Patents

Literature

109results about How to "Convenience for masonry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Blanc fixe cementitious rock soil-like material and method for making simulative rock from the blanc fixe cementitious rock soil-like material

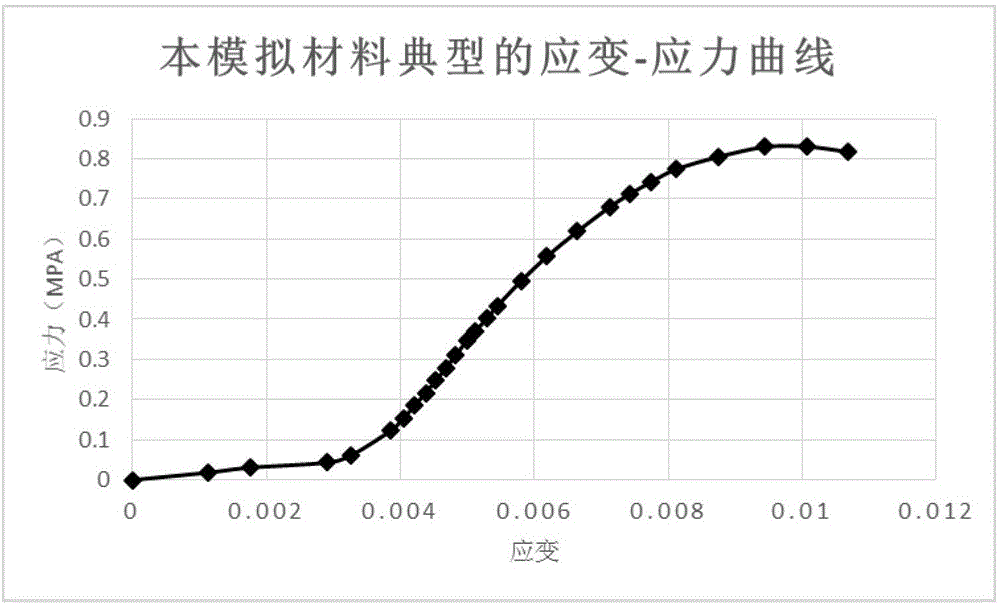

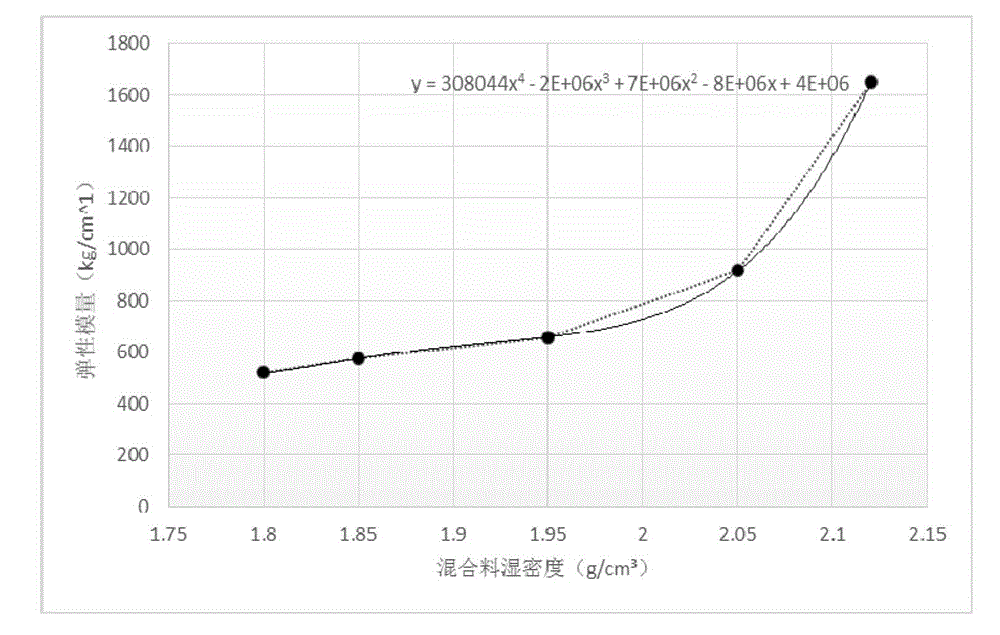

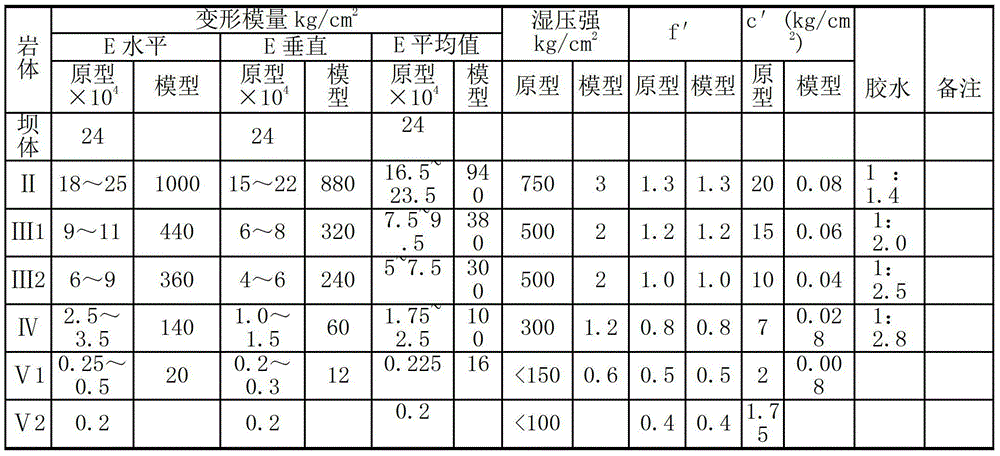

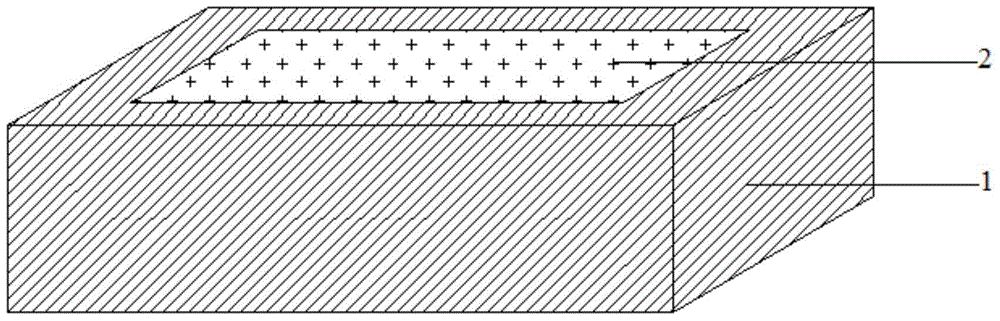

ActiveCN103332885ALow costSpeed upPreparing sample for investigationModel testUltimate tensile strength

The invention relates to a blanc fixe cementitious rock soil-like material and a method for making simulative rock from the blanc fixe cementitious rock soil-like material and belongs to the technical field of rock material simulation in a geomechanical model test. The blanc fixe cementitious rock soil-like material comprises blanc fixe as a aggregate, bentonite as an auxiliary material, and dilute glue composed of 107 glue and water. The method comprises the following steps of drawing a water-binder ratio-shearing strength f curve by the blanc fixe cementitious rock soil-like material, calculating wet density of different batches of the blanc fixe cementitious rock soil-like materials, and making a small test-piece from different batches of the blanc fixe cementitious rock soil-like materials. The blanc fixe cementitious rock soil-like material has a low cost and no toxicity, can be processed into small blocks easily, and can satisfy requirements of a geomechanical model test on the blanc fixe cementitious rock soil-like material. Simulative rock made from the blanc fixe cementitious rock soil-like material does not influence a model building process and can be made fast so that a model test rate is greatly improved. The blanc fixe cementitious rock soil-like material is suitable for the field of a test on a model built by laying small blocks.

Owner:TSINGHUA UNIV

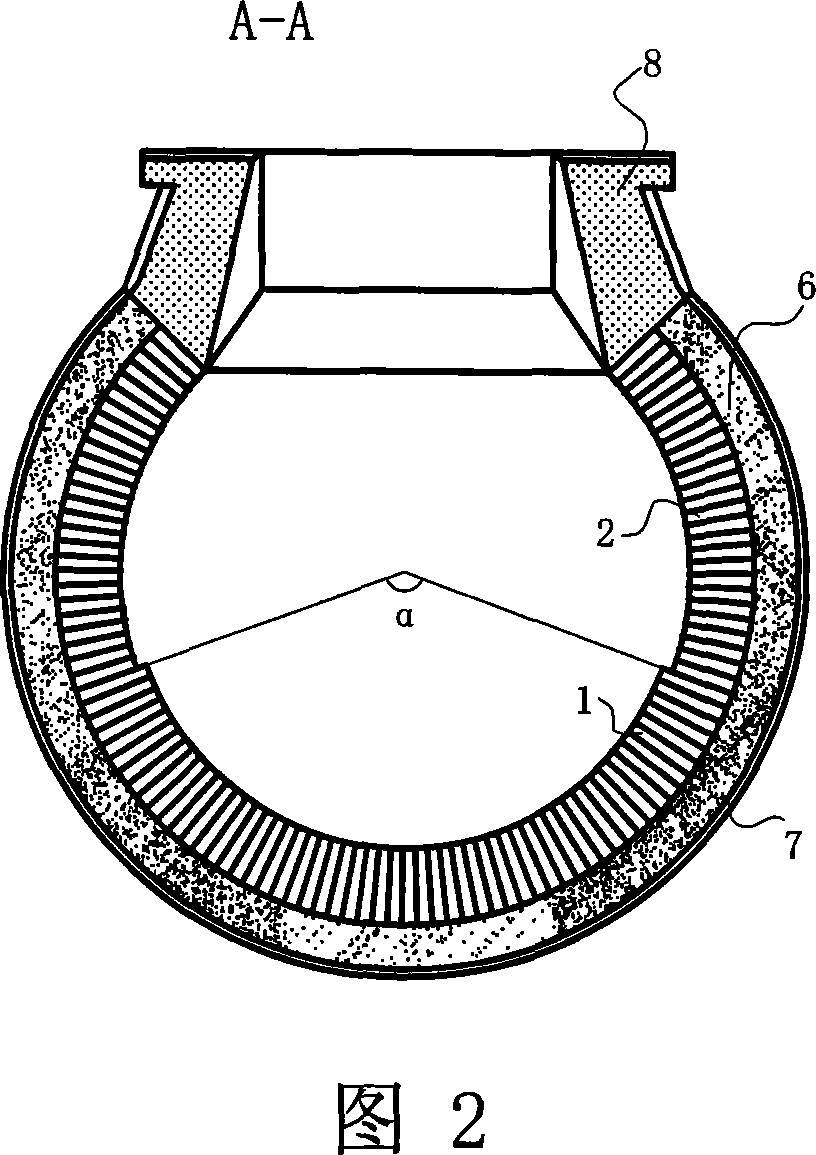

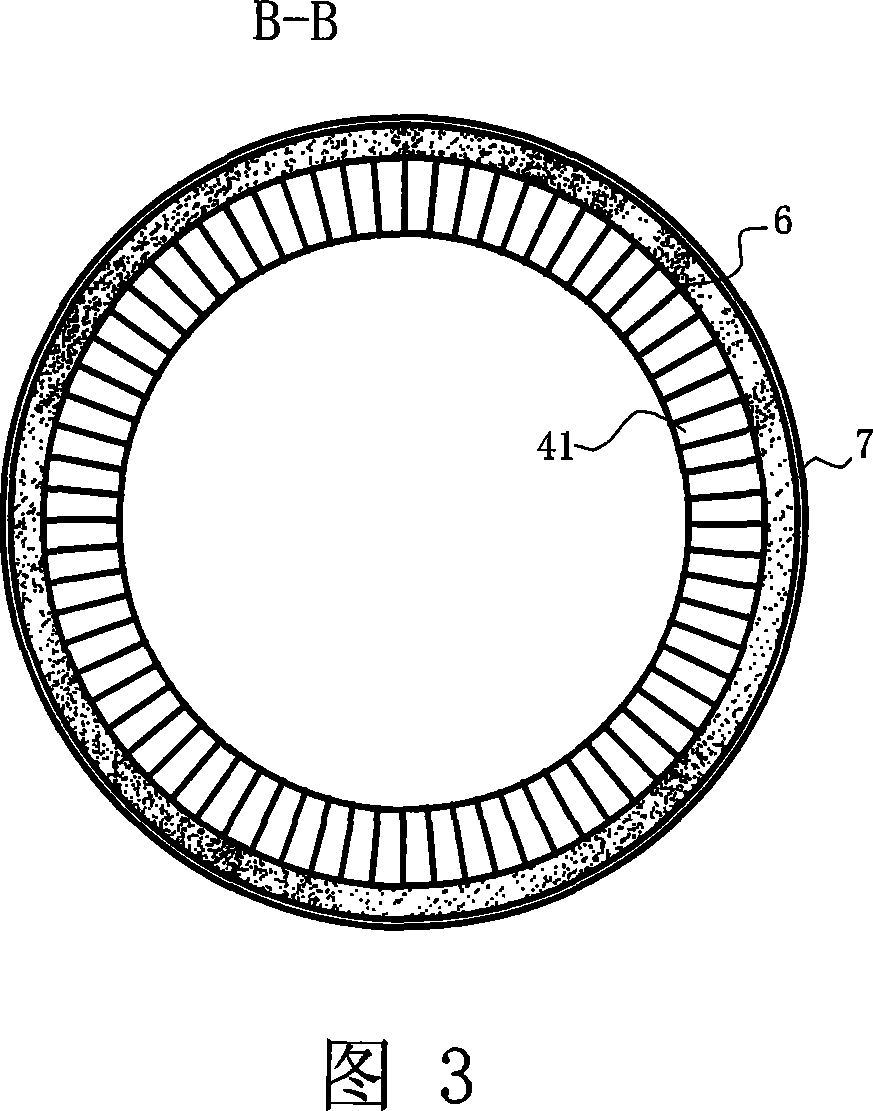

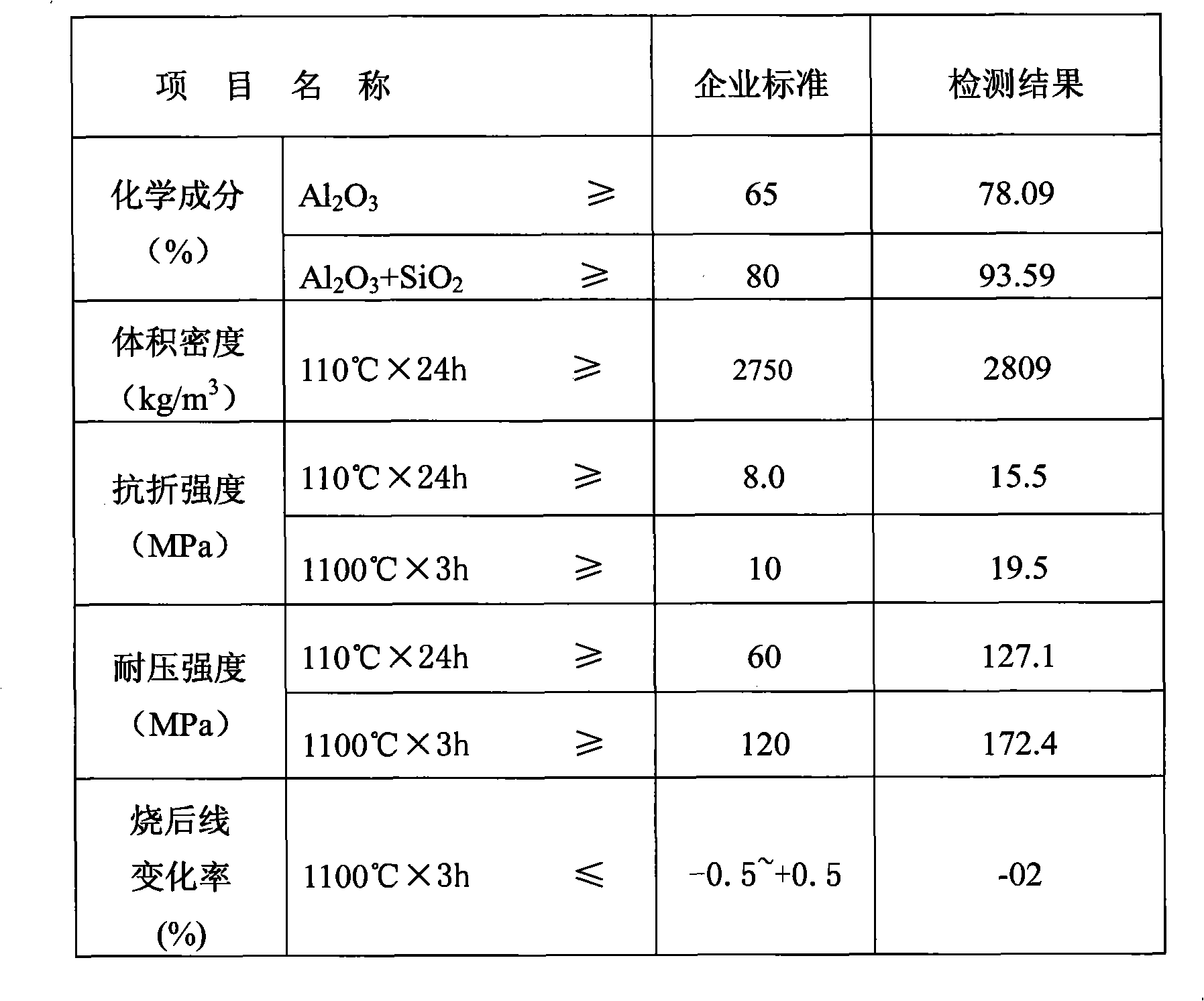

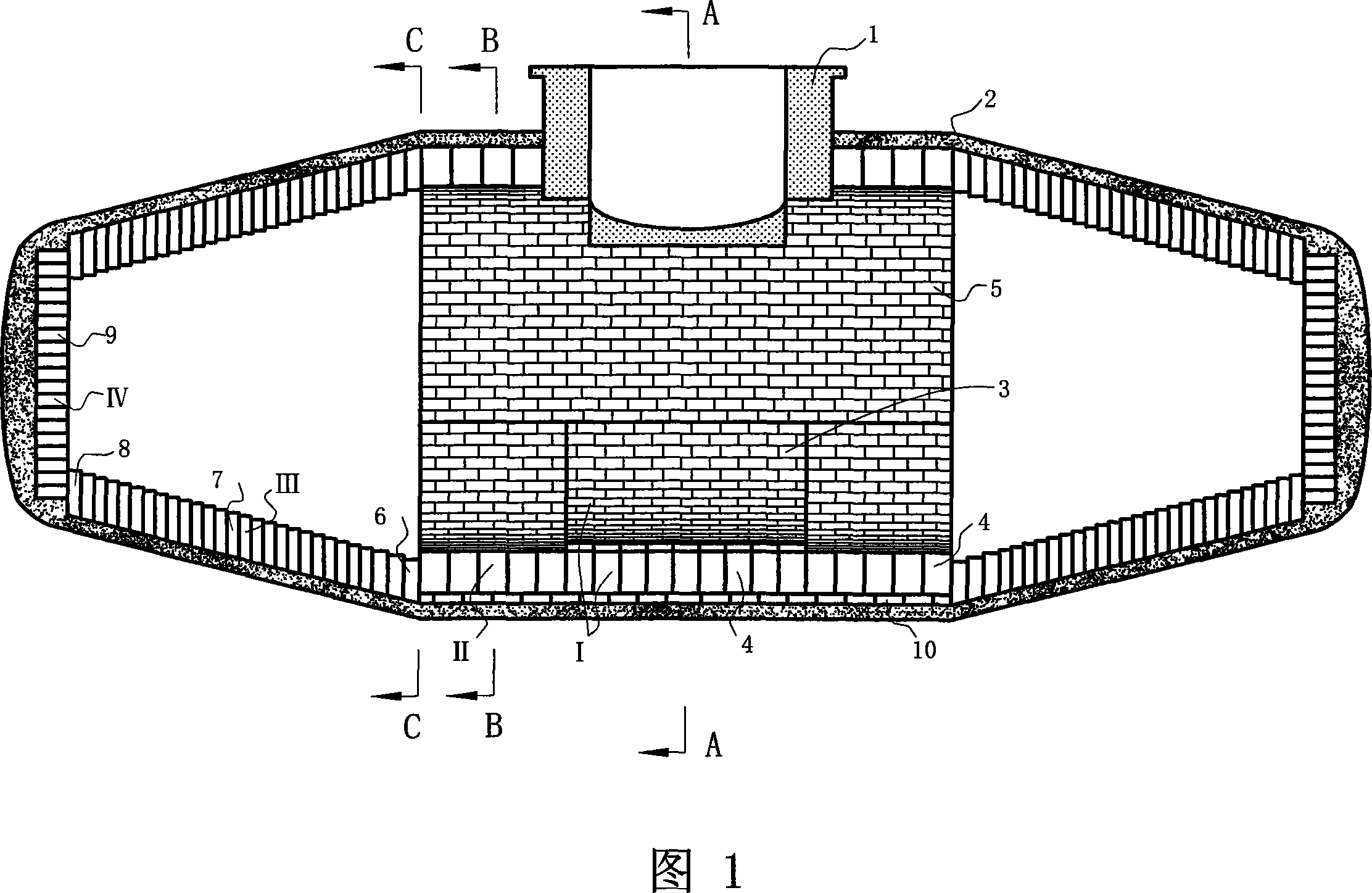

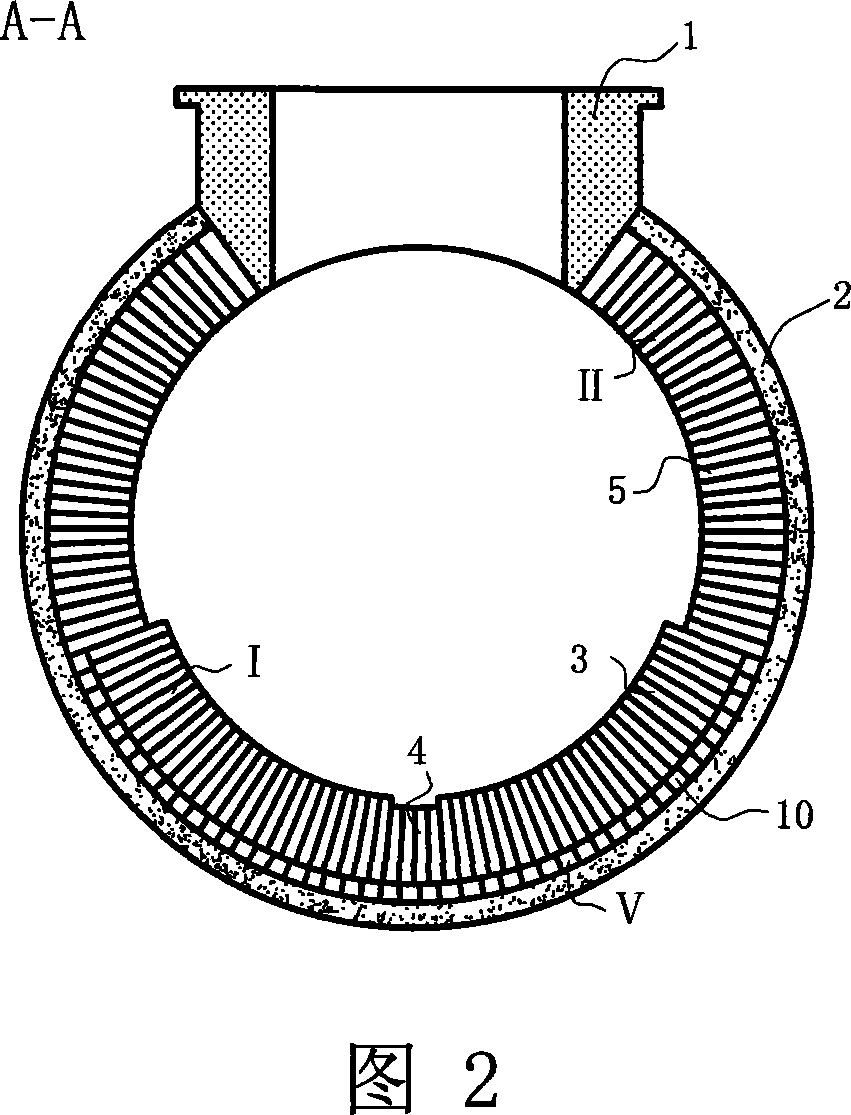

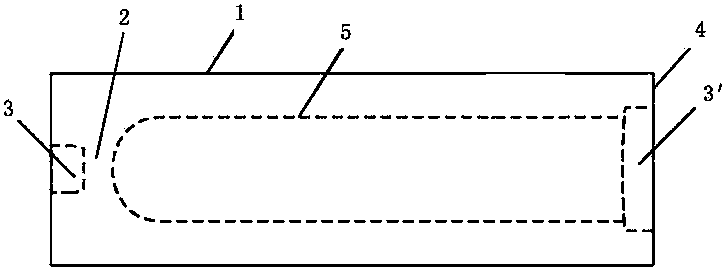

Inner lining structure for torpedo pot and aluminium carbonize silicon carbide brick and high aluminium brick used for torpedo pot

InactiveCN101058116ALifetime SynchronizationChange the phenomenon of less frequent useMelt-holding vesselsBrickCoesite

The invention relates to a torpedo pot liner structure and torpedo pot used aluminum carbonized silicon carbon brick, high aluminum brick. Bottom of the torpedo pot impact part uses nonburning aluminum carbonized silicon carbon brick, most of the rest using burnt stripping resistant high aluminum brick. Material for the aluminum carbonized silicon carbon brick comprises the alumina, electro-melting corundum, carbofrax, carbite, sintered corundum, aluminum, silicon, astringent, and so on, and the high aluminum brick comprises alumina, electro-melting corundum, carbofrax, silicon, silicon powder, bindeton and paper waste liquid. It is reasonable in formulation, mature in production process, with forming no need of high temperature baking with lower production cost. Using these two kinds of bricks, using durability of the overall torpedo can basically reach synchronic feature, application over 1700 times, with good effect and significant economical benefit.

