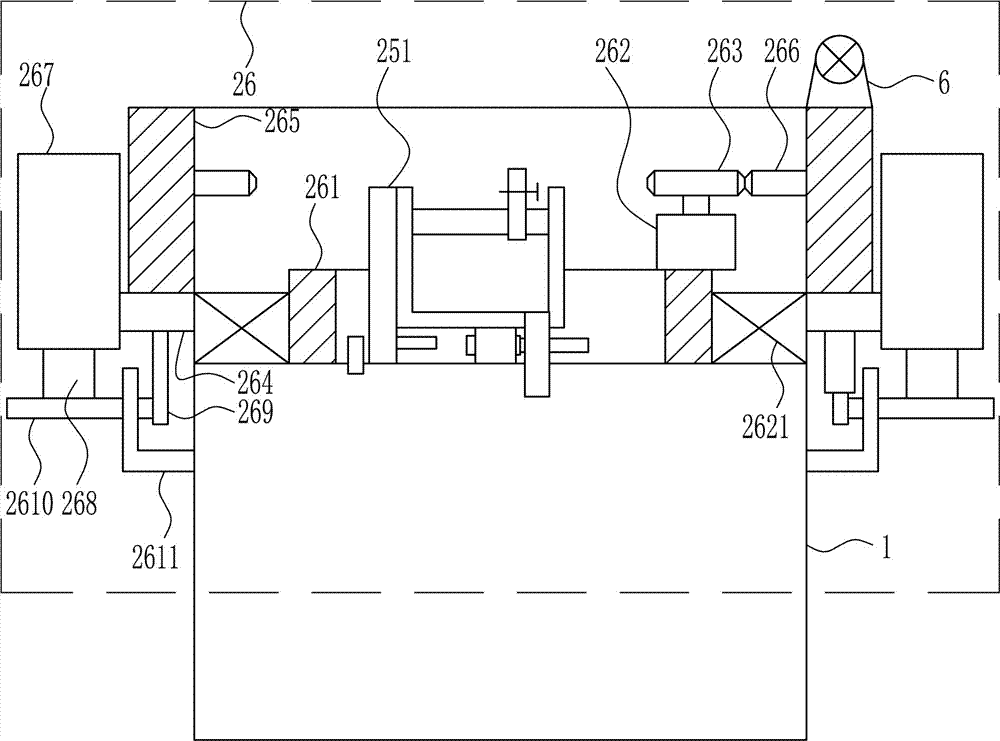

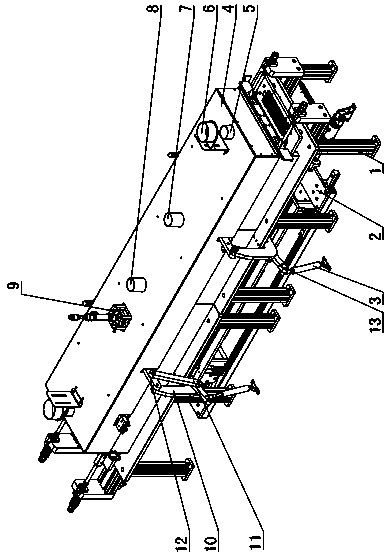

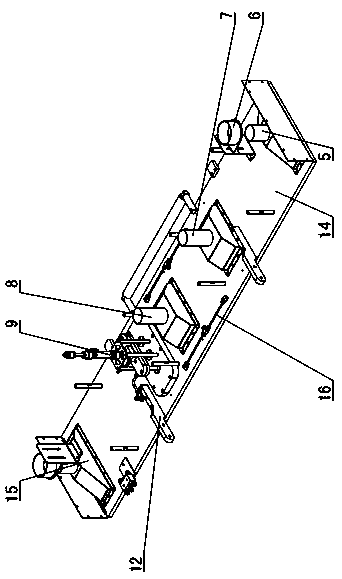

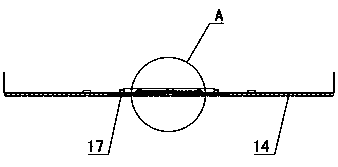

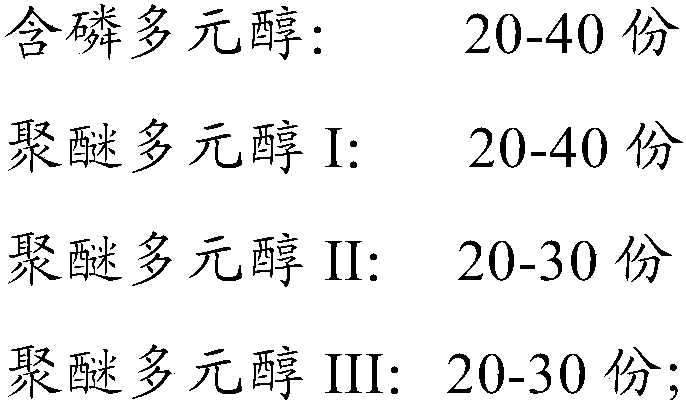

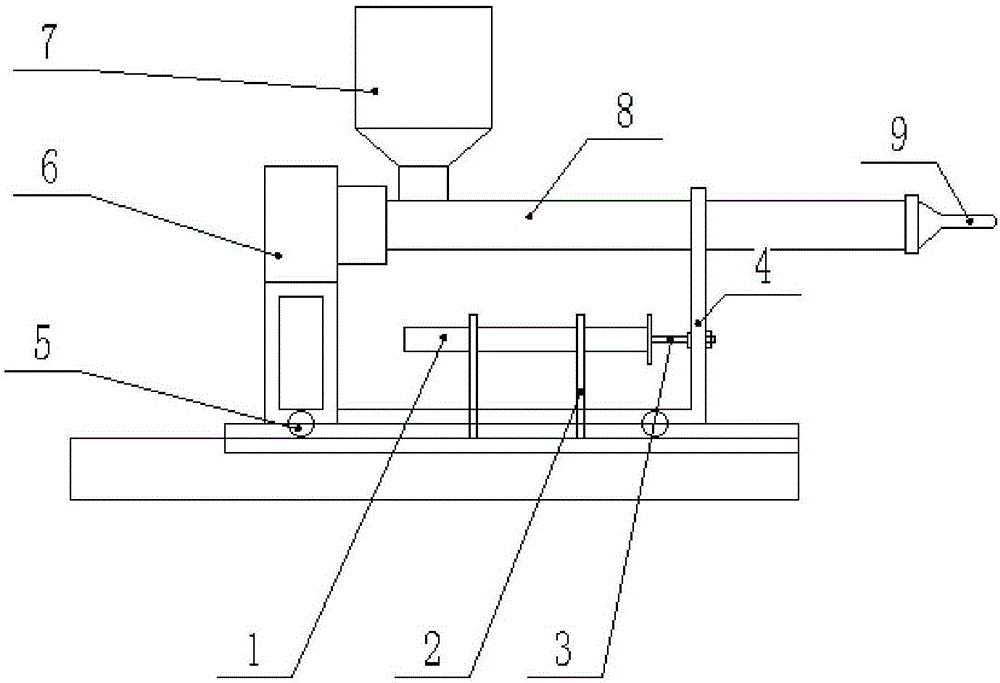

Extrusion feeding mechanism and extrusion injection molding machine

The invention relates to the technical field of extrusion injection molding machines, to solve the problem of low production efficiency of an injection molding machine in the prior art. In particular, the invention relates to an extrusion feeding mechanism, comprising a pushing assembly, a sliding assembly and an extrusion assembly, wherein the pushing assembly drives the extrusion assembly for straight reciprocating motions through the sliding assembly; the pushing assembly comprises a first support frame, a first oil cylinder mounted on the first support frame, and a connecting plate capable of doing straight reciprocating motions under the push of the first oil cylinder; a channel for the first support frame to pass is arranged on the connecting plate; the sliding assembly comprises a substrate and a sliding member; the first support frame passes through the connecting plate to be fixedly connected to the substrate. The invention also specifically relates to an extrusion injection molding machine, comprising the extrusion feeding mechanism, wherein two extrusion feeding mechanisms are arranged, each of which is disposed on each of two sides of an injection mold, and respectively correspond to a first injection molding port and a second injection molding port. The production efficiency of the current injection molding machine can be accelerated, and production costs can be saved.

Owner:昆山普拉斯克机械制造有限公司

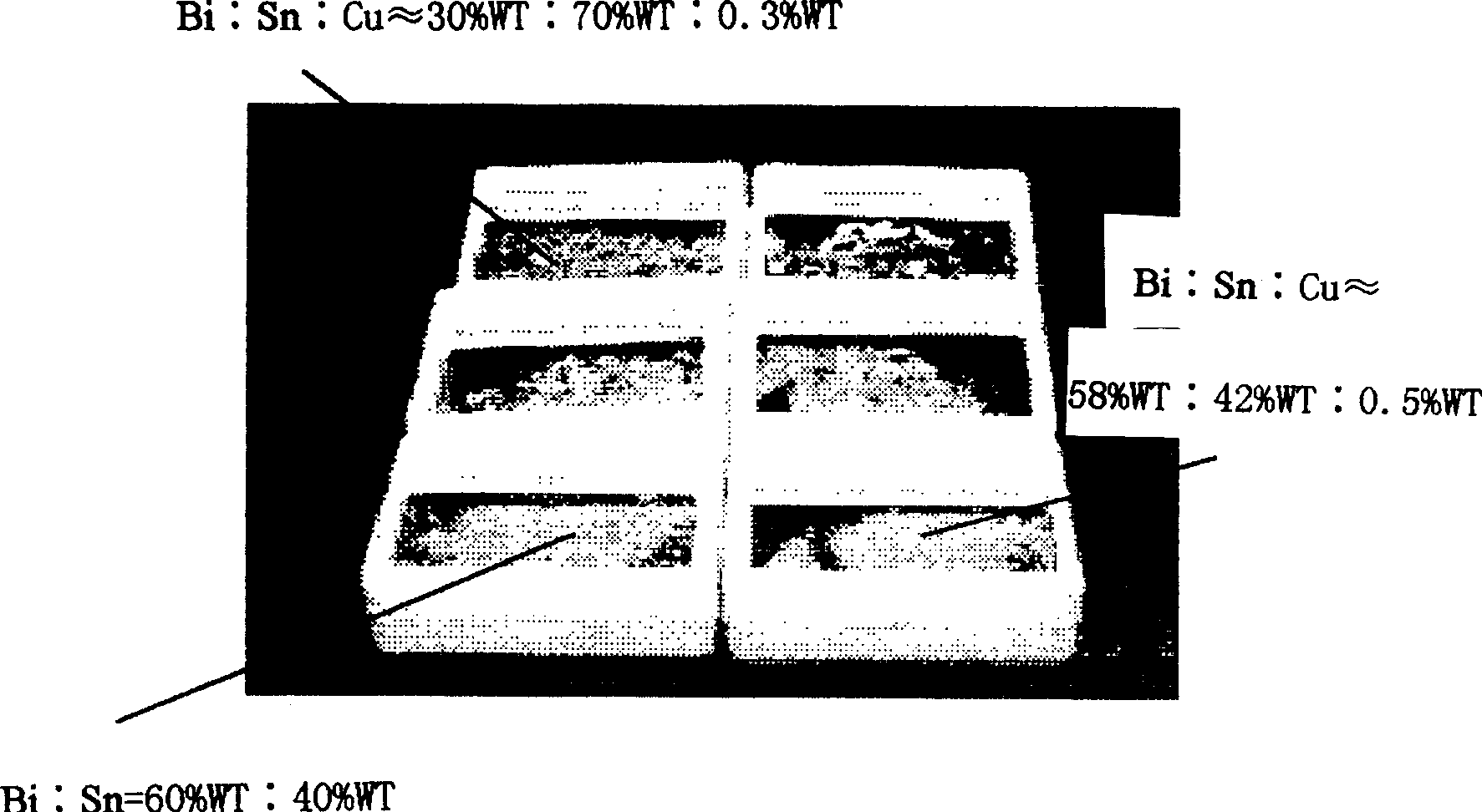

Padding for fixing system with state memory and applied technical procedure

InactiveCN1415774AFacilitate flow velocityFast fullPositioning apparatusMetal-working holdersPressure castingAlloy

A filler for the state-memory installation system contains Bi (15-60 wt.%) Sn (40-85 wt.%), and Cu (0.5 wt.%). It is applied through determining the thickness of filler in error sensitive direction, preheating the installation system, holding the temp for 5-10 min, heating filler while stirring for smelting it, and pressure casting. Its advantages are high flowability and flow speed, high adhesion, and high memory precision.

