Automobile hydraulic cylinder with self-locking function

A technology of hydraulic cylinder and function, applied in the field of automobile hydraulic cylinder, can solve the problems of soft leg phenomenon, easy leakage of hydraulic oil, negative pressure effect, etc., and achieve the effect of avoiding hydraulic oil leakage, avoiding negative pressure effect, and improving self-locking ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

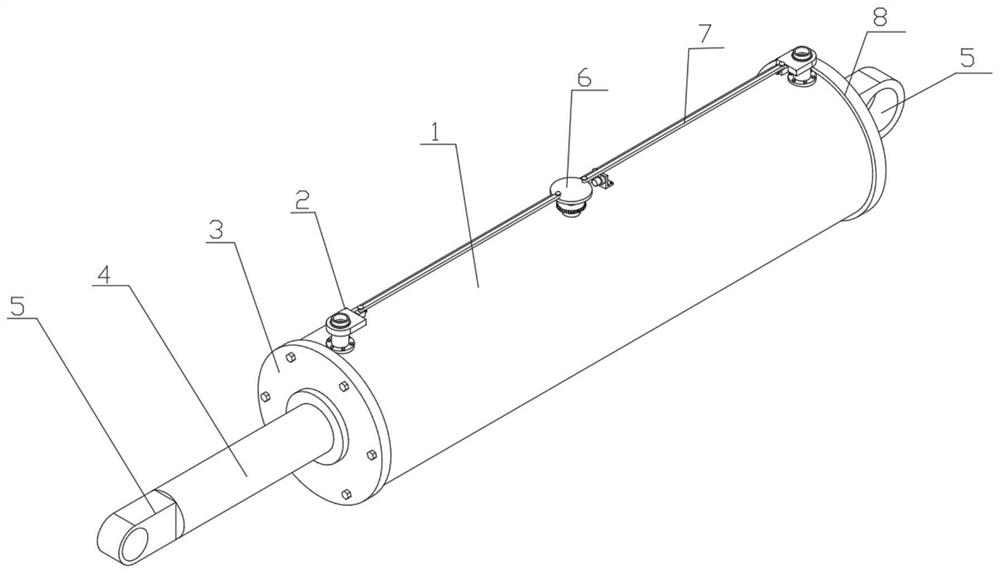

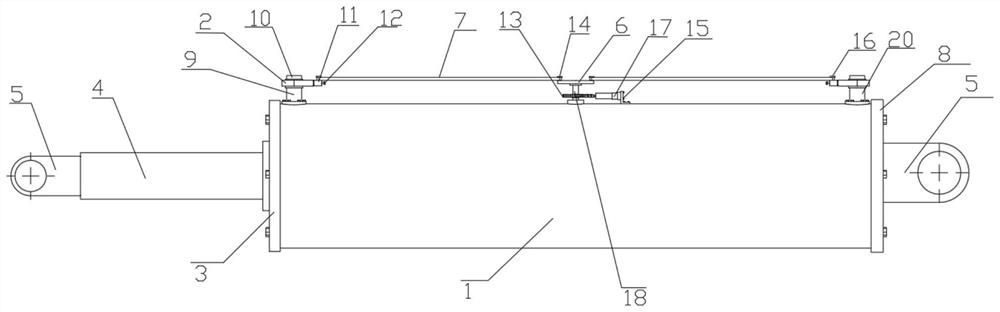

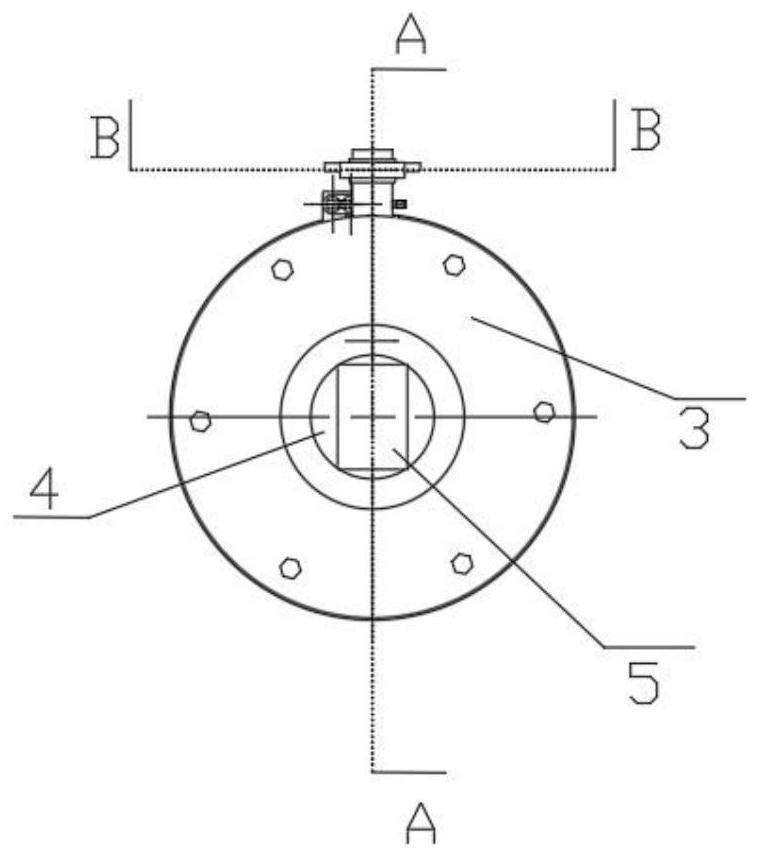

[0033] see Figure 5 with 7 As shown, a kind of automobile hydraulic cylinder with self-locking function comprises a hydraulic cylinder barrel 1, a cylinder cover 3 and a rear cylinder cover 8 are respectively arranged at both ends of the hydraulic cylinder cylinder barrel 1, and a first self-locking cylinder is provided on the inner wall of the rear cylinder cover 8. Lock structure, the first self-locking structure is connected with piston 36, and piston 36 is connected with cylinder rod 4, and cylinder rod 4 is slidingly matched with the movable hole that cylinder cover 3 offers, and cylinder rod 4 outer ends and rear cylinder cover 8 outer ends are all provided with Connecting seat 5, upper oil pipe 9 and lower oil pipe 20 are provided at both ends of the top of hydraulic cylinder barrel 1, lower oil pipe 20 is provided with first self-locking structure, second self-locking structure is evenly provided with connecting pipe 10, connecting pipe 10 and hydraulic pressure Oil ...

Embodiment 2