Owner:GONGYI WINNA SCI & TECH DEV

Flame-proof pouring material special for tertiary air tube shut-off device

ActiveCN101492303AGood chemical resistanceImproved thermal shock stabilityMulliteTemperature resistance

The invention discloses a refractory castable material special for tertiary air duct gates, comprising the following components according to the weight percentage: 70-75% of mullite M70, 5-10% of aluminum oxynitride (AlON), 6-7% of pure calcium aluminate cement, 3-4% of a-Al2O3, 3-5% of silica fume and 5-7% of water. During preparation, dodecacalcium heptaluminate (C12A7) with mass being 2% of the total mass of the mixed six components is additionally added. The refractory castable material special for tertiary air duct gates of the invention has extremely high wear-resisting property and thermal shock resistance. By adding AlON nano fine powder as an antioxidant, high thermal resistance and high temperature resistance to chemical erosion of products are improved; by increasing low temperature oxide of sodium oxide and reducing the sintering temperature of the castable material, the strength and wear-resisting property of products are improved; by adding C12A7 to adjust stripping time of the castable material, different requirements on the construction time and customers are met.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

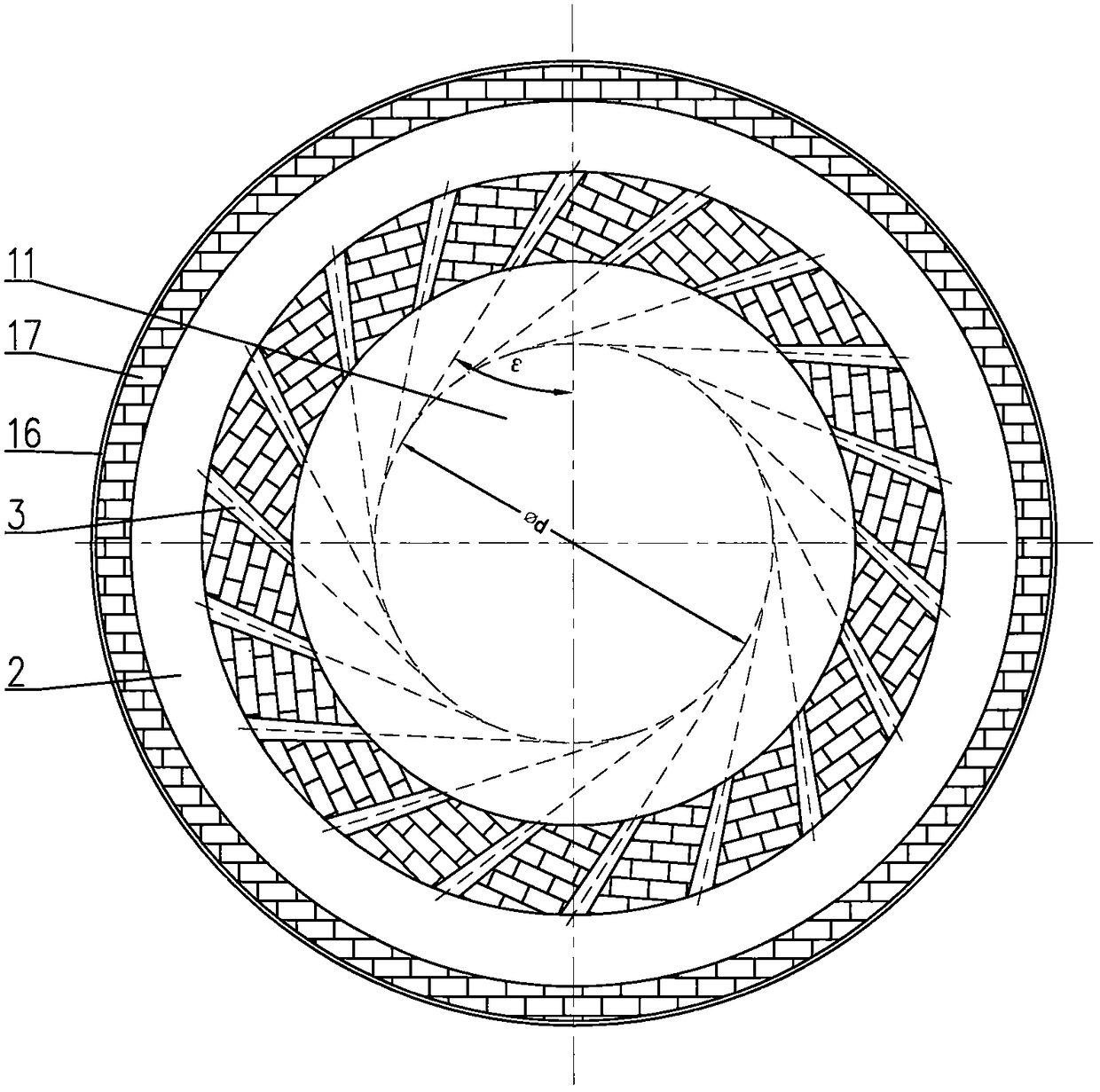

Alumina-silicon carbide-carbon brick for torpedo tank and torpedo tank lining structure therewith

ActiveCN101066880AGood resistance to slag and iron corrosionEasy to match bricks and masonryMelt-holding vesselsAluminiumGraphite

The present invention discloses one kind of alumina-silicon carbide-carbon brick for torpedo tank and the torpedo tank lining structure therewith. The alumina-silicon carbide-carbon brick is produced with the materials including bauxite 10-60 wt%, electromelting corundum 10-50 wt%, silicon carbide 3-20 wt%, graphite 2- 20 wt%, chrome 0.5-5 wt%, metal aluminum 0.2-3 wt%, metal silicon 0.2-3 wt%, binding agent 3-5 wt% and andalusite 3-10 wt%. The brick is suitable for use in torpedo tank, and has high iron slag erosion resistance, high antioxidant capacity and high heat shock stability.

Owner:巩义市第五耐火材料有限公司

Three-dimensional vortex burner

InactiveCN108662581AEasy to adjustAvoid damageNon-combustible gases/liquids supplyGaseous fuel burnerThermal energyNitrogen oxide

The invention relates to a three-dimensional vortex burner and belongs to the technical field of thermal power engineering. The three-dimensional vortex burner is primarily characterized by being provided with an air inlet and a coal gas inlet entering tangentially, a catenary convoluted rectifying room, a primary air nozzle and a secondary air nozzle which are arranged in layers and different indirection and a diversion trench reinforcing throat, so that air is supplied to form conical spiral vortexes to inject the coal gas to fit an extremely low coal gas pressure and staged burning and thick and light burning are achieved to reduce emission of nitric oxide. The three-dimensional vortex burner is full in burning and small in resistance loss, and is particularly suitable for various industrial kilns which are high in power, low in coal gas calorific value, low in coal gas pressure, great in pressure fluctuation and high in demand on emission of nitric oxide. Energy conservation and emission reduction are achieved.

Owner:姜凤山

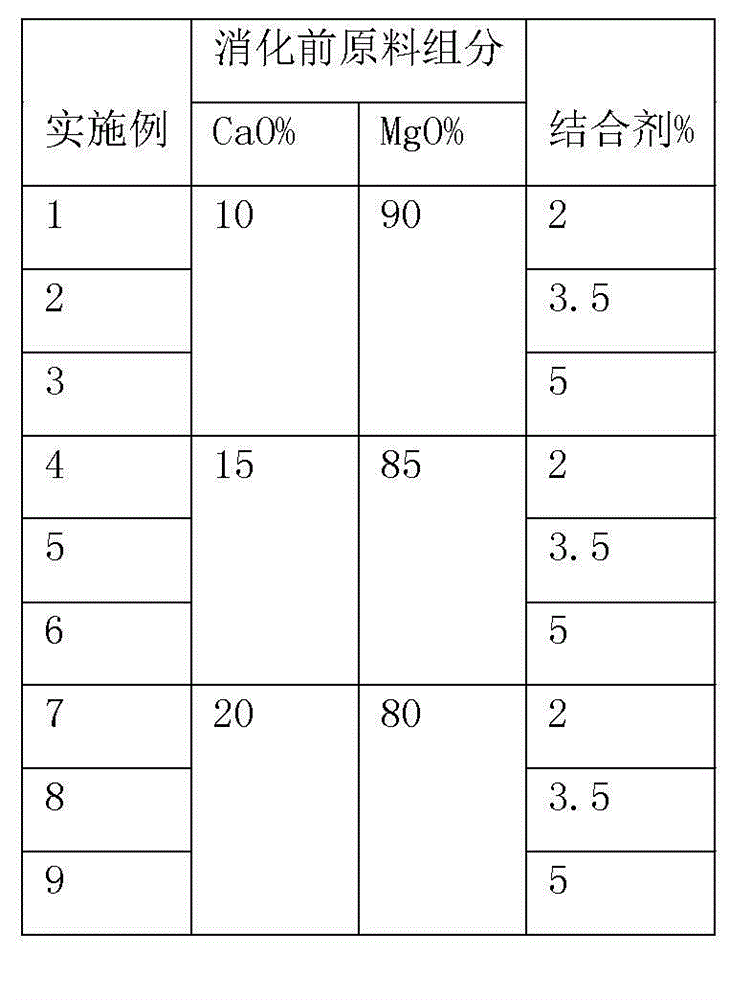

Method for preparing high-quality calcium magnesia by superhigh-temperature calcination

The invention relates to the field of preparation of refractory materials, particularly a method for preparing high-quality calcium magnesia by superhigh-temperature calcination, which is characterized by comprising the following steps: preparing dolomite and magnesite into a raw material in which the CaO content is 15-20 wt% and the MgO content is 80-85%; adding the raw material into a ball milling tank, grinding and mixing, and meanwhile, adding water to carry out slaking and slurrying; and drying the slurry, adding calcium lignosulphonate, evenly mixing, pressing into green bricks, and calcining. The calcination process comprises the following steps: heating to 1100 DEG C, keeping the temperature for 3-5 hours, heating to the final calcination temperature of 2000-2200 DEG C, keeping the temperature for 5-7 hours, vacuumizing, cooling with water to 1000 DEG C, introducing protective hydrogen, and continuing cooling with water to room temperature. Compared with the prior art, the calcium magnesia has the advantages of high hydration resistance and high corrosion resistance, thereby basically solving the problem of high hydration tendency in the magnesium-calcium refractory material, and facilitating the storage, transportation, building and the like in future.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