Owner:DONGHUA UNIV

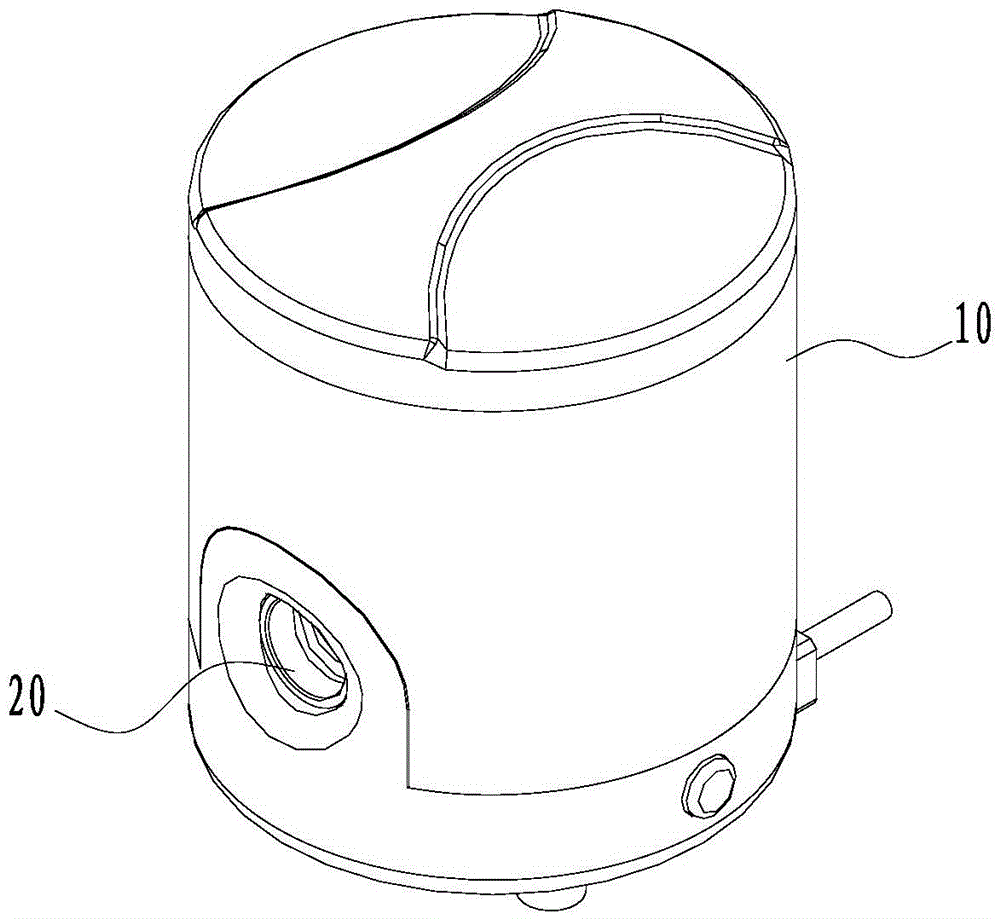

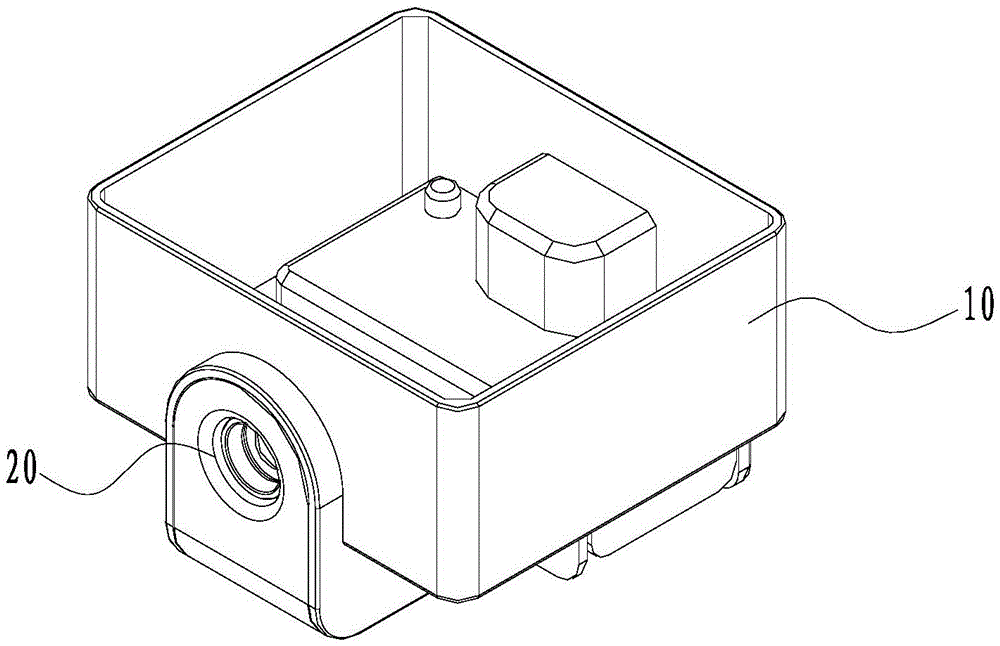

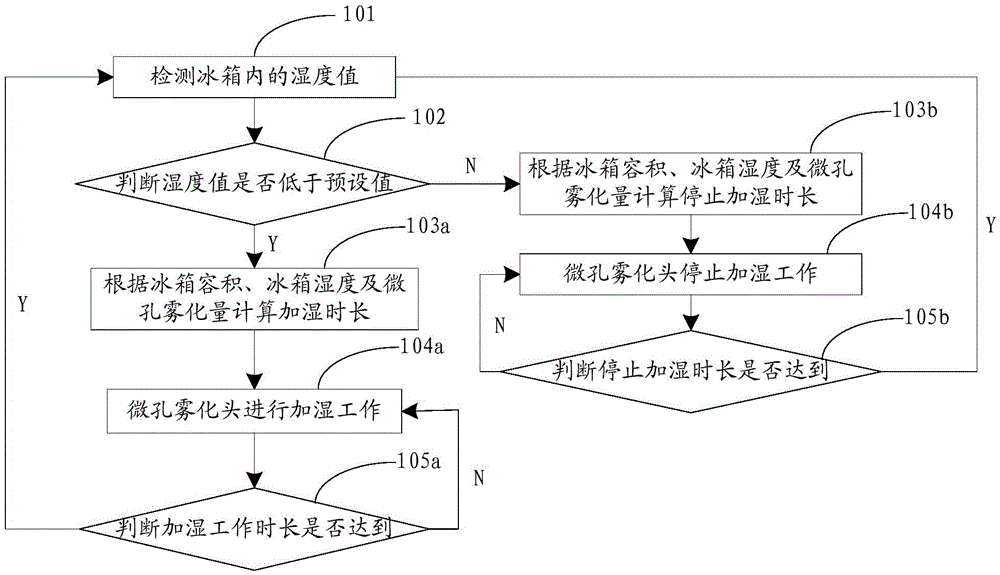

Atomization humidifying device for refrigerator and humidification control method

ActiveCN105650979AEasy accessGood moisturizing effectLighting and heating apparatusCooling fluid circulationEngineeringMoisture sensor

The invention discloses an atomization humidifying device for a refrigerator and a humidification control method. The device comprises a box body, a micro-hole atomization head, a humidity sensor and a circuit control board. The side portion of the box body is provided with a through hole. The micro-hole atomization head is arranged on the side portion of the box body and opposite to the through hole. Both the humidity sensor and the circuit control board are arranged on the box body. The circuit control board is electrically connected with the humidity sensor and the micro-hole atomization head. The humidity sensor is used for detecting the humidity inside the refrigerator and sending the detection information to the circuit control board. The circuit control board is used for controlling the micro-hole atomization head to carrying out humidification work. According to the atomization humidifying device for the refrigerator, water is changed into gas spray through the micro-hole atomization head and sprayed out through micro holes, the airflow spraying-out speed is high, and the refrigerator can be rapidly filled with gas spray. The humidity sensor is directly added in the box body of the atomization humidifying device instead of arranging a humidity sensor and an atomization piece in the refrigerator, so that the atomization humidifying device is high in independence degree, can be put in and taken out of the refrigerator conveniently and good in humidifying effect.

Owner:AUDIOWELL ELECTRONICS GUANGDONG

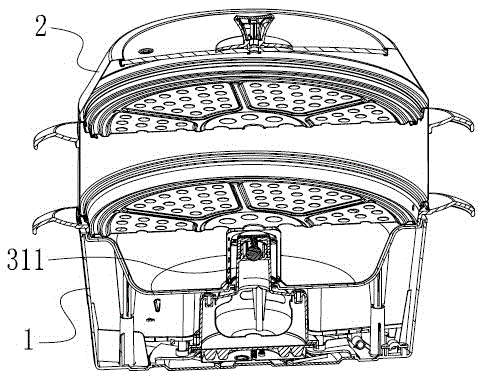

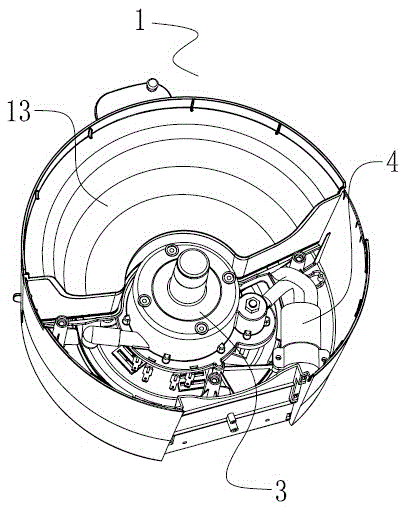

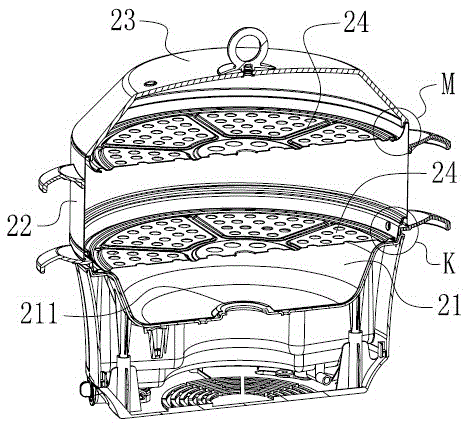

Micropressure steam hotpot

ActiveCN105615628AShorten the flow distanceReduce heat lossSteam cooking vesselsKitchen utensilsHeating efficiency

The invention relates to the technical field of kitchenware used for cooking food in steam and discloses a micropressure steam hotpot which comprises a base and a steamer placed on the base.A steam generator is arranged in the base, the steamer comprises a bottom pot and a pot cover, the steam generator comprises a shell, a steam outlet is arranged at the top of the shell, a pressure control valve blocks the steam outlet, a pressure control valve cover covers the steam outlet and covers the pressure control valve between the steam outlet and the top of the pressure control valve cover, the pressure control valve can move up and down, the pressure control valve cover is provided with steam flow holes, a through hole is formed in the bottom of the bottom pot, and after the steamer is placed on the base, the pressure control valve cover penetrates the through hole to extend into the bottom pot.The steam hotpot has effect of ejecting steam, thereby being conducive to the steamer to be quickly filled with the steam, and heating efficiency is improved.

