Flower basket tie rod I-steel cantilever bearing frame for construction engineering and installation method thereof

A technology of construction engineering and installation method, which is applied in the direction of construction, building structure, and construction material processing, can solve the problems of cumbersome construction of cantilever bearing frames, low material recycling rate, and influence on floor structure, etc., and achieve reduction The hidden danger of water seepage in the external wall, the effect of simple structure and spacious construction surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

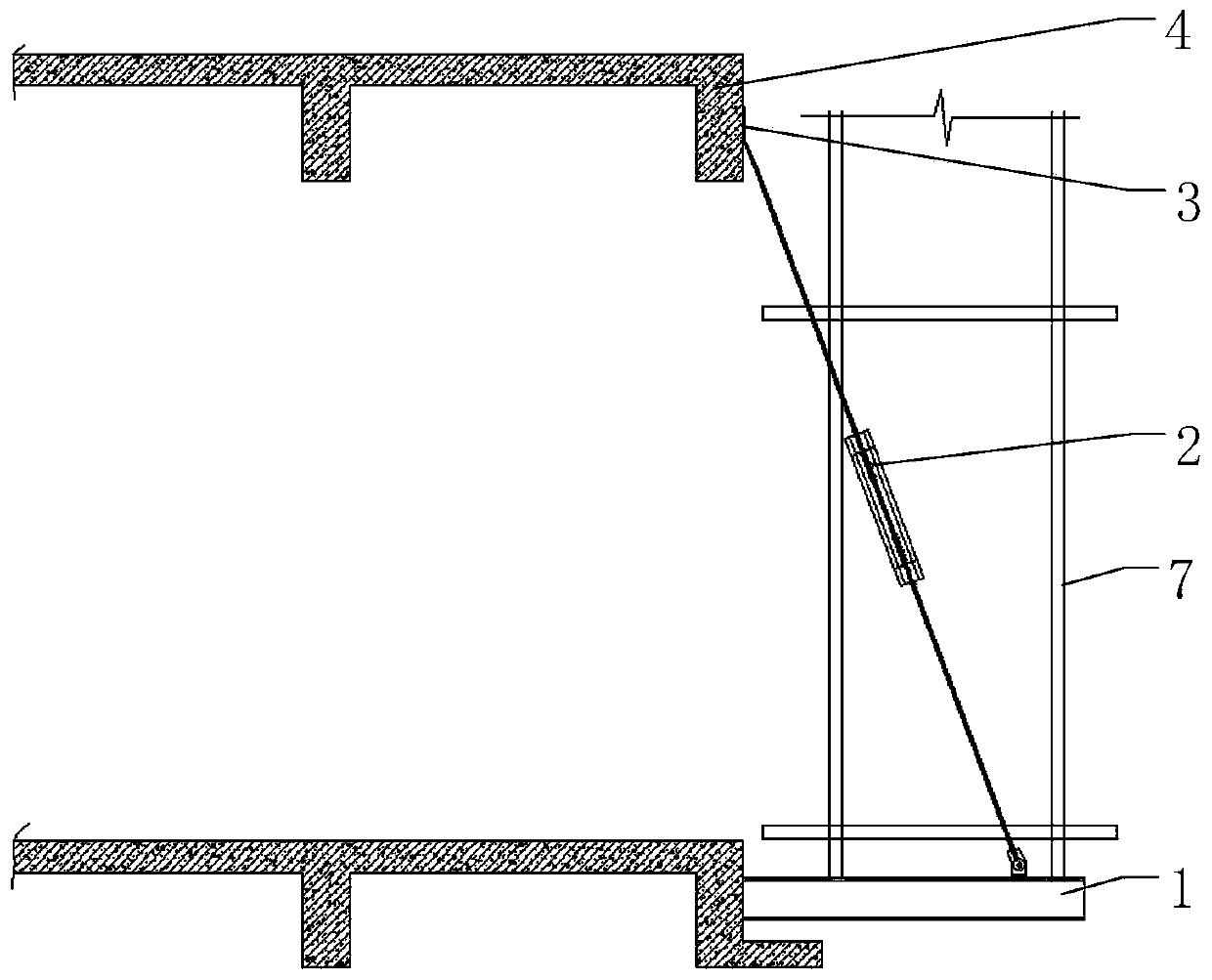

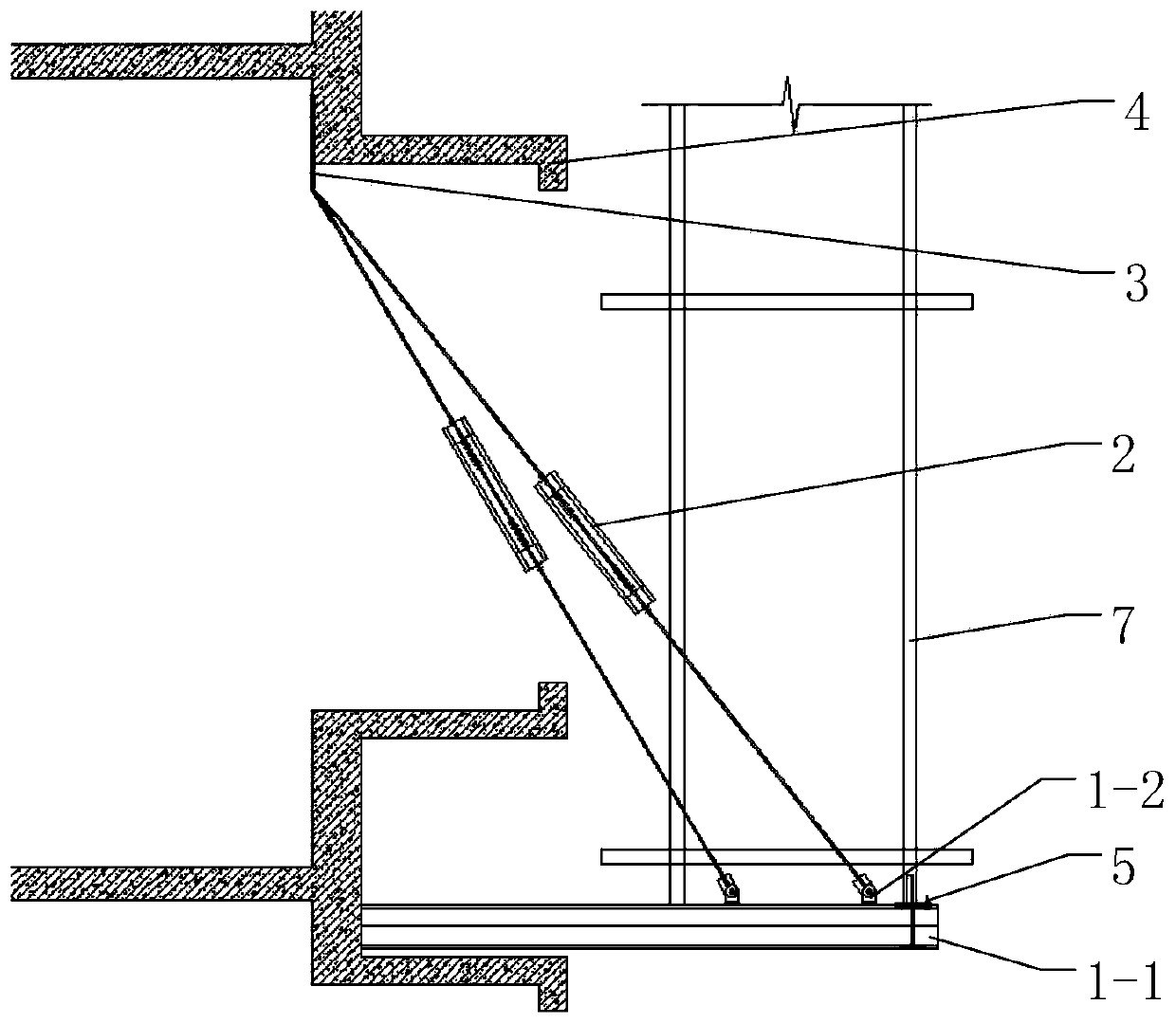

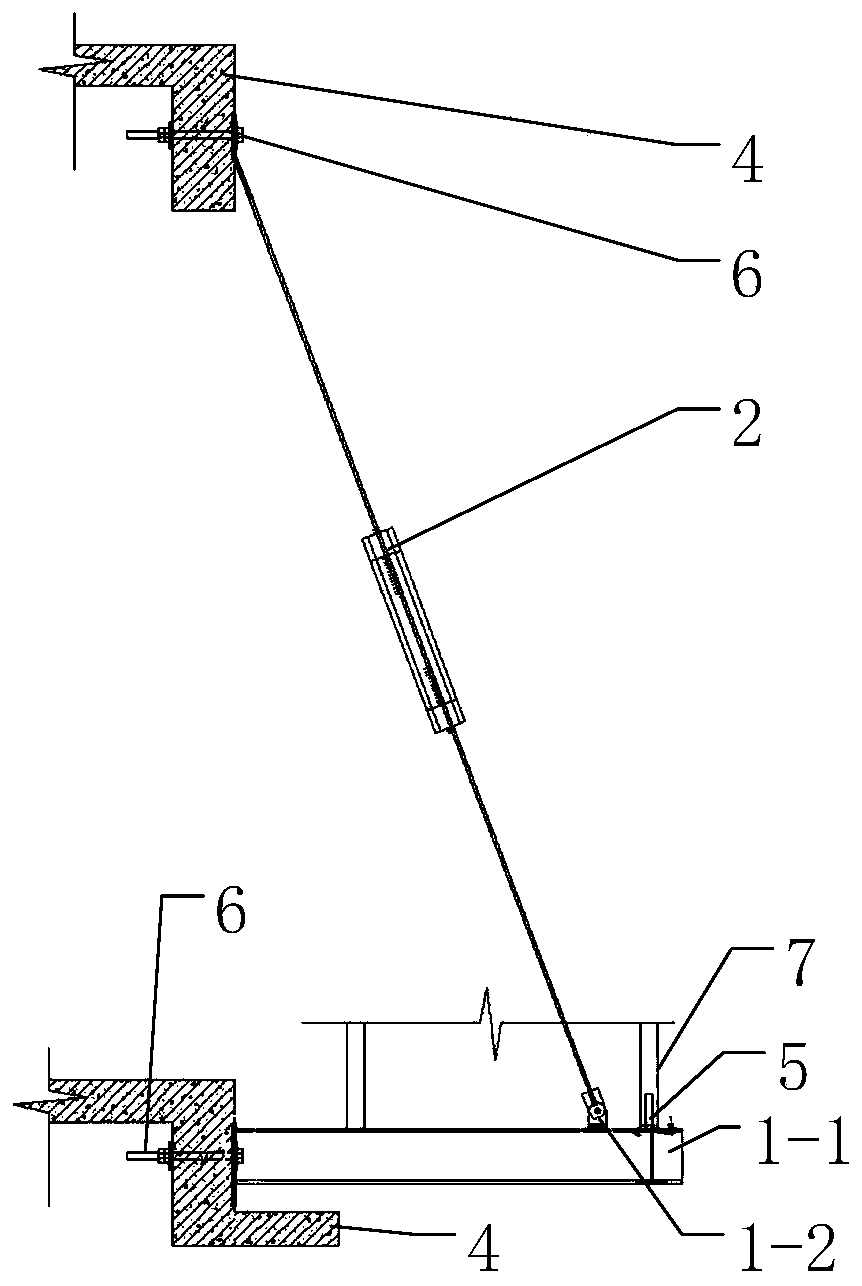

[0044] combine Figure 1-Figure 8Describe this embodiment. In this embodiment, a kind of flower basket tie rod I-shaped steel cantilever load-bearing frame for construction engineering related to this embodiment includes a cantilever frame load-bearing beam 1, a