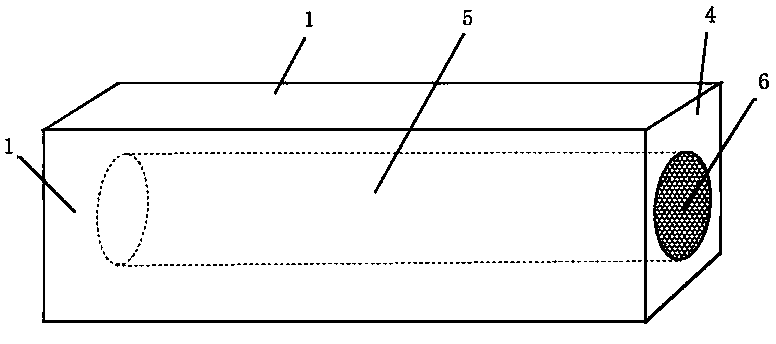

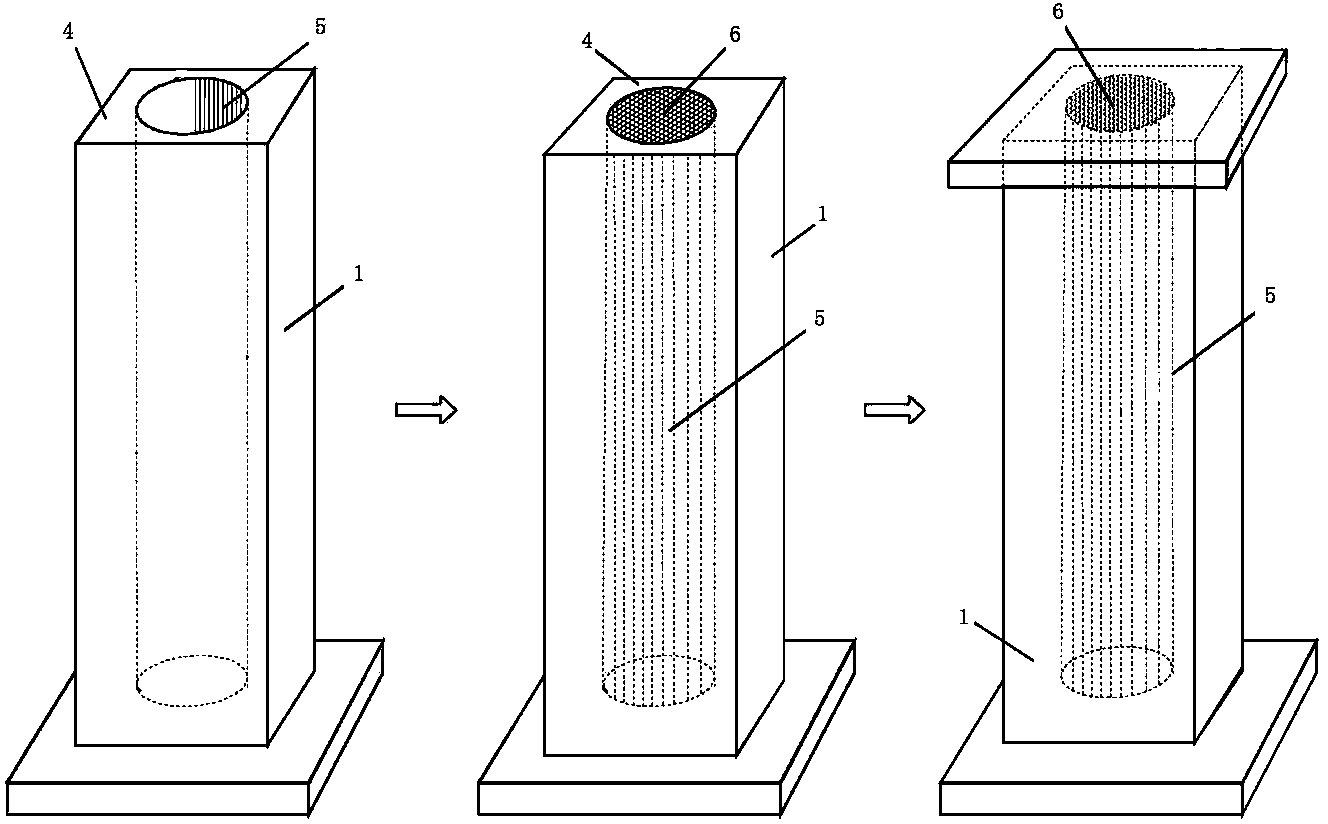

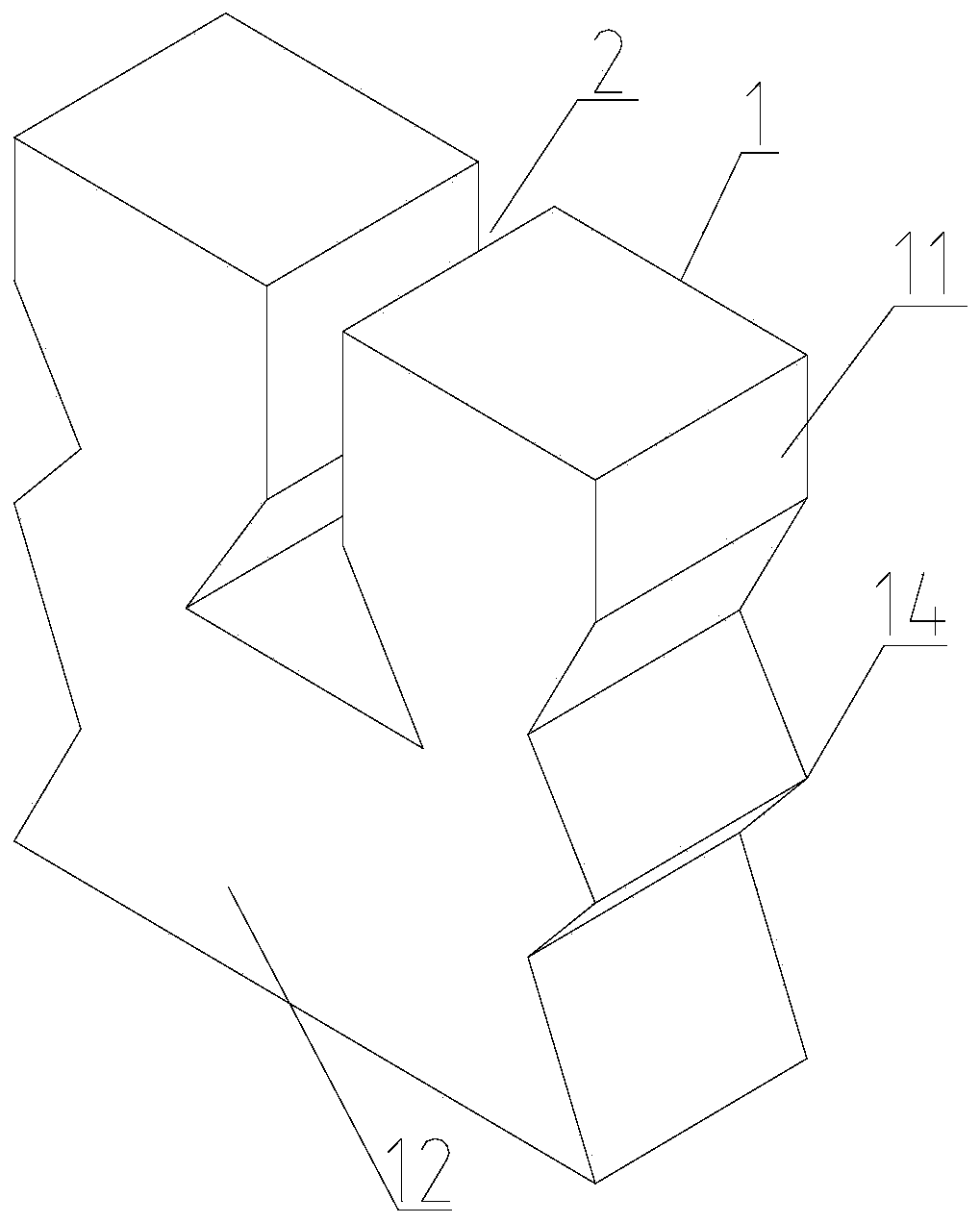

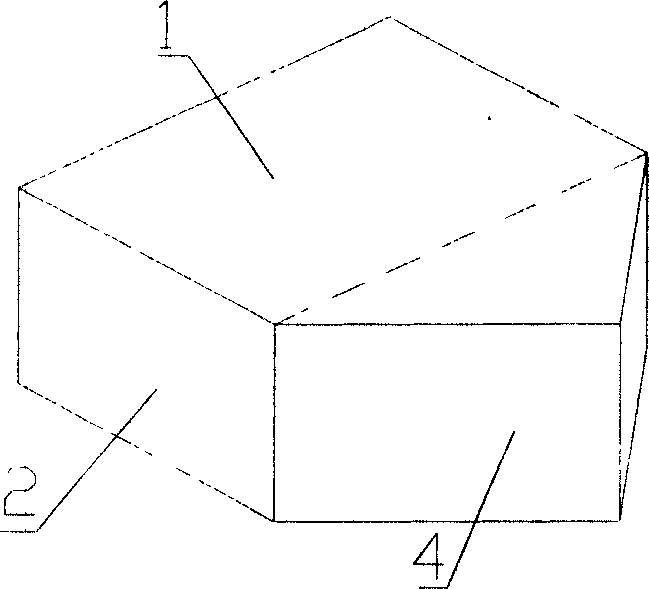

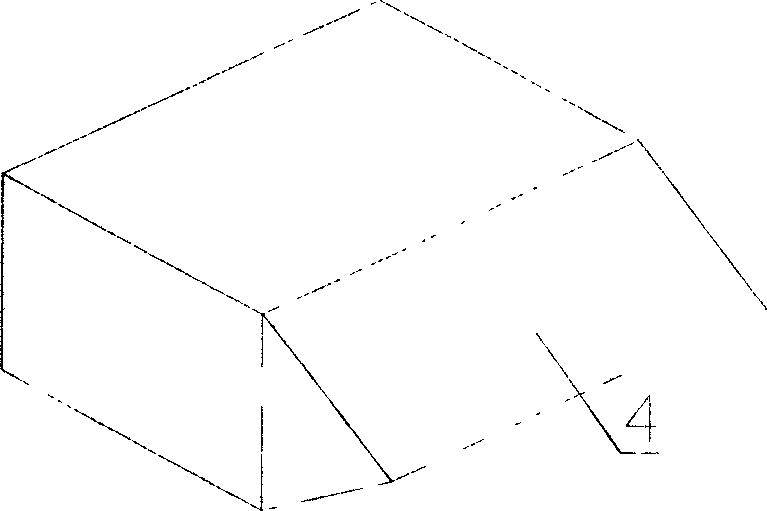

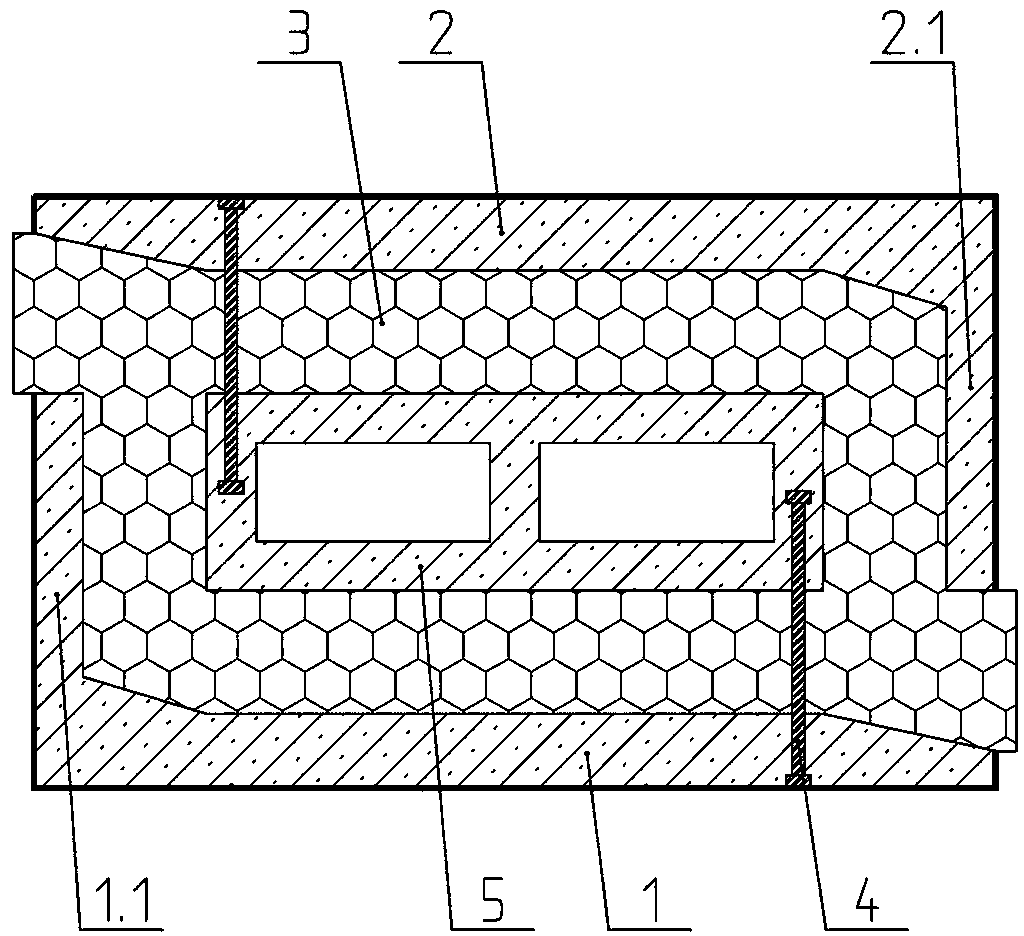

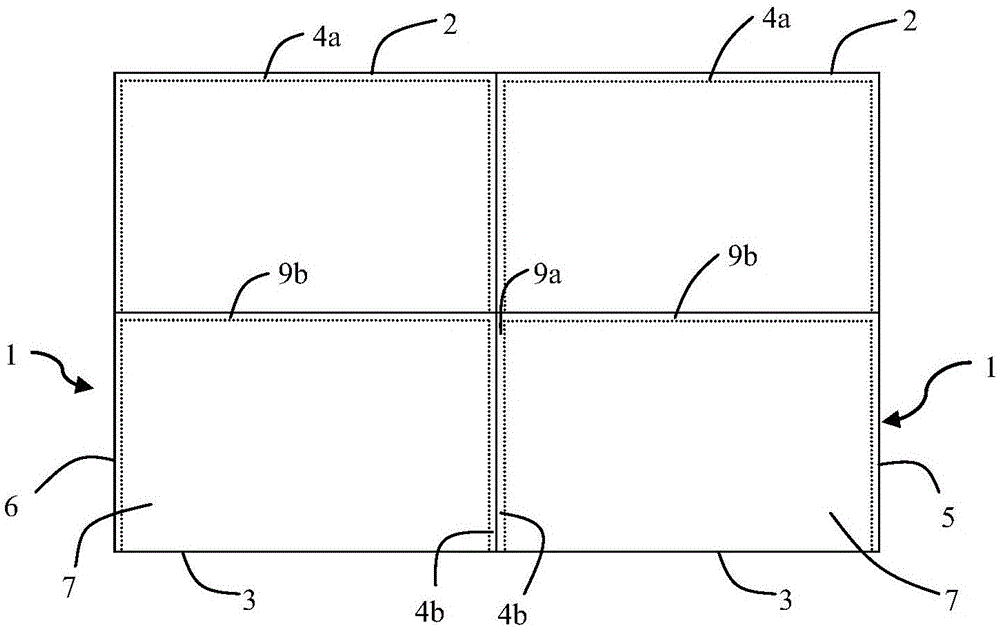

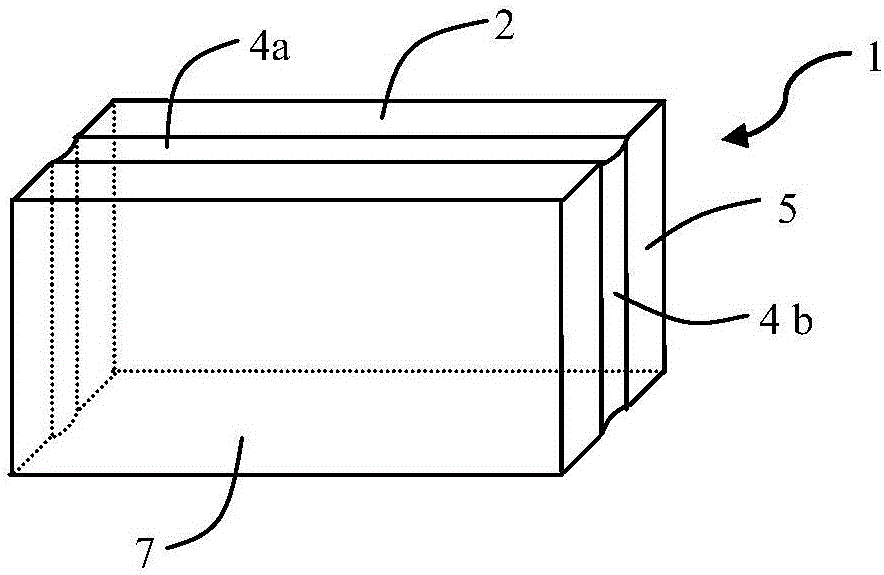

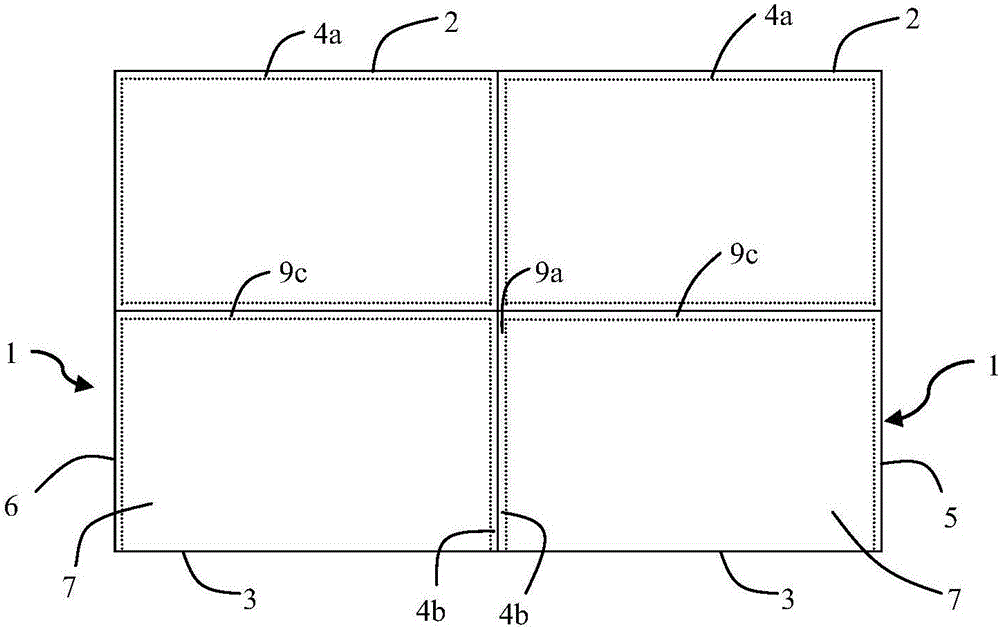

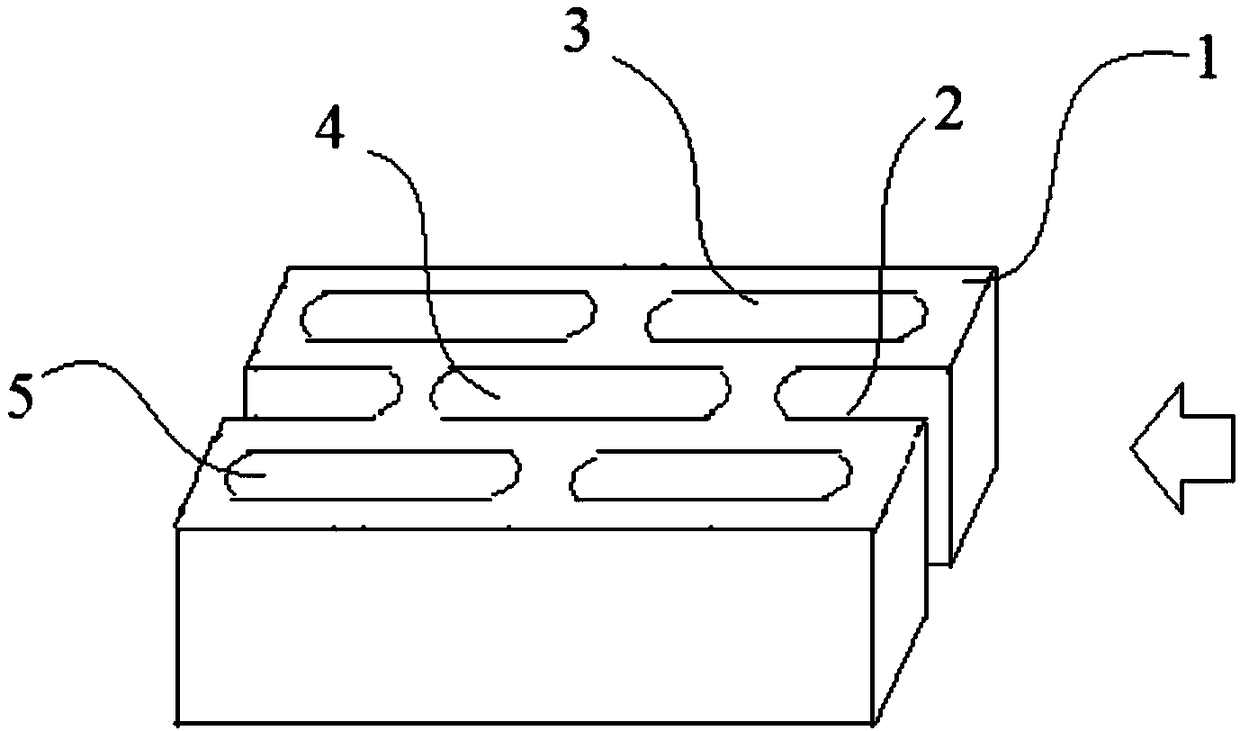

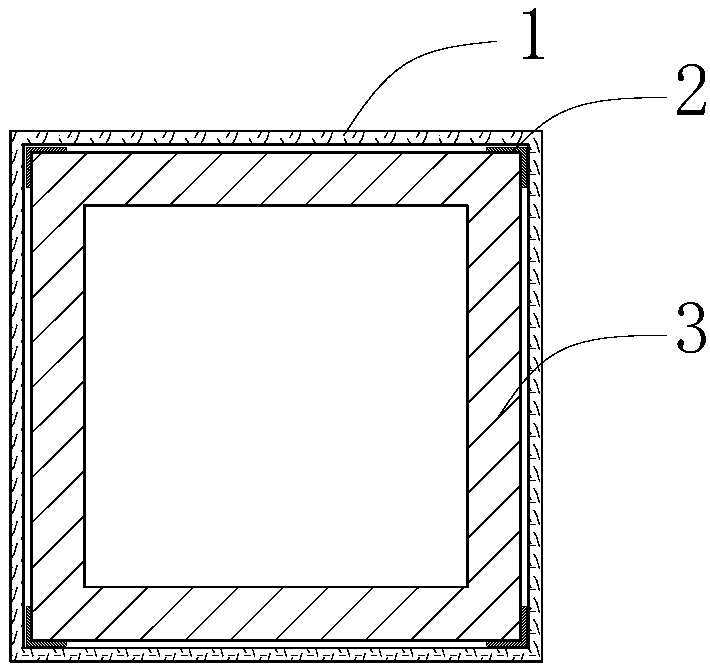

Multifunctional foamed concrete composite self-heat-preservation block and forming method thereof

ActiveCN103628614ADouble the effect of self-insulation and energy savingUnder the premise of being ecological,Construction materialFoam concreteMaterials science

The invention relates to a multifunctional foamed concrete composite self-heat-preservation block and a forming method thereof. The center of a block body is provided with a middle cavity for filling or pouring foamed materials, and the hollow cavity is a through hole with openings located in end faces of double sides, or a blind hole with an opening located in the end face of one side or a blind hole with an opening located in the side wall of one side; the middle cavity is filled with the foamed materials to form a double-foamed block, or the middle cavity is filled with the foamed materials and naturally shrinks to form a double-foamed block with a hollow chamber. The forming method comprises the steps: firstly, making a die box of the block as required, then, sorting, stirring, foaming and pouring in the die box, and distilling by using an autoclave to obtain a hollow shell, wherein the hollow shell is solid outside and is provided with the middle cavity; and (2) pouring the foamed materials into the middle cavity of the hollow shell in a physical or chemical foaming way according to the ratio of less than 300kg / cubic capacity, and then, forming through natural curing or secondary distilling, wherein the hollow shell is prepared in the step (1). The inner hole of the block provided by the invention is subjected to hollow treatment, so that the heat self-preservation and energy saving effects are good.

Owner:段志祥

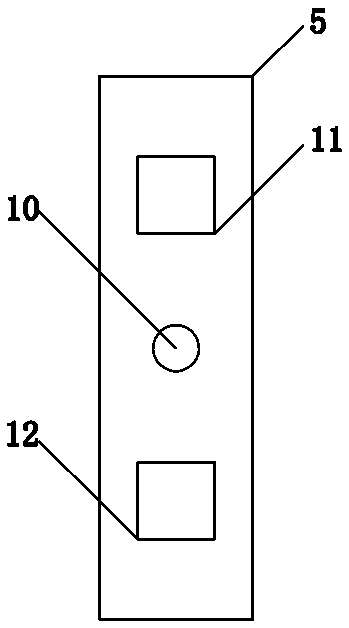

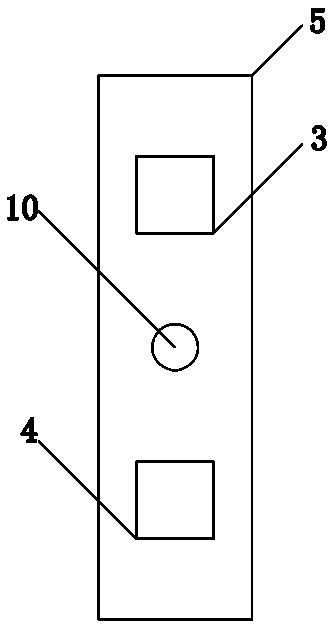

Hanging brick special for kiln covers

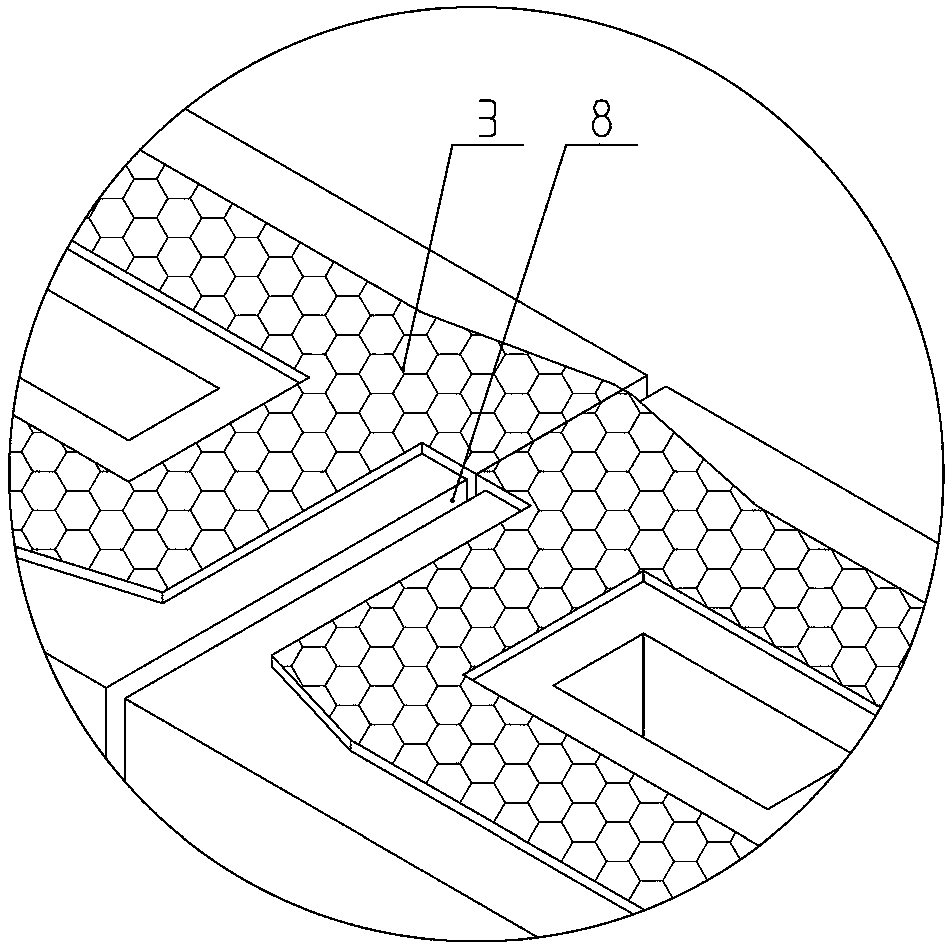

ActiveCN103615896AConvenience for masonryImprove masonry efficiencyFurnace componentsBuilding materialMaterials science

The invention relates to cement production equipment accessories, in particular to a hanging brick special for kiln covers. The hanging brick is characterized in that a hanging structure used for preventing building materials from shedding is arranged on a building surface of a brick body, and due to the fact that the building materials used for brick body building have certain viscosity and the building materials enter the hanging structure during brick body building, the building materials are prone to shedding under the action of the hanging structure and the viscosity of the building materials, convenience in brick body building is achieved, and building efficiency of the a refractory layer of a kiln is improved.

Owner:长兴盛华耐火材料有限公司

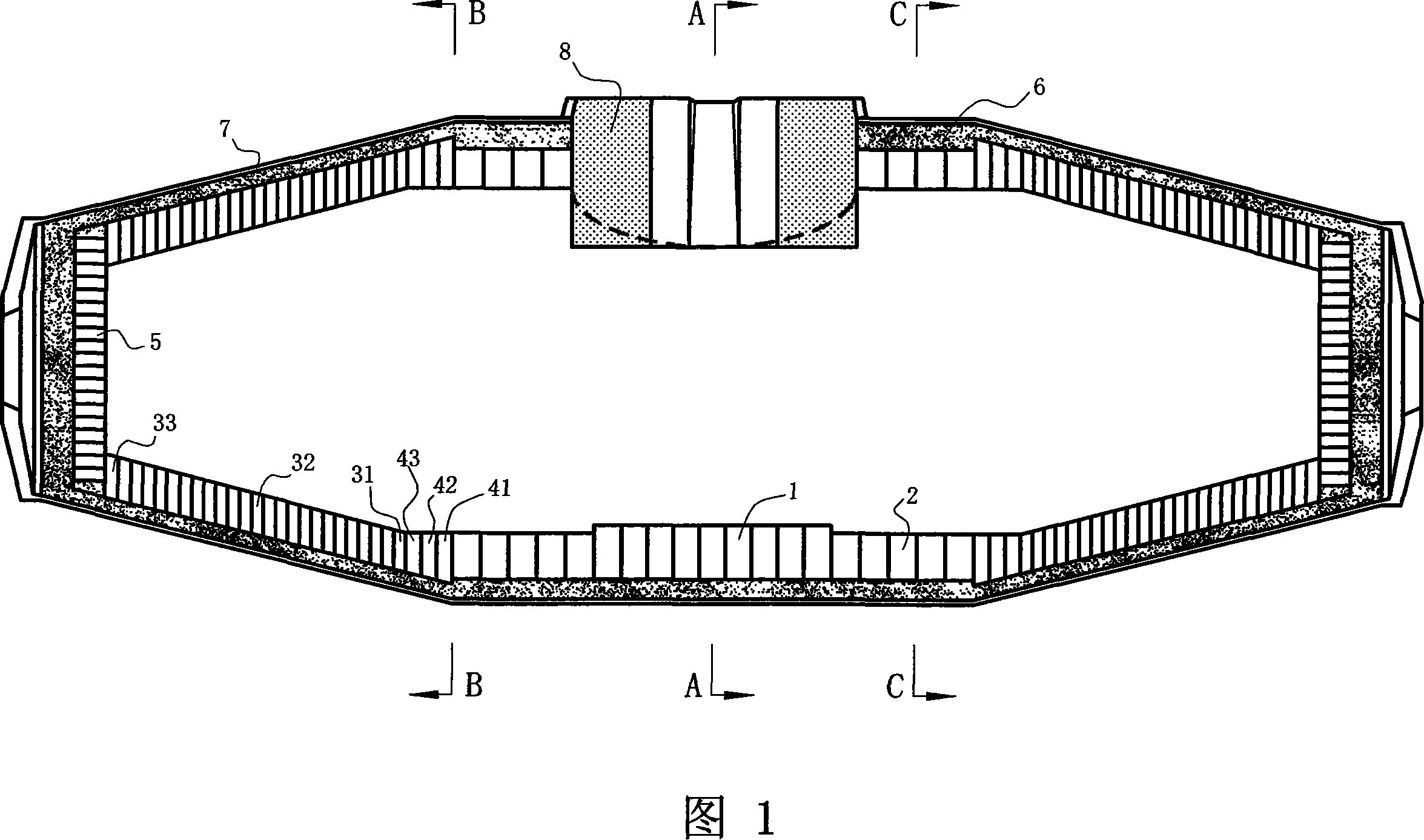

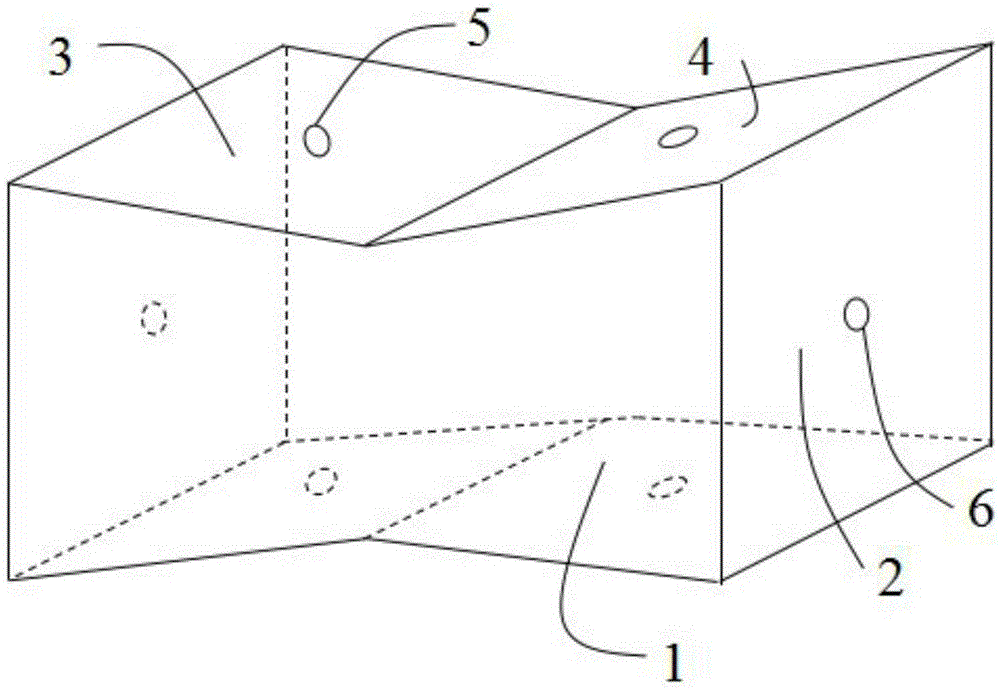

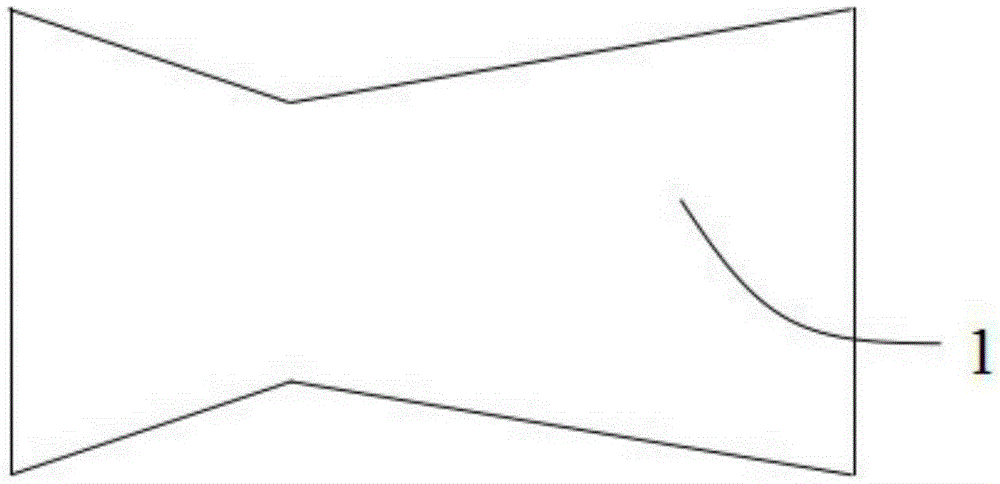

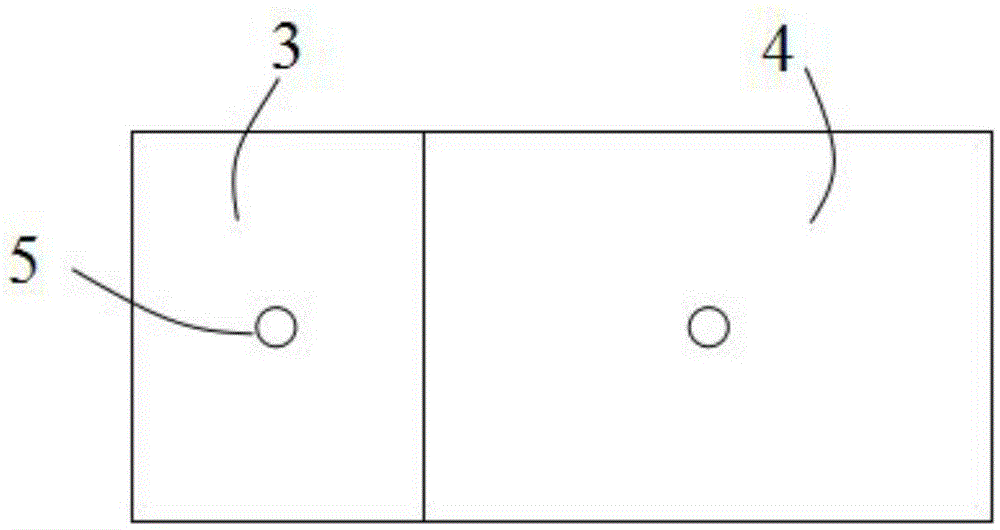

Slope vibration table model test device and method considering hydro-fluctuation belt rock mass degradation