Owner:BEIJING LIVEN SCI TECH

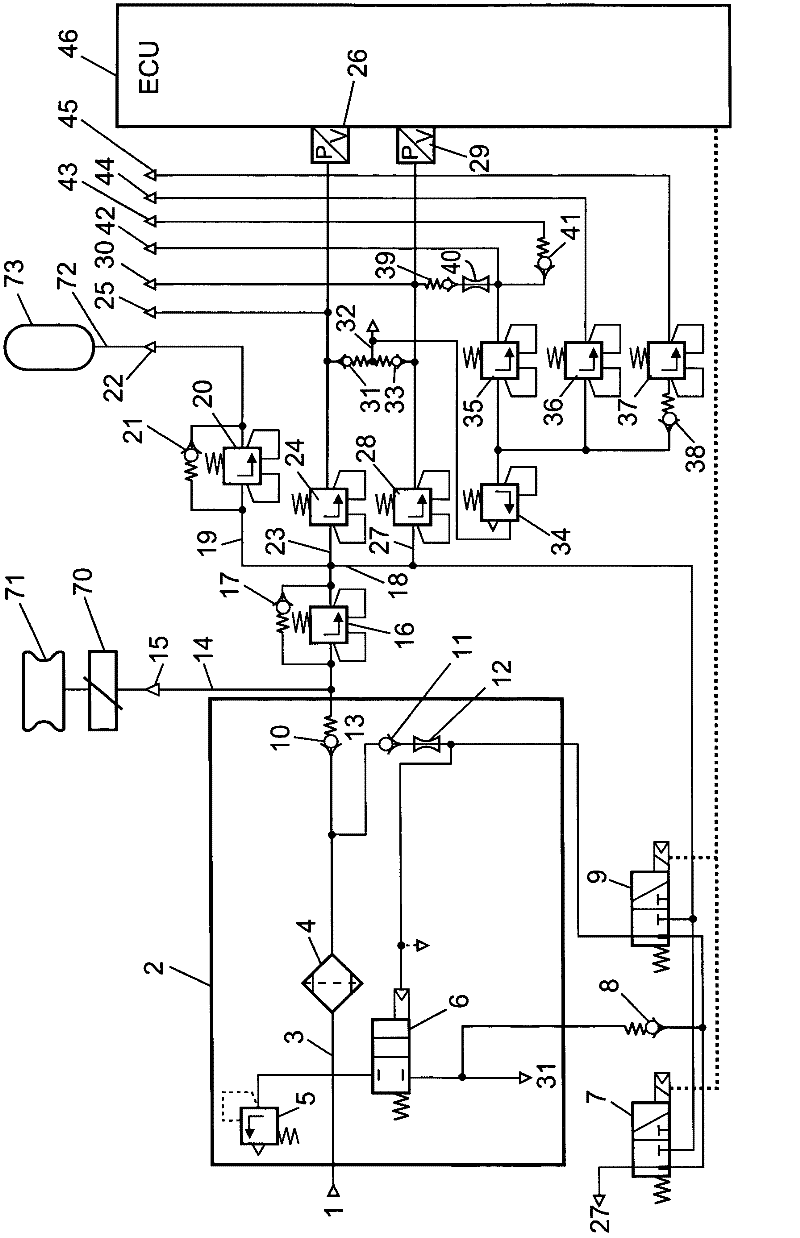

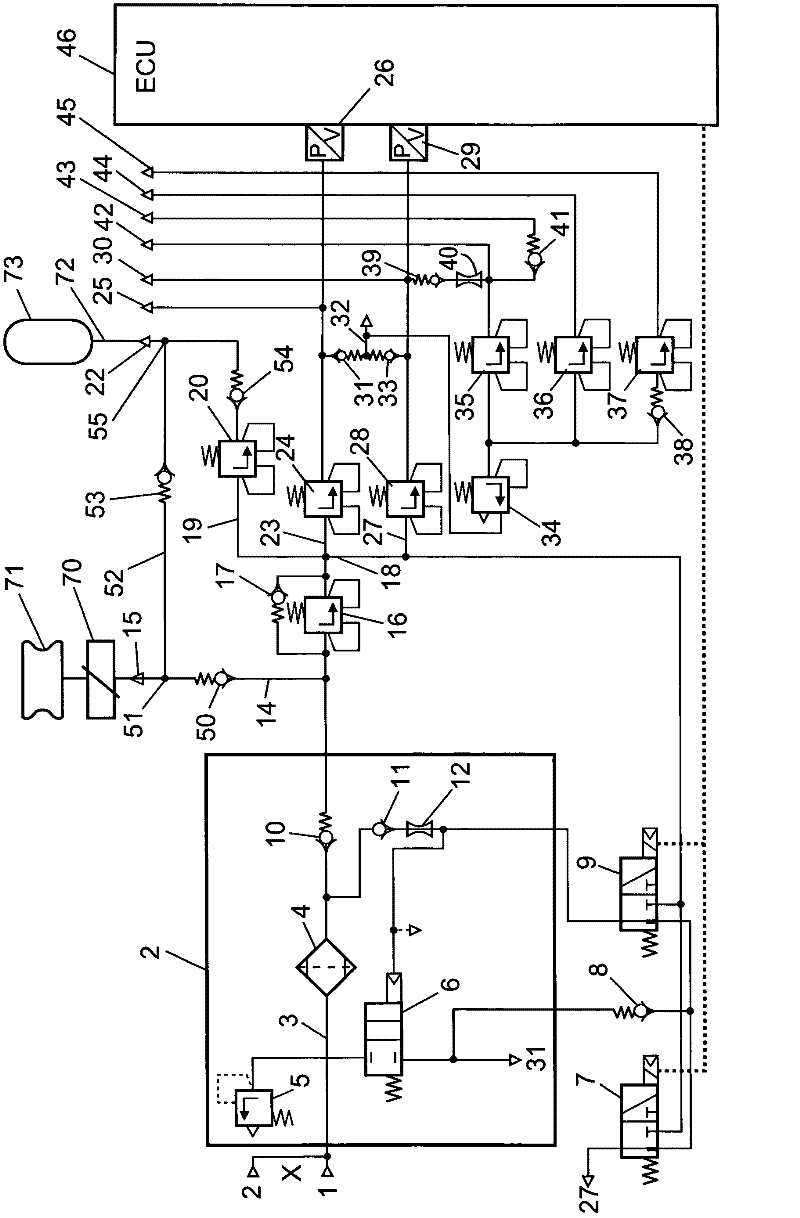

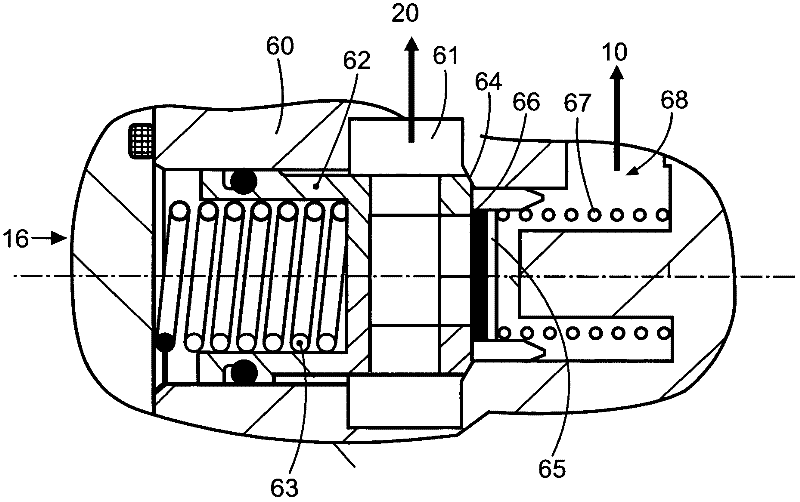

Compressed air supply system for a compressed air consumer circuit, in particular for an air spring system

The invention relates to a compressed air supply system for a first compressed air consumer circuit (70, 71), particularly for an air spring system for a vehicle. The compressed air supply system comprises a first compressed air line (14) leading to the first compressed air consumer circuit and a distribution line (18) leading to further consumer circuits (25, 30, 42, 43, 44, 45). A priority valve arrangement (16) is disposed between the first compressed air line (14) leading to the compressed air consumer circuit and the distribution line (18) leading to the further consumer circuits (25, 30, 42, 43, 44, 45), wherein the first compressed air line (14) comprises no safety valve. The first compressed air consumer circuit (70, 71) can therefore be filled at a higher priority, and achieve operational readiness quickly. Air spring processes, for example, such as lifting or raising activities, can be performed very quickly with priority.

Owner:WABCO GMBH

GGJ low-voltage reactive power compensation cabinet

ActiveCN109698469AFast fullQuick drawFire rescueSubstation/switching arrangement casingsLow voltageEngineering

The invention belongs to the technical field of power equipment and discloses a GGJ low-voltage reactive power compensation cabinet. The GGJ low-voltage reactive power compensation cabinet comprises acabinet body, feedback sealed air bags, and a gas exchange fire extinguishing mechanism. The front side of the cabinet body is hinged with a cabinet door, the upper side of the right wall of the cabinet body is provided with five strip-shaped heat dissipation holes which are orderly arranged from the top to bottom, a right side face of the cabinet body is equipped with a radiating fan corresponding to the strip-shaped heat dissipation holes, the feedback sealed air bags are bonded to gaps at inner sides of top walls of the strip-shaped heat dissipation holes, and the gas exchange fire extinguishing mechanism is arranged outside the cabinet body. According to the GGJ low-voltage reactive power compensation cabinet, by setting a gas exchange mechanism, the quick reaction is performed by using the change of the temperature in the cabinet body, the cabinet body is filled with nitrogen gas, at the same time, fan blades are driven to rotate by using the linkage between a ring and a gas supply shell, a phenomenon that the density of the nitrogen gas is lower than that of air and the nitrogen gas floats on the upper layer of the cabinet body is used, the fan blades quickly extract the airfrom the cabinet body, the cabinet body is quickly filled with the nitrogen gas, and the convection is formed by the filling of the nitrogen gas and the discharge of the air.