flower basket bolt 2, and a connecting plate 3. , embedded parts 4 and mobile positioning piles 5, the embedded parts 4 are pre-buried in the wall, the cantilever frame load-bearing beam 1 is cantilevered on the side of the embedded parts 4, and the connecting plate 3 is set On the side of the embedded part 4 above the suspension frame load-bearing beam 1; the suspension frame load-bearing beam 1 includes I-shaped steel 1-1 and lifting lugs 1-2, and the lifting lugs 1-2 are fixed on the I-shaped on the steel 1-1; one end of the turnbuckle bolt 2 is fixed on the pick lug 1-2, and the other end is fixed on the connecting plate 3; the mobile positioning pile 5 is installed on the I-beam 1-1, and the vertical pole The ste...

Embodiment 2

[0046] combine figure 2 This embodiment will be described with Embodiment 1. In this embodiment, a flower basket pull rod I-shaped steel cantilever bearing frame for construction engineering related to this embodiment has a round hole in the middle of the lifting ears 1-2. The purpose of such setting is: the thickness and size of the anchor plate at the end of the I-beam, as well as the size and shape of the opening of the anchor plate can be replaced within the safety factor. The thickness and size of the anchor plate at the end of the I-beam, and the size and shape of the anchor plate opening can be replaced within the safety factor. H-bolt assembly thickness, size and shape are interchangeable within a factor of safety.

Embodiment 3

[0048] combine Image 6 This embodiment is described with Embodiment 1. In this embodiment, a kind of flower basket pull rod I-beam cantilever bearing frame for construction engineering related to this embodiment, the I-beam 1-1 is preset with a slope mouth, the lug 1-2 is welded at the groove. The purpose of such setting is: the thickness and size of the I-beam groove welding ear plate, and the opening size and shape of the groove welding ear plate can be replaced within the safety factor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com