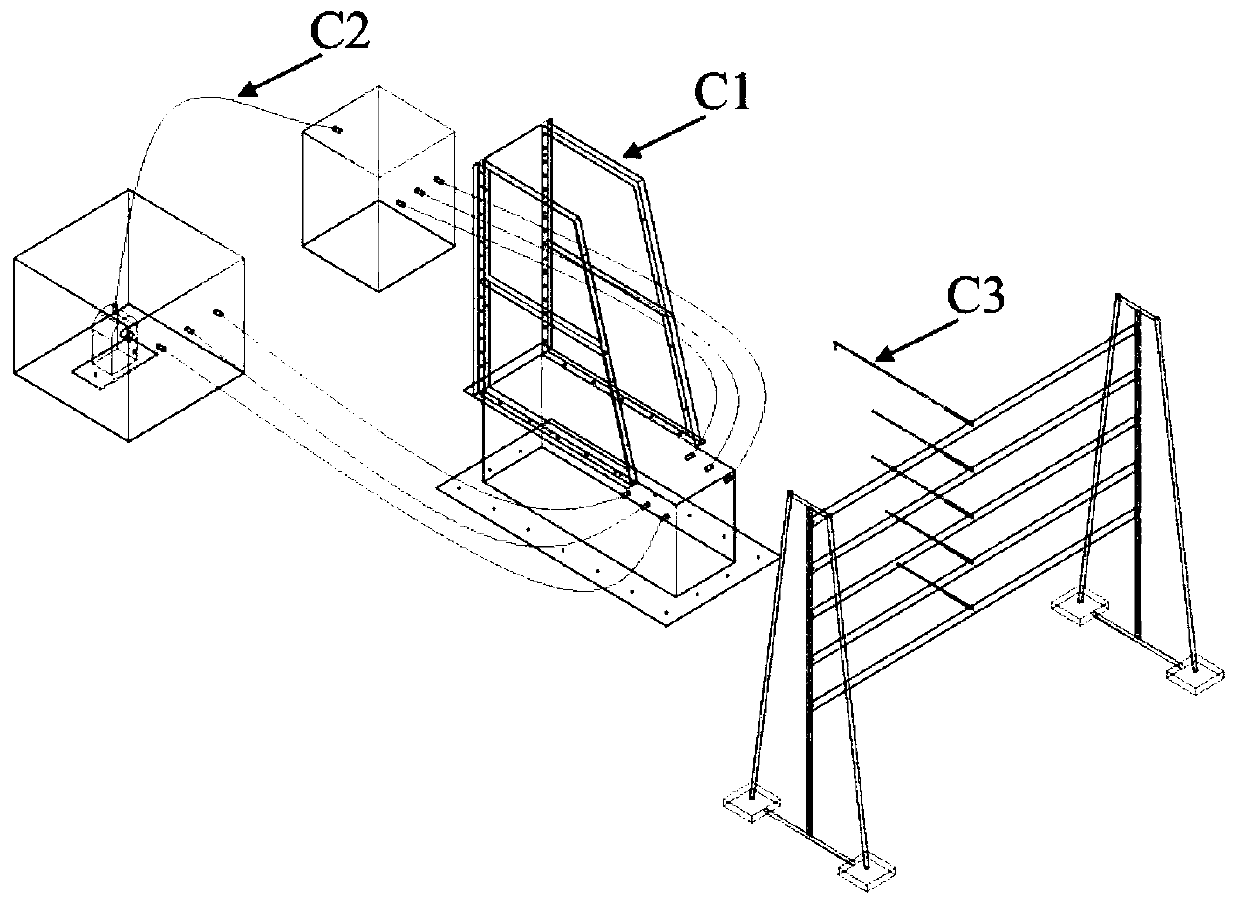

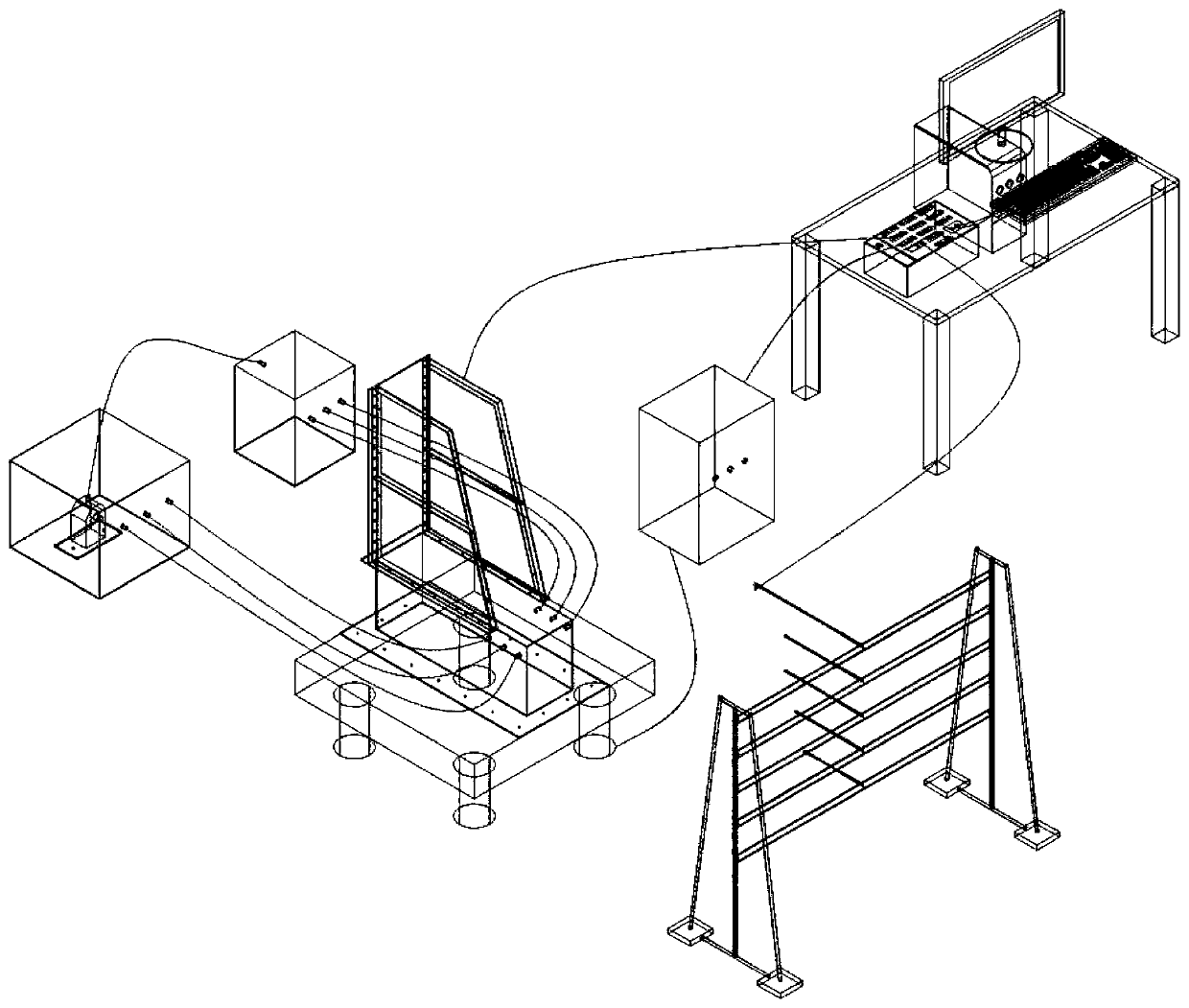

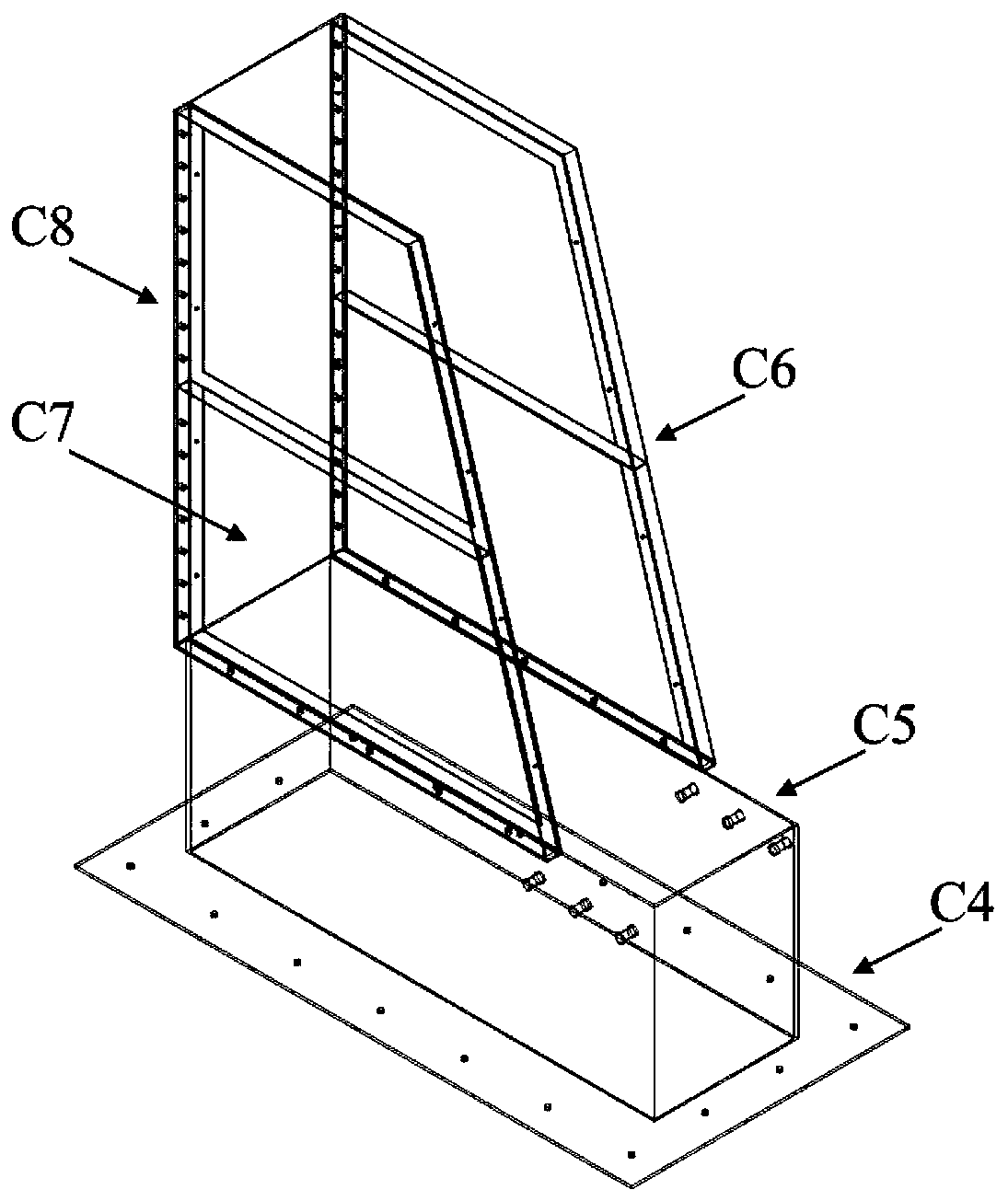

ActiveCN111521362AEasy to adjustOvercoming the disadvantages of non-transparent all-metalVibration testingWater storage tankClassical mechanics

The invention relates to a slope vibration table model test device and method considering hydro-fluctuation belt rock mass degradation, and belongs to the field of geotechnical engineering. The devicecomprises a model box system, a water circulation system and a positioning frame system, wherein the model box system comprises a model box bottom steel plate, a model box middle frame box, a model box upper steel frame, model box upper transparent tempered glass and a model box back steel plate, the water circulation system comprises a small water storage tank, a water inlet pipe, a large waterstorage tank, a water outlet pipe and a water pump, and the positioning frame system comprises a steel vertical frame, a movable steel span beam and a movable steel bar. The method comprises the stepsof assembling a model box system, building a slope model, hoisting the model box system, assembling a water circulation system, assembling a position finding frame system, debugging equipment, starting the water circulation system and loading seismic waves. The device can be used in cooperation with existing equipment in a barrier-free mode and has the design advantages of being visual, detachable, compact in structure, wide in application range and the like.

Owner:CHONGQING UNIV

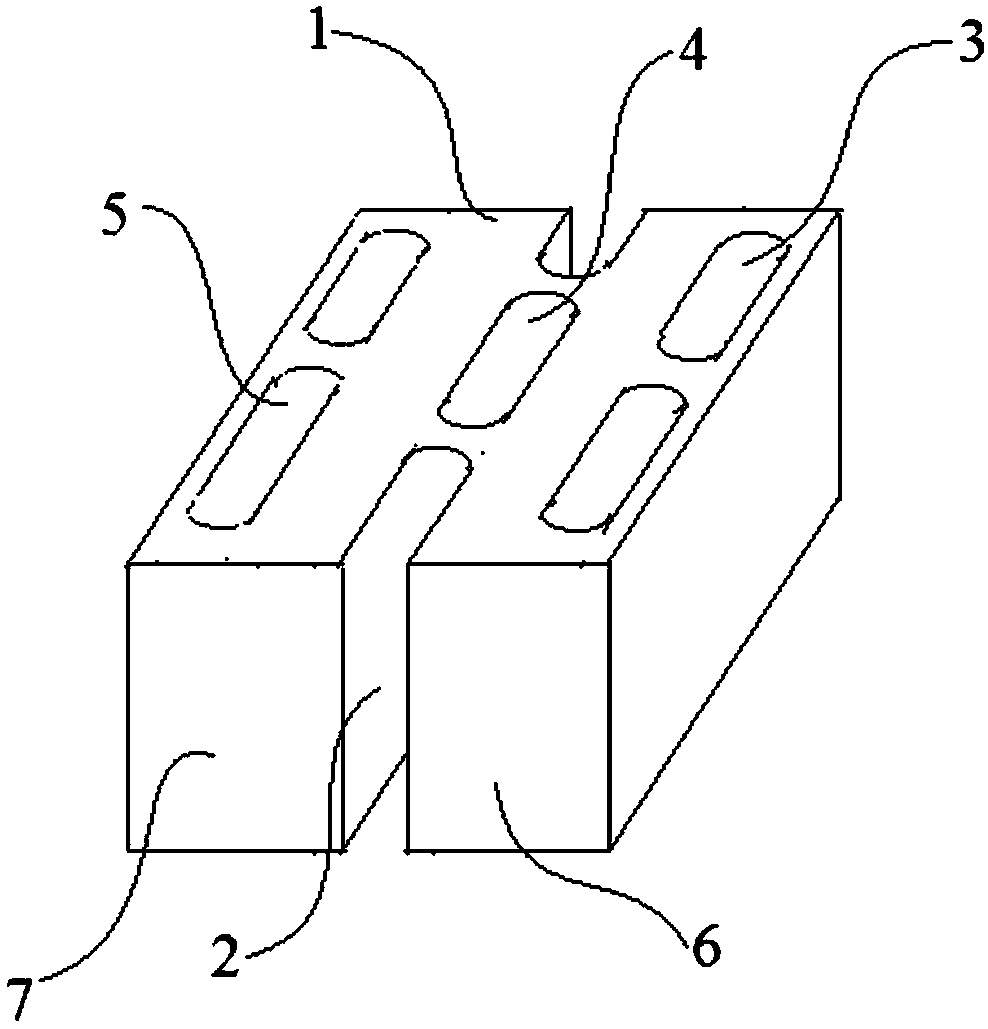

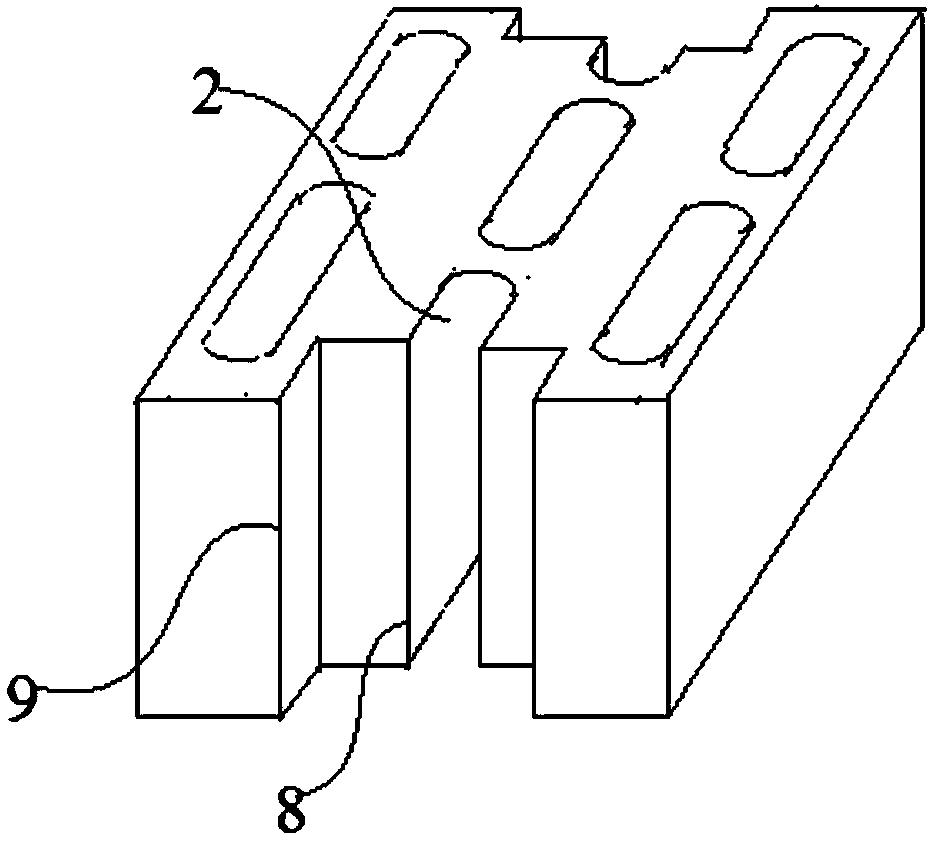

Dewave block for forming dewave wall and its formed wall

InactiveCN1912251AGood wave dissipation effectConvenience for masonryBreakwatersQuaysDislocationEngineering

The invention relates to wave removing building block used to form wave removing wall body. The wave removing building blocks includes building blocks main body includes top side, under side, two end sides. The side surface of the head sea direction is set protrusive convex body includes end and root connected with the building blocks. Many similar wave-removing building blocks are processed dislocation stacking to form wall body. The protrusive convex faces head sea direction. The invention provides wave removing building blocks and the forming wall body with wave removing function.

Owner:汪荣勋

All-obstruction bridge concrete composite self-heat-preservation integrated building block

ActiveCN104278790ASynchronous lifespanLife SynchronizationConstruction materialStructural engineeringConcrete composites