Owner:江西江控电气有限公司

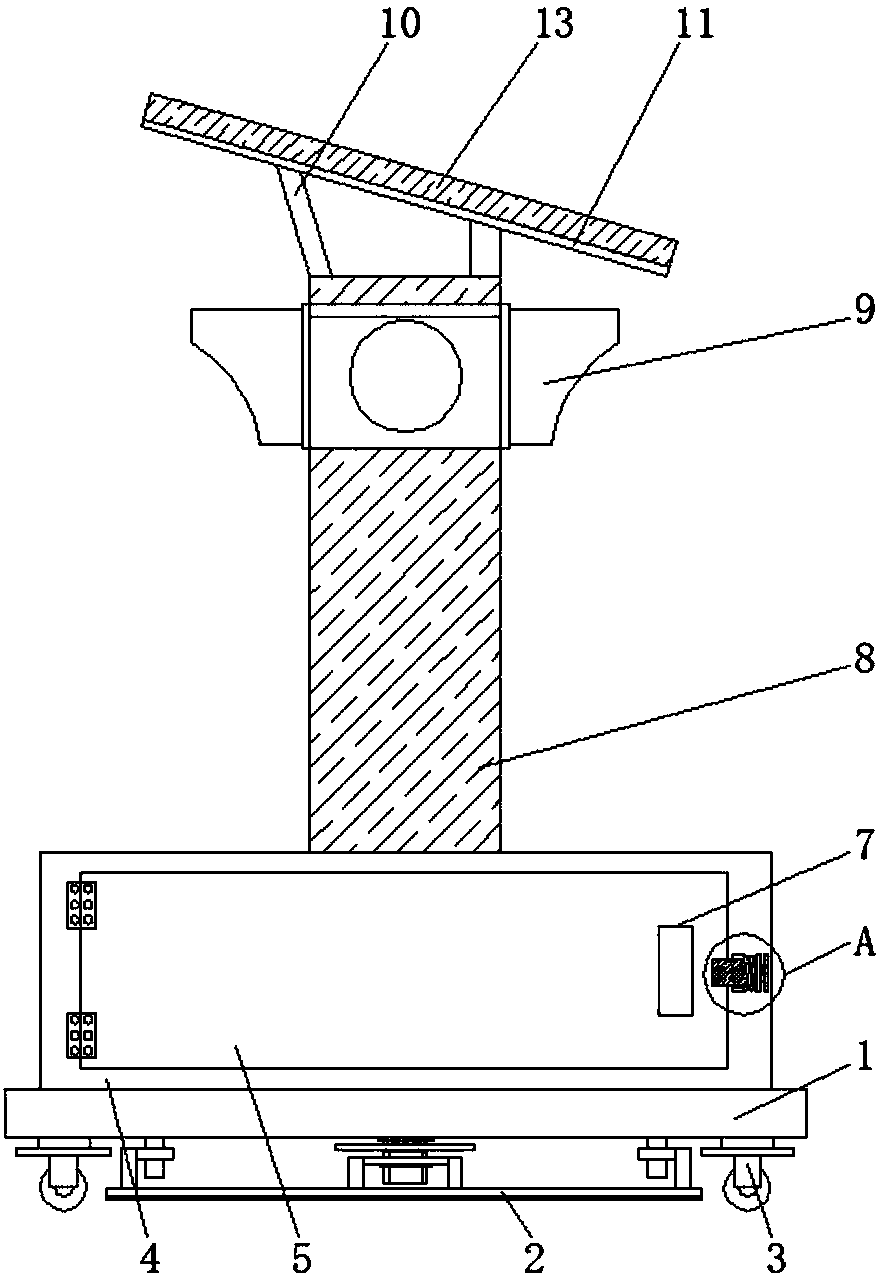

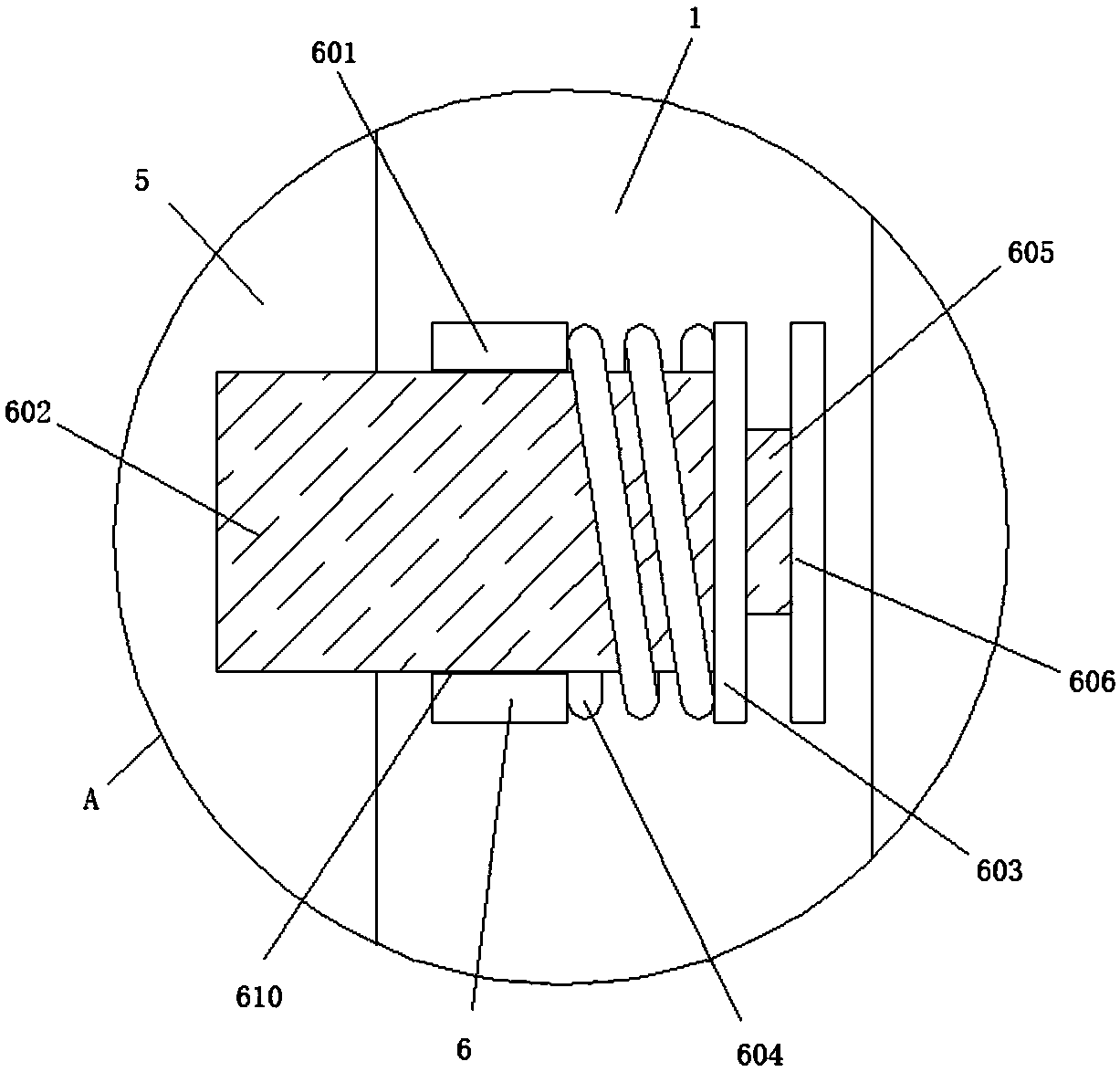

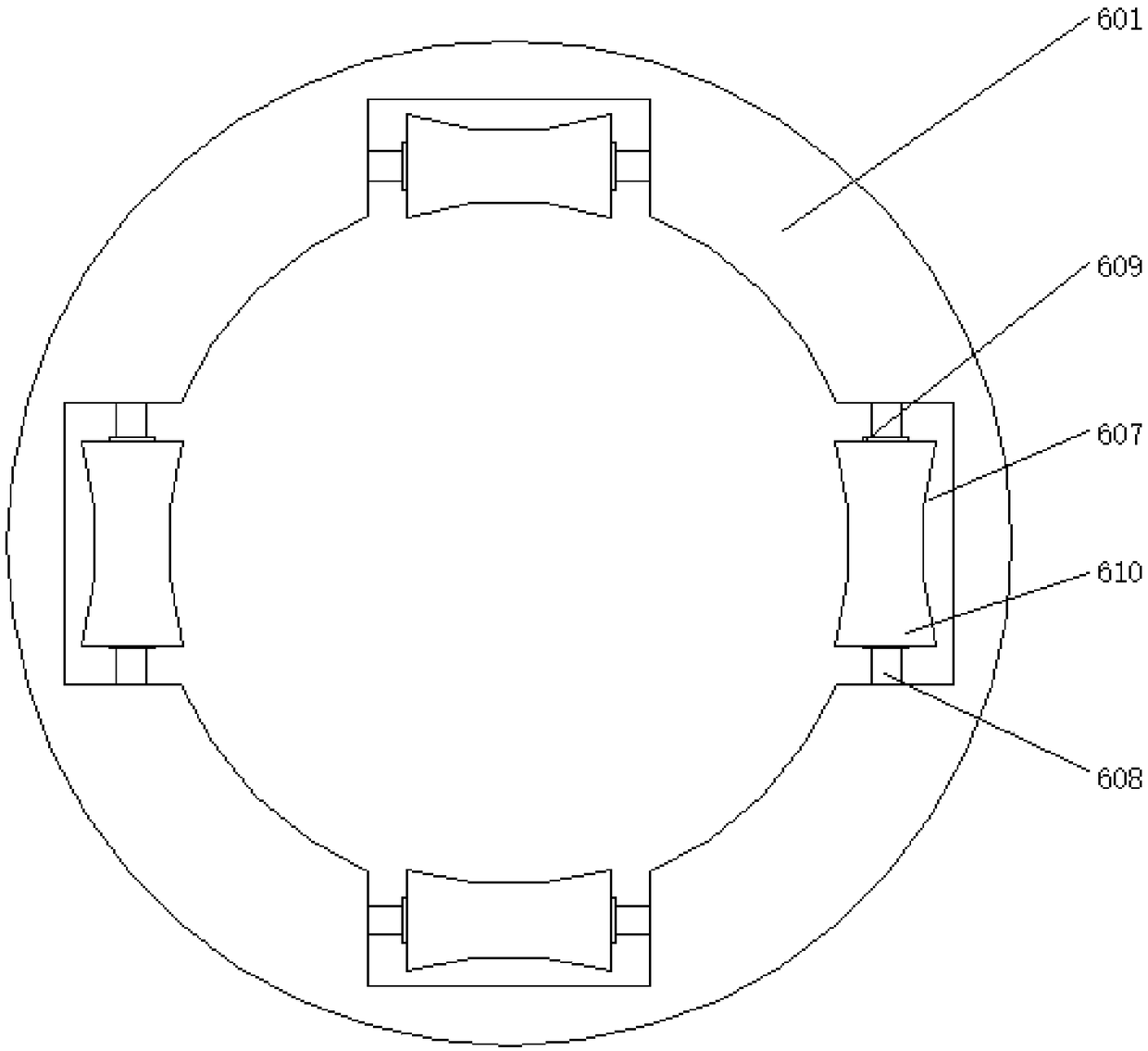

Temporary traffic light for road construction

InactiveCN108510767AImprove power generation efficiencyGuaranteed cleanlinessRoad vehicles traffic controlPhotovoltaic solar energyEngineering

The invention relates to the technical field of road construction equipment, in particular to a temporary traffic light for road construction. The technical problem to be solved by the invention is that the power generation efficiency of a photovoltaic solar panel on the temporary traffic light is lowered, which easily causes the temporary traffic light not to work and affects traffic safety. In order to solve the technical problem, the invention provides the temporary traffic light for road construction, which comprises a base. The bottom of the base is fixedly connected with a positioning device and a universal wheel, the top of the base is fixedly connected with a fixed box, a movable door is fixedly connected to the position of a movable port fixed on the front surface of the fixed box, the front surface of the fixed box is fixedly connected with a fixing device, and the top of the fixed box is fixedly connected with a first supporting rod. According to the temporary traffic lightfor road construction, since the photovoltaic solar panel is provided with a cleaning device, the cleanness of the surface of the photovoltaic solar panel is ensured, thereby improving the power generation efficiency of the photovoltaic solar panel and ensuring that there is sufficient electric power to support the work of the temporary traffic light.

Owner:曾德生

Rapidly extinguished battery tank

PendingCN107579180AShort strokeShorten the timeSecondary cellsFire rescueElectrical batteryEngineering

The invention discloses battery tank fire extinguishing technique and discloses a rapidly extinguished battery tank which comprises channels, wherein the channels are formed in a tank wall; an external interface for connecting the channel with a fire extinguishing agent pipeline is formed in the battery tank; internal ejection holes corresponding to battery packs are formed inside the battery tank; the internal ejection holes are communicated with the channels; one or more channels are formed in the tank wall; a plurality of the channels are uniformly formed in the tank wall at intervals. Thechannels are formed in the tank wall of the battery tank, and a fire extinguishing agent can be directly ejected to the battery packs through the channels, so that the distance and the time that the fire extinguishing agent reaches the battery packs are shortened, the temperature can be rapidly reduced, the battery packs can be prevented from contact with the air, a flame retardancy effect is achieved, a rapid fire extinguishing speed is achieved, and a good effect is achieved.

Owner:SICHUAN CAMY NEW ENERGY CO LTD

Ink box for copying machine

ActiveCN108790415ASpeed up the flowFast fullRotary stirring mixersTransportation and packagingCold airEngineering

The invention relates to the technical field of copying machine equipment and discloses an ink box for a copying machine. The ink box comprises an ink box body and an air guiding box. The ink box bodyis provided with an ink outlet. The air guiding box is provided with air inlets and an air outlet. The ink box body is provided with an air supply box. A guide pipe communicates with the air supply box and is provided with a first three-way valve. The first three-way valve communicates with the air inlets. A rotating shaft is connected into the air guiding box in a rotary manner. A turbine is connected to the rotating shaft in a sleeving manner. One end of the rotating shaft penetrates the air guiding box and extends into the ink box body. A sliding sleeve is connected to the rotating shaft in a sleeving and threaded manner. A stirring plate is fixedly connected to the sliding sleeve. A cavity is formed in the inner wall of the ink box body. A vortex tube is fixedly connected to the ink box body, wherein the vortex tube communicates with the air outlet. The hot air end and the cold air end of the vortex tube each communicate with the cavity. A second three-way valve is connected between the hot air end of the vortex tube and the cavity. A third three-way valve is connected between the cold air end of the vortex tube and the cavity. By means of the ink box, the problem that in theprior art, due to the fact that ink in an ink box is frozen, normal coping cannot be conducted is solved.