[0037] On the basis of embodiment 1, see Figures 1 to 8 As shown, the second self-locking structure includes a U-shaped plate 2, a first rotating plate 6, a second rotating plate 7, an adjustment assembly, a ring gear 13, a first rotating pin 14, a mounting base 15, and a second rotating pin 16 , electric push rod 17, rotating shaft 18, through hole 23, circular plate 22, first sliding plate 26 and U-shaped groove 35, U-shaped plate 2 is provided with U-shaped groove 35, and the inner wall of U-shaped groove 35 is slidably fitted with a circle plate 22, the middle end of the circular plate 22 is provided with a through hole 23, the side wall of the circular plate 22 is provided with a first sliding plate 26, the outer end of the first sliding plate 26 is connected with an adjustment assembly, and the adjustment assembly is provided with a second rotating pin 16 , the second rotating pin 16 rotates with a second rotating plate 7, and the second rotating plate 7 inner ends rota...

Embodiment 3

[0040] On the basis of embodiment 2, see figure 2 with 8 As shown, the adjustment assembly includes an adjustment sleeve 11 and an adjustment screw 12. The first sliding plate 26 is inserted in the adjustment sleeve 11. The outer end of the first sliding plate 26 rotates with an adjustment screw 12 through a bearing. The adjustment sleeve 11 is connected to the adjustment screw through a threaded sleeve 12 threaded connection, the bottom of the second rotating pin 16 is located at the top of the adjusting sleeve 11.

[0041] The adjusting screw 12 of the rotating adjusting assembly, the adjusting screw 12 drives the first sliding plate 26 to move in the adjusting sleeve 11, and the first sliding plate 26 drives the through hole 23 to move, which is convenient for adjusting the relative position of the circular plate 22 and the straight hole of the U-shaped plate 2 , it is convenient to adjust the hydraulic oil flow rate of the upper oil pipe 9 and the lower oil pipe 20, ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com