Owner:刘立才

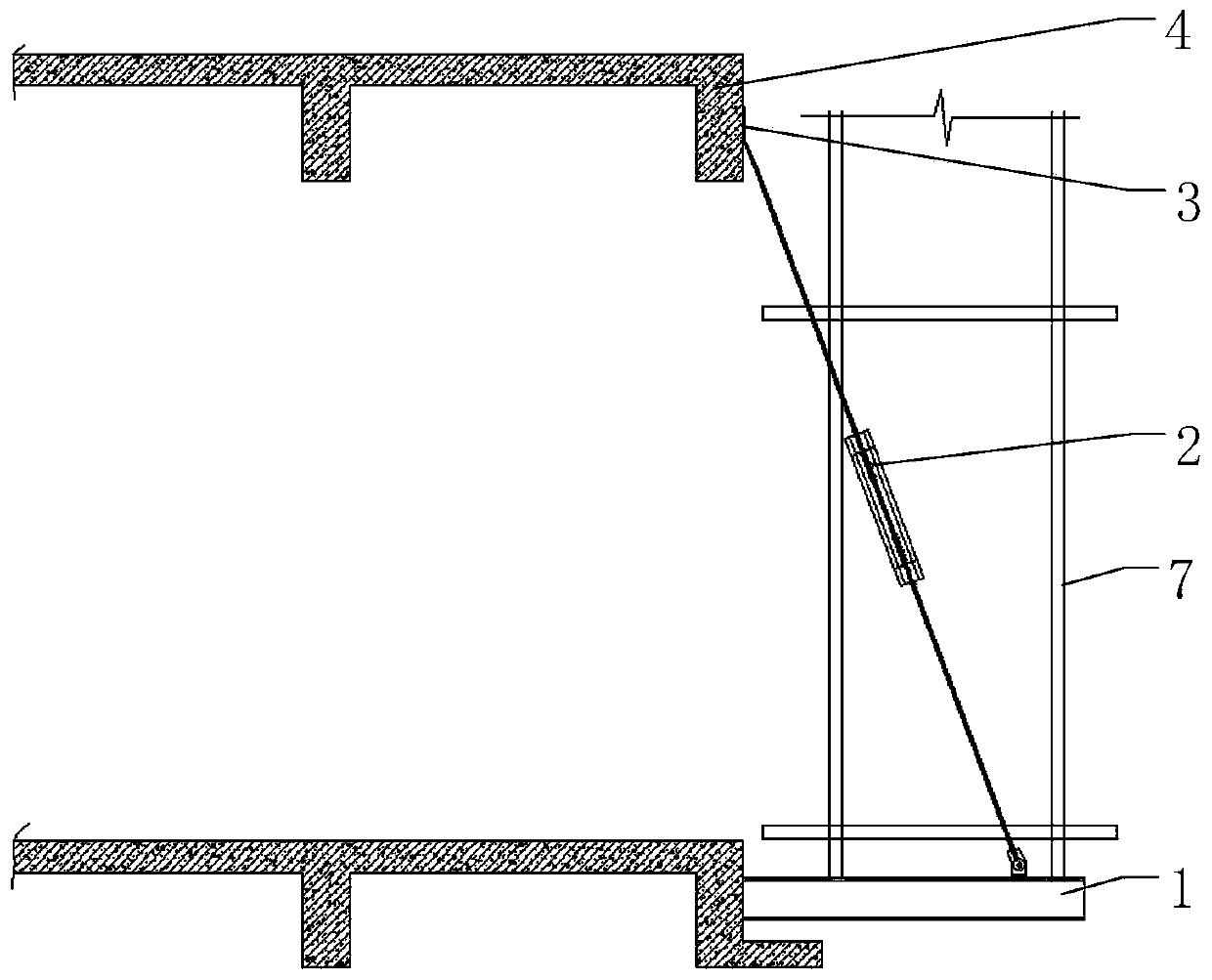

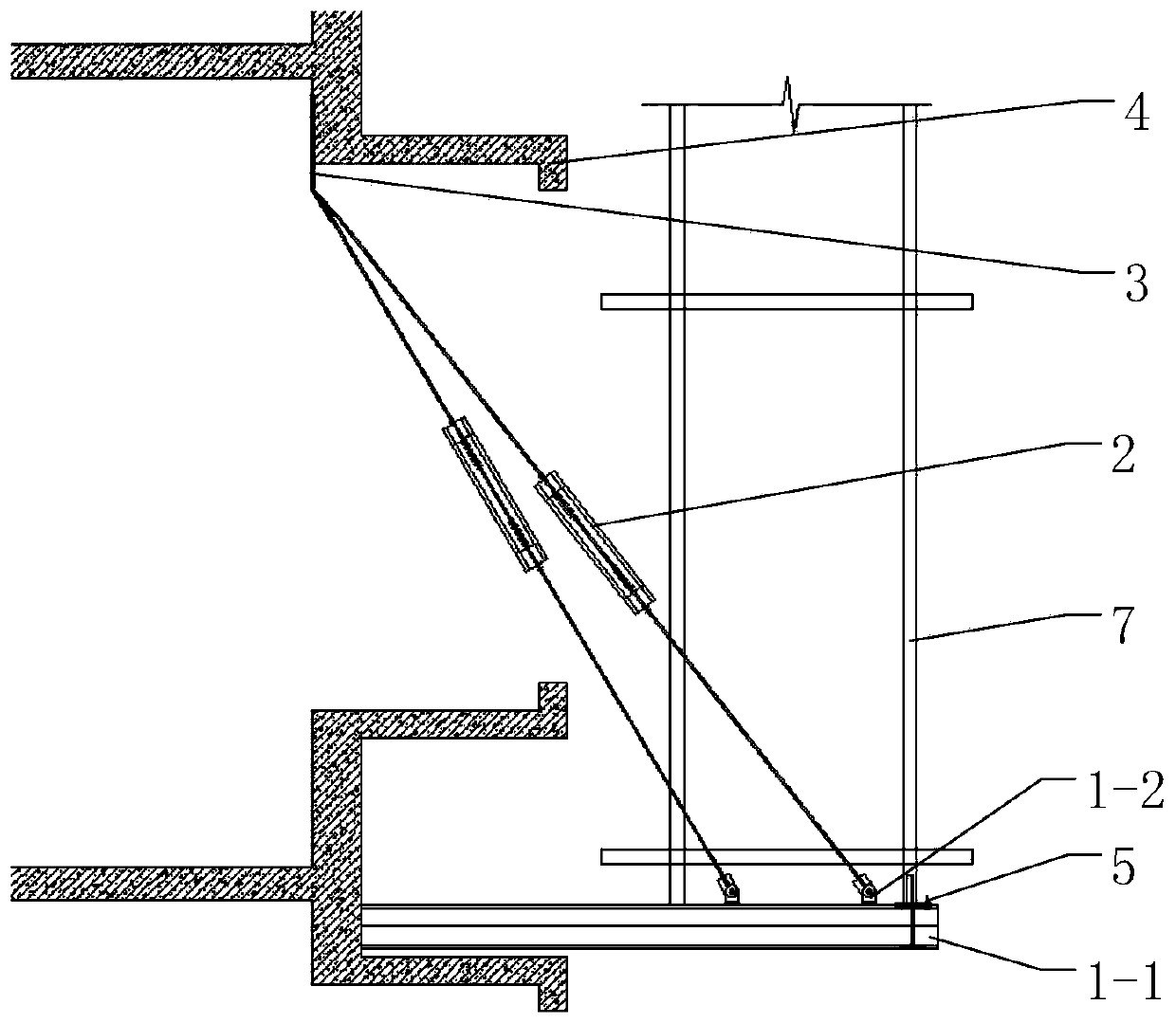

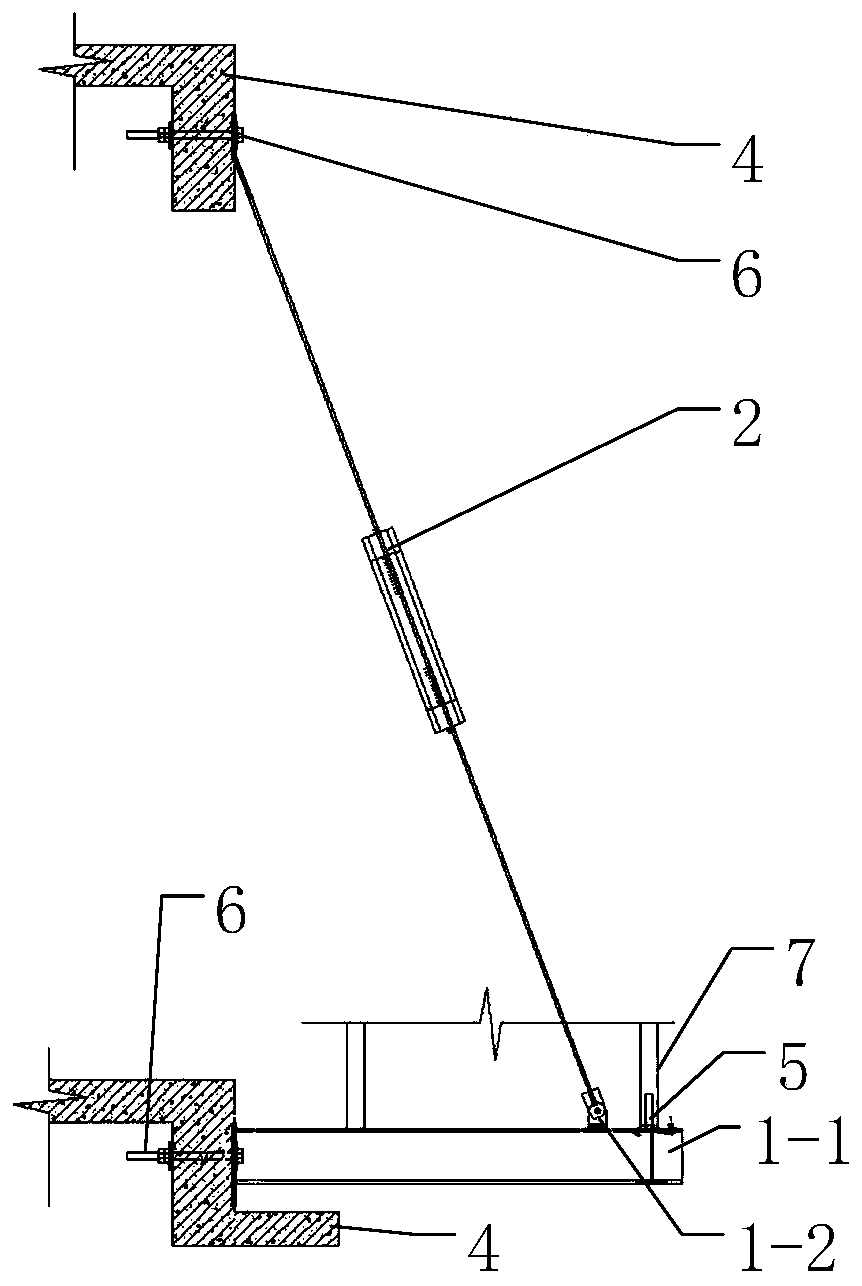

Flower basket tie rod I-steel cantilever bearing frame for construction engineering and installation method thereof

PendingCN111472530ASimple structureFlexible structureBuilding material handlingScaffold accessoriesFalseworkArchitectural engineering

The invention discloses a flower basket tie rod I-steel cantilever bearing frame for construction engineering and an installation method thereof, belonging to the field of cantilever bearing frames. The invention provides a flower basket tie rod I-steel cantilever bearing frame with convenient construction, no damage to the floor structure, convenient disassembly and reusability and an installation method thereof. In the flower basket tie rod I-steel cantilever bearing frame, a cantilever frame bearing beam is cantilevered on the side of an embedded part, and a connecting plate is arranged onthe side of the embedded part above the cantilever frame bearing beam; lugs are fixed on the I-steel; flower basket bolts are fixed between the lugs and the connecting plate; and a mobile positioningpile is installed on the I-steel. The installation method of the flower basket tie rod I-steel cantilever bearing frame comprises the following steps: pre-burying a plurality of embedded parts of a main structural beam in the wall; cantilevering the I-steel on the side of any embedded part; making the I-steel, the wall space and the flower basket bolts form a triangular shaped steel load-bearing system; and sleeving an upright tube steel pipe on the mobile positioning pile. The invention is mainly used for the design, construction and use of cantilevered steel pipe scaffolding.

Owner:INSTALLATION BRANCH WEIHAI CONSTR GRP CO LTD +1

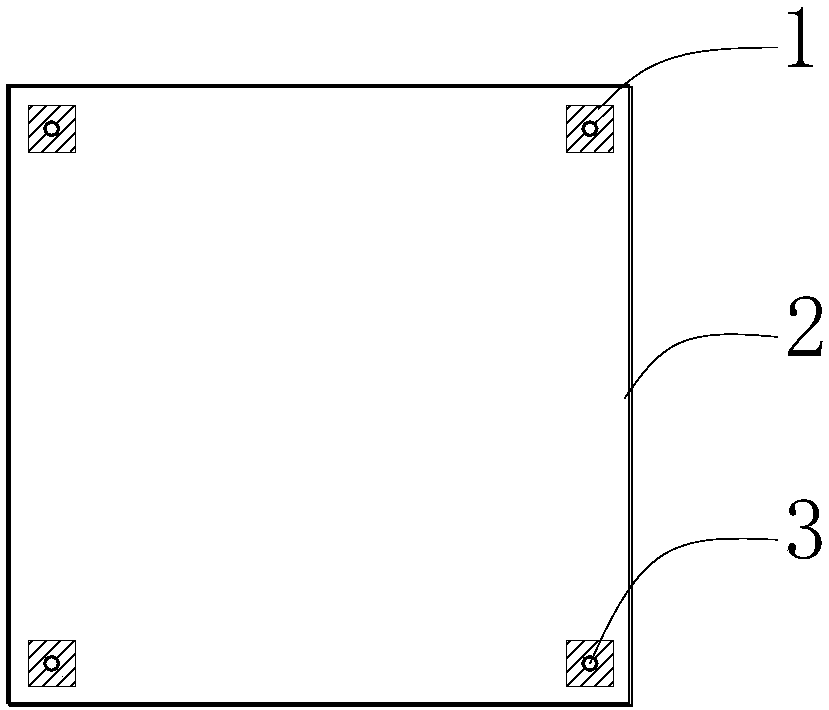

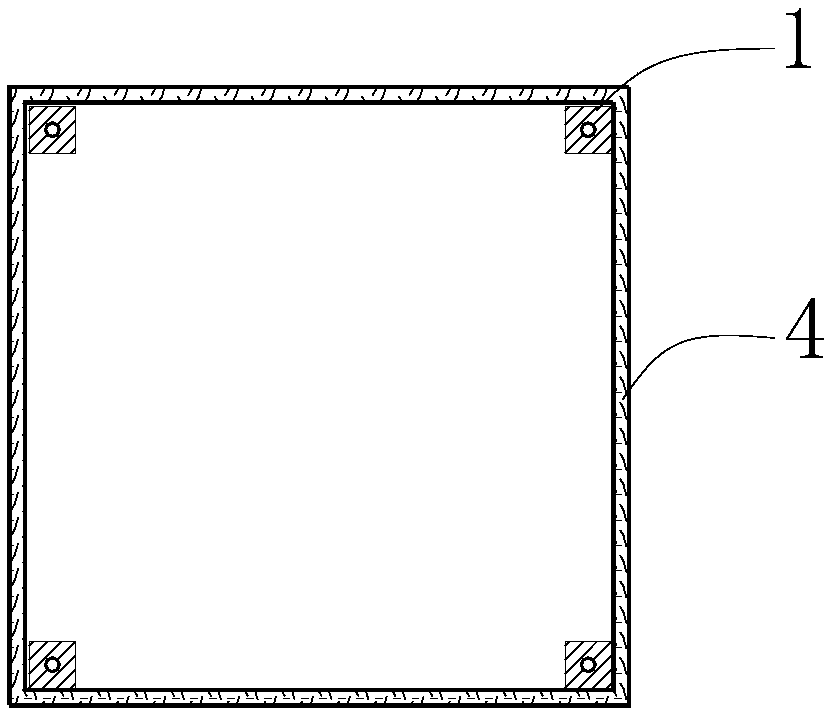

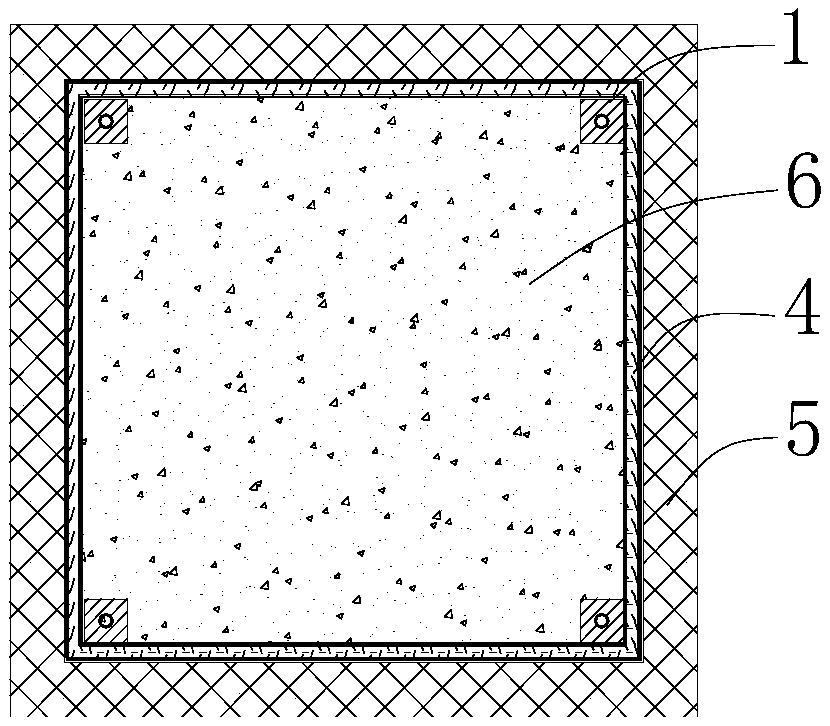

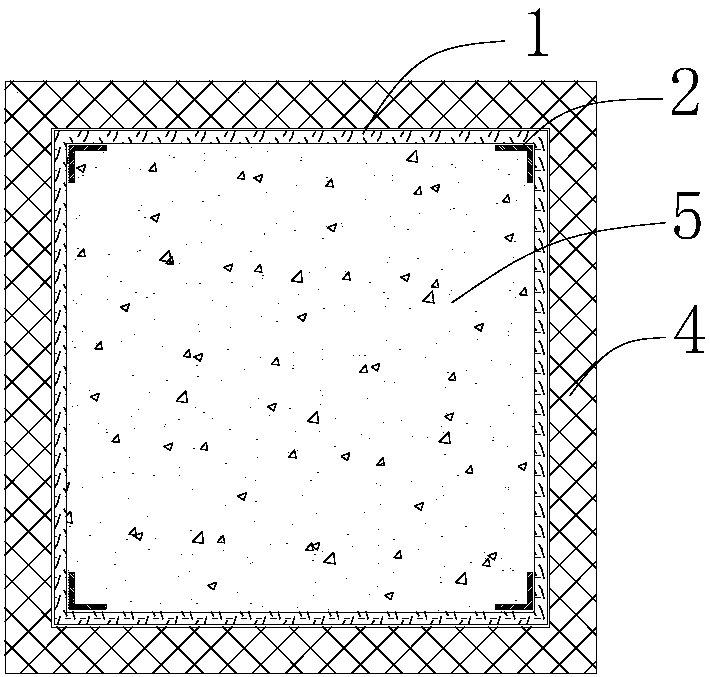

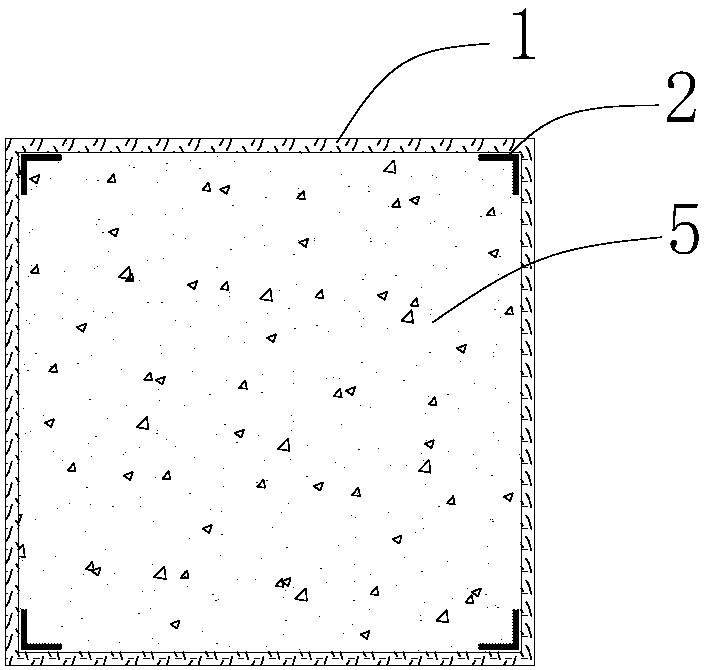

Fabric concrete composite building block and preparation method

ActiveCN108547405AReduce water-cement ratioHigh compressive strengthConstruction materialFrostUltimate tensile strength

The invention discloses a fabric concrete composite building block and a preparation method. The concrete building block is not prone to cracking, the frost resistance is good, the compressive strength of the building block is high, no hole or pitted surface exists, the appearance is smooth, wall cracks are inhibited, and the service life of a wall body to is enabled to be matched with the servicelife of a main structure. The composite building block comprises four upright posts which are arranged to form corners of a rectangular cylinder, a fabric cylinder which is wound and fixed on the upright posts to form a rectangular cylinder structure in a tensioned mode and a filler filling a fabric shell, the cross section of each upright post is rectangular, and the four upright posts are fixedrelative to each other to form a lattice type core cage. The preparation method comprises the following steps that step 1, the core cage is prepared; step 2, the fabric cylinder is prepared; step 3,the fabric cylinder is filled with the filler, pressing and vibrating for compaction are carried out, so that fabric adheres to the inner wall of a steel mold; and step 4, curing and molding are carried out, curing is carried out until the filler is initially set, the steel mold is removed, curing is carried out continuously until the filler is completely solidified, and the fabrication of the composite building block is completed.

Owner:CHANGAN UNIV

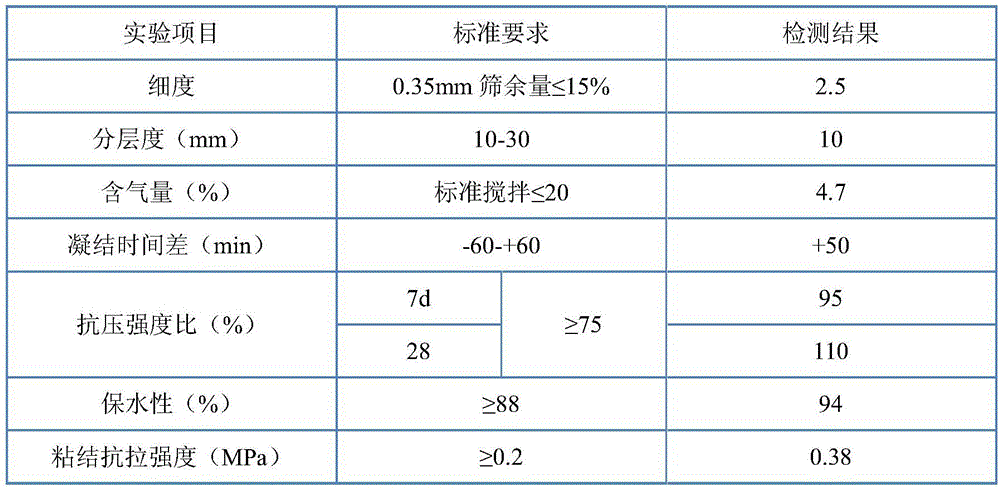

Dry-mixed mortar water retention thickener and preparation method thereof

The invention provides a dry-mixed mortar water retention thickener and a preparation method thereof. The thickener is prepared from, by mass, 45%-55% of aluminum-magnesium silicate, 4%-6% of sulfonate, 30%-40% of cellulose, 4%-6% of air entraining agent and 1.5%-3% of water reducer. The sum of the mass percents of the components is 100%. The preparation method includes the following technological steps that all the raw materials are weighed according to the mass percents, aluminum-magnesium silicate, sulfonate, cellulose, the air entraining agent and the water reducer are put in a mixer to be mixed to be uniform, the dry-mixed mortar water retention thickener is obtained, and finally the finished product is packaged. The water retention thickener is good in peaceability, construction operation of all procedures can be met in the using process, construction efficiency is improved, no salt separation is generated on the surface of mortar after the water retention thickener is used, the stirrer mortar has good peaceability, plastic reduction, seepage proofing and antifreezing performance, and the durability of a building is improved.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