Owner:贵州省仁怀市西科电脑科技有限公司

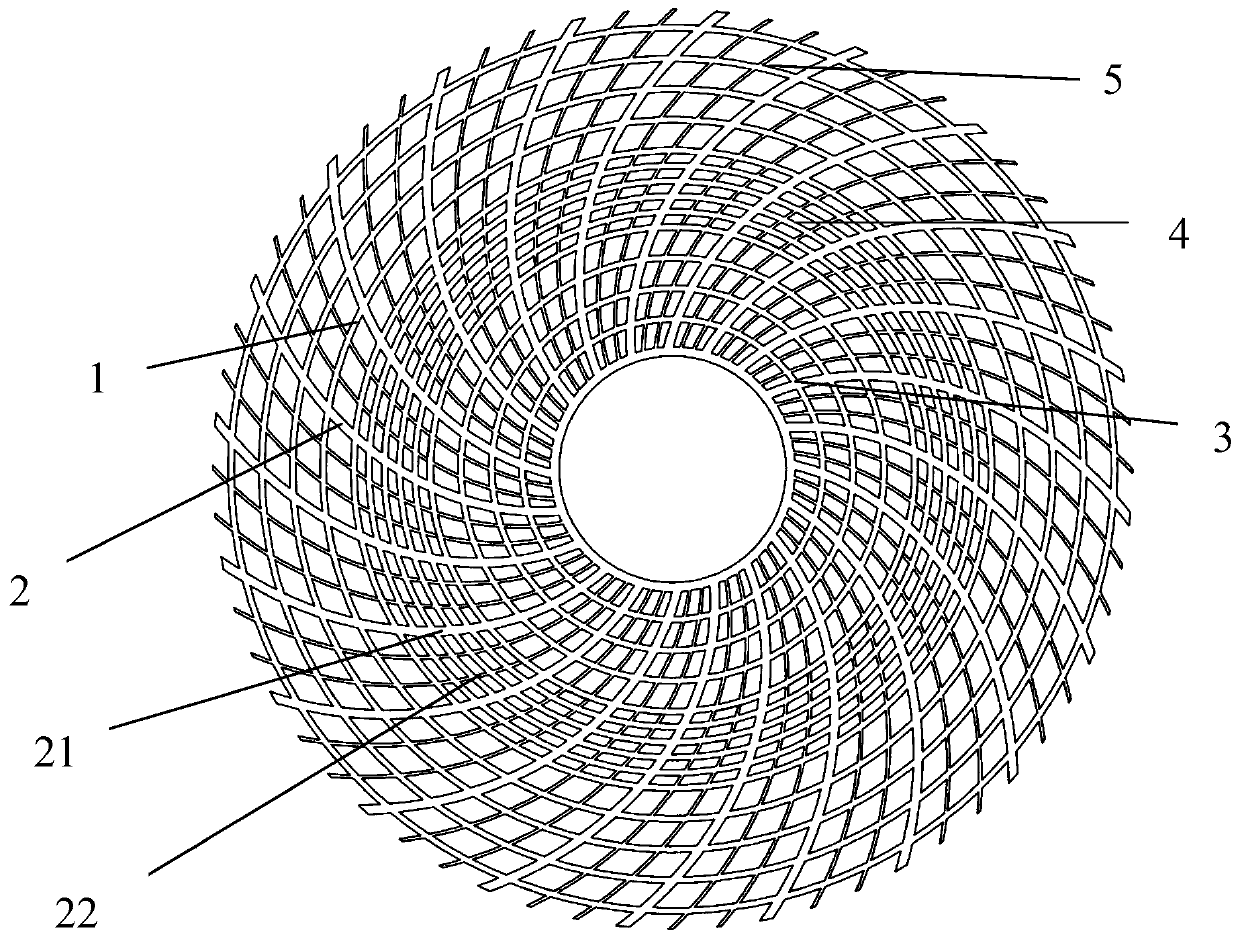

Groove grinding disc and method for manufacturing groove grinding disc

PendingCN110948381AReduce resistanceGood for chip evacuationGrinding devicesLapping toolsGrindingEngineering

The invention provides a groove grinding disc and a method for manufacturing the groove grinding disc. The grinding disc is provided with a groove; the groove is formed by coupling a plurality of concentric grooves with radii gradually increasing and a plurality of spiral line grooves which are arranged at equal intervals; the centers of the spiral line grooves are concentric with the centers of the concentric grooves; the grinding disc is divided into a first area, a second area and a third area from inside to outside in the radial direction; and the distance between the concentric grooves ofthe first area and the distance between the concentric grooves of the third area are greater than the distance between the concentric grooves of the second area. The application of the technical scheme can realize the improvement of the flow performance of grinding liquid in the grinding and polishing process, and the problems of blockage and wear of the grinding disc are obviously improved.

Owner:HUAQIAO UNIVERSITY

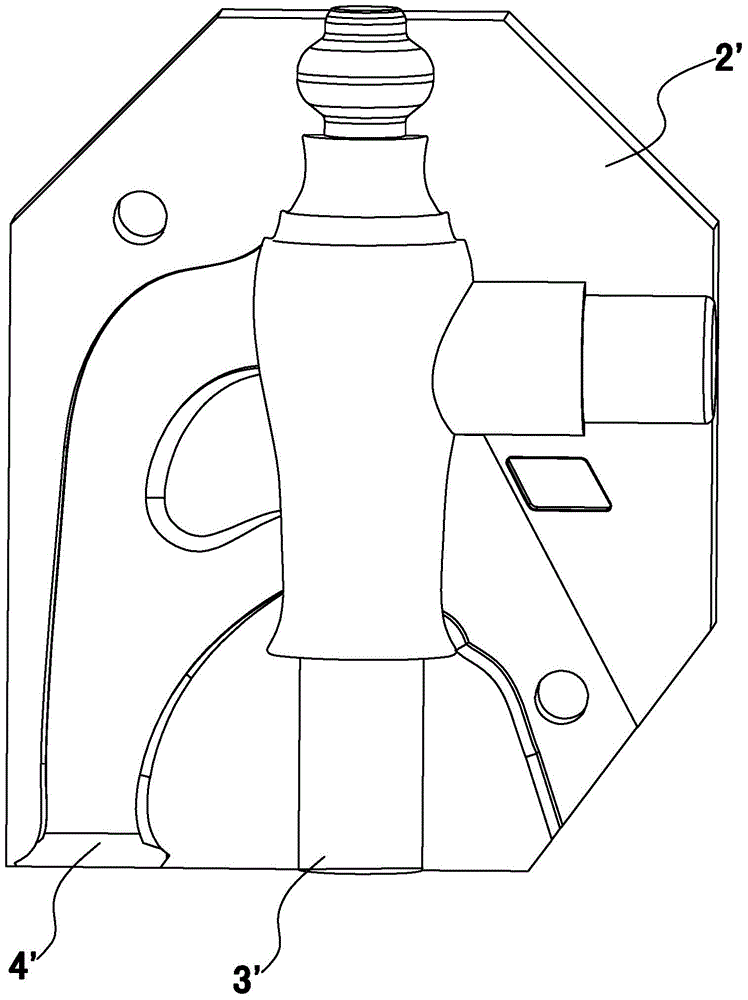

Gravity casting process of lead-free brass tap

The invention provides a gravity casting process of a lead-free brass tap, which has the advantages that a flowing distance of a product in a casting process is short, the simultaneous solidification is achieved, hot cracks are reduced; a heat balance effect of a mould is good, so that heat balance of the product is facilitated, and the stress micro-cracks during cooling are reduced. The gravity casting process of the lead-free brass tap comprises the following step of casting and forming lead-free brass liquid through a gravity casting device, wherein the gravity casting device comprises an upper half mould, a lower half mould and a sand core, wherein mould cavities matched with a tap body in shape are respectively and correspondingly arranged between the upper half mould and the lower half mould, the sand core is arranged in the mould cavities between the upper half mould and the lower half mould, the shape of the sand core is matched with the shapes of a water inlet part and a water outlet part of the tap and an inner cavity of an installing part of a valve core, a casting cavity is formed between the sand core and the mould cavity, a sprue in which lead-free molten copper is cast is arranged in the lower half mould, the sprue is connected with the casting cavity, the sprue is provided with an internal sprue and an external sprue, and the internal sprue is correspondingly arranged at the casting cavity for forming the water inlet part of the tap body.

Owner:LONGYAN HONGHANG SANITARY WARE CO LTD

Condensate water preventing type efficient kit drying device

InactiveCN112460961AReduce consumptionEasy to dryDrying gas arrangementsDrying chambers/containersPhysical chemistryEnvironmental engineering

The invention discloses a condensate water preventing type efficient kit drying device. The condensate water preventing type efficient kit drying device comprises a drying box and an electrifying mechanism, wherein a drying chamber and a rotating cavity are formed in the drying box, the rotating cavity is located below the drying chamber, heating resistance wires are installed on the inner walls of the two sides of the drying chamber, a containing frame is arranged in the drying chamber, the containing frame is composed of a plurality of porous plates, a plurality of kits are placed in the containing frame, and the electrifying mechanism comprises a power generation groove formed in the inner wall of one side of the drying chamber. When the condensate water preventing type efficient kit drying device is used for drying the kits, heat generated by the heating resistance wires can be quickly dispersed in the drying chamber, humid air formed by water evaporation is treated at the same time, and therefore the kits can be quickly dried.

Owner:李银玲

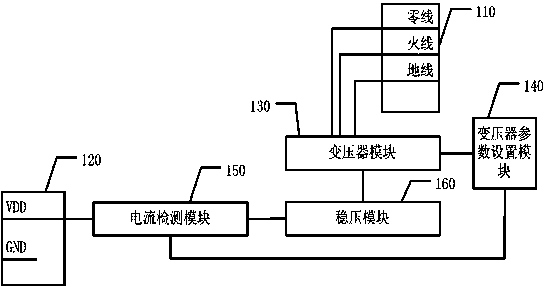

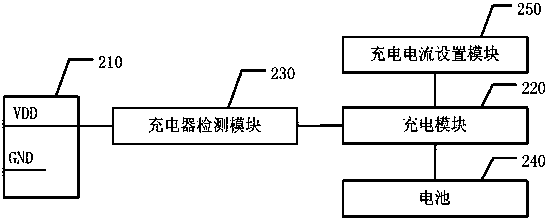

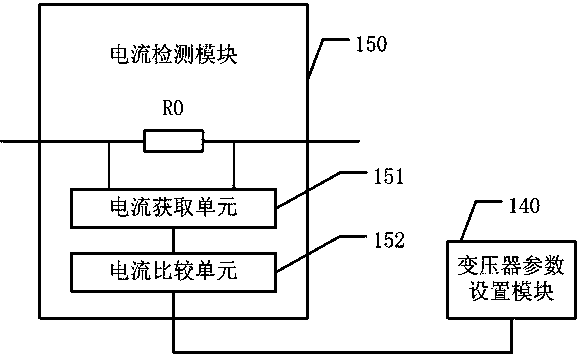

Charge system and charge control method thereof

ActiveCN103633719AFast chargingFast fullBatteries circuit arrangementsSecondary cells charging/dischargingCharge currentTransformer

The invention discloses a charge system and a charge control method thereof. The charge system comprises a charger and a mobile terminal. The charger comprises a power interface, a charge output interface, a transformer module, a transformer parameter setting module, and a current detection module. The mobile terminal comprises a charge input interface, a charge module and a charger detection module. During a charging process, current of the charge output interface is detected through the current detection module; when the current drops below a preset value, the transformer parameter setting module is controlled to raise output voltage of the transformer module; a battery is thoroughly charged fast by means of increasing charge voltage. During the charging process of the battery, charge voltage is automatically increased according to changes in charge current of the battery, and the battery is charged fast.

