Padding for fixing system with state memory and applied technical procedure

An installation system and memory technology, applied in positioning devices, manufacturing tools, metal processing equipment, etc., can solve the problems of affecting the memory accuracy of fixtures, poor fluidity, affecting the bonding force of fillers and workpieces, etc., to improve the process conversion accuracy, The effect of improving fluidity and good engineering application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 7

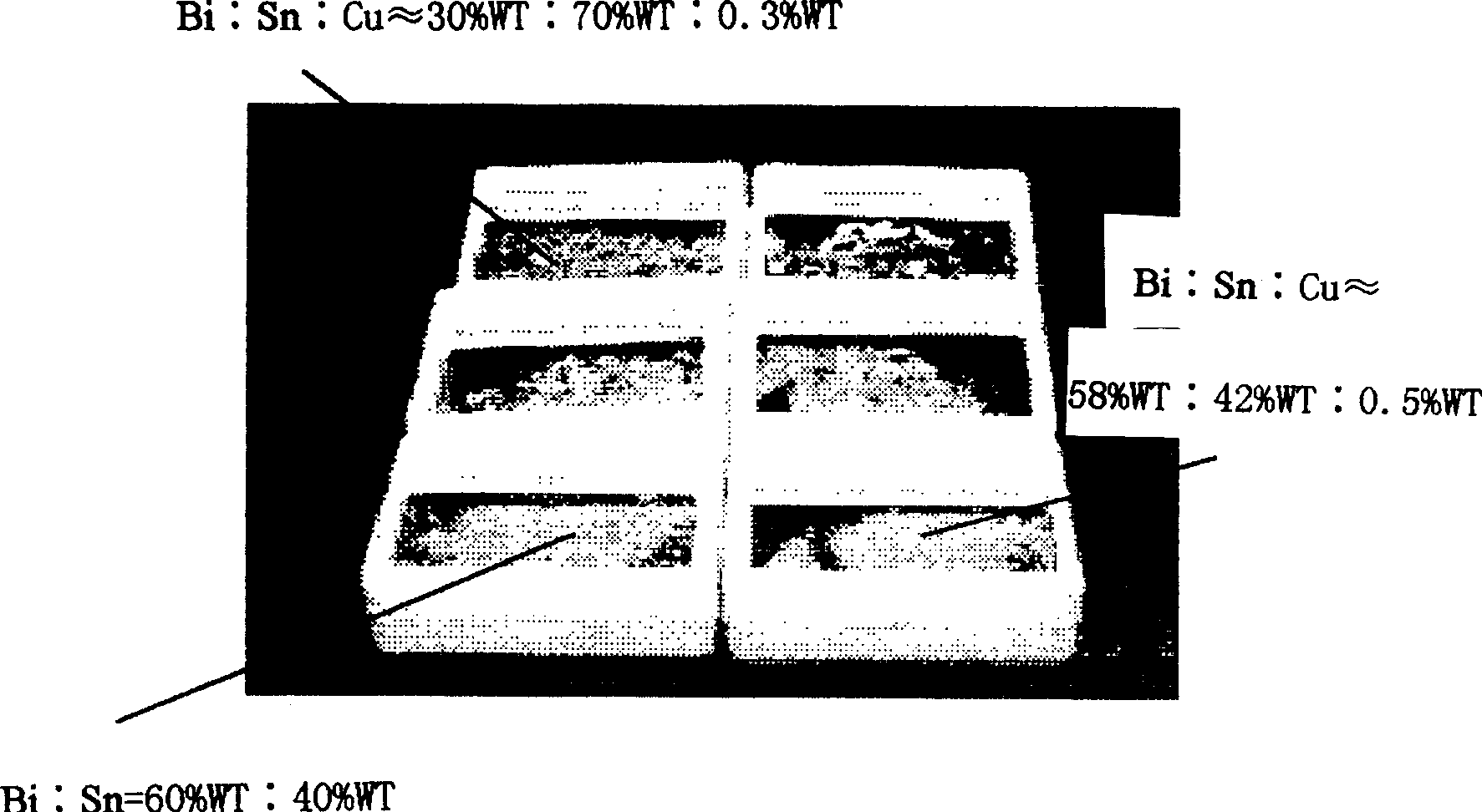

[0030] Embodiment 7: Sessile blade processing. see figure 2 and Figure 4 .

[0031] The maximum and minimum dimensions (mm) of the length, width and height of workpiece 2 are: length 200, 187, width 90, 76, height 36, 0; the material is aluminum alloy; the size of workpiece 2 is 210*102*50; the installation system The cavity size is 220*110*40; the composition ratio of filler 4 is Bi:Sn:Cu=49.75%WT:49.75%WT:0.5%WT≈50%WT:50%WT:0.5%WT. The application process of the filler: put the workpiece 2 into the positioning box 1 and make full contact with the positioning element 3 and pre-tighten; preheat the installation system to 125, heat the filler from 4 to 180°C; inject the molten filler from 4 to H 1 , the bottom of the positioning box 1, that is, the thickness h of the filler in the error-sensitive direction 1 ≤10mm; install the positioning box 1 on the machine tool; mechanically process the convex surface of the blade to meet the requirements of the drawing; close the uppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com