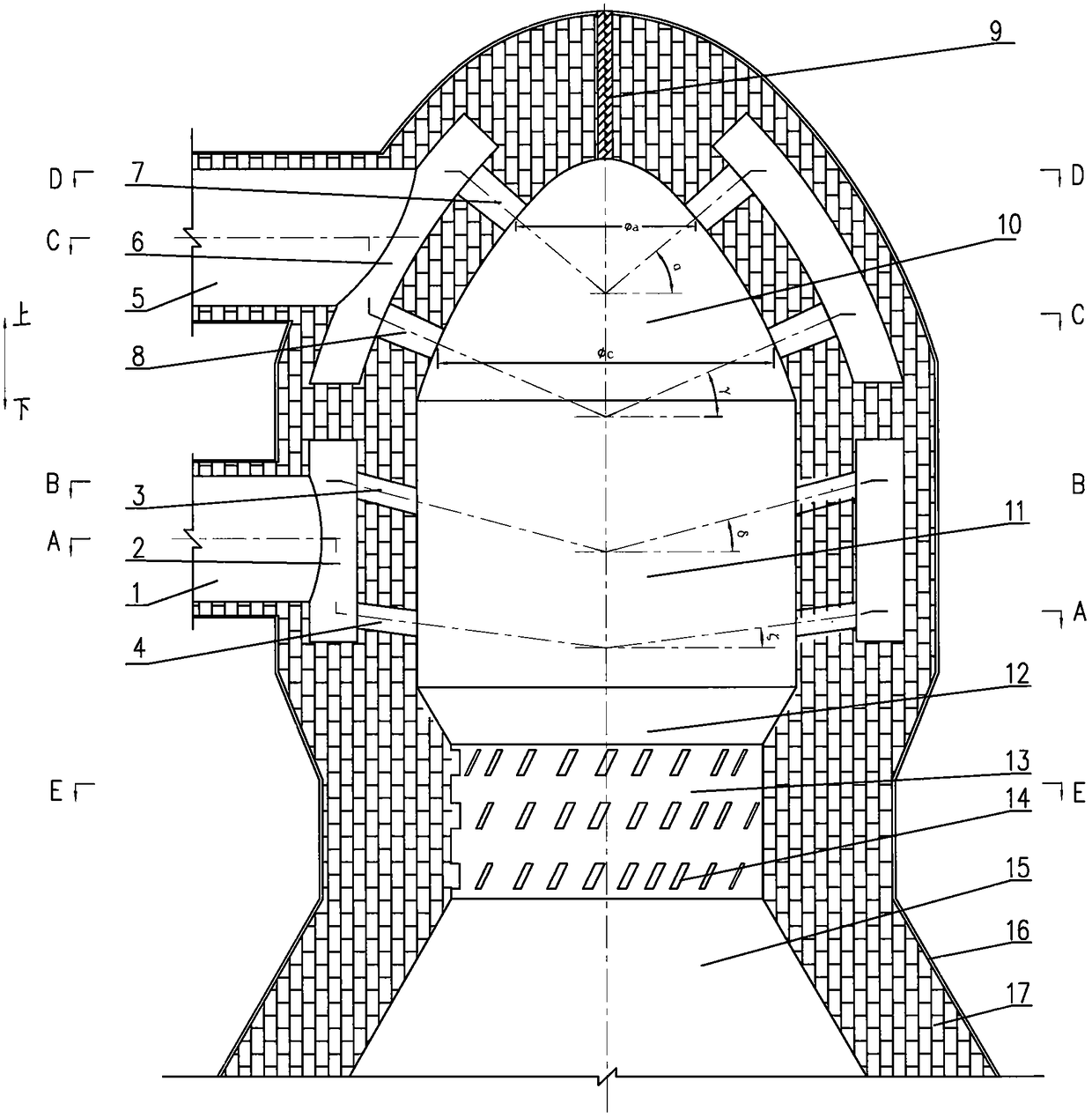

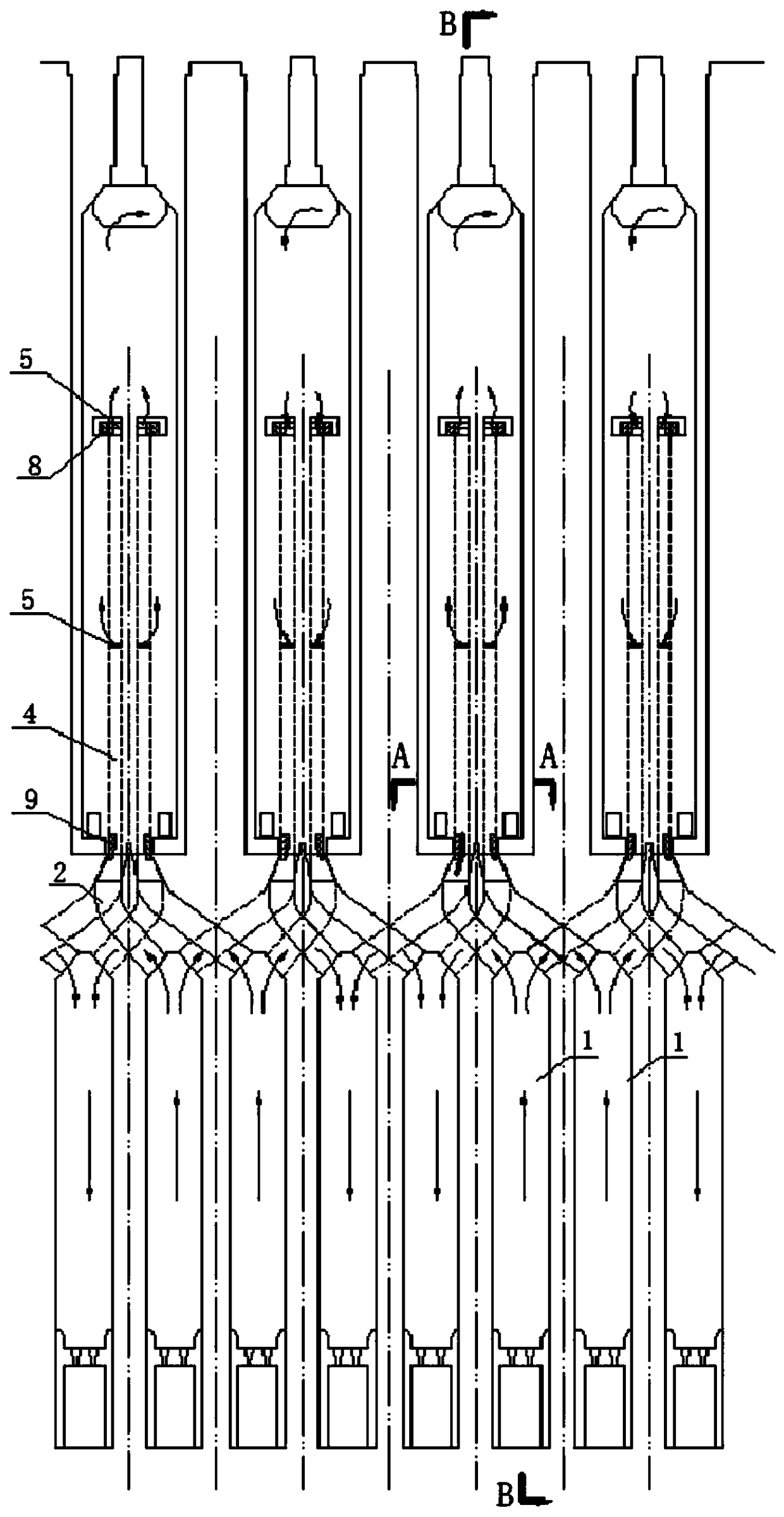

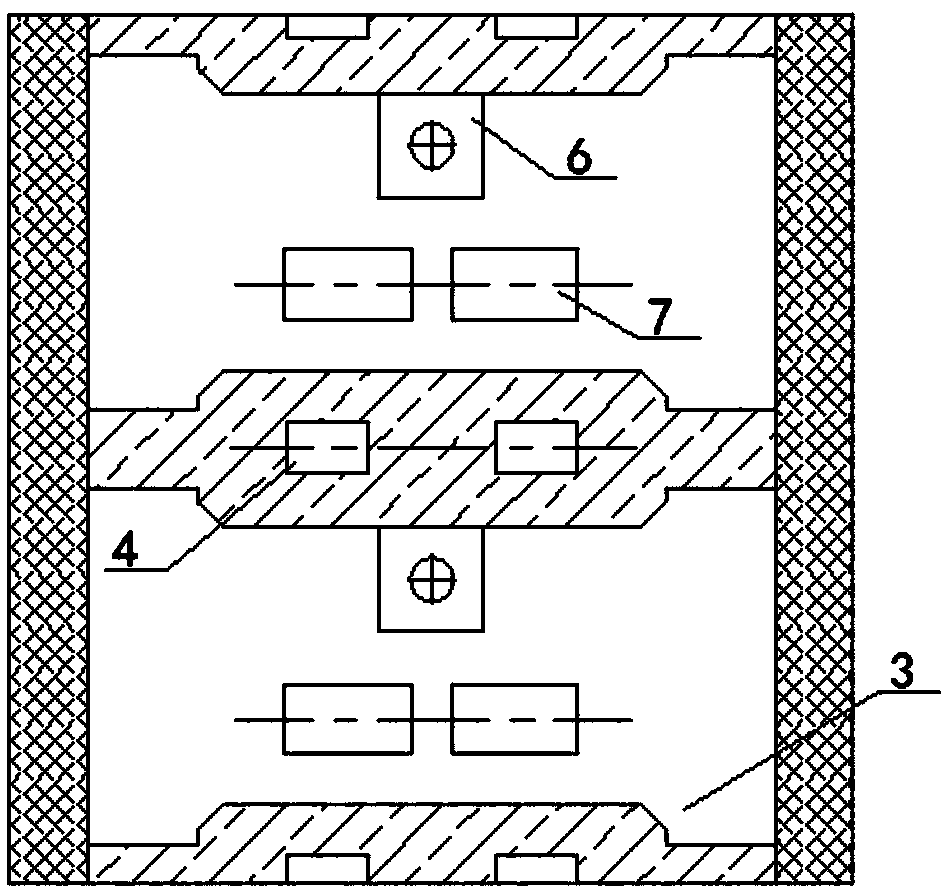

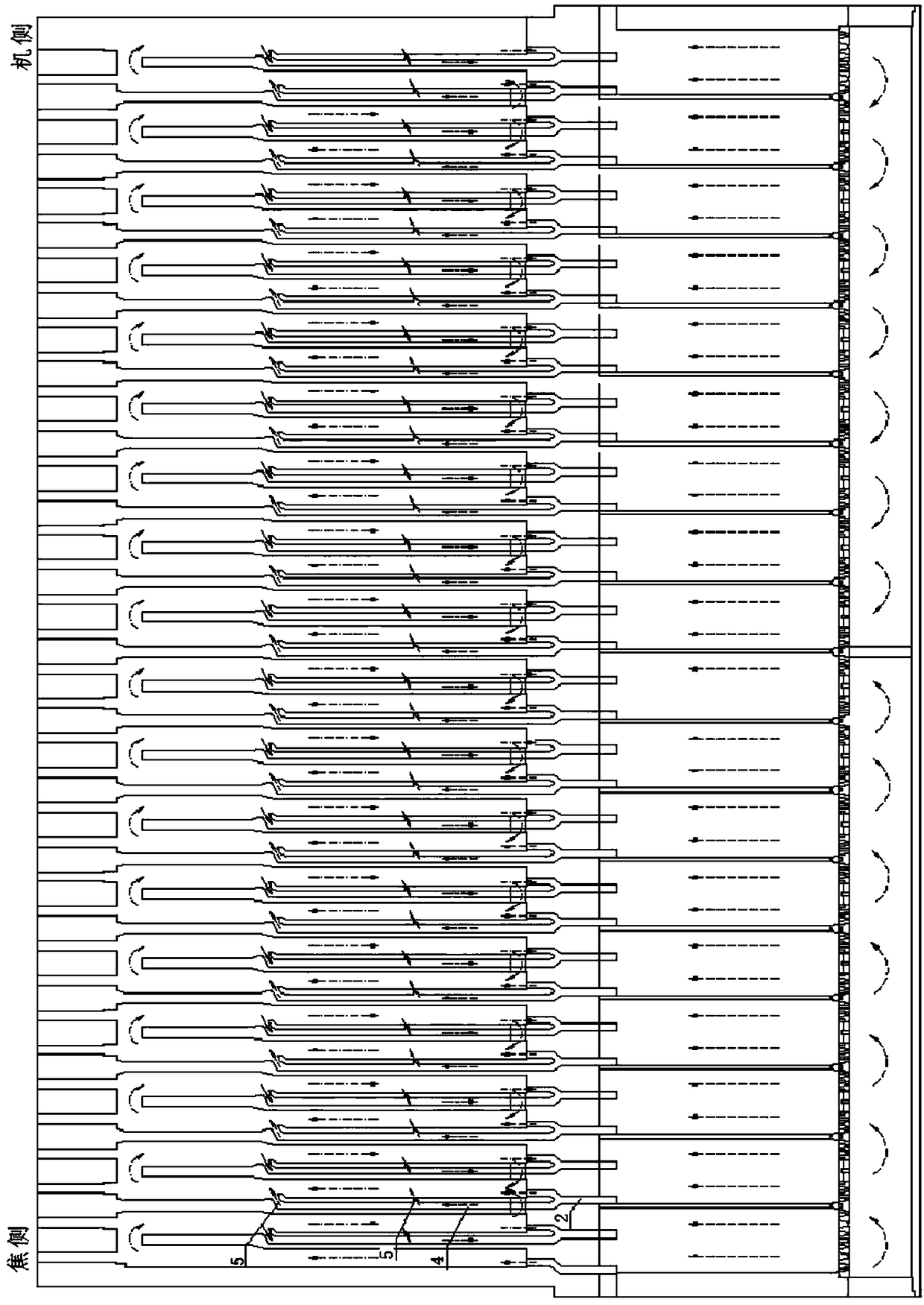

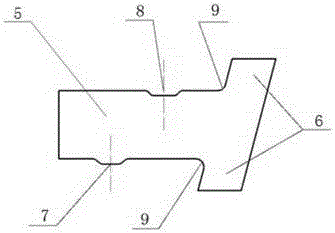

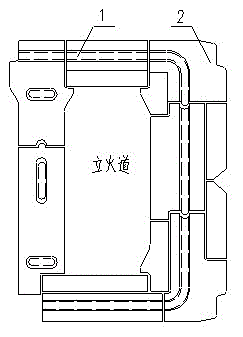

Low nitrogen emission coke-oven heating system adopting rich gas heating and adjustment method thereof

PendingCN108728127AReduce the area of high temperature zoneReduce the formation of nitrogen oxidesCombustible gas coke oven heatingFlueNitrogen oxides

The invention relates to a low nitrogen emission coke-oven heating system adopting rich gas heating and adjustment method thereof. The coke-oven heating system comprises a small flue, a heat exchangepassage, a combustion-supporting gas passage and a combustion chamber. The heat exchange passage comprises a heat exchange passage for gas supply at the bottom of a vertical flue and a heat exchange passage for gas supply at the section of the vertical flue; a small flue connecting pipe corresponding to the heat exchange passage for gas supply at the bottom of the vertical flue is provided with agas supply hole at the bottom of the vertical flue and a gas intake flow adjustment device I, and the heat exchange passage for gas supply at the bottom of the vertical flue is communicated with the outlet of the combustion-supporting gas at the bottom of the vertical flue through the combustion-supporting gas passage; the small flue connecting pipe corresponding to the heat exchange passage for gas supply at the section of the vertical flue is provided with the gas supply hole at the section of the vertical flue and a gas intake flow adjustment device II at the section of the vertical flue, and the heat exchange passage for gas supply at the section of the vertical flue is communicated with the outlet of the combustion-supporting gas in the partition of the vertical flue through the combustion-supporting gas passage. According to the low nitrogen emission coke-oven heating system, the amount of combustion-supporting air entering the bottom, middle, and upper parts of the vertical fluecan be independently and quantitatively adjusted, and the formation of nitrogen oxides can be effectively reduced.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

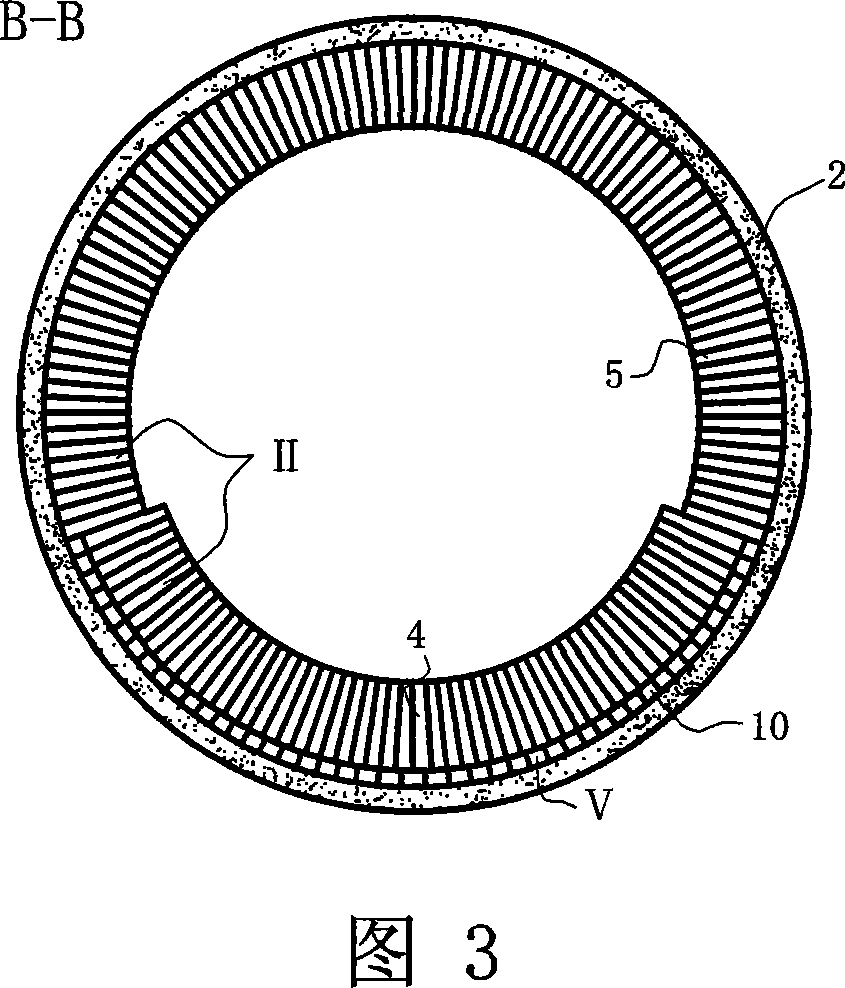

Corbel structure of coke dry quenching furnace

The invention relates toa corbel structure of acoke dry quenching furnace. The corbel structure comprises a corbel column formed by masonry in a ramp area of the coke dry quenching furnace, wherein the masonry comprises corbel support bricks and head-on bricks; each head-on brick is of a T-shaped structure and the head-on bricks are laid at intervals with the corbel support bricks on corresponding sides; bulging wings of the T-shaped head-on bricks are connected sequentially and cover the outer sides of the corbel support bricks to form an integral protective layer. With adoption of the head-on bricks withthe T-shaped structure, the two bugling wings of each T-shaped head-on brick can cover and shield mortar joints of the masonry, loss of refractory mortar in the mortar joint on one side of each head-on brick due to scour of high-temperature recycle gas is avoided, the problems of cracking, collapse and the like of the head-on bricks under the action of shear force are solved, and the service life of the corbel of the coke dry quenching furnace is prolonged effectively.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

High-performance fiber-reinforced cement composite concrete building structure block

ActiveCN106365581AHigh strengthImprove performanceSolid waste managementCeramic shaping apparatusCrack resistanceSlag

The invention discloses a high-performance fiber-reinforced cement composite concrete building structure block. The high-performance fiber-reinforced cement composite concrete building structure block is prepared from the following components: fly ash, cement, attapulgite, sand, waste paper pulp, natural gypsum, manganous slag, polycarboxylic acid, sodium methylsiliconate, colloidal silicon dioxide, fatty acid polyoxyethylene ester, calcium nitrate, naphthalene sulfonic acid sodium salt-formaldehyde condensate, modified lignosulfonate, diboron trioxide and a nano activator. A groove parallel to a block edge is formed in at least any one surface of six surfaces of the block; channels are formed between every two adjacent left and right blocks as well as between every two adjacent upper and low blocks; all the channels are filled with mortar. The block disclosed by the invention has the advantages of impact resistance, high strength, simple structure and convenience in building; the building precision and the stability of a wall body are guaranteed; the lateral force resistance, crack resistance and seismic performance are greatly enhanced.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

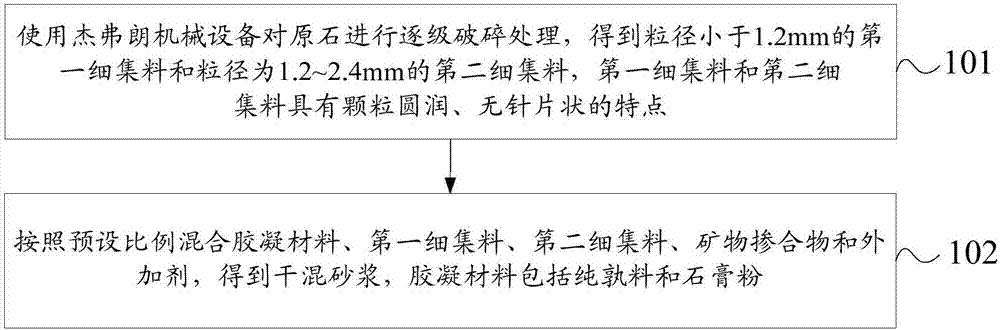

Dry-mixed mortar and preparation method thereof

The invention provides dry-mixed mortar and a preparation method of the dry-mixed mortar. The dry-mixed mortar comprises the following components in parts by weight: 10-20 parts of a binding material, 40-50 parts of a first fine aggregate with the grain size less than 1.2 mm, 20-30 parts of a second fine aggregate with the grain size of 1.2-2.4 mm, 10-20 parts of a mineral admixture, and 0-0.05 part of an additive; the binding material comprises 95-96 parts by weight of a pure clinker and 4-5 parts of gypsum powder. Based on the components and the component proportion of the dry-mixed mortar provided by the embodiment of the invention, the dry-mixed mortar is higher in workability, the construction operations of building, plastering, pumping and the like are convenient to carry out, and the construction efficiency is improved. Moreover, when the dry-mixed mortar is used for building, the one-time slurry spreading length is greatly increased, the times for spreading a slurry on a specified fundamental plane are reduced, the thickness of a slurry layer is reduced, the uniformity of the slurry layer is improved, the quality of the slurry layer is improved, the use level of the mortar is saved, the construction cost is lowered, and the repairing cost and the later maintenance cost of the slurry layer are avoided or reduced.

Owner:辽宁煜梽新型建材有限公司

Converter steelmaking method

InactiveCN104294001AReduce lossesReduce lossManufacturing convertersProcess efficiency improvementSteelmakingEnergy source

The invention discloses a converter steelmaking method and relates to the field of mechanical forging. The converter steelmaking method comprises the treatments of seven steps of molten iron pretreatment, molten iron blending, waste steel block loading, lancing setting, slag charging, tapping and drossing; the molten iron is desulfurized in an iron mixing car at low cost and high efficiency; a molten iron ladle car supplies the molten iron in such a manner that the steps of blast furnace molten iron receiving, transporting, buffering storage, converter molten iron blending and the like are all carried out in the molten iron ladle car, and therefore, the loss of the molten iron and the dissipation of heat are low and the energy sources are saved; the waste steel blocks are added to the converter and reutilized so that the resources are saved and a better environmental protection effect is achieved; a spray lance is inserted deeply into the molten iron to inject oxygen, and a redox reaction is performed between the molten iron and the slag, and the oxygen so that such impurities as phosphorus, sulfur and silicon can be removed efficiently; in the tapping process, an iron alloy is added to a steel ladle for deoxidization and alloying so that the produced steel is high in plasticity and not easy to crack in the rolling process; the residual slag is poured into a slag pot and can be transported to a cement plant for producing cement.

Owner:中山市鸿程科研技术服务有限公司

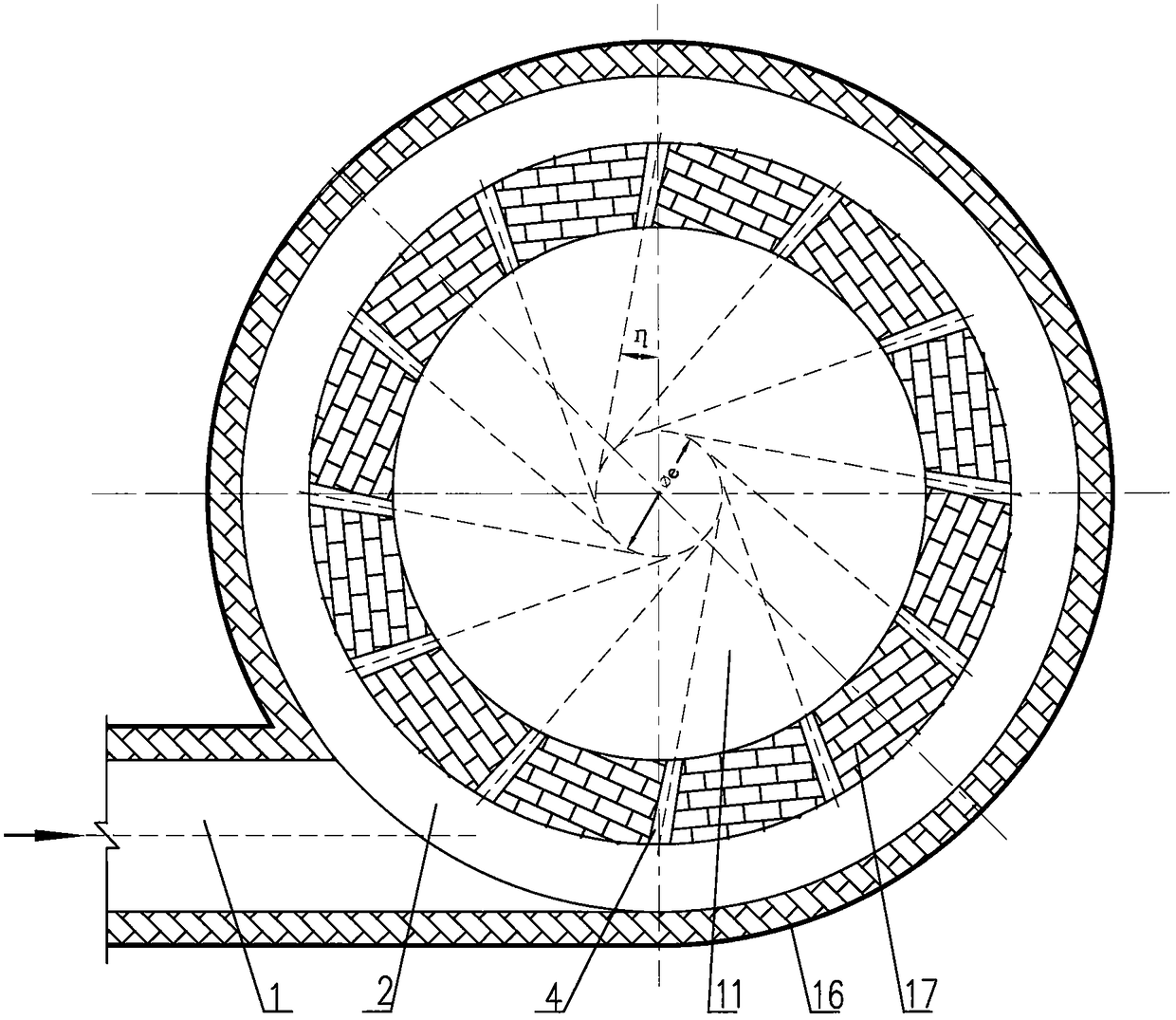

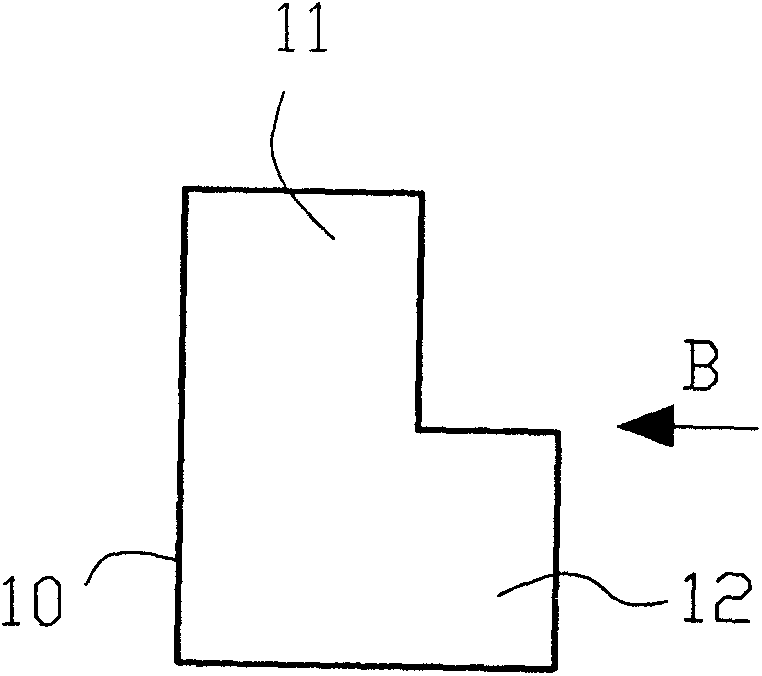

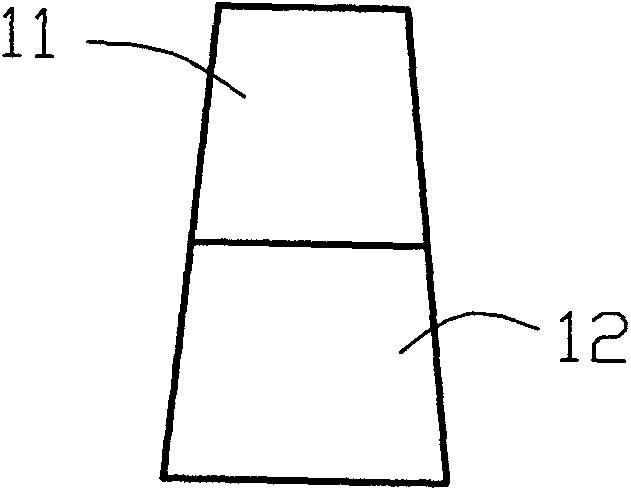

Vertical wedge-shaped refractory brick for rotary limestone kiln

A vertical wedge-shaped refractory brick for a rotary limestone kiln consists of a port wedge-shaped brick body of a wedge-shaped structure, kiln body wedge-shaped brick bodies and a tail end wedge-shaped brick body and is characterized in that the port wedge-shaped brick body consists of a wedge point and a wedge bottom, one side of the port wedge-shaped brick body is a wedge-shaped end face, and steps matched with the kiln body wedge-shaped brick bodies are arranged on one side of the wedge point and the wedge bottom; each kiln body wedge-shaped brick body consists of a wedge point building block and a wedge bottom building block which form an integrated structure, and the ends of the wedge point building block and the wedge bottom building block are respectively provided with steps matched with the port wedge-shaped brick body, another kiln body wedge-shaped brick body or the tail end wedge-shaped brick body; the tail end wedge-shaped brick body consists of a wedge point stopper block and a wedge bottom stopper block, one side of the tail end wedge-shaped brick body is a wedge-shaped tail face, and steps matched with the kiln body wedge-shaped brick bodies are arranged on one side of the wedge point stopper block and the wedge bottom stopper block. The vertical wedge-shaped refractory brick has the advantages of being convenient to lay, high in construction speed and flat in butt joint face.