Owner:SHANDONG WANSHIDA SPECIAL PURPOSE VEHICLE MFG

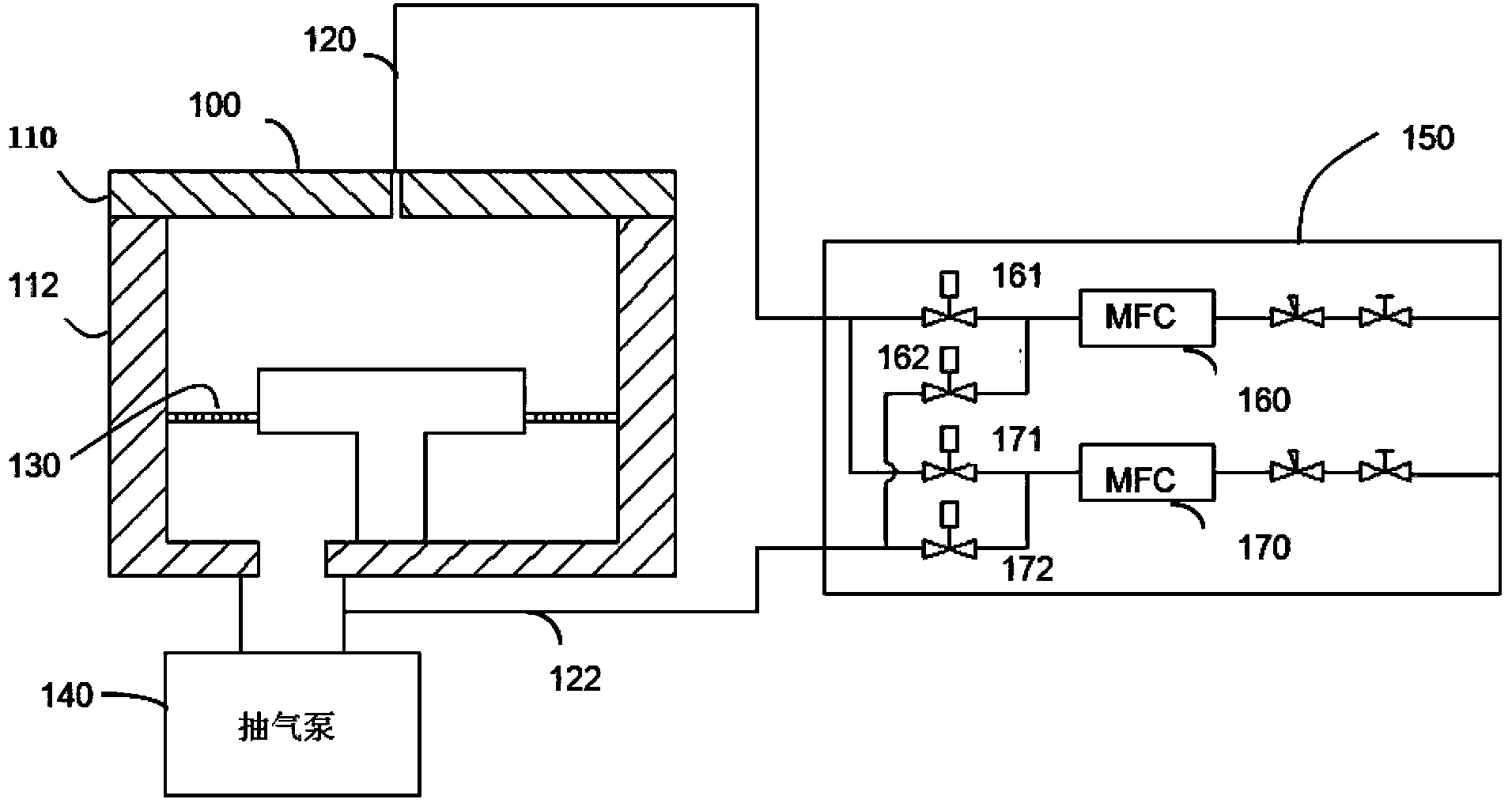

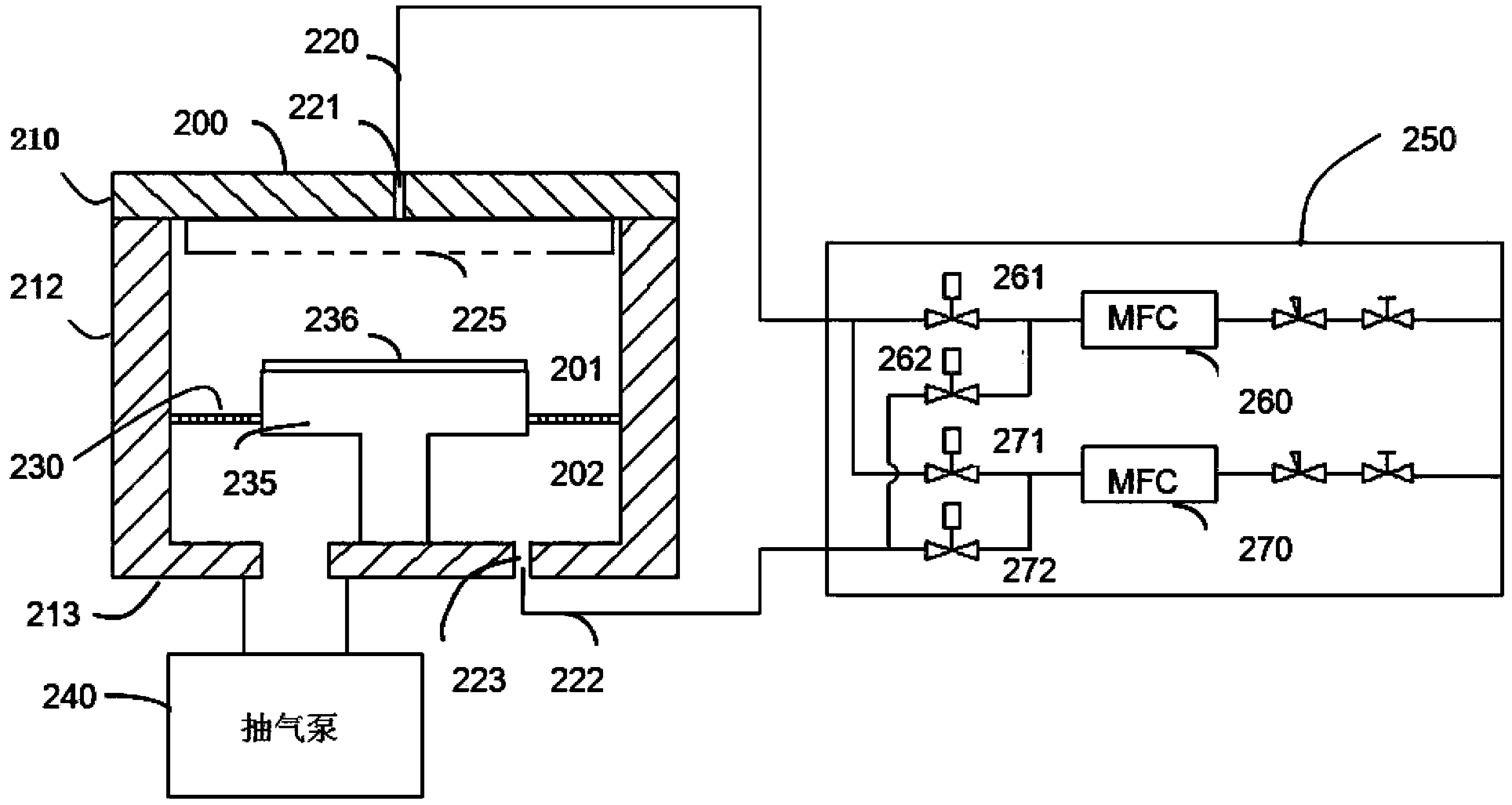

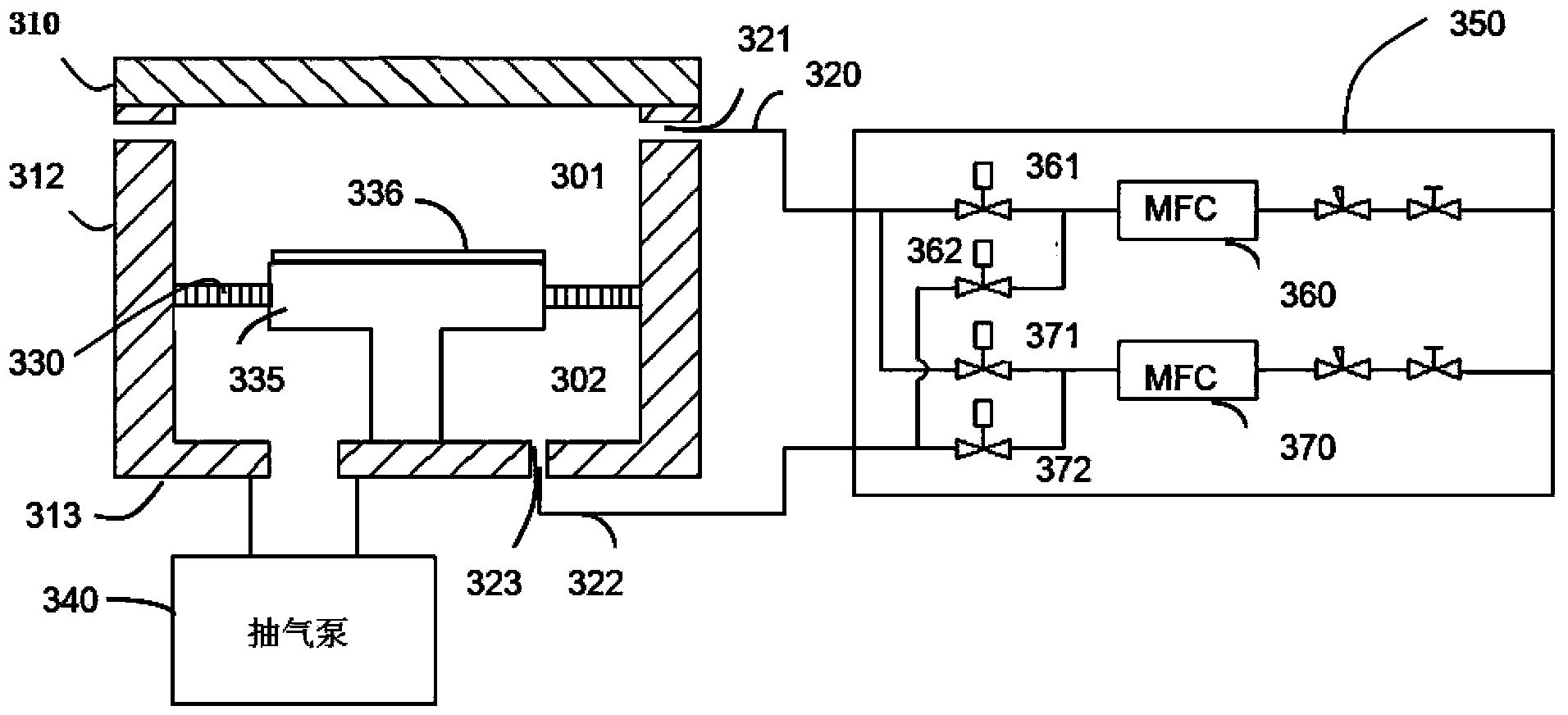

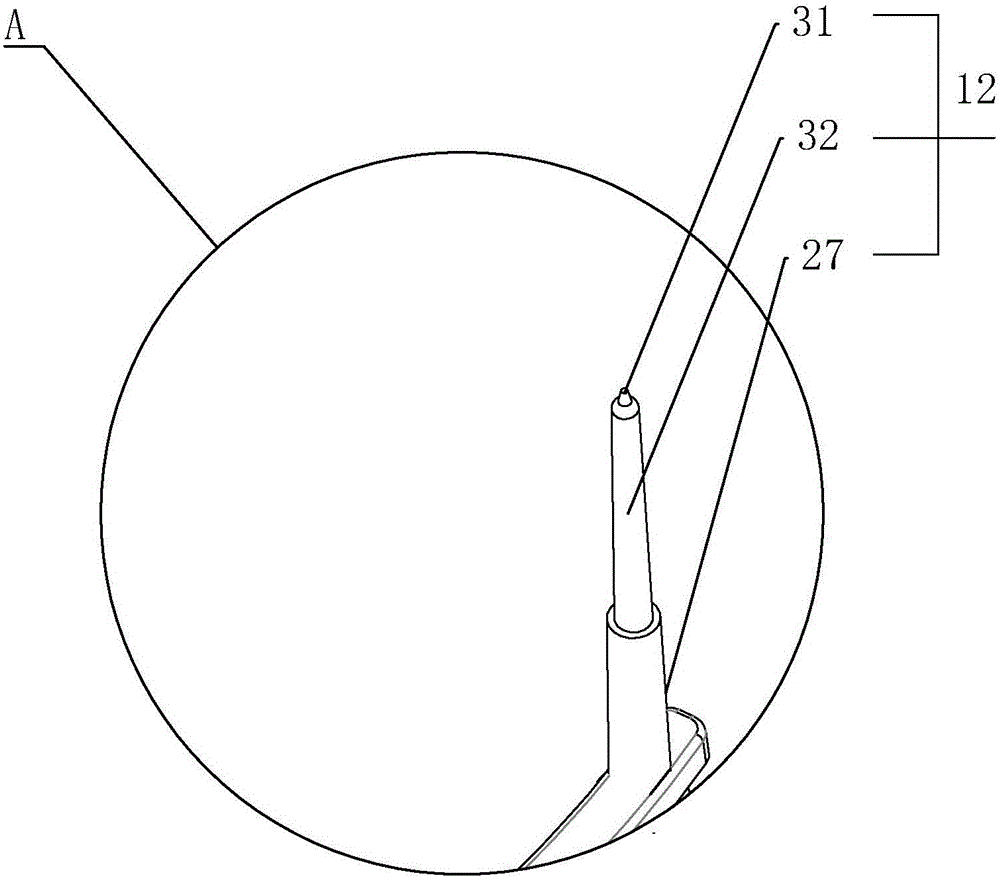

Plasma reaction chamber for realizing fast reaction gas switching and method thereof

ActiveCN104112639ASmall volumeIncrease switching rateElectric discharge tubesChemistryPlasma reaction

The invention discloses a plasma reaction chamber for realizing fast reaction gas switching and a method thereof. By adopting the technical scheme of the invention, the total flows of gases flowing into a reaction chamber in the whole process are the same, which is conducive to the pressure stability of the reaction chamber. Two groups of gases are injected into the reaction chamber respectively from above and below the reaction chamber at the same time, which ensures that etching reaction and deposition reaction of a substrate are not affected, reduces the volume of the reaction chamber in a disguised way, is more conducive to enabling gas to fast fill the reaction chamber, improves the rate of switching between an etching step and a deposition step, and improves the rate of etching of the substrate. Meanwhile, as the air pressure in the reaction chamber is higher than that at an air pump, pressure difference facing a gas flow controller is small, the flow rate of reaction gases can be accurately and stably controlled, and the stability of the manufacturing process is improved.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

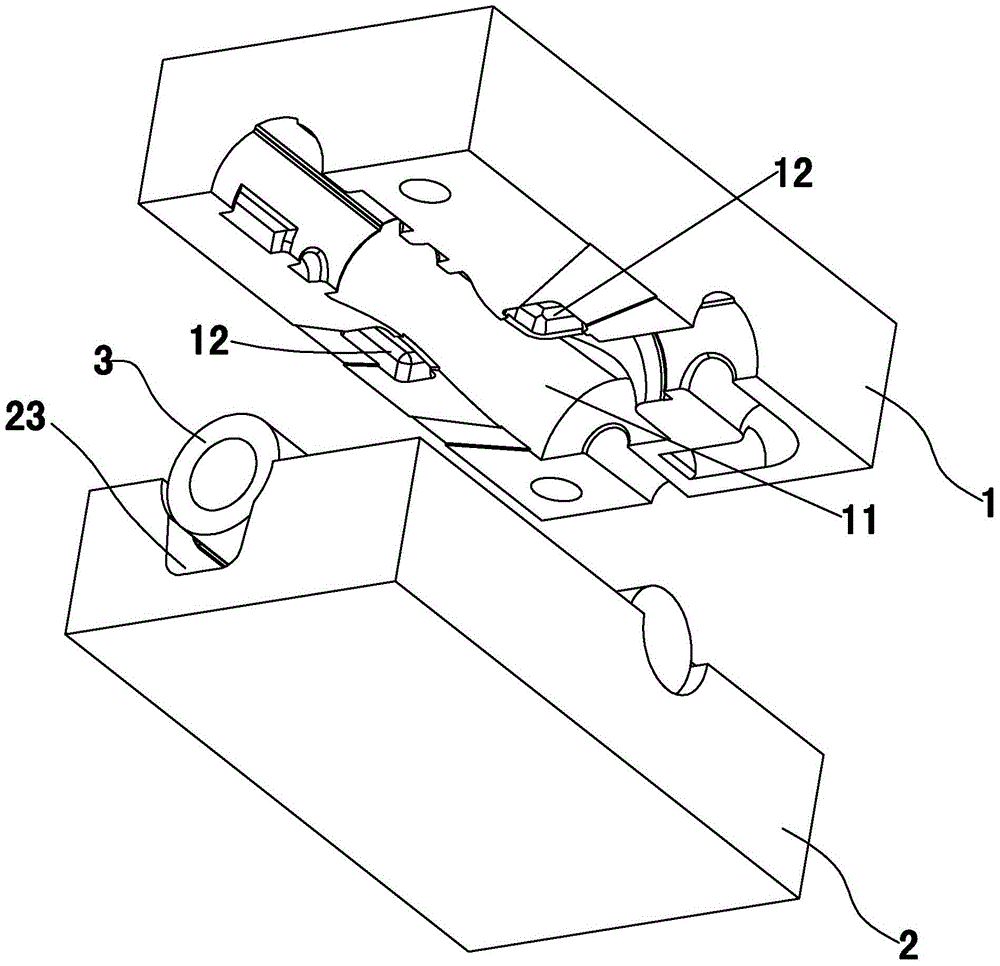

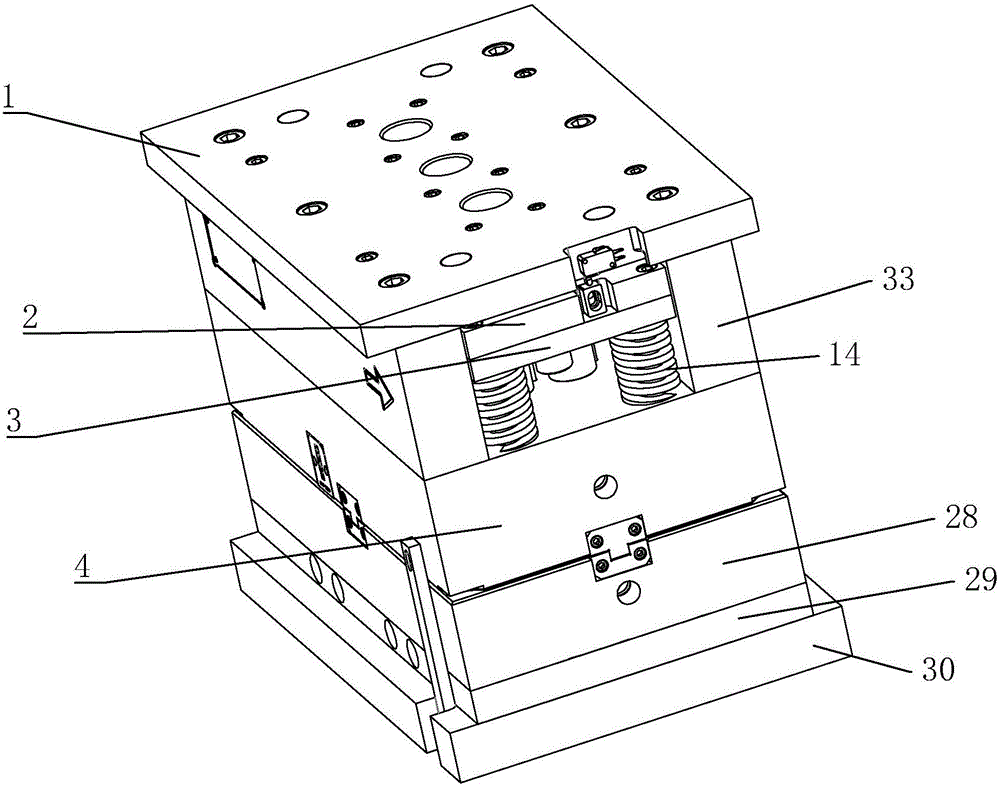

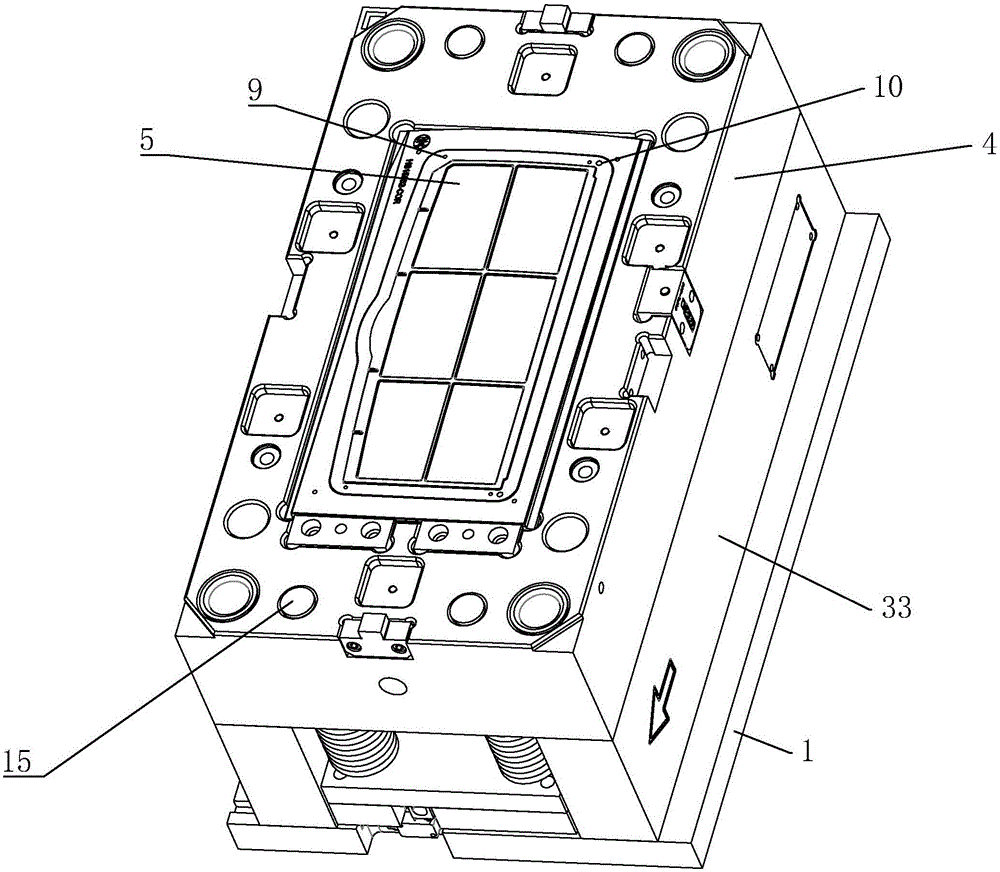

Injection mold for filter screen

The invention discloses an injection mold for a filter screen and belongs to the technical field of injection molds. By means of the injection mold for the filter screen, the filter screen can be molded at a time and a cavity is made to be filled with materials. According to the technical scheme, the injection mold is characterized by comprising a movable mold, an intermediate plate and a fixed mold; the movable mold comprises a concave mold fixing plate; the fixed mold comprises a cushion plate; the concave mold fixing plate is provided with a first concave mold; the side, facing the concave mold fixing plate, of the intermediate plate is provided with a second concave mold matched with the first concave mold; the side, deviating from the second concave mold, of the intermediate plate is provided with a runner; the inner side, facing the intermediate plate, of the runner is provided with a secondary runner perpendicular to the intermediate plate; the side, facing the first concave mold, of the intermediate plate is provided with a plurality of fixing rods used for suspension of the filter screen, and the fixing rods are perpendicular to the intermediate plate; and the concave mold fixing plate is provided with first fixing holes matched with the fixing rods.

Owner:NANJING HUASHUN PRECISION MOLD CO LTD

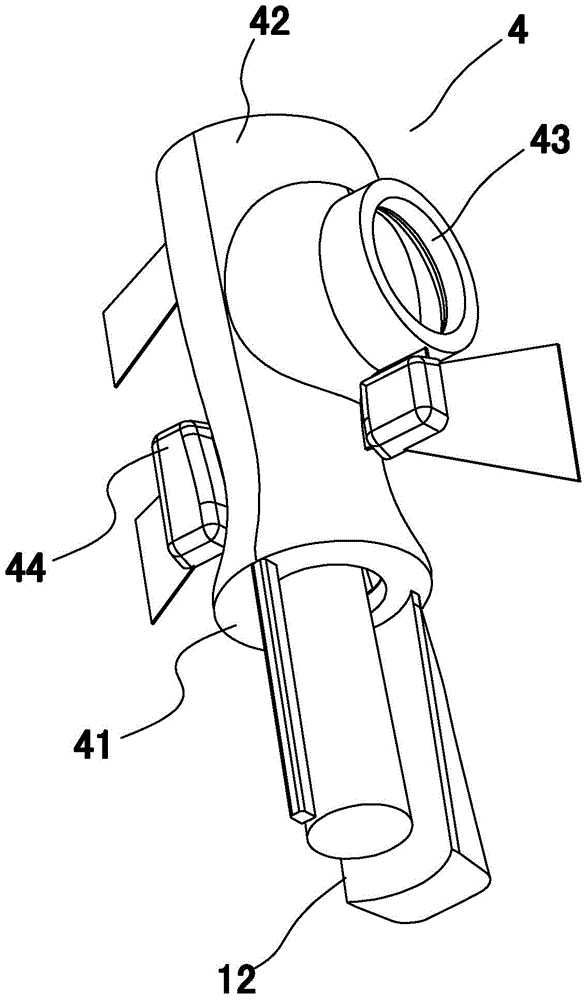

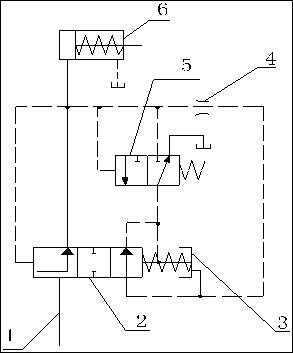

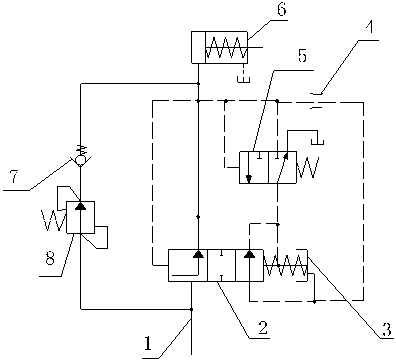

Parallel-connection pressure reducing valve type double-oil-way fast-oil-charging hydraulic gear shift system

A parallel-connection pressure reducing valve type double-oil-way fast-oil-charging hydraulic gear shift system comprises a pressure regulating oil way composed of an existing hydraulic gear shift pressure control valve, and a fast oil charging oil way composed of a check valve and a pressure reducing valve. An oil inlet of the pressure regulating oil way is connected with a main oil way of the system, and an oil outlet of the pressure regulating oil way is connected with a gear shift clutch oil cylinder. An oil inlet of the fast oil charging oil way, namely an oil inlet of the pressure reducing valve, is connected with the main oil way of the system, and an oil outlet of the fast oil charging oil way, namely an oil outlet of the check valve, is connected with the gear shift clutch oil cylinder. An oil outlet of the pressure reducing valve is connected with an oil inlet of the check valve. According to the parallel-connection pressure reducing valve type double-oil-way fast-oil-charging hydraulic gear shift system, in the stage of charging liquid into the clutch hydraulic cylinder, oil is charged into the gear shift clutch hydraulic cylinder jointly through the fast oil charging oil way and the pressure regulating oil way so that the gear shift clutch hydraulic cylinder can be filled with the hydraulic oil faster, and the gear shift time can be effectively shortened.