Owner:刘伟

Interlocking tensile masonry brick

The invention discloses an interlocking tensile masonry brick. The interlocking tensile masonry brick comprises front and rear two surfaces, left and right two end faces, left-section masonry brick upper and lower rectangular pressure bearing surfaces and right-section masonry brick upper and lower rectangular pressure bearing surfaces, wherein the left-section masonry brick upper and lower rectangular pressure bearing surfaces and the right-section masonry brick upper and lower rectangular pressure bearing surfaces are perpendicular to the surfaces, and the included angles between the end faces and the left-section masonry brick upper and lower rectangular pressure bearing surfaces as well as the right-section masonry brick upper and lower rectangular pressure bearing surfaces are acute angles. The interlocking tensile masonry brick is symmetrical along the perpendicular bisection planes of the surfaces and the end faces and adopts an equal-thickness structure. As the interlocking tensile masonry brick adopts interlocking structural design, when the interlocking tensile masonry bricks and facing bricks are laid, the bricks are laid upon one another and engaged with one another so as to form an overlapped zone, and as a result, the tensile strength, the shear strength and the seismic performance of the masonry structure are greatly improved. The interlocking tensile masonry brick made from precast concrete is higher in strength.

Owner:XIHUA UNIV

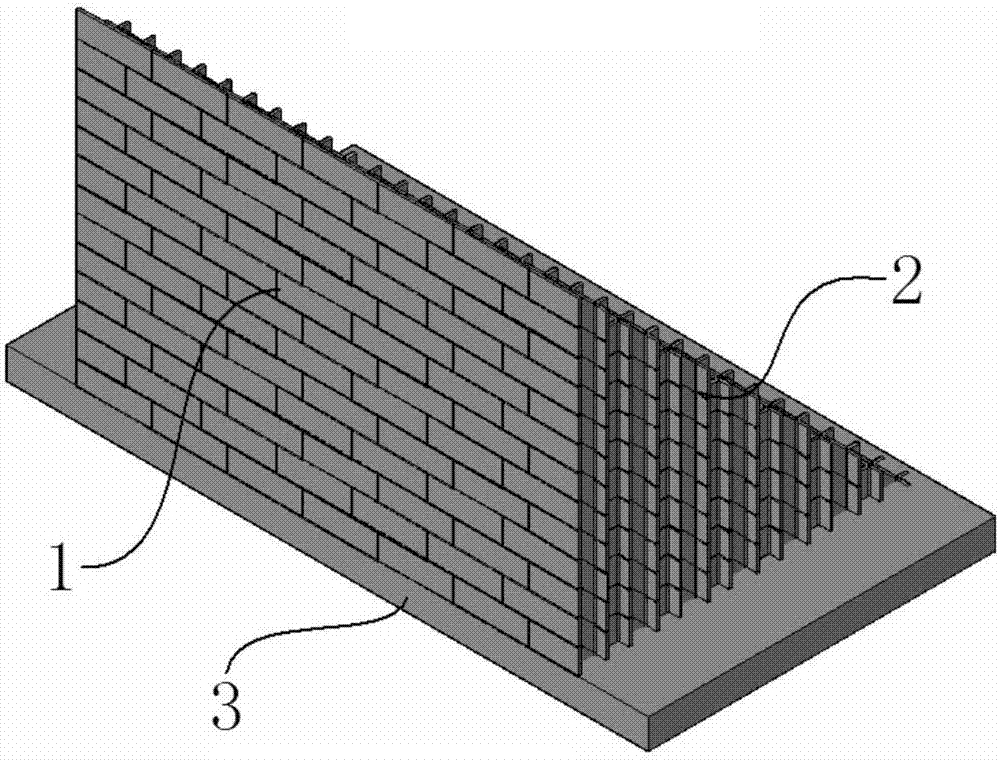

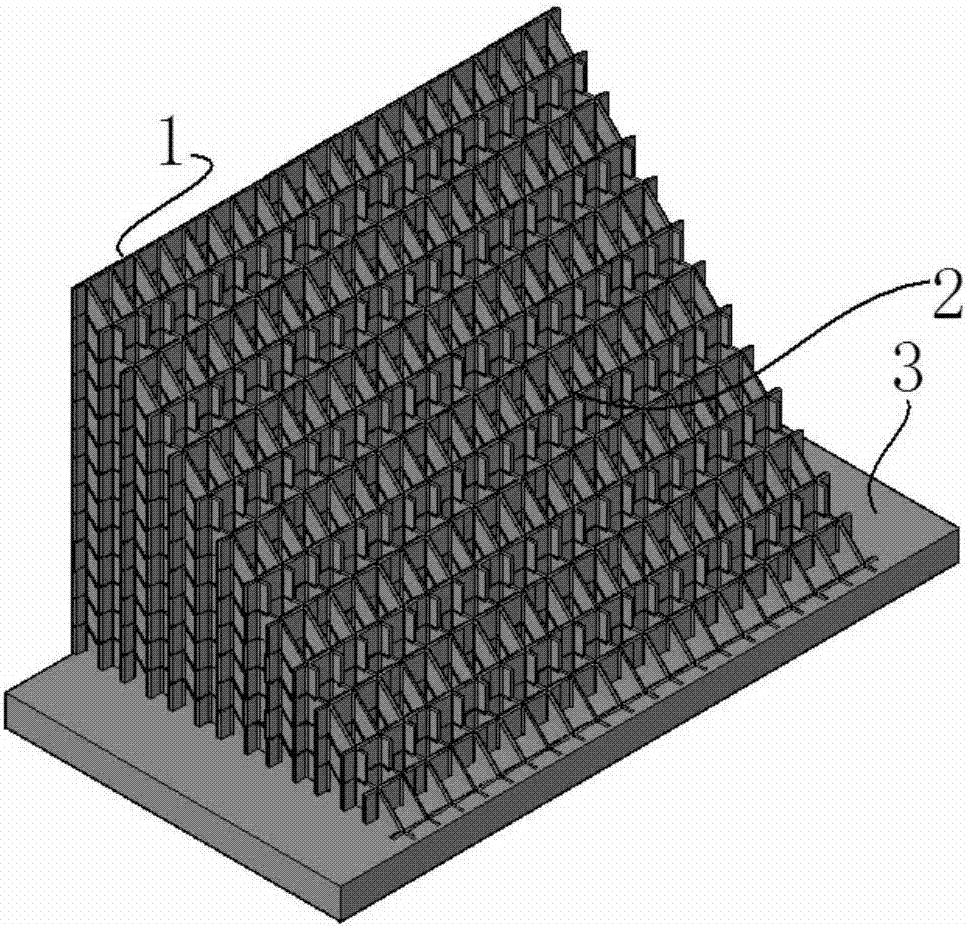

Prefabricated gravity type barrier wall

ActiveCN107288153AReduce dosageLow costArtificial islandsUnderwater structuresArchitectural engineeringRebar

The invention provides a prefabricated gravity type barrier wall. The prefabricated gravity type barrier wall comprises multiple wall face prefabricated blocks, multiple wall body prefabricated blocks, a barrier wall foundation plate and multiple reinforcing steel bars. The wall face prefabricated blocks and the wall body prefabricated blocks are designed into concrete grids which can be overlapped with one another for construction and mounted on the barrier wall foundation plate. Then, all the constructed prefabricated blocks are fixedly connected together through the reinforcing steel bars and mortar. Meanwhile, grid holes are filled with sandy soil so that the weight of the barrier wall can be increased. By means of the prefabricated gravity type barrier wall, the requirement for the bearing capacity of a foundation is low; concrete consumption is greatly saved; a scrapped soil body at site is fully converted into a wall body backfill construction material for the barrier wall; construction cost of a project is greatly saved; the construction period of the project is shortened; and the wall face ecological afforestation environment can be improved conveniently.

Owner:易朋莹

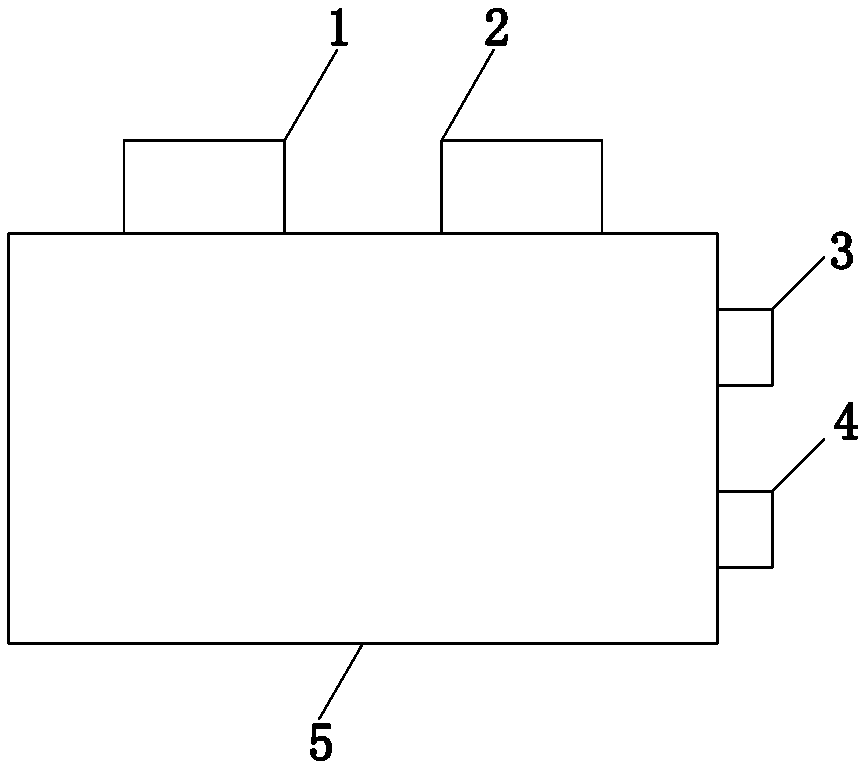

Firebrick prefabricated member

The invention discloses a refractory brick prefabricated part, which comprises a fourth positioning block, a refractory brick body, a third through hole and a fourth positioning hole, the top of the refractory brick body is provided with a first positioning block and a second positioning block, and The first positioning block is set on the left side of the second positioning block, the bottom of the refractory brick body is provided with a first positioning hole and a second positioning hole, and the first positioning hole is set on the left side of the second positioning hole, the refractory brick body A third positioning hole and a fourth positioning hole are arranged on the left side wall, and the third positioning hole is arranged above the fourth positioning hole, and a third positioning block and a fourth positioning block are arranged on the right side wall of the refractory brick body, The top of the refractory brick body is provided with a first through hole and a second through hole, and the right side wall of the refractory brick body is provided with a third through hole. The invention is convenient for masonry, convenient for masonry construction of the kiln body, scientific and reasonable in structure, firm in connection, excellent in heat insulation ability, and can effectively guarantee service life and quality.

Owner:河南格锐新材料科技有限公司

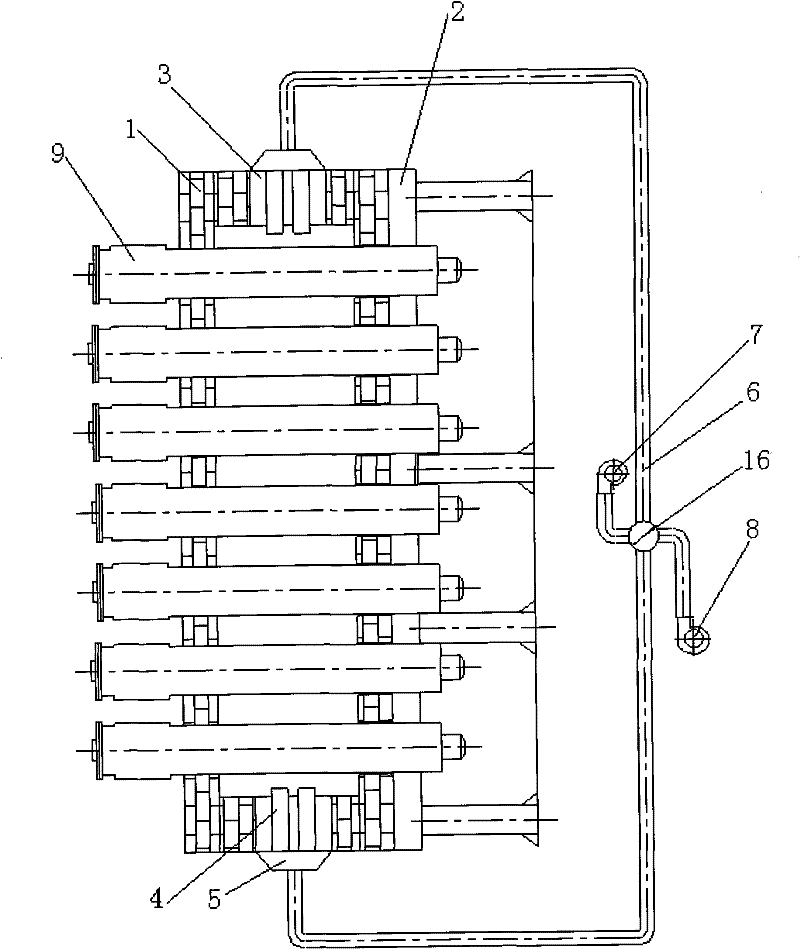

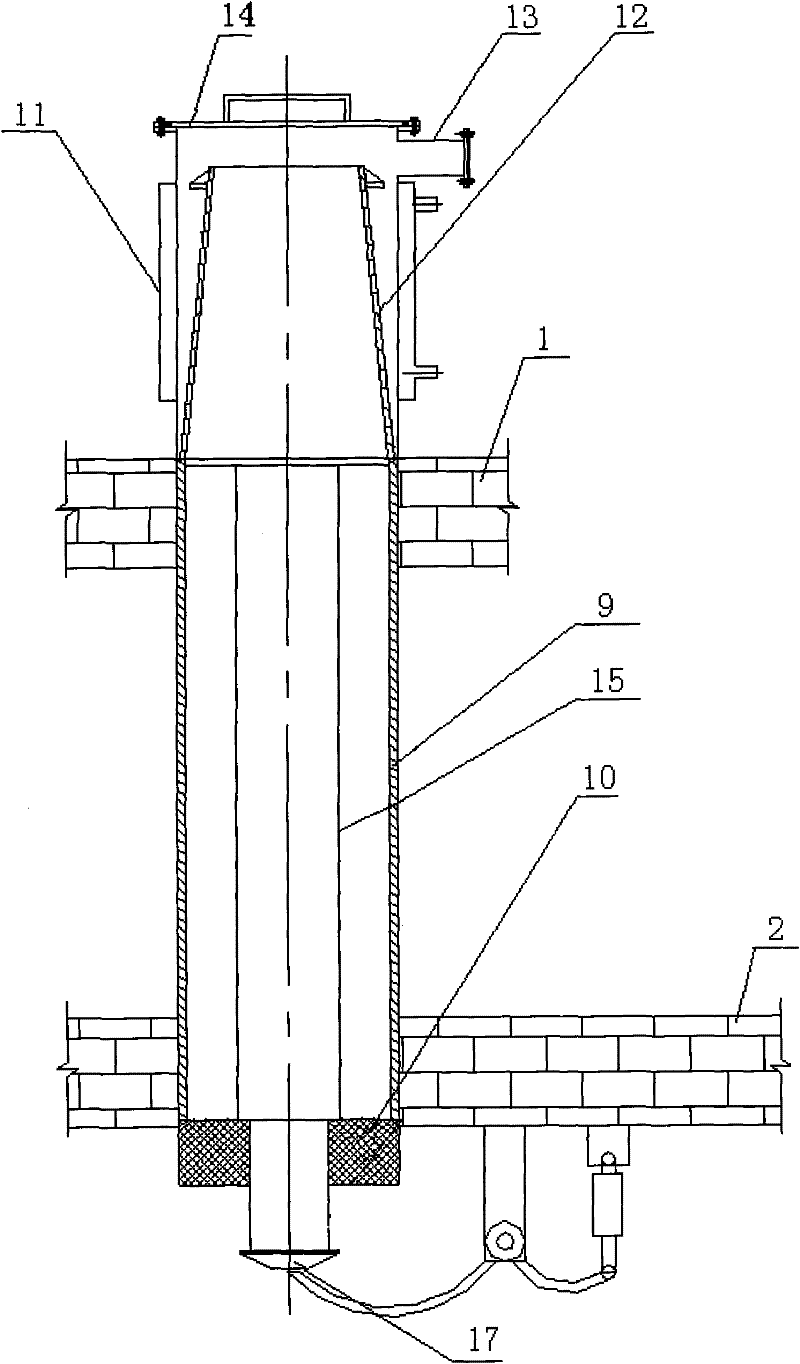

Vertical heat accumulating type reduction furnace

The invention discloses a vertical heat accumulating type reduction furnace, relating to metal magnesium and metal calcium melting, in particular to a vertical metal magnesium and metal calcium reduction furnace. The vertical heat accumulating type reduction furnace is characterized by comprising a reduction furnace body, a heating device, a fuel and combustion supporting gas introducing-in device and a reducing reaction tank in a vertical pipe shape, wherein the center of the reducing tank body between a reducing-tank sealing member and a taper-shaped crystallizer is coaxially provided with a vertical through pipe of which the side wall is provided with a through hole. The vertical heat accumulating type reduction furnace disclosed by the invention has the advantages of short construction period and high speed of becoming effective. The vertical heat accumulating type reduction furnace body is supported by a concrete or steel structure bracket; the furnace structure is not complex and is convenient to build and install. The steps of loading, taking the crystallizer and deslagging can be mechanically and quickly operated to save labor force cost. Hot airflow rises in the hearth, which is favorable for carrying out a reduction reaction and ensures that a reduction period is shortened. Compared with a lateral tank reduction furnace, the vertical heat accumulating type reduction furnace has the advantage of saving more energy.

Owner:于思静 +1

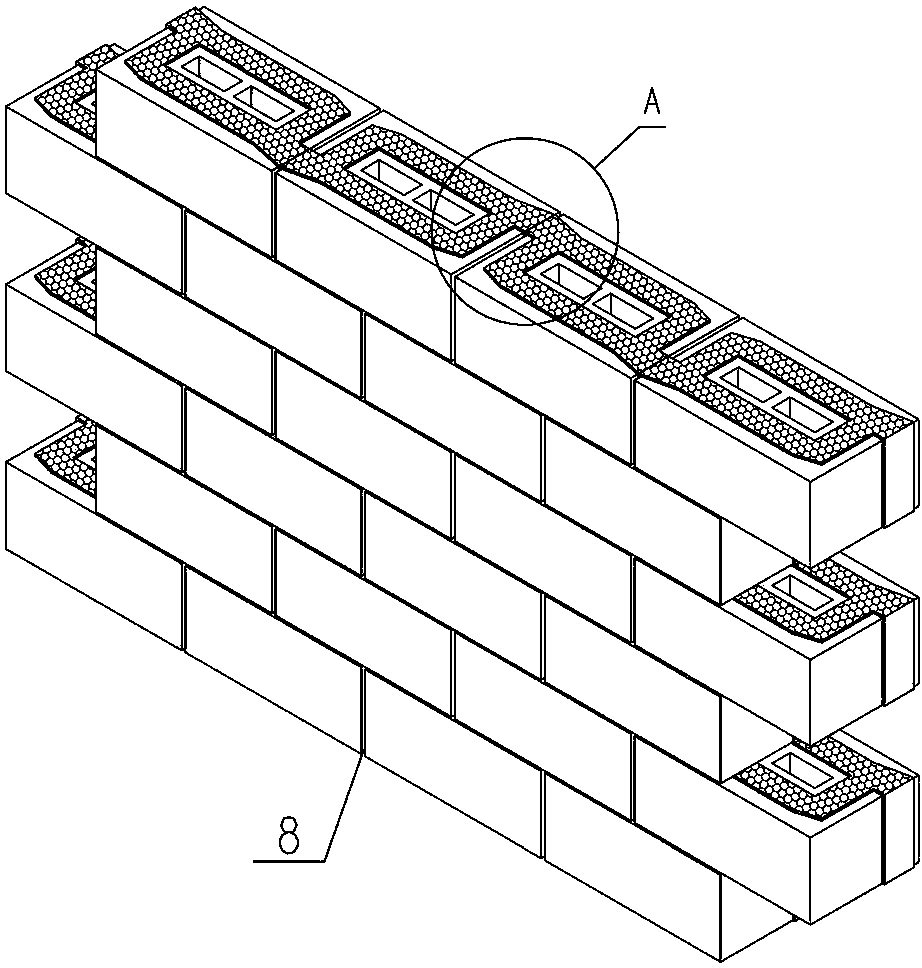

Method for preparing small hollow light aggregate concrete block from industrial solid waste residues

ActiveCN108086576AThe masonry process is convenientLarge poresBuilding componentsWater contentCarbonization

The invention relates to the technical field of building materials, in particular to a method for preparing a small hollow light aggregate concrete block from industrial solid waste residues. Buildingwastes are collected, classified and then crushed into particles respectively, the particles are washed for mud settling treatment, recycled aggregate is obtained, the recycled aggregate is compounded with coal-fired furnace slag and cement, the proportion is controlled, so that the prepared hollow block has the density grade meeting the grade-800 requirement, the strength grade meeting the grade-MU5.0 requirement, the water absorption rate smaller than or equal to 9%, the dry shrinkage rate smaller than or equal to 0.046%, the relative water content smaller than or equal to 32%, the softening coefficient larger than or equal to 0.89, the carbonization coefficient larger than or equal to 0.91, the freezing and thawing strength loss lower than or equal to 12% and the freezing and thawing quality loss lower than or equal to 3.6%. Besides, the adding amount of the industrial solid wastes reaches 86.3%, and the preparation cost of the thermal insulation block is reduced to a great extent.