Owner:SICHUAN UNIV

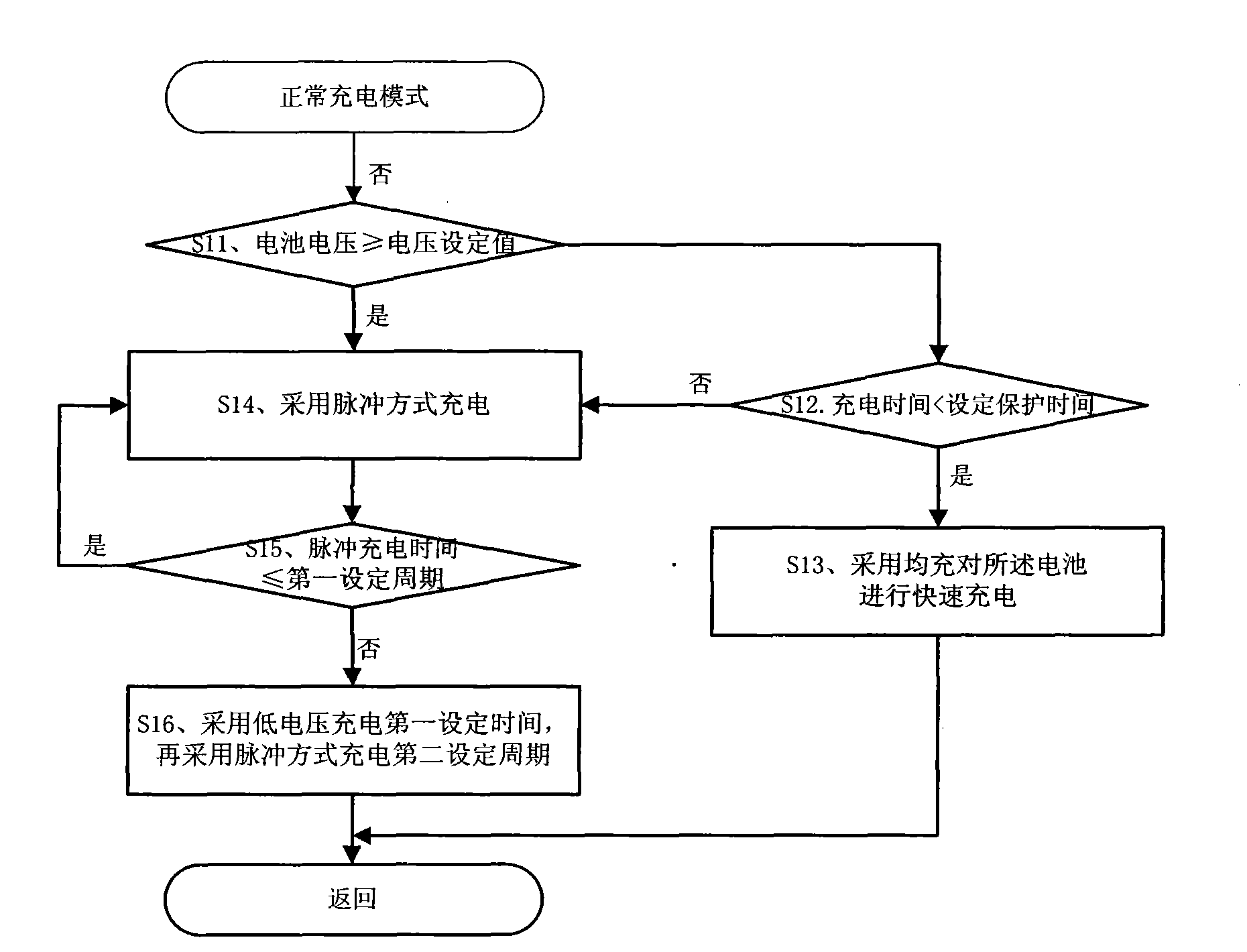

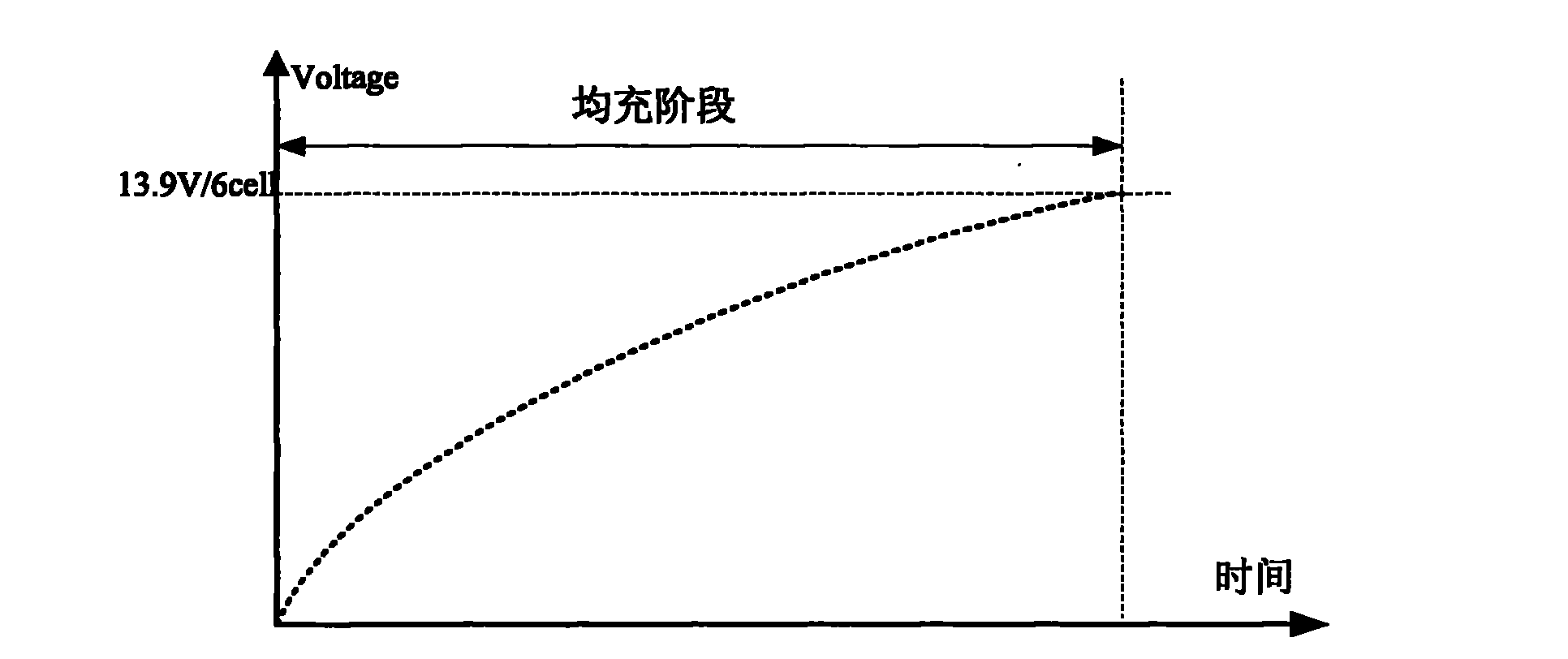

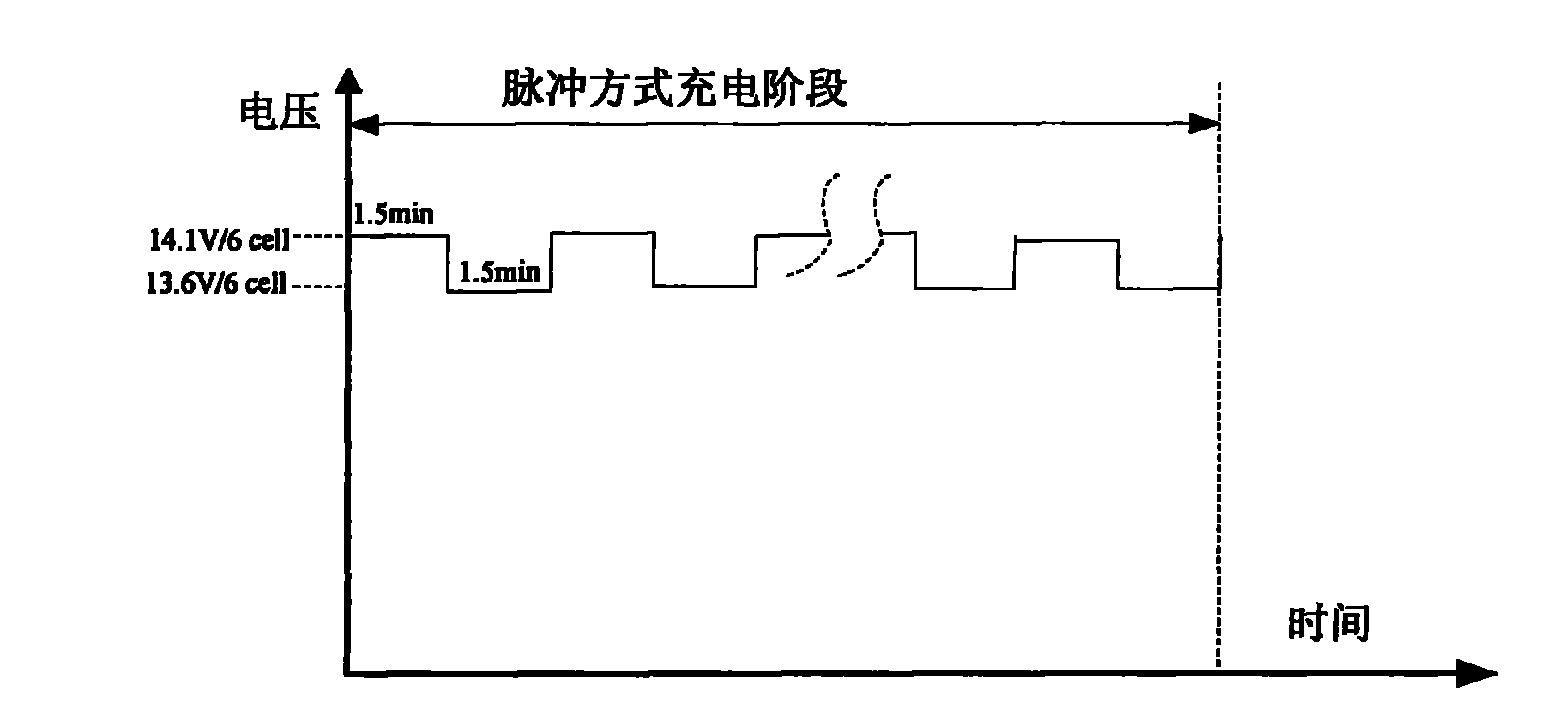

Battery charging method

ActiveCN101931109AFast fullControl temperature riseSecondary cells charging/dischargingElectricitySetting time

The invention relates to a battery charging method comprising: charging a battery according to a normal charging mode, wherein the normal charging mode comprises a step 11; judging whether battery voltage is more than or equal to voltage set value; if so, performing a step 14, otherwise performing a step 12; in the step 12, judging whether charging time is less than set protection time; if so, performing a step 13, or performing a step 14; in the step 13, adopting an equalized charging mode to quickly charge the battery, and returning to the step 11; in the step 14, adopting a pulse mode to charge, and performing a step 15; in the step 15, judging whether charging time is less than or equal to a first set period; if so, returning to the step 14, or performing a step 16; in the step 16, adopting low voltage to charge for a first set time; adopting the pulse mode to charge for a second set period; and performing the step 16 circularly. The implementation of the charging method of the invention can quickly charge in short time; and meanwhile, temperature rise in the charging process can be effectively controlled.

Owner:VERTIV CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com