Owner:盘州市生泰新型建材有限公司

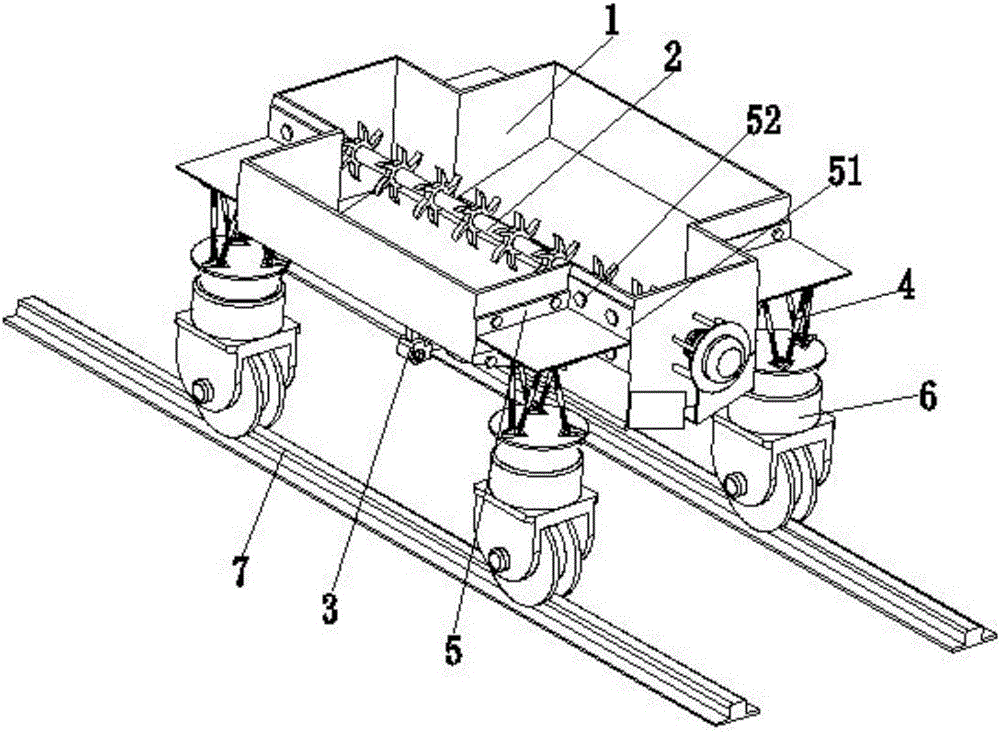

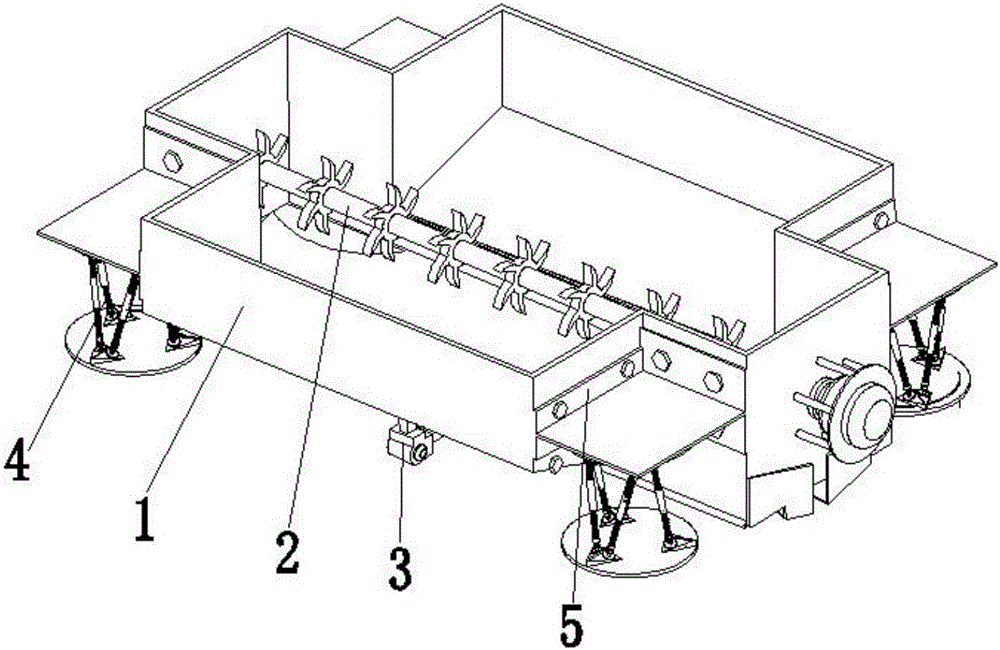

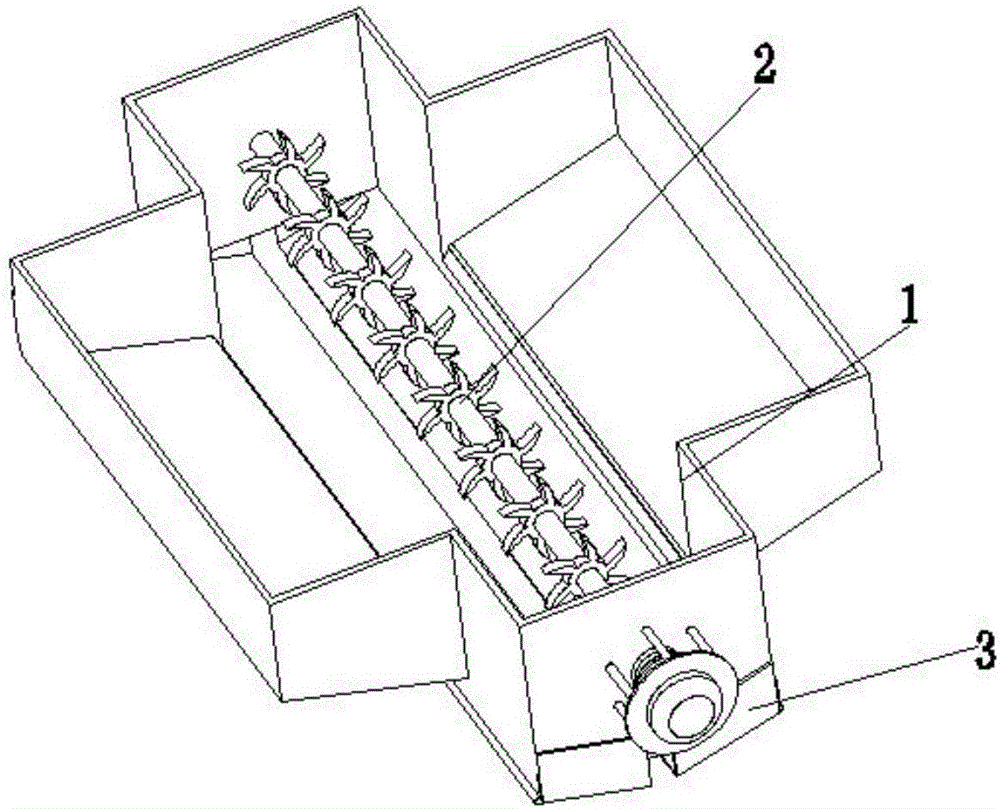

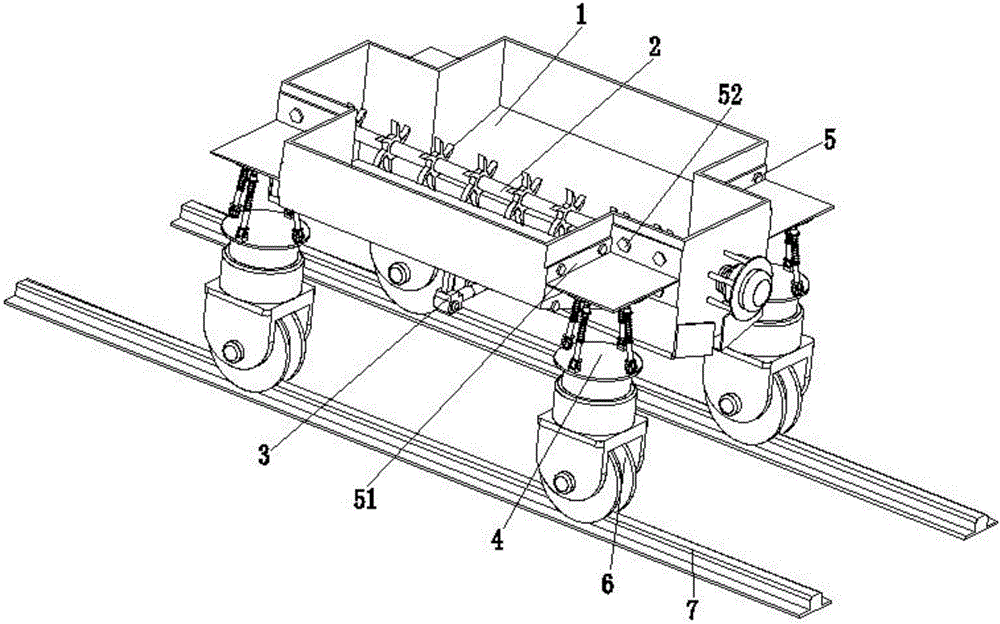

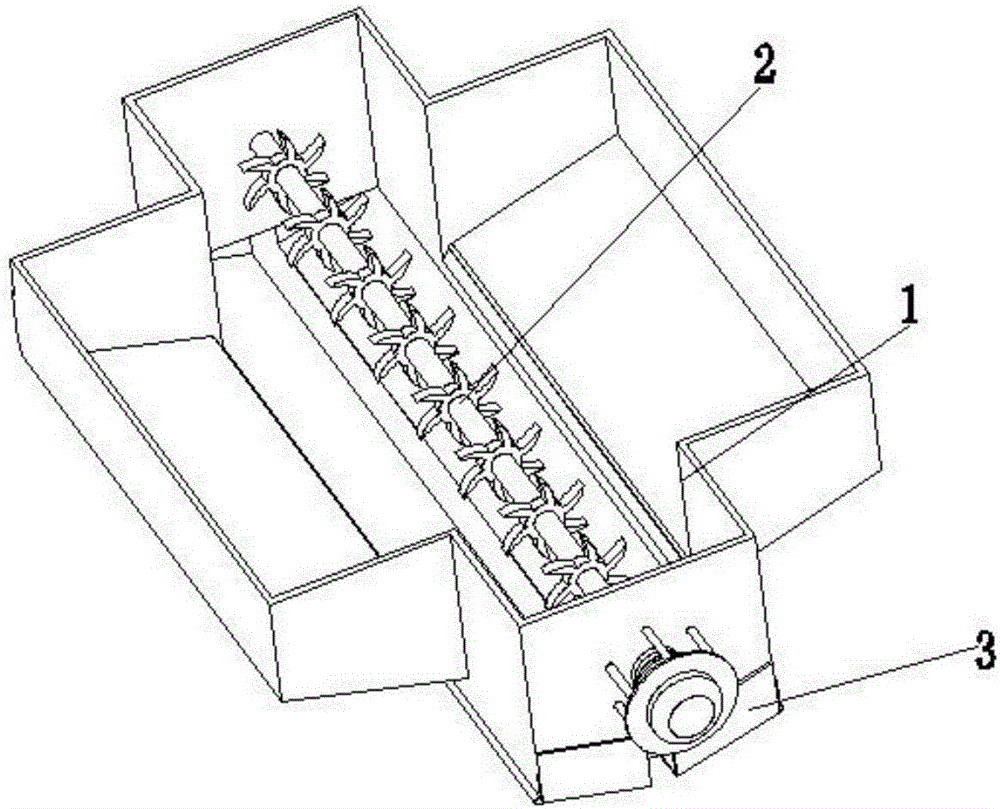

Intelligent robot for laying railway type road borders

ActiveCN106120518AImprove efficiencyQuality improvementRoads maintainenceEngineeringSix degrees of freedom

The invention relates to an intelligent robot for laying railway type road borders. The intelligent robot comprises a material storing tank, a stirring device, an adjustable type discharging device, six-degree-of-freedom parallel connection vibration tables, a fixing device, four walking devices and a railway, wherein the stirring device is located in the material storing tank; the adjustable type discharging devices are located just below a square ventage in the position at the middle part of the lower end of the material storing tank; the six-degree-of-freedom parallel connection vibration tables are respectively located at four vertex angles of the material storing tank, and are mounted on the outer side wall of the material storing tank through the fixing device; and the four walking devices are separately located just below the corresponding six-degree-of-freedom parallel connection vibration table, besides, the upper end of each walking device is connected with the lower end of the corresponding six-degree-of-freedom parallel connection vibration table, and the lower end of each walking device is mounted on the railway. According to the intelligent robot disclosed by the invention, the functions of secondarily stirring concrete, vibrating and mixing, adjustable type discharging and automatic walking are integrated, one machine has multiple functions, besides, the mechanical intelligence degree is high, and the laying efficiency and the laying quality of road borders are effectively improved.

Owner:SHENZHEN MUNICIPAL ENG

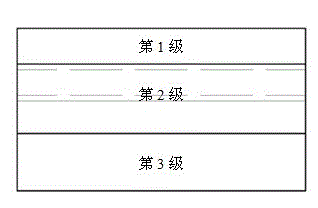

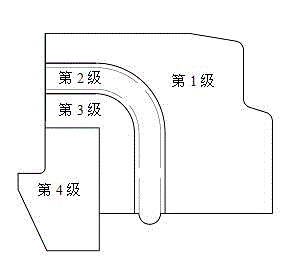

Al2O3-SiO2 content-graded refractory brick for stamp-charging coke oven

The invention relates to an Al2O3-SiO2 content-graded refractory brick for a stamp-charging coke oven. The technical scheme includes that the refractory brick is made of Al2O3-SiO2 raw materials of n grades, wherein n refers to natural numbers ranging from 3 to 10; and the content of Al2O3 and SiO2 in Al2O3-SiO2 raw materials of each grade gradually changes grade by grade, namely the content of Al2O3 in the Al2O3-SiO2 raw materials of the first grade is progressively decreased from being larger than 75wt% to be smaller than 7wt% at the nth grade, and the content of SiO2 in the Al2O3-SiO2 raw materials of the first grade is progressively increased from being smaller than 25wt% to be larger than 93wt% at the nth grade . The preparation method includes: burdening according to Al2O3-SiO2 raw materials corresponding to each grade, and respectively mixing; adding lignin liquor which is 5-10wt% of the raw materials of each grade into the corresponding raw materials of each grade, mixing, pouring the raw materials of each grade into corresponding spaces in a mould respectively, forming and drying; and sending to a tunnel kiln, and calcining at 1400-1500 DEG C for 40h. The Al2O3-SiO2 content-graded refractory brick has the advantages of integral firmness, long service life, low cost and convenience for construction.

Owner:WUHAN UNIV OF SCI & TECH

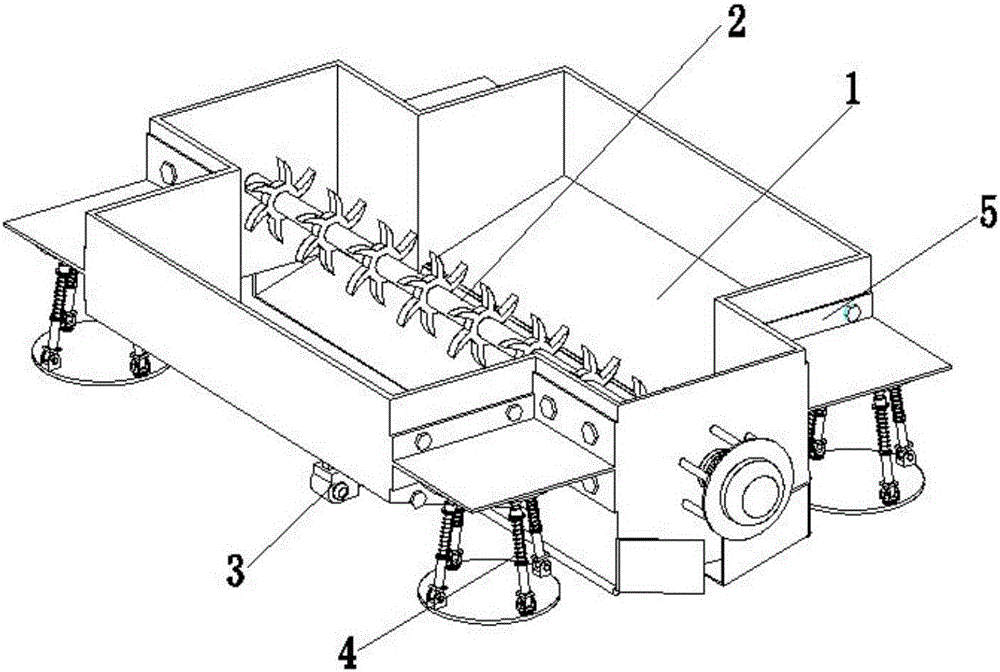

Redundant four-DOF (degree of freedom) intelligent robot for construction of urban municipal greenbelt

ActiveCN106150096AHigh degree of mechanical intelligenceImprove efficiency and qualityUnderwater structuresBuilding material handlingRetaining wallUrban greening

The invention relates to a redundant four-DOF (degree of freedom) intelligent robot for construction of an urban municipal greenbelt. The redundant four-DOF intelligent robot comprises a storage tank, a stirring device, an adjustable discharging device, redundant four-DOF vibrating tables, fixing devices, walking devices and tracks, wherein the stirring device is located in the storage tank; the adjustable discharging device is located right below a square leakage opening in the middle of the lower end of the storage tank; the redundant four-DOF vibrating tables are located at four vertex angles of the storage tank respectively and mounted on the outer side walls of the storage tank through the fixing devices; the walking devices are located right below the redundant four-DOF vibrating tables, the upper ends of the walking devices are connected with the lower ends of the redundant four-DOF vibrating tables, and the lower ends of the walking devices are mounted on the tracks. The redundant four-DOF robot for construction of the urban municipal greenbelt integrates secondary concrete stirring, vibrational mixing, adjustable discharging and automatic walking, thereby being multi-purpose, having high mechanical intelligent degree and effectively improving efficiency and quality of pouring construction of a retaining wall of the urban municipal greenbelt.

Owner:广州市鼎申科技发展有限公司 +1

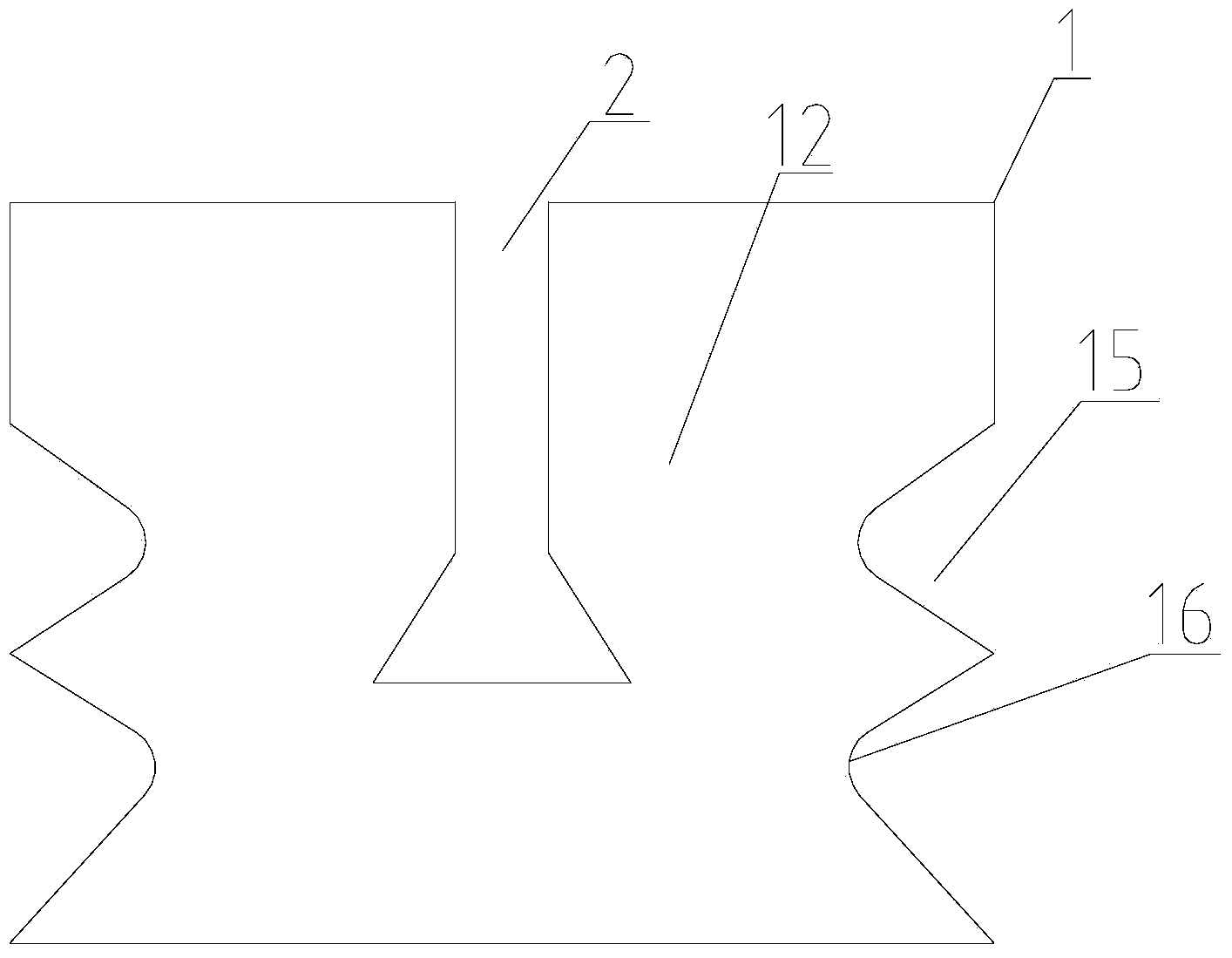

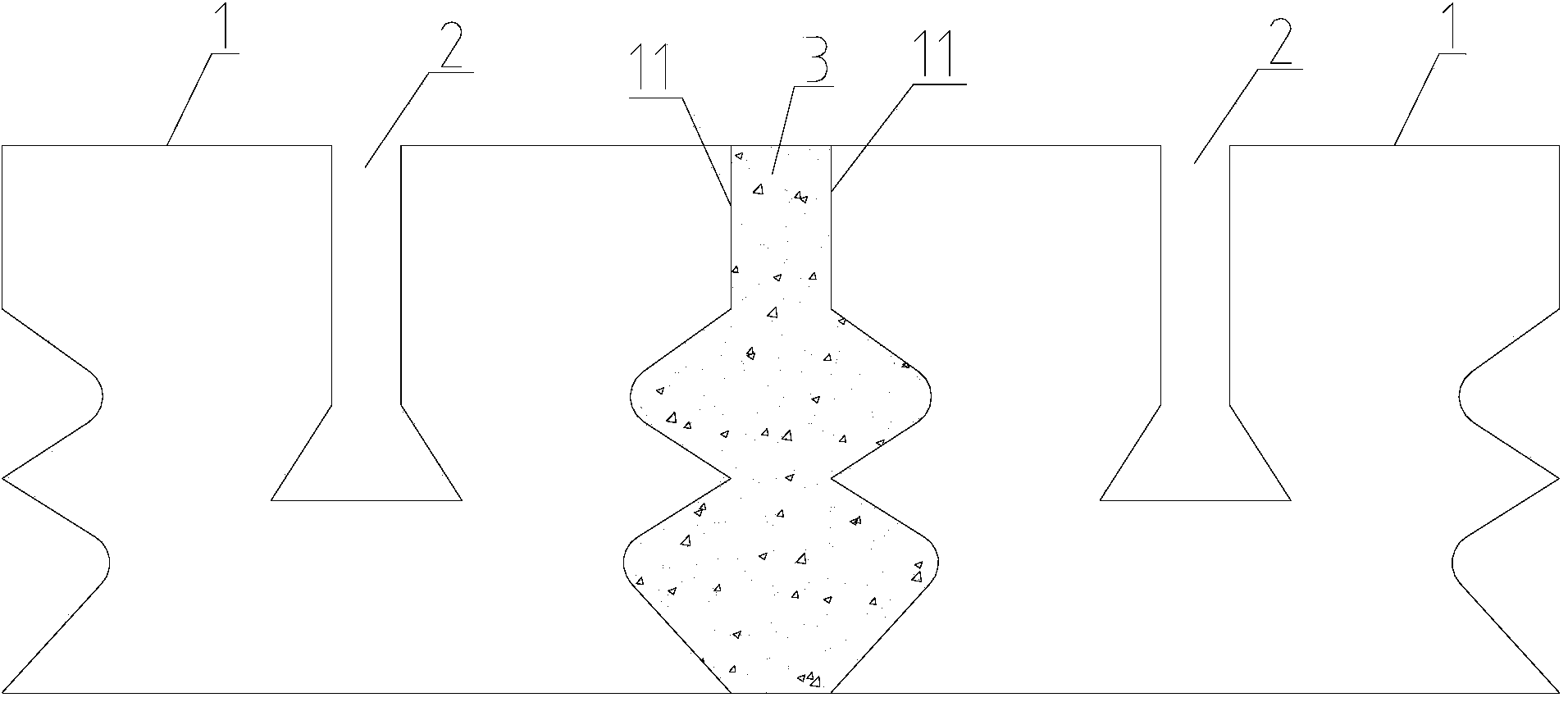

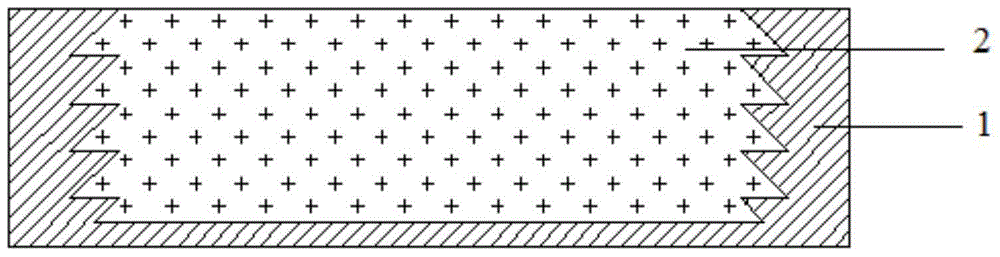

High-alumina composite refractory brick

InactiveCN104457267AConvenience for masonryReduce the amount of constructionFurnace componentsAluminiumAlumina composite

The invention provides a high-alumina composite refractory brick. The high-alumina composite refractory brick comprises a high-alumina refractory material framework and a light high-alumina refractory material filling layer, wherein the high-alumina refractory material framework is of a cuboid concave surface structure, zigzag crinkles are arranged on all four inner sides of the concave surface structure, the high-alumina refractory material filling layer is arranged in the concave portion of the concave surface structure and is tightly attached to the four sides of the concave surface structure, and the upper surface of the high-alumina refractory material framework is flush with the upper surface of the light high-alumina refractory material filling layer. The high-alumina composite refractory brick has the advantages that construction of a heat insulation lining is more convenient, construction intensity is reduced, the structure is simple, production is convenient, service life is long, and heat insulation performance is excellent.

Owner:TIANJIN MROGAN KUNDOM HI TECH DEV

Fabric concrete block and preparation method

ActiveCN108590017AReduce water-cement ratioWith thermal insulation functionConstruction materialCeramic shaping apparatusEngineeringCompressive strength

The invention relates to a fabric concrete block and a preparation method. The block has high crush resistance strength, no holes and pitted surfaces, good appearance quality and strong wall adhesionability, and can restrain wall cracks and prolong wall life to enable the block is matched with the service life of a main structure. The block comprises four L-shaped angle shafts arranged to form arectangular barrel corner angle, a fabric shell which is fixed outside the L-shaped angle shafts in tension winding mode and form a rectangular barrel structure and filler, wherein the fabric shell isfilled with the filler.. The preparation method comprises the steps that 1, the preparation of the fabric shell is carried out; 2, the fabric shell is filled with the filler, pressing and concrete vibrating are carried out to enable the filler to be compact, so that the fabric adheres to the inner wall of a steel mould; and 3, maintenance is carried out for molding, maintenance is carried out until the initial solidification of the filler is completed, the steel mould is removed, maintenance is carried out until the filler is fully solidified, and the block production is completed.

Owner:CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com